Page 1

DATA

708

R9002129

INSTALLATION MANUAL

Page 2

Page 3

BARCO PROJECTION SYSTEMS

Date :

260597

DATA

708

R9002129

INSTALLATION MANUAL

Art. No. :

R5975987A

Page 4

Due to constant research, the information in this manual is subject to change without notice.

Produced by BARCO NV, May 1997.

All rights reserved.

Trademarks are the rights of their respective owners.

BARCO nv/Projection Systems

Noordlaan 5

B-8520 Kuurne

Belgium

Printed in Belgium

Page 5

Table of Contents

TABLE OF CONTENTS

i

WARNINGS .................................................................................................................................................................................... 1-1

SAFETY INSTRUCTIONS ............................................................................................................................................................... 1-1

On safety ................................................................................................................................................................................. 1-2

On installation .......................................................................................................................................................................... 1-2

On servicing ............................................................................................................................................................................. 1-2

On cleaning .............................................................................................................................................................................. 1-2

On repacking............................................................................................................................................................................ 1-2

On illumination ......................................................................................................................................................................... 1-2

UNPACKING & DIMENSIONS ........................................................................................................................................................ 2-1

Unpacking ................................................................................................................................................................................ 2-1

Projector dimensions ................................................................................................................................................................ 2-2

INSTALLATION GUIDELINES ........................................................................................................................................................ 3-1

* Environment .................................................................................................................. ........................................................ 3-1

* What about ambient light ?..................................................................................................................................................... 3-1

* Which screen type? ............................................................................................................................................................... 3-1

* What image size? How big should the image be? ................................................................................................................. 3-1

* Where to install the projector?................................................................................................................................................ 3-2

* How to install the projector? ................................................................................................................................................... 3-2

INSTALLATION SET UP ................................................................................................................................................................. 4-1

Access to controls .................................................................................................................................................................... 4-1

Scan adaptation ....................................................................................................................................................................... 4-2

PROJECTOR SET UP .................................................................................................................................................................... 5-1

Projector Set Up ....................................................................................................................................................................... 5-1

Password mode ....................................................................................................................................................................... 5-1

POWER (MAINS) CONNECTION .................................................................................................................................................... 6-1

Power (mains) cord connection ................................................................................................................................................ 6-1

Fuses ....................................................................................................................................................................................... 6-2

Switching on/off........................................................................................................................................................................ 6-2

INSTALLATION ADJUSTMENTS .................................................................................................................................................... 7-1

Entering the adjustment mode .................................................................................................................................................. 7-1

Overview flow chart installation mode. ...................................................................................................................................... 7-2

Installation mode start up ......................................................................................................................................................... 7-2

Scheimpfug adjustment ............................................................................................................................................................ 7-4

Optical lens focusing ................................................................................................................................................................ 7-5

Electrical focusing .................................................................................................................................................................... 7-5

Raster centering ....................................................................................................................................................................... 7-6

CRT projection angle adjustment.............................................................................................................................................. 7-6

Alignment of the projector......................................................................................................................................................... 7-9

Appendix A : G2 adjustment ............................................................................................................................................................A-1

5975987A BARCODATA 708 260597

i-1

Page 6

Table of Contents

i-2 5975987A BARCODATA 708 260597

Page 7

Safety Instructions

1

SAFETY INSTRUCTIONS

Notice on Safety

This equipment is built in accordance with the requirements of the

international safety standards EN60950, UL 1950 and CSA C22.2

No.950, which are the safety standards of information technology

equipment including electrical business equipment.

These safety standards impose important requirements on the use of

safety critical components, materials and isolation, in order to protect

the user or operator against risk of electric shock and energy hazard,

and having access to live parts.

Safety standards also impose limits to the internal and external

temperature rises, radiation levels, mechanical stability and strength,

enclosure construction and protection against the risk of fire.

Simulated single fault condition testing ensures the safety of the

equipment to the user even when the equipment's normal operation

fails.

INSTALLATION INSTRUCTIONS

Before operating this equipment please read this manual

thoroughly, and retain it for future reference.

Installation and preliminary adjustments should be performed

by qualified BARCO personnel or by authorized BARCO

service dealers.

WARNING

TO PREVENT FIRE OR ELECTRICAL SHOCK

HAZARD, DO NOT EXPOSE THIS EQUIPMENT TO

RAIN OR MOISTURE

FEDERAL COMMUNICATION COMMISSION (FCC STATEMENT)

This equipment has been tested and found to comply with the limits

of a class A digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely

to cause harmful interference in which case the user will be required

to correct the interference at his own expense.

Note :

The use of shielded cables is required to comply within the limits of

Part 15 of FCC rules and EN55022.

* All the safety and operating instructions should be read before using

this unit.

* The safety and operating instructions manual should be retained for

future reference.

OWNER’S RECORD

The part number and serial number are located at the back side of the

projector. Record these numbers in the spaces provided below.

Refer to them whenever you call upon your BARCO dealer regarding

this product.

PART NUMBER :

SER. NUMBER :

DEALER :

The lightning flash with an arrowhead within a

triangle is intended to tell the user that parts

inside this product may cause a risk of electrical

shock to persons.

* All warnings on the equipment and in the documentation manuals

should be adhered to.

* All instructions for operating and use of this equipment must be

followed precisely.

On safety

1. This product should be operated from an AC power source.

This projector may be connected to an IT-power system.

Operating AC power voltage of the projector:

BARCODATA 708

Art.No. R9002129 (

If you are not sure of the type of AC power available, consult your

dealer or local power company.

2. This product is equipped with a 3-wire grounding plug, a plug having

a third (grounding) pin. This plug will only fit into a grounding-type

power outlet. This is a safety feature. If you are unable to insert the

plug into the outlet, contact your electrician to replace your obsolete

outlet. Do not defeat the purpose of the grounding-type plug.

WARNING FOR THE CUSTOMERS: THIS APPARATUS MUST BE

GROUNDED (EARTHED) via the supplied 3 conductor AC power

cable.

(If the supplied power cable is not the correct one, consult your

dealer.)

120V AC

)

The exclamation point within a triangle is intended to tell the user that important operating

and/or servicing instructions are included in the

technical documentation for this equipment.

