Page 1

FLM HD18

R5976986/08

15/03/2010

Users manual

R9004450

Page 2

Barco nv Events

Noordlaan 5, B-8520 Kuurne

Phone: +32 56.36.82.11

Fax: +32 56.36.88.24

E-mail: sales.events@barco.com

Visit us at the web: www.barco.com

Printed in Belgium

Page 3

Changes

Barco provides this manual ’as is’ without warranty of any kind, either expressed or implied, including but not limited to the implied warranties or merchantability and fitness for a particular purpose. Barco may make improvements and/or changes to the product(s) and/or the

program(s) described in this publication at any time without notice.

This publication could contain technical inaccuracies or typographical errors. Changes are periodically made to the information in this

publication; these changes are incorporated in new editions of this publication.

Copyright ©

All rights reserved. No part of this document may be copied, reproduced or translated. It shall not other

stored in a retrieval system without the prior written consent of Barco.

wise be recorded, transmitted or

Federal Communications Commission (FCC Statement)

This equipment has been tested and found to comply with the limits for a class A digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area may

cause harmful interference, in which case the user will be responsible for correcting any interference at his own expense

EN55022/CISPR22 Class A ITE (Information Technology Equipment)

Class A ITE is a category of all other ITE which satisfies the class A ITE limits but not the class B ITE limits. Such equipment should not

be restricted in its sale but the following warning shall be included in the instructions for use:

Warning : This is a class A product. In a domestic environment this product may cause radio interference in which case the user may be

required to take adequate measures.

Guarantee and Compensation

Barco provides a guarantee relating to perfect manufacturing as pa

must immediately inspect all delivered goods for damage incurred during transport, as well as for material and manufacturing faults Barco

must be informed immediately in writing of any complaints.

The period of guarantee begins on the date of transfer of risks, in the case of special systems and software on the date of commissioning,

at latest 30 days after the transfer of risks. In the event of justified notice of complaint, Barco can repair the fault or provide a replacement

at its own discretion within an appropriate period. If this measure proves to be impossible or unsuccessful, the purchaser can demand a

reduction in the purchase price or cancellation of the contract. All other claims, in particular those relating to compensation for direct or

indirect damage, and also damage attributed to the operation of software as well as to other services provided by Barco, being a component

of the system or independent service, will be deemed invalid provided the damage is not proven to be attributed to the absence of properties

guaranteed in writing or due to the intent or gross negligence or part of Barco.

If the purchaser or a third party carries out modifications or repairs on goods delivered by Barco, or if the goods are handled incorrectly,

in particular if the systems are commissioned operated incorrectly or if, after the transfer of risks, the goods are subject to influences not

agreed upon in the contract, all guarantee claims of the purchaser will be rendered invalid. Not included in the guarantee coverage are

system failures which are attributed to programs or special electronic circuitry provided by the purchaser, e.g. interfaces. Normal wear as

well as normal maintenance are not subject to the guarantee provided by Barco either.

The environmental conditions as well as the servicing and maintenance regulations specified in the this manual must be complied with by

the customer.

rt of the legally stipulated terms of guarantee. On receipt, the purchaser

Trademarks

Brand and product names mentioned in t

All brand and product names mentioned in this manual serve as comments or examples and are not to be understood as advertising for

the products or their manufacturers.

his manual may be trademarks, registered trademarks or copyrights of their respective holders.

Software License Agreement

You should carefully read the following terms and conditions before using this software. Your use of this software indicates your acceptance

of this license agreement and warranty.

Terms and Conditions:

1. No redistribution of the software is allowed.

2. Reverse-Engineering. You may

Disclaimer of Warranty:

not reverse engineer, decompile, disassemble or alter anyhow this software product.

Page 4

This software and the accompanying files are sold “as is” and without warranties as to performance or merchantability or any other warranties whether expressed or implied. In no event shall Barco be liable for damage of any kind, loss of data, loss of profi ts, business

interruption or other pecuniary loss arising directly or indirectly. Any liability of the seller will be exclusively limited to replacement of the

product or refund of purchase price.

GNU-GPL code

If you would like a copy of the GPL source code contained in this product shipped to you on CD, please contact Barco. The cost of preparing

and mailing a CD will be charged.

Disposal Information

This equipment has required the extraction and use of natural resources for its production. It may contain hazardous substances for health

and environment. In order to avoid the dissemination of those substances in the environment and to diminish the pressure on natural

resources, we encourage you to use the appropriate take-back systems. Those systems will reuse or recycle most of the materials of your

end of life equipment in a sound way.

The crossed-out wheeled bin symbol invites you to use those systems. If you need more information on the collection, reuse and recycling

systems, please contact your local or regional waste administrator. You can also contact us for more information on the environmental

performances of our products.

Page 5

Table of contents

TABLE OF CONTENTS

1. Safety................................................................................................................. 5

1.1 General ............................................................................................................................... 5

1.2 Important safety instructions ......................................................................................................... 6

1.3 Important warnings concerning FLM flight cases.................................................................................... 8

2. General............................................................................................................... 9

2.1 Installation requirements .. ........................................................................................................... 9

2.2 Unpacking the projector ............................................................................................................. 10

2.3 Box content.......................................................................................................................... 11

2.4 FLM flight case ...................................................................................................................... 12

2.5 Projector configurations.............................................................................................................12

2.6 Projector air inlets and outlets.......................................................................................................16

2.7 Free downloadof ProjectorToolset................................................................................................. 16

3. Physical installation ..............................................................................................17

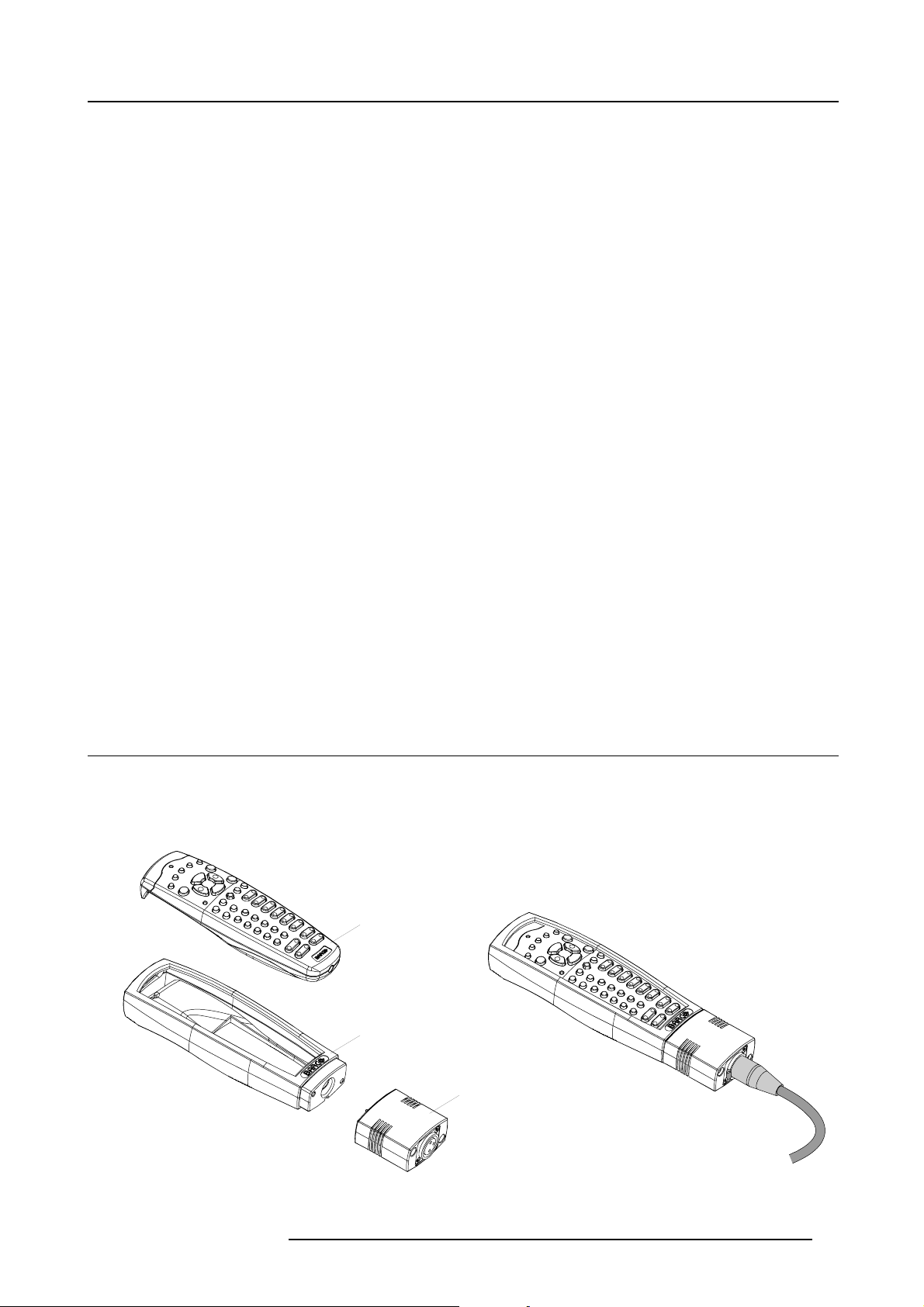

3.1 Remote control unit (RCU) . .........................................................................................................17

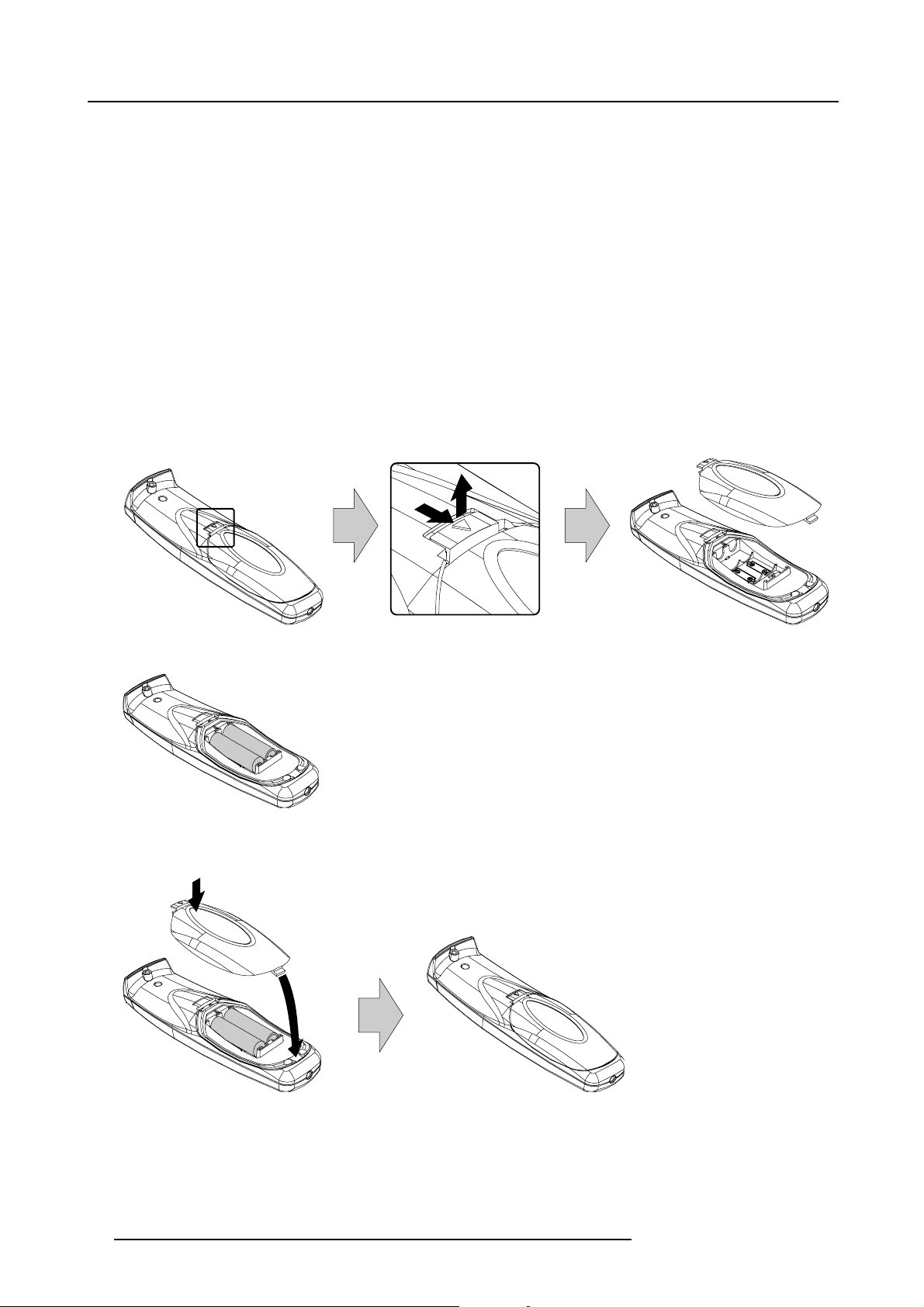

3.1.1 RCU battery installation.......................................................................................................18

