Banner American 370T, 520T, 520HP, 720HP Instruction Manual

FORMICA CZ, s.r.o.

Machines for one-sided paper lamination in the

printing and copying industry

FOLIANT 370T

FOLIANT 520T

FOLIANT 520HP

FOLIANT 720HP

Instruction Manual

(Version 1/2002)

1

2

CONTENTS

1. INTRODUCTION

2. USE

3. TECHNICAL INFORMATION

1 Introduction

This instruction manual describes working with the FOLIANT 370T, FOLIANT 520T,

FOLIANT 520HP, FOLIANT 720HP roll laminators. These machines have identical

construction, they differ only in working width or operating performance. The only

differences are as follows: absence of the cooling ventilator for the roller for the FOLIANT

370T machine, differing diameters of the main rollers and different power consumption of the

element for heating the working roller. These differences are mentioned in the text.

1.1 Liability for damage

The manufacturer and the distributor are not liable for damage caused by operation that does

not comply with the instruction manual and safety instructions. In particular, the manufacturer

or the distributor is not liable for damage caused by applying various kinds of lamination foil

to various kinds of paper. Every combination of materials should be tested prior to standard

use.

1.2 Work safety

This machine is fitted with a range of safety elements to protect the operating staff and to

protect the equipment during its normal use. The safety measures do not, however, cover all

safety aspects. Therefore, the operating staff should read and understand this instruction

manual or the staff should be duly trained by responsible persons before starting to use the

equipment. This will prevent mistakes during the installation and operation of the equipment.

Please do not try to install the equipment before thoroughly reading all the instruction

manuals supplied with the equipment and understanding all functions and procedures.

Three categories of safety instructions are used in the instruction manual

DANGER Ignoring these instructions may result in loss of life

WARNING G Ignoring these instructions may result in serious injury or

serious damage to the equipment

NOTICE F Ignoring these instructions may result in damage to the

equipment or an injury

F Important notice:

The FOLIANT laminating machines are equipped with a "Y" type connection,

therefore only a trained technician from the distribution or service organization may

install the equipment. Please follow safety instructions printed on the labels on the

equipment. Please do not remove or tamper with these labels. If damage is done to the

label, please contact your supplier.

3

GSAFETY ELEMENTS

This equipment is fitted with safety elements protecting the operating staff and the equipment.

The safety elements include the main switch, protective covers, overheating fuse, overload

fuse, and back operation. When working with the machine (lamination), the production

instructions, safety measures, and health protection during work should be complied with. It is

prohibited that the operating staff has loose sleeves or other parts of the clothing during the

lamination. During work, it is prohibited to eat, drink, or smoke. There are information labels

on the machine and labels warning against various dangers.

F Please make sure to follow the safety instructions printed on the labels on the

equipment. Do not remove or tamper with these labels. If the label is damaged, please contact

the distribution company.

