Page 1

Cooling liquid refill

Installation manual

For XLM, DP90 and DP100

R59770032/00

24/08/2006

Page 2

Barco nv Events

aan 5, B-8520 Kuurne

Noordl

Phone: +32 56.36.89.70

Fax: +32 56.36.88.24

sales.events@barco.com

E-mail:

Visit us at the web: www.barco.com

PrintedinBelgium

Page 3

1. About the cooling circuit and cooling liquid

1. ABOUT THE COOLING CIRCUIT AND COOLING

LIQUID

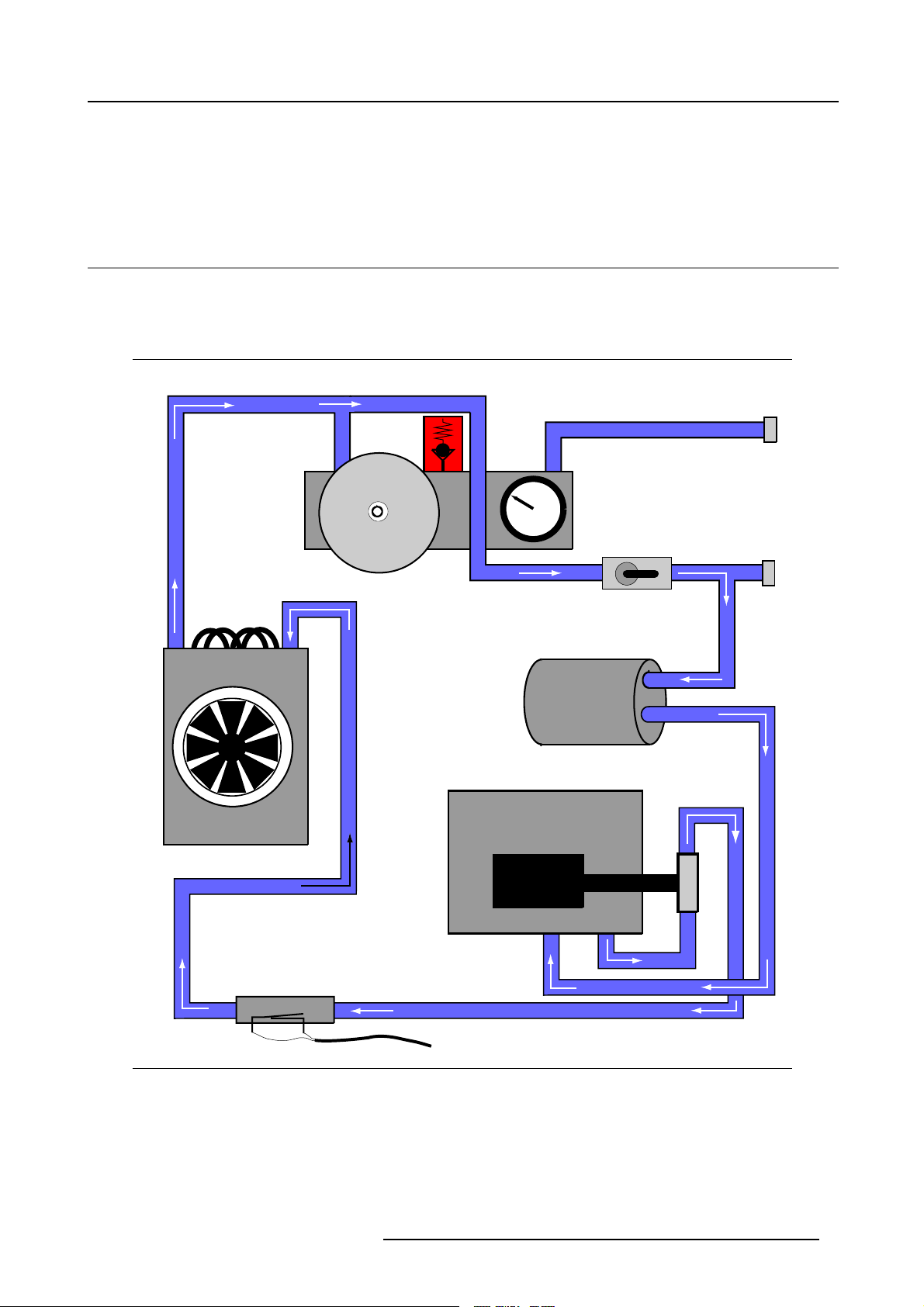

1.1 Overview of the Cooling circuit

Cooling circuit flow and parts

During operation, a closed loop of flexible tubing circulates cooling liquid to critical components, such as the engine and to the

