Page 1

XLM HD30

Owner’s manual

R9004460

R9004461

R59770014/01

25/05/2009

Page 2

Barco nv Events

Noordlaan 5, B-8520 Kuurne

Phone: +32 56.36.89.70

Fax: +32 56.36.88.24

E-mail: sales.events@barco.com

Visit us at the web: www.barco.com

Printed in Belgium

Page 3

Changes

Barco provides this manual ’as is’ without warranty of any kind, either expressed or implied, including but not limited to the implied warranties or merchantability and fitness for a particular purpose. Barco may make improvements and/or changes to the product(s) and/or the

program(s) described in this publication at any time without notice.

This publication could contain technical inaccuracies or typographical errors. Changes are periodically made to the information in this

publication; these changes are incorporated in new editions of this publication.

Copyright ©

All rights reserved. No part of this document may be copied, reproduced or translated. It shall not other

stored in a retrieval system without the prior written consent of Barco.

wise be recorded, transmitted or

Guarantee and Compensation

Barco provides a guarantee relating to perfect manufacturing as part of the legally stipulated terms of guarantee. On receipt, the purchaser

must immediately inspect all delivered goods for damage incurred during transport, as well as for material and manufacturing faults Barco

must be informed immediately in writing of any complaints.

The period of guarantee begins on the date of transfer of risks, in the case of special systems and software on the date of commissioning,

at latest 30 days after the transfer of risks. In the event of justified notice of complaint, Barco can repair the fault or provide a replacement

at its own discretion within an appropriate period. If this measure proves to be impossible or unsuccessful, the purchaser can demand a

reduction in the purchase price or cancellation of the contract. All other claims, in particular those relating to compensation for direct or

indirect damage, and also damage attributed to the operation of software as well as to other services provided by Barco, being a component

of the system or independent service, will be deemed invalid provided the damage is not proven to be attributed to the absence of properties

guaranteed in writing or due to the intent or gross negligence or part of Barco.

If the purchaser or a third party carries out modifications or repairs on goods delivered by Barco, or if the goods are handled incorrectly,

in particular if the systems are commissioned operated incorrectly or if, after the transfer of risks, the goods are subject to influences not

agreed upon in the contract, all guarantee claims of the purchaser will be rendered invalid. Not included in the guarantee coverage are

system failures which are attributed to programs or special electronic circuitry provided by the purchaser, e.g. interfaces. Normal wear as

well as normal maintenance are not subject to the guarantee provided by Barco either.

The environmental conditions as well as the servicing and m

the customer.

aintenance regulations specified in the this manual must be complied with by

Trademarks

Brand and product names mentioned in this manual may be trademarks, registered trademarks or copyrights of their respective holders.

All brand and product names mentioned in this manual serve as comments or examples and are not to be understood as advertising for

the products or their manufacturers.

EN55022/CISPR22 Class A ITE (Information Technology Equipment)

Class A ITE is a category of all other ITE which satisfies the class A ITE limits but not the class B ITE limits. Such equipment should not

be restricted in its sale but the following warning shall be included in the instructions for use:

Warning : This is a class A product. In a domestic environment this product may cause radio interference in which case the user may be

required to take adequate measures.

Federal Communications Commission (FCC Statement)

This equipment has been tested and found to comply with the limits for a class A digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generat

the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area may

cause harmful interference, in which case the user will be responsible for correcting any interference at his own expense

es, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

Disposal Information

This equipment has required the extraction and use of natural resources for its production. It may contain hazardous substances for health

and environment. In order to avoid the dissemination of those substances in the environment and to diminish the pressure on natural

resources, we encourage you to use the appropriate take-back systems. Those systems will reuse or recycle most of the materials of your

end of life equipment in a sound way.

Page 4

The crossed-out wheeled bin symbol invites you to use those systems. If you need more information on the collection, reuse and recycling

systems, please contact your local or regional waste administrator. You can also contact us for more information on the environmental

performances of our products.

Page 5

Table of contents

TABLE OF CONTENTS

1. Packaging and Dimensions ...................................................................................... 5

1.1 ProjectorPackaging.................................................................................................................. 5

1.2 Lens Packaging....................................................................................................................... 5

1.3 Lamp HousePackaging.............................................................................................................. 5

1.4 Boxcontent ........................................................................................................................... 6

1.5 Dimensions ........................................................................................................................... 6

1.6 Free downloadof ProjectorToolset.................................................................................................. 7

2. Installation Guidelines............................................................................................. 9

2.1 General guidelines. . .................................................................................................................. 9

2.2 Restricted Access Location .........................................................................................................10

2.3 Projector configuration .............................................................................................................. 11

2.4 Safety Area around projector .......................................................................................................13

2.5 Lenses ...............................................................................................................................13

2.5.1 Lenses.........................................................................................................................13

2.5.2 Lens formulas .................................................................................................................14

2.5.3 Lens installation ...............................................................................................................14

2.6 Mounting the lamp house . ..........................................................................................................15

2.7 Transporting theprojector...........................................................................................................17

2.8 Battery Insertion in the Remote Control ... . ........................................................................................ 17

2.9 Battery insertion in the Rugged remote control.....................................................................................18

2.10 Charging the batteries of the rugged remote control ...............................................................................19

2.10.1 Preparing the charger.........................................................................................................19

2.10.2 Charging thebatteries ........................................................................................................19

2.10.3 Power save mode .............................................................................................................20

2.11 Stacking Two Projectors............................................................................................................. 20

2.12 Rigging points and clamps ..........................................................................................................21

3. Connections........................................................................................................23

3.1 Power connection . ..................................................................................................................23

3.2 Connection facilities .................................................................................................................25

3.3 Input source connection .............................................................................................................26

3.3.1 Introduction. . . .................................................................................................................26

3.3.2 Removing and Inserting an input module ....................................................................................26

3.3.3 DVI input module..............................................................................................................27

3.3.4 SDI input module.............................................................................................................. 27

3.3.5 HDSDI input module ..........................................................................................................28

3.3.6 YUV / RG(s)B input module ..................................................................................................28

3.3.7 RGB analog input module . . ..................................................................................................29

3.3.8 CVBS / S-VID input module ..................................................................................................30

3.3.9 Dummy input module .........................................................................................................30

3.4 Communication connection .........................................................................................................31

3.4.1 RS232/422 IN/OUT Serial network...........................................................................................31

3.4.2 Ethernet connection. . .........................................................................................................32

3.4.3 Hardwired remote toCTRL 1.................................................................................................32

3.4.4 Bi-directional communication port, CTRL 3 ..................................................................................33

3.5 Monitor output .......................................................................................................................35

4. Getting Started.....................................................................................................37

4.1 Terminologyoverview RCUandlocal keypad......................................................................................37

4.2 Terminology overview Rugged remote control .. ...................................................................................39

4.3 Switching ontheprojector...........................................................................................................40

4.4 Lamp runtime ........................................................................................................................40

4.5 Switching to standby ................................................................................................................40

4.6 Switching off .........................................................................................................................41

4.7 Using theRCU....................................................................................................................... 41

4.8 Using the Rugged remote control...................................................................................................42

4.9 Projector address. . . ................................................................................................................. 42

4.9.1 Address setting ...............................................................................................................42

4.9.2 Displaying and Programming addresses into the RCU . . ....................................................................43

4.9.3 Displaying and Programming addresses into the rugged remote control ...................................................43

4.10 Controlling theprojector.............................................................................................................44

4.11 Quick lensadjustment............................................................................................................... 44

4.11.1 Direct Lens Adjustment (RCU) ...............................................................................................44

4.11.2 Lens adjustment via menus ..................................................................................................45

5. Getting used to the menu structure............................................................................47

5.1 How to start up the menus .......................................................................................................... 47

5.2 Using theDialogboxes..............................................................................................................47

5.3 Menu memory .......................................................................................................................48

6. Adjustment Mode..................................................................................................49

6.1 Adjustment mode overview .........................................................................................................49

R59770014 XLM HD30 25/05/2009

1

Page 6

Table of contents

6.2 Start up of the Adjustment mode. . ..................................................................................................49

6.3 File Service ..........................................................................................................................50

6.3.1 Possible file manipulations ...................................................................................................50

6.3.2 Startup........................................................................................................................50

6.3.3 Load file.......................................................................................................................51

6.3.4 Edit file ........................................................................................................................52

6.3.4.1 Start up .................................................................................................................52

6.3.4.2 Changing the settings ..................................................................................................52

6.3.4.3 Correctvalue ...........................................................................................................53

6.3.5 Rename .......................................................................................................................55

6.3.6 Copy........................................................................................................................... 56

6.3.7 Delete .........................................................................................................................56

6.3.8 File Options ................................................................................................................... 57

6.4 Picture Tuning ....................................................................................................................... 57

6.4.1 Startup........................................................................................................................57

6.4.2 Color Space...................................................................................................................58

6.4.2.1 Color Spaceselection..................................................................................................58

6.4.2.2 Custom color space....................................................................................................58

6.4.3 Color Temperature............................................................................................................59

6.4.3.1 Color Temperatureselection...........................................................................................59

6.4.3.2 Custom color temperature .............................................................................................60

6.4.4 Gamma........................................................................................................................ 60

6.4.5 Noise Reduction ..............................................................................................................61

6.4.6 Input Balance .................................................................................................................61

6.4.6.1 Introduction to Input Balance . . ........................................................................................ 62

6.4.6.2 Adjusting theinput balance ............................................................................................63

6.4.6.3 Input balance for YUV signals . ........................................................................................64

6.5 Window Adjustment ................................................................................................................. 65

6.5.1 Startup........................................................................................................................65

6.5.2 Select Source .................................................................................................................66

6.5.3 Size Adjustment...............................................................................................................66

6.5.4 Window Position ..............................................................................................................67

6.5.5 Z-order ........................................................................................................................ 68

6.5.6 Color Key......................................................................................................................69

6.5.6.1 Color Key activation....................................................................................................69

6.5.6.2 Set up ofthecolor forcolor key........................................................................................70

6.5.6.3 Color key range ........................................................................................................70

6.5.6.4 Color key algorithm.....................................................................................................71

6.5.6.5 Color key palette setup................................................................................................71

6.5.7 Alpha Blending ................................................................................................................72

6.5.8 No Signal ......................................................................................................................73

6.5.9 Exit the Window adjustment menus..........................................................................................74

6.6 LayoutAdjustment...................................................................................................................74

6.6.1 Startup........................................................................................................................74

6.6.2 Load Layout .. ................................................................................................................. 75

6.6.3 Rename Layout ...............................................................................................................75

6.6.4 Delete layout ..................................................................................................................76

6.6.5 Add a window to a layout .. ...................................................................................................76

6.6.6 Remove a window in a layout ................................................................................................77

6.6.7 Edit window . . ................................................................................................................. 77

6.6.8 Keystoneadjustment .........................................................................................................78

6.6.9 Blankingadjustment ..........................................................................................................78

6.6.10 Input locking...................................................................................................................79

6.7 Scenergix ............................................................................................................................80

6.7.1 Introduction. . . .................................................................................................................80

6.7.2 Preparations. . .................................................................................................................81

6.7.3 ScenergiX .....................................................................................................................81

6.7.4 ScenergiX overlap zone (horizontal scenergix) . . ............................................................................82

6.7.5 ScenergiX overlap zone (vertical scenergix).................................................................................83

6.7.6 ScenergiX size adjustment . ..................................................................................................83

6.7.7 Adjusting the black level of the images . . . ...................................................................................85

7. Installation..........................................................................................................87

7.1 Start up of the installation mode . . ..................................................................................................87

7.2 Input slots ............................................................................................................................ 87

7.3 Configuration ........................................................................................................................88

7.4 Lens . . ................................................................................................................................88

7.4.1 Startup thelens functions....................................................................................................88

7.4.2 Lens selection .................................................................................................................89

7.4.3 Lens adjustment ..............................................................................................................89

7.4.4 Lens files......................................................................................................................90

7.4.4.1 Run a lens file ..........................................................................................................90

7.4.4.2 Savelens settings......................................................................................................91

7.4.4.3 Rename lens file........................................................................................................91

7.4.4.4 Copy lens file ...........................................................................................................92

7.4.4.5 Delete lens file..........................................................................................................92

2

R59770014 XLM HD30 25/05/2009

Page 7

Table of contents

7.4.5 Lens absolute positioning. . . ..................................................................................................93

7.5 Tiltadjustment .......................................................................................................................93

7.6 InternalPatterns .....................................................................................................................95

7.7 Quick AccessKeys..................................................................................................................96

7.8 Buttons...............................................................................................................................96

7.9 Macros...............................................................................................................................97

7.9.1 Runa macro ..................................................................................................................97

7.9.2 Edit a Macro................................................................................................................... 98

7.9.3 Rename a macro file..........................................................................................................99

7.9.4 Copy a macro file ............................................................................................................100

7.9.5 Delete a macro file...........................................................................................................100

7.9.6 Create a macro file...........................................................................................................101

8. Service ............................................................................................................ 103

8.1 Start up of the servicemenu ....................................................................................................... 103

8.2 Identification ........................................................................................................................103

8.3 Change Projector Address – Common Address. ..................................................................................104

8.4 Change Customer ID ...............................................................................................................105

8.5 Communication .....................................................................................................................105

8.5.1 Baud rate Setting ............................................................................................................105

8.5.2 Serial Interface setting.......................................................................................................106

8.5.3 RS422Termination ..........................................................................................................106

8.5.4 Network Configuration .......................................................................................................107

8.6 Date and time setup ................................................................................................................108

8.7 Lamp................................................................................................................................108

8.8 Dimming-CLO.......................................................................................................................109

8.9 Thomson worldcam mode. . ........................................................................................................111

8.10 Convergence .......................................................................................................................112

8.11 Reset hardware.....................................................................................................................112

8.12 Factory defaults.....................................................................................................................112

8.13 Diagnosis ...........................................................................................................................113

8.13.1 Start up.......................................................................................................................113

8.13.2 Errors.........................................................................................................................113

8.13.3 Voltages ......................................................................................................................114

8.13.4 Temperatures ................................................................................................................114

8.13.5 Fan speeds. . . ................................................................................................................115

8.13.6 Versions......................................................................................................................115

A. Specifications ..................................................................................................... 117

A.1 XLM HD30 ..........................................................................................................................117

B. Standard Source Set up files................................................................................... 121

B.1 Table overview......................................................................................................................121

C. Maintenance ....................................................................................................... 125

C.1 Pressure check of cooling liquid circuit ............................................................................................125

C.2 Cleaning the dust filters ............................................................................................................126

C.3 Cleaning the lens .. .................................................................................................................128

Glossary ............................................................................................................... 129

Index.................................................................................................................... 131

R59770014 XLM HD30 25/05/2009 3

Page 8

Table of contents

4 R59770014 XLM HD30 25/05/2009

Page 9

1. PACKAGING AND DIMENSIONS

N

1.1 Projector Packaging

Way of Packaging

The projector is packed in a carton box. To provide protection during transportation, the project

package is secured with banding and fastening clips.