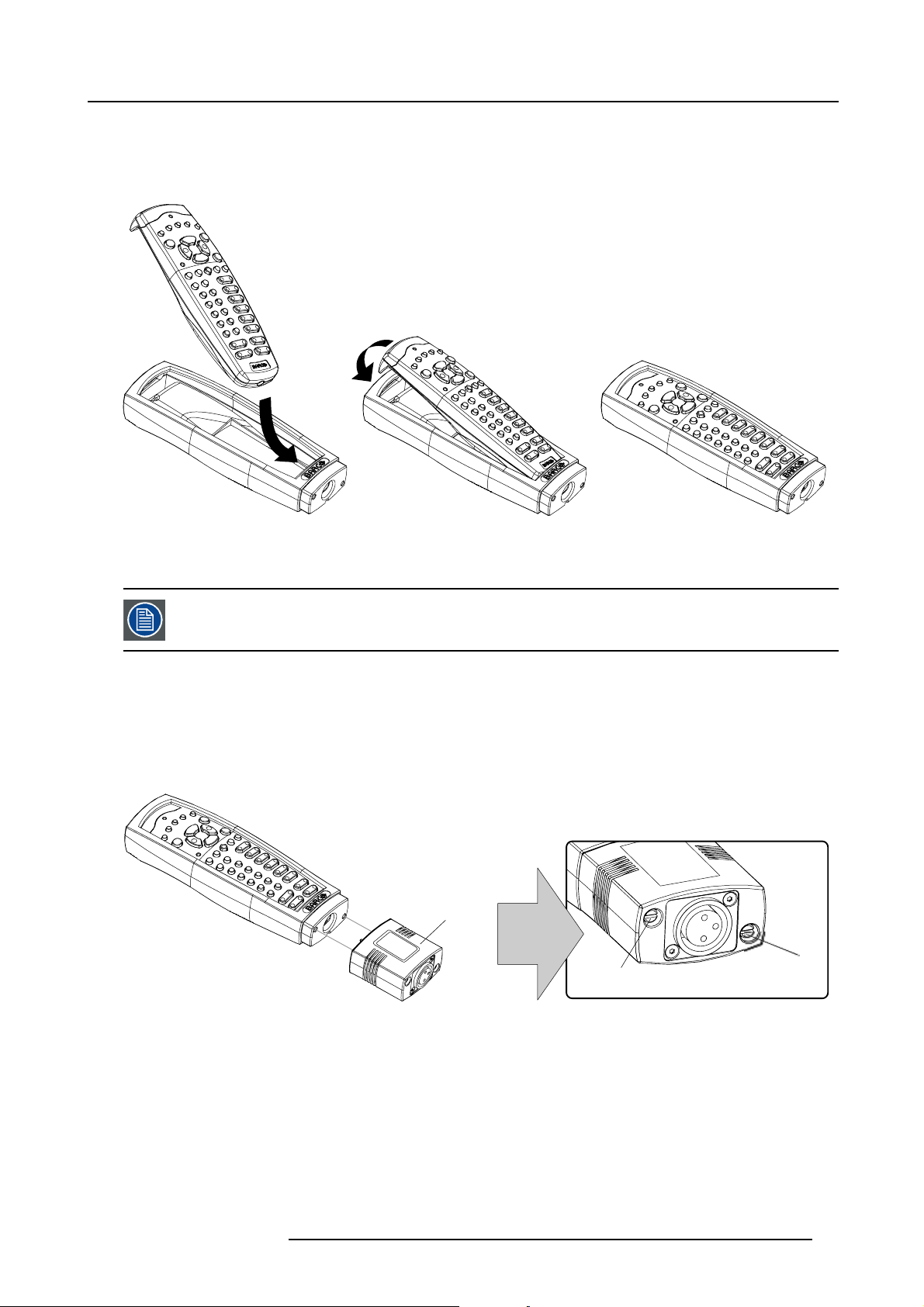

3.1.2 RCU rugged case installation ................................................................................................19

3.1.3 RCU XLR adaptor installation ................................................................................................19

3.1.4 Using the XLR adaptor of the RCU. . . ........................................................................................ 19

3.1.5 RCU usage possibilities ......................................................................................................20

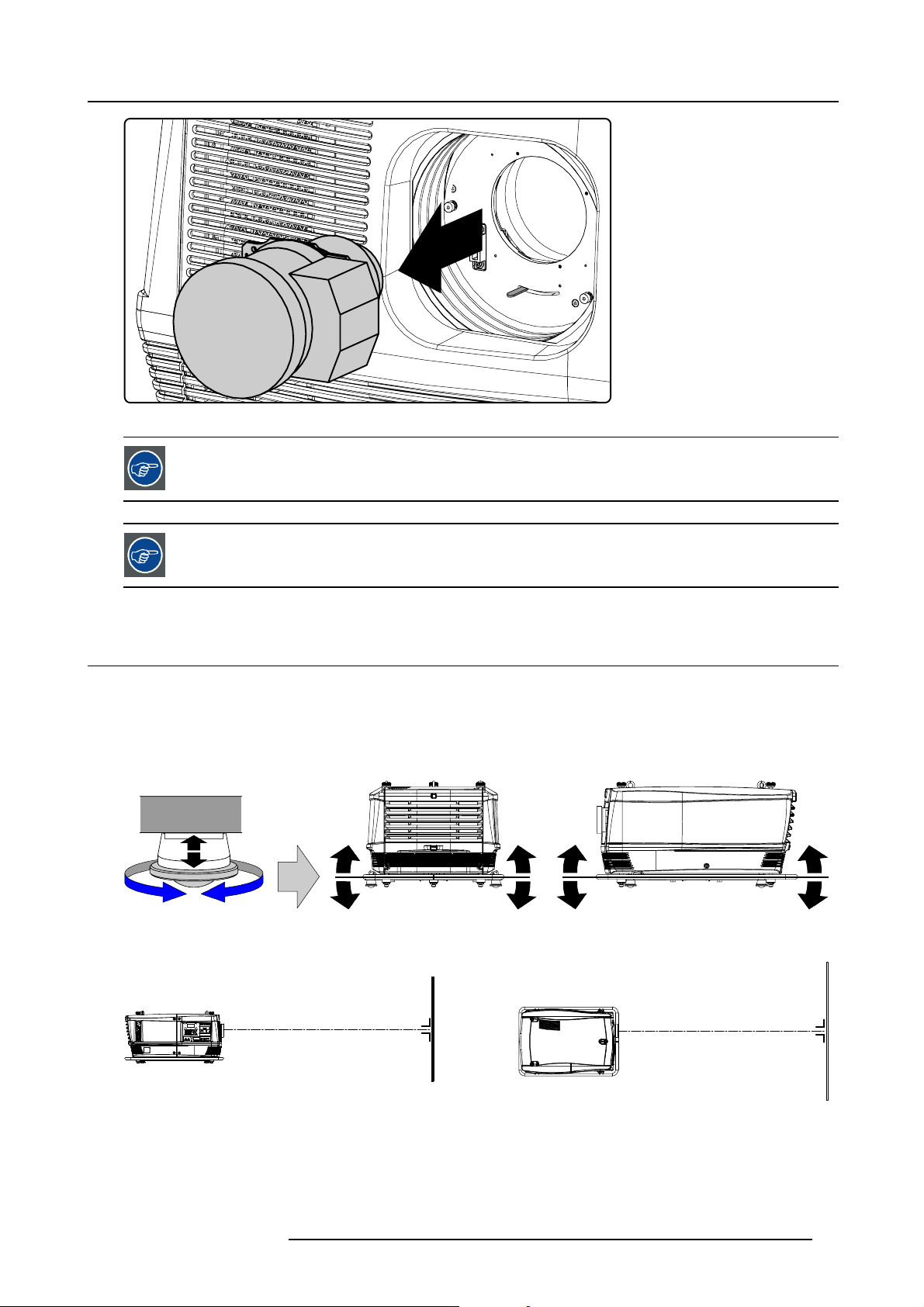

3.2 Lenses ...............................................................................................................................21

3.2.1 Available lenses...............................................................................................................21

3.2.2 Lens selection .................................................................................................................22

3.2.3 Lens formulas .................................................................................................................22

3.2.4 Lens installation ...............................................................................................................23

3.2.5 Lens removal . .................................................................................................................24

3.3 Alignment of a table mount FLM projector. . ........................................................................................25

3.4 Alignment of a ceiling mount FLM projector ........................................................................................ 26

3.5 Suspension of the FLM projector with rigging clamps. . . ...........................................................................26

4. Stacking FLM projectors.........................................................................................31

4.1 Stacking FLM projectors ............................................................................................................31

4.2 Aligning stackedFLM projectors....................................................................................................33

5. Connections........................................................................................................35

5.1 Power connection . .................................................................................................................. 35

5.2 Input source connections. . ..........................................................................................................37

5.3 Communication connections ........................................................................................................38

6. Getting started .....................................................................................................43

6.1 RCU & Local keypad ................................................................................................................43

6.2 Terminology overview ...............................................................................................................43

6.3 Operating the projector..............................................................................................................45

6.3.1 Switching on................................................................................................................... 45

6.3.2 Errors, warnings and messages during start up .. ........................................................................... 46

6.3.3 Switching to standby . .........................................................................................................46

6.3.4 Switching off................................................................................................................... 47

6.4 Using theRCU.......................................................................................................................47

6.5 Quick setup adjustments............................................................................................................49

6.5.1 Text boxes ONor OFF........................................................................................................49

6.5.2 Quick Lens Adjustment .......................................................................................................49

6.5.2.1 Quick Lens Adjustment via LENS key ................................................................................. 49

6.5.2.2 Direct Lens Adjustment (RCU).........................................................................................50

6.5.3 Quick picture inpicture .......................................................................................................50

6.5.4 Quick layout selectionwith Riggingkey......................................................................................51

6.5.5 Quick language selection . . . ..................................................................................................51

6.6 Projector address. . . .................................................................................................................52

6.6.1 Displaying and Programming addresses. . ................................................................................... 52

6.6.2 Controlling the projector ......................................................................................................53

6.7 Source selection.....................................................................................................................53

6.8 Controlling theProjector............................................................................................................. 54

7. Start up of the Adjustment Mode...............................................................................55

7.1 About the adjustment mode .........................................................................................................55

7.2 About theuse of theremote control and the local keypad......................................................................... 55

7.3 Start up the adjustment mode.......................................................................................................55

7.4 Navigation and adjustments......................................................................................................... 56

7.5 On screen menus versus LCD display menus . . ...................................................................................56

7.6 Test patterns in adjustment mode. ..................................................................................................57

7.7 Menu memory .......................................................................................................................57

R5976986 FLM HD18 15/03/2010

1

Page 6

Table of contents

8. Input menu .........................................................................................................59

8.1 Overview flow........................................................................................................................ 59

8.2 Slot module type..................................................................................................................... 59

8.2.1 About Input Setup .............................................................................................................59

8.2.2 Input configuration............................................................................................................60

8.3 Input locking . ........................................................................................................................61

8.4 Minimum delay.......................................................................................................................63

8.5 Native resolution.....................................................................................................................63

8.6 Source switching .................................................................................................................... 65

8.7 No signal .............................................................................................................................65

8.7.1 Backgroundcolor .............................................................................................................66

8.7.2 Shutdownsetting.............................................................................................................. 66

8.7.3 Shutdownretarding time......................................................................................................66

9. Image menu ........................................................................................................69

9.1 Overview flow........................................................................................................................ 69

9.2 How to select the image adjustments? . . . . . ........................................................................................70

9.3 Image Settings.......................................................................................................................70

9.3.1 Contrast .......................................................................................................................71

9.3.2 Brightness.....................................................................................................................71

9.3.3 Saturation ..................................................................................................................... 72

9.3.4 Tint (hue)......................................................................................................................73

9.3.5 Phase..........................................................................................................................73

9.3.6 Sharpness .....................................................................................................................74

9.3.7 Noise reduction ...............................................................................................................75

9.3.8 Color temperature.............................................................................................................76

9.3.8.1 Predefined color temperature..........................................................................................76

9.3.8.2 Set a custom color temperature .......................................................................................77

9.3.9 Input balance..................................................................................................................78

9.3.9.1 Introduction to Input Balance . . ........................................................................................ 78

9.3.9.2 Adjustingthe input balance ............................................................................................79

9.4 Aspect ratio ..........................................................................................................................82

9.5 Timings...............................................................................................................................83

9.5.1 Source timings ................................................................................................................83

9.5.2 Advanced settings ............................................................................................................84

9.5.3 Advanced settings, film mode detection .....................................................................................86

9.6 Image files services .................................................................................................................87

9.6.1 Files and file manipulations. ..................................................................................................87

9.6.2 Manual Load file ..............................................................................................................88

9.6.3 Delete file......................................................................................................................89

9.6.4 Delete all custom files ........................................................................................................89

9.6.5 Rename a file .................................................................................................................90

9.6.6 Copy a file.....................................................................................................................91

9.6.7 File options.................................................................................................................... 91

9.7 Save customsettings................................................................................................................92

10. Layout menu .......................................................................................................95

10.1 Overview flow........................................................................................................................95

10.2 Main window .........................................................................................................................95

10.2.1 Source selection ..............................................................................................................96

10.2.2 Size adjustment............................................................................................................... 96

10.2.3 Position adjustment...........................................................................................................99

10.3 PIP window . ........................................................................................................................100

10.3.1 Introduction to PIP . . .........................................................................................................100

10.3.2 Picture in Pictureactivation..................................................................................................101

10.3.3 Picture in Picturesource selection ..........................................................................................101

10.3.4 Picture in Picture size of the window . .......................................................................................102

10.3.5 Picture in Picture, position window .. ........................................................................................105

