Page 1

INSTALLATION AND OPERATOR’S MANUAL

Manual #26-0208100-00 / Revision E

INSTALLATION AND OPERATOR’S MANUAL

Model VMS-100

Barco Folsom, LLC

11101 Trade Center Drive

Rancho Cordova CA 95670

Phone: (916) 859-2500 • Fax: (916) 859-2515

Page 2

RECORD OF CHANGES

REV #

A 03/18/2003 1001 Release to production. April Luong

B 05/21/2003 1059 Addition of the storage for Keystone and

C 07/03/2003 1066 Addition of the Rotation Mode April Luong

D 10/10/2003 1155 Modify the Capture and Display Menu

E 8/03/04 1301 Expanded to cover new features in Maincode

DATE

ECO #

DESCRIPTION

April Luong

User-defined warp maps

April Luong

interface

Jim Rodeo

release 2.04

Manual # 26-0208100-00

Approved By

Page 3

Operators Safety Summary

Do Not Remove Covers or Panels

There are no user-serviceable parts within the unit. Removal of the top

cover will expose dangerous voltages. To avoid personal injury, do not

remove the top cover. Do not operate the unit without the cover installed

Power Source

This product is intended to operate from a power source that will not

apply more than 230 volts rms between the supply conductors or

between both supply conductor and ground. A protective ground

connection by way of grounding conductor in the power cord is essential

for safe operation.

Grounding the Product

This product is grounded through the grounding conductor of the power

cord. To avoid electrical shock, plug the power cord into a properly wired

receptacle before connecting to the product input or output terminals.

The general safety information in this summary is for operating personnel.

A protective-ground connection by way of the grounding conductor in the

power cord is essential for safe operation.

Use the Proper Power Cord

.

Use only the power cord and connector specified for your product. Use

only a power cord that is in good condition. Refer cord and connector

changes to qualified service personnel.

Use the Proper Fuse

To avoid fire hazard, use only the fuse having identical type, voltage

rating, and current rating characteristics. Refer fuse replacement to

qualified service personnel.

Do Not Operate in Explosive Atmospheres

To avoid explosion, do not operate this product in an explosive

atmosphere.

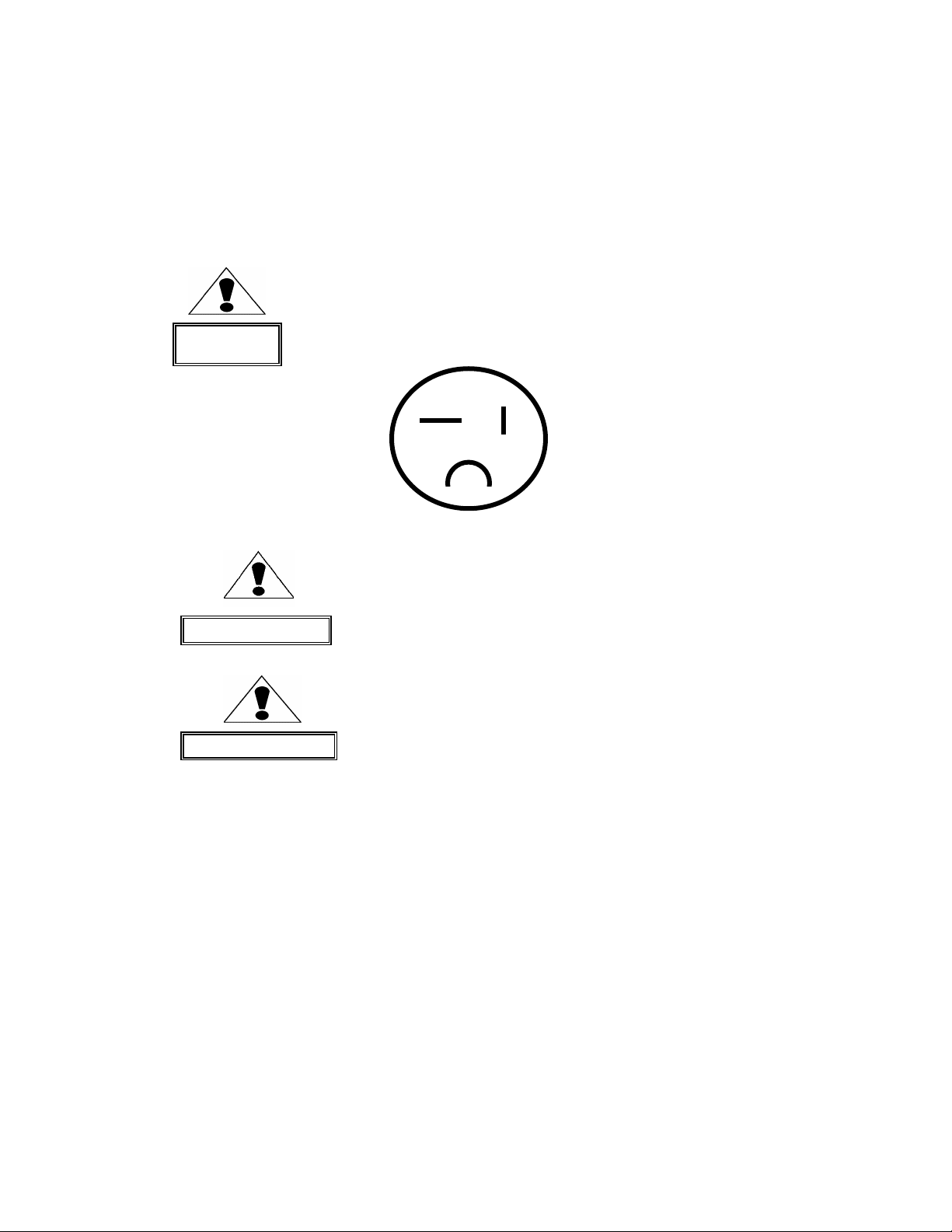

Terms In This Manual and Equipment Marking

WARNING

NOTE Highlights an essential operating procedure,

CAUTION

AVERTISSEMENT!

The exclamation point within an equilateral triangle is

intended to alert the user to the presence of important

operating and maintenance (servicing) instructions in the

literature accompanying the appliance.

Le point d´exclamation dans un triangle equilatéral signale

à alerter l´utilisateur qu´il y a des instructions d´operation

et d´entretien tres importantes dans la litérature qui

accompagne l´appareil

Highlights an operating procedure, practice,

condition, statement, etc., which, if not strictly

observed, could result in injury to or death of

personnel.

condition or statement.

VORSICHT ein Ausrufungszeichen innerhalb eines gleichwinkeligen

den Benutzer auf wichtige Bedienungs-und

Great beiliegenden Literatur aufmerksam zu machen.

Dreiecks dient dazu,

Wartungsanweisungen in der Dem

Page 4

Page 5

ScreenSHAPER

Quick Start Guide

1. Identify the following items supplied with the ScreenSHAPER:

a. ScreenSHAPER system unit

b. ScreenSHAPER AC power cable

c. DVI to HD-15 interface adapters (2 supplied)

d. RS-232 serial cable, 6 ft. P/N 14-9760048-00

e. CDROM containing Setup and Calibration software and manual

2. Set up an external computer (not supplied) to be used to configure and calibrate the ScreenSHAPER. T his

computer requires the following:

a. Windows 95, 98, 2000, NT or XP operating system

b. CDROM drive

c. 20 Megabytes free hard disk space

d. One RS-232 serial port configured as COM1, COM2, COM3, or COM4

e. Video card capable of 1280x1024 output resolution

f. Video monitor capable of 1280x1024 display resolution

g. Keyboard

h. Mouse

3. Equipment Setup

a. Connect the image source to the VIDEO IN connector on the rear of the ScreenSHAPER. Use the

supplied DVI to HD-15 adapter (p/n 15-000002-00 ) as required.

b. Connect the output device to the VIDEO OUT connector on the rear of the ScreenSHAPER. Use the

supplied DVI to HD-15 adapter (p/n 15-0000002-00 ) as required.

c. Connect the supplied serial cable to the RS-232 connector on the rear of the ScreenSHAPER.

d. Connect the other end of the supplied serial cable to the RS-232 serial port of the external computer.

e. Power on the external computer. When it has finished booting, install the setup and calibration software

from the CDROM. Note that this software is not configured for AUTORUN so it will be necessary to

display the contents of the CDROM using Windows Explorer and doub le-click on the installation. Follow

the on-screen instructions to complete the installation.

f. Power on the external output display device (projector or monitor).

4. Power on the ScreenSHAPER and wait for it to complete its initialization sequence. The video source should be

displayed on the output device.

5. Start the Setup and Calibration program by clicking on the Start->Folsom Research->Calibration Software.

6. Follow the instructions in the Setup and Calibration Manual to complete the setup, calibration, and configuration

of the ScreenSHAPER.

This is a quick reference guide. For detailed information on the ScreenSHAPER, pl ease refer to the

Installation and Operating Manual supplied with your unit.

•

Barco Folsom, LLC.

