Page 1

SF-10V display

Installation manual

R59770542/01

10/02/2012

Page 2

Barco nv LiveDots

President Kennedypark 35, B-8500 Kortrijk

Phone: +32 56.23.32.11

Fax: +32 56.26.22.62

Support: www.barco.com/esupport

Visit us at the web: www.barco.com

Printed in China

Page 3

Changes

Barco provides this manual ’as is’ without warranty of any kind, either expressed or implied, including but not limited to the implied warranties or merchantability and fitness for a particular purpose. Barco may make improvements and/or changes to the product(s) and/or the

program(s) described in this publication at any time without notice.

This publication could contain technical inaccuracies or typographical errors. Changes are periodically made to the information in this

publication; these changes are incorporated in new editions of this publication.

The latest edition of Barco manuals can be downloaded from the Barco web site w

h

ttps://my.barco.com.

ww.barco.com or from the secured Barco web site

Page 4

Page 5

Table of contents

TABLE OF CONTENTS

1. Safety................................................................................................................ 3

1.1 Safety guidelines .................................................................................................................... 4

1.2 Important safety instructions ........................................................................................................ 5

1.3 Important warnings .................................................................................................................. 6

2. SF-10V tiles......................................................................................................... 7

2.1 SF-10Vtile ........................................................................................................................... 8

2.2 Stacking SF-10V packages ......................................................................................................... 9

3. Installation requirements . ................ ................ .................. ................ ................ .....11

3.1 Mechanical requirements for the SF-10V display ..................................................................................12

3.2 Electrical requirements for the SF-10V display. ....................................................................................14

3.3 System requirements for the Control software .. ...................................................................................15

4. System overview ..................................................................................................17

4.1 Introduction ..........................................................................................................................18

4.2 SF-10Vtile ...........................................................................................................................20

4.3 Power boxes.........................................................................................................................25

4.4 VideoProcessor ....................................................................................................................26

4.5 Controlsoftware.....................................................................................................................28

4.6 Fiberlinksystem .....................................................................................................................29

5. Physical installation ..............................................................................................31

5.1 Installation of the support structure .................................................................................................32

5.2 Mounting the SF-10V tile .. . .........................................................................................................33

6. Dimensions ................ ................ ................ .................. ................ ................ .......39

6.1 SF-10Vtile ...........................................................................................................................40

6.2 Assemblyof SF-10Vtiles............................................................................................................41

6.3 SF-10Vpackage.....................................................................................................................42

7. Specification .......................................................................................................43

7.1 Specificationsof theSF-10Vtile.....................................................................................................45

8. Order info ...........................................................................................................47

8.1 Orderinfo ............................................................................................................................48

8.2 Spare partandservice kits..........................................................................................................50

9. Environmental information ......................................................................................51

9.1 Disposalinformation.................................................................................................................52

9.2 Rohs compliance ....................................................................................................................53

R59770542 SF-10V DISPLAY 10/02/2012

1

Page 6

Table of contents

2 R59770542 SF-10V DISPLAY 10/02/2012

Page 7

1. SAFETY

About this chapter

Read this chapter attentively. It contains important information to prevent personal injury while installing the SF-10V display. Furthermore, it includes several cautions to prevent damage to the SF-10V tile. Ensure that you understand and follow all safety guidelines,

safety instructions and warnings mentioned in this chapter before installing the SF-10V display. After this chapter, additional “warnings” and “cautions” are given depending on the installation procedure. Read and follow these “warnings” and “cautions” as well.

Overview

• Safety guidelines

• Important safety instructions

• Important warnings

1. Safety

R59770542 SF-10V DISPLAY 10/02/2012

3

Page 8

1. Safety

1.1 Safety guidelines

Personal protection

WARNING: Ensure you understand an d follow all the safety guidelines, safety in structions, warnings and

cautions mentioned in this manual.

WARNING: Be aware of su spended loads.

WARNING: Wear a hard hat to reduce the risk of personal injury.

WARNING: Be careful while working with heavy loads.

WARNING: Mind your fing ers while working with heavy loads.

Installation personnel

This installation must be performed by authorized and qualified technical personnel only.

Accredited safety officers must ensure the safety of the site, construction, assembly, connection, use, dismantling, transport etc. of

such safety critical systems.

Caution

Installation should be performed only after you are thoroughly familiar with all of the proper safety checks and installation instructions.

To do otherwise increases the risk of hazards and injury to the user.

Assembly parts are designed for intended use only in conjunction with SF-10V LED displays.

Do not modify and/or replicate any component. Barco uses specific materials and manufacturing processes in order to achieve part

strength. Consult Barco for assistance with custom applications.

Always follow Barco installation instructions. Cont

The manufacturer assumes no liability for incorrect, inadequate, irresponsible or unsafe assembly of systems.

act Barco if you should have any question regarding the safety of an application.

Product care

Structural & mounting components should be kept dry, clean, lubricated (only if recommended), coated properly, and otherwise

maintained in a manner consistent with part design. Barco products must be used in a manner consistent with their design and

inspected on a routine basis for security, wear, deformation, corrosion and any other circumstances that may affect the load handling

capability of the part.

Barco recommends inspections at regular intervals for all installations and increasing in frequency for more critical installations. If

a part is found to have damage, which may cause a decrease in load capability, the part must be removed for service or replaced

immediately.

Under no circumstances are Barco parts repairable by anyone other than Barco.

4

R59770542 SF-10V DISPLAY 10/02/2012

Page 9

1.2 Important safety instructions

Instructions:

• Read these instructions.

• Keep these instructions.

• Heed all warnings.

• Follow all instructions.

• Clean only with materials or chemicals that are inert, nonabrasive, noncorrosive and non-marking. Consult the manufacturer

for further advice should any doubts exist regarding any cleaning procedure.

• Do not block ventilation openings. Install in accordance with the manufacturers instructions.

• Do not install near any heat sources such as radiators, heat registers, stoves, or other apparatus (including amplifiers) that

produce heat.

• Do not defeat the safety purpose of the polarized or grounding type plugs/sockets. If the provided sockets/plugs are damaged

then replacement of the defective parts must be undertaken immediately.

• Protect the power/data cords from being walked on or pinched particularly at plugs, convenience receptacles, and the point

where they exit from the apparatus. Replace damaged power/data cords immediately.

• Only use attachments/accessories specified by the manufacturer.

• Disconnect the power to this apparatus during lightning storms or provide suitable additional lightning protection. Unplug this

apparatus when unused for long period of time.

• Refer all servicing to qualified service technicians/personnel. Servicing is required when the apparatus has been damaged in

any way, such as power-supply cord or plug is damaged, the apparatus does not operate normally, or has been dropped.

• Use only with systems or peripherals specified by the manufacturer, or sold with the apparatus. Use caution during lifting/moving

or transporting to avoid damage by possible tipping.

1. Safety

R59770542 SF-10V DISPLAY 10/02/2012

5

Page 10

1. Safety

1.3 Important warnings

Important warnings:

Risk of electric shock:

Do not open. To reduce the risk of electric shock, do not remove cover (or back). Remove all power and data cabling before opening

the device for service purposes. No user-serviceable parts inside. Refer servicing to qualified service personnel.

Maximum and m inimum ambient temperature:

The maximum ambient temperature for the LED wall is 45°C, the minimum temperature is -20°C.

High leakag e current:

The combination of multiple tiles in an installation results in increased levels of leakage current. In order to avoid risk of electric

shock due to high leakage current, proper grounding of the installation is required.

Flammable materials:

Keep flammable materials away from the installation (such as curtains). A lot of energy is transferred into heat. The installation

should be such that the amount of air flow required for safe operation of the equipment is not compromised. Proper ventilation must

be provided.

