Page 1

DOC-3200-2

User's Manual

Page 2

DOC-3200-2, Current Version

Title: HERMES DXD – User’s Manual

ID-no.: DOC-3200-2

Date: 2003-09

main issue update

chapter 1 new

chapter 2 new

chapter 3 new

chapter 4 new

chapter 5 new

chapter 6 new

chapter 7 new

new: The corresponding chapters are new or completely revised.

corr.: Passages of the corresponding chapter were corrected; see modification bars.

add.: Passages of the corresponding chapter were added; see modification bars.

Document History

Modifications which result in a new version are indicated by a vertical bar.

Keep this sheet!

Page 3

Trademarks

Brand and product names mentioned in this manual may be trademarks, registered trademarks or

copyrights of their respective holders. All brand and product names mentioned in this manual

serve as comments or examples and are not to be understood as advertising for the products or

their manufacturers.

Copyright © 1999 - 2003 by Barco Control Rooms GmbH

Die Weitergabe sowie die Vervielfältigung aller Unterlagen, die von uns überlassen werden, deren

Verwertung und Mitteilung ihres Inhaltes an Dritte ist nicht gestattet, soweit dies nicht ausdrücklich zugestanden ist. Urheberrechte, insbesondere auch solche an Software, werden nur insoweit

übertragen, als es für die Erreichung des speziellen Vertragszwecks erforderlich ist. Zuwiderhandlungen können zu Schadensersatz verpflichten. Alle Rechte aus der Erteilung eines Patents

oder der Eintragung eines Gebrauchsmusters verbleiben bei uns.

Copyright © 1999 - 2003 by Barco Control Rooms GmbH

All rights reserved. No part of this document may be copied, reproduced or translated. It shall not

otherwise be recorded, transmitted or stored in a retrieval system without the prior written consent

of Barco Control Rooms GmbH.

Guarantee and Compensation

Barco Control Rooms GmbH provides a guarantee relating to perfect manufacturing as part of the

legally stipulated terms of guarantee. On receipt, the purchaser must immediately inspect all delivered goods for damage incurred during transport, as well as for material and manufacturing faults.

Barco Control Rooms GmbH must be informed immediately in writing of any complaints.

The period of guarantee begins on the date of transfer of risks, in the case of special systems and

software on the date of commissioning, at the latest 30 days after the transfer of risks. In the event

of justified notice of complaint, Barco Control Rooms GmbH can repair the fault or provide a replacement at its own discretion within an appropriate period. If this measure proves to be impossible or unsuccessful, the purchaser can demand a reduction in the purchase price or cancellation of

the contract. All other claims, in particular those relating to compensation for direct or indirect

damage, and also damage attributed to the operation of software as well as to other services provided by Barco Control Rooms GmbH, being a component of the system or independent services,

will be deemed invalid provided the damage is not proven to be attributed to the absence of properties guaranteed in writing or due to the intent or gross negligence on the part of Barco Control

Rooms GmbH

If the purchaser or a third party carries out modifications or repairs on good delivered by Barco

Control Rooms GmbH, or if the goods are handled incorrectly, in particular if the systems are

commissioned or operated incorrectly or if, after the transfer of risks, the goods are subject to influences not agreed upon in the contract, all guarantee claims of the purchaser will be rendered invalid. Not included in the guarantee coverage are system failures which are attributed to programs

or special electronic circuitry provided by the purchaser, e. g. interfaces. Normal wear as well as

normal maintenance are not subject to the guarantee provided by Barco Control Rooms GmbH either.

The environmental conditions as well as the servicing and maintenance regulations specified in

this manual must be complied with by the customer.

Page 4

Revision sheet

To:

Barco Control Rooms GmbH

An der Rossweid 5, D-76229 Karlsruhe

Phone: +49-721-6201-0, Fax: +49-721-6201-298

E-mail:

BarcoProjection

Noordlaan5, B-8520 Kuurne, Belgium

Phone: (32) (56) 36-8211, Fax: (32) (56) 36-8251

E-mail: sales.bcd@barco.com , Web:

Please correct the following points in the documentation mentioned above:

docu.de.bcd@barco.com Web: www.barcocontrolrooms.de

www.barcocontrolrooms.com

From:

Date:

page wrong correct

Page 5

Table of Contents

1 Preliminary Remarks.................................................................................................................... 1-1

1.1 How this manual is organized ............................................................................................. 1-2

1.2 Styles and Symbols .............................................................................................................1-3

1.3 Safety Information............................................................................................................... 1-4

1.3.1 Precautions.................................................................................................................. 1-6

1.3.2 Unpacking of Devices ................................................................................................1-6

1.3.3 Transport of Devices .................................................................................................. 1-6

1.3.4 Modification of Devices ............................................................................................. 1-6

2 Summary ...................................................................................................................................... 2-1

2.1 Connecting the graphical controller and the projection cubes............................................2-2

2.2 Assigning inputs to outputs .................................................................................................2-3

2.3 Remote Control ...................................................................................................................2-3

3 Getting started ..............................................................................................................................3-1

3.1 Examining ...........................................................................................................................3-2

3.1.1 The Front Panel .......................................................................................................... 3-2

3.1.2 The Back Panel...........................................................................................................3-4

3.2 Native device settings (default settings).............................................................................. 3-5

3.3 DDC Capability...................................................................................................................3-5

3.4 Cabling ................................................................................................................................3-6

3.4.1 Power Supply..............................................................................................................3-6

3.4.2 Digital Input and Output............................................................................................. 3-7

3.4.3 Remote Control........................................................................................................... 3-7

3.5 Operating Hermes DXD...................................................................................................... 3-8

4 Remote Control ............................................................................................................................ 4-1

4.1 Cabling ................................................................................................................................4-2

4.1.1 Cabling of Hermes DXD (number of devices < 20) .................................................. 4-2

4.1.2 Cabling of Hermes DXD (number of devices > 20) .................................................. 4-3

4.2 Definition of Protocol.......................................................................................................... 4-3

4.2.1 Connection Settings.................................................................................................... 4-3

4.2.2 Communication .......................................................................................................... 4-3

4.2.3 Structure of Messages................................................................................................. 4-4

4.2.4 Acknowledge .............................................................................................................. 4-4

4.2.5 Types of RCS Classes................................................................................................. 4-5

4.3 How to calculate the checksum........................................................................................... 4-5

4.4 The Status Register.............................................................................................................. 4-6

Page 6

5 Controlling Hermes DXD ............................................................................................................ 5-1

5.1 Valid Commands for Hermes DXD .................................................................................... 5-2

5.2 Request commands.............................................................................................................. 5-3

5.3 Switching commands ..........................................................................................................5-4

5.3.1 Switching the Digital Output 1................................................................................... 5-4

5.3.2 Switching the Digital Output 2................................................................................... 5-6

5.4 Enabling/Disabling auto switch ..........................................................................................5-9

5.5 Commands referring to settings ........................................................................................5-11

5.6 Reading the status register.................................................................................................5-14

5.7 Reading the product identification .................................................................................... 5-15

5.8 Error messages ..................................................................................................................5-16

6 Broadcast addressing mode.......................................................................................................... 6-1

6.1 Structure of message ...........................................................................................................6-2

6.2 Processing a command in broadcast mode.......................................................................... 6-2

6.3 Commands for broadcast addressing................................................................................... 6-3

7 Technical Data .............................................................................................................................7-1

7.1 General Data........................................................................................................................ 7-2

7.1.1 Dimensions ................................................................................................................. 7-2

7.1.2 Power Supply..............................................................................................................7-2

7.1.3 Operating Conditions.................................................................................................. 7-3

7.2 Interfaces .............................................................................................................................7-4

7.2.1 Remote In.................................................................................................................... 7-4

7.2.2 Remote Out................................................................................................................. 7-4

7.2.3 Digital In..................................................................................................................... 7-5

7.2.4 Digital Out .................................................................................................................. 7-5

7.3 Parts List.............................................................................................................................. 7-6

7.3.1 Hermes DXD .............................................................................................................. 7-6

7.3.2 Remote Control........................................................................................................... 7-6

7.3.3 User’s Manuals ........................................................................................................... 7-6

7.4 Address................................................................................................................................ 7-7

Page 7

1 Prelim inary Remarks

This User’s Manual describes design, function and operation of HERMES DXD of Barco.

