Page 1

EVENTS

D320PL DIGITIZER

R9851550

OWNER’S MANUAL

13122002 R5976470/01

Page 2

Barco nv Events

Noordlaan 5, B-8520 Kuurne

Phone: +32 56.36.89.70

Fax: +32 56.36.88.24

E-mail: events@barco.com

Visit us at the web: www.barco.com

Printed in Belgium

Page 3

Copyright ©

All rights reserved. No part of this document may be copied, reproduced or translated. It shall not otherwise

be recorded, transmitted or stored in a retrieval system without the prior written consent of BARCO.

Guarantee and Compensation

Barco providesaguarantee relatingto perfect manufacturing aspart ofthe legally stipulatedterms of guarantee.

On receipt,the purchaser must immediatelyinspectalldelivered goodsfor damage incurredduringtransport, as

well as for material and manufacturing faults Barco must be informed immediately in writing of any complaints.

The period of guarantee begins on the date of transfer of risks, in the case of special systems and software

on the date of commissioning, at latest 30 days after the transfer of risks. In the event of justified notic

compliant, Barco can repair thefault or provide a replacement atits own discretion within an appropriate period.

If thismeasure proves tobe impossible or unsuccessful, the purchaser can demand areduction inthe purchase

price or cancellation of the contract. All other claims, in particular those relating to compensation for direct or

indirect damage, and also damage attributed to the operation of software as well as to other services provided

by Barco,being a componentof the systemor independent service, willbedeemed invalidprovidedthedamage

is not proven to be attributed to the absence of properties guaranteed in writing or due to the in

negligence or part of Barco.

If the purchaser or a third party carries out modifications or repairs on good delivered by Barco, or if the goods

are handled incorrectly, in particular if the systems are commissioned operated incorrectly or if, after the transfer of risks, the goods are subject to influences not agreed upon in the contract, all guarantee claims of the

purchaser will be rendered invalid. Not included in the guarantee coverage are system failures which are attributed to programs or special electronic circuitry provided by the purchaser, e.g. interfaces. Normal wear as

well as normal maintenance are not subject to the guarantee provided by Barco either.

tent or gross

eof

The environmental conditions as well as theservicing and maintenance regulations specified in the this manual

must be complied with by the customer.

Changes

Barco provides this manual “as is” without warranty of any kind, either expressed or implied, including but

not limited to the implied warranties or merchantability and fitness for a particular purpose. Barco may make

improvements and/or changes to the product(s) and/or the program(s) described in this publication at any time

without notice.

This publication could contain technical inaccuracies or typographical errors. Changes are periodically made

to the information in this publication; these changes are incorporated in new editions of this publication.

Trademarks

Brand and product names mentioned in this manual may be trademarks, registered trademarks or copyrights

of their respective holders. All brand and product names mentioned in this manual serve as comments or

examples and are not to be understood as advertising for the products or their manufactures.

Federal Communication Commission (FCC Statement)

This equipment has been tested and found to comply with the limits for a class A digital device, pursuant to

Part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. Operation of this equipment in a residential area may

cause harmful interference, in whi

ch case the user will be responsible for correcting any interference.

Page 4

Page 5

Table of contents

TABLE O F CONTENTS

1. Safety............... ................................................................... ................3

1.1ImportantSafetyInstructions ................ ................ ................ ................ ................ ....3

1.2Important Warnings ...............................................................................................4

2. Introduction........................................................... ...............................7

2.1General functionality .............. ................ ................ ................ ................ ................ 7

2.2Order info D320PL Digitizer...................................................................................... 7

2.3Technicalsummary............................................................................................... 7

2.4Dimensionsof theD320PLDigitizer ...... ................ ................ ................ ................ ......9

3. PhysicalInstallation of the D320PLDigitizer.................. .............................11

3.1Installation requirements ... ................ ................ ................ ................ ................ .....11

3.2Connections ......................................................................................................12

3.3Removingand inserting a D320PL Digitizer inputmodule...... ................ ................ .............13

4. Input modules .... ................................................................... ..............15

4.1DVI inputmodule.................................................................................................15

4.2SDI inputmodule.................................................................................................16

4.3HDSDI inputmodule.... ................ ................ ................ ................ ................ .........16

4.4CVBS / S-VIDinputmodule................ ................ ................ ................ ................ .....18

4.5YUV/ RG(s)B inputmodule................ ................ ................ ................ ................ .....18

4.6RGB analog inputmodule.......................................................................................19

4.7Dummy inputmodule ............. ................ ................ ................ ................ ............... 20

5. Cablesandaccessoriesforthe D320PLDigitizer......................................... 21

5.1Cables and accessories.........................................................................................21

6. Configurationschemes ............................................ .............................23

6.1Stand alone configuration .......................................................................................23

6.2Chaining configuration...........................................................................................23

6.3Stacking configuration...........................................................................................24

6.4Combined chained and stackedconfiguration ................................................................25

7. ControlSoftware....................... ........................................................... 27

7.1XLite Toolset..... ................ ................ ................ ................ ................ ................ .27

7.2Version Control Manager (VCM) ...............................................................................27

8. Maintenance of the D320PLDigitizer........................................... ..............29

8.1Cleaningthe dustfilter.................... ................ ................ ................ ................ .......29

8.2Cleaning the cabinet.............................................................................................29

9. Options.................................................. ............................................ 31

9.1Overview. ................ ................ ................ ................ ................ ................ .........31

Index................... ............................................................ .....................33

R5976470 D320PL DIGITIZER 13122002 1

Page 6

Table of contents

2 R5976470 D320PL DIGITIZER 13122002

Page 7

1. SAFETY

1.1 Important Safety Instructions

Instructions:

• Read these instructions.

• Keep these instructions.