Risk of electric shock / Risk of fire:

To protect against risk of fire caused by overloading of power cables, MAXIMUM 2 tiles may be connected in parallel. Each power

source cable supplying maximum 2 tiles should be protected by a circuit breaker or fuses rated 16 A / 250 VAC (15 A / 250 VAC in

the USA and Canada). Note that one SF-10V tile requires 220-240 VAC, 50-60 Hz, 1.56 amps at 230 VAC.

Disconnect device:

When the appliance inlets of the individual tiles are not accessible, the socket outlets supplying the rack shall be installed near the

equipment and be easily accessible, or a readily accessible general disconnect device shall be incorporated in the fixed wiring.

This equipm ent MUST be earthed:

In order to protect against risk of electric shock, the installation should be properly grounded. Defeating the purpose of the grounding

type plug will expose you to the risk of electric shock.

Power system:

It is recommended to use a TN-S power distribution system (a power distribution system with a separate neutral and grounding

conductor) in order to avoid large ground current loops due to voltage differences in the neutral conductor. The total electrical

installation should be protected by an appropriately rated disconnect switch, circuit breakers, over voltage protector and Ground Fault

Current Interrupters. The installation shall be done according to the local electrical installation codes. In Europe special attention

should be given to HD 60364, Harmonization Document for electrical installation of buildings. In Germany VDE 0100 should be

adhered to. In America, special attention should be given to the National Electrical Code, ANSI/NFPA 70.

Mains cords:

The power cords delivered with this system have special properties for safety. They are not user serviceable. If the power cords are

damaged, replace them only with new ones. Never try to repair a power cord.

Salty e nvironm ent

If install in coastal cities, the SF-10V display shall be installed 250 meters away from the shoreline horizontally in dry and cold

climates; 500 meters away from the shoreline in case of high humidity and hot climates. The high humidity and hot climate mean

the climate that the humidity is higher than 80% RH and temperature is higher than 0°C for one third of time every

6

R59770542 SF-10V DISPLAY 10/02/2012

Page 11

2. SF-10V TILES

About this chapter

This chapter described the SF-10V, modular outdoor LED tile.

Overview

• SF-10V tile

• Stacking SF-10V packages

2. SF-10V tiles

R59770542 SF-10V DISPLAY 10/02/2012

7

Page 12

2. SF-10V tiles

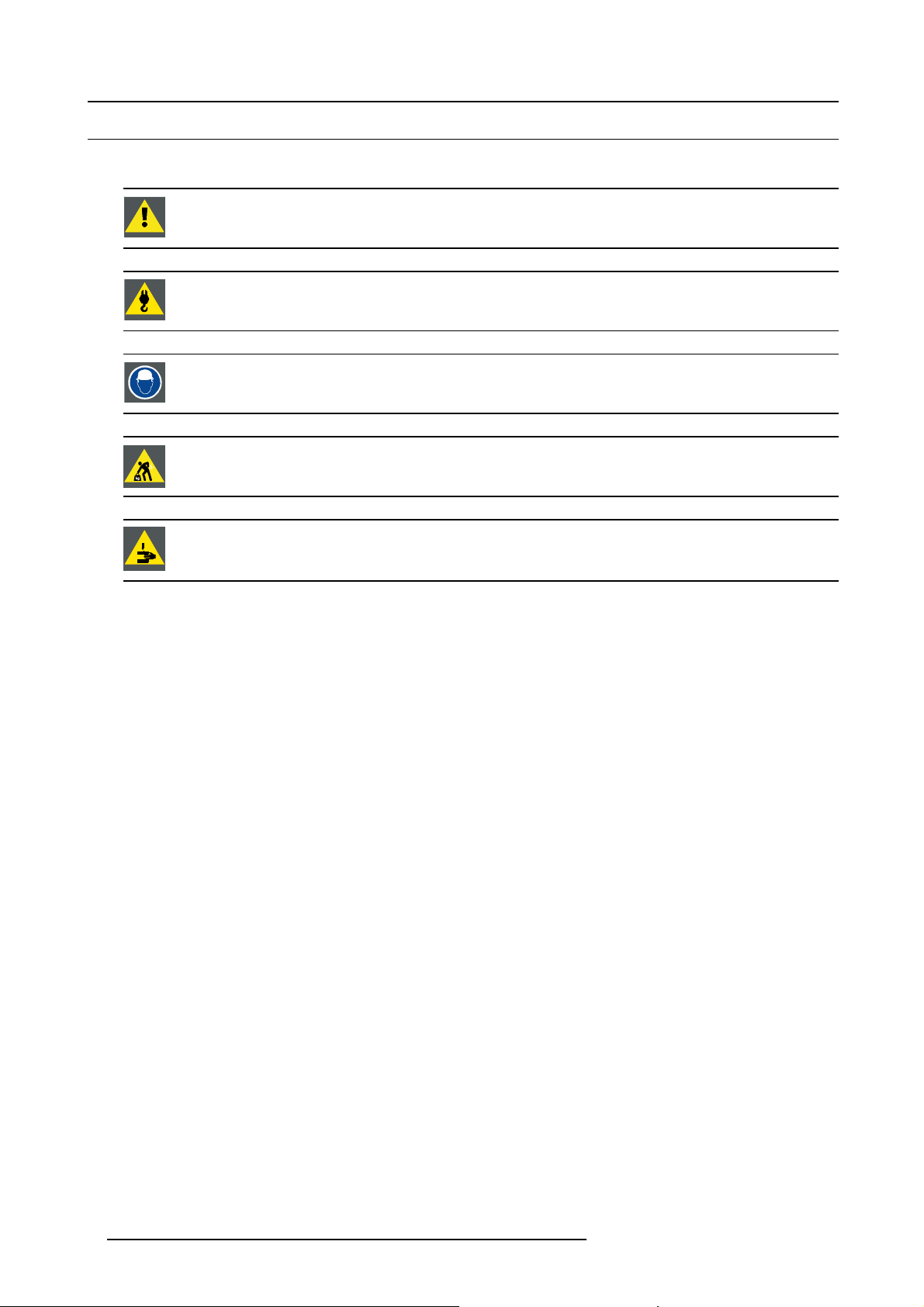

2.1 SF-10V tile

Tile overview

The front and back view of the SF-10V tile.

Image 2-1

Packing

For safe transportation, the SF-10V tiles are stored in a secure way. every tile have its separate package, Maxium 4 SF-10V packages that inner hold the tile can stand in a big wooden pallet.