5975987A BARCODATA 708 260597

1-1

Page 8

Safety Instructions

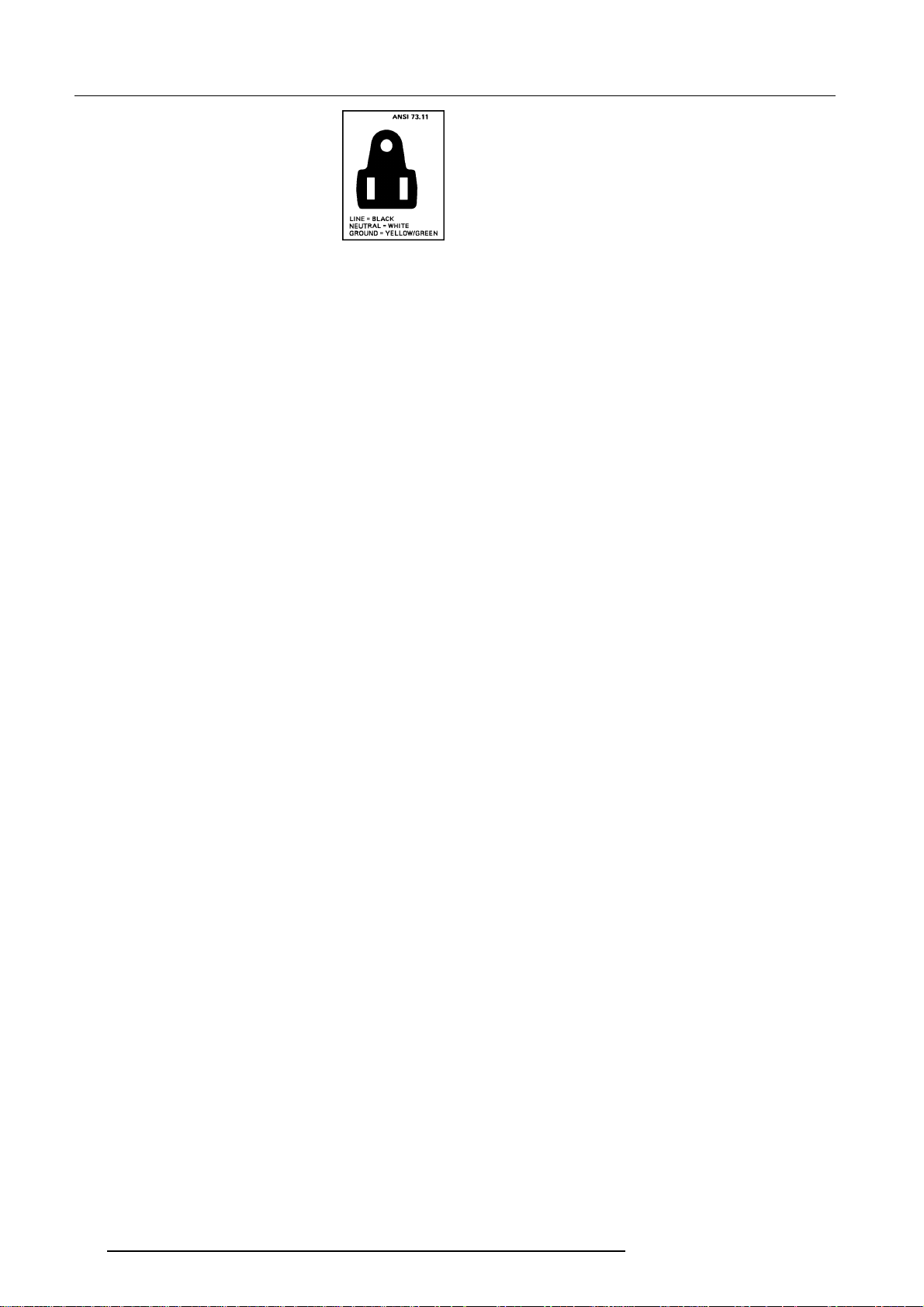

Power cord with ANSI 73.11 plug:

The wires of the power cord are colored in

accordance with the following code.

Green/yellow: ground

White: neutral

Black: line (live)

3. Do not allow anything to rest on the power cord. Do not locate this

product where persons will walk on the cord.

To disconnect the cord, pull it out by the plug. Never pull the cord

itself.

4. If an extension cord is used with this product, make sure that the

total of the ampere ratings on the products plugged into the extension

cord does not exceed the extension cord ampere rating. Also make

sure that the total of all products plugged into the wall outlet does not

exceed 15 amperes.

5. Never push objects of any kind into this product through cabinet

slots as they may touch dangerous voltage points or short out parts

that could result in a risk of fire or electrical shock.

Never spill liquid of any kind on the product. Should any liquid or solid

object fall into the cabinet, unplug the set and have it checked by

qualified service personnel before resuming operations.

6. Lightning - For added protection for this video product during a

lightning storm, or when it is left unattended and unused for long

periods of time, unplug it from the wall outlet. This will prevent

damage to the projector due to lightning and AC power-line surges.

On installation

1. Do not place this equipment on an unstable cart, stand, or table.

The product may fall, causing serious damage to it.

2. Do not use this equipment near water.

3. Slots and openings in the cabinet and the back or bottom are

provided for ventilation; to ensure reliable operation of the product

and to protect it from overheating, these openings must not be

blocked or covered. The openings should never be blocked by

placing the product on a bed, sofa, rug, or other similar surface. This

product should never be placed near or over a radiator or heat

register.

The projector should not be placed in a built-in installation or enclosure unless proper ventilation is provided.

4. Do not block the projector cooling fans or free air movement under

and around the projector. Loose papers or other objects may not be

nearer to the projector than 4" on any side.

On servicing

Do not attempt to service this product yourself, as opening or

removing covers may expose you to dangerous voltage potentials

and risk of electric shock!

Refer all servicing to qualified service personnel.

Unplug this product from the wall outlet and refer servicing to

qualified service personnel under the following conditions:

d. If the product does not operate normally when the operating

instructions are followed.

Note : Adjust only those controls that are covered by the operating

instructions since improper adjustment of the other controls may

result in damage and will often require extensive work by a qualified

technician to restore the product to normal operation.

e. If the product has been dropped or the cabinet has been damaged.

f. If the product exhibits a distinct change in performance, indicating

a need for service.

Replacement parts - When replacement parts are required, be sure

the service technician has used original BARCO replacement parts or

authorized replacement parts which have the same characteristics as

the BARCO original part. Unauthorized substitutions may result in

degraded performance and reliability, fire, electric shock or other

hazards. Unauthorized substitutions may void warranty.

Safety check - Upon completion of any service or repairs to this

projector, ask the service technician to perform safety checks to

determine that the product is in proper operating condition.

On cleaning

Unplug this product from the wall outlet before cleaning. Do not

use liquid cleaners or aerosol cleaners. Use a damp cloth for

cleaning.

- To keep the cabinet looking brand-new, periodically clean it with a

soft cloth. Stubborn stains may be removed with a cloth lightly

dampened with mild detergent solution. Never use strong solvents,

such as thinner or benzine, or abrasive cleaners, since these will

damage the cabinet.

- To ensure the highest optical performance and resolution, the

projection lenses are specially treated with an anti-reflective coating, therefore, avoid touching the lens. To remove dust on the lens,

use a soft dry cloth. Do not use a damp cloth, detergent solution, or

thinner.

On repacking

Save the original shipping carton and packing material; they will

come in handy if you ever have to ship your equipment. For maximum

protection, repack your set as it was originally packed at the factory.

On illumination

In order to obtain the best quality for the projected image, it is essential

that the ambient light which is allowed to fall on the screen be kept to

an absolute minimum.

When installing the projector and screen, care must be taken to avoid

exposure to ambient light directly on the screen. Avoid adverse

illumination on the screen from direct sunlight or fluorescent lighting

fixtures.

The use of controlled ambient lighting, such as incandescent spot

light or a dimmer, is recommended for proper room illumination.

Where possible, care should also be taken to ensure that the floors

and walls of the room in which the projector is to be installed are nonreflecting, dark surfaces. Brighter surfaces will tend to reflect and

diffuse the ambient light and hence reduce the contrast of the

projected image on the screen.

a. When the power cord or plug is damaged or frayed.

b. If liquid has been spilled into the equipment.

c.If the product has been exposed to rain or water.