HERMES DXD is a multiplexer to connect each of two digital projection units alternatively to two

graphical controllers. Barco's product range of digital projection units comprises

ules of the O

E

OS or an ARGUS device. For further orientation on HERMES DXD see chapter 2 Summary, please!

VERVIEW D series and of the OVERVIEW P series, the graphical controller could be an

This chapter explains the structure of the manual itself and the used typographic styles and symbols. Safety information is provided concerning the operation of systems from Barco.

projection mod-

Page 8

1.1 How th i s manual is organized

This manual is divided into seven chapters:

Preliminary Remarks

explains the structure of the manual itself and the used typographic styles and symbols. Safety information is provided concerning the operation of systems from Barco.

Summary

provides a summary of the system components and characteristics.

First steps

describes the interfaces and the cabling of HERMES DXD.

Remote Control

describes cabling, protocol and addressing procedure of the remote control.

Operating Hermes DXD

describes the syntax of the commands and their consequences

Broadcast addressing mode

describes how to address all devices and the valid commands

Technical Data

provides tabular overviews about the technical details of the HERMES DXD

Numbering

Chapters, pages, figures and tables are numbered separately. Chapters are indicated by a »point

syntax«, e. g. 4.2.3, pages by a »dash syntax«, e. g. 2-1, as figures and tables are, e. g. Figure 5-4.

Page 9

1.2 Styles and Symbols

The typographic styles and the symbols used in this document have the following meaning:

Arial bold

Condensed

Courier

Courier

bold

Labels, menus and buttons are printed in the Arial bold font.

Links to both other chapters of this manual and to sites in the Internet are

printed condensed. In the on-line version of this manual all hyperlinks

appear teal.

Names of files and parts from programs are printed in the Courier

font.

Inputs you are supposed to do from the keyboard are printed in Cou-

rier bold font.

This arrow marks tips and notes.

If you do not heed instructions indicated by this symbol there is a risk of damage

to the equipment!

If you do not heed instructions indicated by this symbol there is a risk of electrical

shock and danger to personal health!

Page 10

1.3 Safety I nformation

This section describes safety precautions which must be observed when installing a product from

BARCO.

ERMES DXD is built in accordance with the requirements of the international safety standard

H

IEC950, UL1950 and CSA C22.2 No. 950, which are the safety standards of information technology equipment including electrical business equipment.

The safety standards of information technology equipment impose important requirements on the

use of safety critical components, materials and isolation, in order to protect the user or operator

against the risk of electric shock and energy hazard, and having access to live parts.

Safety standards also impose limits to the internal and external temperature rises, radiation levels,

mechanical stability and strength, enclosure construction and protection against risk of fire.

Simulated single fault condition testing ensures the safety of the equipment to the use even when

the equipment’s normal operation fails.

General safety instructions

All the safety and operating instructions should be read before using this unit.

The operating instructions manual should be retained for future reference.

All warnings on the device and in the documentation manuals should be adhered to.

All instructions for operating and use of this equipment must be followed precisely.

Installation and Service

Installation and preliminary adjustments should be performed by qualified BARCO personnel or

authorized BARCO service dealers.

On Safety

Check the power rating on your outlet before connecting the devices to the

wall outlet or to a power strip. Contact your facilities manager or a qualified

electrician if you are not sure what type of power is supplied to your building.

The devices are designed to operate with single-phase power systems having

a grounded neutral conductor. To reduce the risk of electrical shock, do not

plug into any other type of power system.

A. Mains lead (AC Power cord) with CEE 7 plug:

The colors of the mains lead are colored in accordance with the following code:

Green-and-yellow: Earth (safety

earth)

Blue: Neutral

Brown: Line (live)

B. Power cord with ANSI 73.11 plug:

The wires of the power cord are colored in accordance with the following code:

Green/yellow: Ground

White: Neutral

Black: Line (live)

Page 11

Do not allow anything to rest on the power cord. Do not locate this product where persons will

walk on the cord.

To disconnect the cord, pull it out by the plug. Never pull the cord itself.

If an extension cord is used with this product, make sure that the total of the ampere ratings on

the products plugged into the extension cord does not exceed the extension cord ampere rating.

Also make sure that the total of all products plugged into the wall outlet does not exceed 15

amperes.

Never push objects of any kind into this product through cabinet slots as they may touch dan-

gerous voltage points or short out parts that could result in a risk of fire or electrical shock.

Never spill liquid of any kind on the product. Should any liquid or solid object fall into the

cabinet, unplug the set and have it checked by qualified service personnel before resuming operations.

Warning: Do Not Place Flammable or Combustible Materials Near Device!

BARCO products are designed and manufactured to meet the most stringent safety regulations.

Exposing flammable or combustible materials into close proximity of this device could result in

the spontaneous ignition of that material, resulting in a fire. For this reason, it is absolutely necessary to leave an "exclusion zone" around all external surfaces of the device whereby no flammable

or combustible materials are present. The exclusion zone must be not less than 10 cm (4"). Do not

cover the device with any material while the device is in operation.

Keep flammable and combustible materials away from the device at all times. Mount the device in

a well ventilated area away from sources of ignition and out of direct sun light. Never expose this

product to rain or excessive moisture. In the event of fire, use sand, CO

, or dry powder fire extin-

2

guishers; never use water on an electrical fire.

Always have service performed on this product by authorized BARCO service personnel. Always

insist on genuine BARCO replacement parts. Never use non-BARCO replacement parts as they

may degrade the safety of this device.

Use only the power cord supplied with your device. While appearing to be similar, other power

cords have not been safety tested at the factory and may not be used to power the device. For a replacement power cord, contact your dealer.

Slots and openings in the cabinet and the sides are provided for ventilation; to ensure reliable operation of the device and to protect it from overheating, these openings must not be blocked or

covered. This product should never be placed near or over a radiator or heat register. This product

should not be placed in a built-in installation or enclosure unless proper ventilation is provided.

Page 12

On Servicing

Do not attempt to service this device yourself, as opening or removing covers may expose you to

dangerous voltage potential and risk of electric shock! Refer all service to a qualified BARCO

service center.

Adjust only those controls that are covered by the operating instructions since improper adjustment of the other controls may result in damage and will often require extensive work by a qualified technician to restore the product to normal operation.

Call for service in the following conditions :

When the power cord or plug is damaged or frayed.

If liquid has been spilled into the device.

If the product has been exposed to rain or water.

If the product does not operate normally when the operating instructions are followed.

If the product has been dropped or the cabinet has been damaged;

If the product exhibits a distinct change in performance, indicating a need for service.

When replacement parts are required, be sure the service technician has used original BARCO replacement parts or authorized replacement parts which have the same characteristics as the

BARCO original part. Unauthorized substitutions may result in degraded performance and reliability, fire, electric shock or other hazards. Unauthorized substitutions may void warranty.Upon

completion of any service or repairs to this unit, ask the service technician to perform safety

checks to determine that the unit is in proper operating condition.

1.3.1 Precaut i ons

For your own protection, observe the following safety precautions when installing your device!

Observe all warnings and instructions printed on the devices!

Check that the voltage and frequency of your power supply match those printed on the device

label with the rated electrical values!

Servicing not explicitly mentioned in this manual should never be carried out by unauthorized

personnel!

1.3.2 Unpack i ng of Devices

Note advises on the packaging for unpacking!

1.3.3 Transpo r t of Devices

Devices shall be transported in their original packaging only. Note advises on the packaging for

transport!

1.3.4 Modific a tion of Devices

Mechanical or electrical modifications others than described in this manual must not be made to

the devices. Barco is not liable for damages resulting from modified devices.

Only authorized personnel should carry out other maintenance work not explicitly

mentioned in this manual!

Never open the case of H

ERMES DXD without first disconnecting the power sup-

ply cord! Measurements and tests with the opened device may be carried out only

in the factory or by specially trained personnel, due to the dangers of electrical

shock.

Page 13

2 Summ ary

This chapter gives an overview of the HERMES DXD.