10.4 Layout file services.................................................................................................................106

10.4.1 Load layout . .. ................................................................................................................106

10.4.2 Rename a layout .............................................................................................................107

10.4.3 Delete a layout...............................................................................................................107

10.4.4 Copy / Save asa layout .....................................................................................................108

10.5 Zoom - Focus.......................................................................................................................109

11. Lamp menu........................................................................................................111

11.1 Overview flow.......................................................................................................................111

11.2 Lamppower mode..................................................................................................................111

11.3 Lamppower.........................................................................................................................112

11.4 Lamp Identification .................................................................................................................113

11.5 Z-axisadjustment...................................................................................................................113

12. Alignment menu................................................................................................. 115

12.1 Overview flow.......................................................................................................................115

12.2 Orientation..........................................................................................................................116

12.3 Lens adjustment ....................................................................................................................117

12.4 Side keystone.......................................................................................................................118

2

R5976986 FLM HD18 15/03/2010

Page 7

Table of contents

12.5 Warp geometry settings ............................................................................................................119

12.5.1 About Warp geometry settings ..............................................................................................119

12.5.2 WarpStatus ..................................................................................................................120

12.5.3 Horizontalkeystone correction..............................................................................................121

12.5.4 Vertical keystone correction .................................................................................................122

12.5.5 Rotation ......................................................................................................................123

12.5.6 Pincushion - Barrel correction...............................................................................................124

12.5.7 4 cornercorrection...........................................................................................................125

12.5.8 Reset warp settings.......................................................................................................... 126

12.5.9 Load warp file................................................................................................................127

12.6 Contrast enhancement .............................................................................................................128

12.7 Blanking.............................................................................................................................128

12.8 Gamma .............................................................................................................................130

12.9 Internalpattern......................................................................................................................130

12.10 Color space.........................................................................................................................131

12.11 ScenergiX...........................................................................................................................132

12.11.1 Introduction. . .................................................................................................................132

12.11.2 Preparations. . ................................................................................................................133

12.11.3 ScenergiX activation .........................................................................................................133

12.11.4 ScenergiX overlap zone (horizontal ScenergiX) .. ..........................................................................134

12.11.5 ScenergiX overlap zone (vertical ScenergiX) ...............................................................................135

12.11.6 ScenergiX size adjustment (White level) . . ..................................................................................137

12.11.7 Adjusting the black level of the images . .. ..................................................................................139

13. Projector control ................................................................................................ 143

13.1 Overview flow.......................................................................................................................143

13.2 Projector address . . .................................................................................................................144

13.2.1 Individual projector address .................................................................................................144

13.2.2 Common address ............................................................................................................145

13.3 Serial communication...............................................................................................................146

13.3.1 Baud rate setup............................................................................................................. . 146

13.3.2 Interface standard............................................................................................................146

13.3.3 RS422 termination........................................................................................................... 147

13.4 Network .............................................................................................................................147

13.4.1 Introduction to a Network connection .......................................................................................148

13.4.2 DHCP setup . . ................................................................................................................148

13.4.3 IP-address set up ............................................................................................................149

13.4.4 Subnet-mask set up..........................................................................................................149

13.4.5 Default Gatewayset up......................................................................................................150

13.5 IR control switching.................................................................................................................151

13.6 Art-Net DMX ........................................................................................................................151

13.6.1 DMX address. ................................................................................................................152

13.6.2 DMX universe................................................................................................................ 152

13.6.3 DMX monitor .................................................................................................................153

13.6.4 DMX mode . . . ................................................................................................................154

13.6.5 Art-Net activation.............................................................................................................155

13.6.6 Home lens at startup.........................................................................................................155

13.7 Buttons..............................................................................................................................156

13.7.1 Standby button ...............................................................................................................156

13.7.2 APA (auto) button............................................................................................................ 157

13.7.3 Shortcut keys.................................................................................................................157

13.8 Menuposition.......................................................................................................................158

13.8.1 On screen menu .............................................................................................................158

13.8.2 Bar scale .....................................................................................................................159

13.9 LocalLCD...........................................................................................................................159

13.9.1 Local LCD time out...........................................................................................................159

13.9.2 Local LCD contrast.......................................................................................................... . 160

13.10 Language selection. ................................................................................................................160

14. Service menu..................................................................................................... 163

14.1 Overview flow.......................................................................................................................163

14.2 Identification ........................................................................................................................163

14.3 Diagnosis ...........................................................................................................................165

14.3.1 How to start up the diagnosis? ..............................................................................................165

14.3.2 Versions ......................................................................................................................165

14.3.3 Voltages ......................................................................................................................166

14.3.4 I²C diagnosis . ................................................................................................................167

14.3.5 Temperatures ................................................................................................................167

14.3.6 Fan speeds overview ........................................................................................................168

14.3.7 SPI............................................................................................................................169

14.3.8 Error logging overview....................................................................................................... 170

14.4 Convergence .......................................................................................................................170

14.5 Internalservice patterns............................................................................................................171

14.6 Restore factorydefaults............................................................................................................172

14.7 Reset formatter .....................................................................................................................173

14.8 Save custom settings...............................................................................................................174

R5976986 FLM HD18 15/03/2010

3

Page 8

Table of contents

14.9 Refill mode.. . .......................................................................................................................174

14.10 Broadcast mode....................................................................................................................175

14.11 USB memory .......................................................................................................................176

15. Maintenance...................................................................................................... 179

15.1 Replacement of the dust filter onthe frontside ...................................................................................179

15.2 Replacement of the dust filter onthe bottom side.................................................................................180

15.3 Replacement of the dust filter onthe topside.....................................................................................181

15.4 Pressure verification of the liquid cooling circuit...................................................................................181

15.5 Cleaning the lens ... ................................................................................................................182

15.6 Cleaning the exterior of the projector ..............................................................................................182

16. Servicing.......................................................................................................... 183

16.1 Removal of the lamp house ........................................................................................................183

16.2 Removal of the input & communication unit .......................................................................................184

16.3 Removal of an input module .......................................................................................................185

16.4 Installation of the lamp house ......................................................................................................186

16.5 Installation of the input & communication unit . . . ..................................................................................187

16.6 Installation of an input module .....................................................................................................188

16.7 Realignment of the lamp in its reflector............................................................................................189

17. Removal of the projector covers ............................................................................. 191

17.1 Removalof the frontcover .........................................................................................................191

17.2 Removalof the sidecover..........................................................................................................192

17.3 Removalof the lampcover.........................................................................................................193

17.4 Removal of the input cover.........................................................................................................193

17.5 Installation ofthe front cover .......................................................................................................194

17.6 Installation ofthe side cover .......................................................................................................195

17.7 Installation ofthe lamp cover.......................................................................................................196

17.8 Installation ofthe input cover.......................................................................................................197

A. Dimensions ........................................................................................................ 199

A.1 Dimensions of the FLM HD18......................................................................................................199

A.2 Dimensions of the FLM flight case.................................................................................................200

A.3 Dimensions of the rigging clamps. .................................................................................................201

B. Standard Source Files ........................................................................................... 203

B.1 Table overview......................................................................................................................203

C. DMX chart.......................................................................................................... 205

C.1 DMX chart, basic ...................................................................................................................205

C.2 DMX chart, Extended ...............................................................................................................206

C.3 DMX chart, Full.....................................................................................................................207

D. Troubleshooting ... . . .. . . .. . ... ... . .. . . .. . . .. . ... . .. . ... . .. . . .. . ... . .. . ... . .. . . .. . . .. . ... . .. . ... . .. . . .. . ... . .. . ... 211

D.1 Error codes . ........................................................................................................................211

E. Specifications ..................................................................................................... 219

E.1 Specifications FLM HD18 ..........................................................................................................219

E.2 Specifications FLM 5 cable input (multi purpose) .................................................................................221

E.3 Specifications FLM HDSDI – SDI input . .. . . .......................................................................................222

E.4 Specifications FLM DVI input ......................................................................................................223

E.5 Specifications FLM DVI HDCP input...............................................................................................223

F. Order info........................................................................................................... 225

F.1 Sparepart orderinfo ...............................................................................................................225

Glossary ............................................................................................................... 227

Index.................................................................................................................... 229

4 R5976986 FLM HD18 15/03/2010

Page 9

1. SAFETY

About this chapter

Read this chapter attentively. It contains important information to prevent personal injury while installing and using an FLM HD18

projector. Furthermore, it includes several cautions to prevent damage to the FLM HD18. Ensure that you understand and follow

all safety guidelines, safety instructions and warnings mentioned in this chapter before installing your FLM projector. After this

chapter, additional “warnings” and “cautions” are given depending on the installation procedure. Read and follow these “warnings”

and “cautions” as well.

Overview

• General

• Important safety instructions

• Important warnings concerning FLM flight cases

1.1 General

Notice on safety

This equipment is built in accordance with the requirements of the international safety standards IEC60950-1, EN60950-1,

UL60950-1 and CAN/CSA C22.2 No.60950-1, which are the safety standards of information technology equipment including

electrical business equipment. These safety standards impose important requirements on the use of safety critical components,

materials and insulation, in order to protect the user or operator against risk of electric shock and energy hazard, and having

access to live parts. Safety standards also impose limits to the internal and external temperature rises, radiation levels, mechanical

stability and strength, enclosure construction and protection against the risk of fire. Simulated single fault condition testing ensures

the safety of the equipment to the user even when the equipment’s normal operation fails.

1. Safety

Restricted access location

The FLM HD18 may only be installed in a restricted access location, due to the temperature rise of parts of the equipment (air outlet).

Restricted access location

A location for equipment where both of the following paragraphs apply:

1) Access can only be gained by SERVICE PERSONS or by USERS who have been instructed about the reasons for

the restriction applied to the location and about the precautions that shall be taken.

2) Access is through the use of the tool or lock and key, or other means of security, and is controlled by the authority

responsible for the location.

Installation instructions

• Before operating this equipment please read this manual thoroughly, and retain it for future reference.

• Installation and preliminary adjustments should be performed by qualified Barco personnel or by authorized Barco service dealers.

• All warnings on the projector and in the documentation manuals should be adhered to.

• All instructions for operating and use of this equipment must be followed precisely.

Safety indication on the product

Risk of electrical shock. Do not open. To reduce the risk of electrical shock, do not remove the projector’s covers. No user-serviceable parts inside. Refer servicing to qualified service personnel.

• The lightning flash with an arrowhead within a triangle is intended to tell the user that parts inside this product may cause a risk

of electrical shock to persons.

• The exclamation point within a triangle is intended to tell the user that important operating and/or servicing instructions are

included in the technical documentation for this equipment.

Definition of “qualified service technicians” or ”qualified technicians”: Persons having appropriate technical

training and experience necessary to be aware of hazards to which they are exposed in performing a task and

of measures to minimize the danger to themselves or other persons.

Owners record

The part number and serial number are located at the right side of the projector. Record these numbers in the spaces provided

below. Refer to them whenever you call upon your Barco dealer regarding this product.

R5976986 FLM HD18 15/03/2010

5

Page 10

1. Safety

Product article number

Product serial number

Dealer

1.2 Important safety instructions

To prevent the risk of electrical shock

• This product should be operated from a mono phase AC power source. Power input voltage range must be between 200-240

VAC, 50–60 Hz, 20 amps at 230 VAC

• The power cord of the FLM HD18 is equipped with a 3-wire grounding plug, a plug having a third (grounding) pin. This plug will

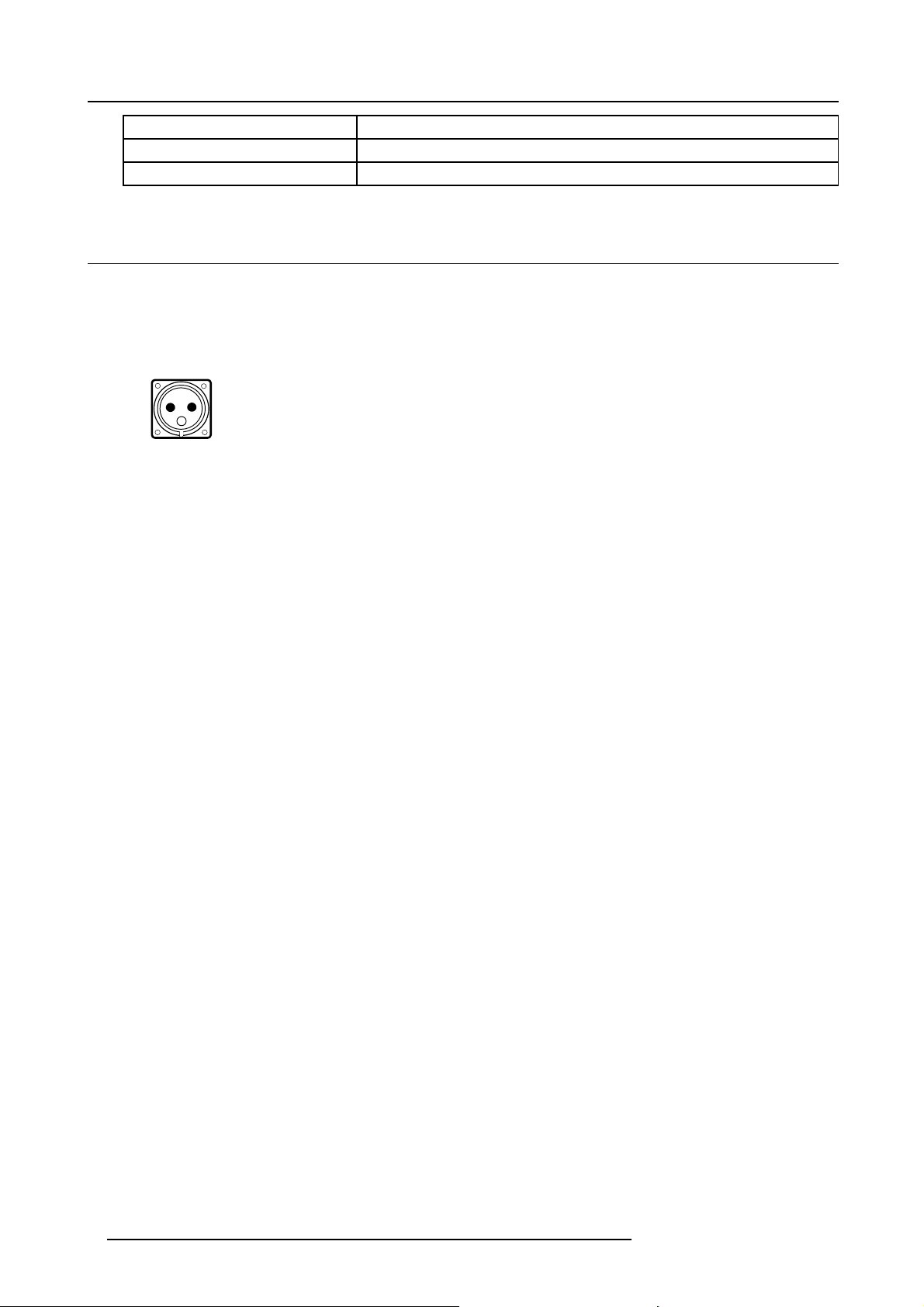

only fit into a grounding-type EN60-309 power outlet. This is a safety feature. Mains power cord with EN60-309 plug:

L

N

E

Warning: This apparatus must be grounded (earthed) via the supplied 3 conductor AC power cable. If the supplied power

cable is not the correct one, consult your dealer.

If you are unable to insert the plug into the outlet, contact your electrician to replace your obsolete outlet. Do not defeat the

purpose of the grounding-type plug.

The wires of the power cord are colored in accordance with the following code:

EN60-309

International plug 32 ampere:

Green/Yellow: ground.

Blue: neutral.

Brown: line (live)

• Do not allow anything to rest on the power cord. Do not locate this product where persons will walk on the cord. To disconnect

the cord, pull it out by the plug. Never pull the cord itself.

• If an extension cord is used with this product, make sure that the total of the ampere ratings on the products plugged into the

extension cord does not exceed the extension cord ampere rating.

• Use only the power cord supplied with your projector. While appearing to be similar, other power cords have not been safety

tested at the factory and may not be used to power the projector. For a replace

• Never push objects of any kind into this product through cabinet slots as they may touch dangerous voltage points or short out

parts that could result in a risk of fire or electrical shock.

• Never spill liquid of any kind on the product. Should any liquid or solid object fall into the cabinet, unplug the set and have it

checked by qualified service personnel before resuming operations.

• Lightning - For added protection for this video product during a lightning storm, or when it is left unattended and unused for

long periods of time, unplug it from the wall outlet. This will prevent damage to the projector due to lightning and AC power-line

surges.

North American plug 30 ampere:

Green/Yellow or Green: ground.

Blue or White: neutral.

Brown or Black: line (live)

ment power cord, contact your dealer.

To prevent personal injury

• Caution: High pressure lamp may explode if improperly handled. Refer servicing to qualified service personnel. The customer

should never attempt to disassemble the lamp casing or to dispose of the lamp casing other than by returning it to Barco.

• To prevent injury and physical damage, always read this manual and all labels on the system before inserting the lamp casing,

connecting to the wall outlet or adjusting the projector.

• To prevent injury, take note of the weight of the projector. Minimum 4 persons are needed to carry the projector.

• To prevent injury, ensure that the lens and all cover plates are correctly installed. See installation procedures.

• Warning: high intensity light beam. NEVER look into the lens ! High luminance could result in damage to the eye.

• Before attempting to remove any of the projector’s covers, you must turn off the projector and disconnect from the wall outlet.

• When performing setup work to a ceiling mounted projector, to prevent injury caused by falling objects or the system, set out

a keep out area.

• Consult a professional structural engineer prior to suspending the projector from a structure not intended for that use. Always

ensure that the working load limit of the structure can handle the load of the projector.

• Never stack more than two (2) FLM projectors in a hanging configuration (truss) and never stack more than three (3) FLM

projectors in a base stand configuration (table mount).

• The power input at the projector side is considered as the disconnect device. When required to switch off the projector, to

access parts inside, always disconnect the power cord at the projector side. In case the power input at the projector side is not

accessible (e.g. ceiling mount), the socket outlet supplying the projector shall be installed nearby the projector and be easily

accessible, or a readily accessible general disconnect device shall be incorporated in the fixed wiring.

• Do not place this equipment on an unstable cart, stand, or table. The product may fall, causing serious damage to it and

possible injury to the user.

6

R5976986 FLM HD18 15/03/2010

Page 11

1. Safety

• When mounting the projector to the ceiling or to a rigging system, always mount security chains.

• Warning: Protection from ultraviolet radiation: Do not look directly in the light beam. The lamp contained in this product is

an intense source of light and heat. One component of the light emitted from this lamp is ultraviolet light. Potential eye and skin

hazards are present when the lamp is energized due to ultraviolet radiation. Avoid unnecessary exposure. Protect yourself and

your employees by making them aware of the hazards and how to protect themselves. Protecting the skin can be accomplished

by wearing tightly woven garments and gloves. Protecting the eyes from UV can be accomplished by wearing safety glasses

that are designed to provide UV protection. In addition to the UV, the visible light from the lamp is intense and should also be

considered when choosing protective eye wear.

• Exposure to UV radiation: Some medications are known to make individuals extra sensitive to UV radiation. The American

Conference of Governmental Industrial Hygienists (ACGIH) recommends occupational UV exposure for an-8hour day to be

less than 0.1 microwatts per square centimeters of effective UV radiation. An evaluation of the workplace is advised to assure

employees are not exposed to cumulative radiation levels exceeding these government guidelines.

To prevent projector damage

• If the Air Filters are not regularly replaced, the air flow inside the projector could be disrupted, causing overheating. Overheating

may lead to the projector shutting down during operation.

• In order to ensure that correct airflow is maintained, and that the projector complies with electromagnetic compatibility (EMC)

requirements, it should always be operated with all of it’s covers in place.

• Slots and openings in the cabinet are provided for ventilation. To ensure reliable operation of the product and to protect it from

overheating, these openings must not be blocked or covered. The openings should never be blocked by placing the product

on a bed, sofa, rug, or other similar surface. This product should never be placed near or over a radiator or heat register. The

projector should not be placed in a built-in installation or enclosure unless proper ventilation is provided.

• Do not block the projector cooling fans or free air movement under and around the projector. Loose papers or other objects

may not be nearer to the projector than 10 cm (4") on any side.

• The projector must always be mounted in a manner which ensures free flow of air into its air inlets and unimpeded evacuation

of the hot air exhausted from its cooling system. Heat sensitive materials should not be placed in the path of the exhausted air.

Leave at least a free safety area of 1 meter (40”) at the rear of the projector.

• Ensure that nothing can be spilled on, or dropped inside the projector. If this does happen, switch off and unplug the mains

supply immediately. Do not operate the projector again until it has been checked by qualified service technicians.

• Consult a professional structural engineer prior to suspending the ceiling mount from a structure not intended for that use.

Always ensure the working load limit of the structure supporting the projector.

• Do not use this equipment near water.

• Special care should be used when DLP projectors are used in the same room as high power laser equipment. Direct or indirect

hitting of a laser beam on to the lens can severely damage the Digital Mirror Devices

• Save the original shipping carton and packing material; they will come in handy if you ever have to ship your equipment. For

maximum protection, repack your set as it was originally packed at the factory.

• Unplug this product from the wall outlet before cleaning. Do not use liquid cleaners or aerosol cleaners. Use a damp cloth for

cleaning. Never use strong solvents, such as thinner or benzine, or abrasive cleaners, since these will damage the cabinet.

Stubborn stains may be removed with a cloth lightly dampened with mild detergent solution.

• To ensure the highest optical performance and res

coating, therefore, avoid touching the lens. To remove dust on the lens, use a soft dry cloth. Do not use a damp cloth, detergent

solution, or thinner.

olution, the projection lenses are specially treated with an anti-reflective

TM

in which case there is a loss of warranty.

To prevent battery explosion

• Danger of explosion if battery is incorrectly installed.

• Replace only with the same or equivalent type recommended by the manufacturer.

• Dispose of used batteries according to the manu

facturer’s instruction.

To prevent fire hazard

• Warning “Risk of fire”. Do not place flammable or combustible materials near the projector !

This projector radiates heat on its external surfaces and from ventilation ducts during normal operation, which is both normal

and safe. Exposing flammable or combustible materials into close proximity of this projector could result in the spontaneous

ignition of that material, resulting in a fire. For this reason, it is absolutely necessary to leave an “exclusion zone” around all

external surfaces of the projector whereby no flammable or combustible materials are present. The exclusion zone must be not

less than 40 cm (16”) for all Barco DLP projectors. The exclusion zone on the lens side must be at least 2 meter (80”).

• Do not cover the projector or the lens with any material while the projector is in operation.

• To reduce the lamp heat of the project

minutes. Then the projector may be switched off with the power switch.

• Mount the projector in a well ventilated area away from sources of ignition and out of direct sun light.

• Never expose the projector to rain or moisture.

• In the event of fire, use sand, CO

• This product should never be placed near or over a radiator or heat register.

• This projector should not be placed in a built-in installation or enclosure unless proper ventilation is provided.

• Projection rooms must be well ventilated or cooled in order to avoid build up of heat.

R5976986 FLM HD18 15/03/2010

or, switch the projector first to standby and let the projector lamp cool down for at least 5

, or dry powder fire extinguishers; never use water on an electrical fire.

2

7

Page 12

1. Safety

On servicing

• Do not attempt to service this product yourself, as opening or removing covers may expose you to dangerous voltage potentials

and risk of electric shock.

• Refer all servicing to qualified service personnel.

• Fence off a restricted area of at least 3 meters around the projector using an eye-catching fence and “KEEP OUT” sings. This

to prevent unauthorized persons coming near the projector during servicing.

• Unplug this product from the wall outlet and refer servicing to qualified service technicians under the following conditions:

- When the power cord or plug is damaged or frayed.

- If liquid has been spilled into the equipment.

- If the product has been exposed to rain or water.

- If the product does not operate normally when the operating instructions are followed. Adjust only those controls that are

covered by the operating instructions since improper adjustment of the other controls may result in damage and will often

require extensive work by a qualified technician to restore the product to normal operation.

- If the product has been dropped or the cabinet has been damaged.

- If the product exhibits a distinct change in performance, indicating a need for service.

• Replacement parts: When replacement parts are required, be sure the service technician has used original Barco replacement

parts or authorized replacement parts which have the same characteristics as the Barco original part. Unauthorized substitutions may result in degraded performance and reliability, fire, electric shock or other hazards. Unauthorized substitutions may

void warranty.

• Safety check: Upon completion of any service or repairs to this projector, ask the service technician to perform safety checks

to determine that the product is in proper operating condition.

1.3 Important warnings concerning FLM flight cases

Important warnings concerning stacking/transporting FLM rental flight cases

• Stack maximum two (2) FLM rental flight cases high. Never higher.

• Surface on which flight case is standing must be level to ensure that the total load is evenly spread out among the four wheels.

The surface must also be able to support the load safely.

• Before stacking or transporting flight cases, check the wheels and their fixation screws for wear or defects.

• Before stacking or transporting flight cases, check that the four lock handles on each flight case are in good working order and

locked securely.

• When stacked, make sure the wheels of the upper flight case are precisely positioned in the stacking dishes of the flight case

below.

•Stackedflight cases may not be moved. Before stacking, the lower flight case must already be in its final resting position before

placing the second upon it.

• Never stack loaded flight cases in a truck or other transport medium

• In the event of a wheel breaking, flight cases must be rigidly strapped tight to prevent a stack collapsing.

• Use an appropriate forklift to raise flight cases and take the necessary precautions to avoid personnel injury.

, unless each flight case is rigidly strapped tight.

8

R5976986 FLM HD18 15/03/2010

Page 13

2. GENERAL

About this chapter

Read this chapter before installing your FLM HD18. It contains important information concerning installation requirements for the

FLM HD18, such as minimum and maximum allowed ambient temperature, humidity conditions, required safety area around the

installed projector, required power net, compatible signal sources, etc.

Furthermore, careful consideration of things such as image size, ambient light level, projector placement and type of screen to use

are critical to the optimum use of the projection system.

Overview

• Installation requirements

• Unpacking the projector

• Box content

•FLMflight case

• Projector configurations

• Projector air inlets and outlets

• Free download of Projector Toolset

2.1 Installation requirements

2. General

Ambient temperature conditions

The maximum allowed ambient temperature for an operating Barco FLM HD18 may not exceed +40 ºC (+104 ºF).

The minimum allowed ambient temperature for an operating Barco FLM HD18 may not drop below +10 ºC (+50 ºF).