1-2 5975987A BARCODATA 708 260597

Page 9

Unpacking and Dimensions

2

UNP ACKING AND DIMENSIONS

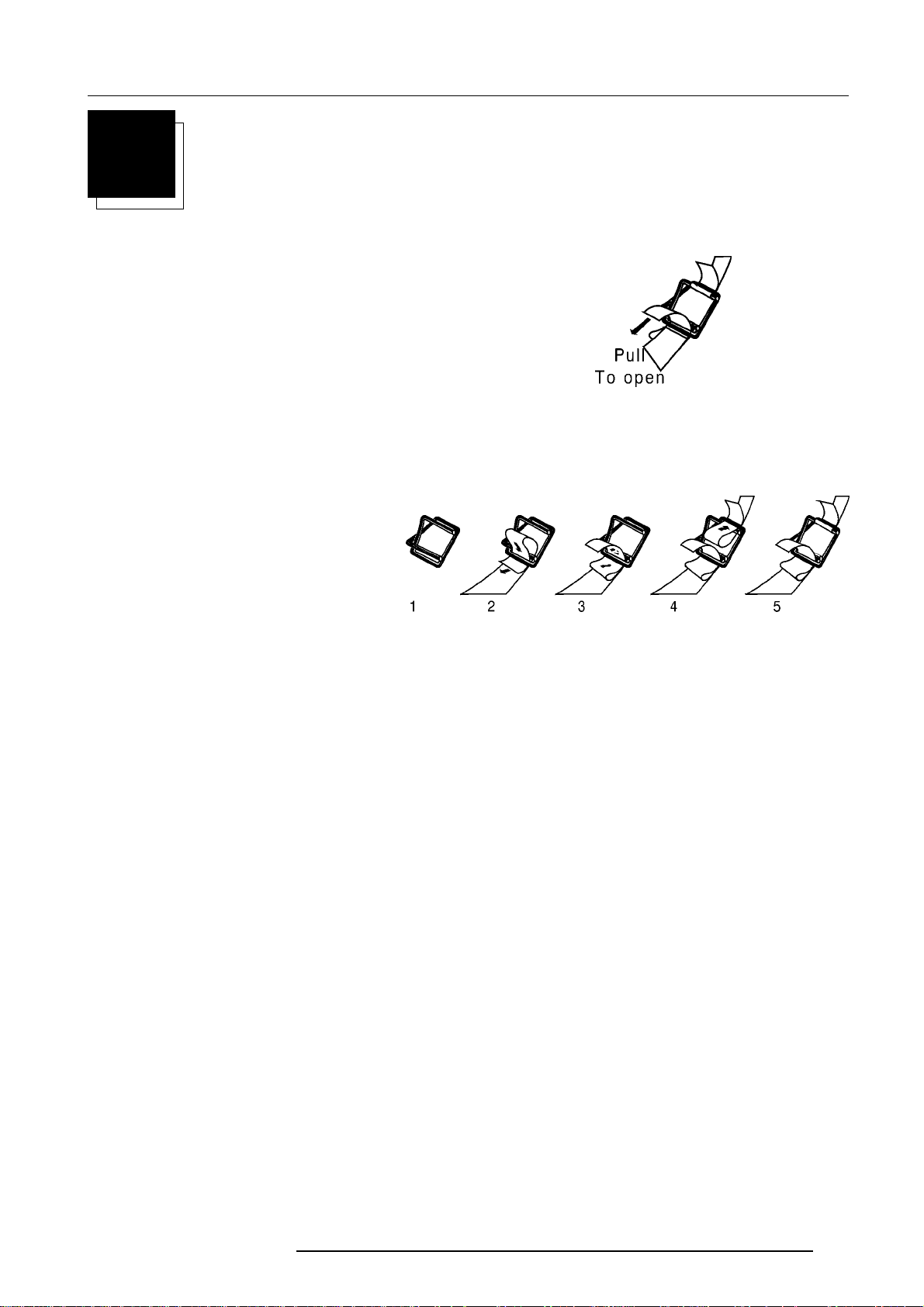

Unpacking

To open de banding, pull on the clip as shown in the first drawing.

Take the projector out of its shipping carton and place it on a table.

Save the original shipping carton and packing material, they will come in handy if you ever have to ship your projector. For maximum protection,

repack your projector as it was originally packed at the factory.

Contents of the shipped box :

- 1 BARCODATA 708.

- 1 remote control + 9V battery

- 1 power cable with outlet plug type ANSI 73.11.

- 1 owner's manual.

- 1 installation manual.

5975987A BARCODATA 708 260597

2-1

Page 10

Unpacking and Dimensions

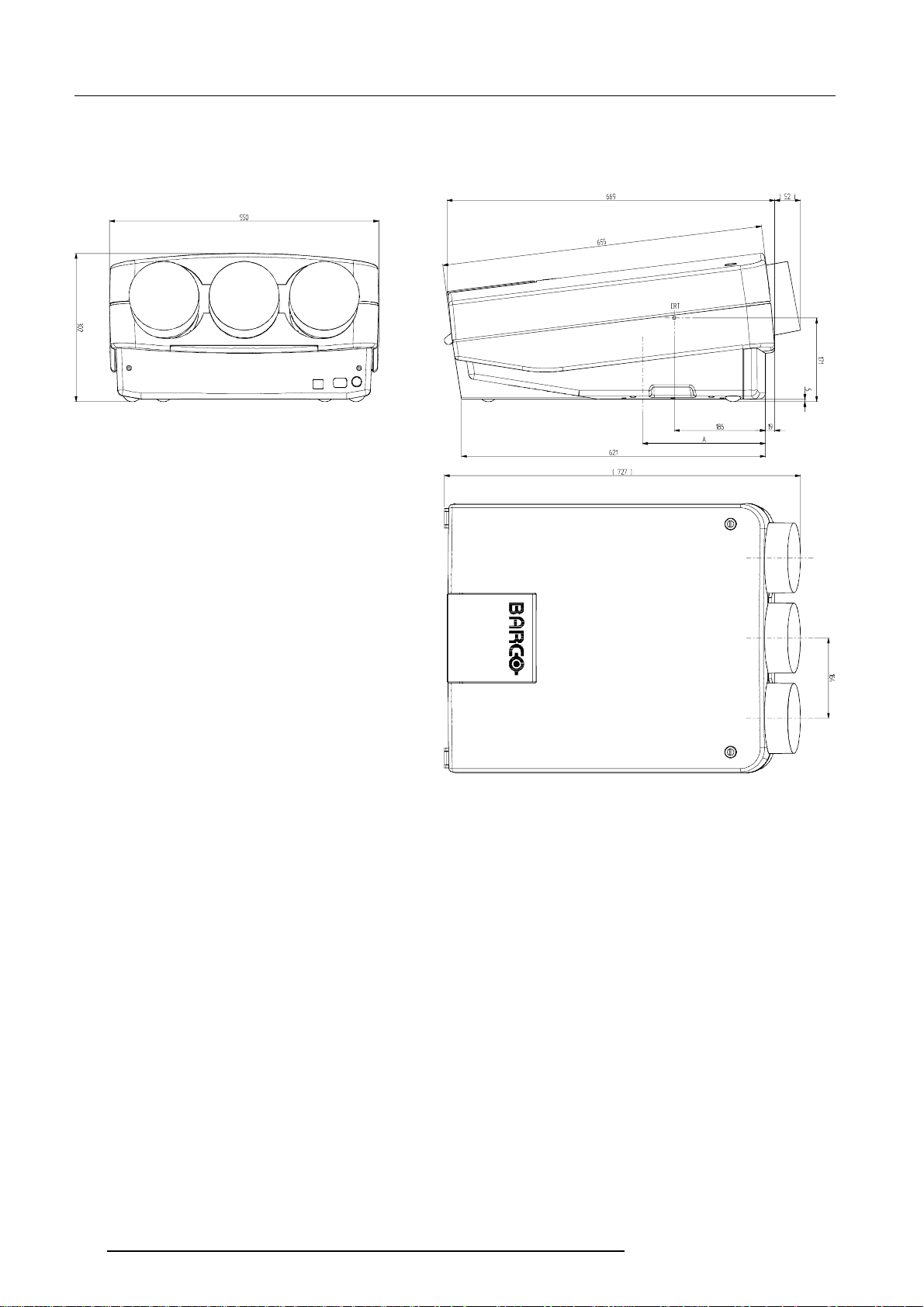

Projector dimensions

(mm)

2-2 5975987A BARCODATA 708 260597

Page 11

Installation Guidelines

Screen wid t h

3

INSTALLATION GUIDELINES

Installation guidelines

Careful consideration of things such as image size, ambient light

level, projector placement and type of screen to use are critical to the

optimum use of the projection system.

* Environment

Do not install the projection system in a site near heat sources such

as radiators or air ducts, or in a place subject to direct sunlight,

excessive dust or humidity. Be aware that room heat rises to the

ceiling; check that the temperature near the installation site is not

excessive.