4

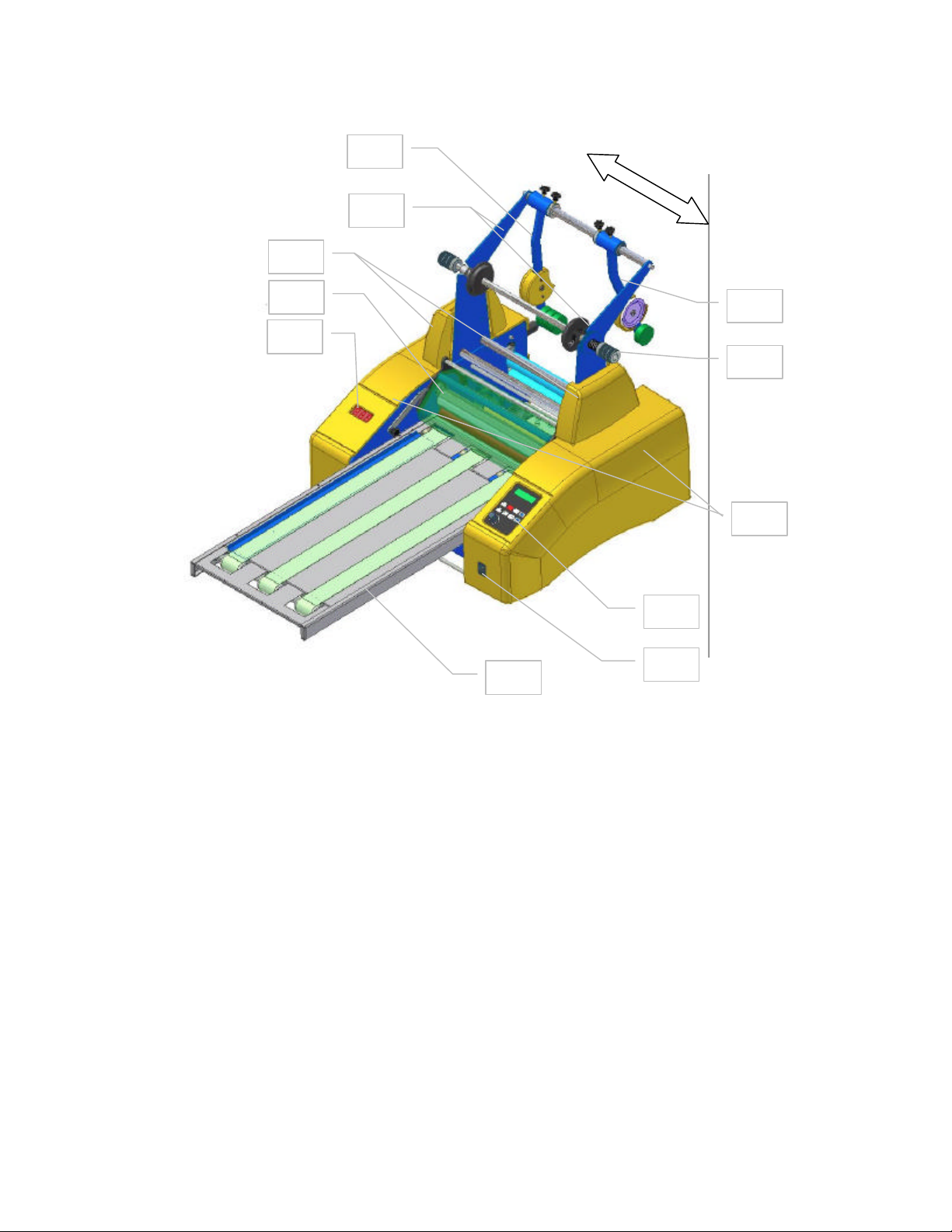

1.3 General description of the machine

LEFT

3

2

1

5

4

RIGHT

SIDE

SIDE

6

7

8

9

10

11

Figure 1

1) Indicator of lamination temperature

2) Cover of the main roller

3) Covers of pylons

4) Pylons

5) Perforation arm

6) Cutter arm

7) Roll carrier

8) Side plates

9) Control panel

10) Main switch

11) Feeding table

5

G1.4 Use:

Power consumption

Operating

Maximum

Minimum

The FOLIANT laminating machines is designed for small and medium printing houses, which

require swift lamination of paper sheets printed on offset machine or by the digital printing

technology such as printed book covers, envelopes for booklets and magazines, postcards, file

folders and boxes before cutting and the like. The machines may be equipped with the

FOLIANT 520 automatic feeding machine and the FOLIANT product line automatic

separator for automatic separation of laminated arches. The feeding machine will hand the

sheets into the laminator with technological overhang, the laminator will cover the paper

sheets with polypropylene or nylon foil. The separator will separate the laminated sheets, it

will count them and will store them in the container.

Glue applied on the polypropylene foil is heated by the heated roller and in the point of

contact it is pressed to stick perfectly to the print. For lamination, the manufacturer

recommends to use foils in rolls with inner diameter of 75 mm and with widths depending on

the material being processed.

Lamination temperatures are regulated from 80 till 140°C. The maximum operating width for

the equipment and the speed of the lamination depend on the type of the equipment.