• Heed all warnings.

• Follow all instructions.

• Do NOT submerge fully or partly in water or other liquids.

• Clean only with materials or chemicals that are inert, nonabrasive, noncorrosive and non-marking.

Consult themanufacturer for furtheradvice should anydoubtsexist regarding anycleaning procedure.

• Do not block ventilation openings. Install in accordance with the manufacturers instructions.

• Do not install near any heat sources such as radiators, heat registers, stoves, or other apparatus

(including amplifiers) that produce heat.

• Do not defeat the safety purpose of the polarized or grounding type plugs/sockets. If the provided

sockets /plugs aredamaged thenreplacement ofthe defective parts mustbe undertak

• Protect the power/data cords from being walked on or pinched particularly at plugs, convenience receptacles, and the point where they exit from the apparatus. Replace damaged power/data cords

immediately.

• Only use attachments/accessories specified by the manufacturer.

• Disconnect the power to this apparatus during lightning storms or provide suitable additional lightning

protection. Unplug this apparatus when unused for long period of time.

• Refer allservicingto qualified service technicians/personnel. Servicing isrequired whenthe apparatus

has been damaged in any way, such as power-supply cord or plug is damaged, the apparatus does

not operate normally, or has been dropped.

• Use only with systems or peripherals specified by the manufacturer, or sold with the apparatus. Use

caution during lifting/moving or transporting to avoid damage by possible tipping.

en immediately.

1. Safety

R5976470 D320PL DIGITIZER 13122002

3

Page 8

1. Safety

1.2 Important Warnings

Important Warnings:

• Risk of electric shock:

Image 1-1

Risk of electrical shock

Risk of electric shock. Do not open. To reduce the risk of electric shock, do not remove cover (or

back). No user-serviceable parts inside. Refer servicing to qualified service personnel.

The lightning flash with an arrowhead within a triangle is intended to tell the user that parts inside this

product may cause a risk of electrical shock to persons.

The exclamation point within a triangle is intended to tell the user that important operating and/or

servicing instructions are included in the technical documentation for this equipment.

• Maximum ambient temperature:

The maximum recommended ambient temperature for this equipment is 40

• Flammable materials:

Keep flammable materials away from the installation (such as curtains). A lot of energy is transferred

into heat. The installation should be such that the amountof air flow required for safe operation of the

equipment is not compromised. Proper ventilation must be provided.

• This equipment MUST be earthed:

In order to protect against risk of electric shock, the in

ing the purpose of the grounding type plug will exposeyou to the riskof electric shock. This apparatus

must be grounded (earthed) via the supplied 3 conductor AC power cord. (If the supplied power cord

is not the correct variant, consult your dealer.)

• Power system:

It is recommended to use a TN-S power distribution system (a power distribution system with a separate neutral and grounding conductor) in order to avoid large ground currents loops due to voltage

differences in the neutral conductor. The total electrical installation should be protected by an appropriate rated disconnect switch, circuit breakers and Ground Fault Current Interrupters. The installation

shall be done according to the local electrical installation codes. In Europe special attention should be

given to EN 60364, the standard for electrical installation of buildings. In Germany VDE 0100 should

be adhered to.

• Mains cords:

The power cords delivered with this system have special properties for safety. They are not user

serviceable. If the power cords are damaged, replace only with new ones. Never try to repair a power

cord.

C.

stallation should be properly grounded. Defeat-

4

R5976470 D320PL DIGITIZER 13122002

Page 9

1. Safety

• Use of an extension cord:

If an extension cord is used with this product, make sure that the total of the ampere ratings on the

products plugged into the extension cord does not exceed the extension cord ampere rating. Also

make sure that the total of all products plugged into the wall outlet does not exceed 15 amperes.

• Cabinet openings:

Never push objects of any kind into this product through cabinet slots as they may touch dangerous

high voltage points or short out parts that could result in a risk of fire or electrical shock.

Never spill liquid of any kind on the product. Should any liquid or solid object fall into the cabinet,

unplug the set and have it checked by qualified service personnel before resuming operations.