To unpack

1. Release the fastening clips.

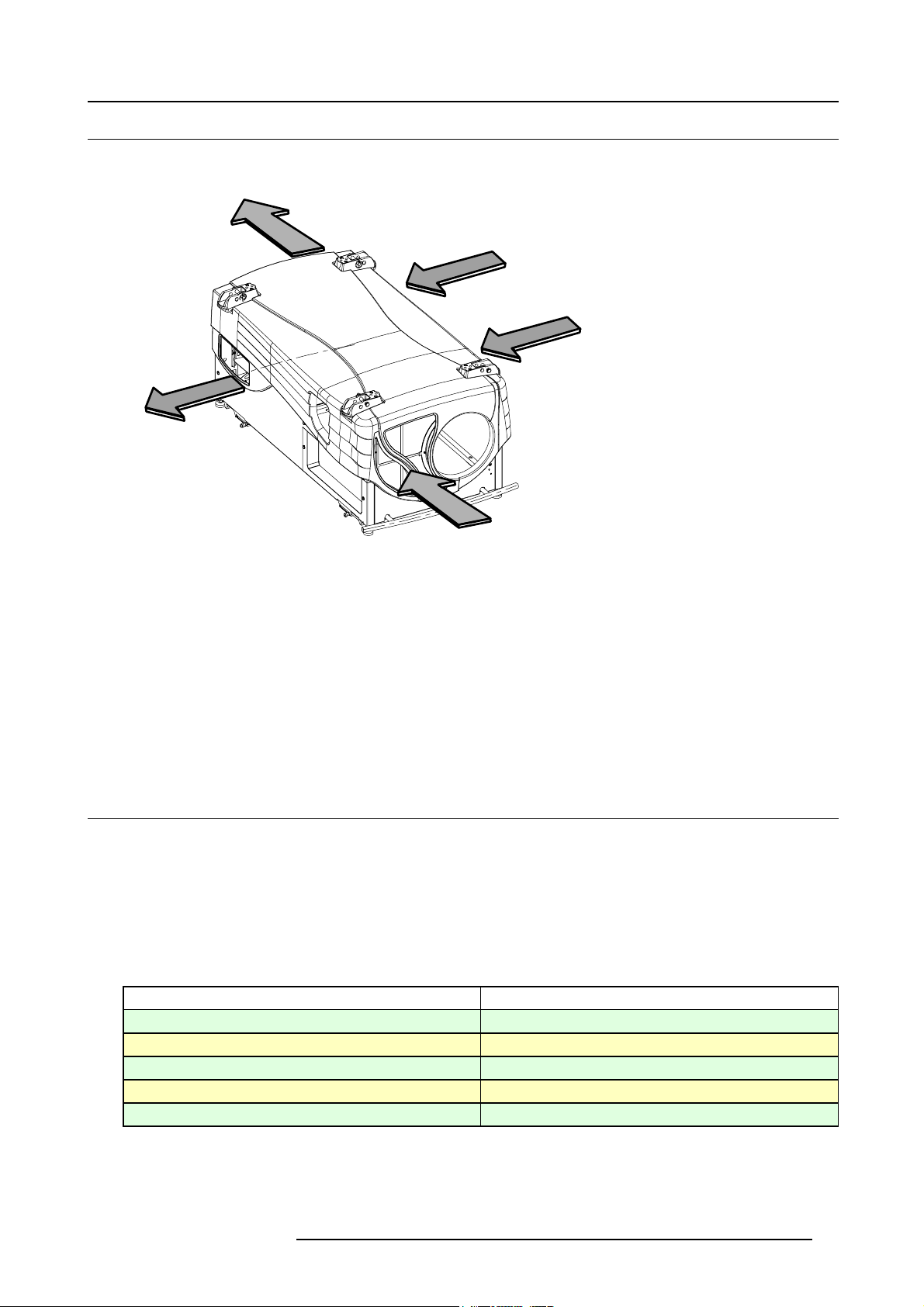

2. Remove the banding. Handle as shown in the drawing. (image 1-1)

3. Take the projector out of its shipping carton and place it on a table.

PULL

TO OPE

Image 1-1

1. Packaging and Dimensions

or is surrounded with foam. The

Save the original shipping carton and packing material, they will be necessary if you ever have to ship your

projector. For maximum protection, repack your projector as it was originally packed at the factory.

CAUTION: Never transport the projector with the lens mounted on it !

Always remove the lens before transporting the projector.

1.2 Lens Packaging

Way of Packaging

Lenses are supplied as an individual item.

They are packed in a carton.

1.3 Lamp House Packaging

Way of Packaging

The lamp house is supplied as an individual item.

They are packed in a carton.

Never transport the projector with the lamp mounted inside the projector.

R59770014 XLM HD30 25/05/2009 5

Page 10

1. Packaging and Dimensions

1.4 Box content

Content

• 1 XLM HD30 projector (weight 180 kg) without lamp house and lens.

• 1 remote control unit (RCU) + 2 batteries

• 1 rugged remote control

• 1 owners manual

• 1 safety manual

• 1 female plug P3 + NE 400V (red)

• 1 female plug P3 + E 250V (blue)

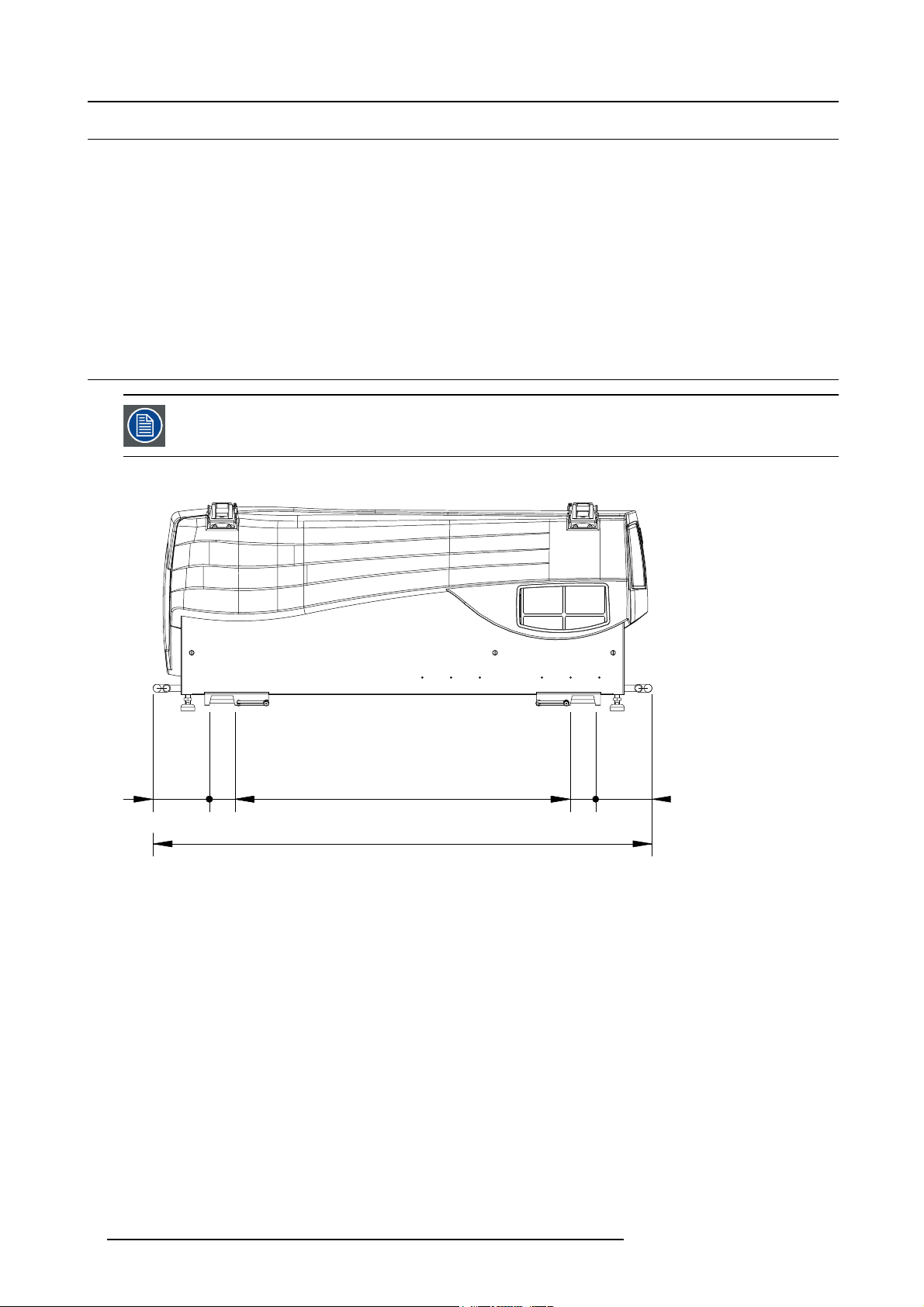

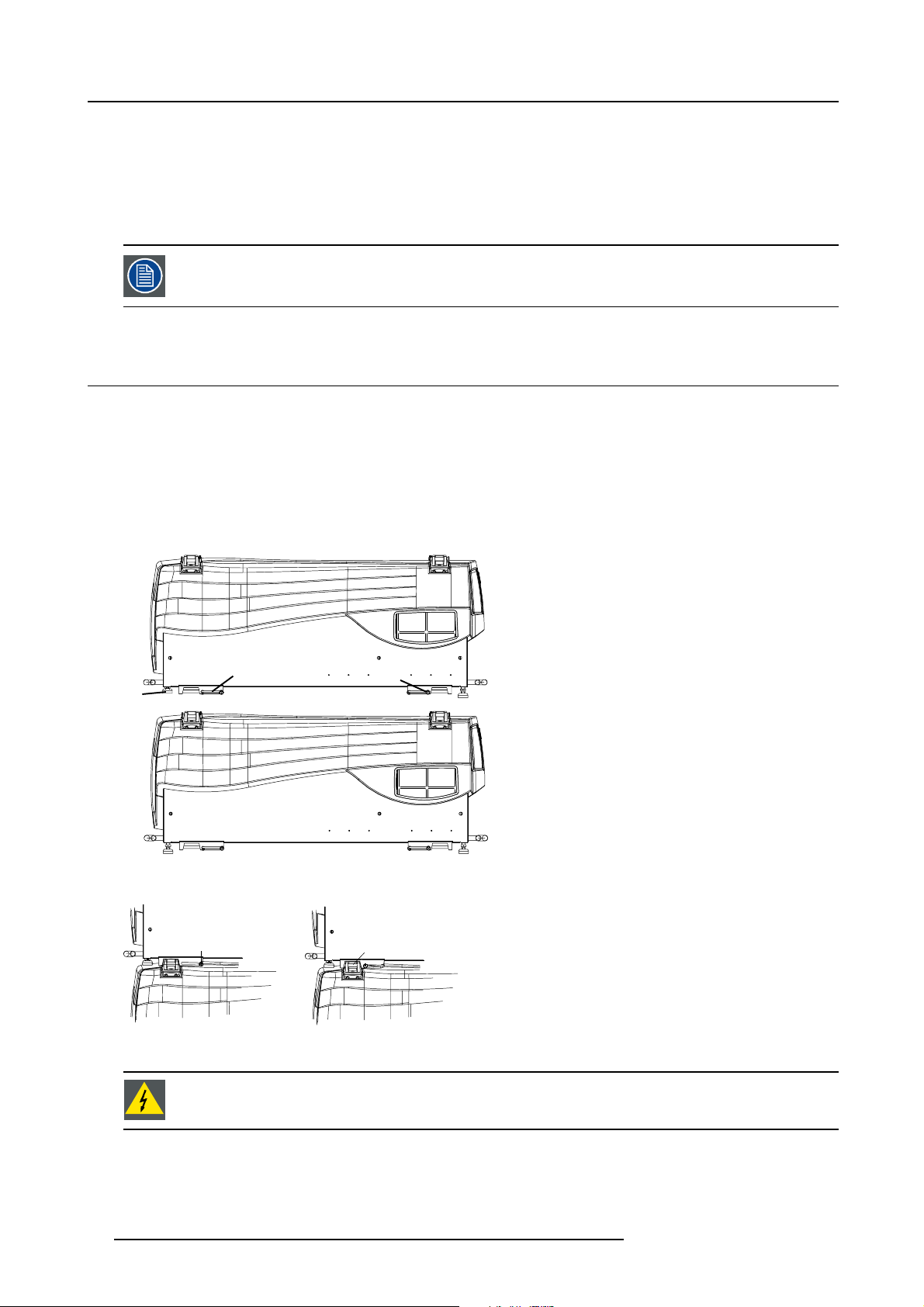

1.5 Dimensions

Dimensions are given without lens.

