Page 1

DP2K-23B

R59770495/00

30/04/2010

Installation manual

Page 2

Barco Inc. Media and Entertainment Division

11101 Trade Center Drive, Rancho Cordova, California 95670, USA

Phone: +1 916 859-2500

Fax: +1 916 859-2515

E-mail: folsomsales@barco.com

Visit us at the web: www.barco.com

Barco nv Media & Entertainment Division

Noordlaan 5, B-8520 Kuurne

Phone: +32 56.36.82.11

Fax: +32 56.36.883.86

E-mail: sales.events@barco.com

Visit us at the web: www.barco.com

Printed in Belgium

Page 3

Changes

Barco provides this manual ’as is’ without warranty of any kind, either expressed or implied, including but not limited to the implied warranties or merchantability and fitness for a particular purpose. Barco m ay make improvements and/or changes to the product(s) and/or the

program(s) desc ribed in this publication at any time without n otice.

This publication could contain technical inaccuracies or typographical errors. Changes are periodically made to the information in this

publication; these changes are incorporated in new editions of this publication.

Copyright ©

All rights reserved. No part of this document m ay be copied, re produced or translated. It shall not other

stored in a retrieval system without the prior written consent of Barco.

wise be recorded, transmitted or

Disposal Information

This equipment has required the extraction and use of natural resources for its production. It may contain hazardous sub stances for health

and environment. In order to avoid the d issemination of those substances in the environment and to diminish the pr essure on natural

resources, we encourage you to use the appropriate take-back systems. T hose systems will reuse or recycle most of the materials of your

end of life equipment in a sound way.

The crossed-out wheeled bin symbol invites you to use those systems. If you need more information on the collection, reuse and recycling

systems, please contact your local or regional waste administrator. You can also contact us for more information on the env ironmental

performances of our products.

EN55022/CISPR22 Class A ITE (Information Technology Equipment)

Class A ITE is a category of all other ITE which satisfies the class A

be restricted in its sale but the following warning shall be included in the instructions for use:

Warning : This is a class A product. In a domestic env ironment this product m ay cause radio interference in which case the user may be

required t o take adequate measures.

ITE limits but not the class B ITE limits. Such equipment should not

Federal Communications Commission (FCC Statement)

This equipment has been tested and found to comply with the limits for a class A digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide r easonable protection against harmful interference when the equipm ent is operated in a commercial

environment. This equipment generates, uses, and can radiate radio f requency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area may

cause harmful interference, in which case the user will be responsible for correcting any interference at his own ex pense

GNU-GPL code

If you would like a copy of the GPL source code contained in this product shipped to you on CD, please contact Barco. The cost of preparing

and mailing a CD will be charged.

Guarantee and Compensation

Barco provides a guarantee relating to perf

must immediately inspect all delivered goods for damage incurred during transport, as well as for material and manufacturing faults Barco

must be informed immediately in writing of any complaints.

The period of guarantee begins on the date of transfer of risks, in the c ase of special systems and software on the date of commissioning,

at latest 30 days after the transfer of risks. In the event of justified notice of com plaint, Barco can repair the fault or provide a replacement

at its own discretion within an appr opriate period. If this measure proves to be impossible or uns uccessful, the purchaser can demand a

reduction in the purchase price or cancellation of the c ontract. All other claims, in particular tho se relating to compensation for direct or

indirect damage, and also da mage attributed to the operation o f software as well as to other services provided by Barco, being a component

of the system or independent service, will be deemed invalid provided the damage is not proven to be attributed to the absence of properties

guaranteed in writing or due to the intent or gross negligence or part of Barco.

If the purchaser or a third party carries out modifications or repairs o n goods delivered by Barco, or if the goods ar e handled incorrectly,

in particular if the systems are com missioned operated incorrectly or if, after the transfer of risks, the goods are subject to influenc es not

agreed upon in the contract, all guarantee claims of the purchaser will be rendered invalid. Not included in the guarantee coverage are

system failures which are attributed to programs or special electronic circuitry provided by the purchaser, e.g. interfaces. Normal wear as

well as normal maintenance a re not subject to the guarantee provided by Barco either.

ect manufacturing as part of the legally stipulated terms of guarantee. On receipt, the purchaser

Page 4

The environmental conditions as well as the servicing and maintenance regulations specified in the this manual must be complied with by

the customer.

Trademarks

Brand and product names mentioned in this manual may be trademarks, registered trademarks or copyrights of their respective holders.

All brand and product n ames mentioned in this manual serve as com men ts or examples and are not to be understood as adv ertising for

the products or their manufacturers.

Software License Agreement

You should carefully read the following terms and conditions before using this software. Your use of this software indicates your acceptance

of this license agreement and warranty.

Terms and C onditions:

1. No redistribution of the software is allowed.

2. Reverse-Engineering. You may not reverse engineer, decompile, disassemble or alter anyhow this software product.

Disclaimer of Warranty:

This software and the accompanying files are sold “as is” and without warranties as to performance or merchantability or any other warranties whether expressed or implied. In no event shall Barco be liable for dam age of any kind, loss of data, loss of profits, business

interruption or other pecuniary loss arising directly or indirectly. Any liability of the seller will

product or refund of purchase price.

be exclusively limited to replacement of the

Information for China ROHS compliance

Table of toxic and hazardous substances/elements and their content, as required by China’s management methods for controlling pollution

by electronic information products

Projector

Part name Toxic or hazardou s substances and elements

Pb Hg Cd Cr6+ PBB PBDE

Metal par ts

Plastic p arts

PCB or PCBA

Lamp

Power s upply/adapter

Power cable

Connectors and cables

Fans

Heat radiation module (metal parts)

Card reader

Speaker (exclude PCB)

Remote control (exclude PCB)

O: Indicates that this toxic or hazardous substance conta ined in all of the homogeneous materials for this part is below the limit

requirement in SJ/T11363-2006.

X: Indicates that this toxic or hazardous substance contained in at least one of the homogeneous materials used for this part is

above the limit requirement in SJ/T11363-2006

oo oo oo

x

x

o

x

x

x

x

x

oo oo oo

oo oo oo

x

ooooo

ooooo

x

ooooo

ooooo

ooooo

ooooo

ooooo

ooooo

oooo

中国大陆 RoHS

根据中国大陆 《 电 子信息产 品 污染控制管理办法》( 也称为 中国大陆 RoHS),以下部份列出了本产品中可能包含的有毒有害物质或元素

的名称 和含量。

Page 5

Projector

零部件名稱 有毒有害物質或元素

金屬機構件

塑膠機構件

电路板组件 *

燈泡

電源模組

电源 线

外部信号连接 线

風扇

散熱模組 (金屬部

分)

讀卡器

喇叭 (電路板組件

除外)

附電池遙控器 (電

铅( Pb)

汞(Hg)

镉( Cd

oooooo

xooooo

xooooo

oxoooo

xooooo

xooooo

xooooo

xooooo

xooooo

oooooo

oooooo

xooooo

六价铬( Cr6+ )

多溴联苯(PBB)多溴 二苯醚

(PBDE )

路板組件除外)

*: 电路板组件包括印刷电路板及其构成的零部件,如电阻、电容、集成电路、连接器等

○:表示该有毒有害物质在 该部件所有均质材料中的含量均在《电子信息产品中有毒有害物质的限量要求标准》规定的限量要求以下

×:表示该有毒有害物质至少在该部件的某一均质材料中的含量超出《电子信息产品中有毒有害物质的限量要求标准》规 定的限量要求;但

是上表中打“×”的部件,其含量超出是因为目前业界 还没有成熟的可替代的技术,且符合歐盟RoHS指令的排外條款及電池指令

Page 6

Page 7

Table of contents

TABLE OF CONTENTS

1. Safety................................................................................................................. 3

1.1 General considerations ............................................................................................................... 4

1.2 Important safety instructions ......................................................................................................... 5

2. General. ................ ................ ................ ................ ................ ................ .............. 9

2.1 Installation requirements . .. .........................................................................................................10

2.2 Unpacking the projector .............................................................................................................12

2.3 Initial inspection......................................................................................................................15

