Page 1

VTB Pick-to-Light Optical Touch Button

0 067570 5

Ergonomic optical touch button for pick-to-light applications

• Microcontroller-based photoelectric touch buttons

• A cost-effective and easy-to-install alternative to capacitive touch switches and mechanical

push buttons for errorproofing and parts-verification applications

• Ergonomically designed to eliminate hand, wrist, and arm stresses associated with repeated switch operation; requires no physical pressure to operate

• Illuminated base provides a bright, easy-to-see job light in one or two colors, depending on

model

• LED power and output indicators

• NPN or PNP output, depending on model

• Immune to ambient light, EMI and RFI interference

• High excess gain cuts through heavy airborne contamination to function in almost any environment; optional protective field cover available

• 12 to 30V dc operation

One-Color Job Light Models

Job Light Color

Green Red Blue

VTBN6 VTBN6R VTBN6B 2 m 4-wire cable

VTBN6Q VTBN6RQ VTBN6BQ 4-pin Euro QD

VTBN6L VTBN6RL VTBN6BL 2 m 4-wire cable

VTBN6LQ VTBN6RLQ VTBN6BLQ 4-pin Euro QD

VTBP6 VTBP6R VTBP6B 2 m 4-wire cable

VTBP6Q VTBP6RQ VTBP6BQ 4-pin Euro QD

VTBP6L VTBP6RL VTBP6BL 2 m 4-wire cable

VTBP6LQ VTBP6RLQ VTBP6BLQ 4-pin Euro QD

Two-Color Job Light Models

Green and Red (see Wiring) Cable* Upper Housing Output Type Job Light Input

VTBN6GR 2 m 5-wire cable

VTBN6GRQ 5-pin Euro QD

VTBN6GRL 2 m 5-wire cable

VTBN6GRLQ 5-pin Euro QD

Cable* Upper Housing Output Type Job Light Input

Polysulfone

NPN 0V dc

Polycarbonate

Polysulfone

PNP +10 to 30V dc

Polycarbonate

Polysulfone

NPN 0V dc

Polycarbonate

VTBP6GR 2 m 5-wire cable

Polysulfone

VTBP6GRQ 5-pin Euro QD

PNP +10 to 30V dc

VTBP6GRL 2 m 5-wire cable

Polycarbonate

VTBP6GRLQ 5-pin Euro QD

Standard 2 m (6.5 ft) cable models are listed. To order the 9 m (30 ft) cable model, add suffix "W/30" to the cabled model number. (For

example, VTBN6 W/30.) Models with a QD connector require a mating cable. (See Quick Disconnect (QD) Cables on page 5).

P/N 067570 Rev. C 5/10/2013

Page 2

Black Polysulfone

or Red Polycarbonate

Translucent White

Polycarbonate

Base/Job Light

Output

Conducting

LED

Power ON/OFF

LED

Switch

"Touch Area"

VTB Pick-to-Light Optical Touch Button

WARNING: Not To Be Used for Personnel Protection

Never use this device as a sensing device for personnel protection. Doing so could lead to serious

injury or death. This device does not include the self-checking redundant circuitry necessary to allow its

use in personnel safety applications. A sensor failure or malfunction can cause either an energized or deenergized sensor output condition.

Overview

Banner VTB Series touch buttons are ergonomically designed to eliminate the hand, wrist, and arm stresses associated with mechanical

push buttons. They require absolutely no physical pressure to operate. LED indicators light when power is on and outputs are activated.

The interfaces to a system controller, which is pre-programmed for a specific sequence of tasks. Mounted in or near each bin in an

assembler’s work station, the sensor job light signals the assembler which bins contain items to be picked in a given operation and in

what order they should be picked.

As the assembler takes a part in sequence , then reaches a finger into the yoke of the corresponding Touch Button, the sensor senses

that the part was removed and it sends an output signal to the controller. The controller then verifies if the correct part was taken and may

respond by turning that job light OFF, activating the job light of the next bin in the sequence.

All models are immune to EMI, RFI, and ambient light interference. VTBs have either a black polysulfone or red polycarbonate upper

housing (depending on model) and a translucent white polycarbonate base. Environmental considerations for use of the two upper housing types differ; see specifications. The entire base section lights to provide a bright job light where a task is to be performed. The 30 mm

threaded base on all models provides easy mounting.