Page 14

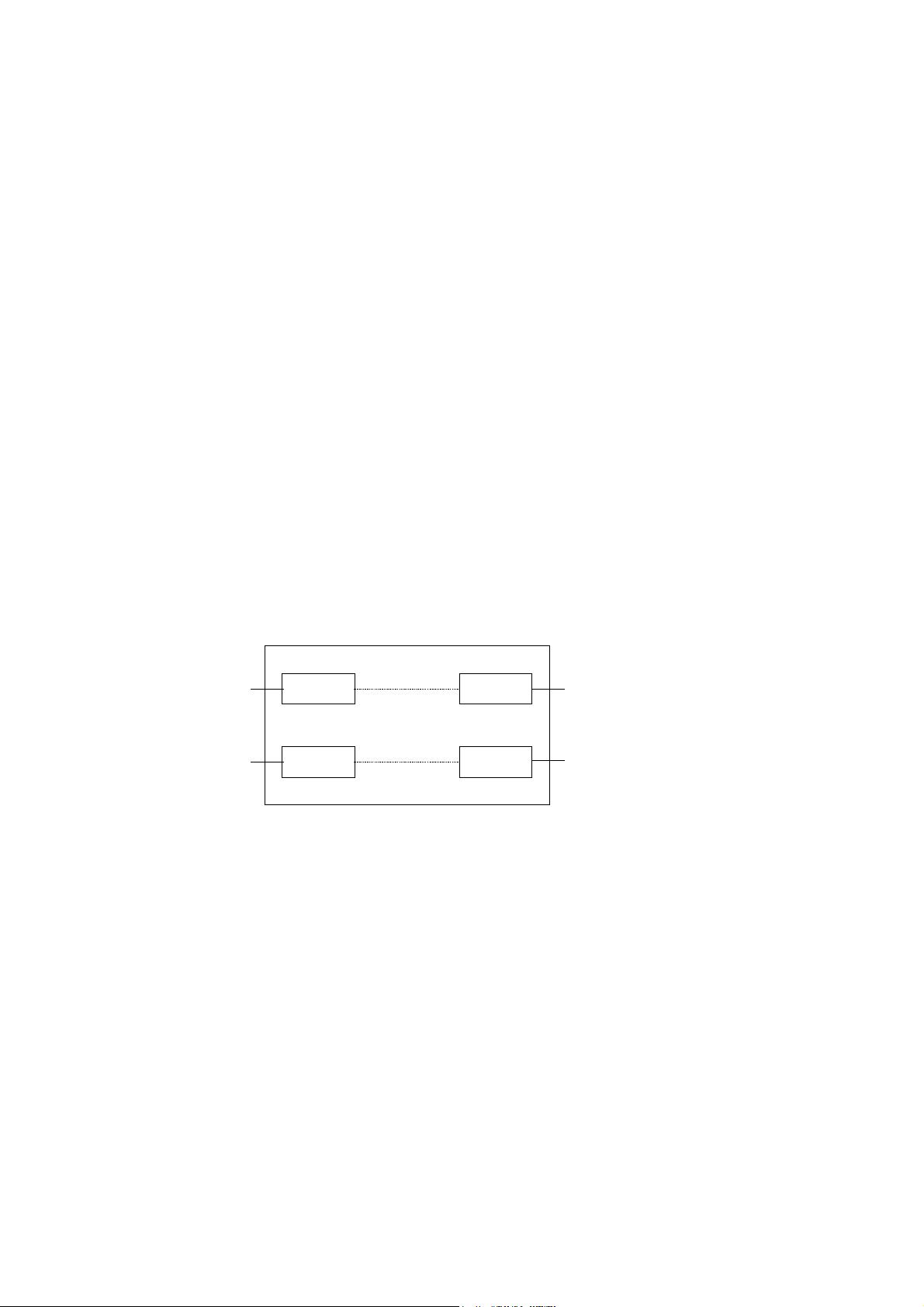

2.1 Conne cting the graphical controller and the projection cubes

n

n

HERMES DXD is equipped with two digital input connectors (Digital In 1, Digital In 2) and two

digital output connectors (

Digital Out 1, Digital Out 2).

The output connectors can be routed to any input connector, resulting in the following fields of

applications:

Hermes DXD as multiplexer

The connection of the projection cubes to different types of graphical controllers via HERMES

DXD allows controlling the Display Wall by different operating systems. Some cubes or the entire

Display Wall can alternatively be used as Windows NT desktop or as root window (X Window

system).

Redundancy

Some fields of application require the connection of the projection cubes to identical graphical

controllers: In a case of malfunction of one graphical controller it is immediately switched to the

other graphical controller. This redundancy guarantees a permanent availability of the Display

Wall.

Splitter

It is also possible to apply one signal to both outputs and thus display the identical information on

two different projection cubes.

Repeater

To increase the distance between graphical controller and projection unit, HERMES DXD can be

used as a two channel repeater.

Controller 1

Controller 2

Input 1

Input 2

Output 1

Output 2

projectio

module 1

projectio

module 2

Figure 2-1

connecting Hermes DXD (schematics)

Page 15

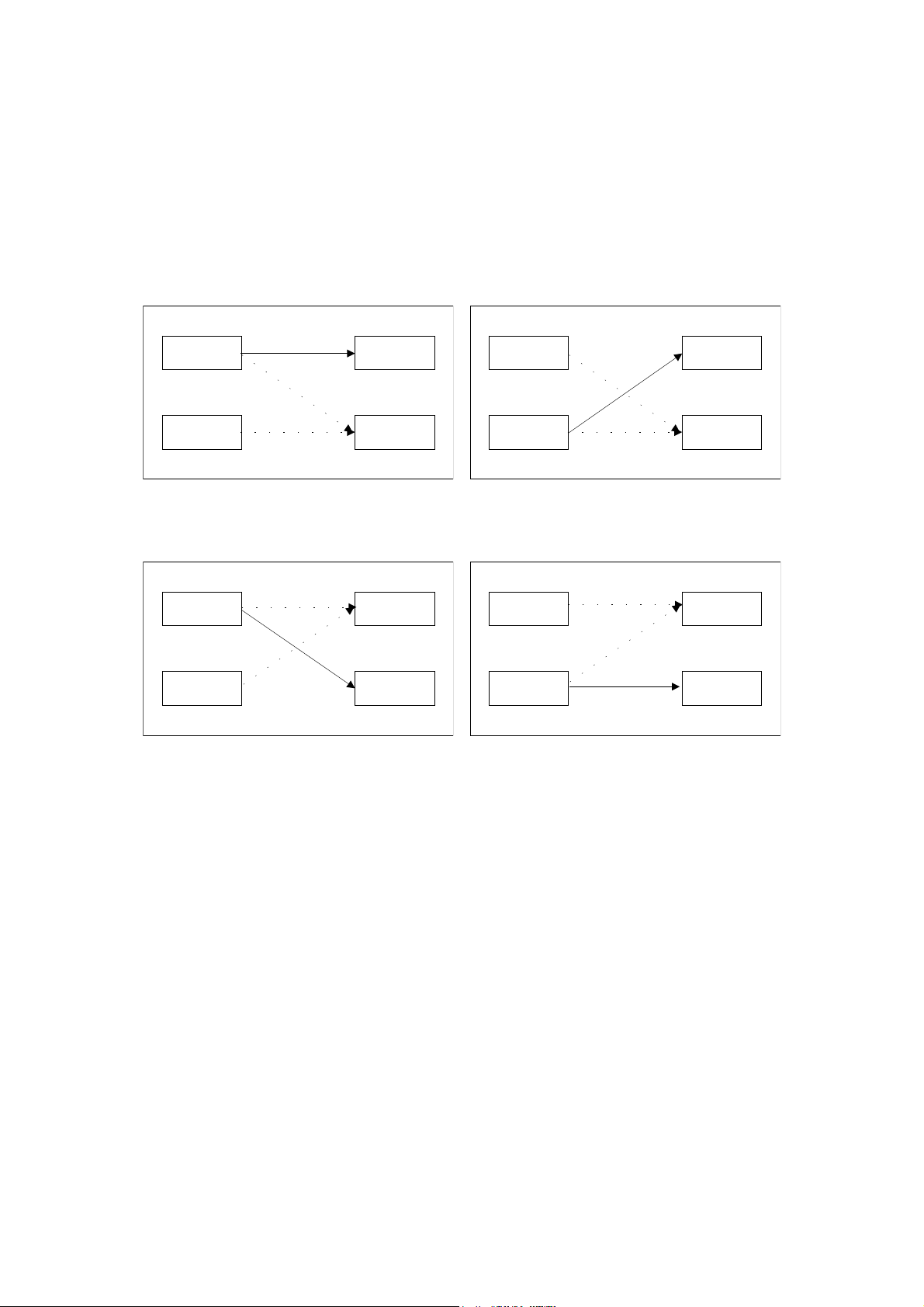

2.2 Assign i ng inputs to outputs

ERMES DXD is operated by means of remote control, and the inputs are routed to the output via

H

the respective command, cf.