integrator rod entry. The cooling circuit flow, during operation, is represented in diagram b elow:

The liquid cooling loop

Pressure relief

valve (3 Bar)

Manometer

Outlet

Heat

Exchanger

Waterflow Sensor

Expansion Vat

Engine

Pump

Vane

Inlet

Light Pipe

entry

to SMPS Control

Image 1-1

Cooling circuit flow

Cooling liquid Info

Over time the coo

To maintain sound cooling properties, we advise ANNUAL replacement o f the cooling liquid.

R59770032 COOLING LIQUID REFILL 24/08/2006

ling liquid may show deterioration and hence less effective cooling characteristics.

1

Page 4

1. About the cooling circuit and cooling liquid

BLUE ANTIFREEZE

DILUTED 1,2 ETHANEDIOL

(1/3 ETHANEDIOL-2/3 DEMI WATER)

HARMFUL

Image 1-2

Safety label

Before ope ning the bottles with fresh cooling liquid, attentively read the safety instruction mentioned on the bottle label and listed

below.

Handling the cooling liquid

NOT FOR HOUSEHOLD USE

KEEP OUT OF REACH OF CHILDREN. HARMFUL

BY ORAL INTAKE. AVOID EXPOSURE TO

PREGNANT WOMEN. AVOID CONTACT WITH

EYES AND SKIN

BARCO KUURNE BELGIUM

R821679

1000ml

• Avoid contact of the liquid with Eyes, Skin and Clothing.

• Avoid inhale of the no xious fumes.

• Conserve the product in the original package a nd on a good ventila ted room.

Personal protection rules

• Handle the cooling liquid in a good ventilated room.

• Under no circumstances eat, drink and smoke while handling the liquid.

• Wear gloves (Butylrubber, PVC....) and Goggles.

• Wear suitable protection clothing.

1.2 Preparation of the projector

What has to be done?

1. Switch Off the projector. (see owners or installation manual of the projector)

2. Removethesidecover.

3. Remove the lamp unit to access the cooling liquid In- and Outlet.

4. Remove the screw cap on the valve of the pressure vat and press the air release valve to release the expansion vat pressure.