Image 2-2

The weight

SF-10V 1 tile 79.5 kg R9004843

SF-10V 4 packed tiles (including pallet) 355 kg R9004843B4

8 R59770542 SF-10V DISPLAY 10/02/2012

Page 13

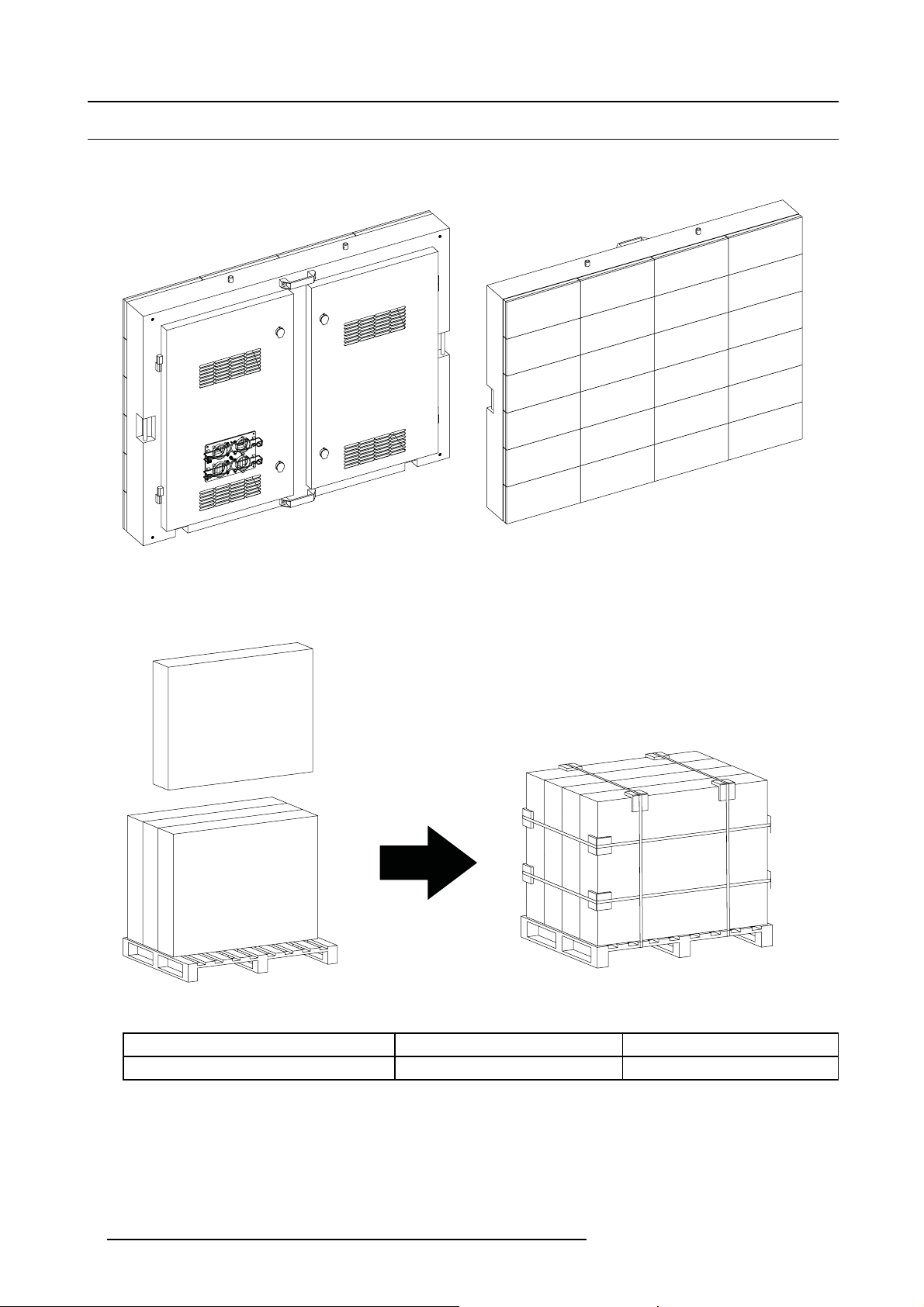

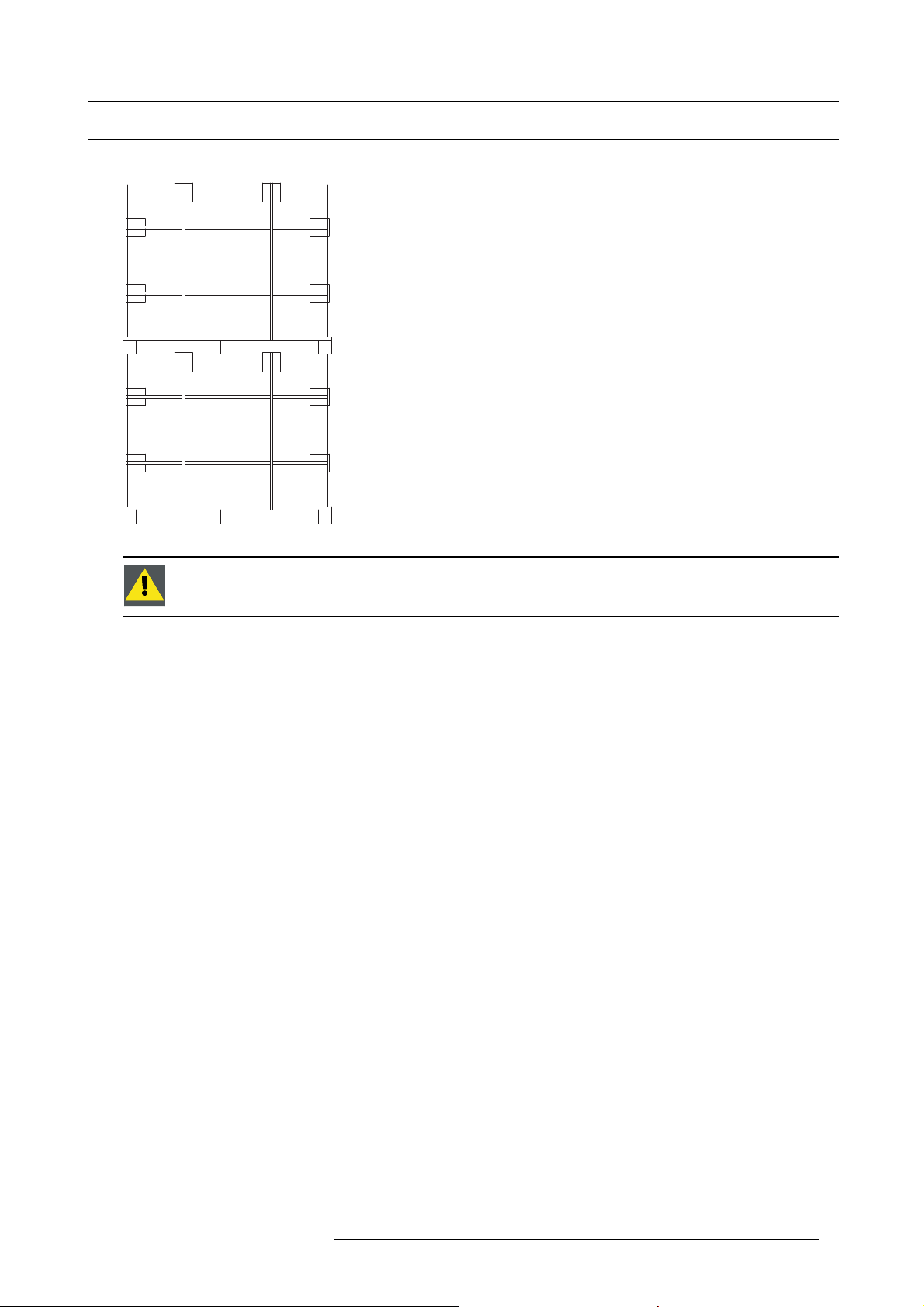

2.2 Stacking SF-10V packages

Stacking possibilities for SF-10V packages

Image 2-3

2. SF-10V tiles

WARNING: Only the configurations illustrated above can be used for stacking. Other configurations will dam-

age the SF-10V tiles.

R59770542 SF-10V DISPLAY 10/02/2012 9

Page 14

2. SF-10V tiles

10 R59770542 SF-10V DISPLAY 10/02/2012

Page 15

3. Installation requirements

3. INSTALLATION REQUIREMENTS

About this chapter

This chapter enumerate the mechanical requirements for the SF-10V display, the electrical requirements to power up the SF-10V

display and the system requirements to run the control software efficient.

Overview

• Mechanical requirements for the SF-10V display

• Electrical requirements for the SF-10V display

• System requirements for the Control software

R59770542 SF-10V DISPLAY 10/02/2012

11

Page 16

3. Installation requirements

3.1 Mechanical requirements for the SF-10V display

Support structure

The support structure can be provided and installed by the customer because they vary from system to system. Although, the

following must be taken into account and must be precisely calculated on individual basis:

1. Weight tolerances : Ensure that the support structure and the floor on which or the wall against which the support structure

has to be installed, is able to handle the complete weight of the SF-10V display.

2. Environmental conditions : Humidity, wind, temperatures, rain, salty etc.

3. Location : Outdoor, altitude, etc.

4. Ground stability

5. Front clearances : For optimal impact ensure that there is sufficient free area in front of the SF-10V display and respect the

maximum viewing distance.