The following schematics show the multiple possibilities for assigning an input to an output. For a

clear arrangement, the connections which can be established in parallel are indicated by gray

dashed lines.

5.3 Switching commands.

Input 1

Input 2

Input 1

Input 2

Output 1

Output 2

Output 1

Output 2

Input 1

Input 2

Input 1

Input 2

Output 1

Output 2

Output 1

Output 2

Figure 2-2

assigning inputs to output

2.3 Remot e Control

H

ERMES DXD is controlled by a serial interface. The remote control is integrated in X Window

(see

7.3.3 User’s Manuals) and available as application for Windows NT/2000/XP (HERMES REMOTE-

C

ONTROL). The protocol is accessible for individual applications.

The general concept of remote control, i. e. cabling, connection settings and protocol are described

separately in chapter

4 Remote Control.

Page 16

3 Gettin g started

This chapter describes the control elements and interfaces of HERMES DXD as well as the cabling.

Page 17

3.1 Examin i ng

3.1.1 The Fro n t Panel

The front panel of your HERMES DXD looks like this or similar:

Figure 3-1

Hermes DXD

POWERDIGITAL OUT 2DIGITAL OUT 1DIGITAL IN 2DIGITAL IN 1REMOTE OUTREMOTE IN

1

23 4 56 78 9 10 11

Figure 3-2

Front Panel of Hermes DXD

1 REMOTE IN

2 REMOTE OUT

3 LED: DIGITAL IN 1

4 DIGITAL IN 1

5 LED: DIGITAL IN 2

6 DIGITAL IN 2

7 LED: DIGITAL OUT 1

8 DIGITAL OUT 1

9 LED: DIGITAL OUT 2

10 DIGITAL OUT 2

11 LED: POWER

The REMOTE IN socket [1] is for plugging in the remote control cable coming from the previous device

(or the controlling PC), the

The

DIGITAL IN 1 socket [4] is for connecting HERMES DXD with the graphic card of a graphical con-

troller. The DVI cable is plugged in here. If a signal is applied to

REMOTE OUT [2] for the cable leading to the next device.

DIGITAL IN 1, the LED [3] is green,

else off.

The

DIGITAL IN 2 socket [6] is for connecting HERMES DXD with the graphic card of a graphical con-

troller. The DVI cable is plugged in here. If a signal is applied to

DIGITAL IN 2, the LED [5] is orange,

else off.

DIGITAL OUT 1 socket [8] is for connecting HERMES DXD with the projection unit of a Barco pro-

The

jection cube. If the signal of

nal of

DIGITAL IN 2 is applied to DIGITAL OUT 1, the LED [7] is orange.

The

DIGITAL OUT 2 socket [10] is for connecting HERMES DXD with the projection unit of a Barco

projection cube. If the signal of

signal of

DIGITAL IN 2 is applied to DIGITAL OUT 2, the LED [9] is orange.

DIGITAL IN 1 is applied to DIGITAL OUT 1, the LED [7] is green, if the sig-

DIGITAL IN 1 is applied to DIGITAL OUT 2, the LED [9] is green, if the

The LED POWER [11] indicates the device is switched on and operating properly. If the LED is off,

H

ERMES DXD is switched off or the internal logic control has detected an error.

Page 18

LEDs allocated to the inputs:

If they are off, there is no signal present. If there is a sync signal present, the LED is

on:

Green stands for (signal present on) input (channel) 1

Orange stands for (signal present on) input (channel) 2

LEDs allocated to the outputs:

The color of the LED indicates which input (channel) is displayed:

In case it is green, input 1 is displayed via the respective output

In case it is orange, input 2 is displayed via the respective output

Color LED LED input 1 LED input 2 LED output 1 LED output 2

off No Signal present No Signal present

green Signal present - output 1 routed to

input 1

orange - Signal present output 1 routed to

input 2

output 2 routed to

input 1

output 2 routed to

input 2

Page 19

3.1.2 The Bac k Panel

The back panel of your HERMES DXD looks like this or similar:

A

BC

A Main Switch

B AC In

C AC Out

Figure 3-3

The Main Switch [A] is for switching HERMES DXD on and off. If the 0 is visible on top of the switch,

the device is switched off, and it can be switched on by pressing the switch.

The

AC In socket [B] is for connecting to a power supply as specified in section 7.1.2 Power Supply.

The AC Out socket [C] is for connecting further devices (of type HERMES DXD only!) to the power supply.

AC Out is connected directly to AC In and is live as soon as AC In is connected to a power supply.

Up to max. ten HERMES DXD devices can be put on top of each other. Thus you can

group the devices into towers next to each other, e. g., in the same order as the projection cubes are arranged.

To protect HERMES DXD from overheating, the air supply openings in the case must

not be covered! If you group the devices into towers standing next to each other a

space between the devices not less than 10 centimeter must be kept!

Page 20

3.2 Native device settings (default settings)

Hermes DXD has auto switch capabilities: in case there is no signal present at the input routed to an

output, the output may switch automatically to the other input. Per default, this auto switch functionality

is enabled. If desired, it can be deactivated, cf. Enabling/Disabling auto switch

Having two graphic channels connected to HERMES DXD, and none of them specified as input source,

the channel connected to

nected to

DIGITAL IN 2 is selected as signal for DIGITAL OUT 2.

DIGITAL IN 1 is selected as signal for DIGITAL OUT 1, and the channel con-

If no signal is detected on the graphic channel connected to

nected to

switch

DIGITAL IN 2 is selected automatically as input for DIGITAL OUT 1 instead, provided auto

is enabled

If no signal is detected on the graphic channel connected to

nected to

switch

DIGITAL IN 1 is selected automatically as input for DIGITAL OUT 2 instead, provided auto

is enabled.

DIGITAL IN 1, then the graphic channel con-

DIGITAL IN 2, then the graphic channel con-

After cabling is complete you can switch on the device with the main switch on the back panel.

Switching between the two graphical controllers is done by means of the remote control (see chapter

Switching commands

.

3.3 DDC C a pability

H

ERMES DXD has DDC capability, i.e. it reads the timing of the connected projection module.

It is mandatory that the projection units connected to the two outputs of a Hermes

DXD are all of the same type, e.g. OverView D

HERMES DXD scans the outputs to get the timing information of the connected projection modules. As

soon as it gets a timing, the scan procedure is finished, and the detected timing information is stored and

used for both inputs!

The graphical channel connected to

DIGITAL IN 1 and the graphical channel connected to DIGITAL IN 2

during the boot procedure look up once the timing of the input and adjust their settings accordingly. To

ensure that HERMES DXD provides the timing information already when booting the controller it is recommend to first switch on H

ERMES DXD, and then switch on the controller.

5.3

Hermes DXD scans the timing of the projection module whenever a connection is

made. If the timing changes, e.g. a projector is disconnected and a different one

connected, Hermes DXD "knows" it immediately and adjusts the information stored

in DIGITAL IN 1 and DIGITAL IN 2 accordingly.

The graphic card looks up the timing information ONLY during the boot procedure.

Thus replacing a projector with a different timing requires re-booting the graphical

controller to get the correct settings!

Page 21

3.4 Cabling

This block diagram gives an overview about the cabling of H

ERMES DXD

The cabling must be done before switching on HERMES DXD or any other system

components!

Signal cables are available in different types (fibre or copper), different interfaces

(PanelLink-to-DVI, DVI-to-PanelLink, DVI-to-DVI) and different lenghts. Therefore

they are not included in the delivery of Hermes DXD, but can be ordered according

the actual requirements, please refer to

3.4.1 Power S u pply

Check the power rating on your outlet before connecting HERMES DXD to a wall

outlet or to a power strip. See section

specification. Contact your facilities manager or a qualified electrician if you are not

sure what type of power is supplied to your building.

HERMES DXD is designed to operate with single-phase power systems having a

grounded neutral conductor. To reduce the risk of electrical shock, do not plug into

any other type of power system.

cabling Hermes DXD

Figure 3-4

7.3 Parts List

7.1.2 Power Supply for the necessary technical

Make sure that the main switch is in the off position. Plug in the female end of the power cord into

AC In.