11101-A Trade Center Drive, Rancho Cordova CA 95670 • (916) 859-2500 • www.folsom.com

Manual # 26-0208100-00 / Revision E ScreenSHAPER – Video Mapping System i

Page 6

Table of Contents

SCREENSHAPER ______________________________________________________________________________________I

QUICK START GUIDE__________________________________________________________________________________I

INTRODUCTION______________________________________________________________________________________ 2

ABOUT THE SCREENSHAPER _____________________________________________________________________________ 2

TYPICAL OPERATION ____________________________________________________________________________________ 2

FEATURES _____________________________________________________________________________________________ 2

INSTALLATION ______________________________________________________________________________________ 4

REAR PANEL CONNECTORS _______________________________________________________________________________ 4

RACK-MOUNT INSTALLATION _____________________________________________________________________________ 4

RS-232 REMOTE CONTROL CONNECTION____________________________________________________________________ 4

VIDEO IN AND VIDEO OUT CONNECTORS ____________________________________________________________________ 5

POWER CORD/LINE VOLTAGE SELECTION ___________________________________________________________________ 6

OPERATION ________________________________________________________________________________________ 10

FRONT PANEL CONTROLS _______________________________________________________________________________ 10

POWER UP INITIALIZATION ______________________________________________________________________________ 10

SYSTEM STATUS DISPLAY________________________________________________________________________________ 11

MENU CONTROL_______________________________________________________________________________________ 11

INPUT SETUP MENU ____________________________________________________________________________________ 12

SAVE SETTINGS ________________________________________________________________________________________ 12

AUTO CONFIG _________________________________________________________________________________________ 12

SYNC SELECT__________________________________________________________________________________________ 12

H TOTAL _____________________________________________________________________________________________ 12

H POSITION ___________________________________________________________________________________________ 13

V POSITION ___________________________________________________________________________________________ 13

CAPTURE AREA SUBMENU ________________________________________________________________________________ 13

H Start_______________________________________________________________________________________________ 14

H Size _______________________________________________________________________________________________ 14

V Start_______________________________________________________________________________________________ 14

V Size _______________________________________________________________________________________________ 14

PHASE OFFSET _________________________________________________________________________________________ 14

CONTRAST AND BRIGHTNESS ADJUSTMENTS __________________________________________________________________ 15

RGB COLOR BALANCE SUBMENU __________________________________________________________________________ 15

RESET COLOR__________________________________________________________________________________________ 15

OUTPUT SETUP MENU __________________________________________________________________________________ 16

SAVE SETTINGS ________________________________________________________________________________________ 16

WARPING _____________________________________________________________________________________________ 16

WARP MAP INDEX ______________________________________________________________________________________ 16

V KEYSTONE __________________________________________________________________________________________ 16

H KEYSTONE __________________________________________________________________________________________ 17

ROTATION ____________________________________________________________________________________________ 17

FLIP _________________________________________________________________________________________________ 17

FREEZE_______________________________________________________________________________________________ 17

FORMAT______________________________________________________________________________________________ 17

FRAME RATE __________________________________________________________________________________________ 17

SYNC SELECT__________________________________________________________________________________________ 17

DISPLAY AREA SUBMENU ________________________________________________________________________________ 18

ii ScreenSHAPER – Video Mapping System Manual # 26-0208100-00 / Revision E

Page 7

Left Edge_____________________________________________________________________________________________ 18

Right Edge ___________________________________________________________________________________________ 18

Top Edge _____________________________________________________________________________________________ 18

Bottom Edge __________________________________________________________________________________________ 18

GAMMA CORRECTION SUBMENU ___________________________________________________________________________ 19

R Gamma ____________________________________________________________________________________________ 19

G Gamma ____________________________________________________________________________________________ 19

B Gamma ____________________________________________________________________________________________ 19

TIMING LOCK__________________________________________________________________________________________ 19

RASTER BOX __________________________________________________________________________________________ 19

TEST PATTERN SETUP MENU _____________________________________________________________________________ 20

PATTERN _____________________________________________________________________________________________ 20

TEST PATTERN GRID ____________________________________________________________________________________ 20

TEST PATTERN BOX _____________________________________________________________________________________ 20

EDGE FEATHER SUBMENU ________________________________________________________________________________ 21

Left Feather ___________________________________________________________________________________________ 21

Left Width____________________________________________________________________________________________ 21

Left Gamma __________________________________________________________________________________________ 21

Right Feather__________________________________________________________________________________________ 21

Right Width___________________________________________________________________________________________ 21

Right Gamma _________________________________________________________________________________________ 21

Curve________________________________________________________________________________________________ 21

SYSTEM SETUP MENU___________________________________________________________________________________ 22

SAVE SETTINGS ________________________________________________________________________________________ 22

SERIAL PORT SUBMENU __________________________________________________________________________________ 22

Echo ________________________________________________________________________________________________ 22

Baud Rate ____________________________________________________________________________________________ 22

Data Bits _____________________________________________________________________________________________ 22

Stop Bits _____________________________________________________________________________________________ 23

Parity________________________________________________________________________________________________ 23

Handshaking __________________________________________________________________________________________ 23

Reset RS-232 _________________________________________________________________________________________ 23

FIRMWARE VERSIONS MENU ______________________________________________________________________________ 23

TECH SUPPORT MENU ___________________________________________________________________________________ 23

DIAGNOSTICS MENU ____________________________________________________________________________________ 23

Front Panel Test _______________________________________________________________________________________ 24

I2C Bus Test __________________________________________________________________________________________ 24

VFD BRIGHTNESS ______________________________________________________________________________________ 24

OPERATION MODE ______________________________________________________________________________________ 24

SYSTEM RESET_________________________________________________________________________________________ 24

REMOTE COMMANDS _______________________________________________________________________________ 26

SCREENSHAPER COMMAND LIST/DESCRIPTION _____________________________________________________ 28

OVERVIEW ___________________________________________________________________________________________ 39

HARDWARE REQUIREMENTS _____________________________________________________________________________ 39

SOFTWARE REQUIREMENTS ______________________________________________________________________________ 39

CONNECTING TO BARCO FOLSOM _________________________________________________________________________ 39

DOWNLOADING NECESSARY FILES ________________________________________________________________________ 39

INSTALLING SCREENSHAPER SOFTWARE FILES AND FLASH FILE LOADER________________________________________ 39

STARTING THE FLASH FILE LOADER UTILITY __________________________________________________________________ 40

PREPARING TO UPGRADE THE SCREENSHAPER UNIT ___________________________________________________________ 40

UPLOADING FILES TO THE SCREENSHAPER UNIT______________________________________________________________ 40

BARCO FOLSOM INFORMATION_____________________________________________________________________ 42

BARCO FOLSOM, LLC WARRANTY ________________________________________________________________________ 42

Manual # 26-0208100-00 / Revision E ScreenSHAPER – Video Mapping System iii

Page 8

ETURN MATERIAL AUTHORIZATION (RMA) _______________________________________________________________ 42

R

BARCO FOLSOM CONTACT INFORMATION___________________________________________________________________ 42

TECHNICAL SPECIFICATIONS _______________________________________________________________________ 44

iv ScreenSHAPER – Video Mapping System Manual # 26-0208100-00 / Revision E

Page 9

CHAPTER ONE

Introduction

What you will find in this chapter…

About The ScreenSHAPER

Typical Operation

Features

1

Model VMS-100

Manual # 26-0208100-00 / Revision E ScreenSHAPER – Video Mapping System 1

Page 10

Introduction

About the ScreenSHAPER

The ScreenSHAPER accepts analog RGB video or digital DVI video from one video source and re-maps the image

for display on a non-flat or off-axis surface using a projector. The output video is generated in analog and DVI format.

An external computer is required to generate the “warp map” used to correct for the non-flat or off-axis surface.

Typical Operation

The ScreenSHAPER can be used whenever it is necessary to project images from a projector to a non-flat or off-axis

surface. Typical applications include advertising displays, flight simulators, ke ystone correction, and home theater.

Features

• Accepts RGB and DVI video input with resolutions up to 1280x1024, non-interlaced

• Automatically locks to the input video and processes it in real-time

• Processes the entire input image or a user-defined “area of interest”

• Supports independent X,Y scaling for aspect ratio corrections

• User-selectable output formats: VGA (640x480), SVGA (800x600), XGA (1024x768), SXGA (1280x1024),

1280x720, 1280x768, 1280x960

• Supports analog RGB and digital DVI concurrent video output

• Simple, intuitive front panel controls support quick setup

• RS-232 serial interface for remote control of all functions with Graphical User Interface software

• Rugged 19” rack-mount chassis

• Non-volatile storage for configuration data

• Built-in test pattern generator

• Backed by a full 3-year parts and labor warranty

2 ScreenSHAPER – Video Mapping System Manual # 26-0208100-00 / Revision E

Page 11

CHAPTER TWO

Installation

What you will find in this chapter…

Rear Panel Connectors

Rack-Mount Installation

Remote Control Connection

Video Input & Output Connections

Power Cord/Line Voltage Selection

2

Model VMS-100

Manual # 26-0208100-00 / Revision E ScreenSHAPER – Video Mapping System 3

Page 12

Installation

Rear Panel Connectors

Figure 2-1: ScreenSHAPER Rear Panel

Rack-Mount Installation

ScreenSHAPER units are designed to be rack mounted and are supplied with front rack-mount hardware. Rear rackmount brackets are available as a kit and are recommended for use when units are mounted in transit cases. When

rack mounting the unit, remember that the maximum ambient operating temperature for the unit is 40 degrees C.

Leave at least one inch of space front and rear to make sure that the airflow through the fan and vent holes is not

restricted. When installing equipment into a rack, distribute the units evenly to prevent hazardous conditions that may

be created by uneven weight distribution. Connect the unit only to a properly rated supply circuit. Reliable grounding

(earthing) of rack-mounted equipment should be maintained.