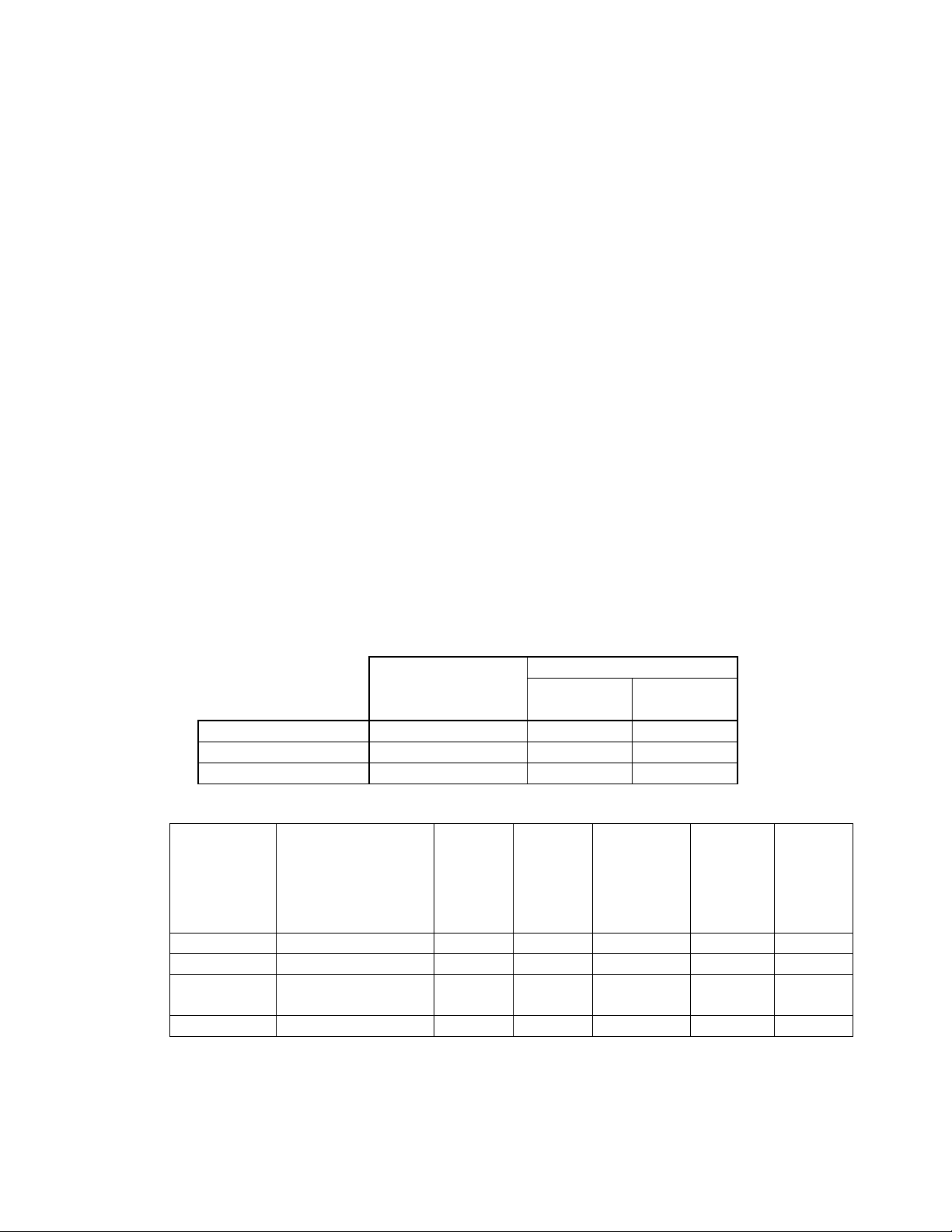

2. TECHNICAL DATA:

Derived alternatives of the equipment:

Derived alternatives of the equipment have the same construction, they vary only in the

operating width, performance, presence or absence of the front conveyor and number of

processed sheets per hour.

Technical parameters for the installation of the machine

WEIGHT [Kg]

DIMENSIONS

FOLIANT 370 T 590x1170x630 60 75

FOLIANT 520 T/HP 780x1170x630 68/77 85/95

FOLIANT 720 T 980x1170x630 90 110

Type

of the machine

Front

conveyor

Without

carriers TOTAL

Sheets *

width

B3/hour

* Information concerning the number of laminated sheets is applicable for lamination of

white paper 135 g/m²

** Information concerning the number of laminated sheets is applicable for lamination of

6

format

[W] [mm] [cm] [cm]

Foliant 370 750 Yes 370 850 37 x 51 20 x 25

Foliant 520T

Foliant 520

HP

Foliant 720T

white paper 135 g/m² using automatic feeding machine

1000 Yes 520 1200 52 x 71 35 x 25

2000 Yes 520 2600 **

52 x 71 35 x 25

2500 Yes 720 1800 B2 ** 72 x 100 50 x 35

format

2.2 The following standards and regulations have been used for the construction of the

equipment.

