Page 1

F35

601-0311/02

07/07/2017

User and Installation Manual

Page 2

Barco Fredrikstad AS

Habornveien 53, N-1630 Gamle Fredrikstad, Norway

Phone: +47 6930 4550

Fax: +47 6930 4580

Support: Support.fre@barco.com

Visit us at the web: www.barco.com

Printed in NO

Page 3

Changes

Barco provides this manual ’as is’ without warranty of any kind, either expressed or implied, including but not limited to the implied warranties or merchantability and fitness for a particular purpose. Barco may make improvements and/or changes to the product(s) and/or the

program(s) described in this publication at any time w ithout notice.

This publication could contain technical inaccuracies or typographical errors. Changes are periodically made to the information in this

publication; these changes are incorporated in new editions of this publication.

The latest edition of Barco manuals can be downloaded from the Barco web site w

h

ttps://www.barco.com/en/sig nin.

ww.barco.com or from the secured Barco web site

Federal Communications Commission (FCC Statement)

This equipment has been tested and found to comply with the limits for a class A digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable p rotection aga inst harmful interference when the equipm ent is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may c ause harmful interference to radio communications. Operation of this equipment in a residential area may

cause harmful interference, in which case the user will be responsible for correcting any interference at his own expense

Changes or modifications not expressly approved by the party responsible for compliance could void the user ’s authority to operate the

equipment

Guarantee and Compensation

Barco provides a guarantee relating to perfect manufacturing as part of the legally stipulated terms of guar antee. O n receipt, the pu rchaser

must immediately inspect all delivered goods for damage incurred during transport, as well as for material and manufacturing faults Barco

must be informed immediately in writing of any complaints.

The period of guarantee begins on the date of transfer of risks, in the case of special systems and software on the date of commissioning,

at latest 30 days after the transfer of risks. In the event of justified notice of complaint, Barco can repair the fault o r p rovide a replacement

at its own discretion w ithin an appropriate period. If this meas

reduction in the purchase pr ice or cancellation of the contract. All other claims, in particular tho se relating to com pensa tion for direct or

indirect damage, and also damage attributed to the operation of software as well as to other services provided by Barco, being a com ponent

of the system or independent service, will be deemed invali

guaranteed in writing or due to the intent or gross negligence or part of Barco.

If the purchaser or a third party carries out m odifications or repairs on goods delivered by Barco, or if the goods are handled incorrectly,

in particular if the systems are operated incorrectly or if, a fter the transfer of risks, the goods a re subject to influences not agreed upon in

the contract, all guarantee claims of the purchaser will be rendered invalid. Not included in the guarantee coverage are sy stem failures

which are attributed to programs or special electronic circuitry provided by the purchaser, e.g. interfaces. Normal wear as well as normal

maintenance are not subjec t to the guarantee provided by Barco either.

The environmental conditions as well as t he servicing and maintenance regulations specified in this manual must be com plied with by the

customer.

ure proves to be impossible or uns ucc essful, the purchaser can demand a

d provided the damage is not proven to be attributed to the absenc e of properties

Page 4

Page 5

Table of contents

TABLE OF CONTENTS

1. Introduction . ................ ................ ................ ................ ................ .................. ..... 3

1.1 About this manual . .................................................................................................................. 3

2. Safety................................................................................................................ 5

2.1 General Considerations ............................................................................................................. 5

2.2 Important safety instructions ........................................................................................................ 6

2.3 Product safety labels ................................................................................................................ 8

3. Get to know the projector........................................................................................11

3.1 Introducing the F35.................................................................................................................. 11

3.2 Main components . . . .................................................................................................................12

3.3 Accessories and peripherals ........................................................................................................12

4. Lenses.................... ................ ................ ................ ................ ................ ...........15

4.1 Lens range . . . ........................................................................................................................15

4.2 Lens monitoring...................................................................................................................... 17

4.3 Replacing a lens .....................................................................................................................17

4.4 Lens shift.............................................................................................................................18

4.5 Adjust zoom, focus and iris.......................................................................................................... 18

5. Installation..........................................................................................................21

5.1 Installing the projector...............................................................................................................21

5.2 Installation c onditions ...............................................................................................................21

5.3 Initial inspection......................................................................................................................23

5.4 Positioning the projector............................................................................................................. 23

5.5 Mount the projector on a flat surface ...............................................................................................24

5.6 Mount the projector on the ceiling. ..................................................................................................25

5.7 Throw distance ...................................................................................................................... 25

5.8 Lens shift.............................................................................................................................28

5.9 Offset Matrix .........................................................................................................................29

5.10 Scheimpflug (Boresight) adjustment ................................................................................................30

5.11 Scheimpflug adjustment procedure .................................................................................................31

6. Input and Communication .... ................ ................ ................ ................ ................ ...33

6.1 Local keypad.........................................................................................................................33

6.2 Projectorstatus indicator............................................................................................................34

6.3 Lamp status indicators ..............................................................................................................35

6.4 LCD Panel ...........................................................................................................................35

6.5 Turn theLCD screen and LED indicators ON or OFF.............................................................................. 36

6.6 Wireless remote control.............................................................................................................37

6.7 Connector Panel .....................................................................................................................38

6.8 Connect to a source .................................................................................................................38

6.9 LAN ..................................................................................................................................39

6.10 3D SYNC ............................................................................................................................ 39

6.11 RS-232............................................................................................................................... 39

6.12 Sync In / Out.........................................................................................................................39

6.13 Dual link DVI.........................................................................................................................40

6.14 VGA ..................................................................................................................................40

6.15 YPbPr................................................................................................................................40

6.16 HDMI................................................................................................................................. 40

6.17 Wired IR..............................................................................................................................41

6.18 Triggers .............................................................................................................................. 41

6.19 USB A................................................................................................................................41

6.20 USB B................................................................................................................................41

7. Change projector settings .............. ................ ................ ................ ................ .........43

7.1 Select a power mode ................................................................................................................ 43

7.2 Use RTC to set projector ON/OFF programs....................................................................................... 43

7.3 Control screens with triggers ........................................................................................................44

7.4 Lock the projector ...................................................................................................................45

7.5 Customize the On Screen Display (OSD) ..........................................................................................45

7.6 Review and change network settings...............................................................................................46

7.7 Review system status ............................................................................................................... 46

7.8 Revert to factorysettings............................................................................................................47

8. Set up the picture .................................................................................................49

8.1 Select the image orientation ........................................................................................................ 49

8.2 Use test images .....................................................................................................................49

8.3 Apply a display profi le ............................................................................................................... 50

8.4 Adjust lamp power...................................................................................................................50

8.5 Use gamma curves..................................................................................................................50

8.6 Adjust brightness, saturation and contrast.......................................................................................... 53

8.7 Choose an aspect ratio ..............................................................................................................53

601-0311 F35 07/07/2017

1

Page 6

Table of contents

9. Advanced setup and picture adjustment ............ ................ ................ ................ .........55

9.1 Set up dual head input ..............................................................................................................55

9.2 Adjust VGA input signal .............................................................................................................55

9.3 Apply source corrections ............................................................................................................56

10. Color calibration.................... ................ ................ ................ ................ ............... 57

10.1 RealColor™ .........................................................................................................................57

10.2 BrilliantColor™ ...................................................................................................................... 58

10.3 Color calibration best practice.......................................................................................................59

10.4 Calibrate projector color.............................................................................................................59

11. Color Wheels.......................................................................................................61

11.1 VizSim................................................................................................................................ 61

11.2 VizSim Bright ........................................................................................................................61

11.3 High Brightness MKIII ............................................................................................................... 62

12. Setup a multichannel installation ........... ................ ................ ................ ................ ...63

12.1 Synchronization best practice.......................................................................................................63

12.2 The Installation - Synchronization menu............................................................................................ 64

12.3 Dual Head Mode.....................................................................................................................64

12.4 Synchronization menu (2D) .........................................................................................................64

12.5 Synchronization menu (3D) .........................................................................................................64

12.6 Troubleshoot source sync issues . ..................................................................................................65

13. Stereoscopic multichannel setup ..............................................................................67

13.1 AS3D modes. ........................................................................................................................67

13.2 The 3D menu ........................................................................................................................68

13.3 Synchronous frame sequential ......................................................................................................69

13.4 Asynchronous frame sequential .. .................................................................................................. 70

13.5 Synchronous side by side . . .........................................................................................................70

13.6 Asynchronous side by side . .........................................................................................................70

14. X-Port............... ................ ................ ................ ................ .................. ............... 73

14.1 X-PORT Installation ................................................................................................................. 73

14.2 X-PORT DCC 120................................................................................................................... 73

14.3 X-PORT 3G-SDI .....................................................................................................................74

15. User Maintenance .................................................................................................77

15.1 Change the projector lamp . ......................................................................................................... 77

15.2 Update the projector firmware.......................................................................................................78

16. Technical Specifications ................ ................ ................ ................ ................ .........81

16.1 F35 ..................................................................................................................................81

16.2 F35 WQXGA ........................................................................................................................ 82

16.3 F35 Panorama .......................................................................................................................83

17. Environmental information......................................................................................85

17.1 Disposal information................................................................................................................. 85

17.2 RoHS compliance ...................................................................................................................85

17.3 Production address . .................................................................................................................86

2

601-0311 F35 07/07/2017

Page 7

1. Introduction

1. INTRODUCTION

Welcome

Congratulations on your purchase of a Barco F35 projector! Th e F35 projectors are part of a proud tradition of quality projectors built

for superior performance, and feature compact footprint, high performance optics and lenses, Active Stereo 3D capabilities, built-in

frame-lock synchronization and are warranted for 24/7 operation.

1.1 About this manual

General

We recommend you read this user m anual before setting up and operating your projector for the first time. Fam iliarizing yourself

with the projectors’ features a nd functions, as well as its safety a nd maintenance features, will help ensure you enjoy many years

of hassle-free projection.

Following is a brief overview of how information in the manual is organized and presented.

The content in this manual is systematized primarily by function, and then topic.

On the first page of each chapter is an overview of the chapter contents.

A menu path is expressed in the following manner: Main Menu — Sub Menu — Sub sub menu. For example, Main Menu —

Installation — Synchronization

All physical measurement units given in this manual are according to the International Standard of Units (SI units). Conversion from

this to other measureme nt units is the responsibility o f the user.

Illustrations used in the manual are for general reference only, and may differ from your product.

601-0311 F35 07/07/2017

3

Page 8

1. Introduction

4 601-0311 F35 07/07/2017

Page 9

2. SAFETY

About this chapter

Read this c hapter thoroughly before attempting to install or operate the projector.

To prevent personal injury to users or physical damage to the projector while installing and using your projector, ensure that yo u

understand and follow all safety guidelines, instructions and warnings included in this chapter and this manual.

Overview

• General Co nsiderations

• Important safety instructions

• Product safety labels

2.1 General Considerations

General safety instructions

• Before operating this equipment please read this manual thoroughly and retain it for future reference.

• All warnings on the projector and in the docum entation manuals shall be adhered to.

• All instructions for operating and use of this equipment shall be followed precisely.

• All local installation codes shall be adhered to.

2. Safety

Owner’s record

The part number and serial number are printed on a label which is stuck on the respective part. Record these numbers in the spaces

provided below. Refer to them wh enever you call upon your B arco dealer regarding this product.

Product article number

Product serial number

Dealer

General conditions for use

• Use only the cables and cords supplied with the projector o r original replacement cables. Using other cables or cords may lead

to malfunction and permanent damage to the u nit.