Indicators

Power ON/OFF (red):

Steady ON when power is applied

Output Conducting (red):

Steady ON when button is activated

OFF when button is not activated

Job Light:

Steady ON or flashing* when a task is to be performed

* Flashing job light is dependent on wiring. Color is dependent

on model and wiring.

2 www.bannerengineering.com - tel: 763-544-3164 P/N 067570 Rev. C

Page 3

bn

bu

-

+

bk

wh

12-30V dc

Job Light Enable

0V dc

Load

bn

bu

-

+

bk

wh

12-30V dc

Job Light Enable

+10-30V dc

Load

bn

bu

-

+

bk

wh

gy

12-30V dc

Green Job Light Enable — 0V dc

Red Job Light Enable — 0V dc

Load

bn

bu

-

+

bk

wh

12-30V dc

Job Light Enable

+10-30V dc

Load

bn

bu

-

+

bk

wh

12-30V dc

Job Light Enable

0V dc

Load

bn

bu

-

+

bk

wh

gy

12-30V dc

Green Job Light Enable — +10-30V dc

Red Job Light Enable — +10-30V dc

Load

2

3

4

1

2

3

4

1

5

VTB Pick-to-Light Optical Touch Button

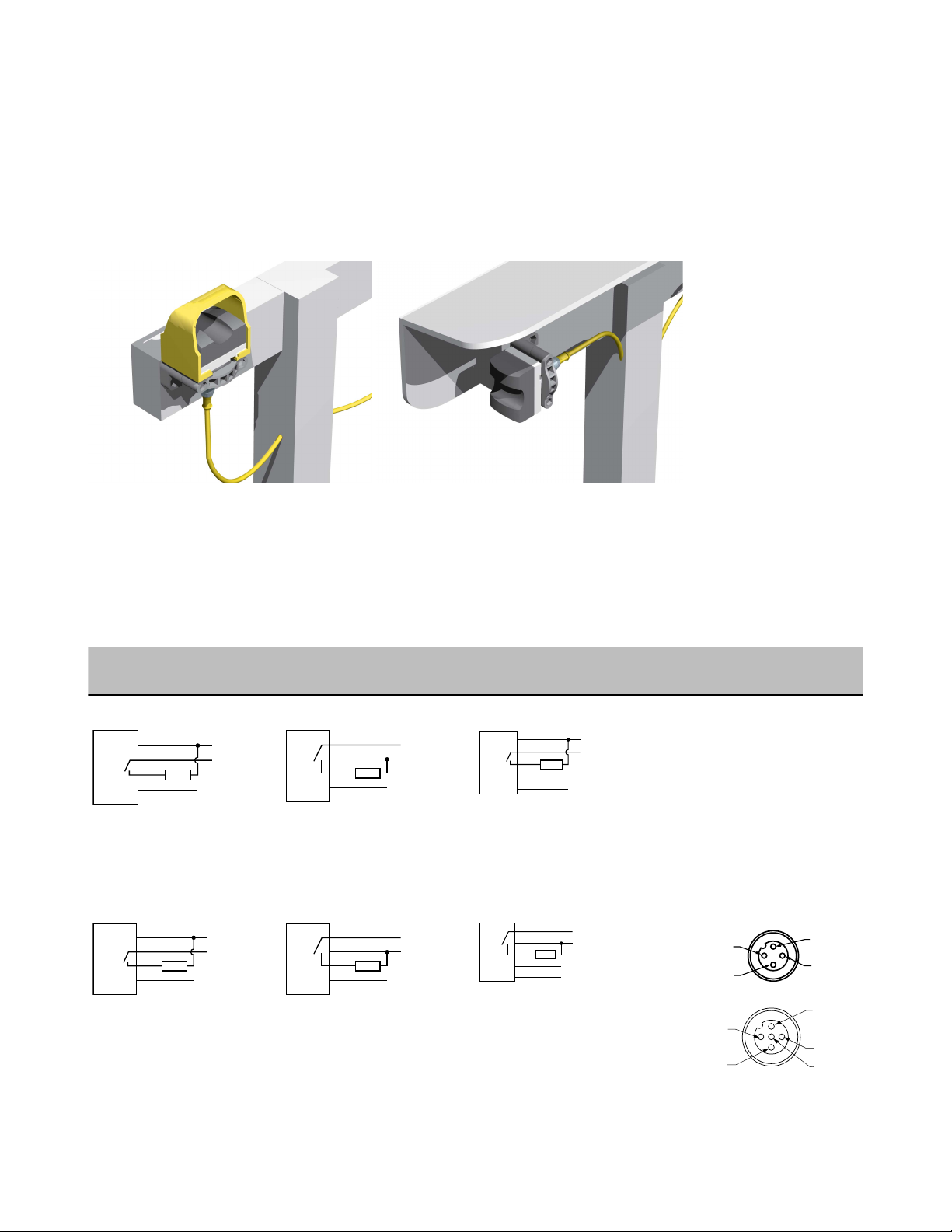

Installation

Consider ergonomic principles to avoid unnecessary fatigue in the installation of the hand controls. Install the touch buttons at a height

and in a location that will be comfortable for the user.

The following figure shows two methods for mounting the touch buttons, to prevent accidental switch actuation. When mounting them on

top of the control bar, the protective field covers should be in place, as shown; or for added protection, mount the touch buttons sideways

under and/or behind a protective hood, rather than on top of the bar, without using the field covers. This side mount prevents an object

from being left in the path of the beam. In addition, shields, covers, rings, collars, dividers, or similar protection may be used to prevent

accidental switch actuation.

Figure 1. Protect VTB touch buttons to prevent defeat or inadvertent actuation

Wiring

Single-color models may be wired for either a solid or flashing job light. The wiring of two-color models determines the job light. Color

flashing job light is not available. Cabled model wiring shown. Cabled and QD model wiring is functionally identical.

• For solid color, use the standard wiring diagram.