2.4 Installation process overview........................................................................................................16

3. Physical installation ..............................................................................................17

3.1 Positioning the DP2K-23B at port window .. ........................................................................................18

3.2 Installation of the exhaust system. .................................................................................................. 21

3.3 Access to the power connection . . ..................................................................................................23

3.4 Connecting the projector with the power net .......................................................................................24

3.5 Power loop through to the projector electronics . ...................................................................................25

3.6 Connecting a U P S to the projector electronics .. ................................................................................... 26

4. Lamp & lamp house. .. . . ... . ... . ... . ... . . . ... . ... . ... . ... . . . ... . ... . ... . . . ... . ... . ... . ... . . . ... . ... . ... . ... . . . ... . 27

4.1 Introduction ..........................................................................................................................28

4.2 Removal of the lamp house .........................................................................................................30

4.3 Removal of the xenon bulb lamp . ................................................................................................... 32

4.4 Installation of the xenon bulb lamp..................................................................................................36

4.5 Installation of the lamp house ....................................................................................................... 40

4.6 Resetting the lamp parameters . . . ..................................................................................................42

4.7 Realignment of the lamp in its reflector .............................................................................................43

5. Lenses & lens holder .............................................................................................45

5.1 Available lenses ..................................................................................................................... 46

5.2 Lens selection .......................................................................................................................47

5.3 Lens formulas ........................................................................................................................48

5.4 Lens installation .....................................................................................................................49

5.5 Lens removal ........................................................................................................................ 51

5.6 Lens shift, zoom & focus . . ..........................................................................................................52

5.7 Scheimpflug adjustment.............................................................................................................53

6. Input & communication ..........................................................................................57

6.1 Introduction ..........................................................................................................................58

6.2 Local keypad of the DP2K-23B projector...........................................................................................59

6.3 Communication ports of the DP2K -23B projector ..................................................................................60

6.4 About General P urpose Inputs & Outputs (GPIO)..................................................................................62

6.5 Source input ports of the DP2K-23B projector . . ...................................................................................64

6.6 LED indications on the Integrated Cinema Processor module. .................................................................... 66

7. Communicator Touch Panel................ ................ ................ ................ ................ .....67

7.1 Introduction ..........................................................................................................................68

7.2 Installation of the touch panel interface. .. .. ........................................................................................70

8. Starting up..........................................................................................................73

8.1 Switching ON the DP2K-23B projector .............................................................................................74

8.2 Switching OFF the DP2K-23B digitalprojector .....................................................................................75

9. Projector registration.............. ................ ................ ................ ................ ............... 77

9.1 Introduction ..........................................................................................................................78

9.2 Download the certificate file .........................................................................................................79

9.3 Registration of new projector........................................................................................................80

9.4 Update registration of an existing projector. ........................................................................................86

10. Removal and installation of the projector covers ........ ................ ................ ................ ...87

10.1 Removal of the lamp cover.......................................................................................................... 88

10.2 Removal of the rear cover........................................................................................................... 90

10.3 Removal of the input cover . .........................................................................................................91

10.4 Removal of the front cover..........................................................................................................93

10.5 Removal of the side cover...........................................................................................................95

10.6 Installation of the front cover ........................................................................................................ 97

10.7 Installation of the input cover........................................................................................................99

10.8 Installation of the lamp cover.......................................................................................................100

10.9 Installation of the rear cover........................................................................................................102

10.10 Installation of the side cover .......................................................................................................103

11. Maintenance...................................................................................................... 105

11.1 Remove and clean the front dust filter.............................................................................................106

11.2 Remove and clean both bottom dust filters........................................................................................107

11.3 Cleaning the lens . . .................................................................................................................108

R59770495 DP2K-23B 30/04/2010

1

Page 8

Table of contents

11.4 Cleaning the exterior of the projector ..............................................................................................109

11.5 Check cooling liquid level ..........................................................................................................110

11.6 Cooling liquid refill..................................................................................................................111

11.7 Authorization to clear security warning on the projector ..........................................................................112

12. Convergence .............. ................ ................ ................ ................ ................ ....... 113

12.1 Open the sealed compartment .....................................................................................................114

12.2 Close the sealed compartment.....................................................................................................116

12.3 Convergence controls ..............................................................................................................117

12.4 Red on blue convergence .. ........................................................................................................119

12.5 Green on blue convergence........................................................................................................120

A. Specifications .......... ................ .................. ................ ................ ................ ......... 121

A.1 Specifications ofthe DP2K-23B....................................................................................................122

A.2 Dimensions of the DP2K-23B......................................................................................................123

A.3 Dimensions of the universal pedestal............................................................................................. . 124

B. Pin configurations................................................................................................ 125

B.1 Pin configurations of the communication ports .. ..................................................................................126

B.2 Pin configurations of the inputs . . . .................................................................................................128

Index....... ................ ................ ................ ................ ................ ................ ............. 129

2 R59770495 DP2K-23B 30/04/2010

Page 9

1. SAFETY

Overview

• General considerations

• Important safety instructions

1. Safety

R59770495 DP2K-23B 30/04/2010

3

Page 10

1. Safety

1.1 General considerations

General safety instructions

• Before operating this equipment please read this manual thoroughly and retain it for future reference.

• Installation and preliminary adjustments should be performed by qualified Barco personnel or by authorized Barco service dealers.

• All warnings on the projector and in the documentation manuals should be adhered to.

• All instructions for operating and use of this equipment m ust be followed precisely.

• All loc al installation codes should be adhered to.

Notice on safety

This equipment is built in accordance with the requirements o f the international safety standards IEC60950 -1, EN60950-1,

UL60950-1 and CAN/CSA C 22.2 No.60950-1, which are the safety standards of information technology equipmen t including

electrical business equipment. These safety standards impose important requirements on the use of safet

materials and insulation, in order to protect the user or operator against risk of electric shock and energy hazard and having access

to live parts. Safety standards also impose limits to the internal and external temperature rises, radiation levels, mechanical stability

and strength, enclosure construction and protection against the risk of fire. Simulated single fau

safety of the equipm ent to the user even when the equipment’s normal operation fails.

lt condition testing ensures the

Users definition

Throughout this manual, the term SERVICE PERSONNEL refers to persons having appropriate technical training and experience

necessary to be knowledgeable of potential hazards to which they are exposed (including, but not limited to HIGH VOLTAGE E LECTRIC and ELECTRONIC CIRCUITRY and HIGH BRIGHTNESS PROJECTORS) in performing a task, and of measures to minimize

the potential risk to themselves or other persons. The term USER and OP ERATOR refers to any person other than SERVICE PERSONNEL, AUTH ORIZE D to operate professional projection systems located in RESTRICTED ACCESS LOCATIONS.

The DLP Cinema Systems are intended "FOR PROFESSIO N AL USE ONLY" by AUTHORIZED PERSON NEL familiar with pote ntial hazards associated with high voltage, high intensity light beam s, ultraviolet exposure and high temperatures generated by the

lamp and associated circuits. Only qualified SERVICE PERSONNEL, knowledgeable of such risks, are allowed to perform service

functions inside the product enclosure.

y critical components,

Restricted access location

The DP2K-23B digital projector may only be installed in a restricted access location, due to the temperature rise of parts of the

equipment (air outlet). The defi nition of a “restricted access location" is a location for equipment where both of following paragraphs

apply:

• Access can only be gained by SERVICE PERSONS or by USERS who have been instructed about the reasons for the restriction

applied to the location and about the precautions that shall be taken.

• Access is through the use of the tool or lock and key, or other means of security, and is controlled by the authority responsible

for the location.

Owner’s record

The part number and serial number are printed on a label which is stuck on the respective part. Rec ord these numbers in the spaces

provided below. Refer to them wh enever you call upon your Barco dealer regarding this product.

Product article number

Product serial number

Dealer

4 R59770495 DP2K-23B 30/04/2010

Page 11

1.2 Important safety instructions

To prevent the risk of electrical shock

• This projector should be operated from an AC power source. E nsure that the m ains voltage and c apacity matches the projector

electrical ratings. If you are una ble to install the AC require ments, contact your electrician. Do not defeat the purpose of the

grounding.