The projector will not operate if the ambient air temperature falls outside this range (+10 ºC → +40 ºC or +50 ºF → +104 ºF). Be

aware that room heat rises to the ceiling. Check if the temperature near the installation site is not excessive.

The minimum storage temperature is -35 ºC (-31 ºF) and the maximum storage temperature is +65 ºC (+149 ºF).

Humidity conditions

Storage: 0 to 98% relative humidity, non-condensing.

Operation: 0 to 95% relative humidity, non-condensing.

Projector weight

Do not underestimate the weight of one Barco FLM HD18, which is about ±100 kg (±225 lb.). Be sure that the table or truss installation on which the projector(s) has to be installed is capable of handling five (5) times the complete load of the complete system.

Power requirements

One Barco FLM HD18 requires 200-240 VAC, 50–60 Hz, 20 amps at 230 VAC.

Clean air environment

A projector must always be mounted in a manner which ensures the free flow of clean air into the projectors ventilation inlets. For

installations in environments where the projector is subject to airborne contaminants such as that produced by smoke machines or

similar (these deposit a thin layer of greasy residue upon the projectors internal optics and imaging electronic surfaces, degrading

performance), then it is highly advisable and desirable to have this contamination removed prior to it reaching the projectors clean

air supply. Devices or structures to extract or shield contaminated air well away from the projector are a prerequisite, if this is not a

feasible solution then measures to relocate the projector to a clean air environment should be considered.

Only ever use the manufacturer’s recommended cleaning kit which has been specifically designed for cleaning optical parts, never

use industrial strength cleaners on the projector’s optics as these will degrade optical coatings and damage sensitive optoelectronics

components. Failure to take suitable precautions to protect the projector from the effects of persistent and prolonged air contaminants will culminate in extensive and irreversible ingrained optical damage. At this stage cleaning of the internal optical units will

be noneffective and impracticable. Damage of this nature is under no circumstances covered under the manufacturer’s warranty

and may deem the warranty null and void. In such a case the client shall be held solely responsible for all costs incurred during any

repair. It is the clients responsibility to ensure at all times that the projector is protected from the harmful effects of hostile airborne

particles in the environment of the projector. The manufacturer reserves the right to refuse repair if a projector has been subject to

knowingly neglect, abandon or improper use.

Which screen type ?

There are two major categories of screens used for projection equipment. Those used for front projected images and those for rear

projection applications.

R5976986 FLM HD18 15/03/2010

9

Page 14

2. General

Screens are rated by how much light they reflect (or transmit in the case of rear projection systems) given a determined amount

of light projected toward them. The ‘GAIN’ of a screen is the term used. Front and rear screens are both rated in terms of gain.

The gain of screens range from a white matte screen with a gain of 1 (x 1) to a brushed aluminized screen with a gain of 10 (x 10)

or more. The choice between higher and lower gain screens is largely a matter of personal preference and another consideration

called the viewing angle. In considering the type of screen to choose, determine where the viewers will be located and go for the

highest gain screen possible. A high gain screen will provide a brighter picture but reduce the viewing angle. For more information

about screens, contact your local screen supplier.

What image size? How big should the image be?

The projector is designed for projecting an image size : minimum 1 meter (3.3 ft.) to maximum 18 meter (59 ft.) (depending on the

ambient light conditions), with an aspect ratio of 16 to 9 (recommended between 1 m (3.3ft) - 12 m (39.4ft)).

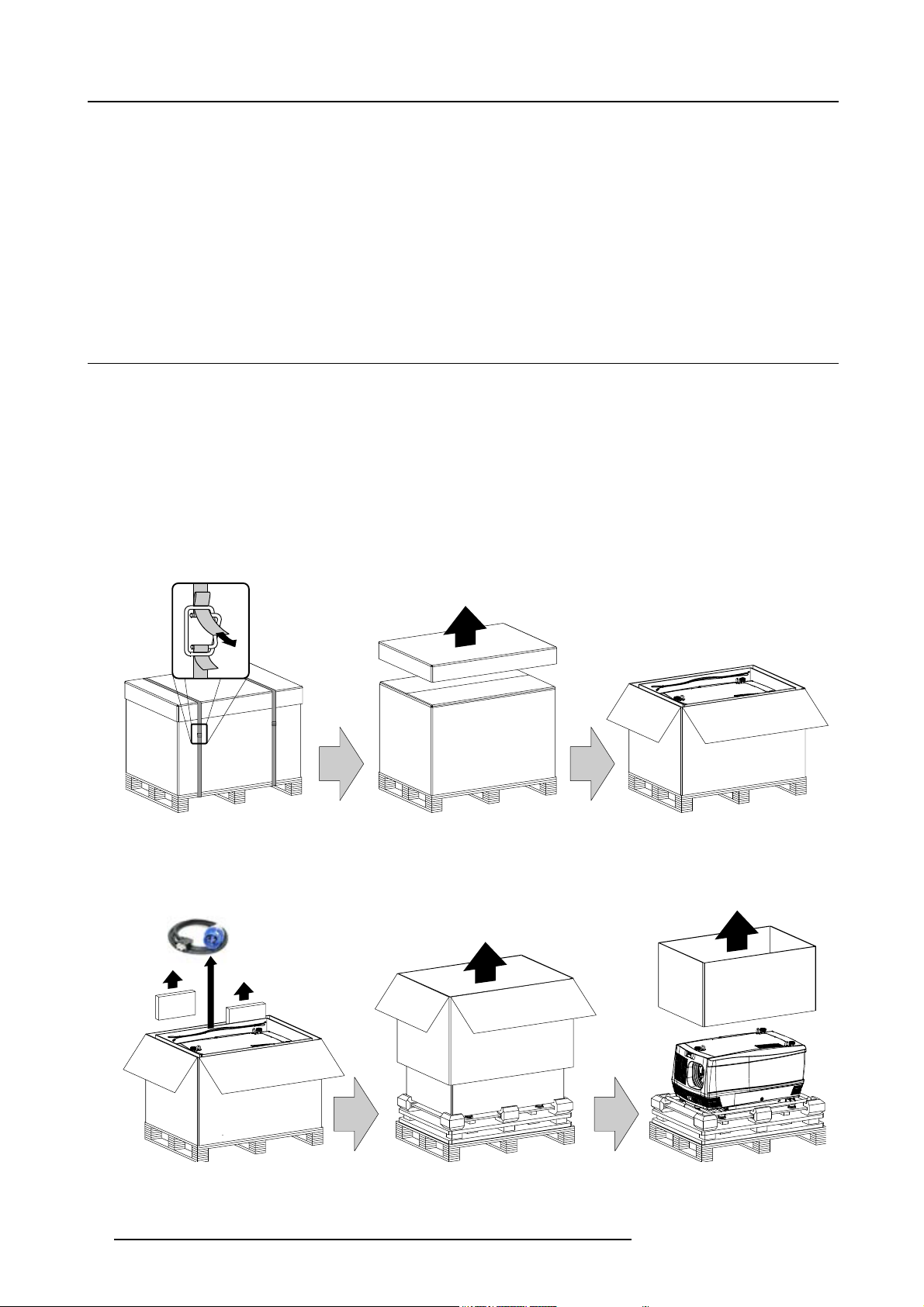

2.2 Unpacking the projector

What has to be done ?

At delivery the projector is packed in a carton box upon a wooden pallet and secured with banding and fastening clips. Furthermore,

to provide protection during transportation, the projector is surrounded with foam. Once the projector is arrived at the installation

site, it has to be removed from the carton box and wooden pallet in a safe manner without damaging the projector.

Necessary tools

• Side cutter.

• 8 mm Allen key.

How to unpack the projector ?

1. Remove the banding around the carton box, by releasing the fastening clips as illustrated, and remove the top cover.

Image 2-1

2. Remove the power cord, which is attached to the packaging with a cable ties, and the two smaller carton boxes, located between

the inner carton sleeve and outer carton box.

Note: The two smaller carton boxes contain the manuals, the remote control unit (RCU), two standard batteries size AA and

four rigging clamps for projector suspension.

Image 2-2

10 R5976986 FLM HD18 15/03/2010

Page 15

2. General

3. Remove the carton box, the inner carton sleeve and the foam around the projector. See image 2-2.

Note: The projector is still attached to a wooden plate, which is detached from the below pallet.

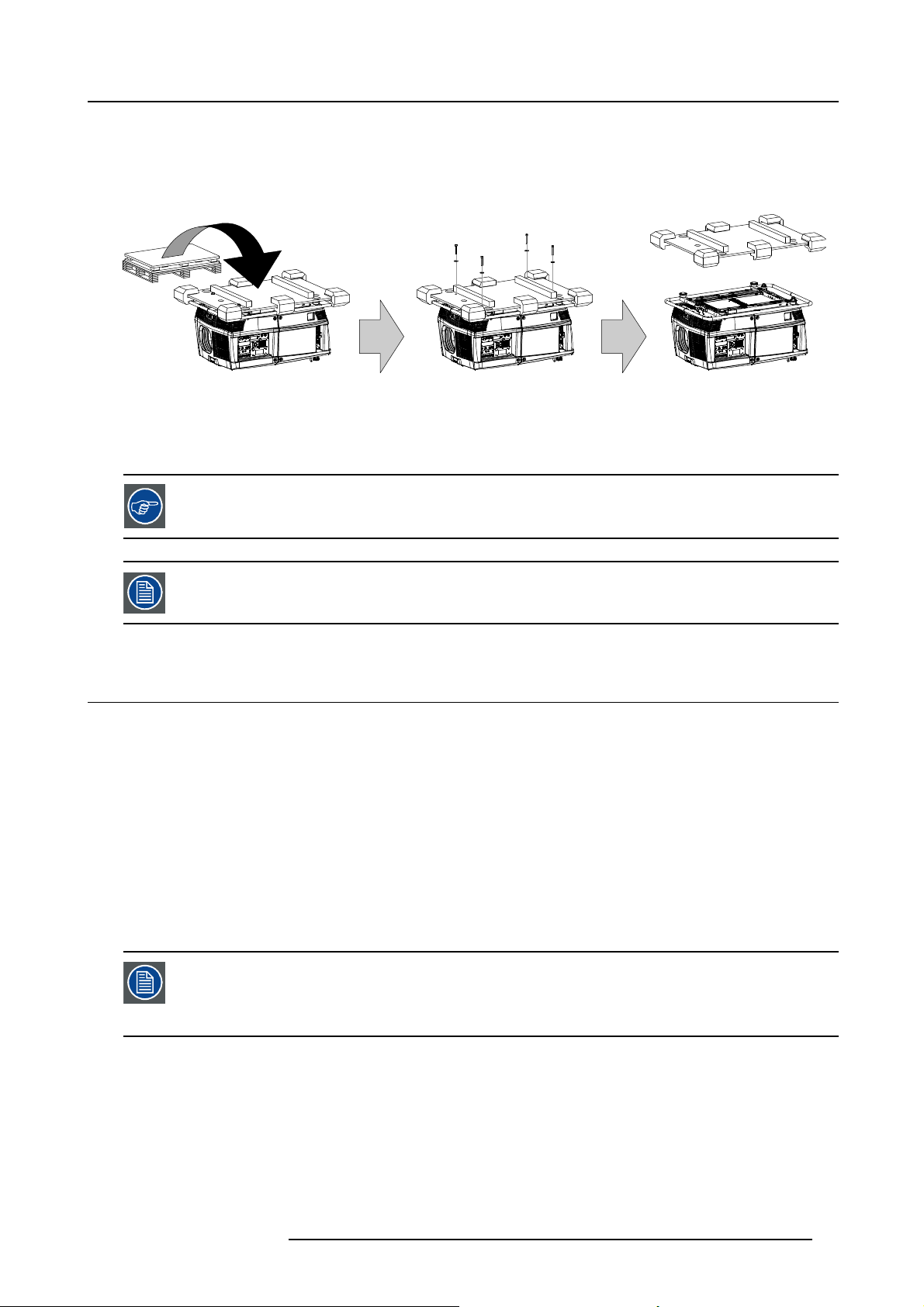

4. Gently turn the projector upside down to gain access to the four bolts, which secure the projector. Note that this wooden plate is

detached from the pallet.

Tip: Lay a blanket (or the earlier removed foam) on the floor to protect the projector housing form scratches while turning.

Image 2-3

5. Remove the wooden plate from the projector bottom, by releasing the four bolts. Use an 8 mm Allen key. See image 2-3.

6. Gently turn the projector back on its feet.

7. Remove the foam rubber around the carrying handle.

Save the original shipping carton and packing material, they will be necessary if you ever have to ship your

projector. For maximum protection, repack your projector as it was originally packed at the factory.

A rubber foam inside a plastic bag is placed into the lens opening of the projector. It’s recommended to reuse

this foam and plastic back each time you transport the projector. This to prevent intrusion of dust and foreign

particles.

2.3 Box content

Content

• One Barco FLM HD18, weight ±100 kg (±225 lb.).

• One Remote Control Unit (RCU).

• Two AA size batteries for the RCU.

• One power cord of 2,5 meter with EN60-309 plug.

• Four rigging clamps for projector suspension.

• One user manual.

Initial inspection

Before shipment, the projector was inspected and found to be free of mechanical and electrical defects. As soon as the projector is

unpacked, inspect for any damage that may have occurred in transit. Save all packing material until the inspection is completed. If

damaged is found, file claim with carrier immediately. The Barco sales and service office should be notified as soon as possible.

