Page 1

Cooling liquid refurbishment

Installation manual

For XLM, DP90 and DP100

R59770032/01

07/12/2006

Page 2

Barco nv Events

aan 5, B-8520 Kuurne

Noordl

Phone: +32 56.36.89.70

Fax: +32 56.36.88.24

sales.events@barco.com

E-mail:

Visit us at the web: www.barco.com

PrintedinBelgium

Page 3

1. LIQUID COOLING CIRCUIT

Overview

• Safety

• Introduction

• Diagnostics

1.1 Safety

WARNING: Hazardous product: Blue antifreeze diluted 1,2 ethanediol (1/3 ethanediol – 2/3 Demi water).

Not for h ousehold use. Keep out of reach of children. Harmful by oral intake. Avoid exposure to pregnant

women. Avoid contact with eyes, skin and clothing. Avoid inhale of the noxious fumes.

Handling the cooling liquid

• Avoid contact of the liquid with Eyes, Skin and Clothing.

• Avoid inhaling of the noxious fumes.

• Conserve the product in the original package and in a well ventilated room.

1. Liquid Cooling Circuit

Personal protection rules

• Handle the cooling liquid in a w ell ventilated room.

• Under no circumstances eat, drink and smoke while handling the liquid.

• Wear gloves (Butylrubber, PVC....) and Goggles.

• Wear suitable protection clothing.

1.2 Introduction

Functionality

Much heat has to be extracted from the DMD’s and from the light pipe entrance during operation of the projector. The liquid cooling

circuit takes care of this. The liquid cooling circuit is a closed loop of flexible tubing comprising of a pump, three cooling blocks for

the DMD ’s, a cooling block for the light pipe entrance, a heat exchan

inside the circuit absorbs the heat of the cooling blocks. Via the pump, the heated-up liquid is transported to the heat exchanger,

which in turn cools down the liquid.

The pressure vessel in the circuit makes it possible to put a small pressure on the cooling liquid. The required pressure exerted via

the pressure vessel serves to prevent cavitation an d hence ensures the good working condition of the pump. Note that the pressure

doesn’t influence the cooling capacity of the system.