• Installation according to the local electrical code and regulations by qualified technical personnel only.

• This product is equipped with a three-terminal barrier strip for the connection of a mono phase power line with a separate

earth ground PE. If you are unable to install the A C Requirements, contact your electrician. Do not defeat the purpose of the

grounding.

• The cross-sectional area of the conductors in the power supply cord shall be not less than 4 mm

The cross-sectional area of the UPS inlet cord and external fan pow er cord shall be not less than 0.75 mm² or AWG 18.

• The electronics of the projector (UPS INLET) must be powered either from a suitable UPS unit or from the po wer outlet socket

(UPS OUTLET) provided on the projector. An adapted short power cord (2-pole 3-wire grounding) is added to the projector

accessories to loop through the power from UP S OUTLET to UPS INLET.

• The provided power output socket (UPS OUTLET) on the projector may only be used to provide power to the p

tronics. Never connect other devices to this power output socket.

• The exhaust fan outlet may only be used to power an external blower, maximum 3A.

• The building installation has to be provided with a circuit breaker of max. 40A to protect the complete unit.

• A readily accessible disconnect device must be incorporated externally to the equipment for removal of the power to the projector mains terminals.

• Disconnect the p ower to the projector mains term inals and unplug the power cord

the projector.

• Warning: High leakage c urrent. Earth connection essential before connecting supply.

• Do not allow anything to rest on the power cord. Do not locate this projector where persons will walk on the cord.

• Do not operate the projector with a damaged cord or if the projector has been dropped or damaged - until it has been examined

and approv ed for operation by a qualified service technician.

• Position the cord so that it will not be tripped over, pulled, or contact hot surface

• If an extension cord is necessary, a cord with a current rating at least equal to that of the projector should be used. A cord rated

for less amperage than the projector may overheat.

• Never push objec ts of any kind into this projector through cabinet slots as they m ay touch dangerous voltage points or short

circuit parts that could result in a risk of fire or electrical shock.

• Do not expose this projector to rain or moisture.

• Do not immerse or expose this projector in water or other liquids.

• Do not spill liquid of any kind on this projector.

• Should any liquid or solid object fall into the cabinet, unplug the set and have it checked by qualified service personnel before

resuming operations.

• Do not disassemble this projector, always take it to an trained s ervice person when service or repair w ork is required.

• Do not use an accessory attachment which is not r ecommended by the m anufacturer.

• Lightning - For added protection for this video product during a lightning storm, or when it is left unattended and unused for

long periods of time, remove all power from the projector. This will prevent damage to the projector due to lightning and AC

power-line surges.

at UPS INLET for remova l of all pow er from

s.

2

or AWG 10.

1. Safety

rojector elec-

R59770495 DP2K-23B 30/04/2010

5

Page 12

1. Safety

To prevent personal injury

• Isolate electrically before replacing the lam p or lamp house. Caution: Hot lamp (house).

• Caution: High pressure lamp may explode if improperly handled. Refer servicing to qualified service personnel.

• To prevent injury a nd physical damage, always read this manual and all labels on the system before inserting the lamp casing,

powering the projector or adjusting the projector.

• To prevent injury, take note of the weight of the pro jector. Minimum 4 persons are needed to carry the projector.

• To preve nt injury, ensure that the lens, exhausting s ystem and all cover plates are correctly installed. See installation procedures.

• Warning: high intensity light beam. NEVER look into the lens ! High luminance could result in damage to the eye.

• Before attempting to remove any of the projector’s covers, disconnect to the projector m ains terminals and unplug the power

cord at UPS INLET for removal of all power from the projector.

• When required to remove all power from the projector, to access parts inside, always disc onnect to the projector mains terminals

and unplug the power cord at UPS INLET

• Do not place this equipment on an unstable cart, stand, or table. The product may fall, caus ing serious damage to it and

possible injury to the user.

• It is haz ardous to op erate without lens or shield. Lenses, s hields or ultra violet screens shall be changed if they have become

visibly damaged to such an extent that their effectiveness is impaired. For example by cr acks or deep scratches.

• Warning: Protection from ultraviolet radiation: Do not look directly in the light beam. The lamp contained in this product is

an intense source of light and heat. One component of the light emitted from this lam p is ultraviolet light. Potential eye and skin

hazards are present when the lamp is energized due to ultraviolet radiation. Avoid unnecessary exposure. Protect yourself and

your employees by making them aware of the hazards and how to protect themselves. P rotecting the skin can be accomplished

by wearing tightly wov en garments and glov es. Protecting the eyes from UV can be ac comp lished by wearing safety glasses

that are designed to provide UV protection. In addition to the UV, the visible light from the lamp is intense and should also be

considered when choosing protective eye wear.

• Exposure to UV radiation: Some m edications are known to make individuals extra sens itive to UV radiation. The A mer ican

Conference of Governmental Industrial Hygienists (ACGIH) recommends occupational UV exposure for an-8 hour day to be

less than 0,1 micro-watts per square centimeters of effective UV radiation. An evaluation of the workplace is advised to assure

employees are not expos ed to c umulative radiation levels exceeding these government guidelines.

WARNING: Never look into the exhaust output. High luminance and U V radiation could result in damage to

the eye. The i nstallation of an exhaust syst em is m and atory before o per

ating the projector.

To prevent fire hazard

• Do not place flammable or combustible materials near the projector!

• Barco large screen projection pr oducts are designed and m anufactured to meet the m ost stringent safety regulations. This

projector radiates heat on its external surfaces and from ventilation ducts during normal operation, which is both nor mal and

safe. Exposing fl ammable or combustible materials into close proximity of this projector could result in the spontaneous ignition

of that material, resulting in a fire. For this reason, it is absolutely necessary to leave an “exclusion zone” arou nd all external

surfaces of the pro jector whereby no flam mable o r combustible m aterials are present. The exclusion zone must be not less

than 40 cm (16”) for all DLP Cinema projectors. The exclusion zone on the lens side must be at least 5 m. Do not cover the

projector or the lens with any material while the projector is in operation. Keep flammable and combustible materials away from

the projector at all times. Moun t the projector in a well ventilated area away from sources of ignition and out of direct sun light.

Never expose the projector to rain or moisture. In the event of fire, us e sand, CO

water on an electrical fire. Alway s have service performed on this projector by authorized Barco service personnel. Always

insist on genuine Barco replacement parts. Never us e non -Barco replacem ent parts as they may degrade the safety of this

projector.

• Slots and openings in this equipment are provided for ventilation. To ensure reliable operation of the projector and to protect

it from overheating, these openings must not be blocked or c overed. The openings should never be blocked by placing the

projector too close t o walls, or other similar surface. T his projector should ne ver be placed near or over a radiator or heat

register. Th is projector should not be placed in a built-in installation or enclosure unless proper ventilation is provided.

• Projection rooms must be well ven

console to the outside of the building. The mandatory exhaust system must include a b lower that m aintain at least 10 m

(350 CFM ) when measured at the projector exhaust opening.

• Let the projector cool completely before storing. Remove cord from the projector when storing.

• Heat sensitive materials should not be placed in the path of the exhausted air or on the lam p house.

tilated or cooled in order to avoid build up of heat. It is necessary to vent hot exhaust air from

or dry powder fire extinguishers. Nev er use

2

3

/min

6

R59770495 DP2K-23B 30/04/2010

Page 13

1. Safety

To prevent projector damage

• This projector h as been designed for use with a specific lamp (house) type. See installation instructions for its correct type.

•Theairfilters of the projector must be cleaned or replaced on a regular basis (a "clean" booth would be monthly-minimum).

Neglecting this could result in disrupting the air flow inside the projector, causing overheating. Overheating may lead to the

projector shutting down during operation.

• The projector must always be installed in a manner which ensures free flow of air into its air inlets and the mandatory exhausted

system must be capable of removing minimum 10 m

• In order to ensure that correct airflow is maintained, and that the projector complies with Electromagnetic Compatibility (EMC)

and safety requirements, it should always be operated with all of it’s covers in place.