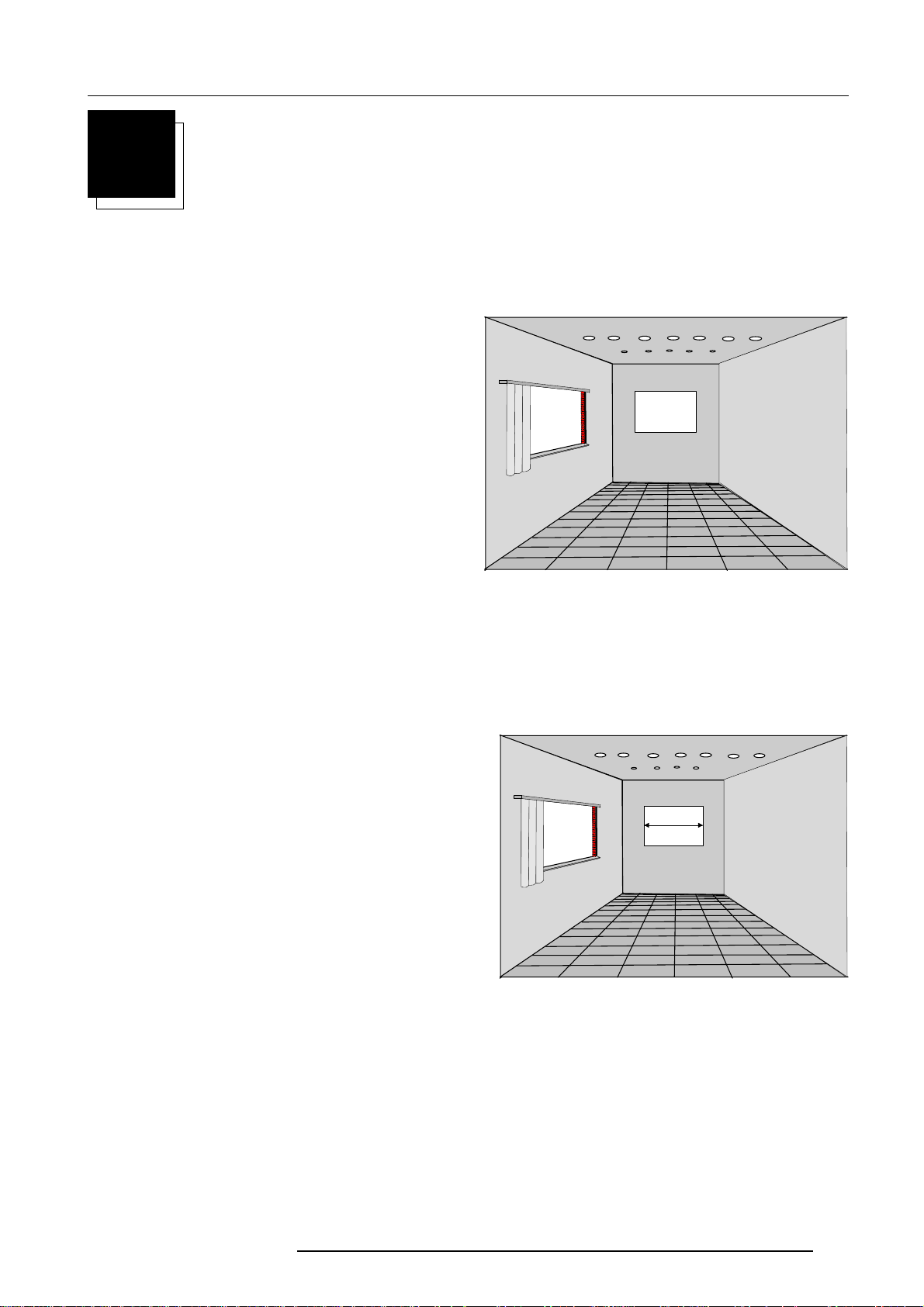

* What about ambient light ?

The ambient light level of any room is made up of direct or indirect

sunlight and the light fixtures in the room. The amount of ambient light

will determine how bright the image will appear. So, avoid direct light

on the screen.

Windows that face the screen should be covered by opaque drapery

while the set is being viewed. It is desirable to install the projecting

system in a room whose walls and floor are of non-reflecting material.

The use of recessed ceiling lights and a method of dimming those

lights to an acceptable level is also important. Too much ambient light

results in a ‘wash out’ of the projected image. This appears as less

contrast between the darkest and lightest parts of the image. With

bigger screens, the ‘wash out’ becomes more important. As a general

rule, darken the room to the point where there is just sufficient light to

read or write comfortably. Spot lighting is desirable for illuminating

small areas so that interference with the screen is minimal.

* Which screen type?

There are two major categories of screens used for projection

equipment. Those used for front projected images and those for rear

projection applications.

Screens are rated by how much light they reflect (or transmit in the

case of rear projection systems) given a determined amount of light

projected toward them. The ‘GAIN’ of a screen is the term used. Front

and rear screens are both rated in terms of gain. The gain of screens

range from a white matte screen with a gain of 1 (x1) to a brushed

aluminized screen with a gain of 10 (x10) or more. The choice

between higher and lower gain screens is largely a matter of personal

preference and another consideration called the Viewing angle.

In considering the type of screen to choose, determine where the

viewers will be located and go for the highest gain screen possible. A

high gain screen will provide a brighter picture but reduce the viewing

angle.

For more information about screens, contact your local screen

supplier.

* What image size? How big should the image be?

The BARCODATA 708 is designed for projecting an image width from

1.4m (4.6') to 7m (23') with an aspect ratio of 4 to 3. It leaves the

BARCO factory, adjusted as a ceiling front projector for a screen width

of 2.4m. Changing the image size from the factory preset requires a

realignment of the projector.

5975987A BARCODATA 708 260597

3-1

Page 12

Installation Guidelines

* Where to install the projector?

To indicate a correct installation position it is necessary to know the

distance :

- projector - ceiling

- projector - screen

To find this correct position for the projector, equipped with HD145

lenses, formulas are given in the next paragraph.

Abbreviations used on drawing and diagrams on next pages

B = Distance between ceiling and top of the screen.

A = Correction Value, extra value to be added to B to obtain the

correct installation position. (In some cases the A value can be

negative.)

CD = Total distance between projector and ceiling.

CD = A + B (When the result is negative, enlarge the distance

between ceiling and top of the screen, mount screen lower, until CD

becomes zero or positive)

SW = Screen width.

PD = Perpendicular distance between screen and projector.

ceiling

B

screen

screen width

SW

PD

CD

A

projector

Front view

Top view

Formulas for Projector to screen distance and correction value A with

regard to the screen width for

HD145 lenses

(metric).

Formulas (metric)

PD[m] = 1.21 x SW[m] + 0.213

A[cm] = 12.95 x SW[m] - 22.83

Max phosphor width on CRT = 11.5 cm

* How to install the projector?

Ceiling mount or table mount?

To install the projector, apply always the BARCO kits which are

specially designed for this function.

BARCO ceiling support.

Always use the BARCO ceiling support to attach your projector to the

ceiling. (BARCO order number : R9827990)

The installation instruction for this support is enclosed in the packet of

the set.

BARCO projection table.

Formulas for Projector to screen distance and correction value A with

regard to the screen width for

HD145 lenses

(inch).

Formulas (inch)

PD = 1.21 x SW + 8.39

A = 0.1295 x SW - 8.99

Max phosphor width on CRT = 4.53 inch

Height adaptable projection table provides a stable stand for your

projector, and makes it possible to adapt the projector perfectly to the

local requirements. (BARCO order number R9827740).

3-2 5975987A BARCODATA 708 260597

Page 13

Installation Set Up

4

INSTALLATION SET UP

Access to controls

Opening procedure :

During the projector set up and installation it is neces-

sary to open the top cover.

To gain access, procede as follow :

*Turn both lock screws with a screwdriver or a coin

counter clockwise.

* Lift up and pivot the top cover.

* Support the top cover with the hand, no support is

incorporated.

During some installations it will become handy to

remove the top cover totally.

Therefore,

- pivote the top cover ± 60°

- push the top cover to the front side of the projector

until it jumps out of its hings.

- Turn the top cover till 90° and lift it up.

Re-install the cover :

Hook the top cover into the cabinet hinges. Pivot the top cover 30°

and pull it backwards until it fits in the hinges. Close the cover and

secure the lock screws by turning clockwise with a screwdriver or

coin.

5975987A BARCODATA 708 260597

1-1

Page 14

Installation Set Up

Scan adaptation

The scanning can be switch by turning the Horizontal and Vertical

scan connectors and the convergence connectors.

To change the scanning, it is necessary to open the projector top

cover and to rotate the chassis.

For opening the projector's top cover, see Getting access to controls.

WARNING

TURN OFF PROJECTOR AND UNPLUG THE POWER CORD

BEFORE CHANGING THE SCAN DIRECTION.

Gaining access to the scan connectors and the convergence connectors.

- Open the top cover (to remove it, see 'Gaining access to controls'.

- To open the chassis, loosen both indicated retaining screws.

Turn the chassis to the front of the projector until it grips in its locks.

COMM PORT

REMOTE

R

(800 peripherals)

RS232 OUTRS232 IN

G(S) B S VID EO

Horiz o nt al s c an

connectors

Vertical sc an

connectors

S-VIDEO

Convergence

connectors

COMM PORT

REMOTE

RG(S)B SVIDEO

(800 peripherals)

RS232 OUTRS232 IN

S-VIDEO

4-2 5975987A BARCODATA 708 260597

Page 15

A : Horizontal scan inversion

Installation Set Up

Three connectors are used, one for each horizontal

deflection coil. When changing the horizontal scan,

insure that all three connectors are set in the same

position. See position of the connectors for the

corresponding projector configuration.

B : Vertical scan inversion

Horizontal scan

connectors

Vertical scan

connectors

Three connectors are used, one for each vertical

deflection coil. When changing the vertical scan,

insure that all three connectors are set in the same

position. See position of the connectors for the

corresponding projector configuration.

Top view of the connectors; upper three connectors

for horizontal scan inversion, lower three for vertical

scan inversion.

C : Convergence connectors

Three connectors are used. The position of these connectors has to

be changed when switching from one configuration to another.