• Always use a grounded (3–pronged) power cord to ensure proper grounding of the unit. Neve r use 2-pronged power cords, as

this is dangerous a nd could lead to electrical shock.

• Do not attempt to open the projector unit. The projector contains no user serviceable parts. Refer all repairs to qualified per sonnel only. Make sure that n o objects enter into the

• Do not spill any liquids on the projector or into the vents or openings of the unit.

• Always remove the lens cap be fore switching on the projector. If the lens cap is not removed, it may melt due to the high energy

light emitted through the lens. Melting the lens cap may permanently damage the surface of the projection lens.

• Only place the projector on a stable surface, or mount it securely using an approved ceiling-mount.

• Always oper ate the projector according to the rotation guidelines. Operating the unit in other positions may reduce lamp life

significantly, and may lead to overheating, re

• Always allow ample airflow through the projector. Never block any of the air vents. Never cover the unit in any way while

running. Allow for sufficient distance to walls and c eilings to avoid overheating.

• Minimum safety (clearance) distance to the sides and rear of the unit is 50cm / 20” in any direction ( 15 cm/ 6” to ceiling).

• Hot air is exhausted from the rear vent. Do not place objects that are sensitive to heat nearer than 50c m / 20” to the exhaust

vent.

• The projector is designed for indoor us e only. N

• Do no t operate the projector outside its temperature and humidity specifications, as this may result in ove rheating and malfunctioning.

• Only connect the projector to signal sources and voltages as des cribed in the technical specification. Connecting to unspecified

signal sources or voltages may lead to malfunction and permanent damage of the unit.

• Wherever possible, use m ain power supply with surge protection to prevent damage to the projector caused by unscheduled

power surges.

sulting in malfunctioning.

vents and openings of the chassis.

ever operate the unit outdo ors.

601-0311 F35 07/07/2017

5

Page 10

2. Safety

• Allow lamp to cool down for at least 60 minutes before changing. USE ONLY ORIG INAL LAMPS.

• Connecting sources to a powered projector m ay result in product failure. I t is recommended that the pow er cable connector

(projector-end) or the mains power socket is accessible whilst the product is in use to enable mains power to be disconnected

or switched off when connecting source devices. This should be considered during product installation.

2.2 Important safety instructions

To prevent the risk of electrical shock

• This projector should be operated from an AC power source. Ensure that the mains voltage and capacity matches the projector

electrical ratings. If you are unable to install the A C requirements, contact your electrician. Do not defeat the purpose of the

grounding.

• Installation according to the local electrical code and regulations by qualified technical personnel only.

• A readily accessible disconnect device mu st be incorporated externally to the equipment for remov

jector cord.

• Warning: High leakage current. Earth connection essential b efore connecting supply.

• Do not allow anything to rest on the power cord. Do not locate this projector w here persons will walk on the cord.

• Do no t operate the projector w ith a damaged cord or if the projector has been dropped or damaged - until it has been examined

and approved for operation by a qualified service technician.

• Position the cord so that it will not be tripped over, pulled, or contact hot surfaces.

• If an extension cord is necessary, a cord with a current rating at least equal to that of the projector should be used. A cord rated

for less amperage than the projector may overheat.

• Never push objects of any kind into this projector through cabinet slots as they m ay touch dangerous voltage points or short

circuit parts tha t could res ult in a risk of fire or electrical shock.

• Do not expose this projector to rain or moisture.

• Do not immerse or expose this projector in water or other liquids.

• Do not spill liquid of any kind on this projector.

• Should any liquid or solid object fall into the cabinet, unplug the set and have it checked by qualified service personnel before

resuming op erations.

• Do not disassemble this projector, always take it to a trained service person w hen service or repair work is required.

• Do not use an accessory attachment whic h is not recommended by the manufacturer.

• Lightning - For added protection for this video product during a lightning storm, or when it is left unattended and unused for

long periods of time, remove all powe r from the projector. This will prevent damage to the projector due to lightning and AC

power-line surges.

al of the power to the pro-

To prevent personal injury

• Isolate electrically before replacing the lam p or lamp house. Caution: Hot lamp (house).

• Caution: High pressure lamp may explode if improperly handled. Refer servicing to qualified service personnel.

• To prevent injury and physical damage, always read this man ual and all labels on the system before inserting the lamp casing,

powering the projector o r adjusting the projector.

• To prevent injury, ens ure that the lens and all cover plates are correctly installed. See installation procedures.

• Warning: high intensity light beam. NEVER look into the lens ! High luminance could result in damage to the eye.

• Warning: extremely high brightness lamps: This projector uses extremely high brightness lamps. Never attempt to look

directly into the lens or at the lamp. If the projection distance is less than 6 meter, any person needs to be at least 4 meters

away from the projected image. Avoid close range reflection of the pr

metal, …) . When operating the projector, we strongly recommend wearing suitable safety g lasses.

• Before attempting to remove any of the projector’s covers, disconnect the projec tor power cord for removal of all power from

the projector.

• When required to remove all power from the projector, to access parts inside, always disconnect the projector power cord for

removal of all power from the projector.

• Do not place this equipment on an unstable cart, stand, or table. The product may fall, causing ser ious damage to it and

possible injury to the user.

• It is hazardous to operate without lens or shield. Lenses , shields or ultra violet screens shall be changed if they hav e become

visibly damaged to suc h an extent that their effective

• Warning: Protection from ultraviolet radiation: Do not look directly in the light beam. The lamp contained in this product is

an intense source of light and heat. One component of the light emitted from this lam p is ultraviolet light. Potential eye and skin

hazards are present when the lamp is energized due to ultraviolet radiation. Avoid unnecessary exposure. Protect yourself and

your employees by making them aware of the hazards and how to protect themselves. Protecting the skin can be accomplished

by wearing tightly woven garm ents and gloves. Protecting the eyes from UV can be accomp lished by wearing safety glasses

that are designed to provide UV protection. In addition to the UV, the visible light from the lamp is intense and should also be

considered when choosing protective eye wear.

ness is impaired. For example by cracks or deep scratches.

ojected image on any reflecting surface (such as glass,

6

601-0311 F35 07/07/2017

Page 11

2. Safety

• Mercury Vapor Warnings: Keep the following warnings in mind w hen using the projector. The lamp used in the projector

contains mercury. In case o f a lamp rupture, explosion there will be a mercury vapor emission. In order to minimize the potential

risk of inhaling mercury vapors:

- Ensure the projector is installed only in ventilated rooms.

- Replace the lamp module before the end of its operational life.

- Promptly ventilate the room after a lamp rupture, explosion has occurred, evacuate the room (particularly in case of a preg-

nant wom an).

- Seek medical attention if unusual health conditions occur after a lamp rupture, explosion, such as headache, fatigue, short-

ness of breath, chest-tightening coughing or nausea.

• Exposure to UV radiation: Some m edications are k nown to make individuals extra sensitive to UV radiation. The American

Conference of Governmen tal Industrial Hygienists (ACGIH) recommends occupational UV exposure for an-8 hour day to be

less than 0,1 micro-watts per s quare centimeters of effective UV radiation. An evaluation of the workplace is advised to assure

employees are not exposed to cumulative radiation levels exceeding these government guidelines.

WARNING: This product contains chemicals, including lead, known to the S tate of California to cause birth

defects or other reproductive harm. Recycle pro perly, do not dispose of in ordinary waste!

WARNING: Service personnel must use eye and skin protection during servicing.

To prevent fire hazard

• Do not place fl ammable or combustible m ate rials near the projector!

• Barco large screen projection products are designed and manufactured to meet the most stringent safety regulations. This

projector radiates heat on its external surfaces and from ventilation ducts during normal operation, which is both normal and

safe. Exposing flamm able or combustible materials into close proximity of this projector could result in the spontaneous ignition

of that material, resulting in a fire. For this reason, it is absolutely necessary to leave an “exclusion zone” around all external

surfaces of the projector whereby no flammable or combustible materials are present. The exclusion zone must be not less

than 40 cm (16”) for all DLP Cinema projectors. The exclusion zone on the lens side mu st be at least 5 m . Do not cover the

projector or the lens with any material while the pr ojector is in operation. Keep flammable and combustible materials away from

the projector at all times. Mount the projector in a well ventilated area away from sources of ignition and out of direct sun light.

Never expose the projector to rain or moisture. In the event of fire, use sand, CO

water on an electrical fire. Always have service performed on this projector by authorized Barco service personnel. Always

insist on genuine Barco replacement parts. Never use non-Barco replacement parts as they may degrade the safety of t his

projector.

• Slots and openings in this equipment are provided for ventilation. To ensure reliable operation of the projector and to protect

it from overheating, these openings must not be blocked or covered. The ope nings should never be blocked by placing the

projector too close to walls, or other simi

register. This p rojector should not be placed in a built-in installation or enclosure unless proper ventilation is provided.

• Projection rooms must be well ventilated or cooled in order to avoid build up of heat. It is ne cess ary to vent hot e xhaust air from

console to the outside of the building.

• Let the projector cool completely before storing. Rem ove cord from the projector when storing.

• Heat sensitive m aterials should not be placed in the path of the exhaust air or on the lamp house.

lar surface. This projector should never be placed near or over a radiator or heat

or dry powder fire extinguishers. Nev er us e

2

To prevent projector damage

• This projector has been designed for use with a specific lamp (house) type. See installation instructions for its correct type.

•Theairfilters of the projector must be cleaned or replaced on a regular basis (a "clean" booth would be monthly-minimum).

Neglecting this could res ult in disrupting the air flow inside the projector, causing overheating. O verheating may lead to the

projector shutting down during operation.

• The projector must always be installed in a manner which ensures free flow of air into its air inlets.

• In order to ensure that correct airflo

and safety requirements, it should always be operated with all of it’s covers in place.

• Slots and openings in the cabinet are provided for ventilation. To ensure reliable operation of the product and to protect it from

overheating, these openings must not be blocked or covered. The openings should never be blocked by placing the p roduct

on a bed, sofa, rug, or other similar surface. This product should never be placed near or over a radiator or heat register. The

device should not be placed in a built-in installation or enclosure unless proper ventilation is provided.

• Ensure that nothing can be spilled on, or dropped inside the projector. If this does happen, switch off and remove all power

from the projector. Do not operate the projector again until it has been checked by qualified service p ersonnel.

• Do not block the projector cooling fans or free air movement around the projector. Loose papers or other objects may not be

nearer to the projector than 10 cm (4") on any side.

• Do not use this equipment near water.

• Proper operation of the projector can only be guaranteed in table mounting. It is not permitted to use the projector in another

position. See installation procedure for correct installation. A ceiling mount will be supported in the future.

w is maintained, and that the projector com plies with Electromagnetic Com patibility (E MC)

601-0311 F35 07/07/2017

7

Page 12

2. Safety

• Special care for Laser Beams: Spec ial care should be used when DLP projectors are used in the same room as high power

laser equipment. Direct or indirect hitting of a laser beam on to the lens can severely da mage the Digital Mirror Devices

which case there is a loss of warranty.

• Never place the projector in direct sunlight. Sunlight on the lens c an severely damage the Digital Mirror Devices

case there is a loss of warranty.

• Save the original shipping carton and packing material. T hey will come in handy if y ou ever have to ship your equipment. For

maximum protection, repack your set as it was originally packed at the factory.

• Disconnect the power to the projector before cleaning. Do not use liquid cleaners or aerosol cleaners. Use a dam p cloth for

cleaning. Never use strong solvents, such as thinner or benzine, or, patrol, or abrasive cleaners, sin

cabinet. Stubborn stains may be removed with a cloth lightly dampened with m ild detergent solution.