• Slots and openings in the cabinet are provided for ventilation. To ensure r eliable operation of the product and to protect it from

overheating, these openings must not be blocked or cov ered. The openings should never be blocked by placing the product

on a bed, sofa, rug, or other similar surface. This product should never be placed near or over a radiator or heat register. The

device should not be placed in a built-in installation or enclosure unless proper ventilation is provided.

• Ensure that nothing can be spilled on, or dropped inside the projector. If this does happen, switch off

from the projector. Do not operate the projector again until it has been chec ked by qualifi ed service personnel.

• Do not block the projector cooling fans or free air movement around the projector. Loose papers or other objects may not be

nearer to the projector than 10 cm (4") on any side.

• Do not us e this equipment near water.

• Proper operation of the cooling circuit can only be guaranteed in table mounting. It is not allowed to use the projector in another

position. See installation procedure for correct installation.

• Special care for Laser Beams: Special care should be used when DLP projectors are used in the same room as high power

laser equipm ent. Direct or indirect hitting of a laser beam on to the lens can severely damage the Digital Mirror Devices

which case there is a loss of warranty.

• Never place the projector in direct sun light. Sun light on the lens can severely damage the Digital Mirror Devices

case there is a loss of warranty.

• Save the original shipping carton and packing material. They will come in handy if you ever have to ship your equipment. For

maximum protection, repack your s et as it was originally packed at the factory.

• Disconnect the po wer to the projectors mains terminals and unplug the power cord at UPS INLET before cleaning. Do not use

liquid cleaners or ae rosol cleaners. Use a damp cloth for cleaning. Never use strong solvents, such as thinner or benzine, or

abrasive cleaners, since these will damage the cab inet. Stubborn stains may be rem oved with a cloth lightly dam pened with

mild detergent solution.

• To ensure the highest optical performance and resolution, the projecti

coating, therefore, avoid touching the lens. To remove dust on the lens, use a soft dry cloth. Do not use a damp cloth, detergent

solution, or thinner.

• Rated maximum ambient temperature, t

=35°C(95°F).

a

• The lamp house shall be replaced if it has become d amaged or thermally deform ed.

3

/min (350 CFM) m easured at the projector’s exhaust opening.

and remove all power

on lenses are specially treated with an anti-reflective

TM

in which

TM

in

On servicing

• Do not attempt to service this product yourself, as openi

and risk of electric shock.

• Refer all servicing to qualified service personnel.

• Attempts to alter the factory-set internal controls or to change o ther control settings not specially discussed in this manual can

lead to permanent damage to the projector and cancellation of the warranty.

• Remove all power from the projector a nd refer servicing to qualified service technicians under the following conditions:

- When the power cord or plug is damaged or frayed.

- If liquid has been spilled into the equipment.

- If the product has b een exposed to rain or water.

- If the product does not operate normally wh en the operating instructions are followed. Adjust only those controls that a re

covered by the operating instructions since improper adjustment of the other controls may result in damage and will often

require extensive work b y a qualified technician to restore the pr oduct to normal operation.

- If the product has been dropped or the cabinet has be

- If the product exhibits a distinct change in performance, indicating a need for service.

• Replacement parts: When replacement parts are required, be sure the s ervice technician has used original Barco replacement

parts or authorized replacement parts which have the same characteristics as the Barco o riginal part. Unauthorized substitutions may result in degraded performance and reliability, fire, electric shock or other hazards. Unauthorized substitutions may

void warranty.

• Safety check: Upon completion of any service or repairs to this projector, ask the service technician to perform safety checks

to de termine that the product is in proper operating condition.

• Possible explosion hazard: Always keep in mind the caution below:

ng or removing covers may expose you to dangerous voltage potentials

en damaged.

R59770495 DP2K-23B 30/04/2010

7

Page 14

1. Safety

CAUTION: Xenon compact arc lamps are highly pressurized. When ignited, the normal operating temperature

of the bulb increases the pressure to a level at which the bulb ma y explode if not handled in strict accordance

to the manufacturer’s instructions. The bulb is stable at room temperature, but may still explode if dropped or

otherwise mishandled. Whenever the lamp house, containing a xenon lamp, has to be dismantled or when ever

the protective container or cloth has to be removed from the xenon lamp, authorized protective clothing MUST

be worn!

To prevent battery explosion

• Danger of explosion if battery is incorrectly installed.

• Replace only with the same or equivalent type recommended by the manufacturer.

• For disposal of used batteries, always consult federal, state, local and provincial hazardous waste disposal rules and regulations

to ensure proper disposal.

8

R59770495 DP2K-23B 30/04/2010

Page 15

2. GENERAL

About this chapter

Read this c hapter before installing your DP2K-23B digital projector. It con tains important information concerning installation requirements for the DP2K-23B digital projector, such as minimum and maximum allowed ambient tem perature, humidity conditions,

required safety area around the installed projector, required power net, etc.

Furthermore, careful consideration of things such as image size, ambient light level, projector placement and type of screen to use

are c ritical to the optimum use of the projection system.

Barco provides a guarantee relating to perfect manufacturing as part of the legally stipulated terms of guarantee. Observing the s pecifi cation mentioned in this chapter is critical for projector performance. Neglecting

this can result in loss of warranty.

Overview

• Installation requirem ents

• Unpacking the projector

• Initial inspection

• Installation process ov erview

2. General

R59770495 DP2K-23B 30/04/2010

9

Page 16

2. General

2.1 Installation requirements

Environment conditions

Table below summarizes the physical environment in which the DP2K-23B digital projector may be safely operated or stored.

Environment Operating Non-Operating

Ambient Temperature 10 °C (50 °F) to 35 °C (95 °F) -15°C (5°F) to 60°C (140°F)

Humidity 5% to 85% R H Non-condensed 5% to 95% RH Non-Condensed

Altitude -60 (-197Ft) to 3000m (9843Ft) -60 (-197Ft) to 10000m (32810Ft)

Let the projector acclimatize after unpacking. Neglecting this may result in a startup failure of the

cessor Unit.

Light Pro-

Cooling requirements

The projector is fan cooled and must be ins talled with sufficient space aroundthe projector head, minimum 20 cm (8 inch) to ensure

sufficient air flow. It should be used in an area where the ambient temperature, as measured at the projectorair inlet , does not

exceed +35°C (+95°F).

The installation of an exhau st system is MANDATORY. The installed exhaust blower must remove an air volume of minimum 10

3

m

/min (350 CFM) measured at the exhaust output of the projector.

Main Power requirements

The DP2K-23B operates from a nominal mono phase power net with a separate earth ground PE. The DP2K-23B requires 200-240

VAC, 50-60Hz, 30A at 200 VAC with a separate earth ground PE.

The power cord required to connect the projector with the power net is not delivered with the projector. It is the responsibility of the

customer to provide the correct type of pow er cord. The cross-sectional area of the conductors in the power supply cord shall not

be less than 4 mm² or 10 AWG, minimum 300V.

To protect operating personnel, the National Electrical Manufact

and cabinet be grounded. In no event shall this projector be operated without an adequa te cabinet ground connection.

The A C supply must be installed by a qualified electrician in conformance to local codes. Hardware, wire sizes and conduit types

must comply with local c odes.

A readily accessible disconnect device s hall be incorporated externally to the equipm ent for removal of the power to the equipment

mains terminals.

The building installation must be provided with a circuit breaker of max. 40A to protect the complete unit.

urers A ssociation (NEMA) recommends that the instrument panel

WARNING: Disconnect the power to the unit mains terminals and unplug power cord at UPS inlet for removal

of all power fro m the unit

UPS requirements

The Un interruptible Power Supply (UPS), also known as a Continuous P ower Supply (CPS), must have an output voltage of 200240V at 50-60Hz and must be capable of delivering an output current of 5,5 amperes.

The connection between the UPS unit and the UPS inlet of the projector must be done with a certified AC power s upply c ord of

minimum 0,75 m m² or 18 AWG and minimum 300V.

CAUTION: T he 200–240V p ower outlet (UPS

unit with power! The UPS OUTLET of the projector may only be used for connection to the UPS INLET of the

projector.

The DP2K-23B does not have a built in UPS unit.