With an open chassis, for a

the connectors must be plugged in with the

from the tubes). For a

connectors must be plugged in with the

front-table

front-ceiling

or a

rear ceiling

configuration,

contacts upwards

or

rear-table

configuration, the

contacts facing the tubes

(away

Front / Table

Contact side

Front / Ceiling

Rear / Table Rear / Ceiling

After scan inversion, close the chassis and close the top cover.

Reconnect the power cord to the wall outlet.

Note

Switching over from floor to ceiling or vice versa requires a complete

readjustment of picture geometry and convergence.

Check of the correct connector position

Note : this check procedure can only be done after power (mains)

connection. So, first continue with the

connections

and then return to this checking procedure.

Switch on the BARCODATA 708 and press

projector set up

and the

ADJUST to start up the

adjustment mode. Select with the control disk 'Service' and press

ENTER. The service menu will be displayed. Select 'PROJECTOR

SET UP' and press ENTER. Select 'IDENTIFICATION' and press

ENTER. On this screen, information is given about the projectors

configuration.

Configuration when leaving the factory : ceiling/front configuration.

Follow next procedure to check the configuration :

- switch on the projector.

- the projector starts up on the last selected source.

- press the

- highlight 'service' with the control disk and press

The

- select with the control disk

The

- Select with the control disk

ADJUST key.

'service mode menu'

will be displayed

'Projector set up menu'

'Projector set up'

will be displayed.

'Identification'

and press ENTER.

.

ENTER

and press ENTER.

The projector displays the Identification screen

ADJUSTMENT MOD E

Select a path from

below:

GUIDED

RANDOM ACCESS

INSTALLATION

SERVICE

IRIS

source 1

Select with or

SERVICE MODE

then <ENTER>

<EXIT> to return

PROJECTOR SET-UP

MEMORY MANAGEMENT

COMMON SETTINGS

I2C DIAGNOSTICS

Select with or

then <ENTER>

<EXIT> to return.

CHANGE PROJECTOR ADDRESS

PROJECTOR SET-UP

IDENTIFICATION

TOTAL RUN TIME

CHANGE PASSWORD

CHANGE LANGUAGE

CHANGE BAUDRATE

POWER UP MODE : operating

BARCO LOGO

Select with or

then <ENTER>

<EXIT> to return.

DATA 708

Proj. address : 001

Soft. Version : 5.00

Config. : Ceiling

front

Baudrate PC : 9600

Text : ON

Serial No. : 10359852

This screen gives information about the projector configuration in the

subject '

config.

'.

5975987A BARCODATA 708 260597

1-3

Page 16

Installation Set Up

4-4 5975987A BARCODATA 708 260597

Page 17

Projector Set Up

Horizontal scan

connectors

Vertical scan

connectors

Convergence

connectors

COMM PORT

(800 peripherals)

REMOTE

RG(S)B SVIDEO

S-VIDEO

RS232 OUTRS232 IN

5

PROJECTOR SET UP

Projector Set Up

The strap on the CPU unit allow a set up of the password mode.

Gaining access to the strap

- Open the top cover (see installation set up)

- Open the chassis (see installation set up)

strap

Password mode

With a strap on the controller unit, the important projector adjustments

can be protected with a password. When the password feature is

enabled (strap mounted on both legs), the customer has to enter a

password before he can enter the specific adjustment.

When the password menus are disabled (strap mounted only on one

leg), all adjustments are free. This position of the strap is useful for

qualified service technicians because they do not need a password

during service.

Position of the strap :

ON : password disabled

OFF : password enabled

Socket for strap

5975987A BARCODATA 708 260597

5-1

Page 18

Projector Set Up

5-2 5975987A BARCODATA 708 260597

Page 19

Power Connection

6

POWER CONNECTION

Power (mains) cord connection

Use the supplied power cord to connect your projector to the wall

outlet. Plug the female power connector into the male connector at

the front of the projector.

See installation instructions before

connecting to the supply

OFF

See installation instructions before

connectin g to the su pply

OFF ON

V NOM 120 Volt

I MAX 5 AMP

FREQ 60 Hz

ON

V NOM 120 Volt

I MAX 5 AMP

FREQ 60 Hz

Fuses

Warning

For continued protection against fire hazard :

- replace with the same type of fuse

- refer replacement to qualified service personnel

Fuse type : 2 x T5A/250V (Barco order number : R314104)

Switching on/off

The projector is switched ON and OFF using the power (mains)

switch ON/OFF.

Pressed : ON

Not pressed : OFF

The projector can start now in the 'operational mode' (image displayed) or in the 'stand by mode', depending on the position of the

'power up' dip switch on the controller unit. This DIP switch is set

during installation by a qualified technician. If you want to change this

start up mode, call a qualified technician.

Stand by indication lamp :

no light up : projector in operational mode

red : projector is in stand by.

Leds on the front plate of the projector

-CONV

+17V

-9V

+9V

+30V

+CONV

+210V

STANDBY

-17V

+HTHD

HOLD DOWN EHT

SF

COINC

HOLD DOWN HD

5975987A BARCODATA 708 260597

6-1

Page 20

Power Connection

6-2 5975987A BARCODATA 708 260597

Page 21

Installation Adjustments

7

INSTALLA TION ADJUSTMENTS

Entering the adjustment mode

Press ADJUST to enter the adjustment mode.

ADJUSTMENT MODE

Select a path from

below:

GUIDED

RANDOM ACCESS

INSTALLA T IO N

SERVICE

IRIS

source 1

Select with or

then <ENTER>

<EXIT> to ret urn

Installation

(only for qualified

technician)

Random Access

Adjustment

IRIS

Service

Guided

Adjustment

5975987A BARCODATA 708 260597

7-1

Page 22

Installation Adjustments

Overview flow chart installation mode.

SCHEIMPFLUG ADJUSTMENT

LOOSEN THE 4

LENS MOUNTING NUTS ON

EACH LENS, UNTIL THE TAG

OF EACH SCHEIMPFLUG RING

CAN BE MOVED TO ITS

DESIRED POSITION

(1.4 M, 2.4 M OR 4.0 M

SCREEN WIDTH°

<ENTER> to continue

<EXIT> to return

CRT PROJECTION ANG LE

ADJUSTMENT

CRT PROJECTION ANGLE IS

THE FIRST STEP OF STATIC

CONVERGENCE ADJUSTMENT.

IT IS CRITICAL THAT THE

RASTER S AR E CENTER E D ON

THE CRT FAC E PLATES

PRIOR TO PERFORMING

THIS STEP.

...

<ENTER> to read more

<EXIT> to return

OPTICAL LENS FOCUSING

1. LOOSEN THE NUT ON THE

REAR OF THE XXXX LENS,

ROTATE THE LENS B ARREL

TO FOCUS THE CENTER

OF THE IMAGE,

THEN TIGHTEN THE NUT

2. LOOSEN THE NUT ON THE

FRONT O F THE XXXX LENS

AND R OTATE THE FRONT

SECTION OF THE LENS TO

FOCUS THE CORN ERS OF THE

IMAGE, THE N TIGHTEN THE NUT.

<ENTER> to continue

<EXIT> to return

This menu is repeated 3

times, first in Green,

then in Red and then in

Blue

CRT PROJECTIO N ANGL E

DURING THIS PROCEDURE,

RED ON GREEN AND THEN

BLUE ON GREEN CROSSHAIRS

WILL BE DISPLAYED

TO ALLOW THE RED AND

BLUE C RTS TO BE ALIGNED

WITH THE GREEN CRT.

LOOSEN BOLT S A AN D B

TO PIVOT THE RED CRT,

AND BOLDS C AND D

TO PIVO T TH E BLUE C RT.

ADJUS TME NT

<ENTER> to continue

<EXIT> to return

RASTER CENTERI NG

CONTRAST LEVEL IS REDUCED

AND BRIGHTNESS INCREASED

TO MAKE TH E RAST ER

VISIBLE ON THE FACE PLATE

OF EACH CR T.

USE THE ARROW KEYS

TO CEN T ER THE RASTER

ON THE GREEN, RED AND

BLUE CRT RESPECTIVELY

<ENTER> to continue

<EXIT> to return

This menu is displayed in green. After ENTER is

pressed, only the green raster is displayed and the

control disk may be used to center the raster on the

CRT surface. This menu is also displayed, once in

red and once in blue.