Image 1-3

Expansion vat pressure release

5. It is advisable to fill the tube of the pump s uct ion side with liquid prior to start-up. Proceed as follows:

2

R59770032 COOLING LIQUID REFILL 24/08/2006

Page 5

1. About the cooling circuit and cooling liquid

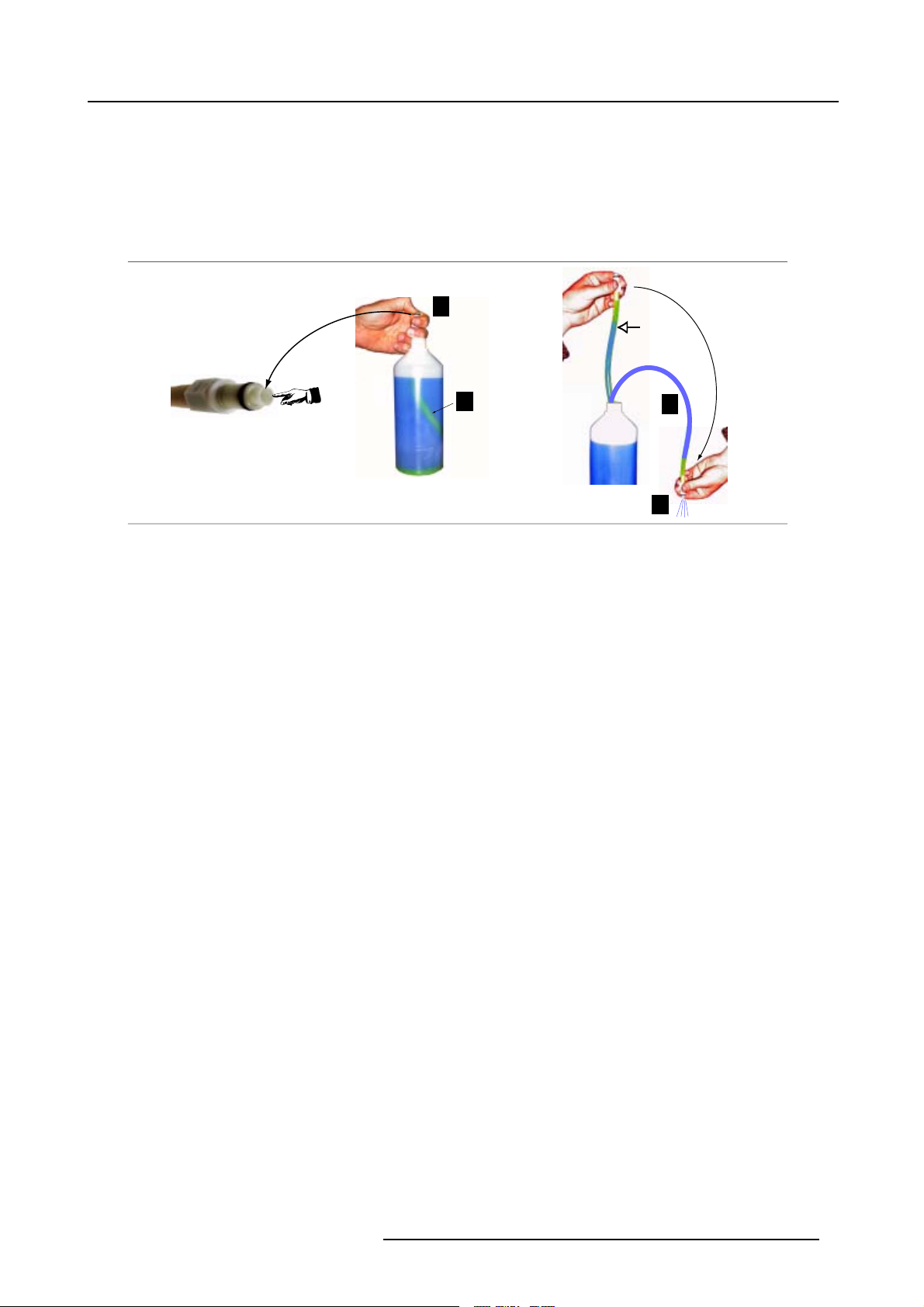

- Immerse the inlet tube e nd without fitting as far as possible into the bottle with fresh cooling liquid (1).

- Open the fitting by pressing-in valve mechanism (2) to allow filling the immersed tubing with liquid.

- Release valve to trap the liquid in the tube.

- Drop the fitting below the liquid level (3).

- Redo valve opening in fitting by pressing-in valve mechanism and allow the liquid to fill the tube (4).

- Release valve mechanism once all air is expelled.

- Remove the inlet tube out of bottle.