OUTLET) of the projector may not be us ed to provide the UPS

Exhaust outlet for external fan

The exhaust outlet has an output voltage of 200–240V at 50–60 Hz; switched and maximum 3 amperes is allowed.

The connection between the exhaust outlet and the ex ternal blower must be done with a certified AC power supply cord of minimum

0,75 mm² or 18 AWG and minimum 300V.

10

R59770495 DP2K-23B 30/04/2010

Page 17

2. General

CAUTION: The 200–240V power outlet (exhaust outlet) of the projector may not be u sed to provide power to

any other device than an external exhaust fan. Maximum allowed current : 3A.

Projector weight

Do not underestimate the weight of the Barco DP2K-23 B digital projector. The projector weights about ±133 kg (±293 lb.) without

lens. Be sure that the pedestal on which the projector ha s to be installed is capable of handling five (5) ti

the system.

Barco offers a pedestal for the DP 2K-23B . T his universal pedestal allows a solid and easy setup of the projector. The universal pedestal has a separate compartment to install the UPS unit for the D P2K-23B. Futhermore,

the u niversal pedestal contains a standard 19” rack to build in the projector peripherals such as alternative

content switchers ( e.g. ACS-2048)

mes the complete load of

R59770495 DP2K-23B 30/04/2010 11

Page 18

2. General

2.2 Unpacking the projector

What has to be done ?

Upon delivery, the projector is packed in a carton box upon a wooden pallet and secure d with banding and fastening clips. Furthermore, to provide protection during transportation, the projector is surrounded with foam. Once the projector has arrived at the

installation site, it needs to be removed from the carton bo x and wooden pallet in a safe manner without damaging the projector.

After unpacking let the projector acclimatises to a room te mp erature higher then 10°C (50°F) and lower then

35°C (95°F). Neglecting this may result in a start u p failure o f the Light Processor Unit.

How to unpack

1. Loosen the banding by pulling the free end of the banding loop in the clip.

Take off the box cover.

Image 2-1

Open banding

2. Open the box.

Take out the small box between the outer and inner box containing the manuals.

Remove the outer carton box

12

R59770495 DP2K-23B 30/04/2010

Page 19

Image 2-2

Remove outer carton

3. Remov e the inner carton box.

2. General

Image 2-3

Remove inner carton

4. Loosen the banding by pulling the free end of the banding loop in the clip.

Take off the upper carton plate (1)

Remove from the wooden pallet (2)

R59770495 DP2K-23B 30/04/2010

13

Page 20

2. General

1

2

Image 2-4

Remove wooden pallet

5. Take the projector from the w oode n board by gripping the bottom of the projector and place the projector on the pedestal.

Image 2-5

Remove projector

14 R59770495 DP2K-23B 30/04/2010

Page 21

2.3 Initial inspection

General

Before shipment, the projector was inspected and found to be free of mechanical and electrical defects. As soon as the projector is

unpacked, inspect for any dam age that m ay have occurred in transit. Save all packing material until the inspection is completed. If

damage is found, file claim with carrier immediately. The Barco Sales and Service office should be notified as soon as possible.

2. General

The packaging of the DP2K-23B digital projector is provided with a shock-watch label. If this shock-watch

label was triggered (red colored at arrival) during transport, indicates that the package was poss

handled by the transport c ompany. In this case, the instructions mentioned on the label, should be followed,

which are: adding a note on the “bill of lading” and informing the transport company and the Barco sales and

service o ffice as s oon as possible.

ibly roughly

Box c ontent

After unpacking the p rojector it is recommended to check if all following items where include

• One short power link cable (mono phase) (in case no UPS is used) - Installed on projector.

• This manual (installation m anual).

•CD

• Safety manual

One xenon lamp is mounted inside the lamp house at delivery. The projector lenses are not included in the

package of the projector.

d:

Mechanical check

This check should confir m that there are no broken knobs or connectors, that the cabinet and panel su rfaces are free of dents and

scratches, and that the operating p anel is not s cratched or cracked. The Barco Sales and Service office should be notified a s soon

as possible if this is not the case.

Tamp e r label s

During installation please inspect the tamper labels, if they are damaged please contact Barco tech support.

The tamper labels are required by DCI to provide easy visual indication if the equipment was tampered with. The projectors are

tested and labeled for shipping to ensure that the system was not compromised before reaching the customers final destination.

These tamper labels ca n be found behind the input cover. See "Removal of the input cover", pag e 91.

R59770495 DP2K-23B 30/04/2010

15

Page 22

2. General

2.4 Installation process overview

Let the projector acclimate to t he amb ient temperature after unpacking. Neglecting this may result in a startup

failure of the light processor unit.

Set up from A to Z

After you have unpacked and checked the projector, you can start with the installation process of your DP2K-23B digital projector.

This chapter gives you an overview of all the different stages in the installation process which you have to follow to set your DP2K-23B

digital projector up and running. Each stage is briefly des cribed and refers to more detailed step by step procedures in this manual.

Use this overview as a checklist to ensure that you have followed all stages in the setup process of your DP2K-23B digital projector.

Set up from A to Z

1. Check if all installation requirements are fulfilled such as the environment conditions of the installation area, capacity of the

exhaust sy stem, electrical facilities, etc. Note that a solid p edestal is required to support the projector head. For more info see

chapter "Installation requirements", page 10.

2. Physical installation of the projector upon its pedestal and connecting the air outlet of the projector with the exhaust system.

Note that the e xhaust system is MANDATORY. See chapters "Positioning the DP2K-23B at port window", page 18, and "Installation of the exhaust system", page 21.

3. Electrical connection with the power net. See chapter "Connecting the projector with the power net", page 24.

4. Installation of a suitable UPS unit or bypass the power in and outlet for the projector electronics. S ee chapters "Power loop

through to the projector electronics", page 25 or "Connecting a UPS to the projector electronics", page 26.

5. Installation of the x enon lamp in case the xenon lamp is not installed in the lamp house yet. To install the xenon lamp the lamp

house has to be removed from the projector. To install the xenon lam

step pr ocedures in the chapter "Lamp & lamp house", page 27.

6. Installation of the lens. First select an appropriate lens which t hrow ratio covers the screen size and the projector - screen

distance. Then install the lens in the lens holder of the projector. For more information about available lenses, lens selection and

lens installation see chapter "Lens installation", page 49.

7. Installation of the Communicator Touch Panel. See chapter "Communic ator Touch Panel", page 67.

8. Alignment of the projected image on the screen. The projector can now be switched on to project its first image (test pattern)

on the screen. Then the image can be a ligned with the screen size of the application. Follow the next steps to achieve that:

a) Place the ON/OFF switch of the projector in the ”I” position. As a result the projector starts to initialize. The status lights of

the projector lights up GREEN once the projector is initializ

b) Press the STANDBY bu tton on the loca l keypad to activate the lamp.

c) P ress the DOWSER button on the local keypad to open the dowser of the projector. The dowser is open if the color of the

DOWSER button is GREEN.

d) Press the TEST PATTERN button on the local k eypad to project one of the internal test patterns of the projector on the screen.

e) Use the lens ZOOM, SHIFT and FOCUS buttons on the local keypad the match the pr ojected image with the screen. Tilt the

projector in case you can not SHIFT the im age complet

9. Resetting the lamp parameters. Th e “LAMP INFO” parameters which are stored on the controller boar d of the projector MUST

be updated after each installation of an xenon lamp inside the lamp house. Neglecting this update will result in poor performance

and short life time of the xenon lamp. See chapter "Resetting the lamp parameters", page 42.

10.Realignment of the xenon lamp in its refl ector. For optimal performance of the xenon lamp it is required to realign the lamp

after installation in the lamp house. See "Realignment of the lamp in its refl ector", page 43 for more information.

11. Adjusting the light path. Normally the lens holder and the convergence of the projector is perfectly a djusted at the factory.

Nevertheless, s ome applications require a readjustment of the lens holder, convergence or both. See procedure "Sc heimpfl ug

adjustment", page 53, to adjust the Scheimpflug and see "Convergence", page 113 to adjust the convergence of the light path.