RS-232 Remote Control Connection

The RS-232 serial port is used to connect the ScreenSHAPER to an external computer to support setup and

calibration of the ScreenSHAPER. The serial port is configured as a DCE device which allows a straight-through

serial cable to be used to connect the ScreenSHAPER to the PC. The cable connecting to the ScreenSHAPER

should have a DB-9 male connector. Pinouts for the remote port are shown below. The cable supplied with the unit,

p/n 14-9760048-00, or equivalent RS-232 serial cable should be used to connect the ScreenSHAPER to the external

computer.

DCE

DB-9 I/O RS-232 Signal Name ScreenSHAPER Signal Description

CD 1 O Carrier Detect Carrier Detect from Remote Control PC

RXD 2 O Received Data Data Sent to Remote Control PC

TXD 3 I Transmitted Data Data From Remote Control PC

DTR 4 I Data Terminal Ready Data Terminal Ready from Remote Control PC

GND 5 x Signal Ground Signal Ground

DSR 6 O Data Set Ready Data Set Ready Output to Remote Control PC

RTS 7 I Request To Send Request To Send from Remote Control PC

CTS 8 O Clear To Send Clear To Send Output to Remote Control PC

RI 9 O Ring Indicator Unused

4 ScreenSHAPER – Video Mapping System Manual # 26-0208100-00 / Revision E

Page 13

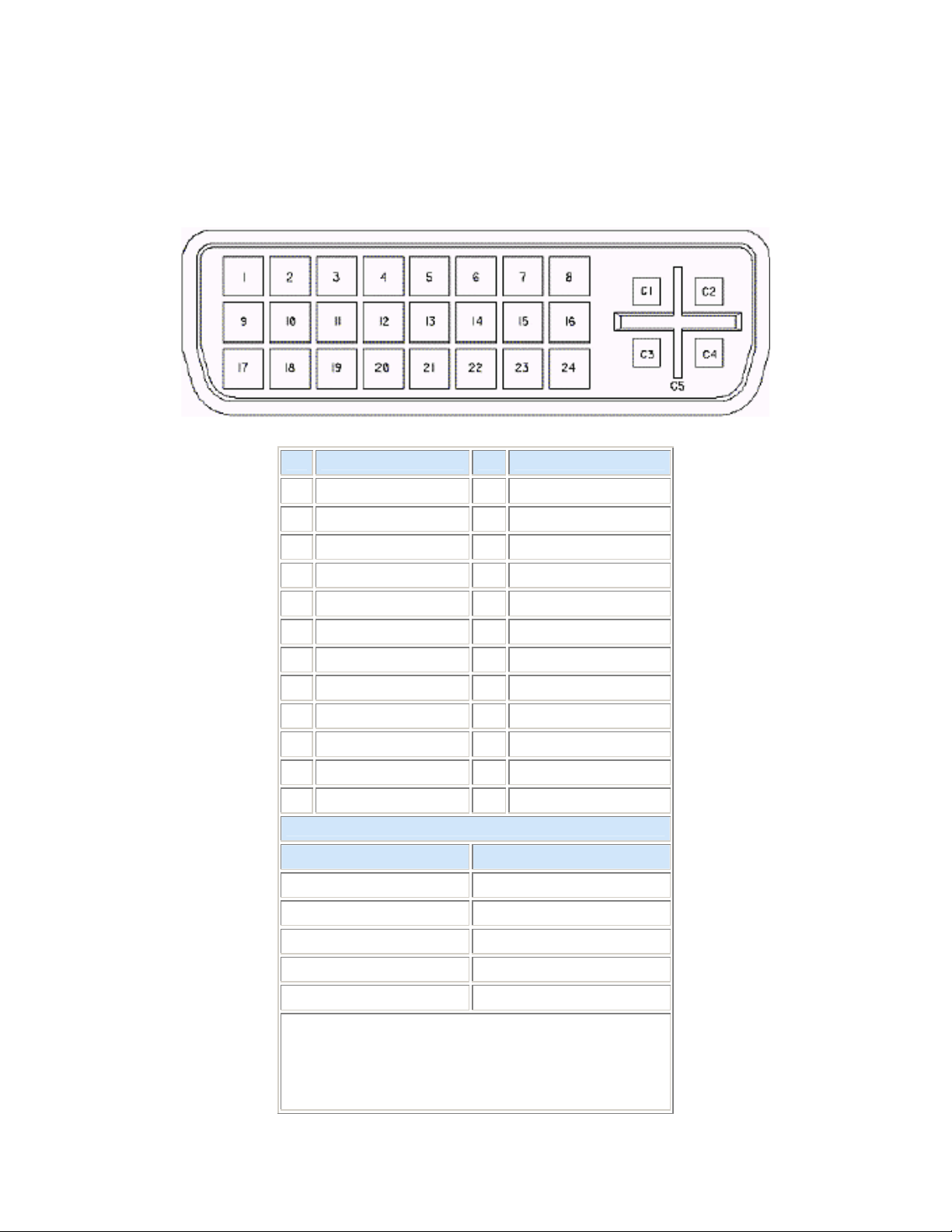

Video In and Video Out Connectors

Two DVI-I female connectors are located on the rear panel of the ScreenSHAPER. One is used for VIDEO IN and

one is used for VIDEO OUT. Adapters are supplied to connect HD-15 cables to the DVI-I connector for analog

devices.

Pin

1 T.M.D.S. Data2- 13 T.M.D.S. Data3+

2 T.M.D.S. Data2+ 14 +5V Power

3 T.M.D.S. Data2/4 Shield 15 ground (for +5V)

4 T.M.D.S. Data4- 16 Hot Plug Detect

5 T.M.D.S. Data4+ 17 T.M.D.S. Data0-

6 DDC Clock 18 T.M.D.S. Data0+

7 DDC Data 19 T.M.D.S. Data0/5 Shield

8 Analog Vertical Sync 20 T.M.D.S. Data5-

9 T.M.D.S. Data1- 21 T.M.D.S. Data5+

10 T.M.D.S. Data1+ 22 T.M.D.S. Cloc k Shield

11 T.M.D.S Data1/3 Shield 23 T.M.D.S. Clock+

12 T.M.D.S. Data3- 24 T.M.D.S. Clock-

Function Pin Function

MicroCross Pins

Pin Function

C1 Analog Red Video

C2 Analog Green Video

C3 Analog Blue Video

C4 Analog Horizontal Sync

C5 Analog Common Ground Return

Legend

DDC = Display Data Channel

T.M.D.S. = Transition Minimized Differential Signal

Manual # 26-0208100-00 / Revision E ScreenSHAPER – Video Mapping System 5

Page 14

Power Cord/Line Voltage Selection

The ScreenSHAPER is rated to operate with the following supplies:

Input Power: 98-264VAC, 47-63 Hz

Power Consumption: 45 watts maximum

The ScreenSHAPER performs line voltage selection automatically. No user controls are required for line voltage

selection.

When the ScreenSHAPER is used with 230-volt supplies, a UL listed line cord rated for

250 volts at 15 amps must be used. This cord will be fitted with a tandem prong-type

plug.

Tandem Plug

La choix de la ligne de voltage se realize automatiquement par Ie ScreenSHAPER

Transformateur Graphique On n’apas besoin du controller usager pour la choix de la ligne

de voltage.

Das ScreenSHAPER -Gerät mu beim Anschlu an 240V ~ mit einer vom VDE auf

250V/10A geprüften Netzleitung mit einem Schukostecker ausgestattet sein.

WARNING

AVERTISSEMENT

AVERTISSEMENT

6 ScreenSHAPER – Video Mapping System Manual # 26-0208100-00 / Revision E

Page 15

Connect ScreenSHAPER to AC power using the power cord supplied with the unit. Locate the power switch on the

power entry module at the rear of the unit and turn the power on. While the main board is initializing, “please wait” will

be displayed and the front panel keys will be turned on and off. When initialization is complete, the Status Display

screen will be displayed.

VORSICHT ein Ausrufungszeichen innerhalb eines gleichwinkeligen

den Benutzer auf wichtige Bedienungs-und

Great beiliegenden Literatur aufmerksam zu machen.

WARNING

disconnect the unit from input AC power. To facilitate disconnection of

AC power, the power cord must be connected to an accessible outlet

near the unit. Building Branch Circuit Protection: For 115 V use 20 A,

for 230 V use 8 A.

WARNING

When the ScreenSHAPER is used in the 230-volt mode, a UL

listed line cord rated for 250 volts at 15 amps must be used

and must conform to IEC-227 and IEC-245 standards. This

cord will be fitted with a tandem prong-type plug.

Dreiecks dient dazu,

Wartungsanweisungen in der Dem

The rear panel ON/OFF switch does not

Manual # 26-0208100-00 / Revision E ScreenSHAPER – Video Mapping System 7

Page 16

Page 17

CHAPTER THREE

Operation

What you will find in this chapter…

Front Panel Controls

System Status Display

Menu Control

Input Video Setup Menu

Output Video Setup Menu

Test Pattern Menu

System Setup Menu

3

Model VMS-100

Manual # 26-0208100-00 / Revision E ScreenSHAPER – Video Mapping System 9

Page 18

Operation

The ScreenSHAPER must be set up and calibrated using an external computer (not supplied) and the

ScreenSHAPER Calibration Software (provided). The front panel can be used to make minor configuration

adjustments to the input and output settings. The front panel controls are described in detail in this section; the serial

port commands are described in the next section.

Front Panel Controls

The Front Panel controls include a vacuum fluorescent display (VFD), an adjustment knob, and six illuminated push

buttons.

The operation of each menu displayed on the VFD is described in detail in the following sections of this document.