• To ensure the highest optical performance and resolution, the projection lenses are spec ially treated with an anti-reflective

coating, therefore, avoid touching the lens. To remove dust on the lens, use a soft dry cloth. Do not use a damp cloth, detergent

solution, or thinner.

• Rated maximum ambient temperature, t

• The lamp house shall be replaced if it has become damaged o r thermally deformed.

= 35°C (95°F).

a

ce these will damage the

TM

TM

in which

On servicing

• Do not attempt to service this pr oduct yourself, as o pening or removing cov ers may expose you to dangerous voltage p otentials

and risk of electric shock.

• Refer all servicing to qualified service personnel.

• Attempts to alter the factory-set internal c ontrols or to change other control settings not specially discussed in this manual can

lead to permanent damage to the projector and cancellation of the warranty.

• Remove all power from the projector and r efer s ervicing to qualified service technicians under the following conditions:

- When the power cord or plug is damaged or frayed.

- If liquid has been spilled into the equipment.

- If the product has been expo sed to rain or water.

- If the product does not operate normally when the operating instructions are followed. Adjust only those controls that are

covered by the operating instructions since improper adjustment of the other con

require extensive work by a qualified technician to restore the product to normal operation.

- If the product has been dropped or the cabinet has been damaged.

- If the product exhibits a distinct chang e in performance, indicating a need for service.

• Replacement parts: When replacement parts ar e required, be sure the service technician has us ed original Barco replacement

parts or authorized replacement parts which have the same characteristics as the B arco original part. Unauthorized substitutions may result in degraded performance and reliability, fire, electric shock or other hazards. Unauthorized substitutions may

void warranty.

• Safety check: Upon c ompletion of any service or repairs to this projector, ask the s ervice technician to perform safety checks

to determine that the product is in proper operating condition.

• Possible explosion hazard: Always keep in mind the caution below:

trols may result in damage and will often

in

To prevent battery explosion

• Danger of explosion if battery is incorrectly installed.

• Replace only with the same or equivalent type recommended by the m anufacturer.

• For disposal of used batteries, always consult federal, state, local and provincial hazardous waste disposal rules and regulations

to ensure proper disposal.

2.3 Product safety labels

Product safety labels

Label image Label description

The Lamp House is very hot after operation. To avoid burns, let the lamp

house cool down for at least 60 minutes before proceeding to handle it.

8 601-0311 F35 07/07/2017

Page 13

Label image Label description

General Warning Hazard

Electric Voltage Haz ard

Hot Surface Hazard

UV Haza rd

2. Safety

Hazardous moving parts.

Keep away from moving fan blades.

Keep fingers and other body parts away.

601-0311 F35 07/07/2017 9

Page 14

2. Safety

10 601-0311 F35 07/07/2017

Page 15

3. Get to know the projector

3. GET TO KNOW THE PROJECTOR

About

This chapter describes the main features and components of the projector, including available acc essories.

Overview

• Introducing the F35

• Main components

• Accessories and peripherals

3.1 Introducing the F35

Superior performance for professional applications

The F35 is the ideal projector for applications that demand high level performance, reliability and functionality, with standard features

including:

• Fail safe dual UHP-lamp architecture w ith hot–swap capabilities

• Easy monitoring of projector status via LCD status screen, LED s tatus indicator, and LED lamp status indicators

• Built in smear reduction processing (SRP)

• DLP® technology for perfect colors and ultimate reliability

• Motorized lens operation (shift, zoom, focus, iris)

• Dual opto-mechanical iris optimizes brightness and contrast control

• Real time clock (RTC) for programming functions

• BrilliantColor™ technology for better color matching and display

• Compatible with the EN1X and EN4X lens ranges

• Warranted for 24/7 operation

• Minimal maintenance and low total cost of ownership (TCO)

User access levels

The projector’s software platform uses access levels to defi ne what each user can do.

There are three user access leve ls:

User level

Standard Functions that relate to set-up and adjustments for various signal sources suc h as PC’s, video

Power

Service Specialist functions related to tuning, service and repair. Service User code must be input into

Scope

equipment etc. These functions are available directly with the remote control, unless the PIN

(Personal Identity Num ber) code function is activated.

Advanced functions that relate to automation and adaptation of the projector in custom

environments. Power User code must be input into the Service menu to activate additional

functionality.

the Service menu to activate additional functionality.

Projector service (LFM)

The F 35 has no user-serviceable parts. The projector

operating hours (colorwheels) and 16000 hrs (fans). Both of these service tasks mus t only be carried out by the m anufacturer or a

manufacturer-authorized service technician. The On Screen Display (OS D) will generate a Service Reminder when a Low Frequency

Maintenance (LFM) check is required.

fans and color wheels require service or replacem ent, typically after 8000

Projector Consumables

The projector lamps have a normal lifetime of approximately 2000 running hours, though this is dependent on the lamp m ode used.

Experienced users can replace the projector lamp. See "Change the projector lamp", page 77 for details of this procedure.

The projector remote control is powered with two (2) non-rechargeable AA batteries.

CAUTION: Disposal of the projector lamp modules and remote control batteries shall be carried out properly,

and in full accordance with the relevant n ation

al legislation.