Side view

176

80

1050

80

176

1563

Image 1-2

Side view

6 R59770014 XLM HD30 25/05/2009

Page 11

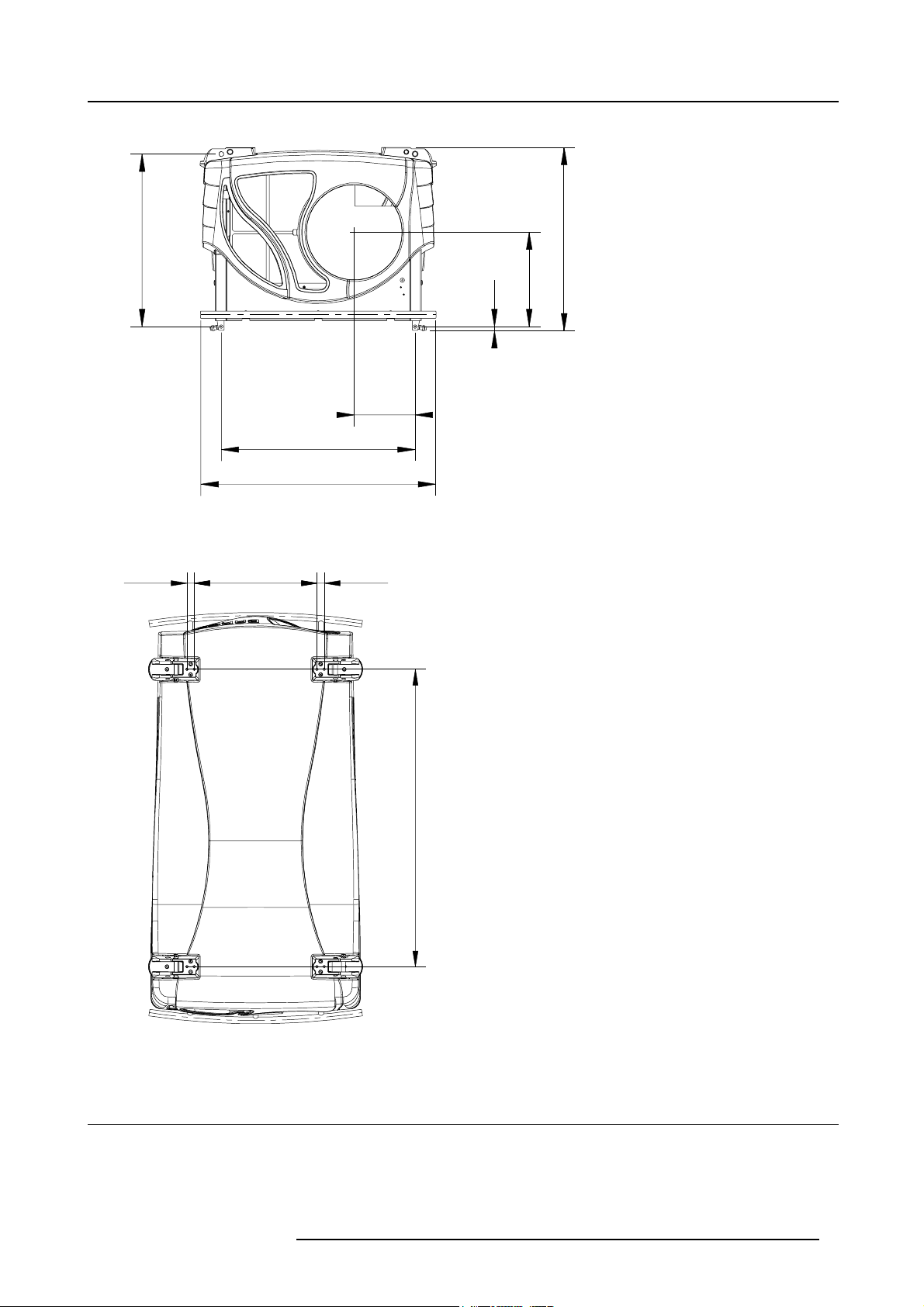

Front view

27,5

468

27,5

1. Packaging and Dimensions

598

Image 1-3

Front v iew

Top v i e w

669

810

210

15

636

327

1130

Image 1-4

To p vi ew

1.6 Free download of Projector Toolset

About Projector Toolset

Projector Toolset is a software tool to set up, configure, manage and control Barco projectors.

R59770014 XLM HD30 25/05/2009

7

Page 12

1. Packaging and Dimensions

The concept of this Projector Toolset software is modular. The basic package can be extended with several optional device plug-in

modules, now and in the future available.

The Projector Toolset software works with configurations that can be loaded. Within a configuration, different snapshots can be take.

A snapshot represents a current state of a configuration and can be reloaded to return to this typical state. These terms will be used

through the complete software.

Projector Toolset is a stand-alone application that runs on a Java Virtual Machine and that does not require extra services to run.

Several configurations can be controlled simultaneously. Even when the configurations are connected via different ways.

Projector Toolset is only available in a download version, no CD can be ordered.

Where to find the download file(s)

The program and all necessary plug-ins, as well as the Reference manual can be downloaded for free from Barco’s Partnerzone,

(URL: w

ww.partnerzone.events.barco.com). Registration is necessary.

If you are not yet registered, click on Partnerzone registration and follow the instructions. With the created login and password, it is

possible to enter the partnerzone where you can download the Projector Toolset software and the device plug-in updates as well as

the corresponding reference manual.

When downloading the complete Projector Toolset, this software contains already the latest devi

the latest core version of Projector Toolset, it is possible to download only device plug-in updates from the same web site location.

As Projector Toolset is a stand alone application, it is not necessary to install any other software. A Java virtual machine is included

with this download.

ce plug-ins. When you already have

Installation

Download first the reference manual (Part number: R5976925) and follow the installation instructions as written in this manual.

8

R59770014 XLM HD30 25/05/2009

Page 13

2. INSTALLATION GUIDELINES

Overview

• General guidelines

• Restricted Access Location

• Projector configuration

• Safety Area around projector

• Lenses

• Mounting the lamp house

• Transporting the projector

• Battery Insertion in the Remote Control

• Battery insertion in the Rugged remote control

• Charging the batteries of the rugged remote control

• Stacking Two Projectors

• Rigging points and clamps

2.1 General guidelines

WARNING: Before installing the projector, read first the safety instructions.

2. Installation Guidelines

Ambient Temperature Conditions.

Careful consideration of things such as image size, ambient light level, projector placement and type of screen to use are critical to

the optimum use of the projection system.

Max. ambient temperature : 35°C or 95 °F

Min. ambient temperature : 10 °C or 50 °F

The projector will not operate if ambient air temperature falls outside this range (10°C- 35°C or 50°F-95°F).

Storage temperature: -35°C to +65°C (-31°F to 149°F)

Humidity Conditions

Storage: 0 to 98 % RH Non-condensing

Operation: 0 to 95 % RH Non-condensing

Environment

Do not install the projection system in a site near heat sources such as radiators or air ducts, or in a place subject to direct sunlight,

excessive dust or humidity. Be aware that room heat rises to the ceiling; check that temperature near the installation site is not

excessive.

Environment condition check

A projector must always be mounted in a manner which ensures the free flow of clean air into the projectors ventilation inlets. For

installations in environments where the projector is subject to airborne contaminants such as that produced by smoke machines or

similar (these deposit a thin layer of greasy residue upon the projectors internal optics and imaging electronic surfaces, degrading

performance), then it is highly advisable and desirable to have this contamination removed prior to it reaching the projectors clean

air supply. Devices or structures to extract or shield contaminated air well away from the projector are a prerequisite, if this is not a

feasible solution then measures to relocate the projector to a clean air environment should be considered.

Only ever use the manufacturer’s recommended cleaning kit which has been specifically designed for cleaning optical parts, never

use industrial strength cleaners on the projector’s optics as these will degrade optical coatings and damage sensitive optoelectronics

components. Failure to take suitable precautions to protect the projector from the effects of persistent and prolonged air contaminants will culminate in extensive and irreversible ingrained optical damage. At this stage cleaning of the internal optical units will

be non-effective and impracticable. Damage of this nature is under no circumstances covered under the manufacturer’s warranty

and may deem the warranty null and void. In such a case the client shall be held solely responsible for all costs incurred during any

repair. It is the clients responsibility to ensure at all times that the projector is protected from the harmful effects of hostile airborne

particles in the environment of the projector. The manufacturer reserves the right to refuse repair if a projector has been subject to

wantful neglect, abandon or improper use.

R59770014 XLM HD30 25/05/2009

9

Page 14

2. Installation Guidelines

Special Care for Laser Beams

Special care should be used when DLP projectors are used in the same room as performant laser equipment. Direct or indirect hitting

of a laser beam on to the lens can severely damage the Digital MicroMirror Devices™ in which case there is a loss of warranty

Which screen type ?

There are two major categories of screens used for projection equipment. Those used for front projected images and those for rear

projection applications.

Screens are rated by how much light they reflect (or transmit in the case of rear projection systems) given a

of light projected toward them. The ‘GAIN’ of a screen is the term used. Front and rear screens are both rated in terms of gain.

The gain of screens range from a white matte screen with a gain of 1 (x1) to a brushed aluminized screen with a gain of 10 (x10)

or more. The choice between higher and lower gain screens is largely a matter of personal preference

called the Viewing angle. In considering the type of screen to choose, determine where the viewers will be located and go for the

highest gain screen possible. A high gain screen will provide a brighter picture but reduce the viewing angle. For more information

about screens, contact your local screen supplier.

determined amount

and another consideration

What image size? How big should the image be?

The projector is designed for projecting an image size : min 1.00m (3.3ft) to max 15 m (49.2ft) (depending on the ambient light

conditions), with an aspect ratio of 1.9:1.

2.2 Restricted Access Location

Installation in a Restricted Access Location

The XLM HD30 can only be installed in a Restricted Access Location.

What is a Restricted Access Location (Definition) ?

Definition of a Restricted Access Location:

A location for equipment where both of the following paragraphs apply:

• Access can only be gained by SERVICE PERSONS or by USERS who have been instructed about the reasons for the restriction

applied to the location and about the precautions that shall be taken.

• Access is through the use of the TOOL or lock and key, or other means of security, and is controlled by the authority responsible

for the location.

What is the Reason for the Applied Restriction?

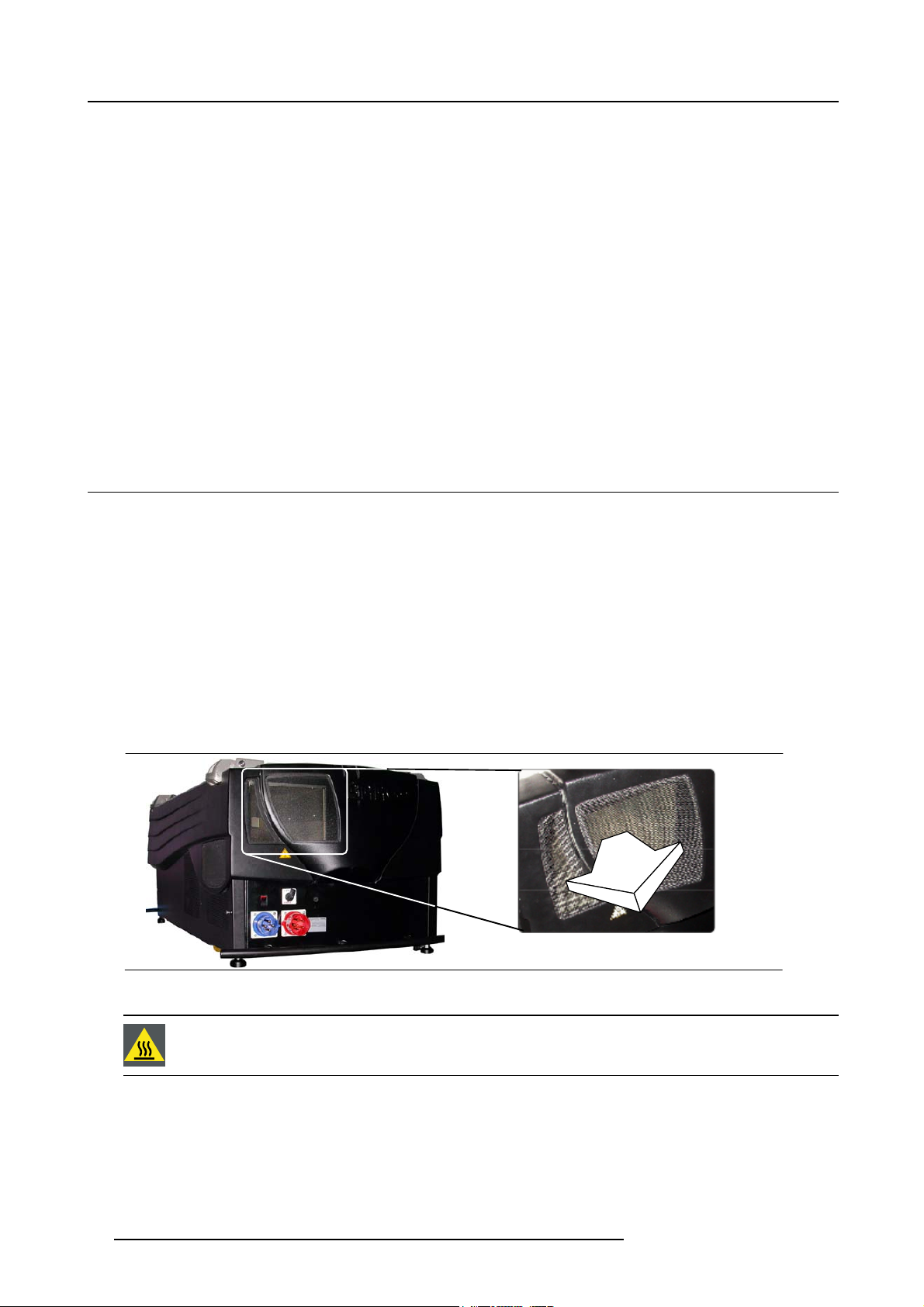

The Air exhaust on the rear of the Projector can reach high temperatures due to the High Light Output Range of the installed lamp.

Image 2-1

The air exhaust on the rear side of the projector.

WARNING: Do not touch this Air Outlet Grill when the projector is running. Respect a cool down period for

at least 10 minutes after the projector has been switched off before touching this Grill .

10 R59770014 XLM HD30 25/05/2009

Page 15

2. Installation Guidelines

2.3 Projector configuration

Which configuration can be used ?

The projector can be installed to project images in four different configurations:

• Front/table

• Rear/table

• Front/ceiling

• Rear/ceiling

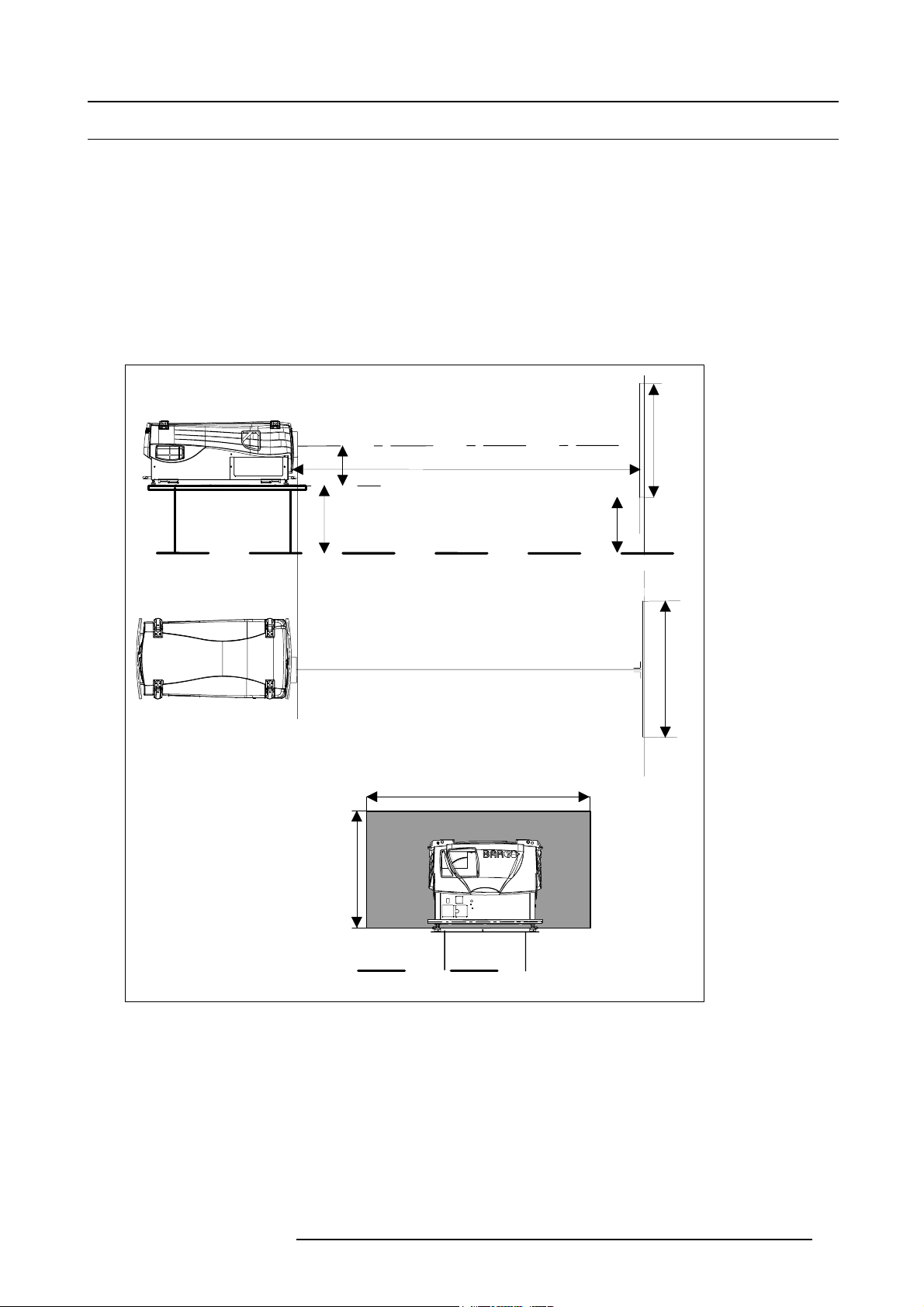

Positioning the projector

The projector should be installed perpendicular with the screen on a distance PD and water leveled in both directions. The mounting

positions in the following images are shown for a nominal lens position.