R5976470 D320PL DIGITIZER 13122002

5

Page 10

1. Safety

6 R5976470 D320PL DIGITIZER 13122002

Page 11

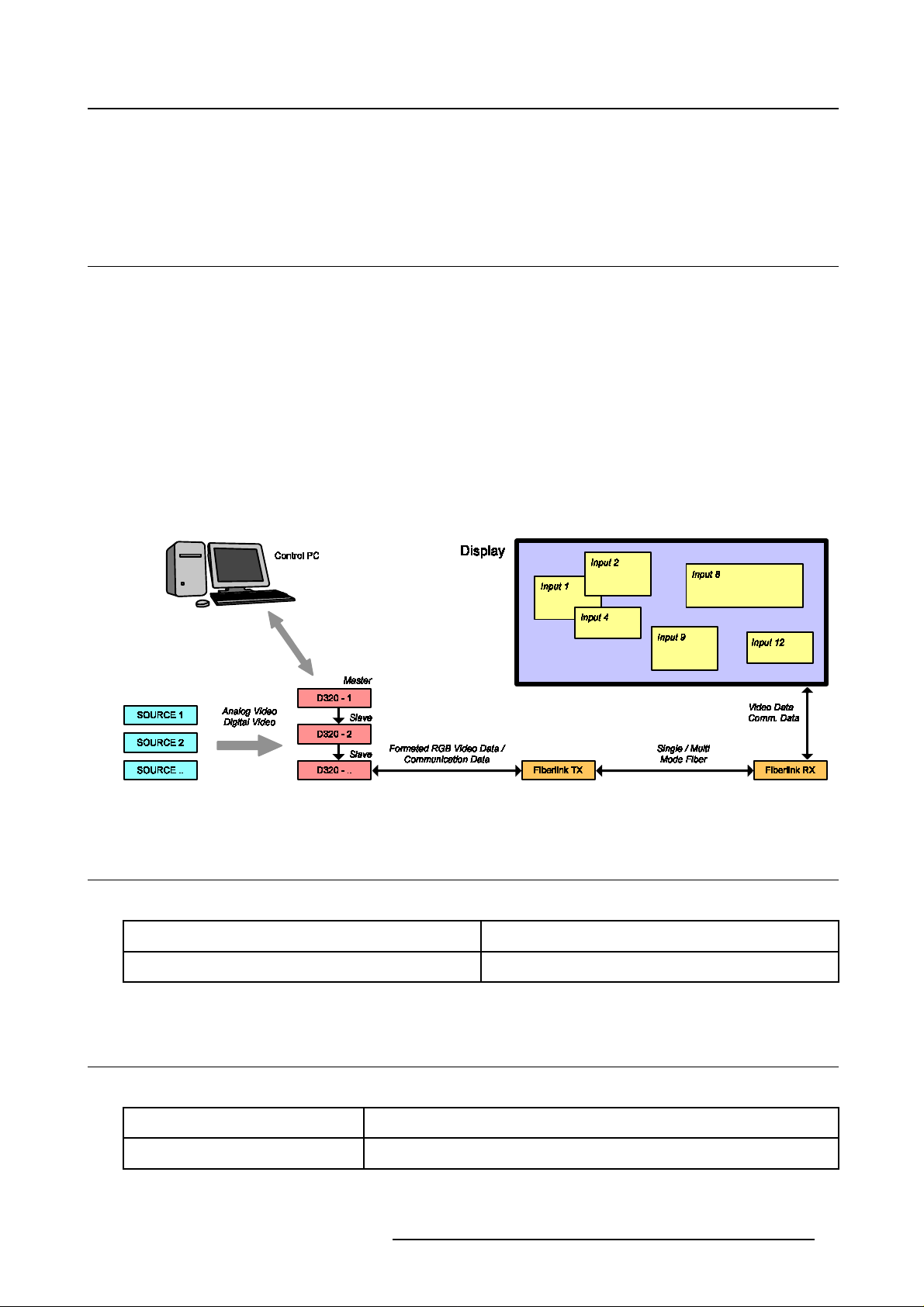

2. Introduction

2. INTRODUCTION

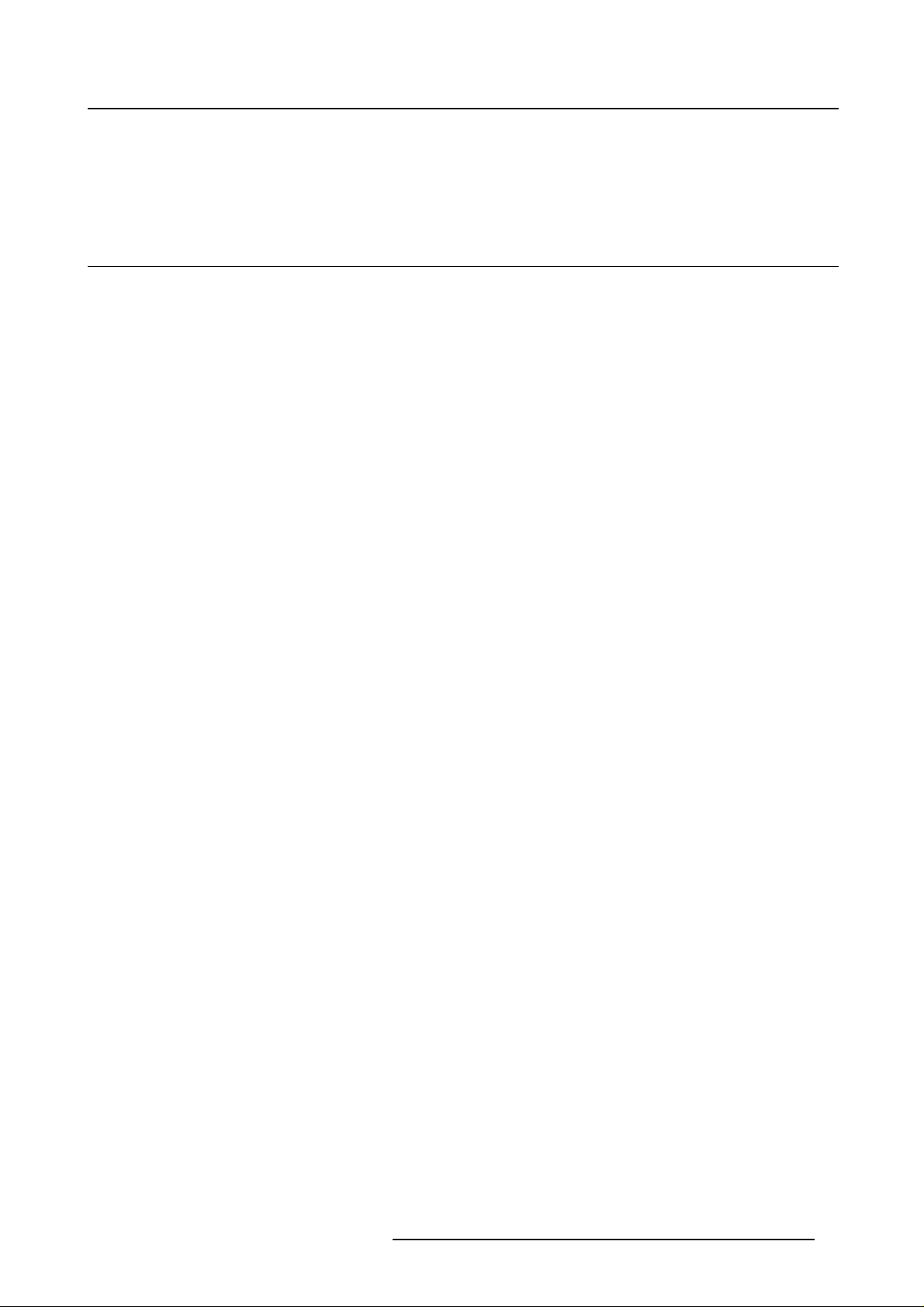

2.1 General functionality

Overview

The D320PL is a video processing device, designed to drive as well Barco LED walls as large screen

projectors, monitors, plasma screens, ... etc. The D320PL is capable of handling all standard output

formats like SVGA, XGA, SXGA and UXGA on an analog RGBHV and digital DVI output.