6. Local regulations regarding such installations

WARNING: Never construct a SF-10V display if there is uncertainty regarding the stability of an installation

or the load holding capabilities. If there are doubts on a systems viability, consult Barco for advice on professional rigging organizations.

Individual basis

Support structures must be assessed on an individual basis. Never construct a wall if there is uncertainty regarding the stability of

an installation or the load holding capabilities. If there are doubts on a system’s viability, consult Barco for advise on professional

rigging organizations.

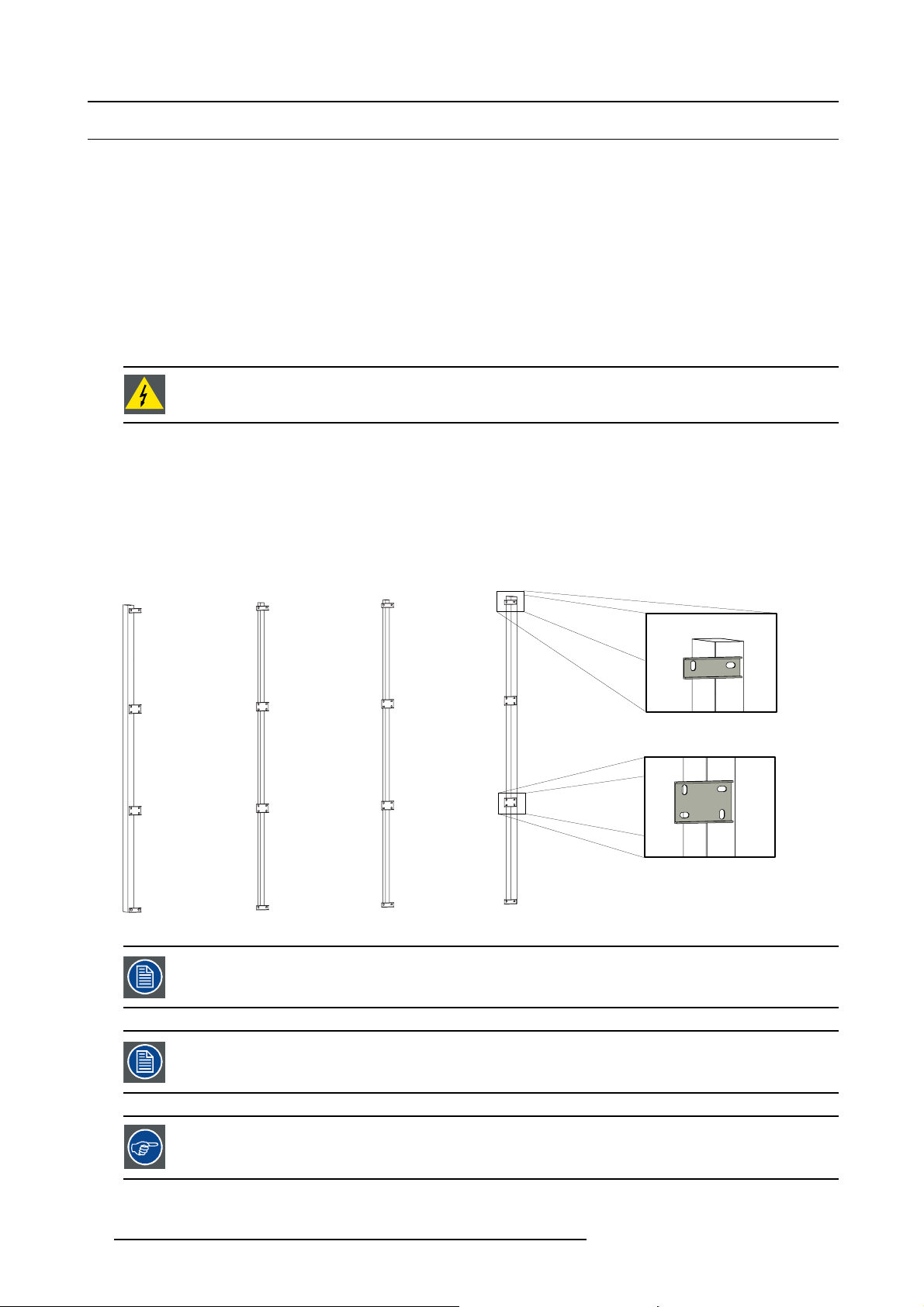

Example of a support structure

The support structure below consists of vertical I beams, when installed the tiles the bottom row tiles will directly stand on the support

structure. The mounting plates located in the back of the support structure when mounting SF-10V tiles.

Image 3-1

The drawing only shows the mounting plates’ location without the tiles, in fact the mounting plates are not

pre-installed on the support structure.

The support structure in the above example is pure illustrative for a SF-10V display consisting of 9 tiles.

It’s recommended to integrate a service platform in every other two row of the support structure . Such a

platform allows a fast and easy interven tion, if req uired.

12 R59770542 SF-10V DISPLAY 10/02/2012

Page 17

3. Installation requirements

WARNING: 90% energy is transferred into heat, which requires a certain amount of airflow at the rear of

the SF-10V display. For that sufficient free space should be available behind the display to ensure a good

ventilation. The higher the display the more free space is required.

R59770542 SF-10V DISPLAY 10/02/2012 13

Page 18

3. Installation requirements

3.2 Electrical requirements for the SF-10V display

Power requirements

One SF-10V tile requires 220-240 VAC, 50-60 Hz, 5.72 amps at 230 VAC. Note that one SF-10V tile correspond with a display surface

of 1,23 m². Power link cables are used to link the power from tile to tile. However, MAXIMUM two (2) tiles, may be connected in

parallel. So, one power source cable has to be provided per two (2) tiles. Every power source cable should be protected by a circuit

breaker or fuses rated 16 A / 250 VAC (15 A / 250 VAC in the USA and Canada).

Barco provides a range of power boxes, which meet the requirements of your SF-10V display. Contact B

for more information about power boxes and power requirements for your SF-10V display.

arco

Power system

It is recommended to use a TN-S power distribution system (a power distribution system with a separate neutral and grounding

conductor) in order to avoid large ground current loops due to voltage differences in the neutral conductor. The total electrical

installation should be protected by an appropriately rated disconnect switch, circuit bre

Current Interrupters. The installation shall be done according to the local electrical installation codes. In Europe special attention

should be given to EN 60364, the standard for electrical installation of buildings. In Germany VDE 0100 should be adhered to. In

America, special attention should be given to the National Electrical Code, ANSI/NF

akers, over voltage protector and Ground Fault

PA 70.

This equipment MUST be earthed

In order to protect against risk of electric shock, the installation should be properly grounded. Defeating the purpose of the grounding

type plug will expose you to the risk of electric shock.

14

R59770542 SF-10V DISPLAY 10/02/2012

Page 19

3. Installation requirements

3.3 System requirements for the C ontrol software

Before you begin

It is assumed you are familiar with the Windows operating system at your site.

The CD-ROM in your package contains a Windows-based installation program. You can install the software from the CD-ROM.

System requirements

Minimum specifications :

• Hardware

- PC Pentium III or equivalent, 2 GHz

- 512 Mb RAM

- Free hard disk space: 300 Mb

- XGA resolution (1024 x 768)

- Serial communication port

- Ethernet connection

• Software

- Windows 7 and Windows Vista.

Recommended specifications :

• Hardware

- PC Pentium IV or equivalent, 2.4 GHz

-1GbRAM

- 300 Mb hard disk free space

- SXGA resolution (1280 x 1024) with 32 Mb video memory

- Serial communication port

- Ethernet connection

• Software

- Windows XP Professional, Windows Vista or Windows 7

The system should be compatibility w ith either D TS or RMS.

The DTS and RMS can not compatibility with Windows Vista.

The DTS and R MS can compatibility with Window s 7 and Windows XP.