Machinery

N V no. 170/1997 Sb. (Directive 98/37/EC)

stipulating technical requirements for machinery, as amended by government regulation no.

15/1999 Sb. and government regulation no. 283/2000 Sb.

CSN (Czech National Standard) EN 292-1:1994 (EN 292-1:1991)

Safety of machinery. Basic terms, general principles for designing

Part 1: Basic terminology, methodology.

CSN EN 292-2:1994+A1:2000 (EN 292-2:1991+A1:1995)

Safety of machinery. Basic terms, general principles for designing

Part 2: Technical principles and specifications.

CSN EN 294:1993 (EN 294:1992)

Safety of machinery. Safe distances for avoiding contact of upper limbs with dangerous

points.

CSN EN 953:1998 (EN 953:1997)

Safety of machinery. General requirements for design and construction of protective covers

(fixed, movable).

CSN EN 954-1:1998 (EN 954-1:1996)

Safety of machinery. Safety elements of control systems. Part 1: General principles for

construction.

CSN EN 1050:1998 (EN 1050:1996)

Safety of machinery. Principles for stipulating rate of risk.

CSN EN 563:996 (EN 563:1994)

Safety of machinery. Temperatures of surfaces accessible to contact. Ergonometric

parameters for determining temperature limits of hot surfaces.

CSN ISO 7000:1996 (ISO 7000:1989)

Pictograms replacing notices on equipment. Glossary and comprehensive table of pictograms.

Electrical equipment

N V c. 169/1997 Sb. (Directive 89/336 EWG)

stipulating technical requirements on products for electromagnetic compatibility, as amended

by government regulation no. 282/2000 Sb.

N V c. 168/1997 Sb. (Directive 73/23 EWG)

stipulating technical requirements on low-voltage electrical equipment, as amended by

government regulation no. 281/2000 Sb.

CSN EN 60335-1:1997 (EN 60335-1:1994)

Safety of electrical household appliances and appliances with similar purpose. Part 1: General

requirements

CSN EN 61000-3-2+A12:97 (EN 61000-3-2+A12:1996)

Electromagnetic compatibility (EMC) – Part 3: Limits – Section 2: Limits for emissions of

harmonic current (equipment with input phase current <=16 A)

CSN EN 61000-3-3:1997 (EN 61000-3-3:1995)

Electromagnetic compatibility (EMC) – Part 3: Limits – Section 3: Reducing voltage

oscillation and flickering in low-voltage distribution networks for equipment with nominal

current <=16 A

CSN 33 0120:2001 (IEC 38:1983)

Electromagnetic regulations. IEC standardized voltage.

CSN EN 1037:1997 (EN 1037:1995)

7

Safety CSN EN 50081-1:1994 (EN 55081:1992)

Electromagnetic compatibility. General standards for radiation. Part one: Residential, retail

and light industry premises.

CSN EN 55014-1:1995 (EN 55014-1:1993)

Electromagnetic compatibility – Requirements on household appliances, electrical equipment

and similar equipment – Part 1: Radiation – Standards for product group.

CSN EN 55014-2:1998 (EN 55014-2:1997)

Electromagnetic compatibility – Requirements on household appliances, electrical equipment

and similar equipment – Part 2: Resistance – Standards for product group.

.