CRT

PROJECTION ANGLE

ADJUSTMENT

Align crosshairs

<ENTER> continue

<EXIT> to return

Installation mode start up

It will be necessary to perform several mechanical adjustments while

in the installation mode. Remove the top cover in order to gain

access to the adjustment points (see Access to controls).

Two possible ways to enter the installation mode :

a) Using the RCU.

Press the

The projector displays the path selection menu.

b) Using the local keypad.

Press the

The projector displays the

Use the control disk to highlight

The path selection menu will be displayed.

ADJUST key.

ADJUST key.

General access menu

enter ADJUST

.

and press ENTER.

ADJUST

STANDBY

GENERAL ACCESS

3 4

1 2

Enter ADJUST

Select with ,

or

then <ENTER>.

<EXIT> to return

EXIT

ENTER

SHARPNESS

TINT

COLOR

BRIGHTNESS

CONTRAST

7-2 5975987A BARCODATA 708 260597

Page 23

Push the control disk up or down to highlight "Installation" and press

enter

password

xxxx

197

WRONG

PASSWORD

!!!

ENTER.

continues displaying a WARNING.

ENTER

EXIT returns to operational mode.

ADJUST returns to operational mode.

Installation Adjustments

ADJUSTMENT MOD E

Select a path from

below:

GUIDED

RANDOM ACCESS

INSTALLATION

SERVICE

IRIS

source 1

Select with or

then <ENTER>

<EXIT> to return

A warning will be displayed on the screen.

If you are qualified installation or service personnel, press

ENTER

to start up the installation mode.

When entering the installation mode, the projector will automatically

switch to the internal pattern on 15 kHz/50 Hz.

ENTER asks for your password.

EXIT returns to the path selection menu.

When the password mode is active, your password will be asked.

Your password contains 4 digits.

a) Adjusting the projector with the RCU.

Enter the digits with the numeric keys on the RCU.

Example : 2 3 1 9

For each digit entered, a 'X' appears on the screen under the

displayed text 'enter password'.

When your password is correct, you get access to the 'Adjustment

mode'.

When the entered password is wrong, The message

word !!!'

will be displayed. The projector stays on the previous

'Wrong pass-

selected item.

WARNING

RISK OF ELECTRICAL SHOCK

NO USER ADJUSTABLE PARTS

INSIDE

THE FOLLOWING

INSTALLATION MENUS

ARE RESERVED TO,

AND TO BE PERFORMED ONLY

BY BARCO PERSONNEL, OR

BARCO AUTHORIZED DEALERS

IF QUALIFIED, PRESS

<ENTER> TO CONTINUE, OR

IF NOT, <EXIT> TO RETURN.

Factory programmed

password :

0000

b) adjusting the projector with the local keypad.

When the 'compose password' menu is displayed, select with the

control disk the first digit of your password and press

ENTER.

Continue by selecting the second digit with the control disk and press

ENTER. Handle in the same way for the third and fourth digit.

When your password is correct, you get access to the 'Adjustment

mode'.

When the entered password is wrong, the message

word'

will be displayed.

'Wrong pass-

COMPOSE

PASSWORD

???

7 8 9

4 5 6

1 2 3

0

Select with ,

or

then <ENTER>

<EXIT> to return

5975987A BARCODATA 708 260597

7-3

Page 24

Installation Adjustments

Scheimpfug adjustment

The scheimpfug correction can be adjusted separately for the three

tubes within 3 ranges:

range 1 : 1.4 m (55") to 1.9 m (75"), optimum screen width 1.4 m

(55")

range 2 : 1.9 m (75") to 3.2 m (126"), optimum screen width 2.4 m

(94")

range 3 : 3.2 m (126") to 6 m (236"), optimum screen width 4 m

(157")

A correct scheimpfug setting gives the possibility to focus the lenses

for a sharp image in all screen areas.

To change the setting from one range to another, some mechanical

actions have to done.

1. Open the top cover (see Gaining access to controls)

2. Loosen the lens bolts (do not remove them), and slide the lens to

the front until the scheimflug ring can move freely (nutdriver 8 mm or

screwdriver).

range 1

min. SW : 1.40 m (55")

max. SW : 1.90 m (75")

range 2

min. SW : 1.90 m (75")

max. SW : 3.20 m (126")

range 3

min. SW : 3.20 m (126")

max. SW : 6.00 m (236")

Lens bolts

Blue lens

Lens bolts

Green lens

1.40m

1.90m

1.90m

3.20m

3.20m

6.00m

Lens bolts

Red lens

See installation inst ructions before

connecting to the supply

V NOM 120/230 Volt

I MAX 5/2.5 A MP

FREQ 60/50 H z

OFF

ON

3. Push the scheimpfug ring to its correct position (front view).

range 1 : to the right

range 2 : in the middle

range 3 : to the left

range 3

Scheimpfug c orrecti on handle

range 3

Green

range 2

Blue

range 2

range 1

range 1

Red

range 2

range 3

See installat ion in s tructions bef o re

connecting to the supply

V NOM 120/230 Volt

I MAX 5 /2.5 AMP

FREQ 60 /50 Hz

OFF ON

range 1

4. Push the lens back till it fits in the ring and secure the four bolts.

7-4 5975987A BARCODATA 708 260597

Page 25

Optical lens focusing

OPTICAL LENS FOCUSING

<ENTER> to continue

<EXIT> to return

1. LOOSEN THE NUT ON THE

REAR OF THE XXXX LENS,

ROTATE THE LENS BARREL

TO FOCUS THE CENTER

OF THE IMAGE,

THEN TIGHTEN THE NUT

2. LOOSEN THE NUT ON THE

FRONT OF THE XXXX LENS

AND ROTATE THE FRONT

SECTION OF THE LENS TO

FOCUS THE CORNERS OF THE

IMAGE, THEN TIGHTEN THE NUT.

The optical focusing procedure is performed separately for each

lens. The appropriate CRT will be switched on as the user proceeds

through the optical focusing adjustment sequence.

Each lens has two focus adjustment points, one at the rear of the lens

and one at the front. The center of the projected image is focused by

loosening the wing nut at the rear end of the lens and rotating the lens

barrel until the center of the image is clearly focused. The corners of

the projected image are focused by loosening the wing nut at the

front end of the lens and rotating the lens barrel until the corners of

the image are clearly focused. Repetition of these adjustments may

be necessary to optimize optical focusing.

Press

ENTER key to continue.

ENTER continues to Raster centering.

EXIT returns to scheimpfug adjustment

ADJUST returns to operational mode.

Installation Adjustments

XXXX = respectively red, green and blue.

Center

focusing

Electrical focusing

The electrical focus for red, green and blue is factory preset. When

they have to be readjusted, follow the procedure as described below:

- Ensure the lenses are correctly focused.

- Open the top cover.

- Adjust separately the focus control for red, green and blue for the

sharpest image on the screen.