601-0311 F35 07/07/2017 11

Page 16

3. Get to know the projector

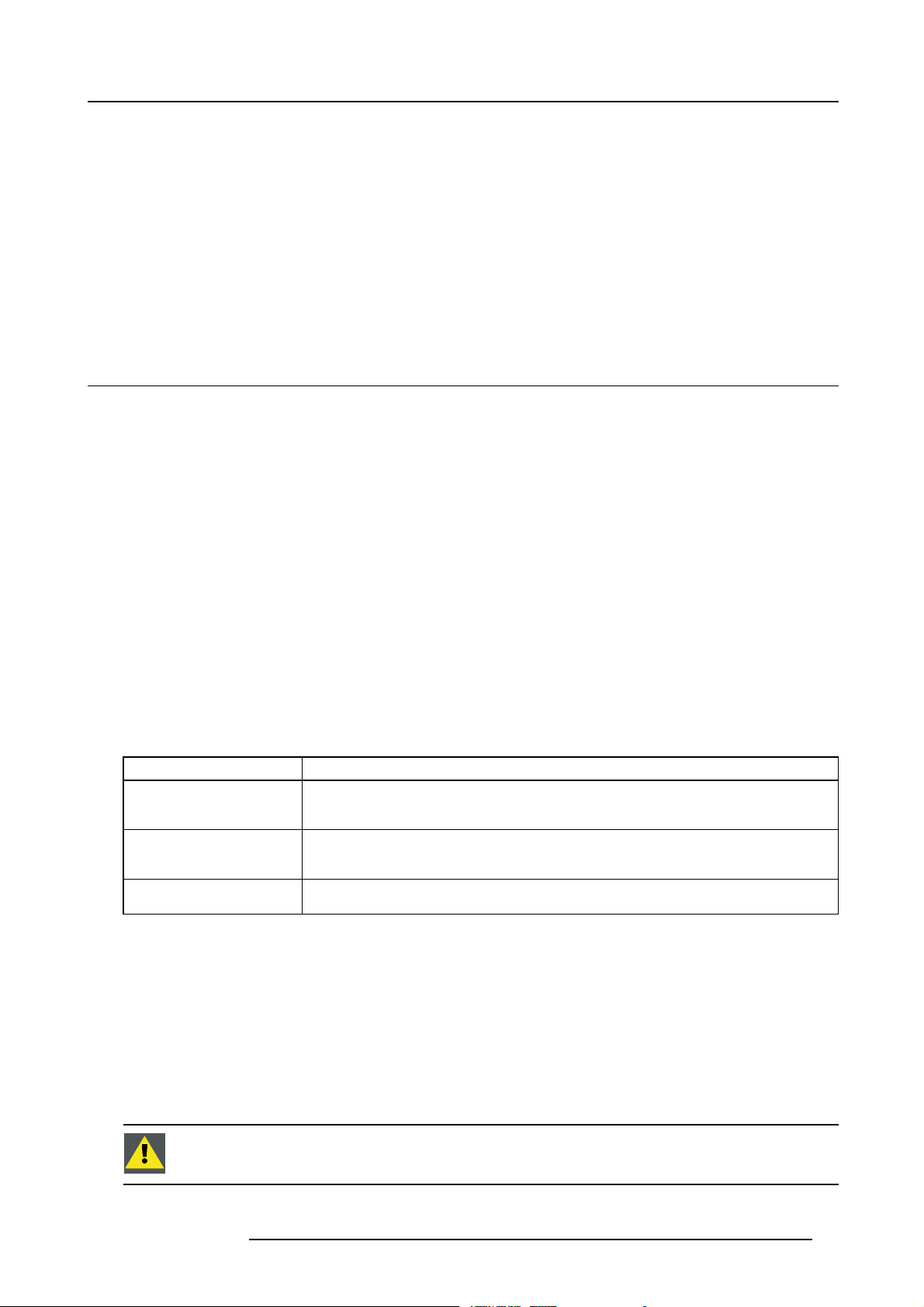

3.2 Main components

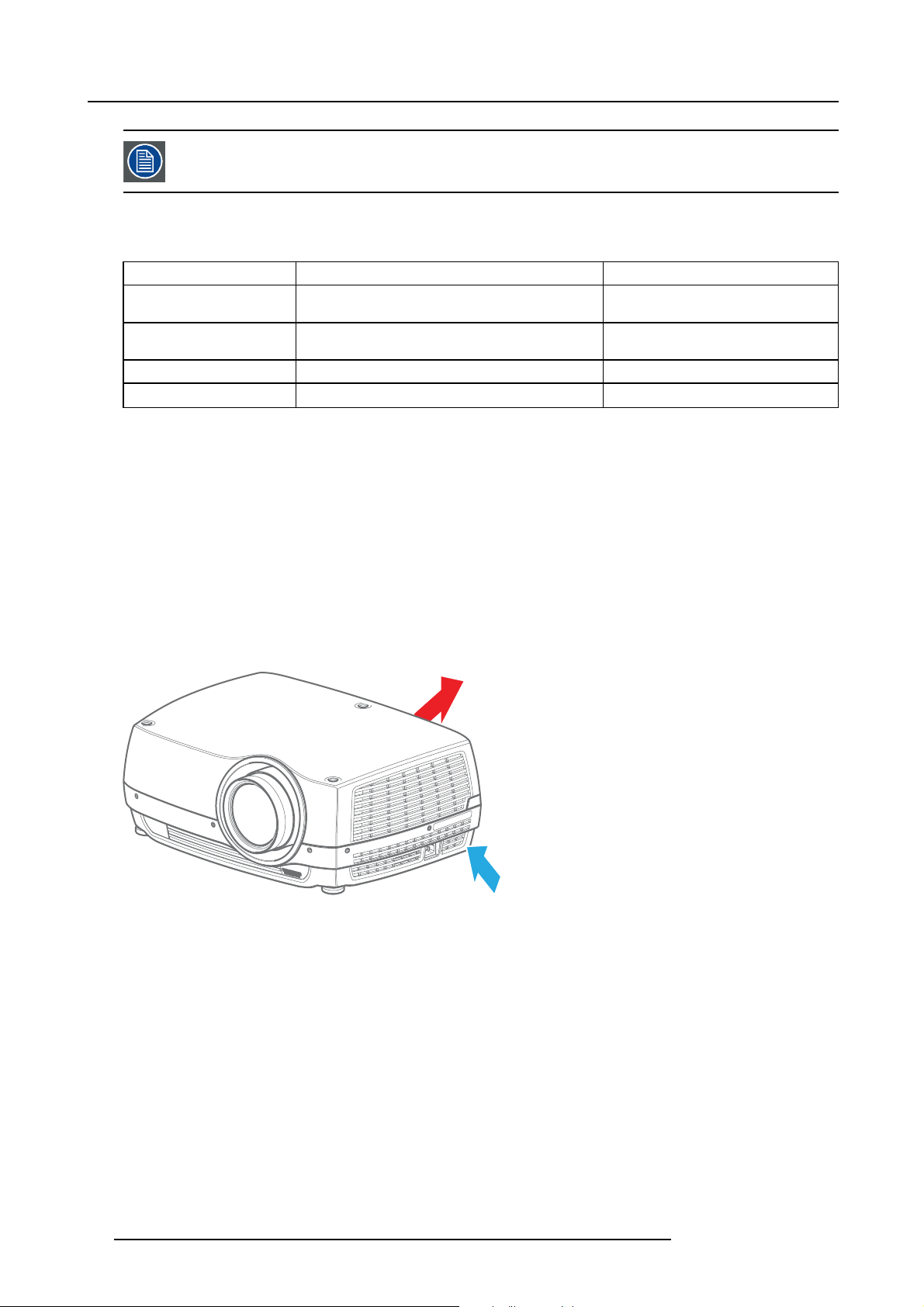

Projector components

1

2

2

Image 3-1

1 IR Receivers

2 Lens

3 Lens release button

4 Ventilation

5 Mains power input

6 Connection panel

7 Local keypad

8 LCD status screen

9 Exhaust

10 Kensington™ Lock

11 UHP lamphouse 1,2

1

5

3

4

6

7

8

9

1

10

211

10

11

11

Image 3-2

10 Ceiling mounts (M4)

11 Adjustable feet

11

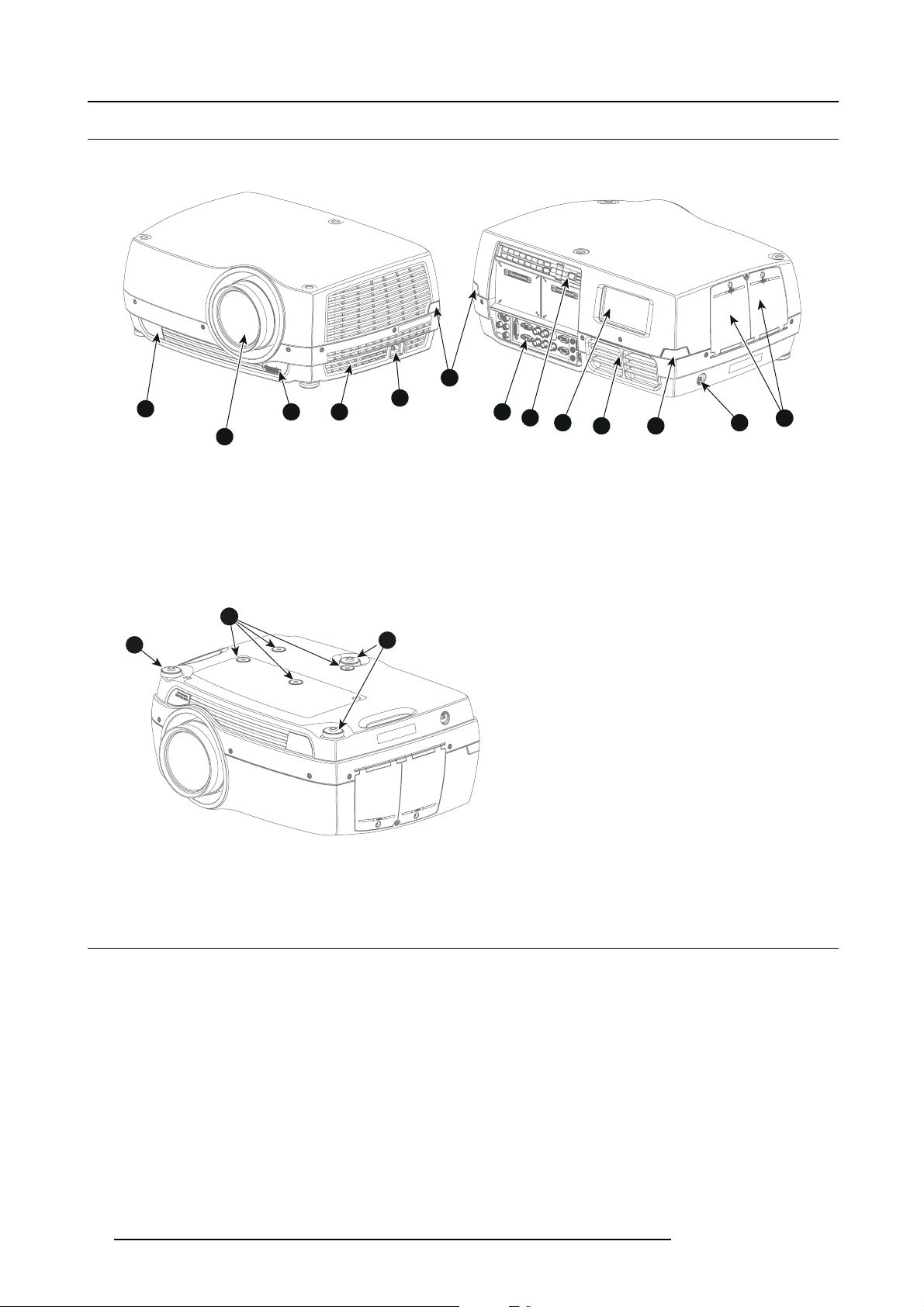

3.3 Accessories and peripherals

Exhaust air kit

Installing the exhaust air kit is recommended for longer term ceiling-mounted installations. The kit is custom designed for the F35

and works both to dir

Installation and removal of the kit is quick, and requires no specialist tools.

ect the exhaust air from the projector and to reduce the operating noise level.

12

601-0311 F35 07/07/2017

Page 17

3. Get to know the projector

Image 3-3

Item num ber Description

R9801376 Exhaust kit (white)

R9801377 Exhaust kit (black)

External multi-image processor

The Barco image processing engine range offers increased control of warp and blend (W B) operations.

Features of the WB range include:

• Camera-based AutoAlign

• Real time warp

• Support for third party camera based AutoAlign

• Barco’s patented Black Level Matching

• Sub-Pixel Le vel Matching

• User-selectable filtering

• Compatible with all p rojector makes, models and brands

Image 3-4

Item num ber Description

R9801223 WB1920 Image Processor

R9801224 WB2560 Image Processor

Cable cover

The cable cover can b e mounted on the projector to conceal the interface cables and power cord when the unit is ceiling mounted.

Image 3-5

Item num ber Description

R9801283

R9801281

Ceiling cover, pearl white

Ceiling cover, black

601-0311 F35 07/07/2017 13

Page 18

3. Get to know the projector

Projector Toolset

Projector Toolset software is Barco’s proprietary projector management software that allows you to manage your Barco projector

easily and quickly from one central location, via a LAN or RS 232 connection. Comprising various tools for brightness settings,

diagnostics, im age adjustment, picture-in-picture and image control, the Projector Toolset is an indispensable tool for efficient vis u alization management. Projector Toolset is available for Linux, Mac OS X, and Windows.

For more information or to download the Projector Toolset software and user guide, visit the Barco website.

Image 3-6

14 601-0311 F35 07/07/2017

Page 19

4. LENSES

About this chapter

This chapter details the available lenses for the F35, and their technical specifications.

The procedure for replacing a lens, shifting the lens, and adjusting zoom, focus and iris (where applicable) is also described in this

chapter.

The projector lens shift and offset matrix is give n in user manual section, "Lens shift", page 28.

Overview

• Lens range

• Lens monitoring

• Replacing a lens

• Lens shift

• Adjust z oom, fo cus and iris

4.1 Lens range

CAUTION: Alw ays remove the lens from the lens holder before moving or transporting the projector. Failure

to do this may cause damage to the lens holder and prism.

4. Lenses

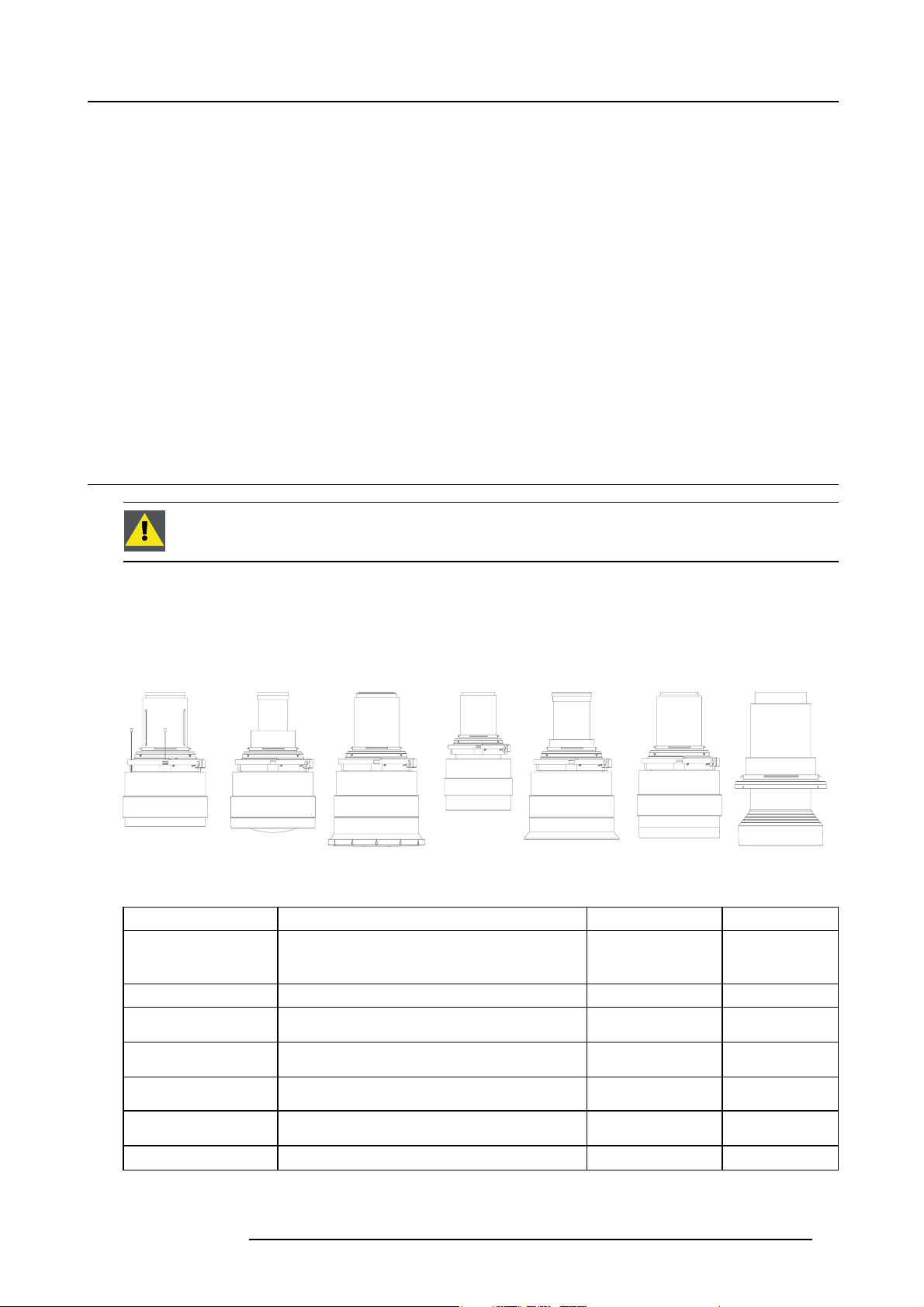

Available lenses — WUXGA

The FLD lens range is custom-engineered for WUXGA and 1080 projectors.