ger, a pressure vessel and a manometer. The cooling liquid

R59770032 COOLING LIQUID REFURBISHMENT 07/12/2006

1

Page 4

1. Liquid Cooling Circuit

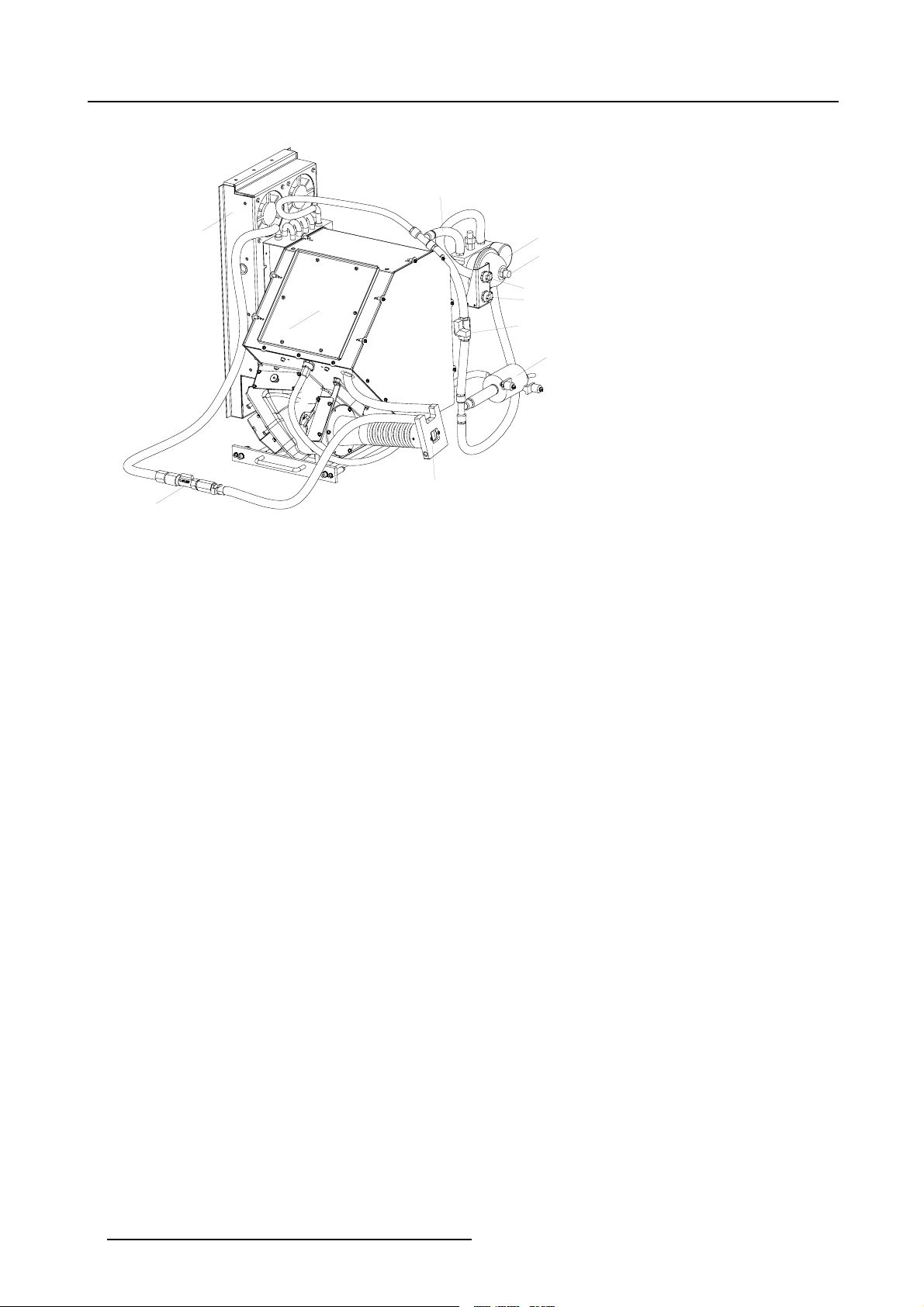

Parts of the liquid cooling circuit

K

J

A

I

Image 1-1

A DMD - Peltier cooling block.

B Manometer.

C Pressure vessel.

D Outlet cooling circuit

E Inlet cooling circuit

F Vane

GPump.

H Cooling block light pipe entrance.

I Flow switch.

J Heat exchanger.

H Transparent tube for visual check.

B

C

D

E

F

G

H

2

R59770032 COOLING LIQUID REFURBISHMENT 07/12/2006

Page 5

Block diagram of the cooling circuit

1. Liquid Cooling Circuit

Heat

Exchanger

Waterflow Sensor

Expansion Vat

Engine

Pressure relief

valve (3 Bar)

Pump

Manometer

Vane

Light Pipe

entry

Outlet

Inlet

Outlet

Inlet

Vane

to SMPS Control

Image 1-2

Block diagram cooling circuit

Order info liquid cooling

Order number

R395198K

B1909086K

Description

Complete liquid cooling refill kit. Includes tubes, valved fittings, syringe, air pump, plastic bottle of 1 liter

filled with cooling liquid and one empty plastic bottle of 1 liter.

Two bottles of 1 liter filled with cooling liquid. (no additional tools)

1.3 Diagnostics

General

Over extended periods theremay be small losses ofpressure in the liquid c ooling system of the projector. It is there for recommended

to check the pressure at regular intervals. In case the pressure drops below 0,5 bar it is recommended to restore the pressure o f

the liquid cooling system.

CAUTION: In case of a rapid l oss in pressure check the liquid cooling circuit for leakage. Solve the problem

before starting up the projector.

Troubleshooting cooling loop

• Any significant or rapid drop in pressure indica tes a leakage of liquid. If this be the case, verify whether the circuit shows any

visible sign of liquid leakage.

• As critical components rely on this liquid cooling, it is essential that any leakage is detected timely.

• Periodic checking of the liquid cooling pressure is essential to guarantee overall good performance of the projector and the

pump.

• The factory pressure preset is approximately 1 bar in the ’Projector Off’ status at a room temperature of 25 °C. This may drop

slightly during operation.

R59770032 COOLING LIQUID REFURBISHMENT 07/12/2006

3

Page 6

1. Liquid Cooling Circuit

Toohighambienttemperature

An Error or warning m essage “Ambient temp high” is displayed on the local LCD panel or touch panel. See manual of the projector

for accessing error messages.