The packaging of the FLM HD18 is provided with a shock-watch label. If this shock-watch label was triggered

(red colored at arrival) during transport, indicates that the package was possibly roughly handled by the transport company. In this case, the instructions mentioned on the label, should be followed, which are: adding

a note on the “bill of lading” and informing the transport company and the Barco sales and service offi ce as

soon as possible.

Mechanical check

This check should confirm that there are no broken knobs or connectors, that the cabinet and panel surfaces are free of dents and

scratches, and that the meter face and operating panel are not scratched of cracked. The Barco sales and service office should be

notified as soon as possible.

R5976986 FLM HD18 15/03/2010

11

Page 16

2. General

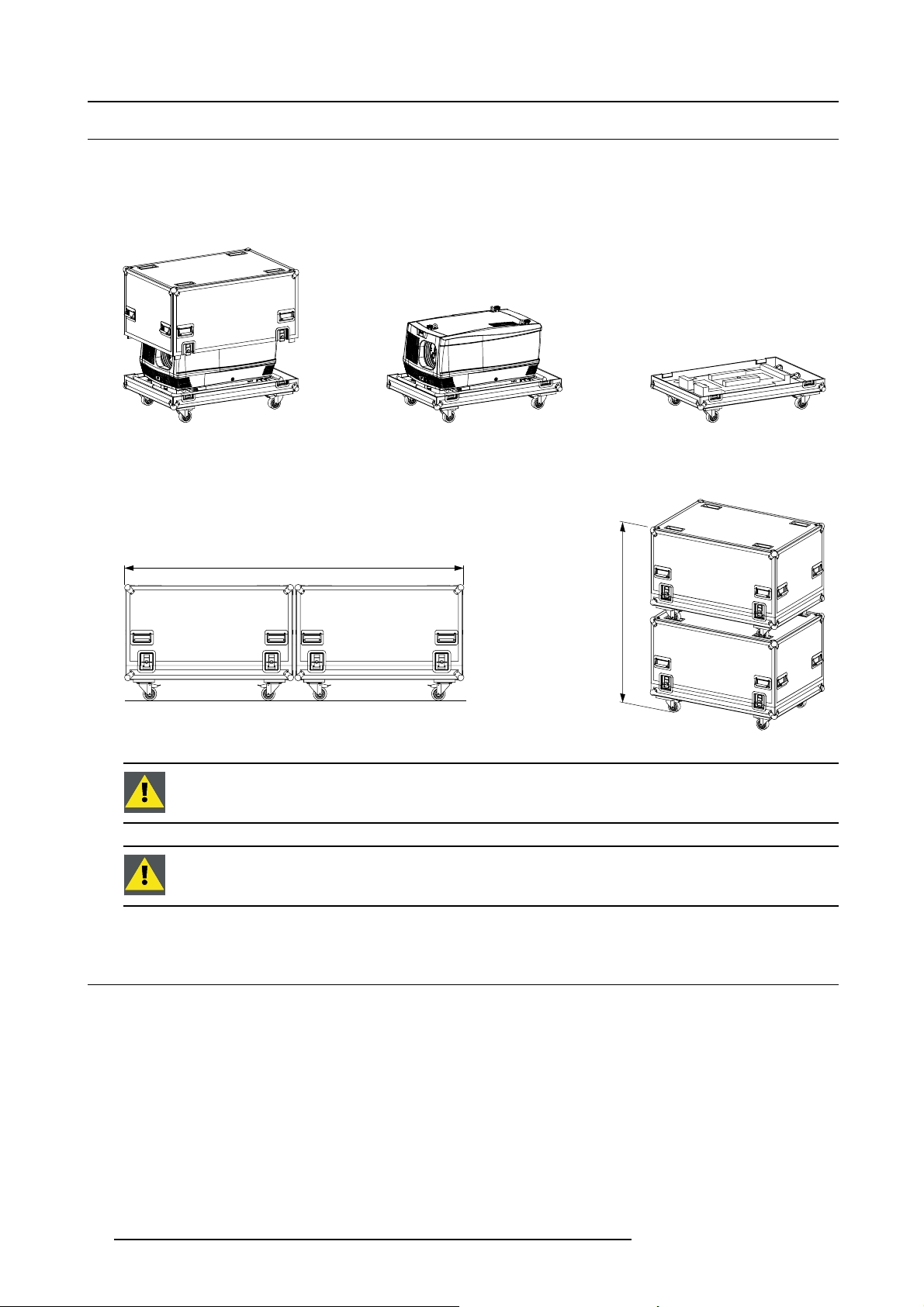

2.4 FLM flight case

Introduction of the FLM flight case

The FLM flight case is designed to transport the FLM HD18 in a safe and secure manner. The four caster wheels, provided with

breaks, and the eight handles make the FLM flight case easy to handle. The fl oor of the flight case wagon is equipped with two

small covered compartments to store the remote control and the rigging clamps. Furthermore, three Velcro strips are attached to

the bottom for fastening the power cord of the projector.

Image 2-4

FLM flight case (R9854510).

The dimensions of the FLM flight case are optimal for maximum utilization of the floor area of a truck. The cover of the FLM flight

case has four stacking dishes, which allows to stack the flight cases.

2400 mm

m

m

0

0

6

1

Image 2-5

WARNING: Maximum stack two (2) FLM flight cases high. Never higher.

CAUTION: Prior to inserting project

or in fl ight case turn in the adjustable feet and interlocking adapters fully.

2.5 Projector configurations

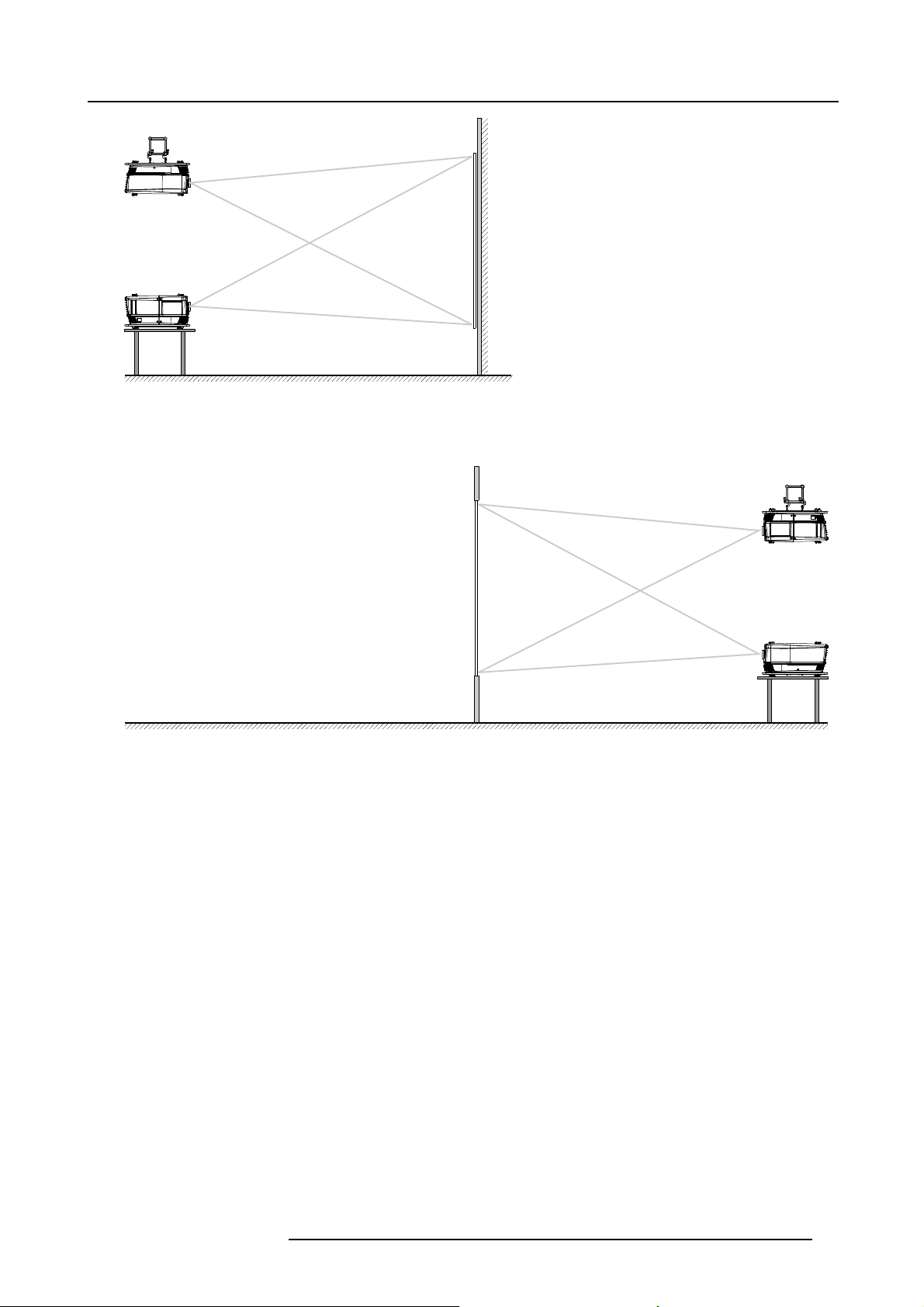

The different configurations

Depending on the installation the projector can be mounted in different ways, the 4 different configurations are:

1. Front / Table (F/T)

2. Front / Ceiling (F/C)

3. Rear / Table (R/T)

4. Rear / Ceiling (R/C)

Front projection

The projector is installed, either in a table mount or ceiling mount configuration, at the same side of the screen as the audience.

12

R5976986 FLM HD18 15/03/2010

Page 17

F/C

2. General

AUDIENCE

F/T

FLOOR

Image 2-6

SCREEN

Rear projection

The projector is installed, either in a table mount or ceiling mount configuration, at th

AUDIENCE BACKSTAGE

N

E

E

R

C

S

FLOOR

Image 2-7

e other side of the screen opposite the audience.

R/C

R/T

R5976986 FLM HD18 15/03/2010 13

Page 18

2. General

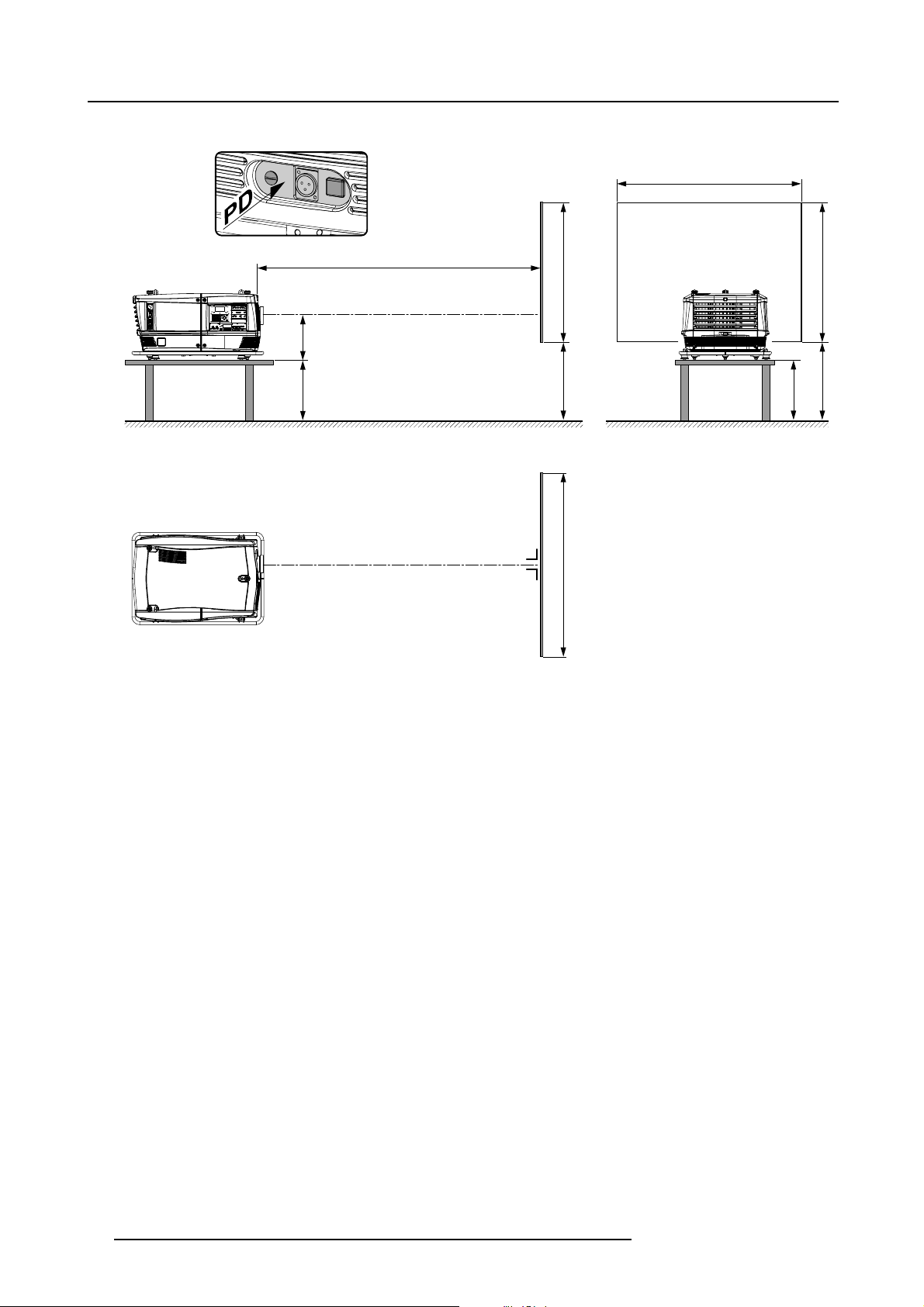

Positioning the projector

SW

PD

ACD

SCREENSCREEN

SHB

SCREEN

SHB

CD

FLOOR

SW

Image 2-8

The projector should be installed at right angles (horizontally and vertically) to the screen at a distance PD. Note the distance (A)

between lens centre and table surface is slight

and the vertical lens shift is set to zero (0).

ly variable. This distance (A) is nominal 35 cm in case all feet are turned in completely

On-Axis / Off-Axis projection

The position of the projector with reference to the screen may also be different depending on the installation. Basically the projector

can be positioned in On-Axis or Off-Axis configuration. On-Axis configuration means that the projector is positioned so as to have

the centre of the lens coinciding with the centre of the screen. Off-Axis projection is obtained by shifting the lens up, down, left or

right. Several parameters can be calculated determining the position in any installation.