8

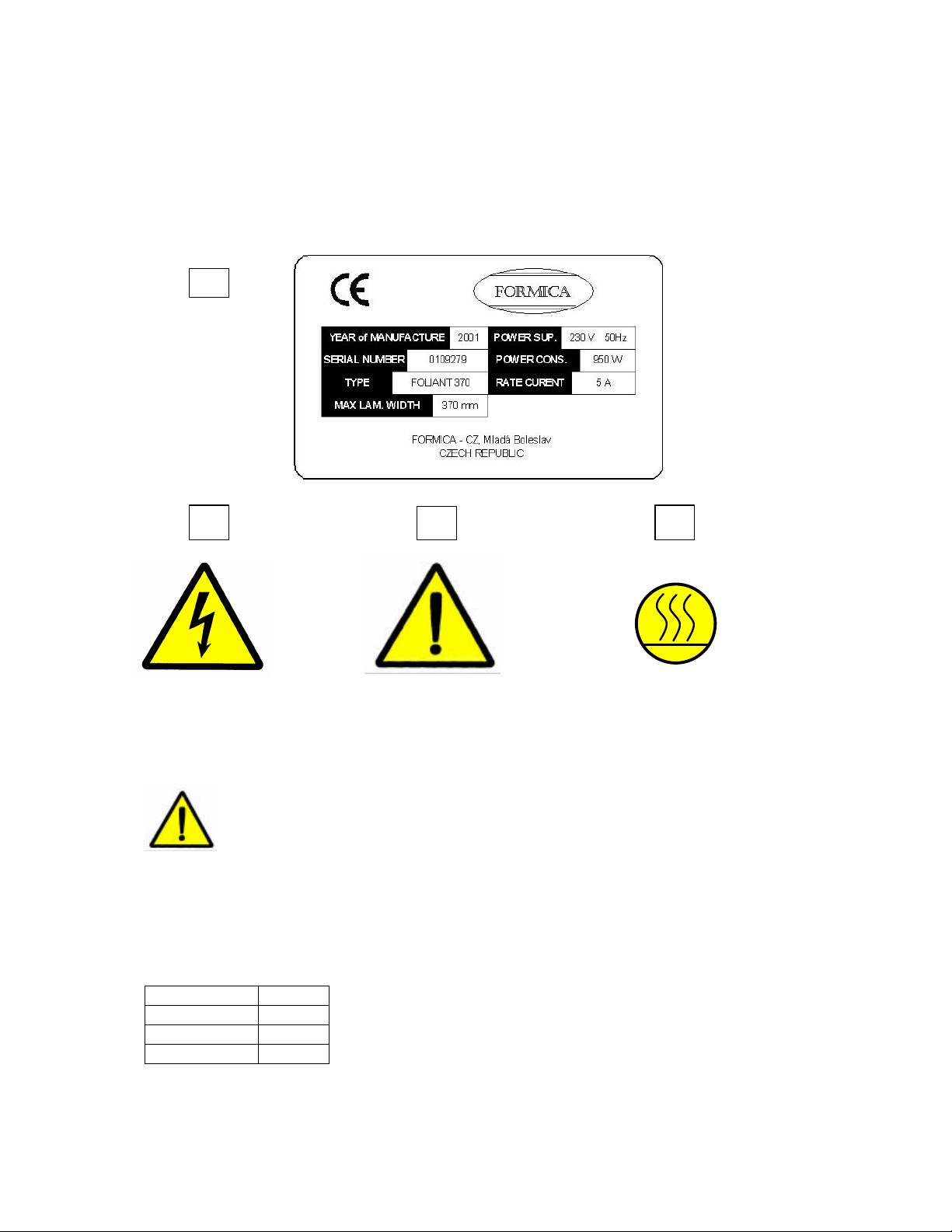

2.3 List of labels:

1.

3. 2.

1. Type model label

2. Warning when removing the cover – danger of injury by electric current

3. Warning when removing the cover – mechanical danger

4. Caution – equipment under operation

The production label is OK, only weight needs to be added and the label should be in several

languages (universal) or specific for the destination country. E.g.:

4.

Labels 2 and 3 must look like this (only black and yellow):

2.4 Electrical installation

The 220 - 230V, 50 Hz sockets for the connection of the equipment must be

located in the vicinity of the equipment and must remain freely accessible. The socket and

the breaker must be dimensioned properly, see the chart of breakers. It is prohibited to use

extension cables and Y-branches. Adjusting the connection of the equipment to the

network to comply with national standards must be performed by a person with

appropriate electro-technical skills.