The liquid cooling loop - Filling the Inlet tubing

2

Valved Straight-Through

Fitting

1

Image 1-4

Filling the inlet tubing

6. Proceed with liquid cooling replacement or liquid cooling refilling.

3

4

R59770032 COOLING LIQUID REFILL 24/08/2006

3

Page 6

1. About the cooling circuit and cooling liquid

4 R59770032 COOLING LIQUID REFILL 24/08/2006

Page 7

2. Replacement of the cooling liquid

2. REPLACEMENT OF THE COOLING LIQUID

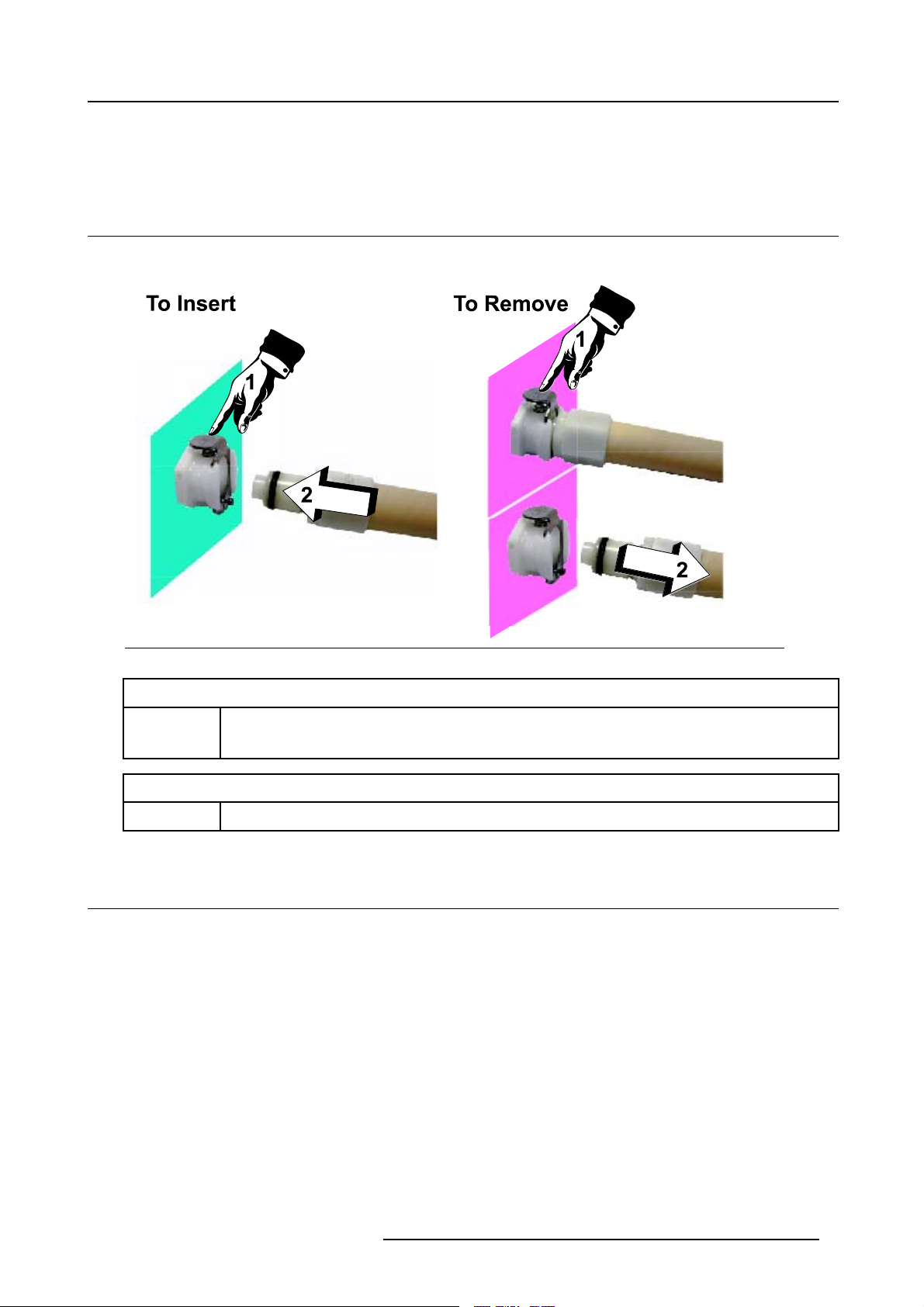

2.1 Insertion/Removing valved fitting

How to handle

Image 2-1

Insertion/Removing hose connectors

Insertion

To avoid damage to the connector seal, always depress connector tab (1) prior to inserting (2).

This prevents damage caused by forcing the gask

Removing

Depress connector tab (1) and remove the valved fitting (2).