Possible cause

Ambient temperature of the projector is too high.

Blocked filter at the front side and the left side of the projector Clean the blocked filter.

Solution

Measure the ambient temperature nearby the projector. In

case the measured temperature is higher than 40 °C take

the necessary measurements to ensure that the ambient

temperature is below 40 °C.

One of the DMD’s is too high in temperature

An Error or warning message “DMD temp high” is displayed on the local LCD panel or touch panel. See manual of the projector for

accessing error messages.

Possible cause

Malfunction Peltier element of the inv

DMD is too high in temperature while the other two DMD’s

have a normal and almost equal temperature.

The wire units of two Peltier elements or there respective

temperature sensors (NTC’s) have been swapped. While the

temperature of one DMD is too high,

be to low.

Poor assembly of DMD or Peltier + cooler block.

olved DMD. Only one

the other will most likely

Solution

1. Check if the wire unit of the involved Peltier is conn ected

with the interface board.

2. Check if the wire unit of the temperature sensor (NTC) is

connected with the interface boa

3. Check the fan control board. In case of malfunctioning

replace the board.

4. Defect Peltier element. Replace Pe

Check if the wire units of all Peltiers and all temperature

sensors (NTC’s) are plugged in there respective connector

sockets on the interface board.

Reinstall the Peltier.

rd.

ltier.

All DMD’s are too high in temperature

An Error or warning message “DMD temp high” is displayed on the local LCD panel.

Possible cause

The liquid cooling circuit of the light pro cessor is mistakenly

excluded from the main liquid cooling circuit.

None of the wire units of the Peltier elements or there

respective temperature sensors (NTC’s) are connected.

Blocked filter of the heat exchanger. Clean the blocked filter.

Solution

Check of the cooling circuit of the light processor is connected

with the pump and heat exchanger.

Check if the wire units of all Peltiers and all temperature

sensors (NTC’s) are plugged in there respective connector

sockets on the interface board.

No flow of the cooling liquid

An Error message “Water flow” is displayed on the local LCD pa nel.

Possible cause

Interruption of the liquid cooling circuit. Check if the loop of the liquid cooling circuit is closed.

No or insufficient liquid inside the cooling circuit. The pump is

sucking air and sounds noisier then normal.

Solution

Fill the cooling circuit with liquid and expel all air. Pressurize

the circuit.

4 R59770032 COOLING LIQUID REFURBISHMENT 07/12/2006

Page 7

1. Liquid Cooling Circuit

Possible cause

Defect pump. When the projector is running, you don’t feel

any vibrations when touching the pump

Defect flow switch. The pump is functioning normally but the

projector displays a water flow error.

Solution

Drain the liquid cooling circuit, replace the pump, fill and

pressurize the liquid cooling circuit.

Tip: It’s not necessary to drain the cooling circuit of the light

processor. Bypass this part of the cooling circuit.

Drain the liquid cooling circuit, replace the flow switch, fill and

pressurize the liquid cooling circuit.

Tip: It’s not necessary to drain the cooling circuit of the light

processor. Bypass this part of the cooling circuit.

R59770032 COOLING LIQUID REFURBISHMENT 07/12/2006 5

Page 8

1. Liquid Cooling Circuit

6 R59770032 COOLING LIQUID REFURBISHMENT 07/12/2006

Page 9

2. Servicing the liquid cooling circuit

2. SERVICING THE LIQUID COOLING CIRCUIT

WARNING: All procedures in this chapter may only be performed by “qualified service technicians” .

Definition of “qualified service tech nicians” or ”qualified technicians”: Persons having appropriate technical

training and experience necessary to be aware of hazards to which they are exposed in performing a task and

of measures to minim ize the danger to themselves or other persons.

All procedures in this chapter require the removal of the side cover of the projector. See user manual of the

projector for instructions on how to remove and install the side cover.

WARNING: All actions performed on the liquid cooling circuit should occur in ambient conditions (25°). The

projector shoul d have sufficiently cooled down (minimum 2 hours).

WARNING: Do not change the air pressure of a calibrated liquid cooling circuit (see marking on pressure

vessel), unless stated explicitly in the servicing procedure.