Table of breakers

FOLIANT 370T 10A

FOLIANT 520T 10A

FOLIANT 520HP 16A

FOLIANT 720HP 16A

9

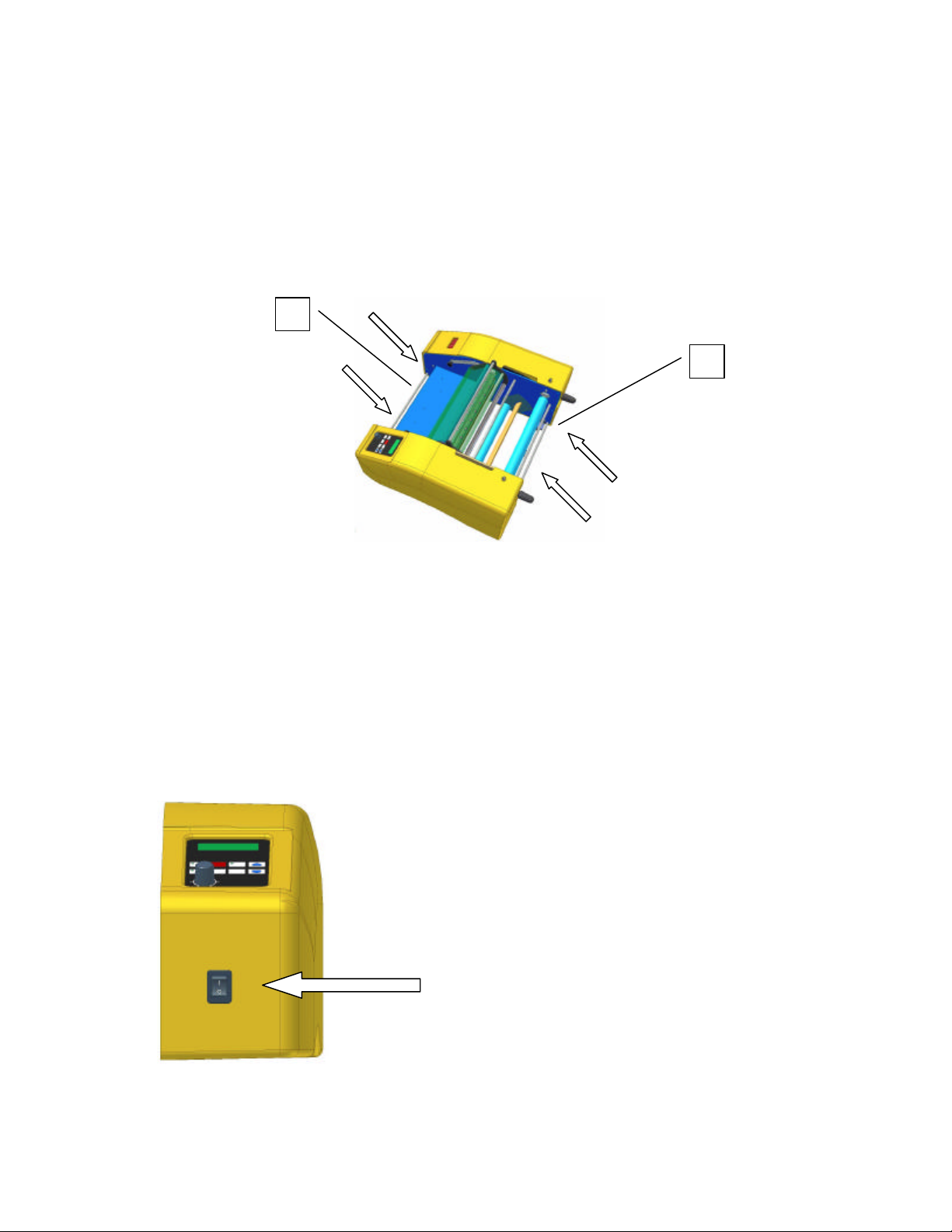

3. Transporting and handling the equipment

A

A

3.1 Transporting and handling the equipment

GThe weight of the equipment is designed so that two persons may install the equipment

and perform any necessary manipulation. Two expanding sticks (A) are used to lift the

machine. After the machine is installed in place, it is necessary to install the arms holding the

foil, the perforation wheel, and the knife.

Figure 2

3.2 Storage of the equipment

The equipment must be placed on a solid and even surface

(Recommended accessories – the FOLIANT table with appropriate width)

Temperature for storing -10°C to 60 °C (-10°F to 140°F)

Relative humidity: 20 to 80%, non-condensing relative humidity

3.3 Location of the equipment

The equipment must be situated on a solid and flat surface (working plate) dimensioned for

the weight of the equipment and must not be placed in the vicinity of other heat sources,

including direct sunlight. All control elements must be freely accessible. The equipment must

have free handling space around it [at least 1 meter]. The main switch (Figure 1 to 10),

serving also as the emergency switch for emergency situations, must also be freely accessible.