(1)

(4)

A

PD

SH

(2)

(3)

CD

CD = SH/2 + B - A

SH

B

(5)

SW

SW

Image 2-2

Front-table configuration

(1) Side view

(2) Top view

(3) Back view

(4) Optical axis projection lens

(5) Floor

CD distance between projector and fl oor

PD Projector distance, distance between screen and projector

SW Screen width (image width)

SH Screen height (image height)

R59770014 XLM HD30 25/05/2009

(5)

11

Page 16

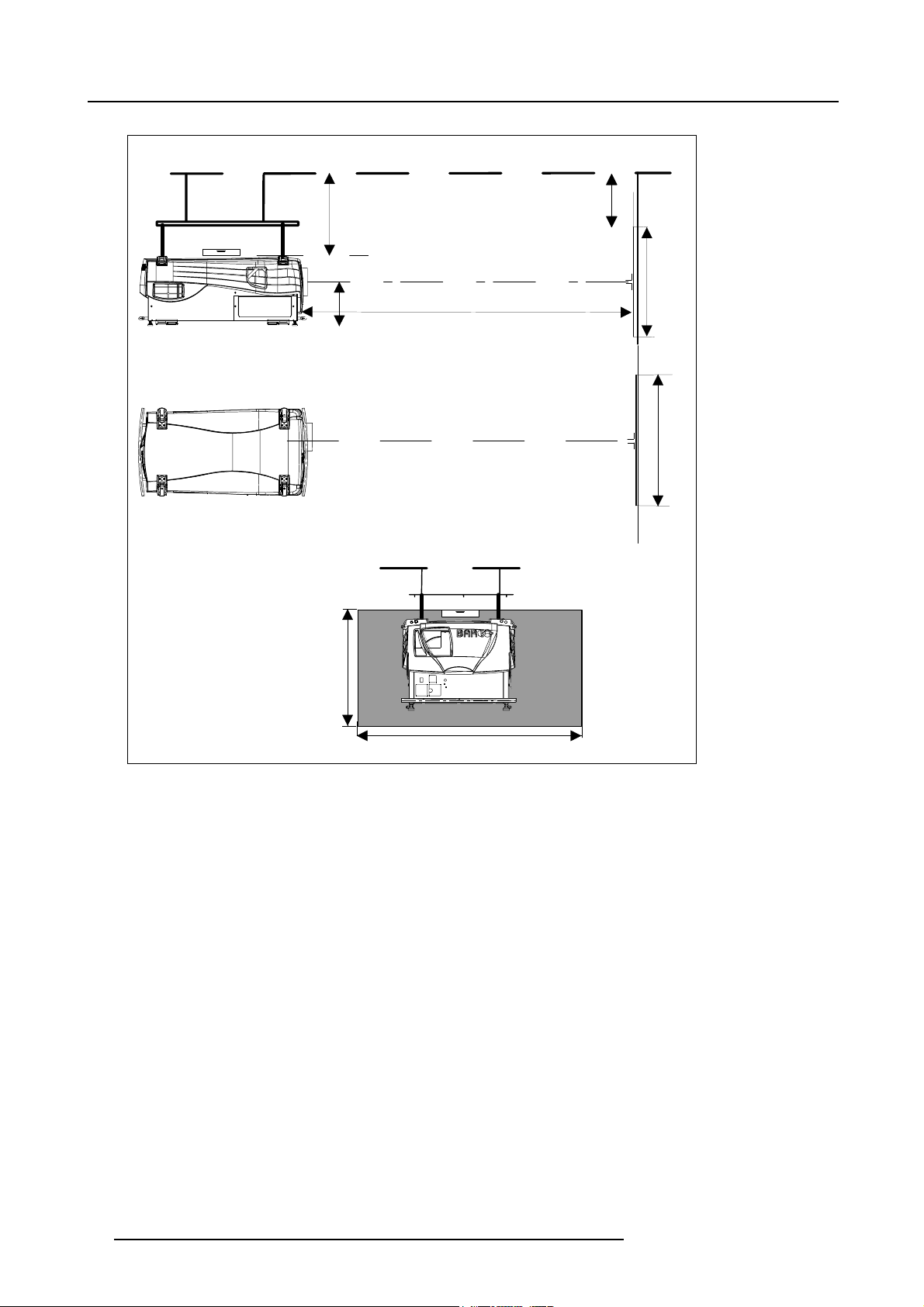

2. Installation Guidelines

(4)

(4)

(1)

(2)

(3)

CD

B

SH

A

PD

SW

SH

Image 2-3

Front-ceiling configuration

(1) Side view

(2) Top view

(3) Back view

(4) Ceiling

CD distance between projector and ceiling

PD Projector distance, distan

SW Screen width (image width)

SH Screen height (image height)

ce between screen and projector

(3)

SW

12

R59770014 XLM HD30 25/05/2009

Page 17

2.4 Safety Area around projector

A

Safety area

B

B

2. Installation Guidelines

A

A

Image 2-4

Air inlet - outlet

A Air inlet

B Air outlet

Due to the air flow, the following free area is recommended :

• Lens side :

- within Light beam : within 2 meter no combustible materials.

- air inlet : 0.5 meter free area

• Backside : within 1 meter no combustible materials.

• Left and right side : 0.5 meter

2.5 Lenses

Overview

• Lenses

• Lens formulas

• Lens installation

2.5.1 Lenses

Available lenses

Lenses

XLD (1.45-1.8:1)

XLD (1.8-2.4:1)

XLD (2.2-3.0:1)

XLD (2.8-5.5:1)

XLD (5.5-8.5:1)

Order number

R9852090

R9852092

R9852094

R9852100

R9852920

R59770014 XLM HD30 25/05/2009 13

Page 18

2. Installation Guidelines

2.5.2 Lens formulas

Formulas

Lenses

XLD (1.45-1.8:1) PD

XLD (1.8-2.4:1) PD

XLD (2.2-3.0:1) PD

XLD (2.8-5.5:1) PD

XLD (5.5-8.5:1) PD

Due to production tolerances the real distances can differ by 2% from these calculated values.

For critical situations (fixed installs that use the lens at one of its extreme zoom positions) this should be

taken into account.

Formulas

=1.45 x SW

min

=1.80 x SW

PD

max

=1.80 x SW

min

=2.40 x SW

PD

max

=2.22 x SW

min

=2.98 x SW

PD

max

=2.84 x SW

min

=5.50 x SW

PD

max

=5.50 x SW

min

PD

=8.50 x SW

max

2.5.3 Lens installation

Howtoinstallalens?

1. Take out the foam rubber.

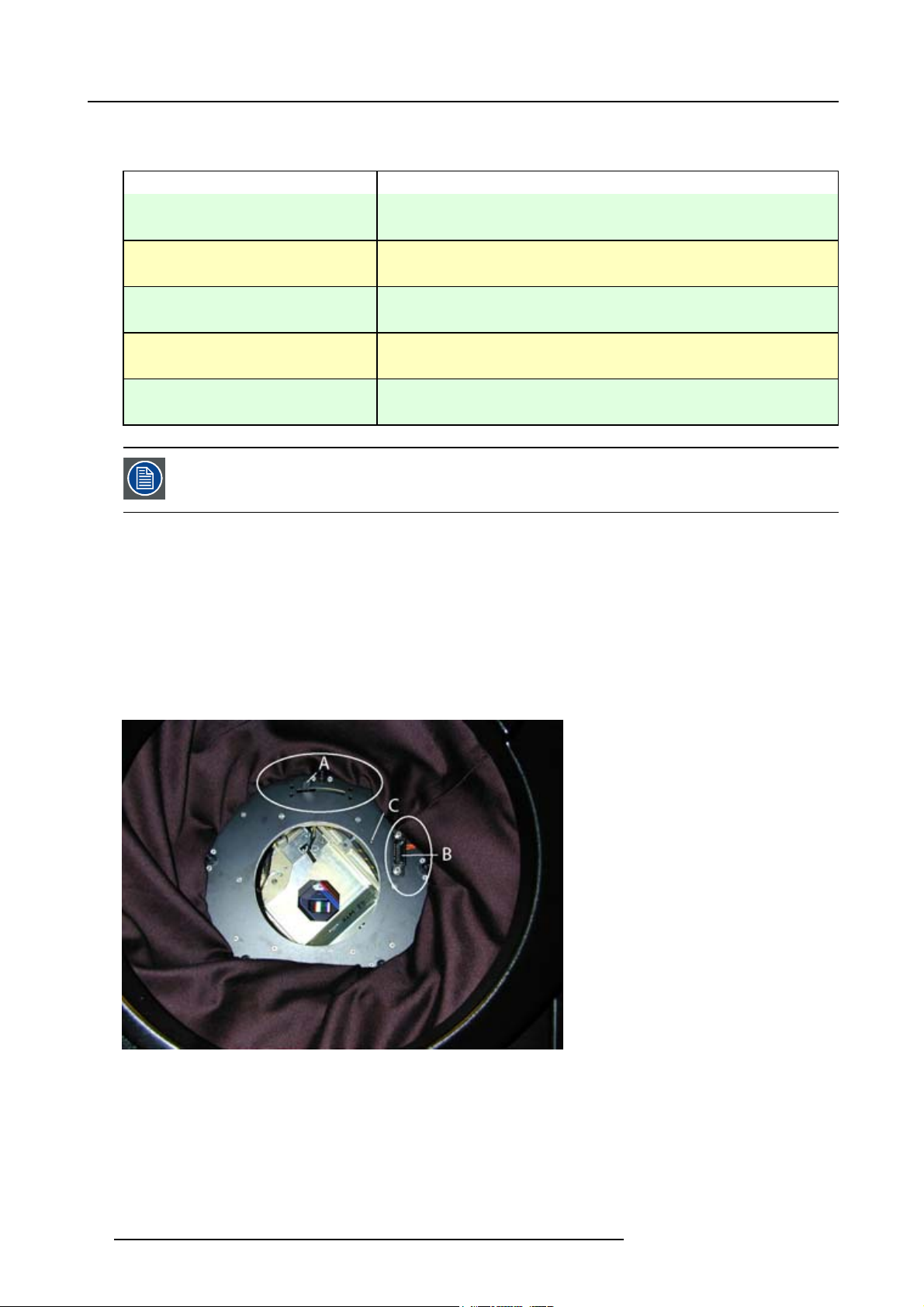

2. Put the lock handler to the left (A). (image 2-5)

3. Insert the lens in such a way that the connector matches the socket (B). (image 2-6)

4. Push on the lens until the connector seats into the socket. The notch (C) will match the hole in the lens.

5. Pull the handle (A) to the right to lock the lens position.

Image 2-5

Lens holder

A Lock handle

B Socket

CNotch

14

R59770014 XLM HD30 25/05/2009

Page 19

2. Installation Guidelines

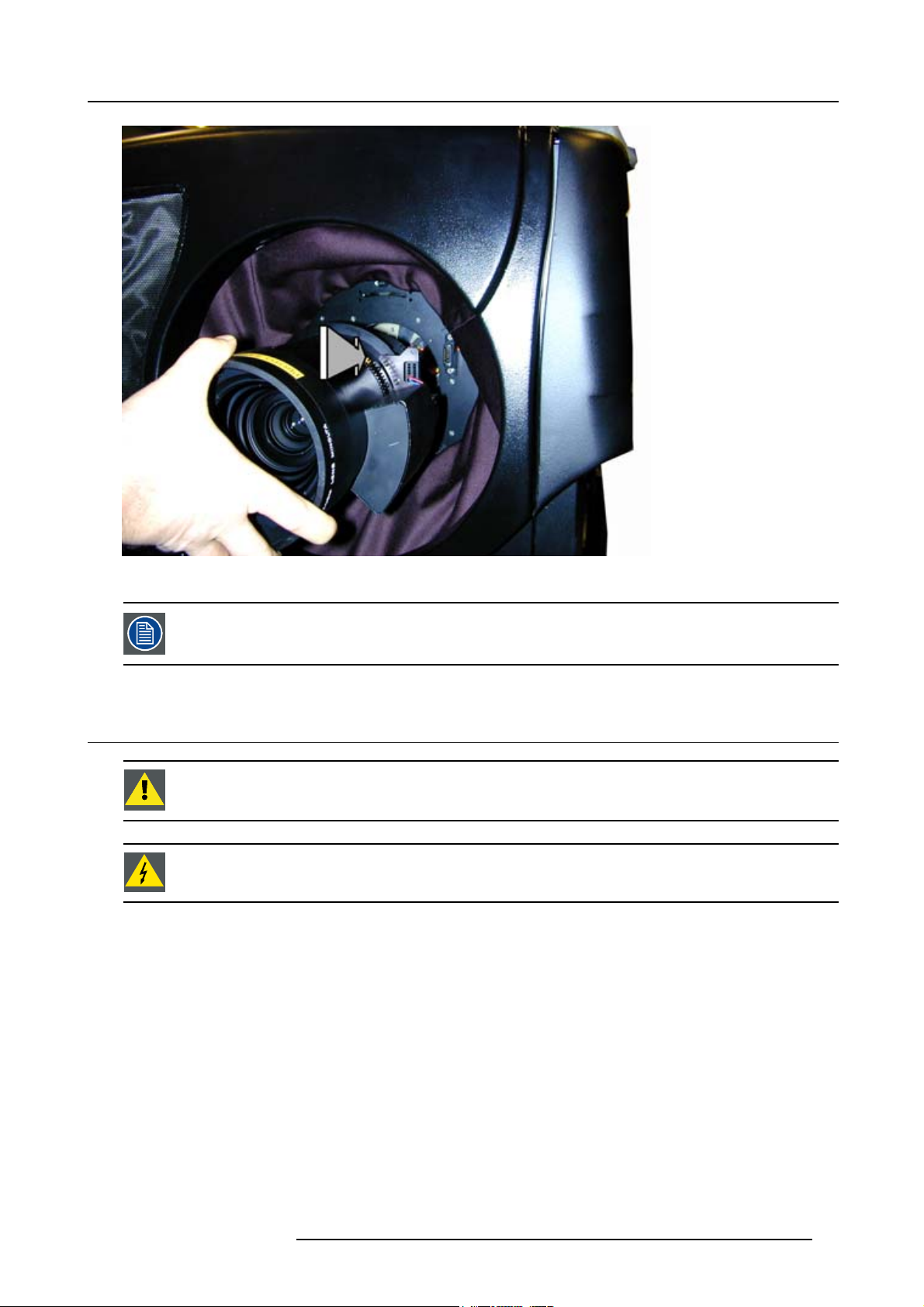

Image 2-6

Mounting lens

For cleaning the lens, see "Cleaning the lens", page 128.