Tools used in the liquid cooling servicing procedures

ABCD E F G

m

m

c

0

6

Image 2-1

m

c

c

0

0

6

6

m

c

0

6

1L

A Syringe with plastic tube (60 cm) and male valved fitting.

B 60 cm plastic tube with male valved fitting.

C 60 cm plastic tube with female valved fitting.

D Female/female valved fitting adaptor.

E Bottle with 1 liter cooling liquid.

F Empty bottle with a volume of 1 liter.

G Air pump with Shrader type air hose fitting.

CAUTION: To avoid damage to the connector seal, always depress the connector tab of the female valved

fitting prior to in serting the male

valved fitting.

R59770032 COOLING LIQUID REFURBISHMENT 07/12/2006 7

Page 10

2. Servicing the liquid cooling circuit

2.1 Preparation for cooling liquid replacement

What has to be done

1. Switch off the projector.

2. Remove the lamp unit to access the cooling liquid in- and outlet.

3. If excluding the light processor is required while handling the cooling circuit procedures, disconnect the circuit at the flow switch

(a). Disconnect the input of the light processor circuit and connect this tube to the flow switch (b).

b

a

Image 2-2

Excluding light processor

2.2 Draining the liquid cooling circuit

In case of part replacement, consider only draining that partof the circuit which contains the defect part. E.g.

in case of pump replacement; it is p referred to bypass the engine circuit. This to exclude the engine from the

problem.

Necessary tools

• 60 cm of plastic tube with male valved fitting.

• Syringe connected with short tube with male valved fitting.

• Empty bottle with a volume of 1 liter.

• Cloths.

Howtodraintheliquidcoolingcircuit

1. Couple a plastic tube with male valved fitting to the outlet. Insert the other end into an empty bottle.

Note: Do not open the valve before the tube end is inserted in an empty bottle.

?

8

R59770032 COOLING LIQUID REFURBISHMENT 07/12/2006

Page 11

OUT

Image 2-3

Drain complete circuit

2. Close the valve.

3. Fill the syringe with air. Press in the valve of the male fitting when extracting air.

2. Servicing the liquid cooling circuit

Image 2-4

4. Couple the air filled syringe to the inlet of the cooling circuit and force air into the circu it via the syringe. Liquid will be expelled

from the circuit exit side into the empty bottle.

OUT

IN

Image 2-5

Draining cooling liquid completely

5. Disconnect the syringe from the cooling circuit and repeat from step 3 until all cooling liquid is drained.

R59770032 COOLING LIQUID REFURBISHMENT 07/12/2006

9

Page 12

2. Servicing the liquid cooling circuit

2.3 Filling the liquid cooling circuit

This procedure can only be used to fill an empty (drained) cooling circuit.

Necessary tools

• 60 cm of plastic tube with male valved fitting.

• 60 cm of plastic tube with female valved fitting.

• Syringe connected with short tube with male valved fitting.

• Bottle w ith cooling liquid.

• Empty bottle with a volume of 1 liter.

• Cloths.

How to fill the liquid cooling circuit ?

1. Close the vane.

2. Couple a plastic tube, which contains a male valved fitting, to the outlet of the cooling circuit and lead the tube end to an empty

bottle.

OUT

Image 2-6

Drain complete circuit

3. Fill th e syringe with cooling liquid as follows:

a) Couple the female (F) fitting of a plastic tube to male (M) fitting of the syringe and emerge the tube end. Make sure that the

piston of the syringe is completely pressed in.

b) Extract cooling liquid into the syringe by pulling out the piston.

c) Turn the syringe upside down, so that th e air inside the syringe is located at the outlet.

d) Push the piston in until all air bubbles inside the syringe and tubes are expelled. Ensure that the tube end in the bottle remains

emerged.

e) Pull out the piston to fill the tubes and syringe completely with cooling liquid.

f) Disconnect the filled syringe from the tube.

10

R59770032 COOLING LIQUID REFURBISHMENT 07/12/2006

Page 13

2. Servicing the liquid cooling circuit

abc d e f

M

F

Image 2-7

4. Couple the filled syringe to the inlet of the cooling circuit and press the cooling liquid inside the circuit.

Caution: Position the empty bottle above the liquid circuit (on top of projector).

a

OUT

b

Image 2-8

Filling cooling liquid circuit

5. Disconnect thesyringe from the cooling circuit and repeat from step 3 untilcooling liquidcomes out the outlet of the cooling circuit.