The D320PL Digitizer allows you to control up to 4 sources on one display. Seamless switch from sou

to source or display sources together, overlay them, customize them. With analog and digital outputs

which allow for the control of displays, as well as built-in-control software, the D320PL gives you control

over everything from basic set-up to configuration and advanced feature control.

The D320PL Digitizer is a generic device. This means that a number of combinations can be made.

Devices canbe chainedin order to generatemore windowsonthe output (4windows perdevice). Devices

can also be stacked in order to be able to split generated output of the devices to multiple screens. For

latter purpose, each input is equipped with an active loop through.

Image 2-1

rce

2.2 Order info D320PL Digitizer

Order info:

Article No. Description

R9851550 D320PL Digitizer

2.3 Technical summary

Summary

Type Value

Input slots 4 input slots, front accessible, auto sensing and hot swappable

R5976470 D320PL DIGITIZER 13122002 7

Page 12

2. Introduction

Type Value

Compatibility Barco Daylight / ILite Displays and large screen projectors,

monitors, plasma screens...

Output DVI-A, DVI-D, Barco LED protocol

Scalability Chaining for more inputs, stacking for more displays

Flexibility User defined input

Scaler 4 input channels [Data-Video] fully independent scalable to desired

output resolution

Z-order control Instant modification of Z-order control, for each output window

Window Positioning Intuitive positioning interface

Connectors RS 232 [RJ 11] — Ethernet [RJ 45]

Effects Anamorphic imaging, Chroma keying [per input], Alpha keying [per

input], Z-order control, Windowing/ View ports

Ruggedness IP 10

Dimensions D320PL 486 x 482 x 53 (W x D x H)

Dimensions D320 Input Units 41 x 181 x 103 (W x D x H)

Weight ±7kg

Operating Temperature 0ºC<>45ºC

Power consumption 130 Watt max at 85–264 Volt (50–60 Hertz)

Stacking Up to 64 units (for 64 different displays)

Chaining Up to 64 units (for 256 inputs)