The electrical connection to the lens motors is via a spring probe contact (pogo) pin array on the bayonet mount.

The p rojector will automatically detect and identify the lens when it is installed. Automatic detection is not available for 3rd party

lenses.

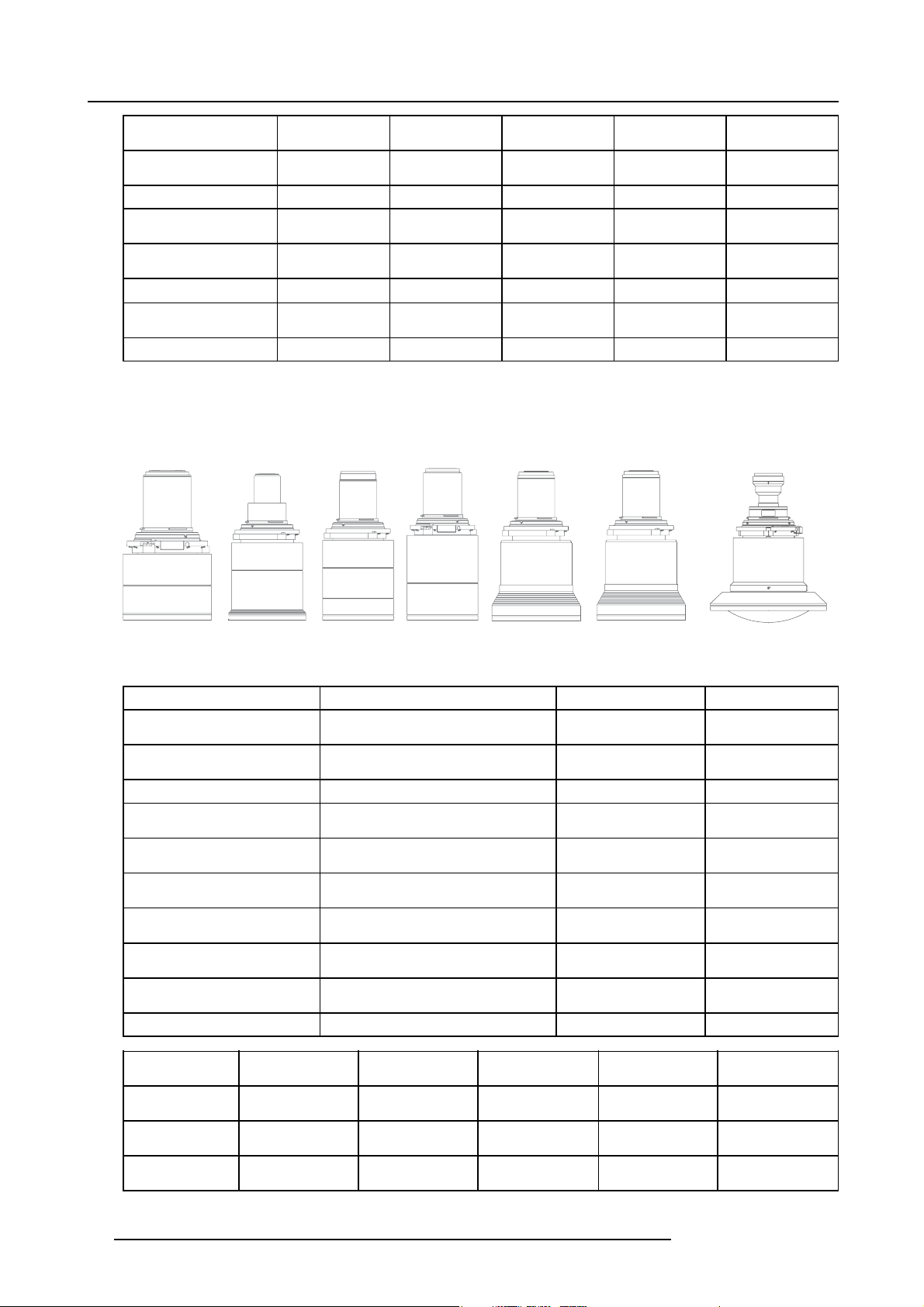

EN11 EN12 EN13 EN14 EN15 EN16 EN33

Image 4-1

Name Description Part number Weight

FLD Lens 1.6 - 2.32 : 1

(EN11)

FLD Lens 0.74 : 1 (EN12) 0.74:1 (WUXGA)

FLD Lens 1.24 - 1.6 : 1

(EN13)

FLD Lens 2.37 - 3.79 : 1

(EN14)

FLD Lens 1.16:1 (EN15) 1.16 : 1 (W UXG A) R9801225 2.4 kg

1.6-2.32 : 1 (WUXGA)

1.24 - 1.6 : 1 (WUXGA)

2.37 - 3.79 : 1 (WUXGA)

R9801214 2.2 kg

R9801218 1.9 kg

R9801228 2.6 kg

R9801209 2.5 kg

FLD Lens 3.80 - 6.50 : 1

(EN16)

FLD Lens 0.92: 1 (EN33 0.92 : 1 (W UXG A)

601-0311 F35 07/07/2017 15

3.8 - 6.5 : 1 (W UX GA) R9801249 2.5 kg

R9801227 0.9 kg

Page 20

4. Lenses

Name

FLD Lens 1.6 - 2.32 : 1

(EN11)

FLD Lens 0.74 : 1 (EN12) 2.1 Yes 2.1-6.5

FLD Lens 1.24 - 1.6 : 1

(EN13)

FLD Lens 2.37 - 3.79 : 1

(EN14)

FLD Lens 1.16:1 (EN15)

FLD Lens 3.80 - 6.50 : 1

(EN16)

FLD Lens 0.92: 1 (EN33

Working F# Iris / Iris F#

2.1-2.52 Yes 2.1-6.5 1.45 33.2-48.1 2.0-15

2.1-2.22 Yes 2.1-6.5 1.3 25.59-33.24 1.0-15

2.1-2.72 Yes 2.1-6.5 1.6 49.1-78.6 3.0-30

2.1 Yes 2.1-6.5

2.1-2.66 Yes 2.1-6.5 1.74 78.3-136.2 4.0-40

2.6 No

Zoom Ratio Focal Length

-

-

-

(mm)

16.35 0.5-5

23.98 1.5-15

19.7 1.0 — 10

Focus Range (m)

Available lenses — 4K, WUXGA, WQXGA

The FLD+ (EN4X) lens range is custom-engineered for WQXGA projectors.

The electrical connection to the lens motors is via a spring probe contact (pogo) pin array on the bayonet mount. The projector will

automatically detect and identify the lens when it is installed. Auto matic detection is not available for 3rd party lenses.

EN41

Image 4-2

Name Description Part number Weight

FLD+ Lens 1.7 - 2.5 : 1 (EN41) 1.58 - 2.33 : 1 (WUXGA) / 1.7 - 2.5 : 1

FLD+ NV Lens 1.7 - 2.5 : 1

(NV41)

FLD+ Lens 0.8 : 1 (EN42) 0.75 : 1 (WUXGA) / 0.8 : 1 (WQXGA) R9801226 2.7 kg

FLD+ Lens 1.2 - 1.7 : 1 (EN43) 1.12 - 1.58 : 1 (WUXGA) / 1.2 - 1.7 : 1

FLD+ NV Lens 1.2 - 1.7 : 1

(NV43)

FLD+ Lens 2.5 - 4.6 : 1 (EN44) 2.33 - 4.3 : 1 (WUXG A) / 2.5 - 4.6 : 1

FLD+ Lens 0.75 - 1 .13 : 1 (EN45) 0.75 - 1.13 : 1 (WUXGA) / 0.8 - 1.21 :

FLD+ Lens 0.75 - 1 .13 : 1 (EN46) 0.75 - 1.13 : 1 (WUXGA) / 0.8 - 1.21 :

FLD+ NV Lens 0.8 - 1.21 : 1

(NV46)

FLD+ Lens 0.65 : 1 (EN47) 0.61 : 1 (WUXGA) / 0.65 : 1 ( W QXG A)

Name

FLD+ Lens 1.7 -

2.5 : 1 (EN41)

FLD+ NV Lens 1.7

- 2.5 : 1 (NV41)

FLD+ Lens 0.8 : 1

(EN42)

EN42 EN43 EN44 EN45 EN46

(WQXGA)

IR Optimized, 1.58 - 2.33 : 1 (WUXGA) /

1.7-2.5: 1(WQXGA)

(WQXGA)

IR Optimized, 1.12 - 1.58 : 1 (WUXGA) /

1.2-1.7: 1(WQXGA)

(WQXGA)

1(WQXGA)

1(WQXGA)

IR Optimized, 0.75 - 1.13 : 1 (WUXGA)

/ 0.8 - 1.21 : 1 (WQXGA)

Working F# Iris / Iris F#

2.1-2.5 Yes 2.1-6.5 1.47 33.70-49.54 1.5 - 15

2.1-2.5 Yes 2.1-6.5 1.47 33.70-49.54 1.5 - 15

2.1 Yes 2.1-6.5

Zoom Ratio Focal Length

-

R9801216 2.54 kg

R9801216 2.54 kg

R9801230 2.84 kg

R9801286 2.84 kg

R9801211 3.08 kg

R9801220 3.04 kg

R9801221 3.14 kg

R9801287 3.14 kg

R9801295 5.4 kg

Focus Range (m)

(mm)

16.12 0.7 - 7

EN 47

16 601-0311 F35 07/07/2017

Page 21

4. Lenses

Name

FLD+ Lens 1.2 -

1.7 : 1 (EN43)

FLD+ NV Lens 1.2

- 1.7 : 1 (NV43)

FLD+ Lens 2.5 -

4.6 : 1 (EN44)

FLD+ Lens 0.75 -

1.13 : 1 (EN45)

FLD+ Lens 0.75 -

1.13 : 1 (EN46)

FLD+ NV Lens 0.8

-1.21: 1(NV46)

FLD+ Lens 0.65 :

1 (EN47)

Working F# Iris / Iris F#

2.4-2.7 Yes 2.4-6.5 1.42 23.95-34.02 1.5 - 15

2.4-2.7 Yes 2.4-6.5 1.42 23.95-34.02 1.5 - 15

2.1-2.93 Yes 2.1-6.5 1.85 49.52-91.60 2.5-25

2.4-3.29 Yes 2.4-6.5 1.51 15.85-23.93 5.0 - 30

2.4-3.29 Yes 2.4-6.5 1.51 15.98-23.99 0.7 - 7

2.4-3.29 Yes 2.4-6.5 1.51 15.98-23.99 0.7 - 7

2.1 Yes 2.1-6.0

Zoom Ratio Focal Length

-

(mm)

12.6 0.5 - 4.0

Focus Range (m)

4.2 Lens monitoring

Using 3rd party lenses with the F35

The F35 features an automatic lens monitoring functionality that identifies when a lens is installed or removed and automatically

opens the lens shutter and realigns the DMD.