12.Registration of the projector. The DP2K-23B digital projector is DCI compliant and should be registered by Barco. Therefore,

the digital certificate inside the projector will be used to secure encryption key communication between the projector and the rest

of the theatre system (server and thea

13.Projection of a digital cinema movie. Apply a single or dual channe l SMPTE or DVI source to the input ports of the projector

and start up the projector. See "Source input por ts of the DP2K-23B projector", page 64 and chapter "Starting up", page 73. Use

the Communicator Touc h Panel to configure the applied source. See the user guide of the Communicator Touch Panel for more

detailed information.

tre management system). For m ore info see chapter "Projector registration", page 77.

ely upon the screen. See "Lens shift, zoom & focus", page 52.

p correctly and in a safe manner, see the detailed step by

ed.

16

R59770495 DP2K-23B 30/04/2010

Page 23

3. PHYSICAL INSTALLATION

About this chapter

This chapter describes ho w the mechanical and electrical set up of the projector has to be done.

Overview

• Positioning the D P2 K-23B a t port window

• Installation of the exhaust system

• Access to the power connection

• Connecting the projector with the power net

• Power loop through to the projector electronics

• Connecting a UP S to the projector electronics

3. Physical installation

R59770495 DP2K-23B 30/04/2010

17

Page 24

3. Physical installation

3.1 Positioning the DP2K-23B at port window

WARNING: The installation of the DP2K-23B projector requires at least 4 persons.

General guide lines

• Use a solid pedestal to put the DP2K-23B projector on. Ensure that the pedestal can handle the weight o

that all feet of the projector are c aptured.

• The pedestal should be placed in front of the port window wall in a manner that the projector front cover is at a minimum distance

of 20 centimeters from the port window.

20 cm

Image 3-1

Positioning at port window

Barco offers a pedestal for the DP2K-23B digital projector. This universal pedestal allows a solid and easy

setup of the projector. The universal pedestal has a separate compartment to install the UPS unit (if available)

for the DP2K-23B digital projector. Futhermore, the universal pedestal contains a sta ndard 19” rack to build

in the projector peripherals like alternative content switchers (e.g. ACS-2048).

f t he projector and

Necessary tools

• 14 mm wrench

• 17 mm wrench

Projector centering

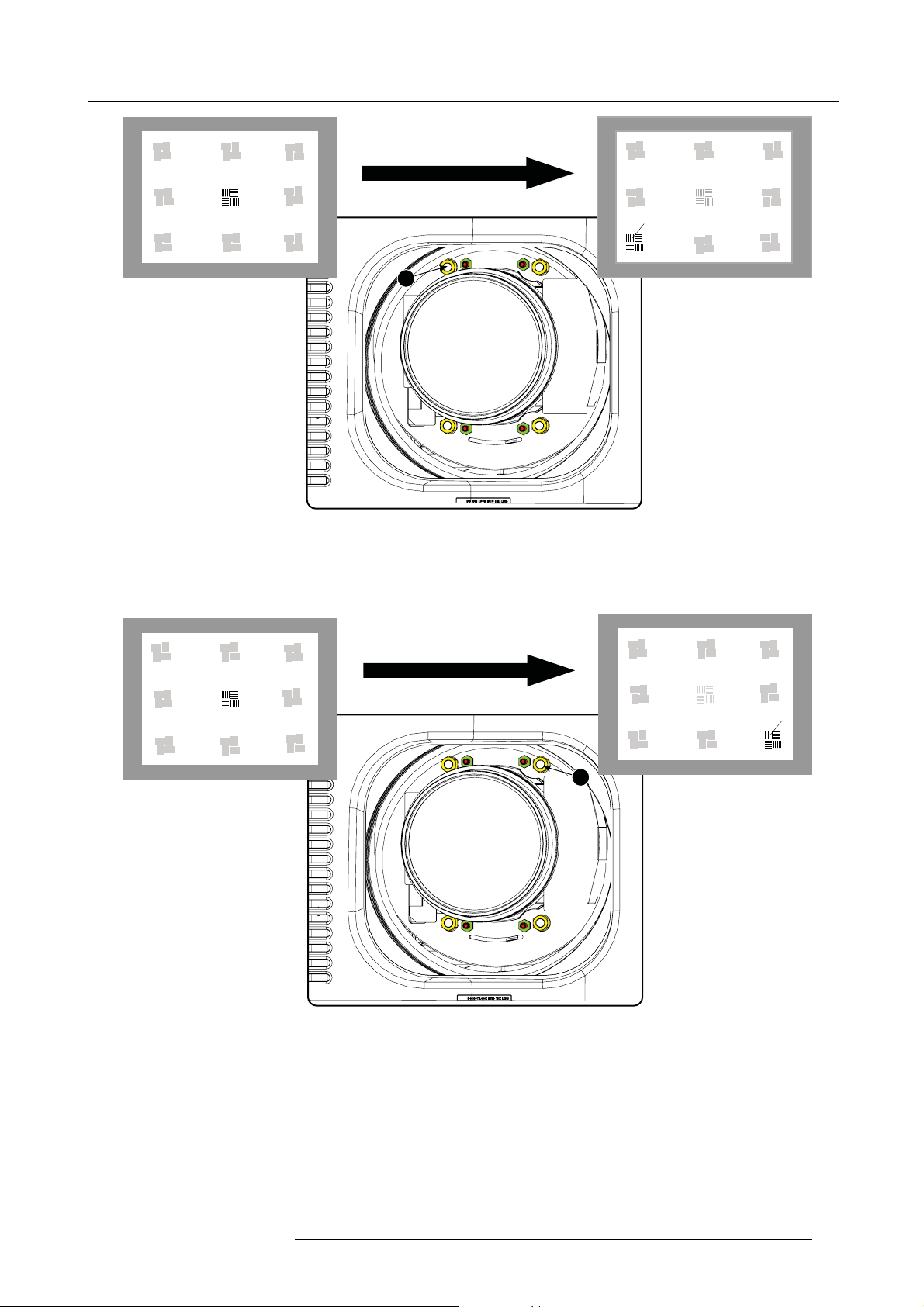

1. If the projector is standalone in front of the port window, center the projector with the theatre screen (see ref A image 3-2).

2. If a film projector is already present (proj

Note: Unlike film projectors, it is best to keep the projector lens surface as parallel to the screen as pos sible, even if it is

significantly above the screen center.

The off-center position slightly increases side keystone, but will minimize horizontal lens offset required.

ector will be off-center), try to optimize aim (see ref B image 3-2).

18

R59770495 DP2K-23B 30/04/2010

Page 25

3. Physical installation

A B

Image 3-2

Projector centering

3. Proceed to level the projector by adjusting the feet of the projector as follows:

- Loosen the nuts (A), using a wrench of 24 mm, on the threaded rod.

- Adjust the height of the 4 legs (B) to level the projector, using a 17 mm wrench.

- Secure the leg height by tightening the nuts (A).

Note: There must be at least 5 cm between the bottom side of the projector and the pedes tal.

SCREEN CENTER SCREEN CENTER

OFF-CENTER

A

B

Image 3-3

Projector leveling

4. Later, when the projector is up-and-running, adjust precise image geome try and placement.

Projector tilting

In an ideal installation, the DP2K- 23B lens surface is centered with and parallel to the screen. This orientation helps to ensure

optimized lens performances with minimal offset. If this position is not pos sible (such as when the projector is significantly higher

than the center of the screen), it is better to rely on o ffset rather than extra tilt.

1. Before adjusting tilt, make sure the projector is as well-centered with the theatre screen as possible for your installation area.

2. Check with theatre personnel for th

3. Tilt the projector to closely match this screen tilt angle as follows:

- Loosen the nuts (A), using a wrench of 24 mm, on the threaded rod.

- Adjust the height of the legs until the projected image ma tches the projection port window and the screen tilt.

- Secure the leg height by tightening the nuts (A).

e degree of screen tilt, or measure this incline with a protractor at the screen.

R59770495 DP2K-23B 30/04/2010

19

Page 26

3. Physical installation

Image 3-4

Projector tilting

Barco offers a pedestal for the DP2K-23B digital projector. This universal pedestal allows you to easily tilt the

projectorforwardupto6°.