R59770542 SF-10V DISPLAY 10/02/2012 15

Page 20

3. Installation requirements

16 R59770542 SF-10V DISPLAY 10/02/2012

Page 21

4. SYSTEM OVERVIEW

About this chapter

This chapter enumerates the fundamental elements of an SF-10V screen display.

Overview

• Introduction

• SF-10V tile

• Power boxes

• Video Processor

• Control software

• Fiberlink system

4. System overview

R59770542 SF-10V DISPLAY 10/02/2012

17

Page 22

4. System overview

4.1 Introduction

The fundamental elements of an SF-10V s creen display system are:

• SF-10V tiles.

• Control PC.

• LED Image Processor.

• Power box.

• Control software.

Block diagram of a SF-10V display

LED-wall

Sources

Image 4-1

If the LED Image Processor is D 320 or Ledpro use the RS232 connection w ith the control PC

Video Processor

RS232

Control

PC

Power

box

Tile 1

Tile 2

Tile 3

18 R59770542 SF-10V DISPLAY 10/02/2012

Page 23

4. System overview

LED-wall

Sources

Image 4-2

If the LED Image Processor is DX–700 and DX-100 use the TCP/IP connection with the control PC.

Video Processor

TCP/IP

Control

PC

Power

box

Tile 1

Tile 2

Tile 3

R59770542 SF-10V DISPLAY 10/02/2012 19

Page 24

4. System overview

4.2 SF-10V tile

Introduction SF-10V tile

The SF-10V series is designed for ultra-large outdoor LED display installations. The SF-10V tile can overlay video and data sources

in their native quality. A unique video processing feature enables the creation of a visual resolution quasi double the physical resolution defined by the cluster of LED’s spread on the surface of the display. The SF-10V tile is an IP65 rating in front of side and an

IP43 rating in back of side.

Parts location of the SF-10V tile

12

5

6

9

11

2

6

5

Image 4-3

1. Hoist point.

2. Handle.

3. Air outl et.

4. Hoist point.

5. Insert nuts for fi xing tile

6. Hinge

7. Lock.

8. Lock

9. Hidden handle

10. Hinge.

11. Air inl et

12. Insert nuts for fix ing tile.

13. Adjust bloc k.

14. Lock.

15. Lock.

16. Handle.

17. Resyncer.

18. Air inl et.

19. Adjust bloc k.

20. Insert nuts for fix ing tile.

21. Hinge.

22. Hidden handle.

23. Air ou tlet.

24. Hinge.

25. Insert nuts for fix ing tile.

3

4

3

2

5

6

7

8

8

9

7

4

11

6

10

5

2

1

10

4

8

8

1

Power cables used between SF-10V tiles

To meet the demands of each SF-10V application Barco offers several lengths of power cables to link power from tile to tile. Note

that the power output port of the last tile in the power chain has to be sealed with a waterproof cap.

20

R59770542 SF-10V DISPLAY 10/02/2012

Page 25

4. System overview

Image 4-4

Power link cable of 1,5 meter (R9850241).

R59770542 SF-10V DISPLAY 10/02/2012 21

Page 26

4. System overview

Image 4-5

Dummy power plug (R9850280).

Data cables used between SF-10V tiles

To meet the demands of each SF-10V application Barco offers several lengths of data cables to link data from tile to tile. Note that

the data output port of the last SF-10V tile in the data chain has to be sealed with a dummy data plug.

22

R59770542 SF-10V DISPLAY 10/02/2012

Page 27

4. System overview

Image 4-6

Data linking ca ble of 1,5 meter (R9850210).

R59770542 SF-10V DISPLAY 10/02/2012 23

Page 28

4. System overview

Image 4-7

Dummydataplug(R9850270).

24 R59770542 SF-10V DISPLAY 10/02/2012

Page 29

4. System overview

4.3 Power boxes

General

To ensure safe and reliable operation of the SF-10V display, a suitable system for AC power distribution must be used. Though 3

party solutions may be used, several sizes and types of power distributions are available from Barco. For smaller system the “Mono

Phase Power Box” can be used, medium sized system may use on of several custom power box solutions.

rd.

Image 4-8

Mono phase power box.

CAUTION: Consult the manual(s) of the used power box for more information about installation and usage

guidelines.

Image 4-9

Custom power box.

R59770542 SF-10V DISPLAY 10/02/2012 25

Page 30

4. System overview

4.4 Video Processor

General

The Video processor processes (image processing, conversion and conditioning) all source signals for digital distribution to every

tile as well as providing a user interface for complete system setup monitoring and control. The video processor can be accessed

directly or via the control software (e.g. DTS). This software is designed as a user interface to be used in conjunction with the Video

processor and display. It should be used on a PC that’s connected to the Video processor through a serial RS232 connection.

SF-10V: Video Processor Overview

Image 4-10

D320 Processor.

Image 4-11

DX-700 Pr ocessor.

Image 4-12

LEDPro Processor.

26 R59770542 SF-10V DISPLAY 10/02/2012

Page 31

4. System overview

CAUTION: Refer to the manual(s) of the u sed vid eo proce ssor for more information about installation and

usage guide li ne s.

D320

The D320L is a video processing device, designed to drive as well Barco LED walls as large screen projectors, monitors, plasma

screens, ... etc. The D320L is capable of handling all standard output formats like SVGA, XGA, SXGA and UXGA on an analog

RGBHV and digital DVI output. The D320L digitizer allows you to control up to 4 sources on one display.

source to source or display sources together, overlay them, customize them. With analog and digital outputs which allow for the

control of displays, as well as built-in-control software, the D320L gives you control over everything from basic set-up to configuration

and advanced feature control. The D320L digitizer is a generic device. This means that a number

Devices can be chained in order to generate more windows on the output (4 windows per device). Devices can also be stacked

in order to be able to split generated output of the devices to multiple screens. For latter purpose, each input is equipped with an

active loop through.

Seamless switch from

of combinations can be made.

Display

Formated Video Data

Input 1

Input 2

Input 4

Input 9

Input 8

Input 12

SOURCE 1

SOURCE 2

SOURCE ..

Image 4-13

Analog Video

Digital Video

Control PC

Master

ViewScape - 1

Slave

ViewScape - 2

DX-700 and DX-100

The DX-700 and DX-100 is a multi-window video processor designed for use as a versatile front-end to all Barco LED products.

Image processing, LED wall configuration and control functions are adjusted from the DX-700 front panel, or from Barco’s Director

Toolset.

LedPro

The LED-PRO is a powerful all-in-one signal processor that accepts a wide range of video input signals, and processes them to

drive Barco LED displays. The LED-PRO allows you to scale visual sources and mix them in multiple ways while still maintaining

superb picture quality. LED-PRO is the ideal solution for converting RGB, HDTV, component, S-video, composite (NTSC, PAL and

SECAM), SDI, DVI, and HDSDI for use with Barco LED walls. LED-PRO has an advanced feature set that includes universal inputs,

aspect ratio conversion, memory presets, test patterns, source lock, picture adjustments, motion adaptive de-interlacing, and 3:2

and 2:2 pull down detection.

R59770542 SF-10V DISPLAY 10/02/2012

27

Page 32

4. System overview

4.5 Control software

General

The control software is designed as a graphic user interface (GUI) and can be used to control and configure the digitizer as well as

the Barco LED wall via a PC (e.g. Director toolset).

Minimum required software version: 2.04

Image 4-14

Control software “Director toolset”.

Remote management software (RMS)

The RMS-1 software is designed to configure, manage, and monitor Barco digital signage LED display systems. It supports

D320L/Lite, DMP-100 and DX-700 video processors as well as SF-10V LED tiles.

The RMS software also has a dedicated user interface which can installed on any windows based PC for remote access the LED

display system.

Image 4-15

CAUTION: R efer to the manual(s) of the used control software for more information about installation and

usage guide li ne s.