H

ERMES DXD offers a power outlet AC Out for connecting another HERMES DXD. When operating

more than one H

ERMES DXD then up to 10 devices in total may be connected in series. Thus a clear lay-

out of cabling is possible.

AC Out is connected directly to AC In and is live as soon as AC In is connected to a

power supply.

Only Hermes DXD devices are allowed to be plugged into the AC Out of a Hermes

DXD.

Page 22

3.4.2 Digital I n put and Output

HERMES DXD has DVI interfaces. Depending on the type of graphical card and/or the type of projection

module, the following kind of cables are required: DVI-to-DVI, DVI-to-PanelLink, PanelLink-to-DVI.

The DVI-DVI cable is available as copper cable (length up to 10m) and fibre cable (length up to 100m).

The DVI-to-PanelLink and the PanelLink-to-DVI adapter are exclusively available as copper cables.

There are no visible differences between these two adapter. To know which is which, please have a look

at the identification label on the adapter and look up the product number in the table below:

Identification

label

Type of adapter

RSCBL3203x PanelLink out to DVI in

RSCBL3205x DVI out to PanelLink in

Plug in the cables from the two graphic channels into DIGITAL IN 1 and DIGITAL IN 2 and the cables

connecting H

ERMES DXD to the digital projection units into DIGITAL OUT 1, DIGITAL OUT 2.

Figure 3-5

PanelLink-to-DVI-adapter

3.4.3 Remote Control

Digital In, DVI interface

Figure 3-6

Digital Out, DVI interface

Figure 3-7

Plug in the remote control cable coming from the previous device into Remote In and the cable leading

to the next device into

(see

4.1 Cabling).

Remote Out. (If there are more than 20 devices a distribution panel must be used)

Remote Control Cabling

Figure 3-8

Page 23

3.5 Operat ing Hermes DXD

After the cabling is done, you can switch on your system. In order to provide the graphic cards with the

correct timing, it is mandatory that H

ERMES DXD is switched on before booting the controller!

The projection engines can be switched on or off: the timing information is received via the data cable

as soon as the connection is established.

Controlling

HERMES DXD is done via RS232 Remote-Control. Either the commands are sent via a dedi-

cated protocol (RFTP = Remote File Transfer Protocol), or via the graphical user interface of H

REMOTE CONTROL, a software tool to intuitively switch the required input to the desired output.

The graphical user interface is described in the user manual HERMES REMOTE CONTROL.

In this manual, the open protocol is explained.

ERMES

Page 24

4 Remo te Control

The remote control is a system for scanning and controlling single devices of Barco Display Wall. As a

certain class of devices H

control the respective input can be switched to a desired output.

This chapter describes the basics of remote control as cabling, protocol and addressing procedure for

H

ERMES DXD.

ERMES DXD can be scanned from a central computer. By means of remote

Page 25

4.1 Cabling

A remote control system consists of three different components:

remote control master (

remote control slave (

RCM)

RCS)

remote control connection

The

RCM is the central computer which controls the slave devices RCS. All control messages are gener-

ated by the

RCS and directed to the RCM without request.

All

RCS are connected in series. Messages sent from the RCM are passed on by an RCS to the next RCS,

and finally return to the

RCM, addressed to a certain RCS device and sent on. Incorrect messages are processed by a

RCM. The messages run in a ring.

The RCM must be connected to each RCS in series. For a clear lay-out of the cabling the different types

of

RCS should be arranged into blocks within the ring, e. g. all HERMES DXD first, then all illumination

units.

4.1.1 Cabling of Hermes DXD (number of devices < 20)

The serial interface of the RCM (COM1) must be connected to the Remote In socket of the first HERMES

DXD. Each following HERMES DXD (Remote In) is connected to the previous HERMES DXD (Remote

Out

). This kind of connection is called daisy chain.

Remote Control Interfaces

Daisy chain cabling of devices

Figure 4-1

Figure 4-2

A shorting plug must be inserted into the REMOTE OUT socket of the last device in

order to close the ring.

If the internal logic control of a RCS detects an error, or if a device is switched off, the input and output

of its remote control interface are short-circuited, such that all other remote control devices can still be

addressed. Pay attention that during the addressing procedure all

RCS are active, in order to prevent

confusion in the addresses

Page 26

4.1.2 Cabling of Hermes DXD (number of devices > 20)

If there are more than 20 devices a distribution panel has to be used. Then the cabling looks like this:

remote control cabling by use of a distriubtion panel

Remote control cabling is available in various length and with adapters for connecting to different devices. See section

7.3.2 Remote Control for the parts list, please!

4.2 Definit ion of Protocol

4.2.1 Connec t ion Settings

The physical medium for data transfer is based on a RS-232-C interface:

signal level RS-232-C

baud rate 9,600 baud

data bits 8

parity bits none

stop bits 1

max. distance 25 meters between two active members (RCS or RCM)

4.2.2 Commu n ication

The devices of HERMES DXD are numbered consecutively. A certain device is addressed by means of

this number. H

quested device receives the command. The command returns unprocessed to the

ERMES DXD executes the received command and passes on the message until the re-

RCM if no HERMES

DXD has been addressed.

In case a device has been addressed, and the command is valid, the command is executed, and the device sends an acknowledge ACK to the master.

In case a device has been addressed, and the command is invalid, the device passes the command unprocessed to the master and adds "

EP" (Error Protocol) to the command.

Basically there are two kind of commands: commands which are answered by an acknowledge including a status information and commands which are passed on or answered without status.

Figure 4-3

Table 4-1

Page 27

4.2.3 Structu r e of Messages

The messages consists out of a RCS-independent and a RCS-dependent layer. The RCS-independent

parts are interpreted the same by all types of devices. The

mands for a certain type of

RCM: the message body.

RCS-dependent parts contain specific com-

A message has the following structure:

<STX> <TYPE> <ADDRH> <ADDRL> <Body> <CHKH> <CHKL> <ETX>

These are the elements of a message in detail:

STX The control character STX (Ctrl-B) is the beginning of a

message. All previously received characters are ignored and

are not sent on. (Ctrl-B is displayed as in most terminal

applications.)

<TYPE> 1 byte ASCII

declares the type of class of addressed RCS.

<ADDRH><ADDRL> 2 bytes ASCII decimal

addresses the n-th RCS within a class of the specified type.

<Body> type-dependent part of the message, e. g. a command

<CHKH><CHKL> 2 bytes ASCII decimal

is the sum over all fields from <TYPE> to <Body>. The

checksum is evaluated by the recipient.

ETX The control character ETX (Ctrl-C)is the end of a message.

(Ctrl-C is displayed as in most terminal applications.)

Four different types of messages are used:

Table 4-2

commands RCM sends command messages to a RCS.

acknowledge RCS sends responses to the RCM after having executed the command

responses RCS sends responses to the RCM on request.

interrupts RCS reports errors to the RCM without request.

4.2.4 Acknow l edge

The acknowledge is composed of the command the RCS has received and executed and the internal

Status Register.

An acknowledge has the following structure:

<STX><TYPE><ADDRH><ADDRL><Body><STATH><STATL><CHKH> <CHKL><ETX>

These are the elements of an acknowledge in detail:

STX The control character STX (Ctrl-B) is the beginning of a message.

All previously received characters are ignored and are not sent on.

(Ctrl-B is displayed as in most terminal applications.)

<TYPE> 1 byte ASCII

declares the type of class of addressed RCS.

<ADDRH><ADDRL> 2 bytes ASCII decimal

addresses the n-th RCS within a class of the specified type.

<Body> type-dependent part of the message, e. g. a command

<STATH><STATL> 2 bytes Hexa decimal

information about the internal Status Register

<CHKH><CHKL> 2 bytes ASCII decimal

is the sum over all fields from <TYPE> to <STATL>. The checksum

is evaluated by the Remote Control Master.

ETX The control character ETX (Ctrl-C)is the end of a message. (Ctrl-

C is displayed as in most terminal applications.)

Table 4-3

Page 28

4.2.5 Types o f RCS Classes

e OVERVIEW-ML

r MULTIMEDIA-TERMINAL MMT-X, MMT-NT, EOS

s MULTIMEDIA-TERMINAL MMT-S

m AVC-BOX, DIGITAL SWITCHBOX, ANALOG INPUT BOX, HERMES D2D,

HERMES V2A, HERMES DXD, HERMES VXA

4.3 How to calculate the checksum

The checksum is being evaluated from the recipient to make sure that the message received has not been

corrupted. The checksum is a kind of sum over all fields from <TYPE> to <Body> or <TYPE> to

<STATL> respectively (Acknowledge).