8 R5976470 D320PL DIGITIZER 13122002

Page 13

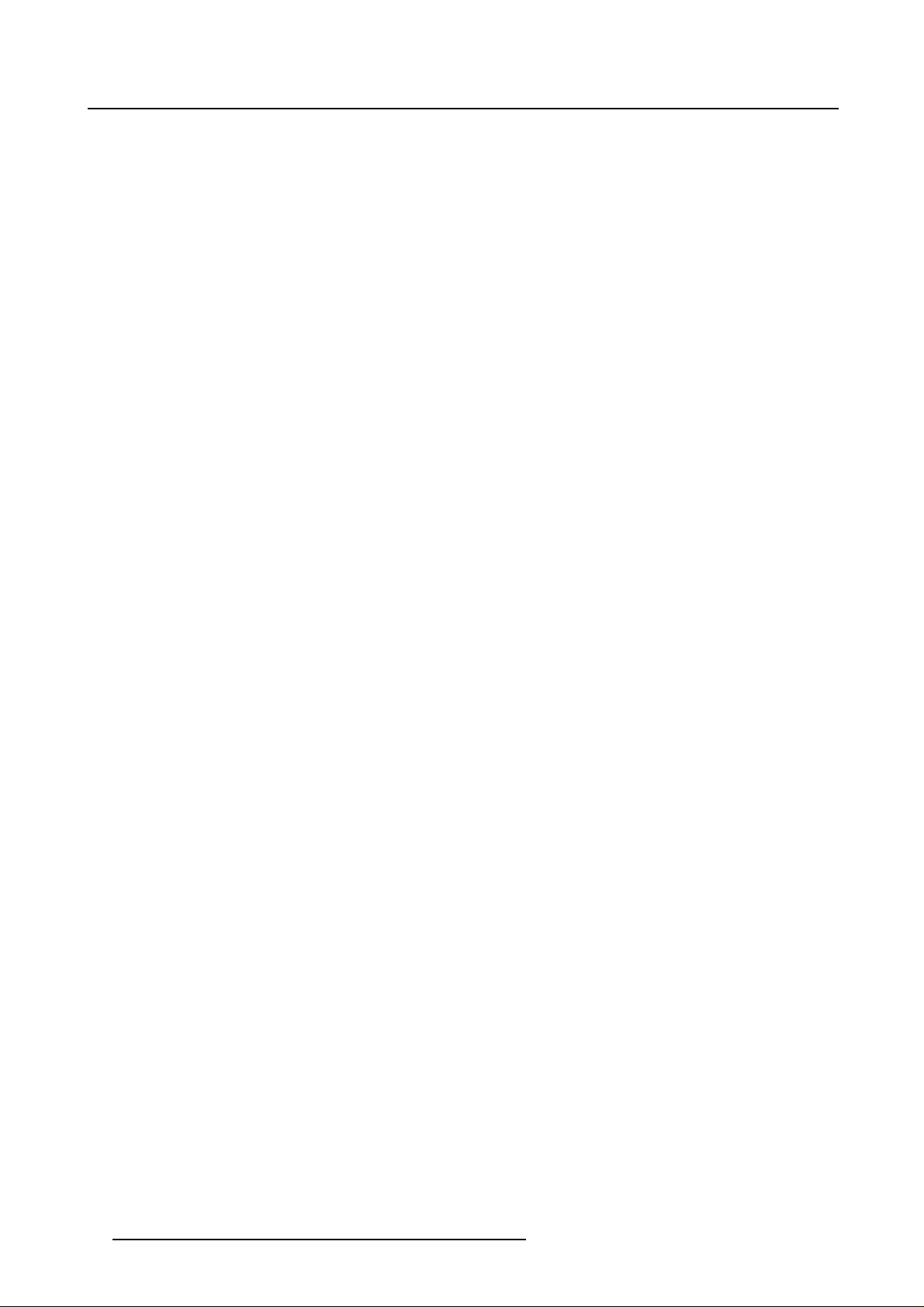

2.4 Dimensions of the D320PL Digitizer

Dimensions

2. Introduction

Image 2-2

R5976470 D320PL DIGITIZER 13122002 9

Page 14

2. Introduction

10 R5976470 D320PL DIGITIZER 13122002

Page 15

3. Physical Installation of the D320PL Digitizer

3. PHYSICAL INSTALLATION OF THE

D320PL DIGITIZER

3.1 Installation requirements

Requirements

• The D320PL Digitizer should not be placed in a built-in installation or enclosure unless proper venti-

lation is provided.

• When using the unit in a multi-unit rack assembly or closed assembly, the ambient temperature inside

the assembly may not exceed the maximum rated ambient temperature of the Digitizer. The installation should be such that the amount of air flow required for safe operation of the equipment in not

compromised.

• When building in the D320PL Digitizer into a rack with cover door, be a

needed between the indicated reference and the cover door. This space is needed to guide the input

cables to the inputs.

ware that a space of 8,5 cm is

Image 3-1

A Reference

• The D320PL Digitizer will require that air flo

reduce the reliability of the unit and lead to the possibility of overheating.

• The D320PL Digitizer should operate from an AC power source. The D320PL Digitizer is equipped

with Power Supply Autoranging from 85 to 264 volt (50–60 Hertz).

• When installed in a rack, the mounting should be such that no hazardous condition is achieved due

to uneven mechanical loading.

• When the mains switch located on the back of the D320PL Digitizer is not accessible due to rack

mounting, the socket outlet supplying the rack shall be installed near the equipment and be easily

accessible or a readily accessible disconnect device shall be incorporated in the fixed wiring. When

using a rack in an installation is advisable to log the serial number of the device and to activate the

warranty figure by registering utilizing the included form.

• Do not place the D320PL Digitizer on an unstable cart, stand or table. The device may fall, causing

serious damage to it.

ws freely in vent holes. Blocking these holes will greatly

R5976470 D320PL DIGITIZER 13122002

11

Page 16

3. Physical Installation of the D320PL Digitizer

3.2 Connections

Rear panel inputs/outputs

Image 3-2

A LED-WALL / PROJECTOR OUTPUT

BPowerSwitch

C Power input

DLOOPIN

ELOOPOUT

F Retractable dust filter

G COM1 : RS232 input

H COM2 : RS232 chaining output

I COM3 : RS232 stacking output

J TCP-IP : Ethernet LAN connector

12

R5976470 D320PL DIGITIZER 13122002

Page 17

3. Physical Installation of the D320PL Digitizer

• A : LED-WALL / PROJECTOR OUTPUT (DVI output connector with 3 functions)

- LED wall out (Barco proprietary protocol).

- RGB HV out (analog).

- DVI digital out. (DVI compliant, eg: monitor, projector, plasma, ... )

• B : Power switch

- The power ON/OFF switch is provide on the rear side of the Digitizer.

o

Switchpressedto1=theunitstarts.

o

Switch pressed to 0 = unit totally switched off.

• C : Power input

- Autoranging from 90 to 260 VAC / 130 Watt.

• D : LOOP IN

- From previous D320PL Digitizer.

- Panel Link MDR26.

- Used for chaining multiple D320PL digitizer to increase the number of usable input sources.

• E : LOOP OUT

- To next Digitizer.

- Panel Link MDR26.

- Used for chaining multiple digitizer to increase the number of usable input sources.

• F : Retractable dust filter

- The fan intake grill of the Digitizer has a retractable dust filter. This filter can be retracted from the

back of the unit. Check the filter for good functionality on a regular basis. Never allow this filter to

become blocked up and never operate the unit without a good working air filter in place.

• G : COM1 : RS232 input

- Direct master.

- RS232 input port for communication links with local PC.

• H : COM2 : RS232 chaining output

- RS232 output port for communication links from other D320PL Digitizers in chain configuration

• I : COM3 : RS232 stacking output

- RS232 output port for communication links from other D320PL Digitizers in stacking configuration.

• J : TCP-IP : Ethernet LAN connector

- For future use.

3.3 Removing an d inserting a D320PL Digitizer input module

There is no need to switch off the D320PL Digitizer to remove or insert an input module.

The input modules are hot swappable.

How to remove an input module from th e D320PL Digitizer

1. Push in the release button underneath the input module which you want to remove. At the same time

pull out the input module by the grip handle. (image 3-3)

R5976470 D320PL DIGITIZER 13122002

13

Page 18

3. Physical Installation of the D320PL Digitizer

Image 3-3

How to insert an input mo dule into the D320PL Digitizer

1. Gently slide in the input module into a free input slot with the grip handle at the top.

2. Locking in the module by pushing the input module completely into the D320PL Digitizer until a definite

click is audible.