28 R59770542 SF-10V DISPLAY 10/02/2012

Page 33

4. System overview

4.6 Fiberlink system

General

If the distance between the digitizer and the LED-wall exceeds 5 meters, a fiber optic connection must be used to ensure signal

integrity and system reliability. Barco offers two complete system solutions including transmitter, fiber and receiver. The choice of

system depends on the length of cable required.

Image 4-16

“Fiberlink 2” transmitter and receiver.

CAUTION: Refer to the manual(s) of the used fi berlink system for more information about installation and

usage guide li ne s.

R59770542 SF-10V DISPLAY 10/02/2012 29

Page 34

4. System overview

30 R59770542 SF-10V DISPLAY 10/02/2012

Page 35

5. Physical installation

5. PHYSICAL INSTALLATION

About this chapter

The setup process below describes roughly the installation stages to follow to install a SF-10V display. Several stages refer to one

or more detailed and illustrated procedures which are also described in this installation manual.

WARNING: Safety fi rst. Fence off the installation area before starting to install your SF-10V display. En-

sure you read, understand and follow all safety instructions mentioned in the chapter "Safety", p

installation manual. Furthermore, make sure that all installation requirements for your SF-10V display are

fulfilled, see chapter "3. Installation requirements", "Installation requirements", page 11.

Overview

• Installation of the support structure

• Mounting the SF-10V tile

age 3 of this

R59770542 SF-10V DISPLAY 10/02/2012 31

Page 36

5. Physical installation

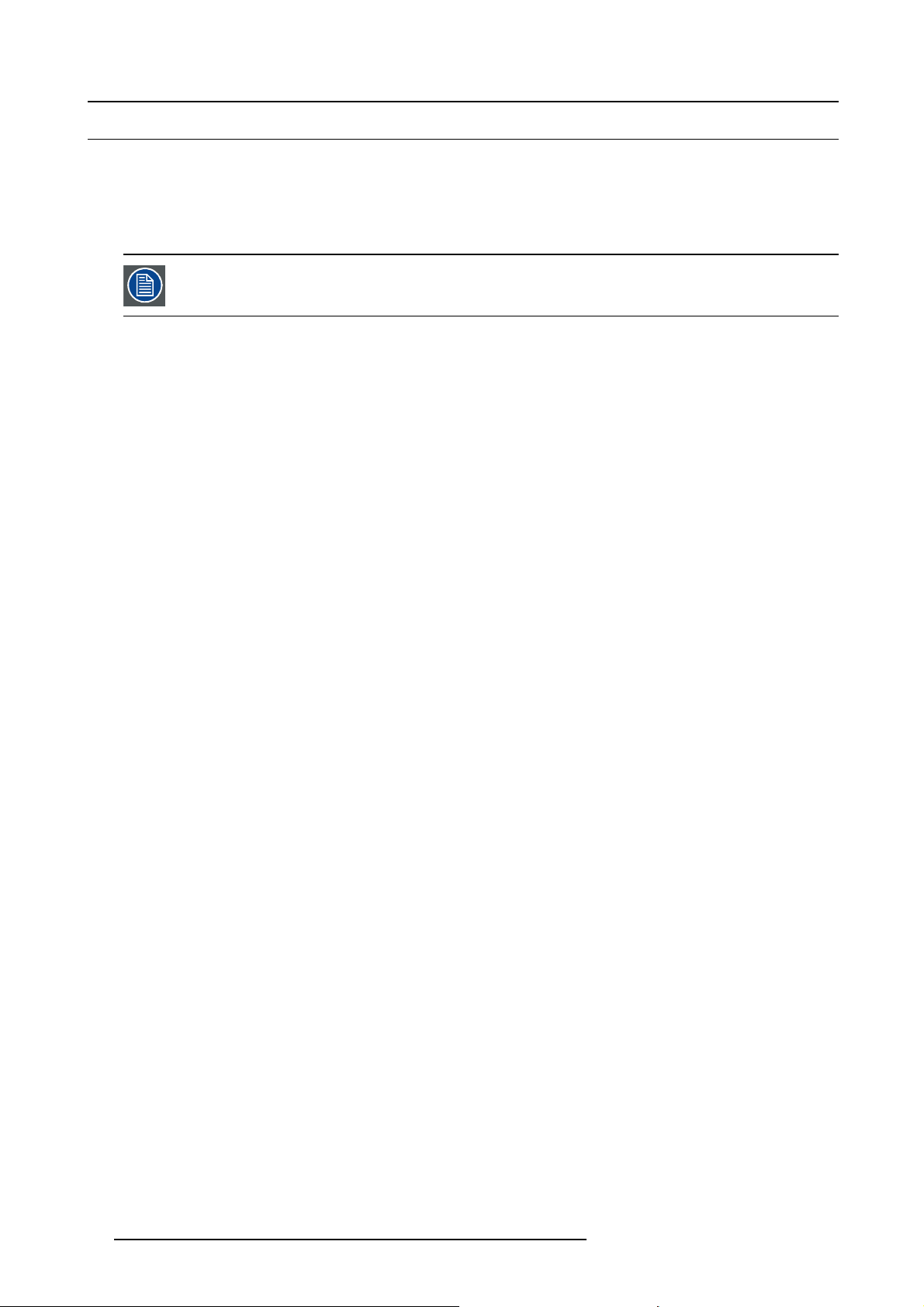

5.1 Installation o f the support structure

What has to be done?

The complete support structure has to be assembled and installed in its final position.

Screen supporting/securing structures vary from system to system. Consult Barco for advise on professional

rigging organizations.

SF-10V mounting plates.

Barco provides mounting plates for the SF-10V tiles which can be used to clamping the tiles to the support structure.

Image 5-1

A Middle mounting plate.

B Top / Bottom mounting plate.

A

B

32 R59770542 SF-10V DISPLAY 10/02/2012

Page 37

5.2 Mounting the SF-10V tile

Necessary tools

• 17 mm open-end wrench.

• 17 mm box-end wrench.

• 14 mm long allen key.

• Scaffold or Z-lift.

Necessary parts

• SF-10V tiles

• Four M10x90 bolts per tile (DIN931 hex cap bolts and partially thread - steel zinc plated). Reference A.

• Four M10 plain washer per tile (DIN433 - steel zinc plated). Reference B.

What has to be done?

The SF-10V tiles have to be mounted onto the support structure.

Take out the SF-10V tiles from the package.

Take out the necessary tiles from their package just before assembling them onto the support structure.

5. Physical installation

Image 5-2

CAUTION: Th e following procedure must be performed by minimum three au thorized and qualified technical

persons, which are thoroughly familiar with the product and all of the prop

To do otherwise increases the risk of hazard and injury to the user.

er safety checks of this p roduct.

SF-10V tile mounting sequence

Build up the SF-10V display row by row from bottom to top. Always start in the middle of the row and complete the row by placing

the SF-10V tiles beside one another from the middle of the row to the sides.

How to mount a SF-10V tile?

1. Bring the SF-10V tile in front of its final position on the LED-wall. Ensure the tile is in the right position, so with the hoist point on

top.

R59770542 SF-10V DISPLAY 10/02/2012 33

Page 38

5. Physical installation

2

3

5

10

4

6

7

4

9

Image 5-3

1. Adjust block

2. Hoist point.

3. Hoist point.

4. Adjust block

5. Insert nuts for fi xing tile

6 Handle

7. Insert nuts for fi xing tile

8. Handle

9. Insert nuts for fi xing tile

10. Insert nuts for fix ing tile

1

8

2. Insert the M10 plain washer (Reference B) into the bolt (Reference A)

3. Insert the bolts into the corresponding holes of the mounting plates and let the mounting plate attache to the support structure.

Caution: Two persons are required at the front of the LED-display to perform this action. Both hands must be free to insert a

tile in a LED-wall. Therefore the use of a ladder to insert a tile is forbidden. Only a solid scaffold or a Z-lift is allowed.