90°

Inclined screen

20 R59770495 DP2K-23B 30/04/2010

Page 27

3.2 Installation of the exhaust system

WARNING: THE USE OF AN EXHAUST SYSTEM IS MANDATORY !

WARNING: Never look into the exhaust output. High luminance and U V radiation could result in damage to

the eye. The installation of an exhaust system is mandatory before operating the projector.

3. Physical installation

CAUTION: The exhaust system must be capable of removing minimum 10 m

projector’s exh aust opening.

3

/min (350 CFM), measured at the

About Exhaust

The exhaust stack of the projector head is designed to fit a 201 mm (7.91 inch) diameter duct. This size must be used throughout

the entire system and installed to eliminate any possibility of downdraft or rain dripping into the lamp house.

The exhaust fan must be capable of removing m inimum 10 m

A built-in vane switch detects if the airflow in the exhaust opening is high enough. When something goes wrong one of the following

error codes can be displayed : 6090 or 6091 (insufficient air flow in exhaust of projector check exhaust fan and/or exhaust air outlet

system).

Check the functioning of this vane switch regularly. Replace if necessary.

3

/min (350 CFM), measured at the pr ojector ’s exhaust opening.

How to install the Exhaust stack

See illustration below:

Image 3-5

Exhaust system

R59770495 DP2K-23B 30/04/2010 21

Page 28

3. Physical installation

Ensure good condition of the lamp house blower. Keep the blower inlet clean for unrestricted air flow.

To ensure maximum lamp life, operate the lamp house blower and the exhaust system for at least ten minutes

after extinguishing the lamp.

Optional electrical connection of the fan to the projector

The exhaust fan may e lectrically be connected with the projector. When that is done, the blower starts working when the lamp is

switched on and stops working after the cool period is completed.

The power socket is located next to exhaust output and may only be used to connect the external exhaus

other devices is allowed.

The ex haust outlet delivers m aximu m 3A, 200-240V at 50-60Hz.

The external fan power cor d shall be not less than 0.75 m m ² or AWG 18.

t fan. No connection with

Image 3-6

Fan power connection

22 R59770495 DP2K-23B 30/04/2010

Page 29

3.3 Access to the po wer connection

Necessary tools

Flat screw driver 6 mm

How to access

1. Remov e the back cover.

2. Loosen both captive screws (1).

3. Physical installation

1

Image 3-7

Power connection cover, captive screws

3. Slide off the power connection cover.

Image 3-8

Terminal strip accessible

The terminal strip and connection plate is accessible.

R59770495 DP2K-23B 30/04/2010

23

Page 30

3. Physical installation

3.4 Connecting the projector with the power net

WARNING: The total electrical installation sh ould be protected by an appropriate rated and readily accessi-

ble disconnect switch, circuit breakers and ground fault current interrupters. The installation shall be done

according t o the local electrical installation codes.

WARNING: Make su re that the voltage range of projector matches with the voltage of the local power net.

CAUTION: The cross-sectional area of the conductors in the Power Supply Cord shall be not less than 4 mm

or AWG 10

Necessary tools

• Flat torque screw driver

• Adjustable wrench

Necessary parts

•Certified power supply cord 4.0 mm ², 10AWG, min. 300V, diameter between 11 mm and 21 mm

• Circuit breaker maximum 40A

How to connect

1. Remov e the back cover.

2. Remov e the power input cover.

3. Loosen the cable gland fixation rin g (1 ).

Note: The cable gland (1) is specified for cables with a diameter between 11mm and 21mm.

1

2

Image 3-9

Power cable connection

4. Push the stripped power supply cable through the cab

end is provided with an end sleeve.

Fix the cable in the cable gland by securing ring 1 w ith an adjustable wrench.

5. Connect the power cord with the terminal barriier strip. Use a flat torque screw driver se t to 2Nm.

Always connect the ground wire (PE) with the connector indicated with PE on the terminal barrier s trip.

Warning: Always connect first the PE w ire .

6. Reinstall the power connection cover and the back cover.

24

le gland. When using a flexible power cord, make sure that each conductor

R59770495 DP2K-23B 30/04/2010

Page 31

3.5 Power loop through to the projector electronics

This procedure explains how to provide the projector electronics with power in case no UPS unit i s used.

Note that the projector is by default configured for use w ithout UPS. So, the short po wer link cable is already

installed.

Necessary tools

No tools.

Necessary parts

Short power link cable with plug type C13/C14

How to loop through the power

1. Plug in the short power cable (1) which was delivered with the projector.

Warning: Always use the Barco short power cable which is delivered with the projector.

3. Physical installation

3

2

1

Image 3-10

Power loop through connection

2. Secure both plugs o f the short cable with

- Squeeze the fixation spring together.

-Slidethefixation spring on the fixation pins (3) while squeezing together and push it against the power plug.

- Release the fixa tion spring.

a fi xation spring (2). Handle as follow:

3

R59770495 DP2K-23B 30/04/2010

25

Page 32

3. Physical installation

3.6 Connecting a UPS to the projector electronics

WARNING: O nly use UPS units which are suitable for the DP2K-23B projector. See chapter ”General”, “In-

stallation requirements” for more information about the requirements of the UPS.

How to connect the UPS

1. Install the UP S according to the instructions of the man ufacturer and the local regulations.

2. Connect the powe r output cord from the UPS unit to the UPS inlet s ocket of the projector (right socket).

Connect directly (A) or drag the cable behind the front cover s o that the front cover can be removed without

INLET cable (B).

removing the UPS

A

2

Image 3-11

UPS connection

3. Secur e the UPS inlet socket with a fixation spring. Handle as follow:

- Squeeze the fixation spring together.

-Slidethefixation sp ring on the fixation pins while s queezing together and push it against the power plug.

- Release the fixa tion spring.

4. Install on the power outlet the second fixation spring to prevent losing it (2).

1

B

CAUTION: The electrical connection w ith the UP S INLET socket of the projector must be done with a certified

AC power supply cord (minimum 0,75 mm² or 18 AWG and minimum 300V)

CAUTION: Do not use the power OUTLET socket of the projector to provide power to other equipment!

26 R59770495 DP2K-23B 30/04/2010

Page 33

4. LAMP & LAMP HOUSE

WARNING: DO NO T PERMIT UNAUTHORIZED PERSONNEL TO PERFORM OR ATTEMPT ANY PHASE OF

XENON LAMP HANDLING OR SERVICE. ONLY TRAINED AND QUALIFIED TECHNICAL SERVICE PERSONNEL

ARE ALLOWED TO HANDLE THE XENON LAMP.

CAUTION: Xenon compact arc lamps are highly pressurized. When ignited, the normal operating temperature

of the bulb increases the pressure to a level at which the bulb ma y explode if not handled in strict accordance

to the manufacturer’s instructions. The bulb is stable at room temperature, but may still explode if dropped or

otherwise mishandled. Whenever the lamp house, containing a xenon lamp, has to be dismantled or when ever

the protective container or cloth has to be removed from the xenon lamp, authorized protective clothing MUST

be worn!

WARNING: Always w ear face protection (full face shield with neck protector) when handling xenon lam ps.

WARNING: Always wear protective clothing (welder’s jacket) when handling xenon lamps.

4. Lamp & lamp house

WARNING: Always wear clean leather gloves with wrist protectors when handling xenon lamps.

Overview

• Introduction

• Removal of the lamp house

• Removal of the xenon bulb lamp

• Installation of the xenon bulb lamp

• Installation of the lamp house

• Resetting the lamp param eters

• Realignment of the lamp in its reflector

R59770495 DP2K-23B 30/04/2010

27

Page 34

4. Lamp & lamp house

4.1 Introduction

Lamp and lamp house

The lamp house of the DP2K -23B projector is delivered with xenon lamp.

B

E

C

A

D

Image 4-1

A Anode of the xenon bulb lamp.

B Envelope of the xenon bulb lamp.

C Cathode of the xenon bulb lamp.

D Anode wire of the xenon bulb lamp.