The checksum is calculated by transforming each character of the message into its ASCII code. The

ASCII values are added, and this sum is converted into a hex number. The checksum uses the last two

digits of this hex number. If the hex number consists of non-numeric characters, these characters have

to be lower case characters.

Example:

Let's consider the addressing procedure. The command for the addressing procedure is

m00Axx

A.

xx is the checksum to be calculated. The <TYPE> of the message is m, the <Body> 00A

message m 0 0 A

ASCII code 109 48 48 65

Summing up 270

converting into a hex number =10EH

<CHKL>

e

character has to be lower case!

<CHKH>

0

Table 4-4

The correct addressing message :

m00A0e

Page 29

4.4 The sta tus register

The status register stores information about which input is provided with a signal, which input is

switched to which output, and if autoswitch modus is enabled or disabled.

The following lists the bits of the Status Register, the

Significant Bit is the most right bit.

Bit Auto Switch Out2 true Out1 true Reserved Out2 target Out1 target Prsnt2 Prsnt1

MSB … LSB

Bit No. Refers to value

Most Significant Bit is the most left bit, the Least

1 Input 1 [0]: there is no sync signal at input 1

[1]: there is a sync signal at input 1

2 Input 2 [0]: there is no sync signal at input 2

[1]: there is a sync signal at input 2

3 Output 1

(target value)

4 Output 2

(target value)

[0]: Digital input 1 is routed to output 1 (default)

[1]: Digital input 2 is routed to output 1

[0]: Digital input 1 is routed to output 2

[1]: Digital input 2 is routed to output 2 (default)

5 For future use [0]: (hard coded specified as 0)

6 Output 1

(true value)

7 Output 2

(true value)

[0]: Digital input 1 is routed to output 1

[1]: Digital input 2 is routed to output 1

[0]: Digital input 1 is routed to output 2

[1]: Digital input 2 is routed to output 2

8 Auto switch [0]: auto switch disabled

[1]: auto switch enabled (default)

Page 30

5 Contr olling Hermes DXD

This chapter describes the commands to control HERMES DXD, the commands and the answers/acknowledge.

Page 31

5.1 Valid C o mmands for Hermes DXD

command description

t selects input from first graphical controller

as signal for Digital Out 1

a selects input from second graphical controller

as signal for Digital Out 1

s selects input from first graphical controller

as signal for Digital Out 2

b selects input from second graphical controller

as signal for Digital Out 2

g Restore default settings

h Restore user settings

i Save user settings

j Enable autoswitch

k Disable autoswitch

o Read status register

q Read user settings

v Read product identification

v Read product identification

A assigns an address

I calls for information

Table 5-1

Page 32

5.2 Reques t commands

Request commands can be sent from the RCS to the RCM or vice versa. The answer of a request command does not include the status information.

Command "R": Calling for Address

Description: Request for an address.

A

RCS that is not provided with an address will send requests for an address at regular

intervals.

This message uses the command

R. It will be received by the RCM and signals the need

for a new addressing procedure.

Example: An

Message <STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

RCS of class m asks for an address:

m0 0 R bf

Command "A": Addressing Procedure

Description: Each member of the remote control chain must have a non-ambiguous address so that

functions can be specifically triggered in the individual devices. The addresses are assigned by an initial addressing message. Since all devices of a certain class have to be

given a non-ambiguous address, and since at the beginning the

many devices exist, the command uses as

<ADDRH> <ADDRL> the "00".

RCM does not know how

Message <STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

The addressing message uses the command A. In the above example all

The first

RCS increases the number. The resulting number is his individual address. Afterwards he cal-

m0 0 A 0e

RCS of class m are addressed.

culates the new checksum and passes this modified message to the next device. Each device consequently increases the numbers before passing the message again. The last

RCM. (The maximum number of RCS in a class is 98). The addressing procedure must be carried

to the

out separately for all types of

Example: Let's consider a class of H

RCS in the remote control ring.

ERMES DXD consisting of 3 devices. They all have to get their non-

ambiguous address by the initial addressing message. The message passed by the last

RCM informs the RCM about the number of devices of this class.

RCM RCS1 RCS2 RCS3

passes

receives

passes

receives

passes

m00A0e

m00A0e

m01A0f

m01A0f

m02A10

receives

passes

receives

m03A11

RCS passes the message back

RCS back to the

m02A10

m03A11

Answer <STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

m0 3 A 11

Page 33

Command "I": Calling for Information

Description: This request is about the identity number of the device and the version of the firmware.

Example: The message sent from the

Message <STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

Answer <STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

m0 1 I 17

RCM to the RCS1 about the identity number is:

m 0 1 I3187-01 7 8

5.3 Switch i ng commands

The switching commands refer exclusively to the input and output involved. The

other input and the other output are not affected!

These messages are processed in a straight forward way. The control character <STX> and the <TYPE>

field are passed on immediately. Each recipient analyzes the content of the <TYPE> field . If the type

does not match (e. g. the recipient is a member of the class d) the message is passed through.

Otherwise if the type does match, the <ADDRH><ADDRL> fields are evaluated.

Again, if the address does not match the message is passed through. But if the address does match, and

if the body contains a valid command and the checksum is correct, the command is executed, and the

RCS sends an acknowledge to the RCM.

In case the body is not valid, the message is sent back to the RCM, and EP is added (Error Protocol).

In case the checksum is not correct, the message is sent back to the

Checksum

)

RCM, and EC is added (Error

5.3.1 Switchi n g the Digital Output 1

The Digital Output 1 can be switched to the Digital Input 2 or to the Digital Input 1.

In case there is a signal present on the desired input, the

In case there is no signal present on the desired output, the

routing: if enabled, the output is automatically routed to the other input, and the

differs from the

input

and the projection module will be white (no picture, since there is no input signal).

In the status register, the correlated bits

target routing. If disabled, the output will be non the less switched to the target

output 1 target / output 1 true (output 2 target / output 2 true)

target routing will be the actual routing.

autoswitch functionality determines the

actual routing then

can be compared to check the configuration.

On the device, the LEDs of the inputs indicate whether a signal is present or not, whereas the LEDs of

the outputs show which signal is routed (green: input 1, orange: input 2)

Page 34

Command "a": interconnection digital input 2 to digital output 1

Description: Via the command a the RCM tells the RCS of class m to switch the signal of the second

DIGITAL IN 2) to the first digital output DIGITAL OUT 1.

input (

The

RCS executes the command and sends the acknowledge which informs via the status

register about the auto switch status (enabled or disabled) and if there is a sync signal on

DIGITAL IN 2 or not.

These conditions together determine the behavior of the

Example: The command a is sent to the second RCS.

Message <STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

m0 2 a 30

Let's assume the second input is provided with a signal, so the actual routing will be the

target routing, no matter of the autoswitch status. For calculating purposes, the bits refering to autoswitch, the first input and the second output will be set to 1. Thus the status

register looks like this:

RCS.

Status Auto Switch Out2

true

Out1

true

Reserved Out2

target

Out1

target

Prsnt2 Prsnt1

1110 1 111

Thus the acknowledge sent from the second RCS to the master reads:

Acknowledge <STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

Result: The actual routing of

DIGITAL INPUT 2 is displayed on the projection module connected to DIGITAL OUT 1.

m0 2 a e ffb

DIGITAL OUT 1 is the target routing, and the signal present on

Page 35

Command "t": interconnection digital input 1 to digital output 1

Description: Via this command the RCM tells the RCS of class m to switch the signal of the first input

DIGITAL IN 1) to the first digital output DIGITAL OUT 1.

(

The

RCS executes the command and sends the acknowledge which informs via the status

register about the auto switch status (enabled or disabled) and if there is a sync signal on

DIGITAL IN 1 or not.

These conditions together determine the behavior of the

Example: The command t is sent to the second RCS:

Message <STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

m0 2 t 43

Let's assume the first input is not provided with a signal. Depending on the status of

autoswitch,

DIGITAL OUT 1 is routed to DIGITAL IN 2 (autoswitch enabled, sync signal

present on input 2), or the projection module is white.

Let's further assume: autoswitch enabled, sync signal present on input 2, output 2 routed

to input 2.