Maximum two HDSDI input modules may be inserted in one D320PL Digitizer.

14 R5976470 D320PL DIGITIZER 13122002

Page 19

4. Input modules

4. INPUT M ODULES

Overview

• DVI input module

• SDI input module

• HDSDI input module

• CVBS / S-VID input module

• YUV / RG(s)B input module

• RGB analog input module

• Dummy input module

4.1 DVI input module

Technical info:

• Computer generated graphical source.

•DVIdatain.

• 162 MHz pixel clock.

• Resolution from VGA to UXGA/60 Hz.

• DVI compliant.

• DVI loop through.

• Amber LED (upper LED on the front side) will be lit indicating module start up.

• When placed in an input slot the green LED (lower LED on the front side) will be lit indicating that the

system acknowledges the module.

Image 4-1

Image 4-2

Order info:

Article No. Description

R9850960 D320PL Digitizer DVI input module

R5976470 D320PL DIGITIZER 13122002 15

Page 20

4. Input modules

4.2 SDI input module

Technical info:

•SDIdatain.

• SDI loop through.

• 270Mbit/s transmission (SMPTE 259M-C).

• 525/625 interlaced.

•Coax(75Ohm).

• Amber LED (upper LED on the front side) will be lit indicating recognition of film, either continuous or

intermittent film detection.

• When placed in an input slot the green LED (lower LED on the front side) will be lit indicating that the

system acknowledges the module.

Image 4-3

Image 4-4

Order info:

Article No. Description

R9850970 D320PL Digitizer SDI input module

4.3 HDSDI input module

Maximum two HDSDI input modules may be inserted in one D320PL Digitizer.

16 R5976470 D320PL DIGITIZER 13122002

Page 21

4. Input modules

Technical info:

• HDSDI data in (SMPTE292M).

• HDSDI loop through (SMPTE292M).

•Coax(75Ohm).

• When placed in an input slot the green LED (lower LED on the front side) will be lit indicating that the

system acknowledges the module.

• Supported HDSDI standards:

- Progressive:

o

1280x720/60/1:1/ (SMPTE 296M)

o

1280x720/59.94/1:1/ (SMPTE 296M)

o

1920x1080/30/1:1/ (SMPTE 274M)

o

1920x1080/29.97/1:1/ (SMPTE 274M)

o

1920x1080/25/1:1/ (SMPTE 274M)

o

1920x1080/24/1:1/ (SMPTE 274M)

o

1920x1080/23.98/1:1/ (SMPTE 274M)

- Interlaced:

o

1920x1035/60/2:1/ (SMPTE 260M)

o

1920x1035/59.94/2:1/ (SMPTE 260M)

o

1920x1080/60/2:1/ (SMPTE 274M)

o

1920x1080/59.94/2:1/ (SMPTE 274M)

o

1920x1080/50/2:1/ (SMPTE 274M)

o

1920/1080/50/2:1 (1250)/ (SMPTE 295M)

o

1920x1080/24/Segmented/ (SMPTE 274M)

o

1920x1080//23.98/Segmented/ (SMPTE 274M)

Image 4-5

Image 4-6

Order info:

Article No. Description

R9850980 D320PL Digitizer HDSDI input module

R5976470 D320PL DIGITIZER 13122002 17

Page 22

4. Input modules

4.4 CVBS / S-VID input module

Technical info:

• Video (BNC)

- CVBS : 1Vpp ±3dB (0,7V Video +0,3V Sync) 75 Ohm termination.

- BNC loop through connector.

• S-Video (4 pins DIN)

- Y : 1Vpp ±3dB (0,7V Video +0,3V Sync) 75 Ohm termination.

- U/V : 0,7Vpp ±3dB 100% color base, 75 Ohm termination.

- Chroma : Multi-Standard (PAL / SECAM / NTSC).

- 4 pins DIN loop through connector.

• Amber LED (upper LED on the front side) will be lit indicating recognition of film, either continuous or

intermittent film detection.

• When placed in an input slot the green LED (lower LED on the front side) will be lit indicating that the

system acknowledges the module.

Image 4-7

Image 4-8

Order info:

Article No. Description

R9850920 D320PL Digitizer CVBS / S-VID input module

4.5 YUV / RG(s)B input module

Technical info:

• Component Video (BNC)

- R-Y : 0,7Vpp ±3dB 75 Ohm termination.

- Ys : 1Vpp ±3dB (0,7V Luma +0,3V Sync) 75 Ohm termination.

- B-Y : 0,7Vpp ±3dB 75 Ohm termination.

• RG(s)B (BNC)

- R : 0,7Vpp ±3dB 75 Ohm termination.

- G(s) : 1Vpp ±3dB (0,7Vpp G + 0,3Vpp Sync) 75 Ohm termination.

- B : 0,7Vpp ±3dB 75 Ohm termination.

• 3 BNC’s loop through connectors.

• Amber LED (upper LED on the front side) will be lit indicating recognition of film, either continuous or

intermittent film detection.

• When placed in an input slot the green LED (lower LED on the front side) will be lit indicating that the

system acknowledges the module.

18

R5976470 D320PL DIGITIZER 13122002

Page 23

4. Input modules

Image 4-9

Image 4-10

Order info:

Article No. Description

R9850940 D320PL Digitizer YUV / RG(s)B input module

4.6 RGB analog input mo dule

Technical info:

• Sub D15 connector for input and loop through.

• R, G, B, Hsync, Vsync : 0 to 1 Vpp ±3dB 75 Ohm termination.

• Black level : 300mV.

• Sync-tip : 0V

• Resolution : SXGA and UXGA version available.

• Amber LED (upper LED on the front side) will be lit indicating recognition of film, either continuous or

intermittent film detection.