R59770032 COOLING LIQUID REFURBISHMENT 07/12/2006

11

Page 14

2. Servicing the liquid cooling circuit

2.4 Refreshing the liquid cooling circuit

Over timethe coolingliquid may show deterioration and hence less effective cooling characteristics. Tomaintain sound cooling properties, we advise ANN UAL replacement of the cooling liquid.

Necessary tools

• 2 x 60 cm of plastic tube with male valved fitting.

• Syringe equipped with male valved fitting.

• Female/female tube adapter (short tube with female valved fitting at both sides).

• Bottle with 1 liter cooling liquid.

• Empty bottle with a volume of one liter.

• Cloths.

How to refresh the liquid cooling circuit ?

1. Close the vane.

2. Insert the tube end of the plastic tube, which contains a male valved fitting, into a bottle filled with a little cooling liquid and then

couple the male valved fitting with the out let of the cooling circuit.

Note: Circuit is pressurized, so first insert tube end into empty bottle.

3. Fill a plastic tube, which contains a male fitting, with cooling liquid as follows:

a) Connect a tube, which contains a male (M) fitting, to the male (M) fitting of the syringe using a female/female (F) adapt er.

b) Emerge the tube end and make sure that the piston of the syringe is completely pressed in.

c) Extract cooling liquid into the syringe by pulling out the piston.

d) Disconnect the filled tube from the syringe. Make sure that the tube remains immersed.

M

bacd

F

F

M

Image 2-9

Caution: It’s important that there is no air inside the tube. T

through small volumes of air.

4. Push the male valved fitting of the filled tube into the inlet of the cooling circuit. Make sure that the inlet of the filled tube remains

immersed.

he pump is not self priming and hence is o nly capable of sucking

12

R59770032 COOLING LIQUID REFURBISHMENT 07/12/2006

Page 15

2. Servicing the liquid cooling circuit

OUT

IN

Image 2-10

Refresh cooling circuit

5. Switch on the projector. After projector boot-up procedure, the internal pump will automatically start sucking-up the fresh liquid

Note: Make sure that the end of the plastic tube remains immersed in the bottle with fresh cooling liquid.

6. Switch off the projector after 2/3 ofthefreshcoolingliquidissuckedupintothecircuit.

7. Proceed with expelling the air from the liquid cooling circuit. See procedure"Expelling air from the liquid cooling circuit", page 13.

Tip: You can use the bottle with the remaining fresh cooling liquid and the same tubes for the expelling procedure.

8. Pressurize the liquid cooling circuit. See procedure "Pressurizing the liquid c ooling circuit", page 15.

2.5 Expelling air from the liquid cooling circuit

Necessary tools

• 2 x 60 cm of plastic tube with male valved fitting.

• Bottle with cooling liquid (minimum 1/3 liter).

• Syringe equipped with male valved fitting.

• Female/female tube adapter (short tube with female valved f ittings at both sides).

• Cloths.

How to expel the air from the liquid cooling circuit ?

1. Close the vane.

2. Fill a plastic tube, which contains a male fitting, with cooling liquid as follows:

a) Connect a tube, which contains a male (M) fitting, to the male (M) fitting of the syringe using a female/female (F) tube adapter.

b) Emerge the tube end and make sure that the piston of the syringe is completely pressed in.

c) Extract cooling liquid into the syringe by pulling out the pis

d) Disconnect the filled tube from the syringe. Make sure that the tube remains immersed.

ton.

R59770032 COOLING LIQUID REFURBISHMENT 07/12/2006

13

Page 16

2. Servicing the liquid cooling circuit

M

bacd

F

F

M

Image 2-11

Caution: It’s important that there is no air inside the tube. The pump is not self priming and hence is only capable of sucking

3. Push the male valved fitting of the filled tube into the inlet of the cooling circuit. Make sure that the inlet of the filled tube remains

immersed.

4. Couple a second plastic tube to the outlet of the cooling circuit and immerge the tube end without fitting in thesame bottle wherein

the first tube is immersed.

through small volumes of air.

OUT

IN

Image 2-12

Expelling air

5. Switch on the projector. After projector boot-up procedure, the internal pump will automatically start sucking-up the fresh liquid

while air bubbles are pressed out of the circuit.