2.6 Mounting the lamp house

CAUTION: Never transport the projector with the lamp casing installed. The lamp casing should always been

transported in a vertical way to avoid damaging the lamp.

WARNING: Never attempt to disassemble the lamp from its housing or to dispose of it other than by returning

it to Barco. Due to its high internal pressure, the lamp may explode in either hot or cold state.

Necessary tools

• Nut driver 10mm

• Flat screwdriver 5mm

Installing the projection lamp

1. Unplug the projector from the wall outlet.

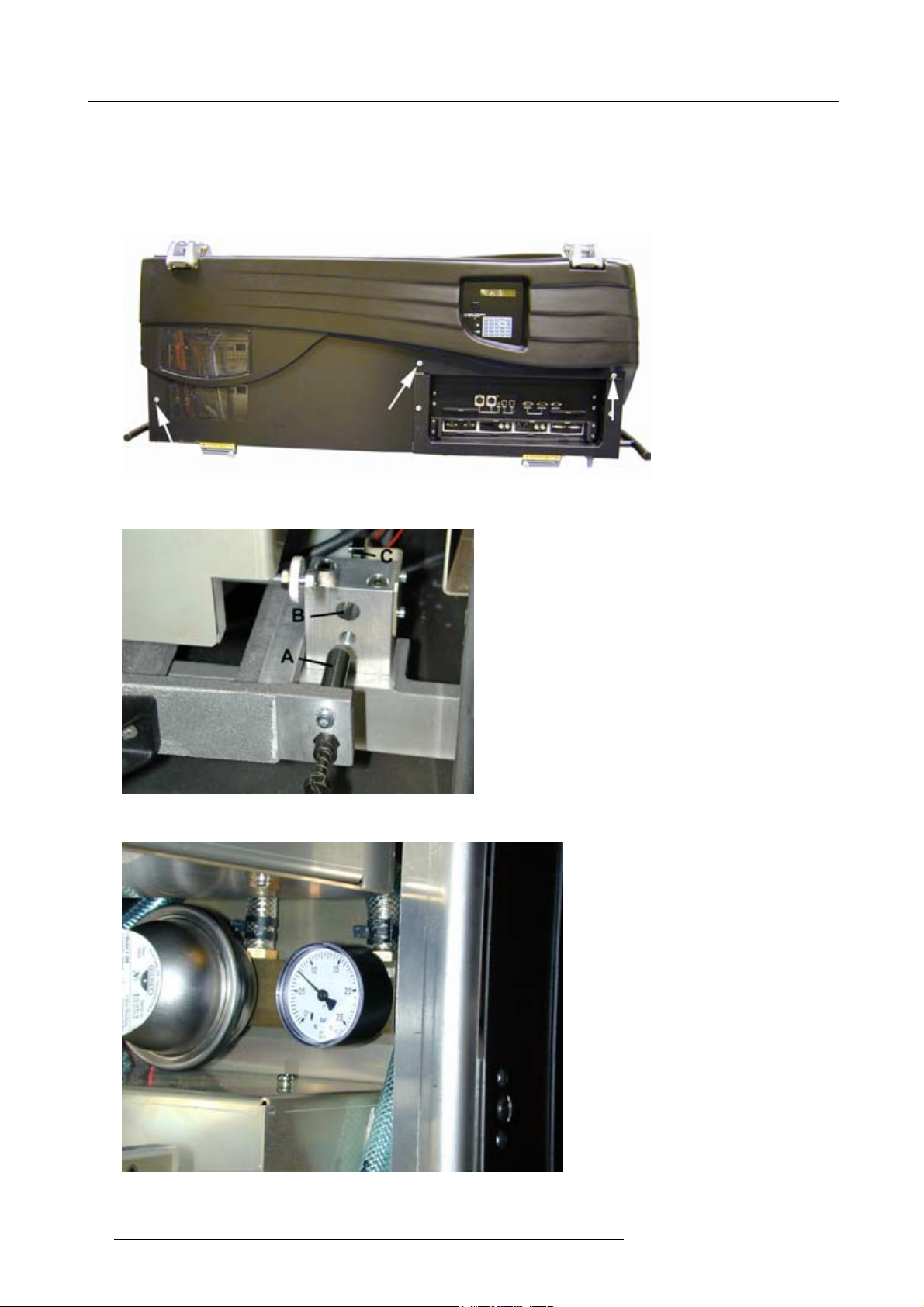

2. On the input side of the projector, remove the side by turning the 3 quarter turn fastener studs a quarter turn counter clockwise.

(image 2-7)

3. Pull the top side of the cover out of its spring locks.

4. Take the lamp casing by both handles carefully out of its shipping box.

5. Place the lamp casing on the optical base plate.

6. Push the lamp casing forward until the lamp slide fully into the projector. Both center pins (A) must match both center (B) holes.

(image 2-8)

If the center pins match the holes, the safety switch (C) will be activated (lamp ignition is possible).

R59770014 XLM HD30 25/05/2009

15

Page 20

2. Installation Guidelines

7. Secure the correct position by turning in both spring lock screws.

8. While the side cover is open, check the manometer. The manometer is situate on the top right of the lamp house compartment.

(image 2-9)

The pressure should be ± 1 bar. When lower than 0.5 bar, a corrective action should be taken by qualified service personnel.

9. Hook on the side cover and close the 3 quarter turn fastener studs a quarter turn clockwise.

Image 2-7

Removing side cover

Image 2-8

Lamp insertion

Image 2-9

Cooling liquid pressure

16 R59770014 XLM HD30 25/05/2009

Page 21

2. Installation Guidelines

CAUTION: While starting up the projector, the electronics detect if a lamp is installed. If no lamp is installed,

it is not possible to start up the projector.

Check the manometer on regular times, at least when replacing the lamp. The pressure should be ± 1 bar.

2.7 Transporting the projector

What to do?

1. Switch the projector to stand by.

2. Let cool down the projector for at least 15 minutes.

3. Switch off the projector and unplug from the wall outlet.

4. On the input side of the projector, remove the side by turning the 3 bolts a quarter turn counter clockwise (image 2-7).

5. Take off the side cover

6. Loosen the retaining bolts of the lamp (image 2-8).

7. Pull out the lamp casing. Wear heat resistant gloves, the case can be hot.

8. Pack the lamp casing into the original lamp packing and transport it vertically.

2.8 Battery Insertion in the Remote Control

Where to find the batteries

The batteries are not placed in the remote control to avoid remote control operation in its package, resulting in a shorter battery life

time.

How to install the batteries

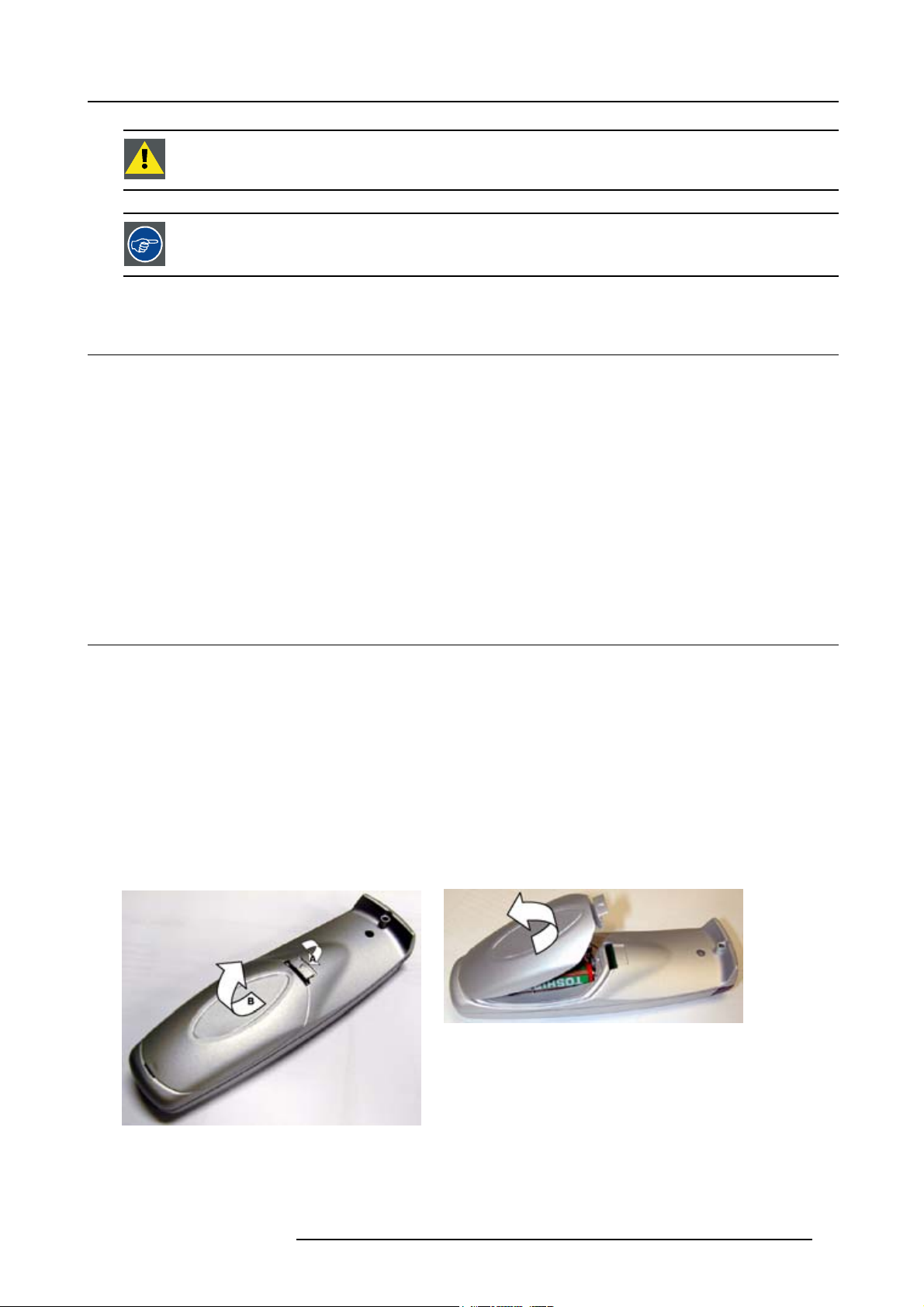

1. Push the cover tab (A) with the fingernail a little backwards and pull upwards the cover top (B). (image 2-10)

2. Slide the cover forwards to remove. (image 2-11)

3. Push the battery body towards the spring and lift it up to remov

4. Insert two AA size batteries, making sure the polarities match the + and – marks inside the battery compartment (image 2-12).

5. Insert the lower tab of the battery cover in the gap at the bottom of the remote control, and press the cover until it clicks in place

(image 2-11).

e. (image 2-12)

Image 2-11

Battery cover removal

Image 2-10

Battery cover unlock

R59770014 XLM HD30 25/05/2009 17

Page 22

2. Installation Guidelines

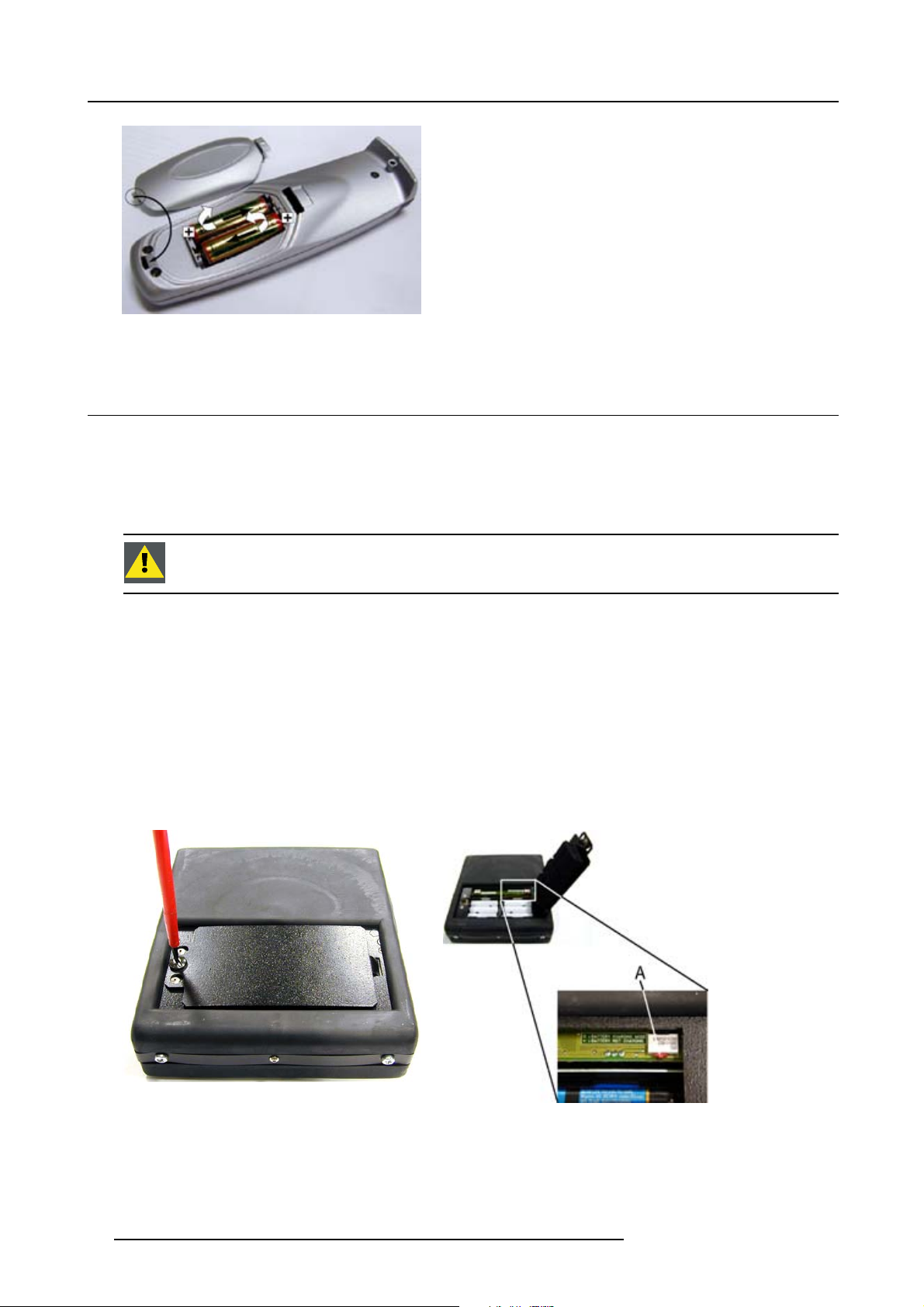

Image 2-12

Battery removal

2.9 Battery insertion in the Rugged remote control

Batteries

The rugged remote control is delivered with 6 rechargeable NiCd batteries, type AA.