VFD Display

Figure 3-1 ScreenSHAPER Front Panel

Power Up Initialization

Locate the power switch on the rear panel and turn the ScreenSHAPER ON. While the system is initializing, the

following message will be displayed on the VFD display:

The version number displayed is the system software version number. The software version number will change as

software upgrades are released.

ScreenSHAPER

VERSION 2.04

INITIALIZING

PLEASE WAIT...

SEL

ESC

IN

ADJ

OUT

ADJ

TEST

PAT

SYS

SETUP

10 ScreenSHAPER – Video Mapping System Manual # 26-0208100-00 / Revision E

Page 19

System Status Display

The System Status Display is displayed whenever a configuration menu is not being dis pla yed. This four-line display

contains “SYSTEM STATUS” on the first line indicating that this is the system status display screen. The second line

contains the video input format and the input type (ANALOG or DIGITAL). The third line contains the output resolution

and frame rate. Depending on the mode of operation, the last line contains the current operation status. The status

information could be the Warping Mode or the Rotation Setting. “TEST” is displayed if a test pattern is being

generated by the internal test pattern generator.

Warp Mode: Rotation Mode:

SYSTEM STATUS

INPUT: SXGA ANALOG

OUTPUT: SXGA 60HZ

WARP OFF LIVE

SYSTEM STATUS

INPUT: SXGA ANALOG

OUTPUT: SXGA 60HZ

ROTATION 0 LIVE

Menu Control

The adjustment knob as well as the SEL and ESC keys is used to navigate through a series of menus displayed on

the VFD display. The menus are used to enter setup parameters. Once setup parameters are entered, they are

stored in non-volatile memory for future use using the system save menu item. Pressing one of the four hot keys will

call up the corresponding menu on the VFD.

The user can scroll through the menu items by turning the ADJUST control knob. A pointer (>) at the left of a menu

item indicates the current position of the scroll bar. When the desired menu item is reached, the user presses the

SEL key to select that menu item. The sub-menu pointer (>>) at the right of a menu item indicates that a sub-menu

will be displayed if that menu item is selected. The pointer at the left hand side of the display ch anges to a pound sign

(#) indicating that a parameter is selected. After a parameter has been selected, the user can modify the associated

parameter values by turning the ADJUST control knob. The operator can accept the changes with SEL or press ESC

to exit the current menu item without modifying current settings.

In this section, the Factory Reset values are displayed in the menu diagram.

Manual # 26-0208100-00 / Revision E ScreenSHAPER – Video Mapping System 11

Page 20

Input Setup Menu

This menu is used to configure the input. It is displayed when the IN ADJ key is pressed on the front panel.

INPUT SETUP

SAVE SETTINGS ^

AUTO CONFIG ^

SYNC SELECT AUTO

H TOTAL 1688

HPOS (PIXELS) 360

VPOS (LINES) 40

CAPTURE AREA N/A

PHASE OFFSET 0

BRIGHTNESS 100.0%

CONTRAST 100.0%

RGB COLOR BAL >>

RESET CONFIG ^

Save Settings

This menu selection is used to save changes made in the Input Setup menu to non-volatile memory. If this menu item

is not selected, changes will not be saved and the previous settings will be restored the next time the system is

powered on.

Auto Config

This menu selection invokes the unit to perform an automatic sampling of the input video. The unit will attempt to

capture the entire input based on the presence of data. The accuracy is higher on inputs that have a bright border

around the entire image. This operation may take a minute or so. Do not perform an Auto Config on an entirely black

image.

Sync Select

The sync format specifies the type of frame sync to be applied to the input video. The following settings are

available:

• AUTO - Automatically determine the output sync format

• H/V - Horizontal and Vertical Sync

• COMP - Composite Sync

• SOG - Sync on Green

The default setting is AUTO.

H Total

This control sets the horizontal total number of pixel clock periods (active and blanking) during one horizontal line.

The default setting is the number of pixels in the input video based on the input resolution.

12 ScreenSHAPER – Video Mapping System Manual # 26-0208100-00 / Revision E

Page 21

H Pos

VSync Region

V Pos

)

h

c

r

o

p

k

c

a

b

(

n

o

i

g

e

R

g

n

i

k

HSync Region

n

a

l

B

l

a

t

n

o

z

i

r

o

H

H Start

Vertical Blanking Region (back porch)

Capture Area

(Area of Interest)

Input Active Window

Vertical B lanking Region (front porch)

H Size

)

h

c

r

o

V Start

p

t

n

o

r

f

(

n

o

i

g

e

R

g

n

i

k

n

a

l

B

l

a

t

n

o

z

i

r

o

H

V Size

Figure 3-2 Capture Area Definition

H Position

This control adjusts the horizontal start of the active video in number of pixels. The default setting is the position of

the expected first pixel of the active video, based on the input resolution. See Figure 3-2 for detail.

V Position

This control adjusts the vertical start of the active video in number of lines. The default setting is the position of the

expected first line of the active video, based on the input resolution. See Figure 3-2 for detail.

Capture Area Submenu

The following four configuration controls, available when operating in the Rotation Mode, are used to set an input

“area of interest”. The default settings define a full-screen based on the resolution of the selected input source.

These settings can be changed to define a particular rectangle within the full screen to zoom into.

CAPTURE AREA

H START 0

H SIZE 1280

V START 0

V SIZE 1024

Manual # 26-0208100-00 / Revision E ScreenSHAPER – Video Mapping System 13

Page 22

H Start

H Start is used to set the horizontal start of the capture area in number of pixels. See Figure 3-2 for detail. The

default setting is 0.

H Size

H Size is used to set the horizontal size of the capture area in number of pixels. See Figure 3-2 for detail. The

default setting and the maximum setting is the number of active pixels of the input video, based on the input

resolution.

V Start

V Start is used to set the vertical start of the capture area in number of lines. See Figure 3-2 for detail. The default

setting is 0.

V Size

V Size is used to set the vertical size of the capture area in number of lines. See Figure 3-2 for detail. The default

setting and the maximum setting is the number of active lines in the input video, based on the input resolution.

Phase Offset

Phase Offset is used to adjust the input sample clock phase. This control can be used to fine tune the image to

eliminate artifacts due to input sampling clock phase errors. Changes can be made between –16 and 1 5. Since DVI

video input requires no phase adjustment, this option is only available when using an anal og video input.

14 ScreenSHAPER – Video Mapping System Manual # 26-0208100-00 / Revision E

Page 23

Contrast and Brightness Adjustments

The Contrast and Brightness controls allow the operator to adjust the overall contrast and brightn ess of the image if

the input is analog. The adjustment range is 75.0% to 125.0%. 100% is the default setting for both contrast and

brightness. Contrast and brightness adjustments are only available when using an analog video input.

RGB Color Balance Submenu

The RGB Color Balance menu item is used to display a submenu where color balance adjustments are performed.

This menu allows the operator to balance the colors on the RGB input source. Independent Contrast and Brightness

adjustments are provided for each color channel.

The adjustment range for Brightness and Contrast is -25.0% to +25.0% with 0.0% as the default value.

The Reset Color menu item resets all the fields in this sub menu to the default value (0.0%). To reset the color

balance controls, scroll to the Reset Color menu item and select the menu item with the SEL key.

Color balance adjustments are not available when using a DVI video input.

RGB COLOR BALANCE

R CONTRAST 0.0%

R BRIGHTNESS 0.0%

G CONTRAST 0.0%

G BRIGHTNESS 0.0%

B CONTRAST 0.0%

B BRIGHTNESS 0.0%

RESET COLOR

Reset Color

This menu selection resets the input parameters to the default settings.

Manual # 26-0208100-00 / Revision E ScreenSHAPER – Video Mapping System 15

Page 24

Output Setup Menu

The OUTPUT SETUP Menu allows the user to control output image configurations. Based on the Operation Mod e,

either the Warp Output Setup or the Rotation Output Setup menu is displayed when the OUT ADJ menu key is

pressed on the front panel.

Warp Mode: Rotation Mode:

WARP OUTPUT SETUP

SAVE SETTINGS ^

WARPING OFF

WARP MAP INDEX 0

V KEYSTONE 0

H KEYSTONE 0

FREEZE DIS

FORMAT SXGA 1280x1024

FRAME RATE 60Hz

SYNC SELECT +H+V

GAMMA CORRECTION >>

TIMING LOCK DIS

ROT OUTPUT SETUP

SAVE SETTINGS ^

ROTATION 0

FLIP OFF

FREEZE DIS

FORMAT SXGA 1280x1024

FRAME RATE 60Hz

SYNC SELECT +H+V

DISPLAY AREA >>

GAMMA CORRECTION >>

TIMING LOCK DIS

RASTER BOX OFF

RASTER BOX OFF

Save Settings

This menu selection is used to save changes made in the Output Setup menu to non-volatile memory. If this menu

item is not selected, changes will not be saved and the previous settings will be restored the next time the system is

powered on.

Warping

The warping function can be set to OFF/ON/KEYSTONE*. The default is set to OFF.

*The keystone function currently only supports these input-output settings:

SVGA, XGA and SXGA inputs to SXGA output

SVGA, XGA and SXGA inputs to XGA output

SVGA and XGA inputs to SVGA output

Warp Map Index

If the warping function is set to ON, the image is processed according to the warp map indexed by this parameter.

There are 9 warp maps that can be loaded and recalled by setting the Warp Map Index. The warp map has to be

loaded prior to turning the warping function ON. It is required that the loaded warp map was generated for the current

input-output resolution.