E Lamp house.

Spare xenon lamps are packed in a protective container or wrapped in a protective cloth. Never remove this protective container or

protective cloth without wearing adequate protective clothing (face shield, clean leather glovers, welder’s jacket).

Image 4-2

Left: Xenon lamp in protective container. Right: Xenon lamp wrapped in protective cloth.

CAUTION: Xenon compact arc lamps are highly pressurized. When ignited, the normal operating temperature

of the bulb increases the pressure to a level at which the bulb ma y explode if not handled in strict accordance

to the manufacturer’s instructions. The bulb is stable at room temperature, but may still explode if dropped or

otherwise mishandled. Whenever the lamp house, containing a xenon lamp, has to be dismantled or when ever

the protective container or cloth has to be removed from the xenon lamp, authorized protective clothing MUST

be worn!

Cathode adaptor

A cathode adaptor is required to mount the xenon lamp in the lamp house. The cathode adapter has to be mounted upon the cathode

side of the xenon lamp prior to mounting the lamp in the lamp house. The p urpose of the cathode adapter is to position the arc of

the xenon lamp in the middle of the reflector inside the lamp house.

Image 4-3

Cathode adapter (R865555)

Supported xenon bulb lamps (without lamp house)

Lamp

Osram xenon lamp of 4

Osram xenon lamp of 3

Osram xenon lamp of

Osram xenon lamp o

f 1.2kW 1200W DHP R9855959

kW 4kW DHP R9855937

kW 3kW DHP R9855938

2kW 2kWDHP R9855956

Typ e

Order info

28 R59770495 DP2K-23B 30/04/2010

Page 35

4. Lamp & lamp house

Lamp Type

Ushio x enon lamp of 4 kW

Ushio x enon lamp of 3 kW

Ushio x enon lamp of 2 kW

Ushio xe non lamp of 1.2kW

Philips xenon lamp of 4 kW XDC-4000B

Yuyu xenon lamp of 4 kW XQ 4000W DHP

Yuyu xenon lamp of 3 kW XQ 3000W DHP

DXL40BAF R9855939

DXL30BAF R9855940

DXL20BAF R9855955

DXL12BAF R9855961

Order info

R9856370

R9856360

R9856350

R59770495 DP2K-23B 30/04/2010 29

Page 36

4. Lamp & lamp house

4.2 Removal of the lamp house

WARNING: This procedure may only be performed by qualified technical service personnel.

WARNING: The lamp house is very hot after operation. To avoid burns, let the projector cool down for at least

15 m inutes before proceeding to remove the lamp house.

CAUTION: Due to its h igh internal pressure, the lamp may explode in either hot or cold states if improperly

handled.

Necessary tools

• Nut driver 10 mm

• Flat screw driver

How to remove

1. Make sure the projector is switched off.

2. Remov e the lamp cover.

3. Release both captive screws at the base of the lamp house.

Image 4-4

Loosen lamp house screws

4. Remov e the lamp house as follows:

a) Grip the lamp house by the bottom handle and partially slide it out of the lamp compartment

b) Grip the lamp house by both handles and remove it completely from the projector.

c) P lace the lamp house on a stable support.

Caution: Be aware of the weight of the lamp assembly. Take the necessary precautions to av oid personal injury.

30

R59770495 DP2K-23B 30/04/2010

Page 37

Image 4-5

Remove lamp house

4. Lamp & lamp house

R59770495 DP2K-23B 30/04/2010 31

Page 38

4. Lamp & lamp house

4.3 Removal of the xenon bulb lamp

WARNING: DO NO T PERMIT UNAUTHORIZED PERSONNEL TO PERFORM OR ATTEMPT ANY PHASE OF

XENON LAMP HANDLING OR SERVICE. ONLY TRAINED AND QUALIFIED TECHNICAL SERVICE PERSONNEL

ARE ALLOWED TO HANDLE THE XENON LAMP.

WARNING: This procedure may only be performed by qualified technical service personnel.

CAUTION: Xenon compact arc lamps are highly pressurized. When ignited, the normal operating temperature

of the bulb increases the pressure to a level at which the bulb ma y explode if not handled in strict accordance

to the manufacturer’s instructions. The bulb is stable at room temperature, but may still explode if dropped or

otherwise mishandled. Whenever the lamp house, containing a xenon lamp, has to be dismantled or when ever

the protective container or cloth has to be removed from the xenon lamp, authorized protective clothing MUST

be worn!

WARNING: Always w ear face protection (full face shield with neck protector) when handling xenon lam ps.

WARNING: Always wear protective clothing (welder’s jacket) when handling xenon lamps.

WARNING: Always wear clean leather gloves with wrist protectors when handling xenon lamps.

Necessary tools

• Two open-end wrenches of 22 mm.

• 5 mm Allen wrench.

• Lamp protective container or protective cloth with two binders.

• Flat blade screw driver.

• 2,5 mm Allen wrench.

How to remove the lamp

1. Remov e the side cover of the Lamp House by releasing the two quarter turn screws (reference 1 image 4-6) at the bottom of the

side cover as illustrated.

1

Image 4-6

Open side cover

32 R59770495 DP2K-23B 30/04/2010

Page 39

4. Lamp & lamp house

2. Remov e the anode wire lug (reference 1 image 4-7) from the anode socket. Use for that an Allen key.

Tip: Place the flat washer (reference 2 im age 4-7) and bolt back on its place after the lug is removed

Note: The most recent Lamp Houses for the DP2K -23B makes it possible to re move the anode socket together with the xenon

lamp from the Lamp House. The anode socket can be release from the xenon lamp once the xenon lamp is safely

sheltered in its protective container or wrapped in a protective cloth.

1

2

3

1

Image 4-7

3. Remov e the hexagon socket head cap screw (reference 9) which fasten the cathode of the xenon lamp. Use a 5 mm Allen

wrench.

Note: The cathode wire remains in its position after the screw (reference 9) and washer (reference 10) are removed.

2

3

10

9

Image 4-8

Cathode fixation

4. Release the four quarter turn screws (reference 2 image 4-9) of the UV blocker asse mbly as illustrated. Make sure that the anode

support remains in its position while releasing the screws.

Caution: Ensure that you wear protective clothing, a full face shield and protective gloves.

2

Image 4-9

5. Support the xenon lamp inside the Lamp House with one hand while removing the UV blocker assem bly from the lamp house.

Note that some xenon lamps are installed with an anode adaptation bushing (reference 12 image 4-10).

Warning: Supporting the xenon lamp with one hand to prevents it from bumping against the chassis of the Lamp House.

R59770495 DP2K-23B 30/04/2010

33

Page 40

4. Lamp & lamp house

12

Image 4-10

Remove UV blocker

6. Gently remove the xenon lamp out of the Lamp House. Do not use excessive force upon the xenon lamp. Normally the xenon

lamp will easily slide out the cathode socket of the Lamp House.

Warning: Supporting the xenon lamp with one hand while pulling it out with other hand prevents it from bumping against the

chassis of t he Lamp House.

Image 4-11

7. Place the xenon lamp in its protective container or wrap the xenon lamp in a protective cloth and secure with two binders.

Image 4-12

Left: Xenon lamp wrapped in a protective cloth. Right: Xenon lamp captured in a protective container.

8. Remov e the cathode adapter from the xenon lamp by releasing the hexagon socket head set sc rew of the adapter as illustrated.

Use for that a 2,5 mm Allen wrench.

Image 4-13

Remove lamp adapter

34 R59770495 DP2K-23B 30/04/2010

Page 41

4. Lamp & lamp house

CAUTION: Expired xenon lam ps.

Dispose o f expired bulbs that are beyond warranty in the following manne r: wrap the bulb tightly in several

layers of canvas or heavy cloth. Place it on hard surface and shatter the en velope with a sharp hammer blow.

DO NO T place a n on shattered bulb in any ordinary refuse container.

When returning a xenon lamp for warranty adjustment, pack it in its original shipping container. Complete

and return all required warranty information.

R59770495 DP2K-23B 30/04/2010 35

Page 42

4. Lamp & lamp house

4.4 Installation of the xenon bulb lamp