Electrical focus

Green

Red

Corner

focusing

Blue

5975987A BARCODATA 708 260597

7-5

Page 26

Installation Adjustments

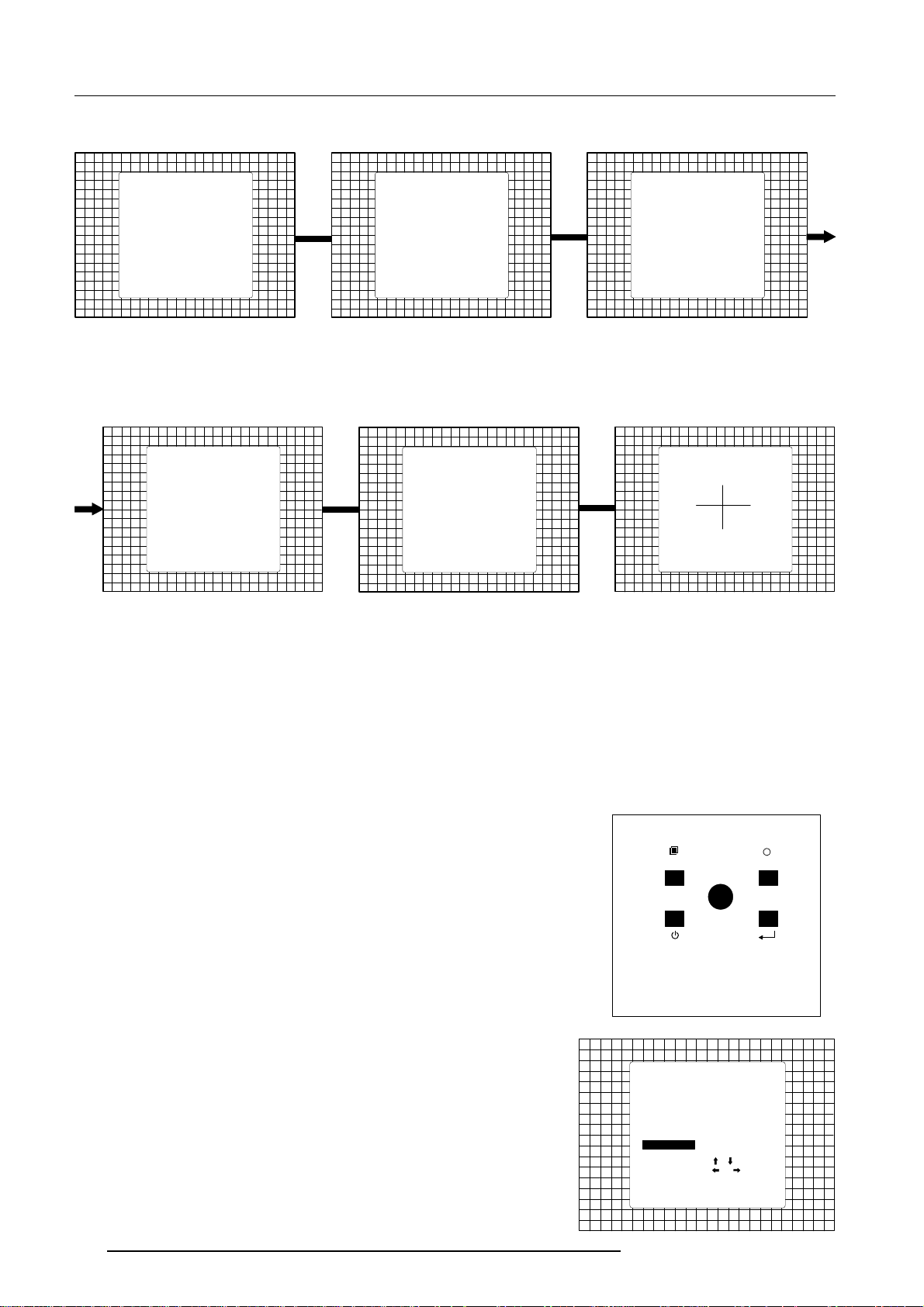

Raster centering

The raster must be centered on the CRT screen surface of each tube,

therefore, it is necessary to look into the lenses.

Caution : To avoid eye discomfort while performing these adjustments, reduce the contrast and gradually increase the brightness

level until the raster becomes visible behind the image.

Warning : In order to ensure maximum CRT

longevity and to avoid CRT damage, do not shift

the raster outside the phosphor area of the CRT.

Press ENTER to display the raster on the green CRT.

Look into the green lens and shift the raster with the control disk until

it is centered in the middle of the CRT faceplate.

forbidden area

projected raster

crt faceplate border

phosphor border

RASTER CENTERING

CONTRAST LEVEL IS REDUCED

AND BRIGHTNESS INCREASED

TO MAKE THE RASTER

VISIBLE ON THE FACE PLATE

OF EACH CRT.

USE THE ARROW KEYS

TO CENTER THE RASTER

ON THE GREEN, RED AND

BLUE CRT RESPECTIVELY

<ENTER> to continue

<EXIT> to return

correct ra ste r po si ti on

wrong raster position

Press ENTER to activate the raster on the Red CRT faceplate.

Shift the raster with the control disk until the raster is centered in the

middle of the CRT faceplate.

Press

ENTER to activate the raster on the Blue CRT faceplate.

Shift the blue raster with the control disk until the raster is centered

on the CRT faceplate.

Press

ENTER to continue with the CRT projection angle adjustment

ENTER continues to CRT Projection angle Adjustment.

EXIT returns to Optical focusing.

ADJUST

returns to operational mode.

7-6 5975987A BARCODATA 708 260597

Page 27

CRT projection angle adjustment

CRT PROJECTION ANGLE

ADJUSTMENT

<ENTER> to continue

<EXIT> to return

DURING THIS PROCEDURE,

RED ON GREEN AND THEN

BLUE ON GREEN CROSSHAIRS

WILL BE DISPLAYED

TO ALLOW THE RED AND

BLUE CRTS TO BE ALIGNED

WITH THE GREEN CRT.

LOOSEN BOLTS A AND B

TO PIVOT THE RED CRT,

AND BOLDS C AND D

TO PIVOT THE BLUE CRT.

The projection angle of the red and blue CRT's is dependent on the

desired size of the projected image. If the centers of green, blue and

red do not coincide, the CRT projection angle must be adjusted.

Never try to correct this misalignment with the shift correction or the

static convergence controls. These controls may only be applied to

correct small errors which cannot be corrected by the CRT angle

adjustment.

Ensure that the rasters are centered on the CRT face.

Press

ENTER to start the CRT angle adjustment procedure. A

crosshairs (green and red) will be displayed on the screen.

ENTER continues to the crosshairs alignment.

EXIT returns to raster shift adjustment

ADJUST returns to operational mode.

Installation Adjustments

CRT PROJECTION ANGLE

ADJUSTMENT

CRT PROJECTION ANGLE IS

THE FIRST STEP OF STATIC

CONVERGENCE ADJUSTMENT.

IT IS CRITICAL THAT THE

RASTERS ARE CENTERED ON

THE CRT FACE PLATES

PRIOR TO PERFORMING

THIS STEP.

...

<ENTER> to read more

<EXIT> to return

Projection angle correctly aligned

for screen width SW1

SW1

The same projection angle is mis-aligned for new

screen width SW2. Re-alignment is necessary.

Each screen width change requires readjustment of the projection angle.

SW2

(SW2>SW1)

5975987A BARCODATA 708 260597

7-7

Page 28

Installation Adjustments

Screws A, B, C and D (M4) : upper

fixation latch. nutdriver 7mm.

Screw A', B', C' and D' (M4) : lower

fixation latch. nutdriver 7mm.

Loosen the four hexagon screws A, A', B and B', upper and lower

fixation latch. These screws fasten the cooling house of the red tube.

Pivot the red CRT until the center of the red image coincides with the

center of the green image. If the angle of the red CRT is corrected,

tighten the four bolts.

A' A B'C'B

A'

A

B'

B

CRT

PROJECTION ANGLE

ADJUSTMENT

C'

C

D'D

C

D'

D

red crosshair

green crosshair

Move the red CRT

towards the green

CRT

red crosshair

green crosshair

Move the red CRT

to the outside, away

from the green CRT

ENTER continues to blue and green crosshairs.

EXIT will return to CRT projection angle adjustment.

Loosen the four hexagon screws C, C', Dand D', upper and lower

fixation latch. These screws fasten the cooling house of the blue tube.

Pivot the blue CRT until the center of the blue image coincides with

the center of the green image. If the angle of the red CRT is corrected,

tighten the four bolts.

blue crosshair

green crosshair

Move the bleu CRT

to the outside, away

from the green CRT

Align crosshairs

<ENTER> continue

<EXIT> to return

CRT

PROJECTION ANGLE

ADJUSTMENT

Align crosshairs

<ENTER> continue

<EXIT> to return

blue crosshair

green crosshair

Move the bleu CRT

towards the green

CRT

ENTER continues to the path selection menu.

EXIT returns to the CRT projection angle adjustment.

7-8 5975987A BARCODATA 708 260597

Page 29

Installation Adjustments

After finishing the installation adjustments procedure, the

selection'

returns on the screen. You are now able to start the

'Path

alignment procedure for the projector. You have the choice between:

- Guided Adjustment Procedure

- Random Access Adjustment Procedure

The result of both procedures will be the same. More explanation

about both procedures is given in the owners manual.

The following paragraph gives an overview of the image corrections.

Alignment of the projector.

Overview of the corrections

For detailed information about these corrections and procedures to

be followed, see owner's manual. (pages given hereafter are for the

random access adjustment mode)

Shift corrections for the Red, Green and Blue image.