• When placed in an input slot the green LED (lower LED on the front side) will be lit indicating that the

system acknowledges the module.

Image 4-11

Image 4-12

Order info:

Article No. Description

R9850950 D320PL Digitizer RGB analog SXGA input

module

R9851710 D320PL Digitizer RGB analog UXGA input

module

R5976470 D320PL DIGITIZER 13122002 19

Page 24

4. Input modules

4.7 Dummy input m odule

Technical info

• Dimensions : 103 x 181 x 41(W x D x H)

Image 4-13

Image 4-14

Order info:

Article No. Description

R9850930 D320PL Digitizer dummy input module

20 R5976470 D320PL DIGITIZER 13122002

Page 25

5. Cables and accessories for the D320PL Digitizer

5. CABLES AND ACCESSORIES FOR THE

D320PL DIGITIZER

5.1 Cables and accessories

List with available cables and accessories

Article No. Description Image

R326103 Power cable with CEE7 plug. image 5-1

R3261115 Power cable with NEMA 5–15 plug. image 5-2

B5580491 Data cable with RJ12 connectors for RS232 connection between

local control PC and COM1 RS232 input port of the master Digitizer.

Also used to connect the COM2 or COM3 port with the COM1 port

of the following Digitizer.

Z3498421 RJ12–SUBD adapter. image 5-4

R9827560 Data cable with SUBD connectors for RS232 connection between

local control PC and COM1 RS232 input port of the master Digitizer.

Z3499209 One meter data cable with MDR connectors. Used to make a

connection between the LOOP OUT connector of the previous

Digitizer and the LOOP IN connector of the next Digitizer.

R9851210 Five meter data cable with DVI connectors. Used to connect the

LED-WALL / PROJECTOR OUTPUT with an ILite display.

R9851216 Five meter data cable with one DVI connector and one waterproof

MDR connector. Used to connect the LED-WALL / PROJECTOR

OUTPUT with an DLite display.

B558072

R9851219 One meter data cable with one DVI conn

DVI-VGA adaptor. Used to connect the LED-WALL / PROJECTOR

OUTPUT connector on the rear side of the Digitizer with a VGA cable

from the projector or monitor or plasma ...

ector and one MDR

connector. Used to connect the LED-WALL / PROJECTOR OUTPUT

with a Fiberlink Transmitter.

image 5-3

image 5-5

image 5-6

image 5-7

image 5-8

image 5-9

image 5-10

Image 5-1 Image 5-2 Image 5-3

R5976470 D320PL DIGITIZER 13122002 21

Page 26

5. Cables and accessories for the D320PL Digitizer

Image 5-4 Image 5-5 Image 5-6

Image 5-7 Image 5-8 Image 5-9

Image 5-10

22 R5976470 D320PL DIGITIZER 13122002

Page 27

6. Configuration schemes

6. CONFIGURATION SCHEMES

6.1 Stand alone configuration

Scheme

Image 6-1

One D320PL Digitizer is sufficient to drive one Barco LED wall with four different sources.

How to set up a D320PL stand alone configuration

1. Connect the RS232 communication port of the local control PC

D320PL Digitizer.

2. Connect the LED-WALL / PROJECTOR OUTPUT from the D320PL Digitizer with the display.

3. Provide the available video sources to the D320PL input modules.

4. Configure the D320PL Digitizer and the Display with the control software installed on the local control

PC.

with theCOM1 RS232 input port ofthe

6.2 Chaining config uration

Scheme

Image 6-2

R5976470 D320PL DIGITIZER 13122002 23

Page 28

6. Configuration schemes

The D320PL Digitizer can be chained in order to generate more windows on the output display (four windows per D320PL Digitizer).

How to set up a D320PL chaining configuration

1. Connect the RS232 communication port of the local control PC with the COM1 RS232 input portof the

first D320PL Digitizer. This Digitizer will act as the master, all following Digitizers are slaves.

2. Connect the LOOP OUT with the LOOP IN of the next D320PL Digitizer in the chain.

3. Connect the COM2 RS232 output port with the COM1 RS232 input port of the next D320PL Digitizer

in the chain.

4. Repeat step 2 and 3 until all D320PL Digitizers in the chain are connected.

5. Connect the LED-WALL / PROJECTOR OUTPUT from the last D320PL Digitizer in the chain with the

display.

6. Provide the available video sources to the input modules of the D320PL Digitizers.

7. Configure the D320PL Digitizers and the Display with the control software installed on the local control

PC.

6.3 Stacking configuration

Scheme

Image 6-3

For some large installations is it necessary to divided a complete large display into two ore more screens

depending on the used frame rate and the amount of pixels per line and the total lines of the complete

display. For each screen a D320PL Digitizer is used in stacking configuration. Consult Barco n.v. for

advise about the number of D320PL Digitizers to be stacked.

24

R5976470 D320PL DIGITIZER 13122002

Page 29

6. Configuration schemes

How to set up a D320PL stacking configuration

1. Connect the RS232 communication port of the local control PC with the COM1 RS232 input portof the

first D320PL Digitizer. This Digitizer will act as the master, all following Digitizers are slaves.

2. Connect the LOOP OUT with the LOOP IN of the next stacked D320PL Digitizer. This is necessary to

avoid synchronization problems between the screens

3. Connect the COM3 RS232 output port with the COM1 RS232 input port of the next stacked D320PL

Digitizer.

4. Connect the LED-WALL / PROJECTOR OUTPUT with the one screen.

5. Repeat step 2, 3 and 4 until all D320PL Digitizers are stacked.

6. Provide the available video sources to the input modules of one of the D320PL Digitizers and use the

active loop through to connect the sources with the other stacked D320PL Digitizers. Make sure the

same input source is used for the same input slot number on the different Digitizers.