Figure 3

10

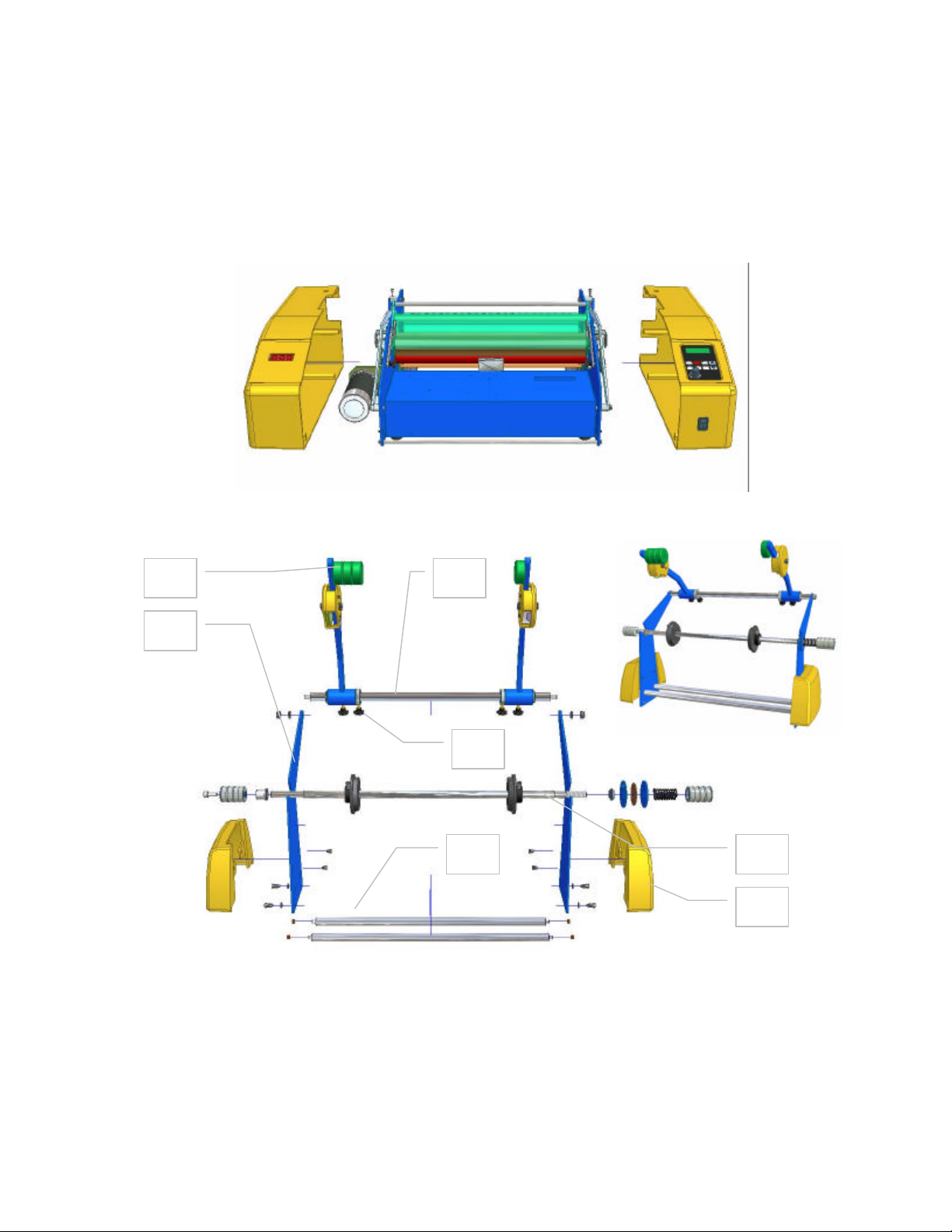

3.4 Installing and assembling the equipment

The equipment is shipped in a wooden pallet, partially dismantled. It is therefore necessary to

assemble the equipment before installation. Assembling the machine is an easy installation

work. The equipment must be disconnected from the power network during installation.

Installation procedure:

1. Placing the foundation of the equipment on the working place

2. Removing side protective covers

Figure 4

3. Installation of the carriers of the roll with equalizing rollers

B

C

A

D

F E

G

Figure 5

A) Pylon B) Weights

C) Additional shaft D) Arrest screws

E) Equalizing rollers F) Carrier of the roll

G) Cover of the pylon

11

Loading...

Loading...