Expected charge and discharge cycles : 1000

When replacing the batteries, all batteries should be replaced at the same time.

CAUTION: Risk of explosion if the batteries are replaced by an incorrect type.

How to insert the batteries ?

1. Turn off the remote and remove all cables.

2. Turn the locking screw counter clockwise to free the metallic cover. (image 2-13)

3. Open the metallic cover.

4. Insert the new batteries correctly in the battery compartment. (image 2-14)

Be sure to install the batteries in the proper polarity and not to short battery terminals together.

5. Set switch A in the Charge position (left position).

6. Close the metallic cover.

7. Turn the locking screw clockwise to lock the metallic cover.

Image 2-13

Open the battery cover

18

Image 2-14

Charge switch

A Charge switch

R59770014 XLM HD30 25/05/2009

Page 23

2.10 Charging the batteries of the rugged remote control

2.10.1 Preparing the charger

What can be done ?

The charger can be fitted with one of the four supplied power plugs.

Image 2-15

Possible power plugs

1ForAustralia

2 For US/Japan

3 Europe

4UK

2. Installation Guidelines

How to mount the correct plug ?

1. Pull the plug to be changed upwards until it is completely removed from the charger. (image 2-16)

2. Place the plug to be mounted on the charger and guide it downwards by using the guiding slots. (image 2-17)

3. Push the plug downwards until it clicks and is locked into the charger. (image 2-18)

4. Check if the plug is well locked.

It must not stick out of the charger.

Image 2-16

Remove plug

Image 2-17

Guiding grooves

Image 2-18

Mounting the plug

2.10.2 Charging the batteries

When charging the batteries

Charging is required whenever the batteries are low. The status of the batteries can be seen on the main menu (third line) or in the

diagnosis menu.

BAT=ACT The remote is working on batteries, there is no supply via external power source.

BAT=LOW The batteries are running low

Possible ways to charge the batteries

The batteries can be charged in one of the following ways :

• Via the battery charger

• Via the XLR connection with the projector when the projector is in standby or in operational mode.

Howtochargeviatheadapter?

1. Plug the female power connector of the charger into the male connector at the right side of the remote control.

2. Connect the charger to the wall outlet.

R59770014 XLM HD30 25/05/2009

19

Page 24

2. Installation Guidelines

2.10.3 Power save mode

Why used ?

When working on batteries, indicated on the main menu as BAT=ACT, the power save mode is enabled if there is no key hit within

2 minutes.

A message will be displayed : “POWER SAVE MODE”.

The remote control is automatically switched off after being approximately 10 minutes in the Power Save

Mode. Use the ON/OFF switch to reset the Remote control.

2.11 Stacking Two Projectors

How to handle

1. Turn in the four feet of the second projector.

2. Pull the handler A of the second projector a little backwards. (image 2-19)

3. Put the second projector on the first one so that the base plate of the second projector matches with the rigging socket of the fi rst

projector.

4. Slide the security pin (handler C) into the hole of the rigging socket of the first projector until the handler jumps into its socket (D).

(image 2-20)

Projector 2

B

Projector 1

Image 2-19

Stacking two projectors

C

Image 2-20

Stacking : security lock

A

A

D

WARNING: Close always the four security pins when stacking two projectors on each other.

20 R59770014 XLM HD30 25/05/2009

Page 25

2. Installation Guidelines

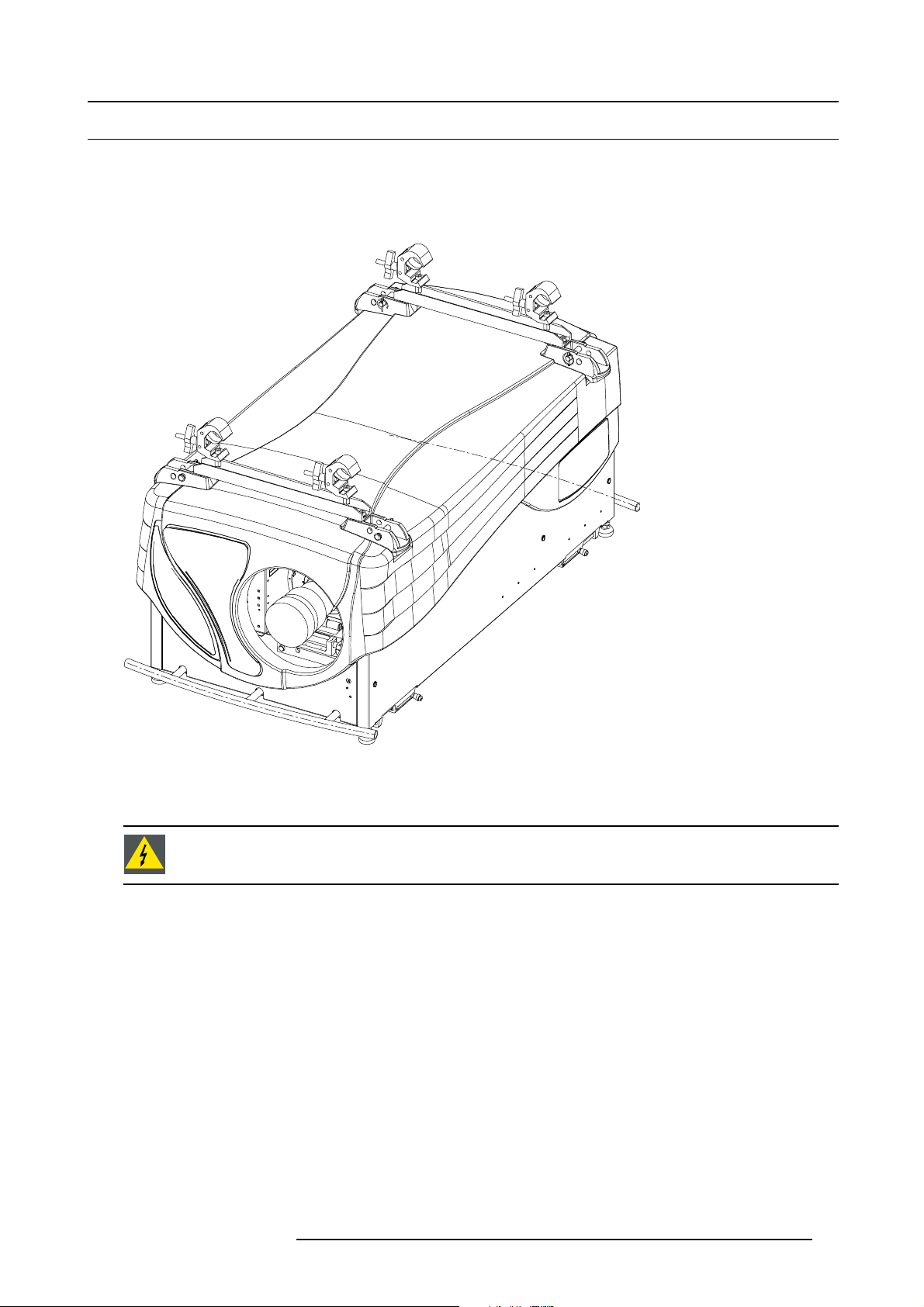

2.12 Rigging points and clamps

Clamps and brackets

Support bars, short and long, are available to be mounted on the projector so that the clamps can be fixed to these bars and the

projector can be mounted to a rigging system.

One example drawing is given below, for more possibilities, consult the complete documentation.

Image 2-21

Rigging kit mounted

Consult a professional structural engineer prior to suspending the ceiling mount from a structure not intended for that use. Always

ensure the working load limit of the structure supporting the projector.

WARNING: When mounting the projector to the ceiling or to a rigging system, always mount security chains.

Complete documentation

For a complete documentation consu

lt manual R5976765.

R59770014 XLM HD30 25/05/2009

21

Page 26

2. Installation Guidelines

22 R59770014 XLM HD30 25/05/2009

Page 27

3. CONNECTIONS

Overview

• Power connection

• Connection facilities

• Input source connection

• Communication connection

• Monitor output

3.1 Power connection

Possibilities

The XLM HD30 can be powered on two ways:

• 3 power lines + neutral + earth line on 400V AC (red connector)

• 3 power lines + earth line on 250V AC (blue connector)

Field configurable via a selection switch.