V Keystone

If the warping function is set to KEYSTONE, this menu selection set the vertical index of the keystone warp. The

default is set to 0.

16 ScreenSHAPER – Video Mapping System Manual # 26-0208100-00 / Revision E

Page 25

H Keystone

If the warping function is set to KEYSTONE, this menu selection set the vertical index of the keystone warp. The

default is set to 0.

Rotation

There are four possible rotation angles that can be selected for the output: 0, 90, 180, and 270 degrees. Zero degree

corresponds to an un-rotated image and is the default setting.

Flip

Flip causes the output image to be “mirrored”. Three settings are available: OFF, HORZ, and VERT. HORZ causes

the output image to be mirrored left/right. VERT causes the output image to be mirrored top/bottom. The default

setting is OFF.

Freeze

Freeze the display image.

Format

The format is the desired resolution of the output video. The following settings are available:

• VGA - 640 x 480*

• SVGA - 800 x 600

• XGA - 1024 x 768

• SXGA - 1280 x 1024

• 1280x720

• 1280x768

• 1280x960

*VGA output is not supported if the input format is 1280x1024.

The default setting is SXGA.

Frame Rate

The frame rate specifies the number of times per second that the image is updated. The following settings are

available:

• 50Hz

• 60Hz

• 75Hz

• 59.94Hz

The default setting is 60Hz.

Sync Select

The sync format specifies the type of frame sync to be applied to the output video. The following settings are

available:

• SOG - Sync on Green

• -C - Composite Sync

• +H+V - Pos Horizontal and Pos Vertical Sync

• +H-V - Pos Horizontal and Neg Vertical Sync

• -H+V - Neg Horizontal and Pos Vertical Sync

• -H-V - Neg Horizontal and Neg Vertical Sync

The default setting is +H+V.

Manual # 26-0208100-00 / Revision E ScreenSHAPER – Video Mapping System 17

Page 26

Display Area Submenu

The following four configuration controls, available when operating in the Rotation Mode, are used to set an output

display area. The default settings define a full-screen based on the selected output resol ution. These settings can

be changed to define a particular rectangle within the active output frame.

DISPLAY AREA

LEFT EDGE 0

RIGHT EDGE 1280

TOP EDGE 0

BOTTOM EDGE 1024

Figure 3-3 Display Area Definition

Left Edge

Left Edge is used to set the output display area. This control adjusts the left edge by changing the width of the blank

area on the left. See Figure 3-3 for detail. The default setting is 0.

Right Edge

Right Edge is used to set the output display area. This control adjusts the position of the right edge. See Figure 3-3

for detail. The default setting is 1280.

Top Edge

Top Edge is used to set the output display area. This control adjusts the top edge by changing the width of the blank

area on the top. See Figure 3-3 for detail. The default setting is 0.

Bottom Edge

Bottom Edge is used to set the output display area. This control adjusts the position of the bottom edge. See Figure

3-3 for detail. The default setting is 1024.

18 ScreenSHAPER – Video Mapping System Manual # 26-0208100-00 / Revision E

Page 27

Gamma Correction Submenu

Gamma Correction can be applied to the individual color components of the output.

R Gamma

The Red Gamma value is applied to the red component of the output. The default setting is 1.0 which is no

correction at all.

G Gamma

The Green Gamma value is applied to the green component of the output. The default setting is 1.0 which is no

correction at all.

B Gamma

The Blue Gamma value is applied to the blue component of the output. The default setting is 1.0 which is no

correction at all.

GAMMA CORRECTION

R GAMMA 1.0

G GAMMA 1.0

B GAMMA 1.0

Timing Lock

Timing Lock is used to lock the output timing to the input timing. It is important to select the output resolution and

frame rate that matches the input resolution and frame rate. The default setting is DIS.

Raster Box

Raster Box is used to enable the display of a one pixel wide box on the output. The settings for this control are ON

and OFF. The default setting is OFF.

Manual # 26-0208100-00 / Revision E ScreenSHAPER – Video Mapping System 19

Page 28

Test Pattern Setup Menu

The Test Menu allows the user to select various pre-programmed test patterns to display for positioning and

calibrating projectors. This menu is displayed by pressing the TEST PAT key on the front panel. Configuration

parameters entered in this menu are saved in non-volatile memory if you issue a SAVE SETTINGS command under

the System Setup Menu.

TEST PATT SETUP

Pattern

The Pattern menu item allows the user to select a test pattern for display. To select a test pattern, scroll to the Pattern

menu item, select the menu item with the SEL key and then turn the adjustment knob to select the desired test

pattern. Each test pattern is displayed as the adjustment knob is turned. Press SEL to accept the newly entered

settings or ESC key to exit without accepting the changes that have been entered. The OFF selection disables the

internal test pattern generator and return to live conversion mode. Available test patterns are:

• OFF Live video is processed (used for normal operation)

• BURST1 One On/One Off test pattern

• BURST2 One On/One Off test pattern

• GRAY H BARS Horizontal gray scale bars

• RED H BAR Red horizo ntal bars

• GREEN H BAR Green horizontal bars

• BLUE H BAR Blue horizontal bars

• YELLOW H BAR Yellow horizontal bars

• CYAN H BAR Cyan horizontal bars

• MAGENTA H BAR Cyan horizontal bars

• BLACK Display a black image

• GRAY 25% Displays a 25% white image

• GRAY 50% Displays a 50% white image

• GRAY 75% Displays a 75% white image

• WHITE Displays a 100% white image

• H RAMP Displays a horizontal ramp

The default pattern setting is OFF.

PATTERN OFF

GRID OFF

BOX OFF

EDGE FEATHER >>

Test Pattern Grid

The Grid menu item allows the user to overlay a grid on the output image. To control the display of the Grid, scroll to

the Grid menu item, select the menu item with the SEL key and then turn the ADJUST control to select the desired

output. The OFF selection is used to disable the display of the grid, ON enables the display. The grid can be

displayed on the test patterns or over live data. The default setting is OFF.

Test Pattern Box

The Test Pattern Box menu item allows the user to overlay a border on the output image. To control the display of the

Test Pattern Box, scroll to the Test Pattern Box menu item, select the menu item with the SEL key and then turn the

ADJUST control to select the desired output. The OFF selection is used to disable the display of the T est Pattern

Box, ON enables the display. The Test Pattern Box can be displayed on the test patterns or over live data. The

default setting is OFF.

20 ScreenSHAPER – Video Mapping System Manual # 26-0208100-00 / Revision E

Page 29

Edge Feather Submenu

The Edge Feather Submenu contains the controls to define the edge feathe r characteristics.

Left Feather

Left Edge Feathering can be Enable/Disable by this control. The default is set to Disable.

Left Width

The width of the left feathering area is a value between 0 and half the horizontal width of the input. The default is set

to 64.

EDGE FEATHER

LEFT FEATHER DIS

LEFT WIDTH 64

LEFT GAMMA 1.0

RIGHT FEATHER DIS

RIGHT WIDTH 64

RIGHT GAMMA 1.0

CURVE EQUATION 3rd

Left Gamma

The gamma value applied to the left edge feathering equation. The default is set to 1.0.

Right Feather

Left Edge Feathering can be Enable/Disable by this control. The default is set to Disable.

Right Width

The width of the left feathering area is a value between 0 and half the horizontal width of the input. The default is set

to 64.

Right Gamma

The gamma value applied to the left edge feathering equation. The default is set to 1.0.

Curve

The Curve selects the edge feather function from 1st, 3rd, 5th, 7th or 9th order equation. The default is the 3rd order

equation.

Manual # 26-0208100-00 / Revision E ScreenSHAPER – Video Mapping System 21

Page 30

System Setup Menu

The System Setup Menu allows the user to control input frame synchronization, change the configuration of the serial

port, provides information for access to factory technical support and allows the system to be completely reset to

factory default values. This menu is displayed by pressing the SYS SETUP key on the front panel.values.

Save Settings

This menu selection is used to save changes made in the System Setup menu to non-volatile memory. If this menu

item is not selected, changes will not be saved and the previous settings will be restored the next time the system is

powered on.

SYSTEM SETUP

SAVE SETTINGS ^

SERIAL PORT >>

F/W VERSIONS >>

TECH SUPPORT >>

DIAGNOSTICS >>

VFD BRIGHTNESS 8

OPERATION MODE WARP

SYSTEM RESET >>

Serial Port Submenu

The ScreenSHAPER has one serial port that is configured for RS-232 operation. The serial port parameters are

under this submenu. Configuration parameters entered in this menu are saved in non-volatile memory if you issue a

SAVE SETTINGS command under the System Setup Menu.

Echo

The user can turn ECHO ON or OFF. When ECHO is ON, commands received by the unit will be transmitted back to

the source device. The default setting is ON.

Baud Rate

The following baud rate settings are supported 1200, 2400, 9600, 19.2K, and 38.4K. The default baud rate setting is

38.4 Kb.

SERIAL MODE RS-232

ECHO ON

BAUD RATE 38.4K

DATA BITS 8

STOP BITS 1

PARITY NONE

HANDSHAKING ON

RESET RS-232 ^

Data Bits

The number of data bits per character can be set to 7 or 8. The default setting is 8.

22 ScreenSHAPER – Video Mapping System Manual # 26-0208100-00 / Revision E

Page 31

Stop Bits

The number of stop bits can be set to 1 or 2. The default setting is 1 stop bit.

Parity

Parity can be set to Even, Odd or None. The default setting is NONE.

Handshaking

Handshaking can be set to On or Off. The default setting is ON.