Caution: Switch off the projector immediately in case the pump is sucking air (no circulation of liquid). Bypass the cooling

Caution: Make sure that air bubbles coming out of the tube in the bottle doesn’t enter the other tube in the bottle.

6. Switch off the projector after all air bubbles are expelled. This will take approximately 10 minutes.

Tip: Air bubbles may no longer come out the exit of the tube in the bottle with cooling liquid.

14

circuit of the light processor and inject cooling liquid into the main cooling circuit using a syringe. Ensure that you

don’t inject air bubbles.

R59770032 COOLING LIQUID REFURBISHMENT 07/12/2006

Page 17

2. Servicing the liquid cooling circuit

7. Uncouple the two plastic tubes.

Note: Make sure that both ends of the plastic tubes in the bottle remains immersed until the plastic tubes are uncoup le from

the liquid cooling circuit.

Tip: Sometimes a little cooling liquid will be spilled. Wrap a small cloth around th e valved fitting while uncoupling to absorb

the spilled cooling liquid.

8. Pressurize the liquid cooling circuit. See procedure "Pressurizing the liquid c ooling circuit", page 15.

Check within 24 hours if the pressure rem ains 1 bar. If not, search for leakage.

2.6 Pressurizing the liquid cooling circuit

Before pressurizing the liquid cooling circuit ensure that the circuit is filled with cooling liquidand that all air

bubbles are expelled.

CAUTION: This procedure is only valid in case the liquid coo ling circuit is calibrated. This means that the

pressure vessel was not subject to any m odifications,i.e. releasing or increasing pressure via the valve of the

vessel. In case the pressure vessel was subject to mo difications use the calibra

the liquid cooling circuit.

tion procedure to pressurize

WARNING: All actions performed on the liquid cooling circuit should occur in ambient conditions (25°). The

projector shoul d have sufficiently cooled down (minimum 2 hours).

Necessary tools

• 60 cm of plastic tube with female valved fitting.

• Syringe connected with short tube with male valved fitting.

• Bottle w ith cooling liquid.

• Cloths.

How to pressurize the liquid cooling circuit ?

1. Fill th e syringe with cooling liquid as follows:

a) Couple the female (F) fitting of a plastic tube to male (M) fitting of t

piston of the syringe is completely pressed in.

b) Extract cooling liquid into the syringe by pulling out the piston.

c) Turn the syringe upside down, so that the air inside the syringe i

d) Push the piston in until all air bubbles inside the syringe and tubes are expelled. Ensure that the tube end in the bottle remains

immersed.

e) Pull out the piston to fill the tubes and syringe completely with c

f) Disconnect the filled syringe from the tube.

he syringe and emerge the tube end. Make sure that the

s located at the outlet.

ooling liquid.

R59770032 COOLING LIQUID REFURBISHMENT 07/12/2006

15

Page 18

2. Servicing the liquid cooling circuit

abc d e f

M

F

Image 2-13

2. Couple the syringe to the inlet of the cooling circuit and press the cooling liquid inside the circuit until the manometer indicates 1

bar pressure. Ensure that no air bubbles are injected into the circuit.

Caution: Maximum 1 bar of pressure is allowed on the liquid coolingcircuit. More pressure than 1 bar may damage the circuit.

IN

Image 2-14

Pressurize cooling circuit

3. Check if the cooling circuit was correctly calibrated. Proceed as follows:

a) Taking note of the liquid level in the syringe, while pressurizing the cooling circuit up to 1 bar (see previous step).

b) Release the plunger. As a result the pressure of the cooling circuit will drop from 1 to 0 bar and cooling liquid is automatically

expelled from the circuit into the syringe.

c) Check if the amount of expelled liquid is between 50 a nd 70 ml. If not, s tart the procedure "Calibrating the liquid cooling

circuit", page 17.

d) Push the plunger of the syringe to reinject the expelled liquid back into the circuit. The pressure would hence return to 1 bar.

4. Disconnect the syringe from the cooling circuit. Make sure that the pressure remains 1 bar.

5. Check that the vane is open.

16

R59770032 COOLING LIQUID REFURBISHMENT 07/12/2006

Page 19

Check within 24 hours whether th e pressure has stabilized close to 1 bar. If not, search for leakage.