3. Connections

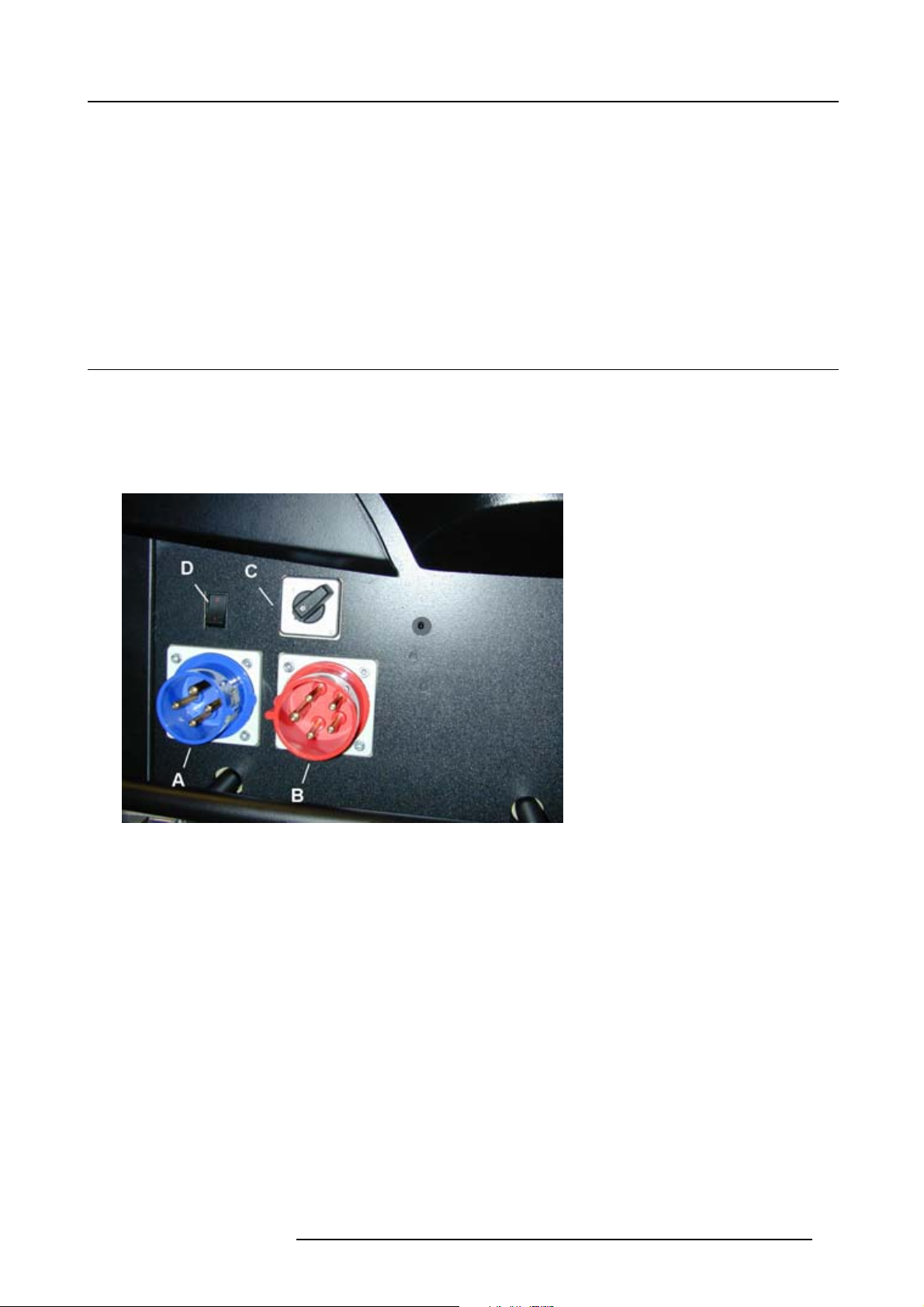

Image 3-1

Possible power connections

A 3 power lines + earth on 250V AC

B 3 power lines + neutral + earth on 400V AC

C Power selection switch

D Power switch

Power consumption : 8 kW

R59770014 XLM HD30 25/05/2009

23

Page 28

3. Connections

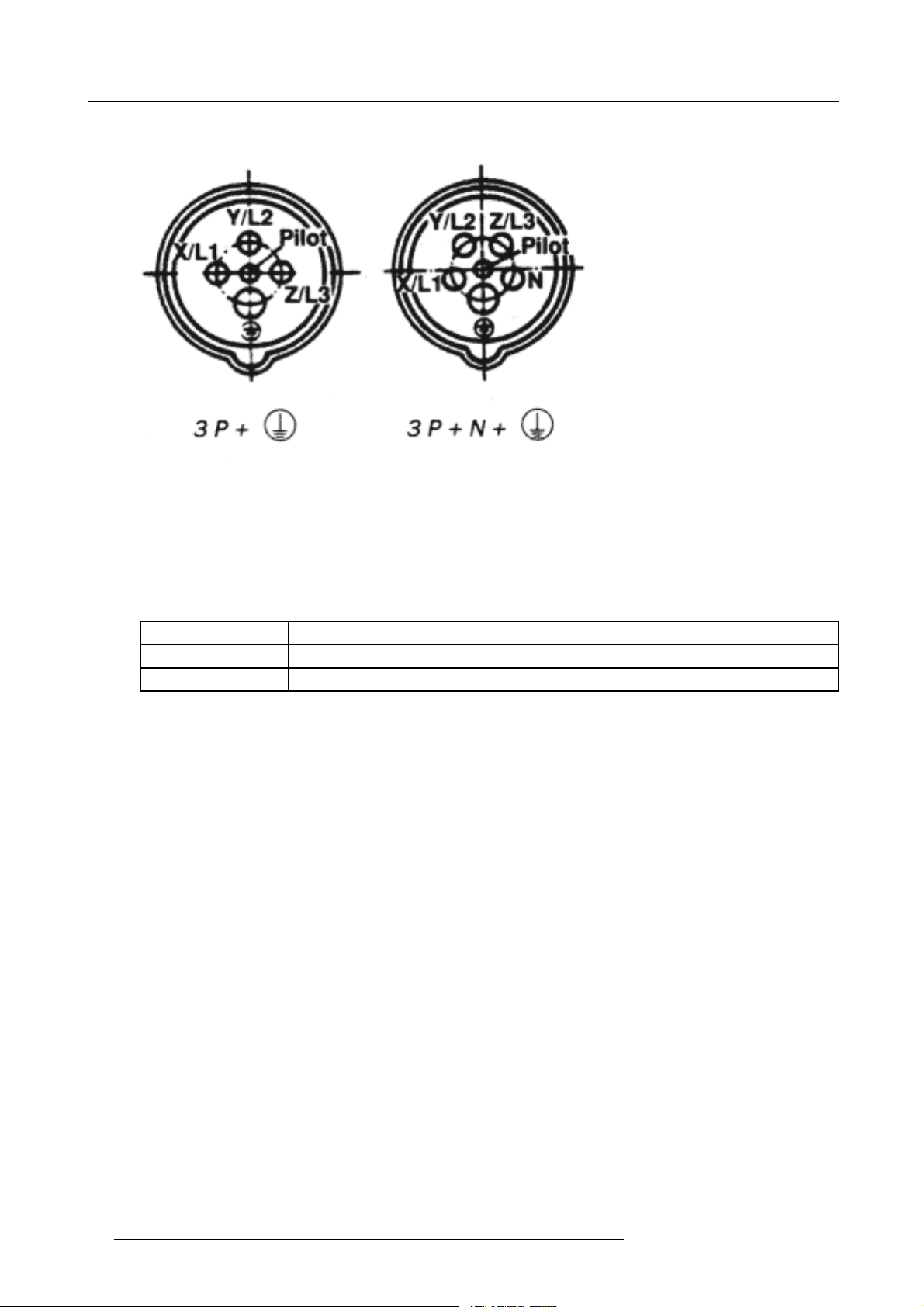

Pin connections of the power plug

Image 3-2

View from projector side.

How to connect ?

1. Plug the female connector of the power cord into the corresponding male connector on the projector.

Caution: Power Cord: the cross-sectional area of the conductor in the power s upply cord shall be not less than 4 mm

AWG 10.

2. Put the voltage selection switch in the correct position.

2

or

Switch position

Upper left

Lower left

3. Put the male connector of the power cable into the wall outlet

Description

3 x 208V

3 x 400V

.

24

R59770014 XLM HD30 25/05/2009

Page 29

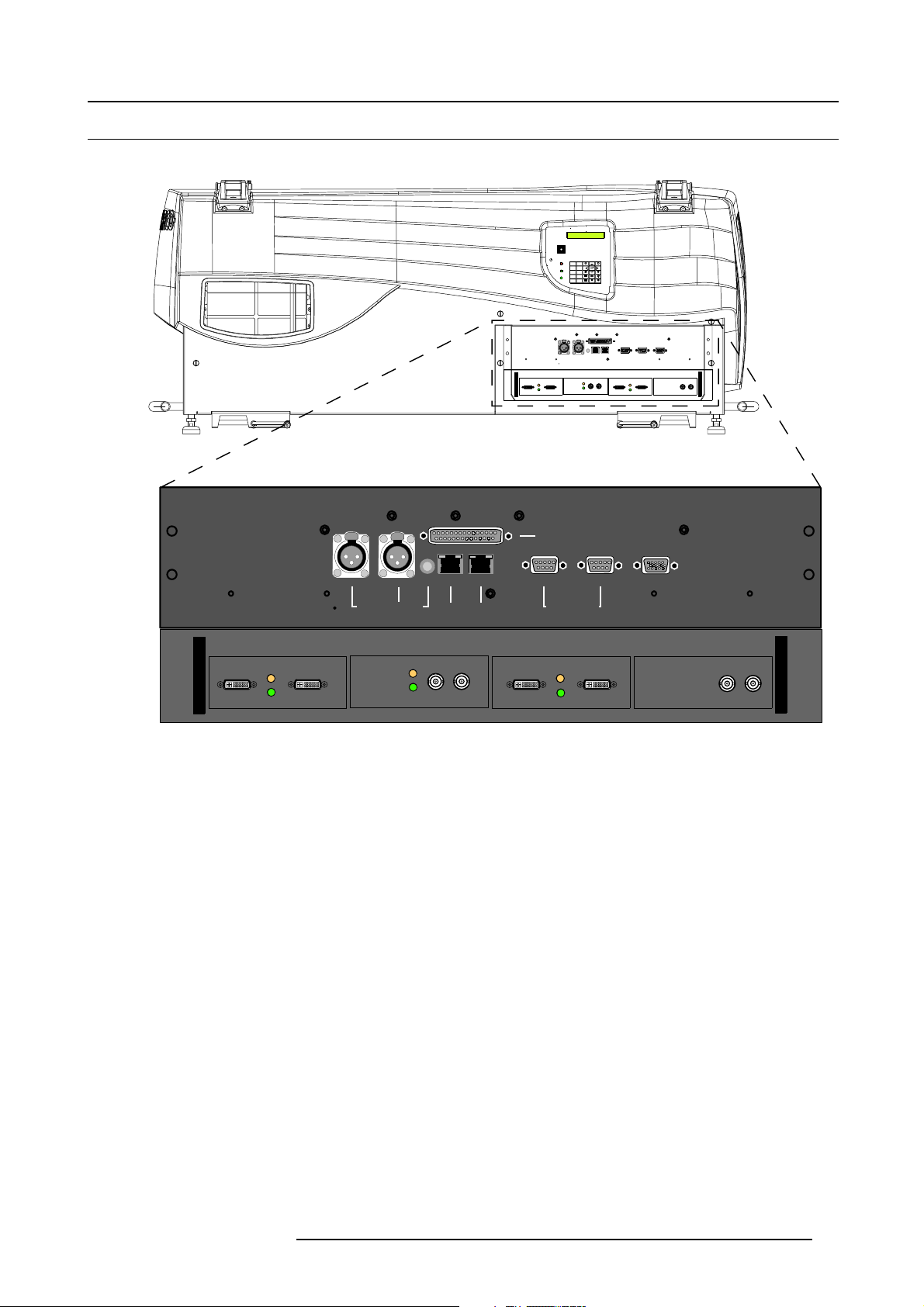

3.2 Connection facilities

Overview

GREEN : OPERATIONAL

RED : STAND-BY

3. Connections

EXIT

STANDBY

8097

ENTER

IR

56

TEXT

PAUSE

3

4

TINT

BRIGHTN

SHARPN

OK

21

COLOR

PHASE

CONTRAST

PUSH

PUSH

2

2 1

1

3

3

BI-DIRECTIONAL UNI-DIRECTIONAL

PUSH

L1

2

CTRL 3

3

L2

Image 3-3

Input facilities

• Layer 1 : communication input/outputs

• Hardwired remote

o

CTRL 1 : wired RCU

o

CTRL 2 : Uni-directional hardwired remote

o

CTRL 3 : Bi-directional hardwired remote

• Ethernet communication

o

Port 1 10/100 BaseT

o

Port 2 10/100 BaseT

- Wireless remote (optional)

- Serial network RS232/RS422 In/Out

- Monitor out

• Layer 2 : source inputs (standard)

-SDI

- HDSDI

-DVIuptoUXGA

- RGBHV analogue

Video and S-Video are optional inputs.

PUSH

1

2 1

3

CTRL 2 CT RL 1 PORT 1

HARDWIRED REMOTE 10/100 BASE T

PORT 2

WIRELESS REMOTE

RS232/422 IN

SERIAL NETWORK

RS232/422 OUT

MONITOR OUT

MONITOR OUT

R59770014 XLM HD30 25/05/2009

25

Page 30

3. Connections

3.3 Input source connection

Overview

• Introduction

• Removing and Inserting an input module

• DVI input module

• SDI input module

• HDSDI input module

• YUV / RG(s)B input module

• RGB analog input module

• CVBS / S-VID input module

• Dummy input module

3.3.1 Introduction

Overview

The source input layer (L2 on image 3-3) consists out of different input modules. Any combination is possible. Within the next topics

each input module will be discussed.

If no input module is inserted, the slot must be filled up by dummy input.

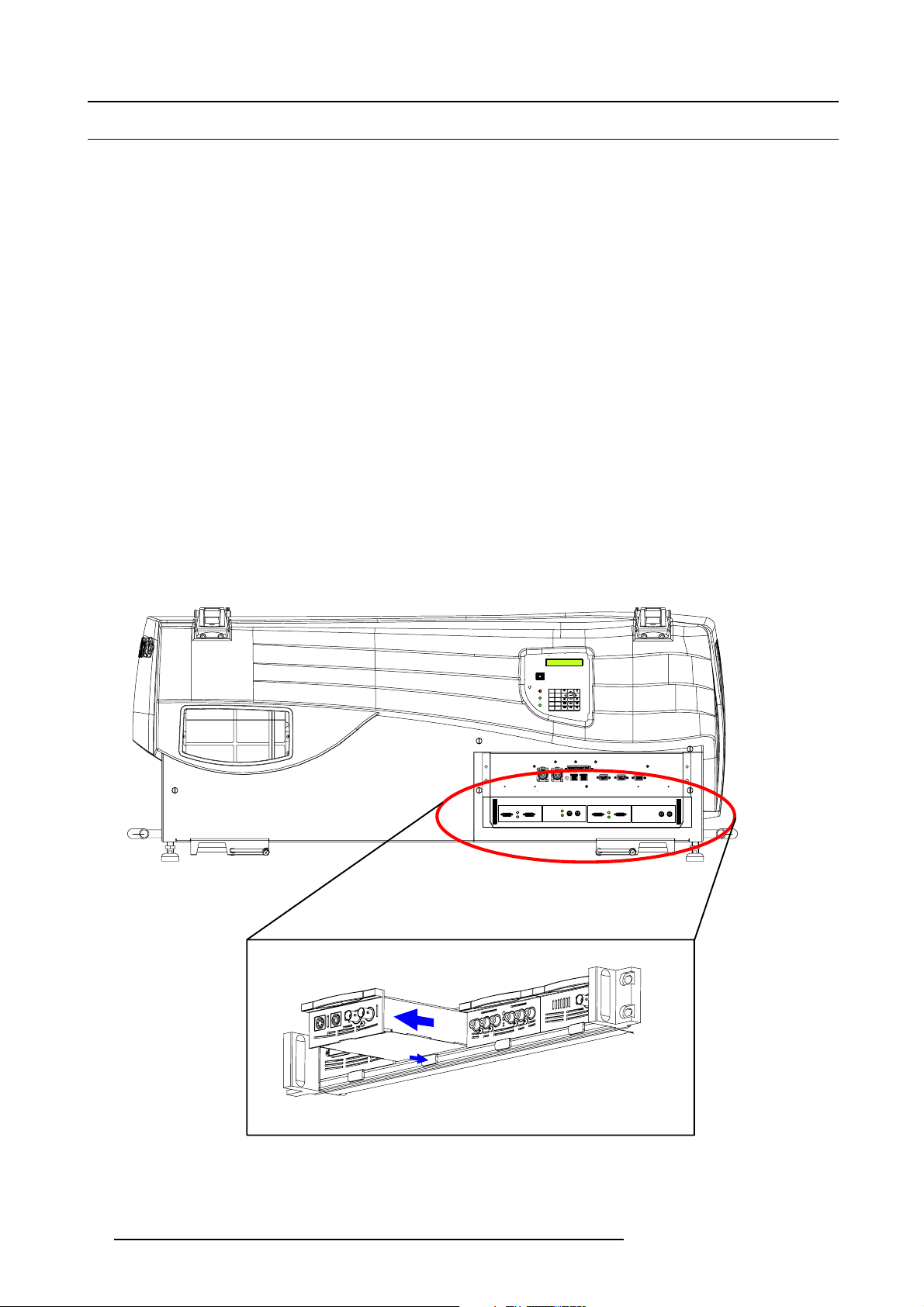

3.3.2 Removing and Inserting an input module

How to remove an input module?

1. Push on the release button underneath the input module (1) which you want to remove. At the same time pull out the input

module by the grip handle (2). (image 3-4)

GREEN : OPERATIONAL

RED : STAND-BY

EXIT

STANDBY

8097

ENTER

IR

56

TEXT

PAUSE

3

4

TINT

BRIGHTN

SHARPN

OK

21

COLOR

PHASE

CONTRAST

PUSH

PUSH

2

2 1

1

3

3

2

1

Image 3-4

Module insertion

26 R59770014 XLM HD30 25/05/2009

Page 31

3. Connections

How to insert an input module ?

1. Gently slide in the input module into a free input slot with the grip handle at the top.

2. Locking in the module by pushing the input module completely into the slot until a defi nite click is audible.

3.3.3 DVI input module

Technical info:

• Computer generated graphical source.

• DVI data in.

• 162 MHz pixel clock.

• Resolution from VGA to UXGA/60 Hz.

• DVI compliant.

• DVI loop through.

• Amber LED (upper LED on the front side) will be lit indicating module start up.

• When placed in an input slot the green LED (lower LED on the front side) will be lit indicating that the system acknowledges

the module.

IN OUT

Image 3-5

D320 DVI

Image 3-6

Order info:

Article No. Description

R9850960 D325Digitizer DVI input module

3.3.4 SDI input module

Technical info:

• SDI data in.

• SDI loop through.

• 270Mbit/s transmission (SMPTE 259M-C).

• 525/625 interlaced.

• Coax (75 Ohm).

• Amber LED (upper LED on the front side) will be lit indicating recognition of film, either continuous or intermittent film detection.

• When placed in an input slot the green LED (lower LED on the front side) will be lit indicating that the system acknowledges

the module.

IN OUT

Image 3-7

D320 SDI

Image 3-8

Order info:

Article No. Description

R9850970

R59770014 XLM HD30 25/05/2009 27

D325Digitizer SDI input module

Page 32

3. Connections

3.3.5 HDSDI input module

CAUTION: Maximum two HDSDI input modules may be inserted in one D325Digitizer.

Technical info:

• HDSDI data in (SMPTE292M).

• HDSDI loop through (SMPTE292M).

• Coax (75 Ohm).

• When placed in an input slot the green LED (lower LED on the front side) will be lit indicating that the system acknowledges

the module.