Tip: Use the hoist point hole on the top side to lift the SF-10V tile, using a crane and the hoist system to the desired height.

This hoist point have two functions, not only can lift the tile and also can located the two tiles when install the display.

Image 5-4

34 R59770542 SF-10V DISPLAY 10/02/2012

Page 39

5. Physical installation

B

A

4X

Image 5-5

4. Place a prevailing torque for the bolt (reference A) with the washer (reference B ) on each insert nuts of tiles. Do not fasten yet.

5. Level out the SF-10V tile. Use the adjust block in the bottom of tile for the height alignment;

Tip: For maximum adjustment space in horizontal direction place the hex cap bolts of the every first SF-10V tile that is placed

on the mounting plate in the middle of the corresponding slots.

6. Fasten the SF-10V tile. At least one person at the front keeps the SF-10V tile steady until the tile is completely fasten.

7. Release the adjust block.

R59770542 SF-10V DISPLAY 10/02/2012

35

Page 40

5. Physical installation

Example of SF-10V tile mounting

1

3

2

4

5

Image 5-6

6

How to get the height alignment between tiles

Open the back door, u

key clockwise rotate the adjust block will go up, if rotate counter-clockwise the adjust block will go down.

sing the long allen key rotate the socket head screw that located the bottom of tile as illustrated. If the allen

A

Image 5-7

B

36 R59770542 SF-10V DISPLAY 10/02/2012

B

Page 41

5. Physical installation

DVI-in

DVI-out

AC-in

AC-out

DVI-in

DVI-out

AC-in

AC-out

DVI-in

DVI-out

AC-in

AC-out

DVI-in

DVI-out

AC-in

AC-out

DVI-in

DVI-out

AC-in

AC-out

DVI-in

DVI-out

AC-in

AC-out

DVI-in

DVI-out

AC-in

AC-out

DVI-in

DVI-out

AC-in

AC-out

DVI-in

DVI-out

AC-in

AC-out

S

0v

l

10v

0v

10v

10v

0v

0v

10v

0v

DVI-in

DVI-out

AC-in

AC-out

DVI-in

DVI-out

AC-in

AC-out

DVI-in

DVI-out

AC-in

AC-out

DVI-in

DVI-out

AC-in

AC-out

DVI-in

DVI-out

AC-in

AC-out

DVI-in

DVI-out

AC-in

AC-out

0v

10v

10v

10v

10v

DVI-in

DVI-out

AC-in

AC-out

DVI-in

DVI-out

AC-in

AC-out

DVI-in

DVI-out

AC-in

AC-out

10vF-10v

A Adjust block screw.

B Long allen key(14mm)

About cabling of Data cable between tiles.

Considering the position of the data in/out sockets in SF-10Vtiles and dataI cable length, the cabling ways illustrated as follows are

the only 2 possible ways. That is, the data cable must go into the SF-10Vdisplay from the left side (back view), connect all the tiles

in a column from upper or lower corner, and then connect the next column from the other corner, repeat this from left to right (back

view) until all tiles are connected.

ata signa

Image 5-8

F-

F-1

F-1

F-1

F-

F-1

F-

F-

F-

F-

F-1

F-

Data signal

F-10v

F-1

Image 5-9

R59770542 SF-10V DISPLAY 10/02/2012 37

F-

F-

F-10v

Page 42

5. Physical installation

38 R59770542 SF-10V DISPLAY 10/02/2012

Page 43

6. DIMENSIONS

About this chapter

This chapter contains drawings of the SF-10V tiles and its package, with the most important dimensions.

Overview

• SF-10V tile

• Assembly of SF-10V tiles

• SF-10V package

6. Dimensions

R59770542 SF-10V DISPLAY 10/02/2012

39

Page 44

6. Dimensions

6.1 SF-10V tile

Dimensions of the SF-10V tile

Image 6-1

1280 mm

480 mm

1200 mm

910 mm

960 mm

M10

188mm

223.85mm

40 R59770542 SF-10V DISPLAY 10/02/2012

Page 45

6.2 Assembly of SF-10V tiles

Main dimensions of an a assembly of SF-10V tiles

6. Dimensions

80

480 mm

80

1200 mm

80

910 mm

50

910 mm

50

910 mm

1200 mm

80

1200 mm

80

Image 6-2

R59770542 SF-10V DISPLAY 10/02/2012 41

Page 46

6. Dimensions

6.3 SF-10V package

Dimensions of the SF-10V tile package containing 4 tiles.

Image 6-3

1384mm

1364mm

1424 mm

1041 mm

115 6mm

115 mm

1092 mm

1032 mm

42 R59770542 SF-10V DISPLAY 10/02/2012

Page 47

7. SPECIFICATION

7. Specification

R59770542 SF-10V DISPLAY 10/02/2012 43

Page 48

7. Specification

44 R59770542 SF-10V DISPLAY 10/02/2012

Page 49

7.1 Specifications of theSF-10V tile

Specifications of the SF-10V tile

Pixel Pitch 20mm

LED configur a tion 2R, 1G, 1B

Pixel Density (real mode) 2,500 px/m²

Pixel Density (virtual mode) 10,000 px/m²

LED density

Pixel per module HxV (real mode)

Pixel per module HxV (virtual mode)

Contrast ratio

Minimum Brightness 6,840 NIT

Typical Brightness 7,200–9,800 NIT

Color Processing 14 bit/color

Colors

Dimming 8bit

Refresh Rate (real m ode)

10,000 LEDs/m²

64x48

128x96

2,000:1

4.4 trillion

1,600 Hz

7. Specification

Refresh Rate (v irtual m ode)

Horizontal Viewing Angle (color shift) -75°/+75°

Horizontal Viewing Angle (50%

brightness)

Vertical Viewing Angle (color shirt) -40°/+30°

Vertical Viewing Angle (50%

brightness)

Max Power consumption 1,027 W/m²

Typical Power consumption 151 W/m²

Operation Power Voltage and

frequency

LED Lifetime

Environmental

Working Temperature

Tile total resolution (real/virtual) 3072/12288 px/tile

Total resolution (real/virtua l) 2500/10000 px/sqm

Operational Humidity 10–99%

Storage Temperature 10–99%

Ruggedness (IP rating, Front/Back) IP65/IP43

Sea Worthiness (IEC 60068-2-52) Sev. 2

Dimensions (HxWxD)

Module surface 1.23 m²

Weight

Installation Access back

Service Access(front/back) back

1,000 Hz

-55°/+55°

-23°/+20°

110-240V

50-60Hz

60,000

-20°C/+50°C (-4°F to 122°F)

960x1280x220 mm

37.8x50.4x7.6 inch

13.24 ft²

64.7 kg/m²

43.5 lbs/m²

79.5 kg/tile

R59770542 SF-10V DISPLAY 10/02/2012 45

Page 50

7. Specification

Compatibility

D320L/Lite

LedPro Yes

DX-700 Yes

DMP-100 No

AEC-4000 (in combination w ith DTS)

AEC-4000 (in combination w ith RMS)

Fiberlink II Ye s

CAT5 Link

DTS Software

RMS Software

XVS

Certifications CE/RohS/ETL

Yes

Yes

No

Yes

Yes

No

Yes

46 R59770542 SF-10V DISPLAY 10/02/2012

Page 51

8. ORDER INFO

About this chapter

This chapter contains the order numbers of several important SF-10V peripherals.

Overview

• Order info

• Spare part and service kits

Consult the secured partner zone on WWW.My barco.com for an updated list with order numbers of the available S F-10V products.

8. Order info

R59770542 SF-10V DISPLAY 10/02/2012 47

Page 52

8. Order info

8.1 Order info

List with order numbers for SF-10V products

Order info

Description

R9004843B1

R9852560

R9852350 BME P SLITE RAIL KIT 896

R9850241 Power link cable of 1.5 meter.

R9850250 Power link cable of 4.5 meter.