2.2 Cooling liquid replacement

How to replace

1. CLOSE THE VANE.

et end into a closed connector. Listen for a “click”.

R59770032 COOLING LIQUID REFILL 24/08/2006

5

Page 8

2. Replacement of the cooling liquid

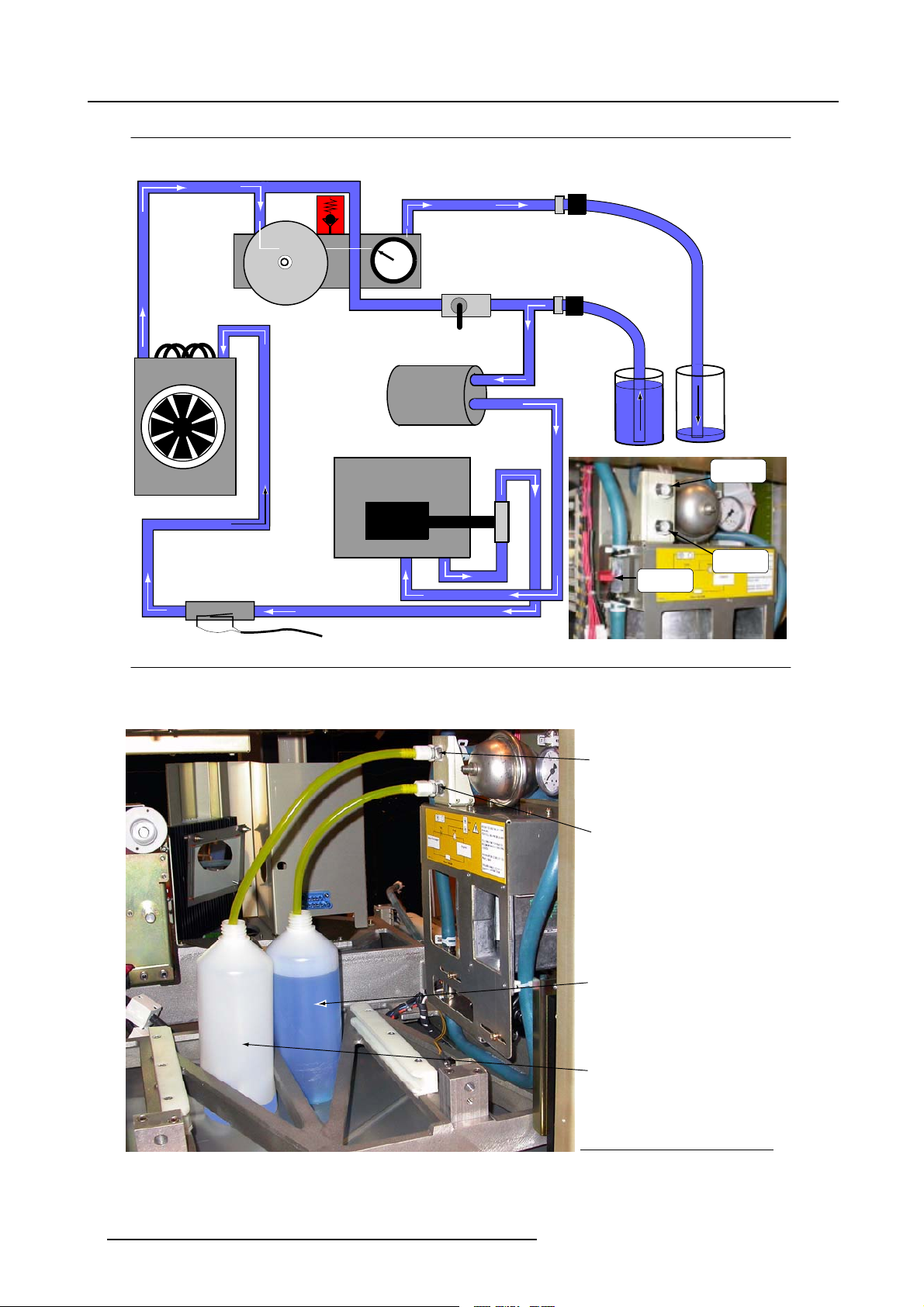

The liquid cooling loop - Replacement of liquid

Heat

Exchanger

Waterflow Sensor

Expansion Vat

Engine

Pressure relief

valve (3 Bar)