Formula to calculate the distance CD for On-Axis projection: CD=SH/2+B-A

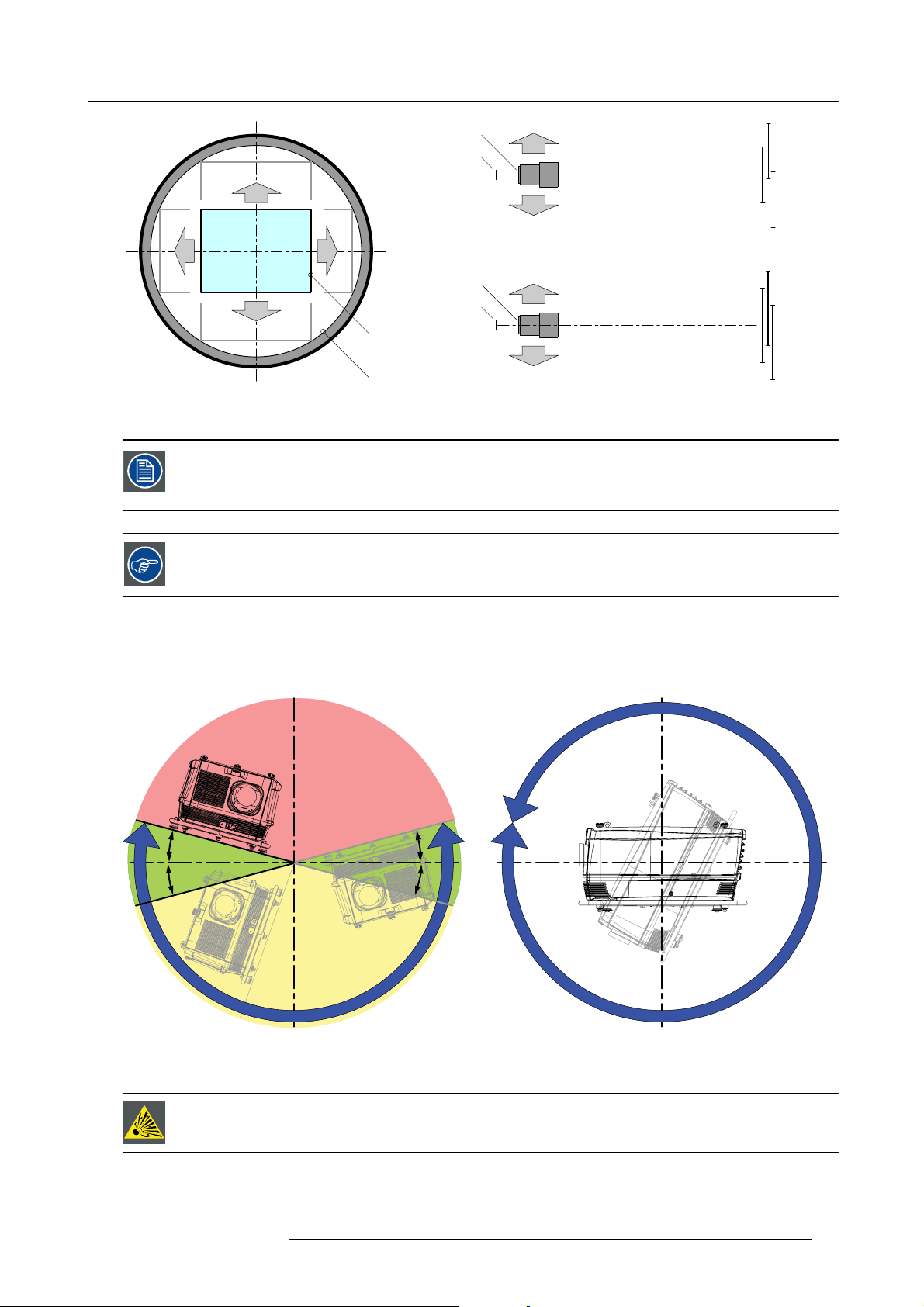

Shift range

The lens can be shifted with respect to the DMD (P) which result in a shifted image on the screen (Off-Axis). A 100% shift means that

the centre point of the projected image is shifted by half the screen size. In other words, the centre point of the projected image falls

together with the outline of the image in an On-Axis projection. Due to mechanical and optical limitations it’s recommended to keep

the shift values within the field of view (F) as illustrated below. Within these shift ranges the projector and lens perform excellently.

Configuring the projector outside these shift ranges will result in a slight decline of image quality.

14

R5976986 FLM HD18 15/03/2010

Page 19

2. General

U

-52% +52%

L R

D

Image 2-9

PDMD.

F Field of view.

It’s mechanical possible to shift outside the recommended field of view (±120% UP/DOWN and ±70%

LEFT/RIGHT), but this will result in a slightly decline of image quality depending on the used lens and the

zoom position of the used lens. Furthermore, shifting too much in both directions will result in a blurred

image corner.

Best image quality is projected in the On-Axis configuration.

+110%

-110%

F

P

F

P

P

F

U

D

L

R

SIDE VIEW

TOP VIEW

+110%

-110%

-52%

+52%

Horizontal and vertical projector tilt ranges

The projector can be rotated and mounted at any vertical angle. In other words, you can tilt the lens side of the projector as much

as desired for your application. Side to side tile, however, must not exceed ±15°. This limit ensures that the lamp in the projector

operates properly and safely. More tilting within area C is allowed but lamp flicker can happen.

B

MAX

15°

15°

A

A

15°

15°

MAX

360°

C

Image 2-10

A Tilting allowed without prob lems

B No tilting allowed in this area

C Tilting allowed but lamp flicker possible

CAUTION: Always respect the allowed tilt range of the projector. Neglecting this will result in lamp flicker,

which reduces the light output and the life span of the lamp substantially. Furthermore, in the long term, the

possibility exist that the lamp explodes.

R5976986 FLM HD18 15/03/2010 15

Page 20

2. General

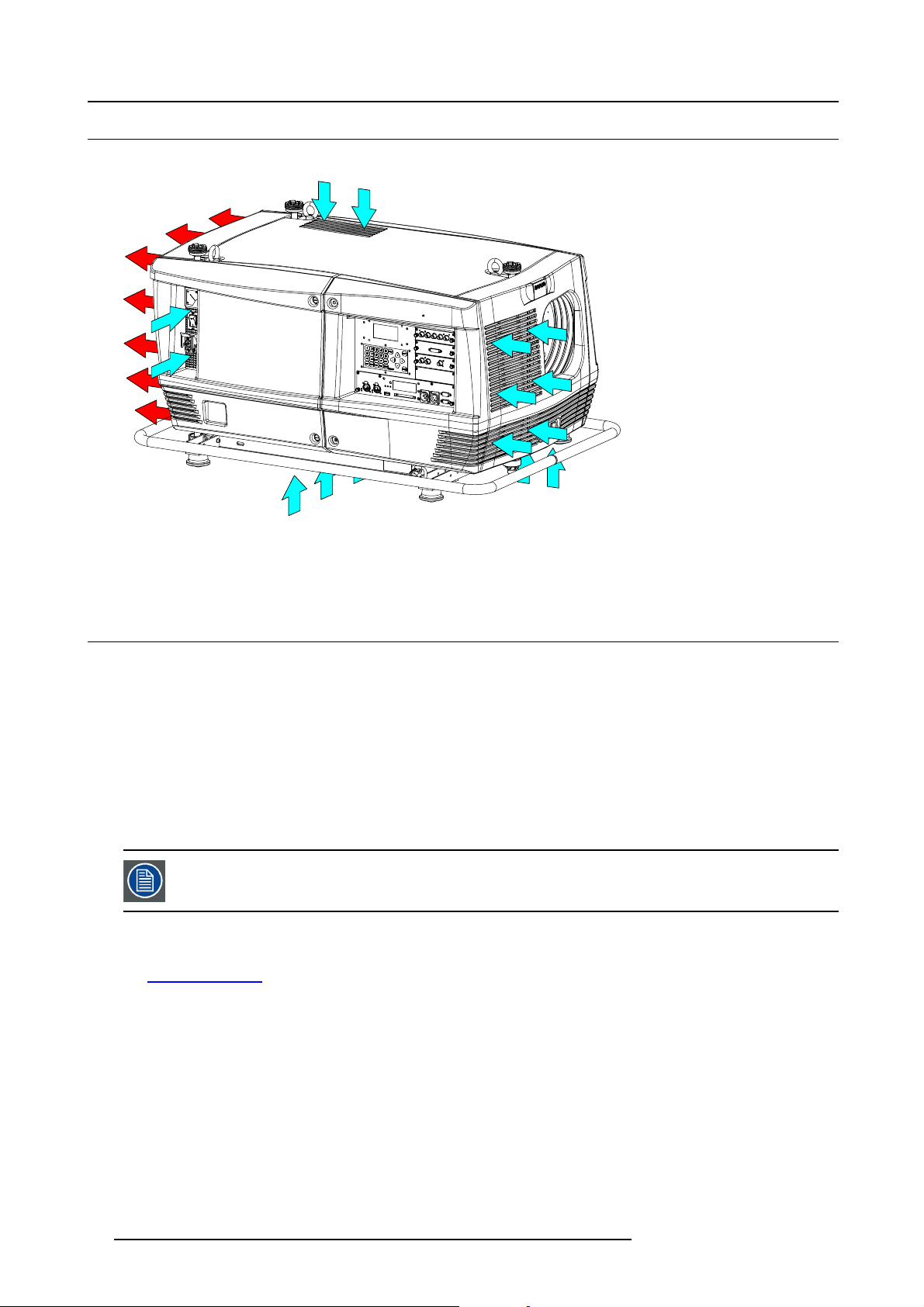

2.6 Projector air inlets and outlets

Air inlets and outlets

Image 2-11

The FLM HD18 has 5 air inlet channels and one air outlet. The air outlet is located at the rear of the projector. The air inlets are

located at the front, bottom, top and right side of the pr

ojector.

2.7 Free download of Projector Toolset

About Projector Toolset

Projector Toolset is a software tool to set up, configure, manage and control Barco projectors.

The concept of this Projector Toolset software is mod

modules, now and in the future available.

The Projector Toolset software works with configurations that can be loaded. Within a confi guration, different snapshots can be

taken. A snapshot represents a current state of a configuration and can be reloaded to return to this typical state. These terms will

be used through the complete software.