• Supported HDSDI standards:

- Progressive:

o

1280x720/60/1:1/ (SMPTE 296M)

o

1280x720/59.94/1:1/ (SMPTE 296M)

o

1920x1080/30/1:1/ (SMPTE 274M)

o

1920x1080/29.97/1:1/ (SMPTE 274M)

o

1920x1080/25/1:1/ (SMPTE 274M)

o

1920x1080/24/1:1/ (SMPTE 274M)

o

1920x1080/23.98/1:1/ (SMPTE 274M)

- Interlaced:

o

1920x1035/60/2:1/ (SMPTE 260M)

o

1920x1035/59.94/2:1/ (SMPTE 260M)

o

1920x1080/60/2:1/ (SMPTE 274M)

o

1920x1080/59.94/2:1/ (SMPTE 274M)

o

1920x1080/50/2:1/ (SMPTE 274M)

o

1920/1080/50/2:1 (1250)/ (SMPTE 295M)

o

1920x1080/24/Segmented/ (SMPTE 274M)

o

1920x1080//23.98/Segmented/ (SMPTE 274M)

IN OUT

Image 3-9

D320 HDSDI

Image 3-10

Order info:

Article No. Description

R9850980 D325Digitizer HDSDI input module

3.3.6 YUV / RG(s)B input module

Technical info:

• Component Video (BNC)

- R-Y : 0,7Vpp ±3dB 75 Ohm termination.

- Ys : 1Vpp ±3dB (0,7V Luma +0,3V Sync) 75 Ohm termination.

- B-Y : 0,7Vpp ±3dB 75 Ohm termination.

•RG(s)B(BNC)

- R : 0,7Vpp ±3dB 75 Ohm termination.

- G(s) : 1Vpp ±3dB (0,7Vpp G + 0,3Vpp Sync) 75 Ohm termination.

- B : 0,7Vpp ±3dB 75 Ohm termination.

• 3 BNC’s loop through connectors.

28

R59770014 XLM HD30 25/05/2009

Page 33

3. Connections

• Amber LED (upper LED on the front side) will be lit indicating recognition of film, either continuous or intermittent film detection.

• When placed in an input slot the green LED (lower LED on the front side) will be lit indicating that the system acknowledges

the module.

• Supports MacroVision™.

IN OUT

Image 3-11

D320 YUV/RGSB

Image 3-12

Order info:

Article No. Description

R9850940 D325Digitizer YUV / RG(s)B input module

3.3.7 RGB analog input module

Technical info:

• Sub D15 connector for input and loop through.

• R, G, B, Hsync, Vsync : 0 to 1 Vpp ±3dB 75 Ohm termination.

• Black level : 300mV.

•Sync-tip:0V

• Resolution : SXGA and UXGA version available.

• Amber LED (upper LED on the front side) will be lit indicating recognition of film, either continuous or intermittent film detection.

• When placed in an input slot the green LED (lower LED on the front side) will be lit indicating that the system acknowledges

the module.

IN OUT

Image 3-13

D320 RGB-AN

Image 3-14

Order info:

Article No. Description

R9850950

R9851710

R9853120

R59770014 XLM HD30 25/05/2009 29

D325Digitizer RGB analog SXGA input module

D325Digitizer RGB analog UXGA input module

D325Digitizer RGB analog input module

Page 34

3. Connections

3.3.8 CVBS / S-VID input module

Technical info:

• Video (BNC)

- CVBS : 1Vpp ±3dB (0,7V Video +0,3V Sync) 75 Ohm termination.

- BNC loop through connector.

• S-Video (4 pins DIN)

- Y : 1Vpp ±3dB (0,7V Video +0,3V Sync) 75 Ohm termination.

- U/V : 0,7Vpp ±3dB 100% color base, 75 Ohm termination.

- Chroma : Multi-Standard (PAL / SECAM / NTSC).

- 4 pins DIN loop through connector.

• Amber LED (upper LED on the front side) will be lit indicating recognition of film, either continuous or intermittent film detection.

• When placed in an input slot the green LED (lower LED on the front side) will be lit indicating that the system acknowledges

the module.

• Supports MacroVision™.

IN OUT

Image 3-15

IN OUT

D320 CVBS/S-VID

Image 3-16

Order info:

Article No. Description

R9850920 D325Digitizer CVBS / S-VID input module

3.3.9 Dummy input module

Technical info

• Dimensions : 103 x 181 x 41(W x D x H)

Image 3-17

D320 DUMMY

Image 3-18

Order info:

Article No. Description

R9850930 D325Digitizer dummy input module

30 R59770014 XLM HD30 25/05/2009

Page 35

3.4 Communication connection

Overview

• RS232/422 IN/OUT Serial network

• Ethernet connection

• Hardwired remote to CTRL 1

• Bi-directional communication port, CTRL 3

3.4.1 RS232/422 IN/OUT Serial network

RS232

An Electronic Industries Association (EIA) serial digital interface standard specifying the characteristics of the communication path between two devices using either D-SUB 9 pins or D-SUB 25 pins connectors. This standard is used for

relatively short-range communications and does not specify balanced control lines. RS-232 is a serial control standard

with a set number of conductors, data rate, word length and type of connector to be used. The standard specifies component connection standards with regard to computer interface. It is also called RS-232-C, which is the third version

of the RS-232 standard, and is functionally identical to the CCITT V.24 standard. Logical ’0’ is > + 3V, Logical ’1’ is < 3V. The range between -3V and +3V is the transition zone.

RS422

An EIA serial digital interface standard that specifies the electrical characteristics of balanced (differential) voltage,

digital interface circuits. This standard is usable over longer distances than RS-232. This signal governs the asynchronous transmission of computer data at speeds of up to 920,000 bits per se

standard for Macintosh computers. When the difference between the 2 lines is < - 0.2V that equals with a logical ’0’.

When the difference is > +0.2V that equals to a logical ’1’..

3. Connections

cond. It is also used as the serial port

Application

1. Remote control:

- easy adjustment of projector via a computer.

- allow storage of multiple projector configurations.

- wide range of control possibilities.

2. data communication

Pin configuration

BI-DIRECTIONAL UNI-DIRECTIONAL

PUSH

2 1

CTRL 3

Image 3-19

RS232/RS422 serial network connection

RS232/422 Serial Network IN

1

Data Carrier Detect (CD) 6 RXC+ Data Set Ready (DSR)

2 RXC- Receive Data (RD or RX or RXD)

3 TXC- Transmitted Data (TD or TX or TXD)

4TXC+ Data Terminal Ready (DTR)

5 GND Signal Ground (GND)

PUSH

2

3

1

3

CTRL 2 CTRL 1 PORT 1

HARDWIRED REM OTE 10/100 BASE T

PORT 2

WIRELESS REMOTE

RS232/422 IN

SERIAL NETWORK

MONITOR OUT

RS232/422 OUT

7

8

9

MONITOR OUT

Request to send (RTS)

Clear To Send (CTS)

Ring Indicator (RI)

-

RS232/422 Serial Network OUT

1

2RXB-

3TXB-

-

Receive Data (RD or RX or RXD)

Transmitted Data (TD or TX or TXD)

6RXB+

7

8

Data Set Ready (DSR)

-

-

R59770014 XLM HD30 25/05/2009 31

Page 36

3. Connections

RS232/422 Serial Network OUT

4TXB+

Data Terminal Ready (DTR)

5 GND Signal Ground (GND)

9

--

-

3.4.2 Ethernet connection

Connection

Connect port 1 or port 2 to a LAN by using a straight cable or a crossed cable. The connection is a 10/100 baseT.

Image 3-20

Ethernet connection

BI-DIRECTIONAL UNI-DIRECTIONAL

PUSH

PUSH

2 1

2 1

3

3

CTRL 3

CTRL 2 CTRL 1 POR T 1

HARDWIRED REMOTE 10/100 BASE T

PORT 2

WIRELESS REMOTE

RS232/422 IN

SERIAL NETWORK

RS232/422 OUT

MONITOR OUT

MONITOR OUT

The projector must have an IP address and the IP address of the connected PC must be within the same range of IP addresses.

Once getting access, it is possible to check and manipulate all projector settings. Remote diagnostics, control and monitoring become very simple.

The 2 ports are functionally identical. Both ports are connected via the projector hub.

Pin configuration

Ethernet 10/100 base T Port 1 & 2

1TXD+

2TXD- 6 RXD-

3RXD+

4 ++2.5VA 8 GNDM

5

++2.5VA

7

RXD-

3.4.3 Hardwired remote to CTRL 1

How to connect

1. Plug one end of the remote cable in the connector on the bottom of the RCU. (image 3-21)

2. Plug the other end in the connector in the input pan

Specifications of the CTRL 1 input:

-U

=9V

in

=80mA

-I

max

• Internal IR receiver can be disabled:

o

monojack: onpluginofthejack

o

stereo jack : on plug in or using an external switch bringing the right channel (B) to ground level. (image 3-22)

32

el of the projector labelled CTRL 1.

R59770014 XLM HD30 25/05/2009

Page 37

Image 3-21

Hardwired RCU

GREEN : OPERATIONAL

RED : STAND-BY

3. Connections

STANDBY

EXIT

8097

ENTER

IR

6

5

TEXT

PAUSE

3

4

TINT

BRIGHTN

SHARPN

OK

21

COLOR

PHASE

CONTRAST

PUSH

PUSH

2 1

2 1

3

3

D

AB C

2

3

1

1

2

Image 3-22

Stereo jack pin configuration

A tip : left channel

B ring : right channel

C screen : common (GND)

Dexternalswitch

1Stereojack

2 Mono jack

The Remote connection uses a standard two wire cable terminated on each end with a 3.5 mm male

(mono/stereo) phone jack.

This cable is not delivered but is available in most electronic or audio shops.

3.4.4 Bi-directional communication port, CTRL

3

What can be connected

The rugged remote control can be connected to the Bi-directional communication port CTRL 3.

With this rugged remote control all control functions can be taken over. The LCD panel on this rugged remote displays the same

information as the panel on the projector itself.

Pin assignment two way connector

12

3

Image 3-23

R59770014 XLM HD30 25/05/2009 33

Page 38

3. Connections

Pin Description

1

GND

2DATA+

3DATA-

How to connect via a cable ?

1. Plug one end of the twisted pare cable with XLR connector in the two way connector on the rugged remote (CTRL3). (image 3-24)

Fixed rate : 57600 baud

2. Plug the other end in the Bi-directional connector (CTRL 3) on the projector. (image 3-25)

Image 3-24

Rugged remote control, backside

GREEN : OPERATIONAL

RED : STAND-BY

0

9

STANDBY

EXIT

8

7

ENTER

IR

56

TEXT

PAUSE

43

BRIGHTN

TINT

SHARPN

OK

21

PHASE

COLOR

CONTRAST

PUSH

PUSH

2 1

2 1

3

3

Image 3-25

Bi-directional rugged remote control

How to set up the rugged remote control ?

1. Press ADJ key once.

The main menu of the rugged remote

2. Push the cursor key ↑ or ↓ to select Instal. Settings.

34

control will be started.

R59770014 XLM HD30 25/05/2009

Page 39

3. Press ENTER to select.

4. Push the cursor key ↑ or ↓ to select Communication.

5. Press ENTER to select.

6. Push the cursor key ↑ or ↓ to select Com m. Port.

7. Press ENTER to select.

8. Press ENTER to toggle between [Auto], [XLR], [RS232] and eventually [RF]

Select the corresponding setting. Two are possible in this setup.

Auto The rugged remote listens to according its priority. XLR has the highest priority.

XLR

The rugged remote is forced to XLR.

3.5 Monitor output

What can be done ?

A monitor can be connected to this output to preview the projected image.

Pin configuration

Monitor output

1

Red Out

2

Green Out

3

Blue Out

nc

4

5

Ground

6

Ground

7

Ground

8

9

10 ground

11

12

13

14

Ground

nc

nc

nc

Hor. Sync

Ver t. S ync

3. Connections

R59770014 XLM HD30 25/05/2009 35

Page 40

3. Connections

36 R59770014 XLM HD30 25/05/2009

Page 41

4. GETTING STARTED

Overview

• Terminology overview RCU and local keypad

• Terminology overview Rugged remote control

• Switching on the projector

• Lamp runtime

• Switching to standby

• Switching off

• Using the RCU

• Using the Rugged remote control

• Projector address

• Controlling the projector

• Quick lens adjustment

4.1 Terminology overview RCU and local keypad

Overview

The following table gives an overview of the different functions associated to the keys

4. Getting Started

.

1

F2

LOGO

F3

PIP

DIGI

ZOOM

PHASE

TINT

COLOR

BRIGHTN

CONTR

LENS

SHIFT

VOL

BACK

ENTER

19

2

0

9

7

5

3

1

STANDBY

8

6

4

SHARPN

2

TEXT

PHASE

ENTER

COLOR

TINT

EXIT

PAUSE

BRIGHT N

CONTRAST

3

4

5

6

7

8

9

10

F1

MENU

PAUSE

AUTO IMAGE

TEXT

90

SDI

7

DVI

5

VIDEO S-VIDEO

3

RGB

1

LENS

ZOOM

LENS

FOCUS

SB-PC

8

6

4

PC

2

21

20

18

17

16

15

14

13

12

11

Image 4-1

No. Key name Description

1 Function keys not used

R59770014 XLM HD30 25/05/2009 37

Page 42

4. Getting Started

No. Key name Description

2 MENU Menu key, to enter or exit the menus.

3 Address key

4

LOGO key

5

PAUSE to stop projection for a short time, press ’PAUSE’. The image disappears but full power is

6 STBY standby button, to start projector when the power switch is switched on and to switch off the

7

TEXT to deactivate or activate the on screen dialog boxes and menus.

8

AUTOIMAGE

9 Digit buttons direct input selection.

10 Lens control

11

VOL

12 Picture controls use these buttons to obtain the desired picture analog level.

13

DIGI ZOOM

14 FREEZE

15 PIP not used

16 ENTER

17

Cursor keys Cursor Keys on RCU or on the local keypad : to make menu selections or to access the

18

BACK to leave the selected menu or item (go upwards to previous menu).

19

EFFECTS

20

PIP ADJUST

21

RC operating indication lights up when a button on the remote control is pressed. (This is a visual indicator to

(recessed key), to enter the address of the projector (between 0 and 9). Press the recessed

address key with a pencil, followed by pressing one digit button between 0 and 9.

Lens adjustment key

retained for immediate restarting.

projector without switching off the power switch.

Attention : Switching to Standby. When the projector is running and you want to go

to standby, press the standby key for 2 seconds.

not used

use these buttons to obtain the desired ZOOM, SHIFT, FOCUS.

Not used

not used

press to freeze the projected image.

to confirm an adjustment or selection in the MENU.

menu bar.

not used

window select

check the operation of the remote control)

38 R59770014 XLM HD30 25/05/2009

Page 43

4.2 Terminology overview Rugged remote control

Overview

4. Getting Started

Image 4-2