The bayonet mount is fitted with a spring probe contact (pogo) pin array that detects standard Barco FLD/FLD+ lenses. When an

FLD/FLD+ lens is installed, the projector detects this and o pens the mechanical lens shutter and moves the DMD to the ’On’ position.

The reverse happens when a lens is removed.

Non standard or passive lenses, such as the EN33, the HR95 and 3rd party lenses, do not facilitate automatic lens monitoring. In

these instances, Lens Monitoring must be disabled and the lens s hutter manually opened and closed.

Disabling the Lens Monitor function can be done:

•ViatheOSD,Main menu — Settings — Service — Lens Monitor

• Via the RS-232 control interface

• Via the Barco GP3 Lens Monitoring app, available for download from the product w ebsite

You must have Power or Service User rights to enable or disable lens monitoring.

Once Lens Monitoring is disabled, use the SHUTTER function on the wireless remote control, local key pad or via your RS-232

control interface to manually open and close the lens shutter.

4.3 Replacing a lens

CAUTION: When changing p rojection lens, exercise great care wh en inserting or extracting the lens to pre-

vent damage to the ‘pogo’ pins in the bayonet mount.

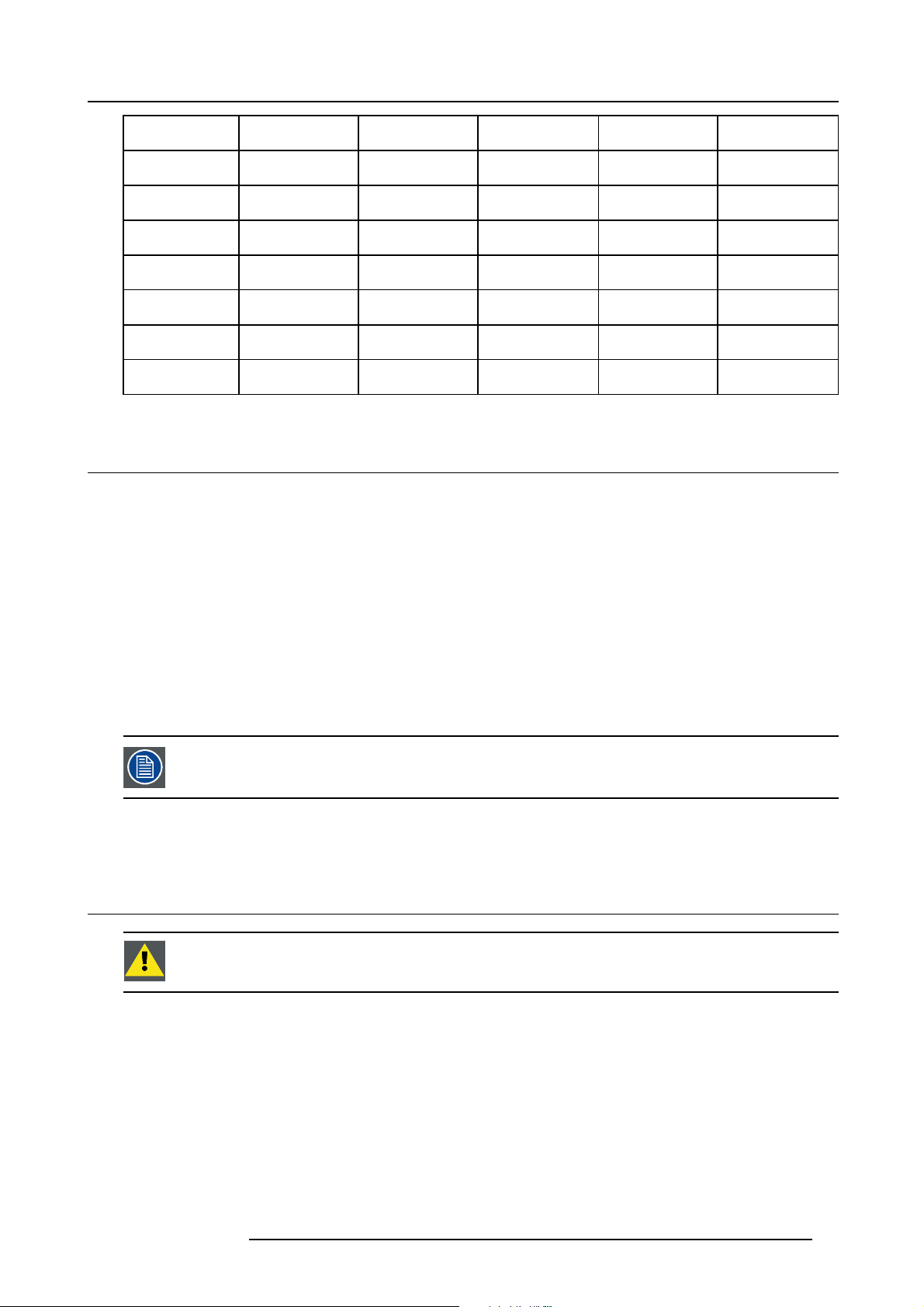

Install a lens

1. R emov e the lens m ount protection c ap on the projector.

2. Remove the lens cap at the bayonet

3. A lign the lens so that the red line on the lens bayonet is pointing towards the top of the projector cabinet.

4. Insert the lens bayonet into the lens mount and turn clockwise until the pogo pins engage and the lens clicks into position.

Caution: The lens is fragile. Do not try to force the lens into position. If there is any resistance, remove the lens from the

projector and then try again.

end of the lens.

601-0311 F35 07/07/2017

17

Page 22

4. Lenses

Image 4-3

Removealens

1. Depress and hold the lens release button.

2. Turn the lens anticlockwise until the bayonet is free of the lens mount.

3. P ull the lens straight out of the lens mount.

Note: To prevent damage to the lens or dust contamination in the projector light processor, always replace the lens bayonet

cap, lens cap and projector lens cap (if applicable) immediately after removing the lens.

Image 4-4

4.4 Lens shift

General

This section describes how to shift the lens using the projector keypad and the r emote control.

For information on the available sh ift and offset values for each lens, see "Lens shift", page 28.

All F35 lenses have limited downwards shift.

Lens shift can also be carried out via the R S232 communication interface. See the ASCII Commands Protocol for more details.

Shift the lens using the keypad

1. P ress SHIFT to activate lens shift

2. U se the arrow keys to m ove the lens up, down, left, and right.

Shift the lens using the remote control

1. P ress the SHIFT button to activate lens shift.

2. U se the navigation arrows to move the lens up, down, left and right.

4.5 Adjust zoom, focus and iris

General

Zoom controls the size of the projected image.

Focus controls the sharpness of the projected image.

18

601-0311 F35 07/07/2017

Page 23

4. Lenses

Iris controls the contrast and focus depth of the image. Dec reasing the iris stop will increase contrast and image depth, at the same

time as it decreases brightness.

Lens zoom, focus and iris adjustments are motorized. You can use the remote control, local keypad, OSD and/or RS -232 commands

to adjust the lens zoom , focus and iris positions.

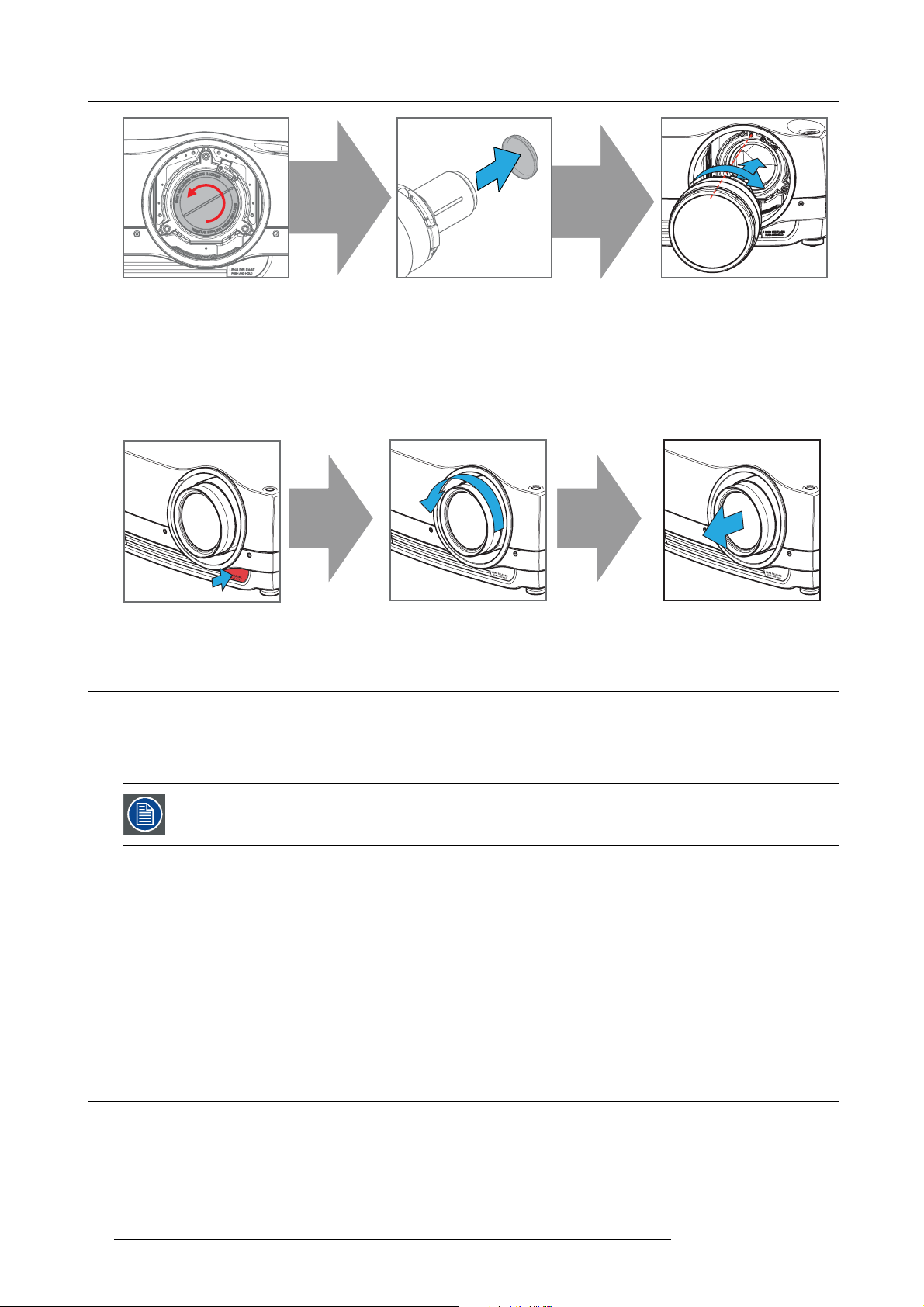

Not all lenses have zoom or iris control. The matrix b elow shows what controls are available per lens.

EN11 EN12 EN13 EN14 EN15 EN16 EN33 EN41 EN42 EN43 EN44 EN45 EN46 EN47

Iris

Zoom

Focus

For best results, lens adjustments should be done in the following order: zoom, focus and then iris (w here applicable).

✔✔✔✔✔✔

✔

✔✔✔✔✔✔✔✔✔✔✔✔✔✔

✖

✔✔

✖

✔

✖

✔✔✔✔✔✔✔

✖

✔

✖

✔✔✔✔

✖

601-0311 F35 07/07/2017

19

Page 24

4. Lenses

20 601-0311 F35 07/07/2017

Page 25

5. Installation

5. INSTALLATION

General

This chapter explains how to physically install the projector, and what considerations you should take whe n designing and s etting

up the projection installation. E ach projector installation is unique, and as such the information in this chapter is only provided as a

guideline. Likewise, any images or graphical representations show n here are for illustrative purposes only.