7. Configure the D320PL Digitizers and the Display with the control software installed on the local control

PC.

6.4 Combined chained and stacke d configuration

Scheme

Image 6-4

It is possible to stack several chained D320PL Digitizers in order to create a larger display with more than

4 windows. On condition that each chain in the stacked configuration has the same number of D320PL

Digitizers.

R5976470 D320PL DIGITIZER 13122002

25

Page 30

6. Configuration schemes

How to set up a mixed configuration

1. Connect the RS232 communication port of the local control PC with the COM1 RS232 input portof the

first D320PL Digitizer. This Digitizer will act as the master, all following Digitizers are slaves.

2. Connect the LOOP OUT of each previous Digitizer with the LOOP IN of the next Digitizer.

3. Connect the LED-WALL / PROJECTOR OUTPUT of the last Digitizer of eachchain with a screen. Do

this ina logical order to simplifythe configuration withthe controlsoftware. First chain drives first screen

from the left, second chain drives second screen from the left and so on.

4. Connect each COM2 RS232 output port of the previous chained Digitizer with the COM1 RS232 input

port of the next chained Digitizer.

5. Connect each COM3 RS232 output port of the previous stacked Digitizer with the COM1 RS232 input

port of the next stacked Digitizer.

6. Provide the available video sources to the input modules and use the active loop through to connect

the sources with the other stacked input modules.

Note: The control software will recognize the chained Digitizers as one Digitizer in a stacked configura-

tion. But instead of only 4 input slots the software will detect a plural of 4 input slots. Make sure

the same input source is used for the same input slot number on the different stacked Digitizers.

7. Configure the D320PL Digitizers and the Display with the control software installed on the local control

PC.

26

R5976470 D320PL DIGITIZER 13122002

Page 31

7. Control Software

7. CONTROL SOFTWARE

7.1 XLite Toolset

General introduction

The XLite Toolset (R9850042) is used to configure and control the D320PL Digitizer from basic set-up to

advanced features such as chroma keying, alpha blending or window positioning. Refer to the manual

(R5976380) for more information about the XLite Toolset.

7.2 Version Control Manager (VCM)

General introduction

The Version Control Manager (R9850044) is a stand alone program to update the software and firmware

ofD320PL Digitizer. The software runs fromCD-ROM and actslike a wizard. So noinstallation isrequired.

The software runs on a Windows platform. Refer to the manual (R5976407) for more information about

the Version Control Manager.

R5976470 D320PL DIGITIZER 13122002

27

Page 32

7. Control Software

28 R5976470 D320PL DIGITIZER 13122002

Page 33

8. Maintenance of the D320PL Digitizer

8. MAINTENANCE OF THE D320PL

DIGITIZER

8.1 Cleaning the dust filter

The fan intake grill of the D320PL Digitizer has a retractable dust filter which must

be checked for good functionality on regular basis. Never allow this filter to become

blocked up.

How to clean the dust filter

1. Softly press down the lid of the dust filter at the rear side of the D320PL Digitizer and pull out the filter.

(image 8-1)

2. Blow out all the dust from the filter and remove remaining dust with a dry cloth.

3. Place the clean dust filter back in the D320PL Digitizer.

Image 8-1

8.2 Cleaning the cabinet

Do not use liquid cleaners or aerosol cleaners. Never use st rong solvents, such as thinner or benzine, or abrasive cleaners, since these will damage the cabinet.

How to clean the cabinet

1. Unplug the D320PL Digitizer from the wall outlet before cleaning.

2. Clean the cabinet with a damp cloth. Stubborn stains may be removed with a cloth lightly dampened

with mild detergent solution.

To keep the cabinet looking brand-new, periodically clean it with a soft dry cloth.

R5976470 D320PL DIGITIZER 13122002 29

Page 34

8. Maintenance of the D320PL Digitizer

30 R5976470 D320PL DIGITIZER 13122002

Page 35

9. OPTIONS

9.1 Overview

Order info:

Article No. Description

R9851510 Climate Control Case for using the D320PL

Digitizer outdoor

9. Options

R5976470 D320PL DIGITIZER 13122002 31

Page 36

9. Options

32 R5976470 D320PL DIGITIZER 13122002

Page 37

INDEX

Index

A

Accessories 21

C

Cables 21

Cleaning 29

Air dust filter 29

Cabinet 29

Configuration scheme 23–25

Chaining 23

Mixed 25

Stacking 24

Stand alone 23

Configuration schemes 23

Connections 12

D320PL 12

D

D320PL 7, 9, 11, 15, 31

Dimensions 9

Functionality 7

Input modules 15

Installation 11

Requirements 11

Options 31

Technical summary 7

I

Input module 13, 15–16, 18–20

CVBS / S-VID 18

Dummy 20

DVI 15

HDSDI 16

Insert 13

Remove 13

RGB analog 19

SDI 16

YUV / RG(s)B 18

Introduction 7

D320PL 7

M

Maintenance 29

O

Options 31

D320 31

Order info 7

D320PL 7

S

Safety 3–4

Important Instructions 3

Warnings 4

Software 27

D320PL 27

VCM 27

XLite Toolset 27

R5976470 D320PL DIGITIZER 13122002

33

Page 38

Index

34 R5976470 D320PL DIGITIZER 13122002

Page 39

Revision Sheet

To:

Barco nv Events/Documentation

Noordlaan 5, B-8520 Kuurne

Phone: +32 56.36.89.70, Fax: +32 56.36.88.24

E-mail: antoon.dejaegher@barco.com, Web: www.barco.com

From:

Date:

Please correct the following points in this documentation (R5976470/01):

page

wrong

correct

R5976470 D320PL DIGITIZER 13122002

Loading...

Loading...