Reset RS-232

All RS-232 parameters can be reset to factory defaults by selecting this menu item and pressing the SEL key.

Firmware Versions Menu

The Firmware Versions Menu displays the revision information for the system firmware. A sample revision display is

shown below.

FIRMWARE REVISIONS

MAIN AAAA 8/14/2004

BOOT BBBB 8/14/2004

LOADR CCCC 8/14/2004

VMINC DDDD 8/14/2004

VMMUX EEEE 8/14/2004

BOARD S/N 1

Tech Support Menu

The Tech Support Menu displays the current firmware version number, the customer service telephone n umber to

contact for technical assistance, and the Internet address to obtain product news and to download firmware revisio ns.

TECH SUPPORT

VERSION 02.04

PHONE: 866-374-7878

WEB: www.folsom.com

Diagnostics Menu

Selecting DIAGNOSTICS will display the following menu:

Manual # 26-0208100-00 / Revision E ScreenSHAPER – Video Mapping System 23

Page 32

DIAGNOSTICS

FRONT PANEL TEST >>

I2C TEST >>

Front Panel Test

This selection tests the front panel VFD display, the knob, and the key LEDs. All pixels on the display are tested from

top to bottom and then from left to right. The display should illuminate all pixels. The next test will chang e the display

brightness in 16 steps. Then the key LEDs are tested and the user is asked to turn the knob and verify that the

displayed position indicator changes correctly.

I2C Bus Test

The I2C Test verifies the operation of the internal communication paths to major system components including the

input analog to digital converter, the warp processor, and the EEPROM. All tests should indicate “PASS” when done.

VFD Brightness

The VFD Brightness menu selection controls the intensity of the front panel vacuum fluores c ent display (VFD). The

adjustment range is 0 to 15. 0 is the dimmest setting and 15 is the brightest. We recommend using a low intensity

setting to avoid “burn-in” of the display. The default setting is 8.

Operation Mode

This control selects the mode of operation. Under the Warp Mode, the ScreenSHAPER unit can process images

using previously stored user-defined warp maps or keystone warp maps. Under the Rotate Mode, the

ScreenSHAPER unit can rotate images and adjust the capture and display area.

System Reset

Selecting SYSTEM RESET will display the following menu:

Confirm System Reset

SEL = YES

ESC = NO

Pressing the SEL key will reset the system to factory configuration and reboot the system. All stored input

configuration files are cleared.

Pressing the ESC key will return the user to the SYSTEM SETUP Menu.

24 ScreenSHAPER – Video Mapping System Manual # 26-0208100-00 / Revision E

Page 33

CHAPTER FOUR

Remote Commands

What you will find in this chapter…

ScreenSHAPER Command List/Description

4

Model VMS-100

Manual # 26-0208100-00 / Revision E ScreenSHAPER – Video Mapping System 25

Page 34

Remote Commands

BAUD n Baud Rate: n[0|1|2|3] 1.2K|9.6K|19.2K|38.4K

BLKLVL n n n Black Level Mode, Threshold and Offset Intensity:

n[0-3] n[0-255] n[0-255]

CAP n n n n Capture Input: HStart, HSize, VStart, Vsize

COLEN n n Color Enable: n[0|1|2|3] All|Red|Green|Blue

CONF Reconfigure Board (FACTORY USE ONLY)

CSUM Display Checksum of Files in Flash

CURVE n Blend Curve Selection: n[0-4] 1

DBIT n Data Bit: n[7|8]

DEBUG password Debug Mode: For internal use only.

DISP n n n n Display Region: HStart, HEnd, VStart, Vend

ECHO n Echo Enable/Disable: n[0|1] DISABLE|ENABLE

EFTA s en w exp Advanced Edge Feather Lut: side, enable, width, exponent

s[L|R] en[0|1] w[0-640] exp[1.0-5.0]

FLIP n Flip Image: n[0-2] No Flip|H Flip|V Flip

FREEZ Freez Image: n[0|1] DISABLE|ENABLE

FSB n Force Scaler Black: n[0|1] OFF|ON

GAM n n n Gamma Value command: n[1-3] VPC|GPC|DPC

n[0-3] All|Red|Green|Blue n[0.0 - 5.0]

HELP I Help Command: i[A-Z], Help Index

IBRT op nnn Input Brightness:

op[C|R|G|B|I|D] (C)n[75..125]% (R,G,B)n[-25..25]%

ICNT op nnn Input Contrast:

op[C|R|G|B|I|D] (C) n[75..125]% (R,G,B)n[-25..25]%

ICPHO op nn Input Clock Phase Offset:

op[A|M] Auto|Manual nn[-16..15]

ICPL op nnnn Input Clocks Per Line:

op[A|M] Auto|Manual nnnn[0..4096]

ICREC n n Input Configuration Recall:

n[0-6]CNF Index, n[User|Standard]

Standard: 640x480|800x600|1024x768|1280x1024

1280x720|1280x768|1280x960

ICRST Input Configuration Reset

ICSAV Input Configuration Save

ID Query Board ID

st|3rd|5th|7th|9th

26 ScreenSHAPER – Video Mapping System Manual # 26-0208100-00 / Revision E

Page 35

INFO System Information Command: FACTORY USE ONLY

INFO2 System Information Command: FACTORY USE ONLY

IRSP n n Input Raster Size/Position: n[L|R|T|B] n[-999..999]

ISYNC n Input Sync.: n[0..3] SOG|CSYN|H&V|AUTO

KEY n n Load Keystone warp: n[0-10] n[-8-8], VIndex HIndex

LNW Load new warp coefficients

LOADR Loader Mode: Place Warper Board into Loader Mode

MAP n Load User-defined warp map: n[0-8]

OCRECF n Output Resolution: n[0..6]

640x480|800x600|1024x768|1280x1024| 1280x720|1280x768|1280x960

OFRATE n Output Frame Rate n[0|1|2|3] 50Hz|60Hz|75Hz|59.94Hz

OP n Operation Mode: n[0|1] WARP|ROTATE

ORAS n Output Raster Box: n[0|1], Disable|Enable

OSYNC n Output Sync.: n[0..5] SOG|-C|+H+V|+H-V|-H+V|-H-V

PAR n Parit y Type: n[0|1|2] NONE|ODD|EVEN

RESET op Reset - Factory Defaults: op[ A] All

ROT n Rotate Image: n[0|90|180|270]

SAVE Save System Settings

SBIT n Stop Bit: n[1|2]

SYNC n Select Output Sync Mode: n[ 0|1|2] Freerun|Linelock|Framelock

TLCK n Lock Output to Input Timing Command: n[0|1|2]

(Off|Lock to Input|Lock to Ext Sync)

TPAT typ bx gr Test Pattern Type: typ[0-15] (Off|Burst1|Burst2|Grey H Bars|Red H Bars|

Green H Bars|Blue H Bars|Yellow H Bars|Cyan H Bars|

Magenta H Bars|Black|Gray 25%|Gray 50%|Gray 75%|

White|Horz Ramp) bx[0|1] OFF|ON gr[0|1] OFF|ON

VER Version Information

WARP n Warping Enable: n[0-2], OFF|ON|Keystone

Manual # 26-0208100-00 / Revision E ScreenSHAPER – Video Mapping System 27

Page 36

ScreenSHAPER Command List/Description

Command:

BAUD n

Description: Set the baud rate for serial comman d port.

Parameters: n [0|1|2|3] 1.2K|9.6K|19.2K|38.4K

Query:

BAUD ?

Returns the current baud rate

=n

Example: BAUD 3 (Set the baud rate to 38.4K)

Command:

BLKLVL n n n

Description: Set the parameters for black l evel a djustment on non-blended region of the image. The Adjustment

Mode determines how the Threshold and Offset value are applied to the non-blended region of the image.

Parameters: n Black Level Adjustment Mode,

0 = Bypass

1 = Floor Method. If image intensity is less then Threshold, then set the image intensity to

Offset Intensity.

2 = Floor Offset. If image intensity is less then Threshold, then add the Offset Intensity to

the image intensity.

3 = Force Offset. Add the Offset Intensity to the image intensity regardless of the image

intensity.

n Non-blended region threshol d Intensity, [0-255]

n Non-blended region offset Intensity, [0-255]

Query:

BLKLVL ?

Returns the parameters that defines the black level adjustment.

= n n n

Example: BLKLVL 2 128 10 (Add 10 to the non-blended region if the intensity is less then 128).

BLKLVL 1 128 190 (Set the intensity of the non-blended region to 190 if the intensity is less then

128).

Command:

CAP n n n n

Description: Capture an area of interest on the input.

Parameters: n - Horizontal Start on the input image

n - Horizontal Size on the input image

n - Vertical Start on the input image

n - Vertical Size on the input image

Query:

CAP ?

Returns the Hstart, Hwidth, Vstart and Vlength of the input.

= n n n n

Example: CAP 0 1280 0 1024 (Capture the standard image for SXGA input.)

Command:

COLEN n n

Description: Allows independent On/Off control over each color channel.

Parameters: n – [0-3] All|Red|Green|Blue

n – [0|1] Disable|Enable

Query:

COLEN ?

Returns the enable status of Red Green and Blue.

= r g b

Example: COLEN 1 0 (Turn off the red color channel.)

28 ScreenSHAPER – Video Mapping System Manual # 26-0208100-00 / Revision E

Page 37

Command:

CONF

Description: Reconfigure board. Factory use only.

Parameters: None

Query: None

Example: Conf (The ScreenSHAPER resets using current configuration values.)