If you require further information and assistance during the installation process, contact a qualified projection technician or your local

support office for advice.

For information on setting up multi-channel installations, see user manual chapter "Setup a multichannel installation", page 63.

Overview

• Installing the projector

• Installation conditions

• Initial inspection

• Positioning the projector

• Mount the projector on a fl at surface

• Mount the projector on the ceiling

• Throw distance

• Lens shift

•OffsetMatrix

• Scheimpflug (Boresight) adjustment

• Scheimpflug adjustment procedure

5.1 Installing the projector

Installation sequence

1. Verify the installation area meets the physical and environmental requirements of the projector as outlined in "Installation condi-

tions", page 21.

2. Decide where the projector w ill be mounted. See "Positioning the projector", p age

the be st physical location.

3. Unpack the projector, and check that all equipment is present and in good working order. See "Initial inspection", page 23.

4. M ount the projector. The projector can be mounted on a flat surface, see "Mount the projector on a flat surface", page 24 or using

a ceiling-mount, see "Mount the projector on the ce iling", page 25.

5. C onnect the video and/or data sources. See "Connector Panel", page 38 for more information and specification s.

6. Install the projector lens. See "Replacing a lens", page 17.

7. Connect the projector to the mains powe r net. The projector will go through the initialization proc ess. Progress will be displayed

on the LCD screen.

8. O nc e the initialization progress is complete , the projector status indicator will turn to steady orange. See section "Projec tor status

indicator", page 34 for more information on the projector status indicator.

9. P ress the power button on the k eypad or remote control to start the warm up proce ss. The status indicator will turn to steady

green when the projector is warmed up and ready for use.

10.Select the display s ource. Read more about sources, in

Communication", page 33.

11.Adjust the projected image on the screen. Read chapter "Set up the pic ture", page 49 for more information.

cluding technical specifications, in the User Manual chapter "Input and

23 for guidelines and advice on determining

5.2 Installation conditions

General

This section contains important physical and env ironmental information that will help you determine the optimal installation pos ition

and conditions for your projector.

601-0311 F35 07/07/2017

21

Page 26

5. Installation

Barco projectors are manufactured according to specifi c design standards, which also include environmental

conditions. Failing to follow the terms and conditions outlined in this chapter can result in loss of product

warranty.

Environmental conditions

The table below summarizes the physical environment in which the projector may be safely operated or stored.

Environment Operating Non-Operating

Ambient Temperature @

1500 m

Ambient Temperature @

3000 m

Air cleanliness

Relative Humidity (RH) 20% to 80% RH Non-condensed 10% to 90% RH Non-Condensed

10 °C (50 °F) to 40 °C (104 °F) -20 °C (-4 °F) to 60 °C (140 °F)

10 °C (50 °F) to 35 °C (95 °F) -20 °C (-4 °F) to 60 °C (140 °F)

Clean office environment

n.a.

Mains power requirements

Projector Power requirements

F35

To protect operating personne l, the National Electrical Manufacturers Association (NEM A) recommends that the instrument panel

and cabinet be grounded. In no event shall this p rojector be operated without an adequate cabinet ground connection.

The AC supply must be installed by a qualified electrician in conformance to local codes. Hardware, wire sizes and conduit types

must comply with local codes.

100 — 240 V, 50 — 60 Hz, 16 A @ 240 V

Ventilation

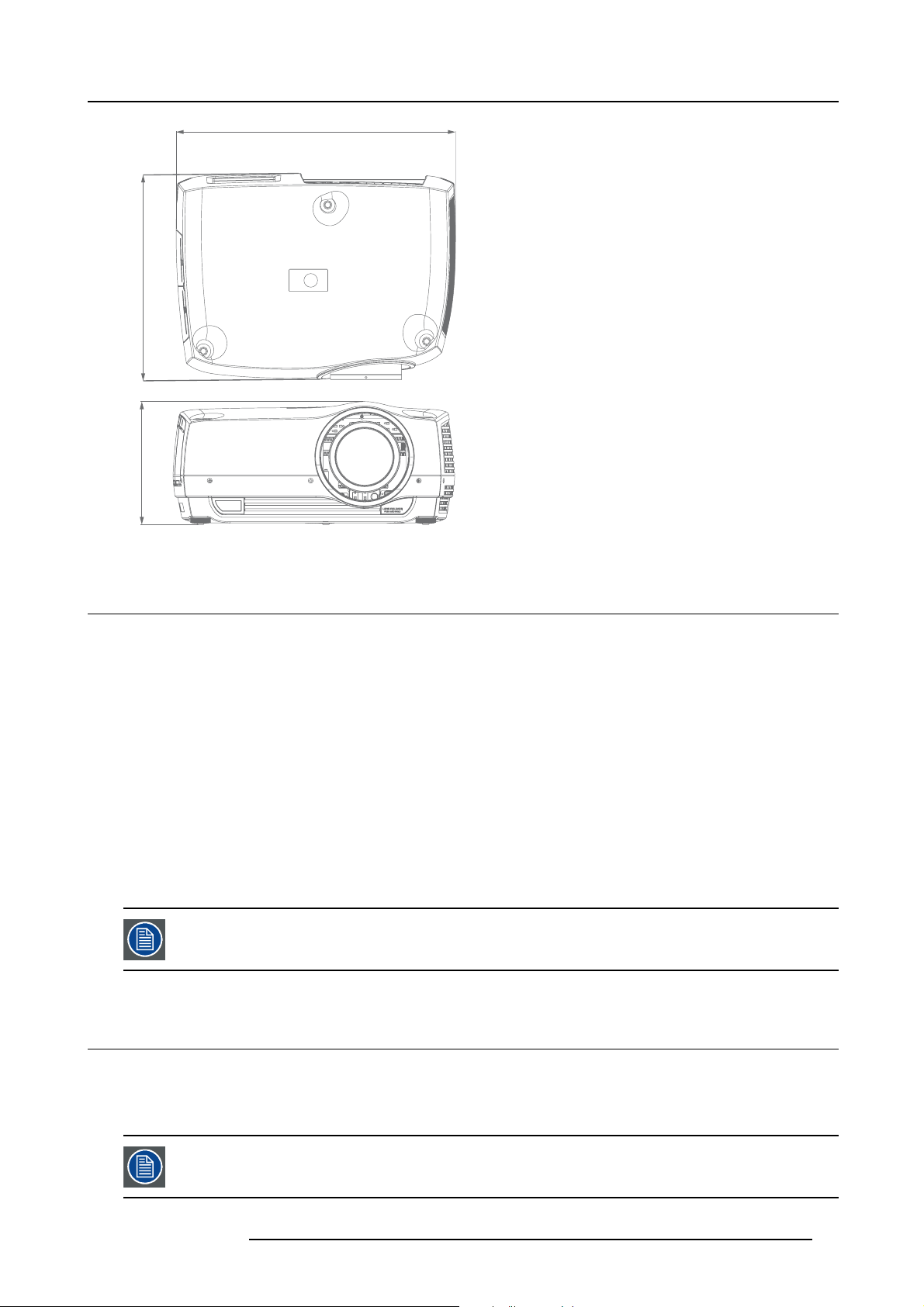

The projector is fan cooled and must be installed with sufficient space around the projector to ensure sufficient air flow.

Ventilation inlets are loc ated on the left side of the projector. Hot air is exhausted from the rear vent, see image 5-1.

Min. 50 cm

to nearest object

Min. 20 cm

Image 5-1

to nearest object

Projector weight and footprint

Weight: 13 kg (exclusive o f lens)

22

601-0311 F35 07/07/2017

Page 27

376 mm

223.4 mm

Image 5-2

5. Installation

510 mm

5.3 Initial inspection

General

Each projector is inspected and rigorously tested at our production facility to ensure that it is free from any mechan ical or electrical

defects.

Upon receipt of the projector, we recom mend that customers inspect the projector for any signs of damage that may have occurred

in transit. If damage is found, file a claim with the shipping carrier im mediately. Notify the Barco Sales and Se rvice office, or your

preferred Barco agent, of the damage as soon as possible.

Box Contents

Your projector box should contain the following:

• Projector unit

• Power cord (suitable for region)

• Quick start guide

• Safety manual

• Remote Control

The projector lens is delivered in a separate box.

5.4 P ositioning the projector

General guidelines

Proper positioning of the projector will ensure a better image on screen and may lessen the time needed to adjust and align the

image on screen.

Focus and sharpness of the image c

projection surface.

601-0311 F35 07/07/2017 23

an be adversely affected if the lens axis is not fully perpendicular to the

Page 28

5. Installation

The following guidelines can help you determine the best physical location for the projector.

• The ambient air temper ature of the room or enclosure should not be greater than 40 °C (at 1500 m altitude), and there must be

sufficient ventilation area around the projector. See section "Installation c onditions", page 21 for more detailed information.

• Use the throw r atio of the installed lens as a guideline for determ ining the projector’s physical distance from the s creen. See

"Throw distance", page 25 for more information.

• Ensure that the source signal interface and cable lengths are matched to the installation. In general:

- 3G-SDI a re long-haul interfaces and suitable for bespok e installations using relatively long cables

- DP, HDMI, DVI and VG A are short-haul interfaces using pre-assem bled cables with limited cable lengths. Using extended

cable lengths may result in reduced image quality as well as loss of control information such as EDID (Extended Display

Information Data).

• Wherever possible, the projector lens surface sh ould be positioned so that it is perfectly perpendicular to

screen. Offset (lens shift), rather than physical angling, should be used primarily to c orrect any off-center positioning.

• Installing the projector on a tilt is not recommended as it may impact negatively on lamp and image performance. If it is absolutely necessary to install the projector on an angle, ensure that it is w ithin the guidelines illustrated in image 5-3

the center of the

+ 20˚

360˚

- 20˚

Image 5-3

5.5 Mount the projector on a flat surface

Suggested procedure

1. P lace the projector on a pedestal or similar, sturdy object. Make sure that all three projector feet are in contact with the surface

of the installation area.

2. A djust the projector legs so that so that the projector is completely level. To do this, turn the collar on each foot clockwise or

anti-clockwise until the c orrect level is achieved.

Lower

Image 5-4

3. In an ideal installation, the projector lens surface is centered with and parallel to the screen. This orientation helps to ensure

optimized lens performance with minimal offset. If this position is not poss ible (such as when the projector is significantly higher

than the center of the screen), it is better to rely on offset (lens shift) rather than extra tilt. If tilt is required, mak e sure that it does

not exceed 20 degrees on the s ide-to-side axis, as illustrated in image 5-3.

Raise

24

601-0311 F35 07/07/2017

Page 29

5. Installation

5.6 Mount the projector on the ceiling

Necessary tools

Screwdriver, type dependent on screws used.

Necessary parts

• Ceiling mount or rig frame

• 4x M4 screws, us er supplied. See procedure be low for information on sizing.

Suggested procedure

1. C onfi rm that the physical c onditions of the proposed installation area c omplies with the projector installation requirements.

2. In an ideal installation, the projector lens surface is centered with and parallel to the screen. This orientation helps to ensure

optimized lens performance with minimal offset. If this position is not poss ible (such as when the projector is significantly higher

than the center of the screen), it is better to rely on offset (lens shift) rather than extra tilt. If tilt is required, mak e sure that it does

not exceed 20 degrees on the s ide-to-side axis, see "Positioning the projector", page 23.