Thus the status register looks like this:

RCS.

Status Auto Switch Out2

true

1110 1 0 1 0

Out1

true

Reserved Out2

target

Out1

target

Prsnt2 Prsnt1

Thus the acknowledge sent from the second RCS to the master reads:

Acknowledge <STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

m0 2 t e a09

Result: The actual routing of

present on

OUT 1

DIGITAL INPUT 2 is displayed on the projection module connected to DIGITAL

. As soon as there is a signal present on DIGITAL INPUT 1, the routing changes to

DIGITAL OUT 1 is different from the target routing, and the signal

the target routing!

5.3.2 Switchi n g the Digital Output 2

The Digital Output 2 can be switched to the Digital Input 2 or to the Digital Input 1.

In case there is a signal present on the desired input, the target routing will be the actual routing.

In case there is no signal present on the desired output, the

routing: if enabled, the output is automatically routed to the other input, and the

differs from the

input

and the projection module will be white (no picture, since there is no input signal).

target routing. If disabled, the output will be non the less switched to the target

autoswitch functionality determines the

actual routing then

In the status register, the correlated bits output 2 target / output 2 true (output 1 target / output 1 true)

can be compared to check the configuration.

On the device, the LEDs of the inputs indicate whether a signal is present or not, whereas the LEDs of

the outputs show which input is routed (green: input 1, orange: input 2)

Page 36

Command "b": interconnection digital input 2 to digital output 2

Description: Via this command the RCM tells the RCS of class m to switch the signal of the second in-

DIGITAL IN 2) to the second digital output DIGITAL OUT 2.

put (

The

RCS executes the command and sends the acknowledge which informs via the status

register about the auto switch status (enabled or disabled) and if there is a sync signal on

DIGITAL IN 2 or not.

These conditions together determine the behavior of the

Example: The command b is sent to the second RCS:

RCS.

message

<STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

m0 2 b 31

Let's assume the second input is not provided with a signal. Depending on the status of

autoswitch,

DIGITAL OUT 2 is routed then to DIGITAL IN 1 (autoswitch enabled, sync sig-

nal present on input 2), or the projection module is white.

Let's further assume: autoswitch disabled, sync signal present on input 1, output 1 routed

to input 1.

Thus the status register looks like this:

Status Auto Switch Out2

true

0 1 1 011 0 1

Out1

true

Reserved Out2

target

Out1

target

Prsnt2 Prsnt1

Thus the acknowledge sent from the second RCS to the master reads:

Acknowledge <STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

m0 2 b 6 dcb

Result: The actual routing of

present on

DIGITAL INPUT 2, the projection module connected to DIGITAL OUT 2is white.

DIGITAL OUT 2 is the target routing, but since there is no signal

Page 37

Command "s": interconnection digital input 1 to digital output 2

Description: Via this command the RCM tells the RCS of class m to switch the signal of the first input

DIGITAL IN 1) to the second digital output DIGITAL OUT 2.

(

The

RCS executes the command and sends the acknowledge which informs via the status

register about the auto switch status (enabled or disabled) and if there is a sync signal on

DIGITAL IN 1 or not.

These conditions together determine the behavior of the

Example: The command s is sent to the second RCS:

RCS.

message

<STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

m0 2 s 42

Let's assume the first input is provided with a signal. Independent from the the status of

autoswitch,

DIGITAL OUT 2 is routed then to DIGITAL IN 1.

Let's further assume: autoswitch disabled, sync signal present on input 2, output 1 routed

to input 2.

Thus the status register looks like this:

Status Auto Switch Out2

true

0 0 1 001 0 1

Out1

true

Reserved Out2

target

Out1

target

Prsnt2 Prsnt1

Thus the acknowledge sent from the second RCS to the master reads:

Acknowledge <STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

m0 2 s 2 5a9

Result: The actual routing of

DIGITAL INPUT 1 is displayed on the projection module connected to DIGITAL OUT 2.

DIGITAL OUT 2 is the target routing, and the signal present on

Page 38

5.4 Enablin g /Disabling auto switch

The auto switch functionality allows H

ERMES DXD to automatically connect an output to the other input

if there is no longer a sync signal on the input previous connected to this output. This functionality provides redundancy (inspite of a crash, there will be signal displayed on the projection modules), but

sometimes it might be useful to disable this behavior (e.g. to check if all sources connected to the input

are still ok).

Per default, every H

ERMES DXD leaves production with the auto switch functionality enabled.

The status of the auto switch functionality can be derived from the status register.

Command “j”: Enabling auto switch

Description: Via this command the RCM tells the RCS of class m to enable auto switch

RCS executes the command and sends the acknowledge which informs via the status

The

register about the auto switch status.

Example: The command

j is sent to the second RCS:

Message

<STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

m0 2 j 39

case 1: auto switch was already enabled: nothing changes

case 2: auto switch has been disabled before and is now enabled

Since this command only affects the auto switch, the status of the inputs and outputs does

not matter and are assumed 1. The assumptions are written in italic. Then the status register looks like this:

Status Auto Switch Out2

true

1 11 0 1111

Out1

true

Reserved Out2

target

In both cases the acknowledge sent from the RCS to the RCM is the same:

Acknowledge

<STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

m0 2 j e f04

Result: auto switch functionality is enabled.

Out1

target

Prsnt2 Prsnt1

Page 39

Command “k”: Disabling auto switch

Description: Via this command the RCM tells the RCS of class m to disable auto switch

RCS executes the command and sends the acknowledge which informs via the status

The

register about the auto switch status.

Example: The command

k is sent to the second RCS:

Message

<STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

m0 2 k 3a

case 1: auto switch was already disabled: nothing changes

case 2: auto switch has been enabled before and is now disabled

Since this command only affects the auto switch, the status of the inputs and outputs does

not matter and are assumed 1. The assumptions are written in italic. Then the status register looks like this:

Status Auto Switch Out2

true

0110 1111

Out1

true

Reserved Out2

target

In both cases the acknowledge sent from the RCS to the RCM is the same:

Acknowledge

<STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

m0 2 k 6 fd6

Result: auto switch functionality is disabled.

Out1

target

Prsnt2 Prsnt1

Page 40

5.4.1 Comma n ds referring to settings

The connections of HERMES DXD (which input is connected to which output) as well as the status of the

auto switch functionality make up the settings of H

ERMES DXD and can be saved and restored on the

device.

The native configuration (factory configuration) of H

cludes the connection of

DIGITAL OUTPUT 2 and auto switch functionality enabled.

DIGITAL INPUT 1 to DIGITAL OUTPUT 1, the connection of DIGITAL INPUT 2 to

ERMES DXD is saved in the default settings. It in-

The user can adjust these settings to her/his needs and store the desired configuration as user settings. If

afterwards some changes were made, these changes can be re-called by applying the

user settings

again.

Command “g”: restore default settings

Description: Via this command the RCM tells the RCS of class m to restore the default settings:

connect

connect DIGITAL INPUT 2 to DIGITAL OUTPUT 2

enable auto switch

The RCS executes the command and sends the acknowledge which informs via the status

register about status of auto switch, outputs and inputs.

Example: The command

DIGITAL INPUT 1 to DIGITAL OUTPUT 1

g is sent to the second RCS:

Message

<STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

m0 2 g 36

This command affects the connections of the output and inputs while auto switch is enabled. To realize the default settings, it is mandatory then to provide a sync signal on both

inputs, otherwise (due to auto switch enabled) the output connected to an input where no

sync signal is present, will switch to the other input and thus not being configured as it

should compared to the default settings.

Status Auto Switch Out2

<STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

Acknowledg

e

true

1100 1011

m0 2 g c bfb

Result: The configuration of H

above, no matter whether they were the same before or different. The actual routing will

be the target routing if both inputs are provided with a sync signal! In case there is no signal present on an input, the corresponding output is switched automatically to the other

input, and the actual routing differs from the target routing. As soon as the default input

provides a signal, the device then adjust itself to the default configuration.

Out1

true

Reserved Out2

target

Out1

target

Prsnt2 Prsnt1

ERMES DXD is set to the connections and functionalities described

Page 41

Command “i”: save user settings

Description: Via this command the RCM tells the RCS of class m to save the current configuration as

user settings. These are the features to be saved:

connection of

connection of DIGITAL OUTPUT 2

status of auto switch

The RCS executes the command and sends the acknowledge which informs via the status

register about status of auto switch, outputs and inputs.