Command:

CSUM

Description: Display the checksum of the files in flash. For debug use only.

Parameters: None

Query: None

Example: CSUM (The checksum of the files in flash will be display in the terminal.)

Command:

CURVE n

Description: Select the blend curve al gorithm for edge feathering.

Parameters: n [0-4] 1st|3rd|5th|7th|9th

Query:

CURVE ?

Returns the current select curve algorithm.

=n

Example: CURVE 0 (Select the linear blend curve algorithm.)

Command:

DBIT n

Description: Set the number of data bits for serial comma nd port.

Parameters: n [7|8]

Query:

DBIT ?

Returns the number of data bits

=n

Example: DBIT 8 (Set 8 data bits)

Command:

DEBUG password

Description: Enter or exit the Debug Mode.

Parameters: password Enter the debug mode, 0 to exit the debug mode.

Query:

DEBUG ?

Returns the current debug mode

=n

Example: DEBUG 0 (Exit debug mode.)

Command:

DISP n n n n

Description: Define the regi on on the output to display image. The numbers are based on the start of the active

display window. This command is only recognized in the ROTATE Operation Mode.

Parameters: n - Horizontal Start on the display

n - Horizontal End on the display

n - Vertical Start on the display

n - Vertical End on the display

Query:

DISP ?

Returns the HStart, HEnd, VStart, VEnd in the following format:

= n n n n

Example: DISP 128 896 96 672 (Set the display region accordingly.)

Manual # 26-0208100-00 / Revision E ScreenSHAPER – Video Mapping System 29

Page 38

Command:

ECHO n

Description: Turn echo OFF/ON for the serial port.

Parameters: n [0|1] OFF/ON

Query:

ECHO ?

Returns the current echo mode

=n

Example: ECHO 1 (Turn echoing ON)

Command:

EFTA s en w exp

Description: Set the edge feathering parameters.

Parameters: s [L|R] Left|Right

en [0|1] Disable|Enable

w Width of feathering area: [0-640]

exp gamma value: [1.0-5.0]

Query:

EFTA s ?

Returns the edge feathering parameters

=en w exp

Example: EFTA L 1 64 1.0 (Apply edge featheri ng to 64 pixels on the left side of the image with a gamma of

1.0.)

Command:

FLIP n

Description: Flip the Display Image. This command is only recognized in the ROTATE Operation Mode.

Parameters: n - flip mode; [0|1|2], No Flip|Horizontal Flip|Vertical Flip

Example: FLIP 1 (Flip the display image left to right.)

FLIP 2 (Flip the display image top to bottom.)

Command:

FREEZ n

Description: Freeze Display Image

Parameters: n - freeze mode; [0|1], DISABLE|ENABLE

Example: FREEZ 1 (display will be freezed.)

FREEZ 0 (display will processed from input.)

Command:

FSB n

Description: Force Display Black

Parameters: n - force display black mode; [0|1], OFF|ON

Example: FSB 1 (display will show a black screen.)

FSB 0 (display will show the current input source.)

30 ScreenSHAPER – Video Mapping System Manual # 26-0208100-00 / Revision E

Page 39

Command:

GAM n n n

Description: Set the gamma value of the warper chip. Note: This is not the gamma value used for the edge

feathering. Default is set to 1.0.

Parameters: n Table selection, 1-3, VPC|GPC|DPC

n Color selection, 0-3, All|Red|Green|B lue

n Gamma Value; 0.0-5.0

Query:

GAM ?

Returns the current gamma value.

GPC/VPC = n.n n.n n.n

DPC = n.n n.n n.n

Example: GAM 2 0 1.5 (Set the gamma value to 1.5 for all colors on the GPC.)

GAM 3 1 1.0 (Set the gamma value to 1.0 for Red on the DPC.)

Command:

HELP i

Description: Displays the list of available commands that begin with i

Parameters: i Help index

Example: HELP o (Display the commands that begin with “o”.)

Command:

IBRT op nnn.n

Description: Adjusts the Input Brightness value of the curr ent source.

Parameters: op - Select Brightness Control; [C|R|G|B], Common|Red|Green|Blue

nnn.n - Brightness value; C Range 75 to 125%, RGB Range -25 to 25%

Query:

IBRT ?

Returns the Input Brightness of the Common, Red, Green, and Blue of the current source in the

format:

=ccc.c rr.r gg.g bb.b

Example: IBRT C 110 (Adjusts the Input Brightness for the current source to be

110%.)

IBRT ? (Returns the Input Brightness for Common, Red, Green,

and Blue.)

Command:

ICNT op nnn.n

Description: Adjusts the Input Contrast values of the current source.

Parameters: op - Select Contrast Control; [C|R|G|B], Common|Red|Green|Blue

nnn.n - Contrast value; C Range 75 - 125%, RGB Range -25 - 25%

Query:

ICNT ?

Returns the Input Contrast of the Common, Red, Green, and Blue of the current source in the

format:

=ccc.c rr.r gg.g bb.b

Example: ICNT C 100 (Adjusts the Common Input Contrast value as 100%.)

ICNT ? (Returns the input Contrast for Common, Red, Green and

Blue.)

Manual # 26-0208100-00 / Revision E ScreenSHAPER – Video Mapping System 31

Page 40

Command:

ICPHO op nn

Description: Adjusts the Input Clock Phase Offset of the current source.

Parameters: op option[A|M] Auto|Manual

nn Phase value; [-16…15]

Query:

ICPHO ?

Returns the Input Clock Phase of the current source in the format:

=nn

Example: ICPHO m 7 (Set the input phase offset to 7.)

ICPHO d (Enter the debug mode for adjusting the input phase offset.)

Command:

ICPL op nnnn

Description: Adjusts the Input Clocks Per Line of the current source.

Parameters: op option[A|M] Auto|Manual

nnnn Clocks per Line value; [0 - 4096]

Query:

ICPL?

Returns the Input Clocks Per Line of the current source in the format:

=nnnn

Example: ICPL m 1688 (Set the input clocks per line to 1688.)

ICPL d (Enter the debug mode for adjusting inp ut clocks per li ne. In the debug mode,

I = Increment

D = Decrement

.. = Exit debug mode.)

Command:

ICREC n n

Description: Recall an inp ut configuration.

Parameters: n Configuration index[0-6] for standard library

Configuration index[1] for user library

n Library[User|Standard

Standard: 640x480|800x600|1024x768|1280x1024|

1280x720|1280x768|1280x960

Example: ICREC 1 0 (Loads the user saved input configuration index by 1.)

ICREC 2 1 (Loads the standard input configuration for 1024x768 video)

Command:

ICRST

Description: Resets the input configur ation of the current source.

Parameters: None

Example: ICRST (Resets the input configur ation for the current source.)

Command:

ICSAV n

Description: Saves all of the Input Conf igurations to non-volatile RAM (NOVRAM)

Parameters: n Configuration index[1]

Example: ICSAV 1 (Saves the all the current input configurations to

NOVRAM.)

Command:

ID

Description: Query Board I D

Parameters: None

Example: ID

Returns the Board ID.

=n

32 ScreenSHAPER – Video Mapping System Manual # 26-0208100-00 / Revision E

Page 41

Command:

INFO

Description: System Information Command. For internal use only

Parameters: NONE

Example: NONE

Command:

INFO2

Description: System Information Command. For internal use only

Parameters: NONE

Example: NONE

Command:

IRSP n n

Description: Adjust the input active window.

Parameters: n Edge to adjust, L|R|T|B, Left|Right|Top|Bottom

n Offset, [-999..999].

Example: IRSP l 2 (Adjust the left edge 2 pixels to the right.)

IRSP B -2 (Adjust the bottom edge 2 lines up.)

Command:

ISYNC n

Description: Adjusts the Input Sync selection of the current source.

Parameters: n - Mode; [0|1|2|3], SOG|COMP|H/V|AUTO

Query:

ISYNC?

Returns the Input Sync Mode of the current source in the format:

=n

Example: ISYNC 0 (Sets Scaler to expect SOG on the input channe l.)

Command:

KEY n n

Description: Load a new keystone warp map from flash into the coefficient dual port ram of the warper chip.

This command is only recognized in the WARP Operation Mode.

Parameters: n - V Index of keystone, [0-10]

n - H Index of keystone, [-8-8]

Query:

KEY ?

Returns the currently selected keystone indexes.

= n n

Example: KEY 1 1 (The keystone warp map (1,1) is loaded into the DPR.)

Command:

LNW

Description: Load a new user defined warp map from flash into the coefficient dual port ram of the warper chip.

This command is only recognized in the WARP Operation Mode.

Parameters: None

Query:

None

Example: LNW (The user defined warp map is loaded into the DPR.)

Command:

LOADR

Description: Places unit into loader mode. This mode is used to perform field upgrades

Parameters: None.

Manual # 26-0208100-00 / Revision E ScreenSHAPER – Video Mapping System 33

Page 42

Command:

MAP n

Description: Index a user-defined warp map. The warp map has to be loaded prior to turning the warping

function ON. It is required that the loaded warp map was generated for the current input-output

resolution. This command is only recognized in the WARP Operation Mode.

Parameters: n - Index of the user-defined warp map, [0-8]

Query:

MAP ?

Returns the currently selected user-defined warp map.

= n

Example: KEY 2 (The user-defined warp map [2] is loaded.)