3. T here are four (4) mount holes that are used to install the projector onto a ceiling mount or rig frame. See image 5-5.

1

Image 5-5

4. Installation screws are not supplied by the manufacturer. The length of the screw is dependent on the dimensions o f the ceiling

mount or frame you are using. The screw should not protrude more tha

Caution: Correct screw length is extremely important. Failing to observe these limitations may c ause damage to your projector.

5. Install the projector to the ceiling mount or rig frame using the four screws. Do not ov ertighten!

n 15 mm into the projector chassis.

5.7 Throw distance

Calculate the installation throw distance

Throw is the distance (D) measured from your projector lens to the screen. To calculate the throw distance for an installation, you

will need two pieces of data: the selected lens throw ratio (L) and the horizontal width (W) of the screen. For example, if the screen

width (W) is 2.4 m eters and the projector lens has a

Calculation: 2.4 x 0.99 = 2.38

The following graphs illustrate the image size (W) and projection distance (D) for each of the projector lenses.

Tolerances are typically +/- 5% due to optical (lens) variation.

throw ratio (L) of 0.99:1, then the throw distance (D) will be 2.38 meters.

601-0311 F35 07/07/2017 25

Page 30

5. Installation

Throw distance, FLD WUXGA

7.50

Image width

m

12.00

Screen diagonal

14.00

7.00

6.50

6.00

5.50

5.00

4.50

4.00

3.50

3.00

2.50

2.00

1.50

1.00

0.50

0.00

FLD Lens 0.74:1 (EN12) (0.5 - 5m)

FLD Lens 1.16:1 (EN15) (1.5 - 15m)

FLD Lens 1.24 - 1.6 : 1 (EN13) (1.0 - 15m)

FLD Lens 1.6 - 2.32 : 1 (EN11) (2.0 - 15m)

FLD Lens 2.37 - 3.79 : 1 (EN14) (3.0 - 30m)

FLD Lens 3.80 - 6.50 : 1 (EN16) (4.0 - 40 m)

11.00

10.00

9.00

8.00

7.00

6.00

5.00

4.00

3.00

2.00

1.00

0.00

13.00

12.00

11.00

10.00

9.00

8.00

6.00

5.00

4.00

3.00

2.00

1.00

0.00

Image 5-6

Projection distance

26 601-0311 F35 07/07/2017

Page 31

Throw distance, FLD+ WQXGA

Image height

7.50

5. Installation

Image width

m

12.00

Screen diagonal

14.00

7.00

6.50

6.00

5.50

5.00

4.50

4.00

3.50

3.00

2.50

2.00

FLD+ Lens 0.65 : 1 (EN47) (0.5 - 4m)

1.50

1.00

0.50

0.00

FLD+ Lens 0.8 : 1 (EN42) (0.7 - 7m)

FLD+ Lens 0.8 - 1.21 : 1 (EN46) (0.7 - 7m)

FLD+ Lens 0.8 - 1.21 : 1 (EN45) (5 - 30m)

FLD+ Lens 1.2 - 1.7 : 1 (EN43) (1.5 - 15m)

FLD+ Lens 1.7 - 2.5 : 1 (EN41) (1.5 - 15m)

FLD+ Lens 2.5 - 4.6 : 1 (EN44) (2.5 - 25 m)

11.00

10.00

9.00

8.00

7.00

6.00

5.00

4.00

3.00

2.00

1.00

0.00

13.00

12.00

11.00

10.00

9.00

8.00

6.00

5.00

4.00

3.00

2.00

1.00

0.00

Image 5-7

Projection distance

601-0311 F35 07/07/2017 27

Page 32

5. Installation

Throw distance, FLD+ WUXGA

7.50

Image width

m

12.00

Screen diagonal

14.00

7.00

6.50

6.00

5.50

5.00

4.50

4.00

3.50

3.00

2.50

2.00

1.50

1.00

0.50

0.00

FLD+ Lens 0.65 : 1 (WUXGA) (EN47) (0.5 - 4m)

FLD+ Lens 0.75 - 1.13 : 1 (WUXGA) (EN46) (0.7 - 7m)

FLD+ Lens 0.75 : 1 (WUXGA) (EN42) (0.7 - 7m)

FLD+ Lens 0.75 - 1.13 : 1 (WUXGA) (EN45) (5 - 30m)

FLD+ Lens 1.12 - 1.58 : 1 (WUXGA) (EN43) (1.5 - 15m)

FLD+ Lens 1.58 - 2.33 : 1 (WUXGA) (EN41) (1.5 - 15m)

FLD+ Lens 2.33 - 4.3 : 1 (WUXGA) (EN44) (2.5 - 25 m)

11.00

10.00

9.00

8.00

7.00

6.00

5.00

4.00

3.00

2.00

1.00

0.00

13.00

12.00

11.00

10.00

9.00

8.00

6.00

5.00

4.00

3.00

2.00

1.00

0.00

Image 5-8

Projection distance

5.8 Lens shift

Adjusting the horizontal and vertical position of the i mage

Ideally in any ins tallation the projector is po sitioned totally perpendicular to the screen to ensure a wholly rectangular image. However, physical limitations mean th

One way to correct this is by adjusting, or shifting, the vertical or horizontal position of the image.

The amount of available vertical or horizontal offset is dependent on what type of lens is installed in the projector and the projector

resolution, see image 5-9 which illustrates the vertical offset values of an image. The same theory applies to horizontal shift. The

middle of the image is the optical a xis (0%), i.e. no shift. 100% shift equals half of t he image height.

at this is not always possible to do and the result is a trapezoidal effect upon the displayed image.

W

-100%

H

Image 5-9

On axis (0% shift)

0%

+100%

Front elevation Side elevation

On axis (0% shift)

0% Lens Shift e quals on axis (i.e. no shift). 100% Lens Shift equa l s half of image height / width.

28 601-0311 F35 07/07/2017

Page 33

5. Installation

Vertical lens shift formula

Vertical shift = Screen Height x (Max. Lens S hift Vertical (%) ÷ 2) ÷ 100

If the screen is 1.2 m eters high and the vertical lens offset value is +120% to +150% (min/max), then the v ertical lens shift will be

75% (0.9 meters). T his means that the (centre of the) image can be shifted up or down a maximum of 90 centimeters.

Calculation: 1.2 * (150 ÷ 2 = 75) 75 ÷ 100 = 0.9

Horizontal lens shift formula

Horizontal shift = Screen Width x (Max Lens Offset Horizontal (%) ÷ 2) ÷ 100

If the screen is 4.2 meters wide and the horizontal lens m axim um offset value is +42% , then the horizontal lens shift will be 21%

(0.89 meters). This m eans that the (centre of the) image can be shifted left or right by a maximum of 89

Calculation: 4.2 * (42 ÷ 2 = 21) 21 ÷ 100 = .882

1

centimeters.

Motorized lens shift

The F35 lens shift function is fully motorized and can be controlled via the projector keypad, wireless remote c ontrol, or wired control

interface e.g. RS-232.

To activate lens shift, press the SHIF T button on the keypad or remote control. Use the corresponding arrows to m ove the lens up,

down, right and left.

For information on using the RS-232 or LA N control interfaces, please refer to the relevant ASCII Commands Protocol available for

download at www.barco.com.

5.9 Offset Matrix

F35 offset matrix

EN11 EN12 EN13 EN14 EN15 EN16 EN33

+/- (%) +/- (%) +/- (%) +/- (%) +/- (%) +/- (%) +/- (%)

1080

Vertical 150 20 150 150 150 150 84

Horizontal 68 6 68 68 68 68 32

SXGA+

Vertical 120 10 120 120 120 120 60

Horizontal 80 6 80 80 80 80 38

WUXGA

Vertical 134 8 134 134 134 134 66

Horizontal 68 4 68 68 68 68 30

EN41 EN42 EN43 EN44 EN45 E N46 EN47

+/- (%) +/- (%) +/- (%) +/- (%) +/- (%) +/- (%) +/- (%)

1080

Vertical 146 0 114 146 50 50 72

Horizontal 60 0 48 60 18 18 28

SXGA+

Vertical 106 0 84 106 30 30 50

Horizontal 70 0 52 70 20 20 30

WUXGA

Vertical 120 0 100 120 34 34 60

Horizontal 60 0 44 60 14 14 26

Panorama

Vertical 212 52 21 212 130 130 164

1. rounded up to two decimal points

601-0311 F35 07/07/2017 29

Page 34

5. Installation

EN41 EN42 EN43 EN44 EN45 E N46 EN47

+/- (%) +/- (%) +/- (%) +/- (%) +/- (%) +/- (%) +/- (%)

Horizontal 78 10 78 78 32 32 42

WQXGA

Vertical 146 0 116 144 50 50 80

Horizontal 70 0 56 70 24 24 36

5.10 Scheimpflug (Boresight) adjustment

What is Scheimpflug?

The lens holder has to be adjusted s o that the “sharp focus plane” of the projected image falls toge

(Fp1→Fp2). This is achieved by changing the distance between the DMD plane and the lens plane (Lp1→Lp2). The closer the lens

plane comes to the DMD plane the further the sharp focus plane will be. It can occur that you won’t be able to get a complete focused

image on the screen due to a t ilt (or swing) of the lens plane with respect to the DMD plane. Th

law. To solve this the lens plane must be placed parallel with the DMD plane. This can be achieved by turning the lens holder to

remove the tilt (or swing) between lens plane and DMD plane (Lp3→Lp4).

ther with the plane of the screen

is is also known as Scheimpflug’s

Lp1

Lp2

DMD

Image 5-10

Scheimpflug principle

Scheimpflug principle

The "plane of sharp focus" can be changed so that any plane can be brought into sharp focus. W hen the DMD plane

and lens plane are parallel, the plane of sharp focus will also be parallel to these two planes. If, however, the lens

plane is tilted with r espect to the DMD plane, the plane of sharp focus will also be tilted according to geometrical and

optical properties. The DMD plane, the principal lens plane and the sharp focus plane will intersect in a line be low the

projector for downward lens tilt.

SCREEN

Fp1

Fp2

DMD

Lp3

Lp4

(Scheimpflug)

Fp4

Fp3

SCREEN

Scheimpflug adjustment points

Scheimpflug adjustment points are located on the lens mount. The F35 has three (3) set screws and three (3) adjustment screws.

When to apply Scheimpflug?

Scheimpflug correction procedures may only be carried out by suitably trained and experienced tech nicians.

A Scheimpflug correction should only be applied w h en the overall focus of the projected image is not equally sharp (for example, if the

projector is NOT in parallel with the screen or as a result of a previously misaligned Scheimpfl ug). Be aware that the consequence of

applying Scheim pflug correction upon a screen not in parallel with the projector is that the projected image differs from the rectangle

shaped image. In other words “distortion” of the projected image occurs. Masking will be required to solve the distortion.

The disadvantage of Masking

projection screen and use the SHIFT functionality of the Lens Holder to match the projected image with the projection screen. If the

SHIFT range is not sufficient then the projector can be tilted and Scheimpflug can be applied.

30

is loss of content. Therefore it is strongly recommended to place the projector in parallel with the

601-0311 F35 07/07/2017

Page 35

5. Installation

5.11 Scheimpflug adjustment procedure

Necessary tools

• Scheimpflug tool, size 4 hex

• Projector screen

• Focus plane / Scheimpflug test pattern

Preparation