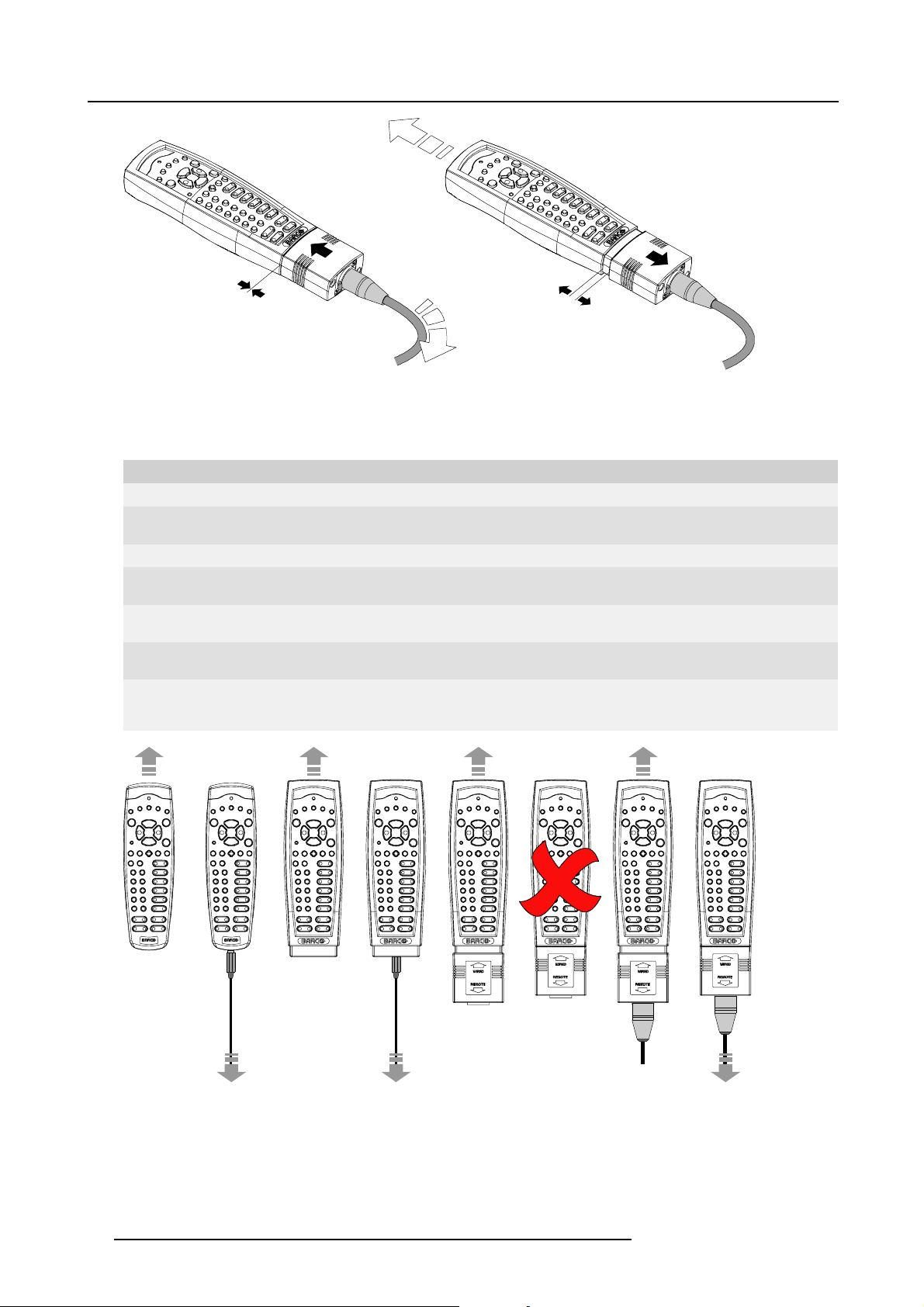

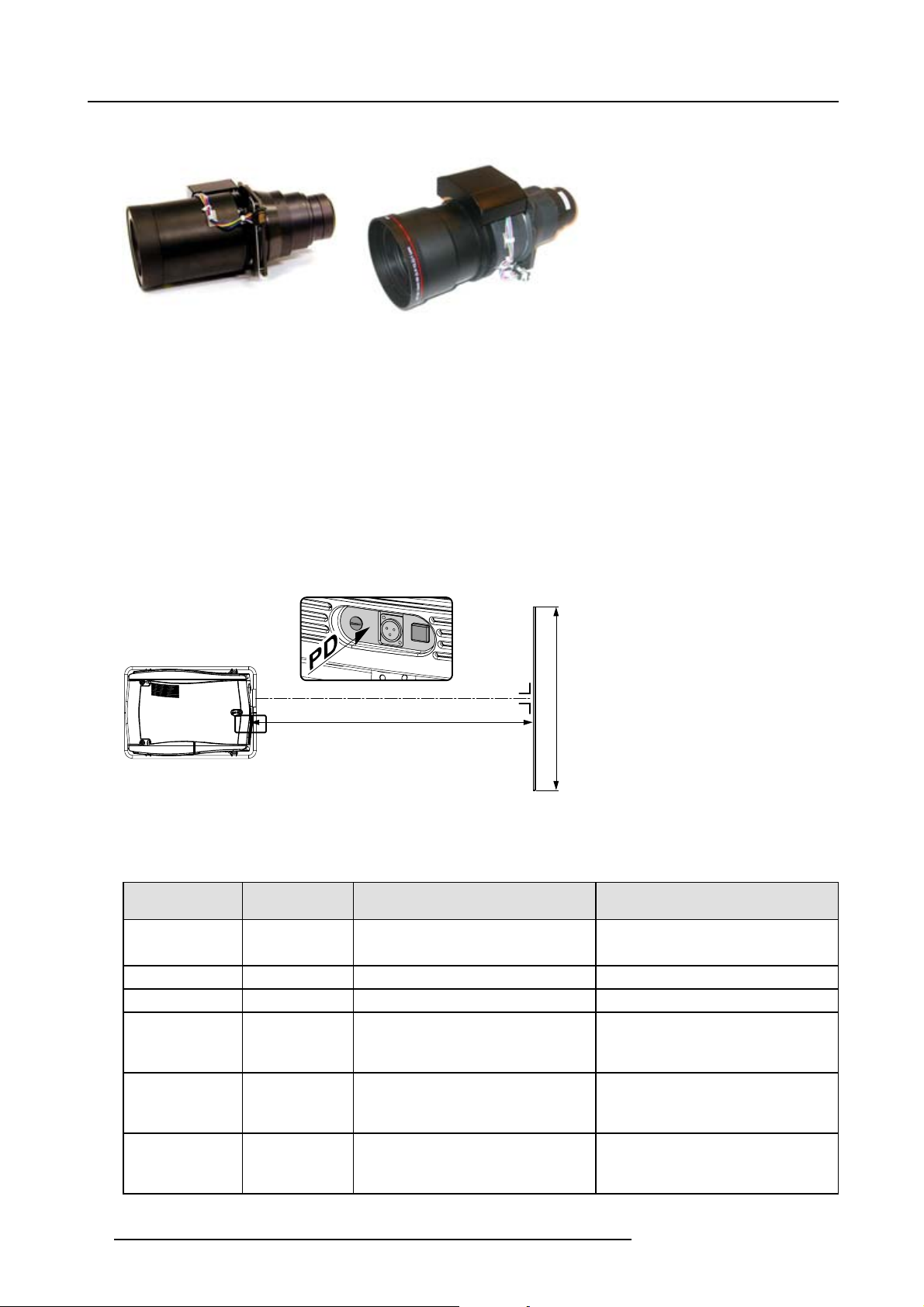

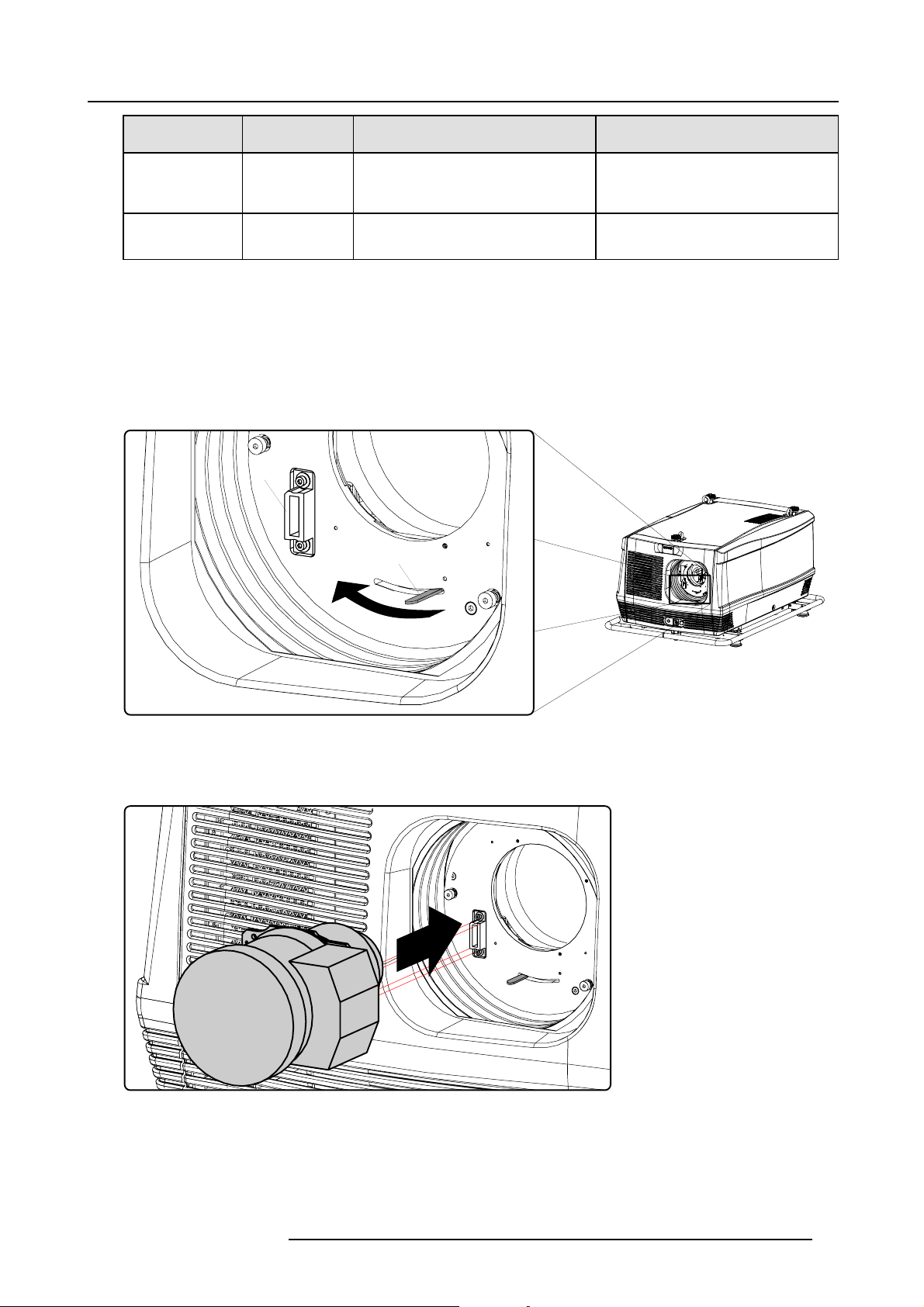

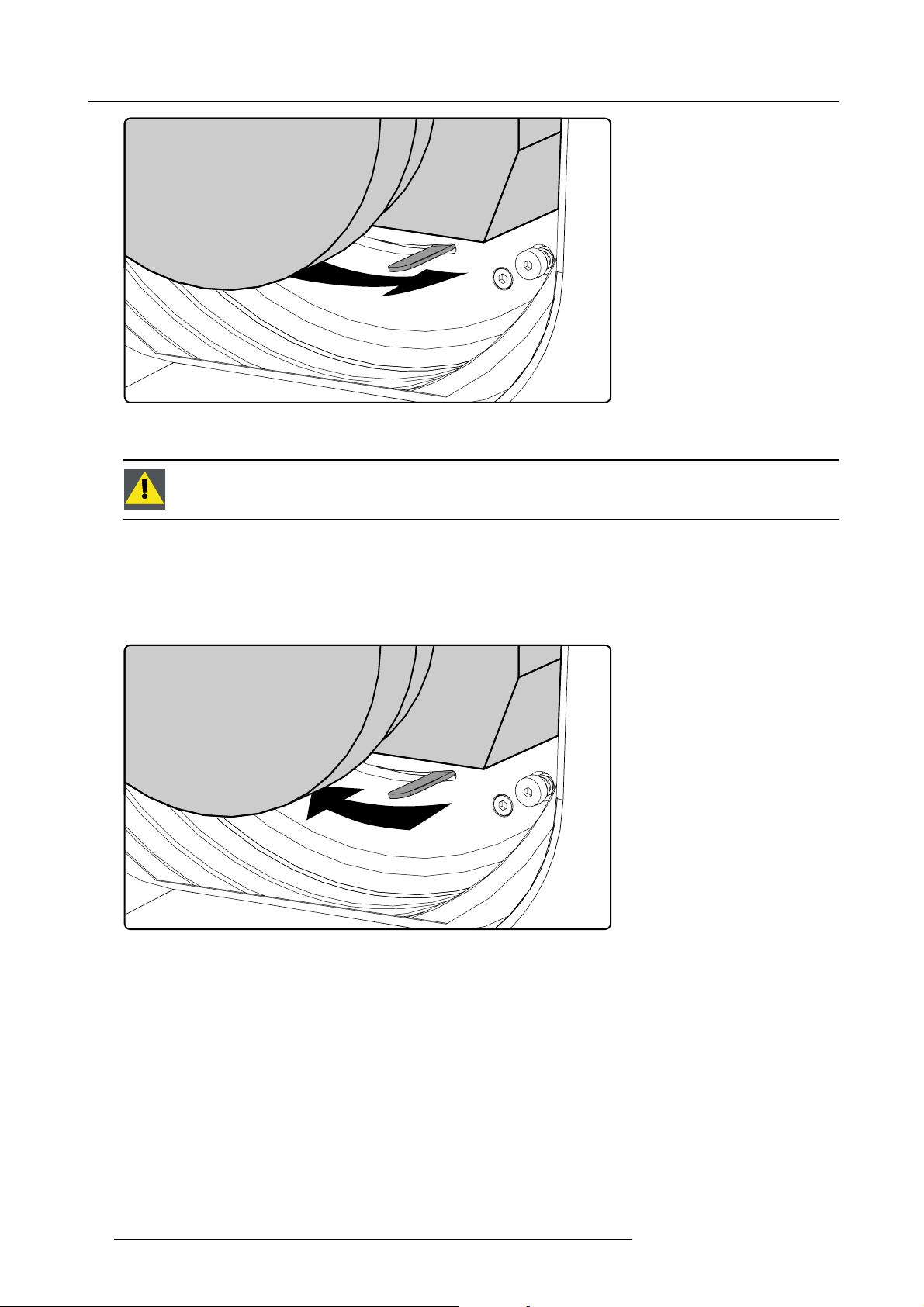

Projector Toolset is a stand-alone application that runs on a Java Virtual Machine and that does not require extra services to run.