Command:

OCRECF n

Description: Select the Output Resolution

Parameters: n - Output Resolution

0 = VGA, 640x480*

1 = SVGA, 800x600

2 = XGA, 1024x768

3 = SXGA, 1280x1024

4 = 1280x720

5 = 1280x768

6 = 1280x960

*VGA is not supported if the input format is 1280x1024

Query:

OCRECF ?

Returns the Output Resolution in the format:

=n

Example: OCRECF 2 (Select output format to be XGA.)

Command:

OFRATE n

Description: Adjusts the Output Frame Rate.

Parameters: n - frame rate; [0|1|2|3], 50Hz|60Hz|75Hz|59.94Hz

Query:

OFRATE ?

Returns the Output Frame Rate in the format:

=n

Example: OFRATE 1 (Sets the output frame rate to 60Hz.)

Command:

OP n

Description: Set the operati on mode for ScreenShaper products. The warping functions are only available when

operating in WARP mode and the rotation functions are only available when operating in ROTATE mode.

Parameters: n - operation mode, [0|1] WARP|ROTATE

Query:

OP ?

Returns the operation mode:

=n

Example: OP 1 (Set the ScreenShaper unit to operation in ROTATE mode.)

OP 0 (Set the ScreenShaper unit to operation in WARP mode.)

34 ScreenSHAPER – Video Mapping System Manual # 26-0208100-00 / Revision E

Page 43

Command:

ORAS n

Description: Puts a white raster box on the output display if Rotation is at 0 degree. If Rotation is at 90, 180 or

270, the output raster box can not be enabled.

Note: If the display area is not full screen, the edge area will be white when Output Raster Box is

Enabled.

Parameters: n - [0|1] Disable|Enable

Query:

ORAS ?

Returns the output raster box mode:

=n

Example: ORAS 1 (Select to put a white raster box on the output display).

Command:

OSYNC n

Description: Adjusts the Output Sync.

Parameters: n - Sync mode; [0|1|2|3|4|5], SOG|-C|+H+V|+H-V|-H+V|-H-V

Query:

OSYNC ?

Returns the Output Sync mode in the format:

=n

Example: OSYNC 3 (Adjusts the Output Sync value to be +H-V.)

Command:

PAR n

Description: Set the parity type for serial command port.

Parameters: n [0|1|2] NONE|ODD|EVEN

Query:

PAR ?

Returns the parity type

=n

Example: PAR 1 (Set ODD parity)

Command:

RESET op

Description: Resets all system variables or reset the system to factory defaults

Parameters: op - Reset operation; [A|F], All|Factory

Example: RESET A (Resets all system variables.)

Command:

ROT n

Description: Rotate image. T his command is only reco gnized in the ROTATE Operation Mode.

Parameters: n [0|90|180|270]

Query:

ROT ?

Returns the current rotation setting

=n

Example: ROT 90 (Rotate the image 90 degree.)

Command:

SAVE

Description: Saves the system parameters to non-volatile RAM. Upon power up, the system

parameters stored in non-volatile RAM are used for system configuration.

Parameters: None

Example: SAVE (S ystem parameters are saved to non-volatile RAM.

Manual # 26-0208100-00 / Revision E ScreenSHAPER – Video Mapping System 35

Page 44

Command:

SBIT n

Description: Set the number of stop bit for serial command port.

Parameters: n [1|2]

Query:

SBIT ?

Returns the number of stop bit.

=n

Example: SBIT 1 (Set the serial port for 1 stop bit)

Command:

SYNC n

Description: Selects the output sync method.

Note: External sync input required if non-zero.

Parameters: n [0|1|2] Freerun|Line Locked|Frame Locked

Query:

SYNC ?

Returns the current sync mode

=n

Example: SYNC 2 (Frame lock output timing to external vertical sync.)

Command:

TLCK n

Description: Selects HSync source to use for pixel clock generation.

Note: External sync required if n=2

Parameters: n [0|1|2] Freerun|Lock to input timing|Lock to external sync

Query:

TLCK ?

Returns 0 for free-run mode and 1 for lock output to input

=n

Example: TLCK 1 (Lock output timing to input timing.)

Command:

TPAT typ bx gr

Description: Set the test pattern parameters.

Parameters: typ Test pattern type, [0-15]

(Off|Burst1|Burst2|Grey H Bars|Red H Bars|Green H Bars|Blue H Bars|Yellow H

Bars|Cyan H Bars|Magenta H Bars|Black|Gray 25%|Gray 50%|Gray 75%|White|Horz

Ramp)

bx Raster Box, [0|1] OFF|ON

gr Overlay Grid, [0|1] OFF|ON

Query:

TPAT ?

Returns the test patter parameters

=typ, bx, gr

Example: TPAT 2 1 0 (Output Burst1 with raster box.)

Command:

VER

Description: Display version informatio n.

Parameters: NONE

Example: VER (Display the version information)

36 ScreenSHAPER – Video Mapping System Manual # 26-0208100-00 / Revision E

Page 45

Command:

WARP n

Description: Enable/Disable the warp function. If the warp function is set to ON, the warp map used is set by

the MAP command. If the warp function is set to KEYSTONE*, the warp mapused is set by the

KEY command. This command is only recognized in the WARP Operation Mode.

*Note: The keystone function currently only supports these input-output settings:

SVGA, XGA and SXGA inputs to SXGA output

SVGA, XGA and SXGA inputs to XGA output

SVGA and XGA inputs to SVGA output

Parameters: n [0|1|2], [OFF|ON|Keystone]

Query:

WARP ?

Returns the warp status

=n

Example: WARP 1 (Enable the warping function for user defined warp.)

Manual # 26-0208100-00 / Revision E ScreenSHAPER – Video Mapping System 37

Page 46

5

CHAPTER FIVE

Software Upgrade Instructions

What you will find in this chapter…

Software Upgrade Instructions

Model VMS-100

38 ScreenSHAPER – Video Mapping System Manual # 26-0208100-00 / Revision E

Page 47

Software Upgrade Instructions

Overview

The ScreenSHAPER units incorporate the system software in a Flash memory component. Flash memory allo ws

easy upgrades without the need to send the unit back to the factory due to software or firmware changes.

The loader utility provides the capability to update the system Flash module with the latest revision of software. The

upgrade utility can be run from a hard drive (recommended) or a floppy drive. Running the loader from a floppy drive

is discouraged due to the slow speeds associated with disk access.

Hardware Requirements

* IBM compatible computer with an available COM port

* Serial cable conforming to EIA RS-232 specifications (i.e. Standard Modem cable)

(The cable should have a DB-9 male connector on one end). The cable supplied with the unit is recommended.

Software Requirements

* Window 95/98/NT/2000/XP

* Flash File Loader

* ScreenSHAPER Software files

The Flash File Loader with the Software files can be downloaded from our FTP site

as described below.

Connecting to Barco Folsom

Barco Folsom's FTP site address is: ftp.folsom.com

If you are using an FTP client, logon to our site using "anonymous" for the user

name and your email address as the password (ex. johndoe@somecompany.com

However, if you are using a web browser to access our FTP site, point the browser to: ftp://ftp.folsom.com

).

.

Downloading Necessary Files

ScreenSHAPER Software Files and Flash File Loader

Directory Location: ftp://ftp.folsom.com\ Products \ Video \ ScreenSHAPER \

File to download: "ScreenSHAPER_Rev###.exe"

Installing ScreenSHAPER Software Files and Flash File Loader

Before installing the files, it is recommended that all running programs

be properly shut down.

1. Click on the Start button and select Run.

2. Click on the Browse button and locate the " ScreenSHAPER _Rev###.exe" file on your hard drive.

3. Double click on this file and then click OK to start the installation process.

4. Follow the on screen instructions to complete the install.

Manual # 26-0208100-00 / Revision E ScreenSHAPER – Video Mapping System 39

Page 48

Starting the Flash File Loader Utility

After the files have been installed the Flash File Loader can be selected to run.

1. Click on the Start button and select Programs.

2. Find the Folsom Research folder and select Flash File Loader.

Preparing to Upgrade the ScreenSHAPER Unit

1. Plug the DB-9 male connector into the port labeled “RS-232” on the back of the ScreenSHAPER unit.

2. Make sure the other end of the cable is attached to the available COM port on the back of the computer

performing the upgrade.

3. In the loader program, click on the RS232 Config menu and select COM Port.

4. In the Communication Settings window, select the COM port the ScreenSHAPER port is attached to by

clicking on the appropriate COM # choice.

5. The ScreenSHAPER RS-232 serial port defaults to a baud rate of 38400 baud (38.4K).

Uploading Files to the ScreenSHAPER Unit

1. Once communications have been established and verified, click on the “Open script file to read and upload”

button to begin the upgrade process.

2. Browse to the location where the “field_upgrade.sld” file is located and click on it. Then click on “Open” to

start transferring the files to the ScreenSHAPER.

3. A TRANSFER STATUS box will open and show the status of the upload as it progresses.

4. After several minutes, the loader utility will inform the user that the process is complete.

5. Power cycle the ScreenSHAPER.

40 ScreenSHAPER – Video Mapping System Manual # 26-0208100-00 / Revision E

Page 49

CHAPTER SIX

Barco Folsom Information

What you will find in this chapter…

Warranty

RMA Information

Technical Support/General Contact Information

6

Model VMS-100

Manual # 26-0208100-00 / Revision E ScreenSHAPER – Video Mapping System 41

Page 50

Barco Folsom Information

Barco Folsom, LLC Warranty

All video products are designed and tested to the highest quality standards and are backed by a full 3-year parts and

labor warranty. Warranties are effective upon delivery date to customer and are non-transferable. Barco Folsom,