Left-Right adjustments

- Vertical center line bow and skew

- Left and right keystone adjustment

- Left and right bow adjustment

- Horizontal size adjustment

Top-Bottom adjustments

- Horizontal centerline bow and skew

- Top keystone adjustment

- Top bow adjustment

- Bottom keystone adjustment

- Bottom bow adjustment

ADJUSTMENT MODE

GUIDED

RANDOM ACCESS

INSTALLATION

SERVICE

IRIS

Select with or

then <ENTER>

<EXIT> to return

source 1

Size-linearity adjustments

- Horizontal size adjustment

- Vertical linearity adjustment

- Vertical size adjustment

- Horizontal phase adjustment

Convergence adjustments

- Green only

- Red on green

- Blue on green

Blanking adjustment

- Top-Bottom, Left-Right

Color adjustments

5975987A BARCODATA 708 260597

7-9

Page 30

Installation Adjustments

7-10 5975987A BARCODATA 708 260597

Page 31

G2 Adjustment

SAFETY

NOTICE

RISK OF ELECTRICAL SHOCK

G2 ADJUSTMENT SHOULD BE

PERFORMED

BY BARCO PERSONNEL,

OR BARCO AUTHORIZED

DEALERS.

IF QUALIFIED, PRESS

<ENTER> TO CONTINUE, OR

IF NOT, <EXIT> TO RETURN.

131

A

G2 ADJUSTMENT

G2 adjustment

Enter the adjustment mode by pressing ADJUST and highlight

Service

. Press ENTER to start up the service mode.

Highlight 'Common settings' and press ENTER.

ENTER starts up the Common settings menu.

EXIT returns to the adjustment mode menu.

Highlight G2 adjust and press ENTER.

ADJUSTMENT MOD E

Select a path from

below:

GUIDED

RANDOM ACCESS

INSTALLATION

SERVICE

IRIS

source 1

Select with or

then <ENTER>

<EXIT> to return

MEMORY MANAGEMENT

COMMON SETTINGS

G2 ADJUSTMENT

CRT RUN IN CYCLE

PROJECTOR WARM UP

SERVICE MODE

PROJECTOR SET-UP

COMMON SETTINGS

I2C DIAGNOSTICS

Select with or

then <ENTER>

<EXIT> to return.

A safety notice will be displayed to warn the operator.

If you are qualified, press

ment, otherwise press

ENTER to continue with the G2 adjust-

EXIT to return to the service menu.

If ENTER is pressed, the G2 menu will be displayed.

Select with or

then <ENTER>

<EXIT> to return.

G2 ADJUSTMENT

Use the potentiometers

on the G2-Adj module

toset the screen grid

voltage for Red,

Green and Blue.

Adjust until the LED

on the corresponding

output amplifier is turned off

<EXIT> to return.

5975987A BARCODATA 708 260597

A-1

Page 32

G2 Adjustment

A green LED for each color is mounted on the driver board, below the

CRT's. When selecting the G2 adjustment menu, these green LEDs

must be out. If not, follow the procedure to adjust the G2 :

- Loosen the retaining screws of the upper electronic chassis and

pivot it to the lenses.

- Adjust the G2 potentiometers very slowly with a screwdriver until the

corresponding LED just stops illuminating. Repeat the adjustment

for the other colors.

- Once the three G2 potentiometers have been correctly adjusted,

close the upper electronic chassis and secure with the retaining

screws.

Loosen scre ws and move t he cover plate

to the left to access the G2 controls.

Cover the G2 contro ls agai n aft er align men t.

G2 Adjustments

Red

Green

Blue

Green G2 LED

Picture of the green LED. The other LED's are mounted in the

same neighbourhood.

A-2 5975987A BARCODATA 708 260597

Page 33

MATERIAL SAFETY DATA SHEET

MANUFACTURER'S NAME AND FSCM

ADDRESS

CHEMICAL NAME AND SYNONYMS

CHEMICAL FAMILY

SECTION I

FEDERAL STOCK NUMBER

MIL-STD-1341/NATIONAL FIRE PROTECTION ASSOCIATION STD 704M SIGNAL

FLAMMABILITY.................... HEALTH.................. REACTIVITY................. SPECIFIC HAZARD.............

PAINTS, PRESERVATIVES, AND

BARCO N.V.

(Number, Street, City, State, and ZIP Code)

Noordlaan 5 B-8520 KUURNE

Ethylenglycol & Glycerol

Polyalcohols

(FSN)

SOLVENTS

(Federal Supply Code for Manufacturer's)

%

GROSS WEIGHT

TRESHOLD LIMIT

VALUE

(Units)

TRADE NAME AND SYNONYMS

Cooling liquid 512334

FORMULA

(LBS)

ALLOYS AND METALLIC COATINGS

C

2H6O2+C3H8O3

OUTSIDE PACKAGE DIMENSIONS (Inches)

Form Approved

Bureau Budget No. 45-R0338

EMERGENCY PHONE NO.

32-56-368211

TRESHOLD LIMIT

%

VALUE

(Units)

PIGMENTS

CATALYST

VEHICLE

SOLVENTS

ADDITIVES

OTHERS

SECTION II - HAZARDO US I NGREDIE NTS

BOILING POINTS

BASE METAL

ALLOYS

METALLIC COATINGS

FILLER METAL

PLUS COATING OR CORE FLUX

OTHERS

HAZARDOUS MIXTURES OF OTHER LIQUIDS, SOLIDS, OR GASES

(°C.)

201°C

SPECIFIC GRAVITY

(H2O=1)

TRESHOLD LIMIT

%

VALUE

1.15

(Units)

SECTION III

PHYSICAL DATA

SECTION IV - FIRE AND

EXPLOSION HAZARD DATA

DD

VAPOR PRESSURE

VAPOR DENSITY

SOLUBILITY IN WATER

APPEARANCE AND ODOR

FLASH POINT

EXTINGUISHING MEDIA

SPECIAL FIRE FIGHTING PROCEDURES

UNUSUAL FIRE AND EXPLOSION HAZARDS

FORM

1 JUN 71

1813

(mm Hg.)

(AIR=1)

(Method used)

* GPO 794/043/30

3 mm Hg

2.2

PRECENT VOLATILE

BY VOLUME

EVAPORATION RATE

(.............................=1)

FLAMMABLE

LIMITS

LOWER EXPLOSIVE LIMIT

(%)

UPPER EXPLOSIVE LIMIT

S/N 0102-026-1080

Page 34

TRESHOLD LIMIT VALUE

100ppm

EFFECTS OF OVEREXPOSURE

EMERGENCY AND FIRST AID PROCEDURES

SECTION V

HEALT HAZARD DATA

STABILITY

INCOMPATABILITY

UNSTABLE

STABLE

(Materials to avoid)

CONDITIONS TO AVOID

X

HAZARDOUS DECOMPOSITION PRODUCTS

SECTION VI

REACTIVITY DATA

HAZARDOUS

POLYMERIZATION

MAY

OCCUR

WILL NOT

CONDITIONS TO AVOID

X

OCCUR

STEPS TO BE TAKEN IN CASE MATERIAL IS RELEASED OR SPILLED

Rinse with water

WASTE DISPOSAL METHOD

SECTION VII

SPILL OR LEAK PRO CEDURES

RESPIRATORY PROTECTION

VENTILATION

LOCAL EXHAUST

MECHANICAL

(Specific type)

(General)

PROTECTIVE GLOVES

SECTION VIII - SPECIAL

OTHER PROTECTIVE EQUIPMENT

PROTECTION INFORMATION

PRECAUTIONS TO BE TAKEN IN HANDLING AND STORING

SPECIAL

OTHER PRECAUTIONS

SECTION IX

PRECAUTIONS

SPECIAL

OTHER

EYE PROTECTION

Harmful if swallowed

Keep out of the reach of children

To avoid from oxidants

THE INFORMATION CONTAINED HEREIN IS BASED ON DATA CONSIDERED ACCURATE.

HOWEVER, NO WARRANTY IS EXPRESSED OR IMPLIED REGARDING THE ACCURACY OF

THESE DATA OR THE RESULTS TO BE OBTAINED FROM THE USE THEREOF.

VENDOR ASSUMES NO RESPONSABILITY FOR INJURY TO VENDEE OR THIRD PERSONS

PROXIMATELY CAUSED BY THE MATERIAL IF REASONABLE SAFETY PROCEDURES ARE NOT

ADHERED TO AS STIPULATED IN THE DATA SHEET. ADDITIONALLY, VENDOR ASSUMES NO

RESPONSABILITY FOR INJURY TO VENDEE OR THIRD PERSONS PROXIMATELY CAUSED BY

ABNORMAL USE OF THE MATERIAL EVEN REASONABLE SAFETY PROCEDURES ARE FOLLOWED. FUTHERMORE, VENDEE ASSUMES THE RISK IN HIS USE OF THE MATERIAL.

Loading...

Loading...