R9850260 Power link cable of 9 meter.

R9850280 Five dummy power plugs (for power output sockets)

R9850210 Data link cable of 1.5 meter

R9850220 Data link cable of 5 meter

R9850270

R9870092

R9870093

R9870094

R9870095

R9828833

R98522780

R98522781

R98522782

R9004640 BME DX-100

R9851570 BME D320L

R9851560 BME D320 LITE

R9850960 BME D320 INP DVI

R9853130

BME SF-10V 1TL BOX

BME P SLITE HOIST KIT

Two dummy data plugs (for data output sockets)

BME CATLINK DVI-MDR 10M

BME CATLINK MDR-MDR 50M

BME CATLINK MDR-MDR 10M

BME CATLINK DVI-MDR 50M

BME DMP-100 DIG MED PROCESSOR

BME DX-700 BASE UNIT

BME DX-700 INPUT MODULE

BME DX-700 DVI OUTPUT MODULE

BME P (HD) SDI IN D320/XLM

R9853350

R9853360

R9853370

R9853371 BME FIBERLINK II TX INPUT M-M

R9853361

R9851260

R9851261

R9851262 POWER VEAM CABLE 30M

R9851263 POWER VEAM CABLE 50M

R9851250 POWER BOX 3 PHASE 380V 2 OUTPUT

R9851251 POWER BOX 3 PHASE 380V 3 OUTPUT

R9851252 POWER BOX 3 PHASE 380V 4 OUTPUT

48 R59770542 SF-10V DISPLAY 10/02/2012

BME FIBERLINK II BASE UNIT

BME FIBERL II RX S-MODE

BME FIBERL II TX INP S-M

BME FIBERLINK II RX M-MODE

POWER VEAM CABLE 10M

POWER VEAM CABLE 20M

Page 53

8. Order info

R9851253

R9851254

R9850058

R838621

R838622

POWER BOX 3 PHASE 380V 5 OUTPUT

POWER BOX 3 PHASE 380V 6 OUTPUT

BME DLITE PWR BOX220

BME SF Middle Mounting Plate

BME SF Side Mounting Plate

R59770542 SF-10V DISPLAY 10/02/2012 49

Page 54

8. Order info

8.2 Spare part and service kits

General

Barco provides several kits for servicing SF-10V tiles. Below you find an order list of existing spare part and service kits. In the

future new kits can be added to this list. Contact Barco to get an updated list.

Order info

R9870040

R9870043

R9870049

R9870050

R9870052

R9870055

R9870057

R765866K

Description

BME K SF-10V LED Frame Kit

BME K SF-10V Shader Kit

BMEKSFSeriesFanKit

BME K SF Series Power Supplier

BME K SF-10V Data Cable Kit

BME K SF-10V Power Cable Kit

BME K SF Series tooling Kit

BME K SF-10 Ctr Board Kit

R765938K

BME K TF-10 I/O Box Kit

50 R59770542 SF-10V DISPLAY 10/02/2012

Page 55

9. ENVIRONMENTAL INFORMATION

Overview

• Disposal information

• Rohs compliance

9. Environmental information

R59770542 SF-10V DISPLAY 10/02/2012

51

Page 56

9. Environmental information

9.1 Disposal information

Disposal Information

Waste Electrical and Electronic Equipment

This symbol on the product indicates that, under the European Directive 2002/96/EC governing waste from electrical and

electronic equipment, this product must not be disposed of with other municipal waste. Please dispose of your waste equipment by

handing it over to a designated collection point for the recycling of waste electrical and electronic equipment. To prevent possible

harm to the environment or human health from uncontrolled waste disposal, please separate these items from other types of waste

and recycle them responsibly to promote the sustainable reuse of material resources.

For more information about recycling of this product, please contact your local city office or your municipal waste disposal service.

For details, please visit the Barco website at: h

ttp://www.barco.com/en/AboutBarco/we

Disposal of batteries in the product

This product contains batteries covered by the Directive 2006/66/EC which must be collected and disposed of separately

from municipal waste.

If the battery contains more than the specified values of lead (Pb), mercury (Hg) or cadmium (Cd), these chemical symbols will

appear below the crossed-out wheeled bin symbol.

By participating in separate collection of batteries, you will help to ensure proper disposal and to prevent potential negative effects

on the environment and human health.

ee

52

R59770542 SF-10V DISPLAY 10/02/2012

Page 57

9. Environmental information

9.2 Rohs compliance

Turkey RoHS compliance

Türkiye Cumhuriyeti: EEE Yönetmeliğine Uygundur.

[Republic of Turkey: In conformity with the EEE Regulation]

中国大陆 RoHS (Information for China ROHS compliance)

根据中国大陆《电子信息产品 污 染控制管理办法》(也称为中国大陆RoHS ),

以下部分列出了Barco产品中可能包含的有毒和/或有害物质的名称和含量。中国大陆RoHS指令包含在中国信息产业部MCV标 准:

“电 子信息产 品中有毒物质的限量要求”中。

According to the “China Administration on Control of Pollution Caused by Electronic Information Products” (Also called RoHS of

Chinese Mainland), the table below lists the names and contents of toxic and/or hazardous substances that Barco’s product may

contain. The RoHS of Chinese Mainland is included in the MCV standard of the Ministry of Informati

section “Limit Requirements of toxic substances in Electronic Information Products”.

Table of toxic and hazardous substances/elements and their content, as required by China’s management methods for controlling

pollution by electronic information products

on Industry of China, in the

零件项目( 名称)

Component Name

印制电路配件

Printed Circuit Assemblies

风扇

Fan

外接电( 线)缆

External Cables

內部 线 路

Internal wiring

电源供应 器

Power Supply Unit

金属外壳

Metal Enclosure

塑胶外壳

Plastic Enclosure

有毒有害物质或元素

Hazardous Substances or Elements

铅

(Pb)

XOOOOO

OOOOOO

OOOOOO

OOOOOO

OOOOOO

OOOOOO

OOOOOO

汞

(Hg)

镉

(Cd)

六价 铬

(Cr6+)

多溴联苯

(PBB)

多溴 二苯醚

(PBDE)

螺帽,螺钉( 栓),螺旋( 钉),垫圈 , 紧

固件

Nuts, bolts, screws, washers,

fasteners

文件说明 书

Paper Manual

光盘说明 书

CD Manual

O:表示该有毒有害物质 在 该部件所有均质材料中的含量均在 SJ/T 11363-2006 标准 规定的限量要求以下.

R59770542 SF-10V DISPLAY 10/02/2012

OOOOOO

OOOOOO

OOOOOO

53

Page 58

9. Environmental information

O: Indicates that this toxic or hazardous substance contained in all of the homogeneous materials for this part is below the limit

requirement in SJ/T11363-2006.

X:表示该有毒有害物质至少在该部件的某一均质材料中的含量超出 SJ/T 11363-2006 标准 规定的限量要求.

X : Indicates that this toxic or hazardous substance contained in at least one of the homogeneous materials used for this part is

above the limit requirement in SJ/T11363 2006.

在中国大陆销售的相应电子信息产品(EIP)都必须遵照中国大陆《电子信息产品污染控制标识要求》标准贴上 环保使用期限(EFUP)

标签。Barco产品所采用的EFUP标签(请 参阅实例,徽标内部的编号使用于制定产品)基于中国大陆的《电子信息产品 环保使用期限

通则》 标 准。

All Electronic Information Products (EIP) that are sold within Chinese Mainland must comply with the “Electronic Information Products

Pollution Control Labeling Standard” of Chinese Mainland, marked with the Environmental Friendly Use Period (EFUP) logo. The

number inside the EFUP logo that Barco uses (please refer to the photo) is based on the “Standard of Electronic Information Products

Environmental Friendly Use Period” of Chinese Mainland.

10

54 R59770542 SF-10V DISPLAY 10/02/2012

Loading...

Loading...