The configuration is saved on the device itself.

Example: The command

DIGITAL OUTPUT 1

i is sent to the second RCS:

Message

<STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

m0 2 i 38

Let's assume that there is a sync signal on

INPUT 2

Status Auto Switch Out2

Acknowledge

<STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

, and both outputs are connected to DIGITAL INPUT 1, auto switch is enabled:

true

1000 0001

m0 2 i 8 1a1

Out1

true

DIGITAL INPUT 1, no sync signal on DIGITAL

Reserved Out2

target

Out1

target

Prsnt2 Prsnt1

Result: The current configuration is saved as user settings.

Command “q”: read user settings

Description: Via this command the RCM tells the RCS of class m to read the currently saved user con-

figuration. These are the desired information:

(target) connection of DIGITAL OUTPUT 1

(target) connection of DIGITAL OUTPUT 2

status of auto switch

Depending on autoswitch enabled or disabled and depending on the presence of a sync

signal on the inputs in question, the true connections might differ from the target connection. That's why the user might want to read the target configuration of the saved user settings.

RCS executes the command and sends the acknowledge which informs via the status

The

register about status of auto switch, outputs and inputs.

Example: The command

Message

<STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

m0 2 q 40

q is sent to the second RCS:

Page 42

Let's assume that the following routing is saved as user settings:

DIGITAL OUTPUT 1 is connected to DIGITAL INPUT 2

DIGITAL OUTPUT 2

Autoswitch

enabled

is connected to DIGITAL INPUT 1

Let's further assume that there is a sync signal on DIGITAL INPUT 1, and no sync signal on

DIGITAL INPUT 2.

Therefore the actual configuration differs from the target configuration (the first output is

automatically switched to the second input).

Status Auto Switch Out2

Answer

<STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

true

1000 0101

Out1

true

Reserved Out2

target

Out1

target

Prsnt2 Prsnt1

m0 2 q 8 5ad

Result: The status register shows the actual current configuration and the saved user settings.

Command “h”: restore user settings

Description: Via this command the RCM tells the RCS of class m to restore the configuration which is

saved in the user settings. This command has impact on:

the connection of

the connection of DIGITAL INPUT 2

the status of auto switch

The RCS executes the command and sends the acknowledge which informs via the status

register about status of auto switch, outputs and inputs.

Example. The comamnd

Message

<STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

m0 2 h 37

DIGITAL INPUT 1

h is sent to the second RCS:

Assumption:The following configuration represent the user settings: sync signal on

DIGITAL INPUT 1, no sync signal on DIGITAL INPUT 2, and both outputs are connected to

DIGITAL INPUT 1, while auto switch is disabled.

Status Auto Switch Out2

Acknowledge

<STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

true

0000 0001

Out1

true

Reserved Out2

target

Out1

target

Prsnt2 Prsnt1

m0 2 h 0 198

Result: The user settings are restored, previous made modifications of these connections and

functionalities are re-called.

Restoring configurations is an undo command.

Page 43

5.5 Readin g the status register

Although the information about the status register is sent back by the

RCS as part of the acknowledge, it

might be useful to ask it directly.

Command “o”: read status register

Description: Via this command the RCM tells the RCS of class m to read the status register.

RCS executes the command and sends the acknowledge which informs about the

The

contents of the status register.

Example: The command

Message

<STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

o is sent to the second RCS:

m0 2 o 3e

Assumption: H

ERMES DXD is operated in the default configuration (DIGITAL INPUT 1

connected to DIGITAL OUTPUT 1, DIGITAL INPUT 2 connected to DIGITAL OUTPUT 2,

auto switch enabled)

Status Auto Switch Out2

<STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

Acknowledg

e

true

0100 1011

Out1

true

Reserved Out2

target

m0 2 o 6 bd6

Result: The status register is read and the value is sent back to the

Out1

target

RCM.

Prsnt2 Prsnt1

Page 44

5.6 Readin g the product identification

The entire product information "finger print" is saved in an EEPROM and can be read and evaluated.

This information is a very useful diagnostic help for the Barco support technician.

Command “v”: read product information

Description: After having received this command, the RCS will send the desired finger print informa-

tion to the

have to be added which should be read (byte position and length). The following table

lists some of the parameters.

In the command, the <

<

OP> <LEN> <ADR>

In the answer, the <

<

OP> <LEN> <ADR> <DATA(0)> <DATA(0)> …..<DATA(LEN-1)>

RCM. This command consists not only of the code "v" but also the parameters

Body> then has the following structure:

Body> then has the following structure:

Information Value ADR

(positon)

LEN

(length)

Location KA (for Hermes DXD) 0 2

Version ASCII identifier of version of this structure 2 2

Ident number ASCII, product number of the device 4 9

Serial number ASCII, serial number of the device during production 16 8

Engineering

Change

One bit for modifications A-Z, another 6 bits for

*1 to *6

24 4

FMWStatus ASCII, firmware number and status 32 6

CTWStatus ASCII, control ware number and status 40 6

Example: To get the information about the engineering change, the following command has to be

sent to the RCS:

v (read information) 4 (length of information) 23 (address of information (engineering

change))

Message

<STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

m 0 2 v424 1 e

In case it is the engineering change B, the

RCS answers via information:

Acknowledge

<STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

m 0 2 v424B 2 1

Page 45

5.7 Error m essages

Three different kind of errors might occur:

The body is an invalid command

The checksum is not correct

The device cannot be addressed (it might be switched off…)

The information sent back to the RCM about these errors does not include the status register

Error Protocol "EP"

Description: Via this answer the RCM is told by the RCS of class m that the body has been an invalid

command.

Example: The

Message

RCM has sent a command x to the RCS.

<STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

m0 2 y 48

Since the command y does not exist for an

back to the

RCM, adds the extension EP (Error Protocol), and calculates the new check-

RCS of class m, the RCS sends this message

sum.

Answer

<STX> <TYPE> <ADDRH> <ADDRL> <Body> <chksm> <ERR> <CHKH> <CHKL> <ETX>

m 0 2 y 48 EP 4 9

Error Checksum "EC"

Description: Via this answer the RCM is told by the RCS of class m that the checksum has not beeen

correct.

Example: The

Message

RCM has sent the following command:

<STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

m0 2 t 30

Answer

The correct checksum of the above command is 43. The

sends the command back to the

<STX> <TYPE> <ADDRH> <ADDRL> <Body> <chksm> <ERR> <CHKH> <CHKL> <ETX>

RCM and adds the extension EC (Error Checksum)

RCS detects an checksum error,

m 0 2 t 30 EC 2 e

Page 46

Original message is sent back to the RCM

Description: Via this answer the RCM recognizes that the desired RCS cannot be addressed (might be it

has been switched off…)

Example: The

Message

<STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

The second

command is passed to

Answer

<STX> <TYPE> <ADDRH> <ADDRL> <Body> <STATH> <STATL <CHKH> <CHKL> <ETX>

If the internal logic control of a RCS detects an error, the input and output of its remote control interface are short-circuited, such that all other remote control devices

can still be addressed. Pay attention that during the addressing procedure all

active, in order to prevent confusion in the addresses.

RCM has sent the following command:

m0 2 t 43

RCS cannot be addressed, and via the closed remote control ring the original

RCM again.

m0 2 t 43

RCS are

Page 47

6 Broad cast addressing mode

This chapter describes how all Remote Control Slaves of a class are addressed simultaneously.

Page 48

6.1 Structu r e of message

The messages consists out of a RCS-independent and a RCS-dependent layer. The RCS-independent

parts are interpreted the same by all types of devices. The

mands for a certain type of

RCM: the message body.

RCS-dependent parts contain specific com-

A message has the following structure:

<STX> <TYPE> <ADDRH> <ADDRL> <Body> <CHKH> <CHKL> <ETX>

These are the elements of a message in detail:

STX The control character STX (Ctrl-B) is the beginning of a

message. All previously received characters are ignored and

are not sent on. (Ctrl-B is displayed as in most terminal

applications.)

<TYPE> 1 byte ASCII

upper case class code to specify broadcast addressing.

<ADDRH><ADDRL> 2 bytes ASCII decimal

in broadcast addressing it is always 00

<Body> type-dependent part of the message, e. g. a command

<CHKH><CHKL> 2 bytes ASCII decimal