Pump

Manometer

Vane

Light Pipe

entry

Outlet

Inlet

Outlet

Inlet

Vane

Image 2-2

Replacement of the cooling liquid (Principle)

to SMPS Control

Outlet

Inlet

Bottle filled with fresh

cooling liquid

Bottle filled with a few

cooling liquid

Image 2-3

Replacement of the cooling liquid (in practice)

6 R59770032 COOLING LIQUID REFILL 24/08/2006

Page 9

2. Replacement of the cooling liquid

2. Push the valvedfittingo f the filled tube into theInlet’IN’ of the cooling circuit. Ensure the loose end of thetuberemains immersed

in the liquid.

3. First, immerse the loose end of the other tube into the a bottle filled with a little liquid, to prevent the inlet tube from draining, and

next push the valved fitting into the Outlet ’OUT’ of the cooling circuit.

4. Switch on the projector. After projector boot-up procedure, the internal pump will automatically start sucking-up the fresh liquid

supply and expelling aged liquid into the empty bottle.

5. Timely switch Off the projector to prevent the fresh liquid level dropping below the free tube inlet. This again to avoid unwanted

air being sucked into the cooling loop.

6. Continue with the procedure for expelling unwanted air.

2.3 Expelling of any unwanted air

Expelling of any unwanted air

1. Close the vane, if not yet closed.

2. Put the free tube inlet of the tube connected to the ’OUT’ outlet into the remaining fresh liquid.

The liquid cooling loop - Expelling air bubbles

Heat

Exchanger

Waterflow Sensor

Expansion Vat

Engine

Pressure relief

valve (3 Bar)

Pump

Manometer

Vane

Outlet

Inlet

Light Pipe

entry

to SMPS Control

Image 2-4

Unwanted bubbles expelling (principle)

R59770032 COOLING LIQUID REFILL 24/08/2006 7

Page 10

2. Replacement of the cooling liquid

Outlet

Inlet

Bottle filled with fresh

cooling liquid

Image 2-5

Unwanted bubbles expelling (in practice)

3. Switch On the projector. Via circulation any unwanted air bubbles will be expelled.

Tip: Let circulate for 10 minutes, opening and closing the vane at intervals of 2–minutes (This expels any accumulated air

in and around the vane).

4. Switch Off the projector.

5. Check the transparent inspection tube. No air should be present in this tube.

Transparant

Inspection

Tube

Image 2-6

Transparent tube

6. Disconnect tubes from In- and Outlet cooling loop.

Note: Removing the tube fittings from the In- Outlet of the cooling loop brings about liquid spilling. Always clean spilled liquid.

7. OPEN THE VANE.

8

R59770032 COOLING LIQUID REFILL 24/08/2006

Page 11

8. Pressure cooling loop to 1 Bar, using appropriate air pump and adapter.

Image 2-7

Pressurizing expansion vat

2. Replacement of the cooling liquid

OK

R59770032 COOLING LIQUID REFILL 24/08/2006 9

Page 12

2. Replacement of the cooling liquid

10 R59770032 COOLING LIQUID REFILL 24/08/2006

Page 13

3. Liquid Cooling Refilling, expelling air

3. LIQUID COOLING REFILLING, EXPELLING AIR

3.1 Refilling, expelling air

When?

Minor drops in pressure over time are to be expected. Once the minimum pressure of 0.5 bar is reached, proceed with refilling

procedure.

Max

Min

Image 3-1

Manometer read out

Procedure to follow

• Prepare the projector ("Preparation of the projector", page 2 ).

• Expel the unwanted air in the cooling circuit ("Expelling of any unwanted air", page 7 ).

• Pressure cooling loop to maximum 1 bar, using ap propriate air pump and adapter

OK

R59770032 COOLING LIQUID REFILL 24/08/2006

11

Loading...

Loading...