2.7 Calibrating the liquid cooling circuit

To check if th e pressure vessel is correctly calibrated you may connect the syringe with the cooling circuit

and measure the amount of liquid that is automatically expelled. The pressure would have dropped from 1 to

0 bar. The expelled amount of cooling liquid should be between 50 and 70 ml. Make sure th at there are no air

bubbles in the syringe while doing this. Reinject the expelled liquid back into the circuit. The pressure would

hence return to 1 bar.

A calibrated liquid cooling circuit means that the ratio between the volume of cooling liquid in the circuit and

the volume of air in the pressure vessel is defined. This is achieved by first filling the vessel completely with

liquid consequently expelling air from the vessel. Secondly a predefined volume of cooling liquid is extracted

from the circuit. Finally the liquid cooling circuit has to be p ressurizedto 1 bar by pumpingair into the vessel.

Make sure that all air is expelled from the liquid cooling circuit before starting the calibration procedure.

2. Servicing the liquid cooling circuit

Necessary tools

• 60 cm of plastic tube with female valved fitting.

• Syringe connected with short tube with male valved fitting.

• Bottle w ith cooling liquid.

•Airpump.

• Cloths.

How to calibrate the liquid cooling circuit ?

1. Remove the valve cap of th e pressure vessel and release the pressure.

Image 2-15

2. Fill the syringe with cooling liquid as fo llows:

a) Couple the female (F) fitting of a plastic tube to male (M) fitting of the syringe and emerge the tube end. Make sure that the

piston of the syringe is completely pressed in.

b) Extract cooling liquid into the syringe by pulling out the piston.

c) Turn the syringe upside down, so that th e air inside the syringe is located at the outlet.

d) Push the piston in until all air bubbles inside t

emerged.

e) Pull out the piston to fill the tubes and syringe completely with cooling liquid.

f) Disconnect the filled syringe from the tube.

he syringe and tubes are expelled. Ensure that the tube end in the bottle remains

R59770032 COOLING LIQUID REFURBISHMENT 07/12/2006

17

Page 20

2. Servicing the liquid cooling circuit

abc d e f

M

F

Image 2-16

3. Fill the pressure vessel with liquid as follows:

a) Couple the syringe with the inlet of the cooling circuit.

b) Increase the pressure by pushing in the piston of the syringe (maximum 1 bar indicated on the manometer).

c) While pressing, expel air from the pressure vessel.

d) Continue expelling air while pressurizing the circuit (up to 1 bar) until the valve of the vessel becomes hard to push in. This

indicates that the pressure vessel is completely filled with cooling liquid.

IN

Image 2-17

Expelling air of vessel

18 R59770032 COOLING LIQUID REFURBISHMENT 07/12/2006

Page 21

2. Servicing the liquid cooling circuit

4. Now that the pressure vessel is liquid filled you have to increase the pressure to 1 bar by pushing in the piston of the syringe.

Then immediately extract 75 ml back into the syringe by doing the following:

a) Taking note of the liquid level already in the syringe, release the plunger.

b) Now fill the syringe by slowly pumping air into the vessel (connect air pump to valve).

c) Stop once 75 ml has been expelled.

d) Disconnect the syringe from the cooling circuit.

Note: 75 ml does not include the liquid already in the syringe.

75 ml

IN

Image 2-18

Calibrate cooling circuit

5. Remove the syringe connection.

6. Pump up the air pressure to 1bar(on manometer) and reinstall the valve cap tightly on the pressure vessel.

Image 2-19

Pressurize to 1 bar

7. Mark the pressure vessel wit

8. Check that the vane is open.

R59770032 COOLING LIQUID REFURBISHMENT 07/12/2006

h the calibration date for future reference.

19

Page 22

2. Servicing the liquid cooling circuit

The air hose fitting of the air pum p must be of the Shrader valve type (A) to match with the pressure vessel,

so the Presta valve type (B) has to be removed. Futhermore, the pin (C) inside the Shrader valve has to be

removed as w ell.

A

B

Check within 24 hours whether th e pressure has stabilized close to 1 bar. If not, search for leakage.

A

B

A

C

C

20 R59770032 COOLING LIQUID REFURBISHMENT 07/12/2006

Loading...

Loading...