• For flashing (2 Hz), use the alternate wiring diagrams.

One-Color Job Light, NPN

(Sinking) Output Models

Solid Job Light Solid Job Light NPN (Sinking) Output Models

Flashing Job Light Flashing Job Light PNP (Sourcing) Output Models Pinouts

One-Color Job Light, PNP

(Sourcing) Output Models

Two-Color Job Light Models Wiring Key

1 = Brown

2 = Blue

3 = Black

4 = White

5 = Gray

6 = Load

7 = Job light enable

8 = Green job light

9 = Red job light

P/N 067570 Rev. C www.bannerengineering.com - tel: 763-544-3164 3

Page 4

VTB Pick-to-Light Optical Touch Button

Specifications

Supply Voltage and Current

One-color job light models: Less than 120 mA max current @ 12V dc and less than 70 mA max current @

30V dc (exclusive of load)

Two-color job light models: Less than 67 mA max current @ 12V dc; less than 40 mA max current @ 24V

dc; and less than 35 mA max current @ 30V dc (exclusive of load)

Supply Protection Circuitry

Protected against transient voltages (fast-transient and

over-voltage) and reverse polarity

Output Configuration

1 current sinking (NPN) open collector transistor or 1

current sourcing (PNP) open collector transistor, depending on model

Output Rating

Max. load: 150 mA

On-state saturation voltage: < 1.5V @ 150 mA

Off-state leakage current: < 10 μA

Output Protection Circuitry

All models protected against false pulse on power-up

(outputs held OFF for 1 second at power-up), overload

and short-circuits.

Output Response Time

100 milliseconds ON/OFF

Indicators

2 green LED indicators: Power ON and Output Conducting

Base lights green, red or blue (depending on model

and hookup) as a job light when input line is enabled.

One-color models may be wired for flashing, rather

than solid color operation.

Connections

PVC-jacketed 2 m (6.5') cables or 4-pin Euro-style QD

fitting, depending on model; integral 9 m (30') cables

are also available. Accessory QD cables required for

QD models.

Ambient Light Immunity

Up to 120,000 lux (direct sunlight)

EMI/RFI Immunity

Immune to EMI and RFI noise sources, per IEC

947-5-2

Environmental Rating

Meets NEMA standards 1, 3, 4, 4X, 12 and 13; IEC

IP66

Construction

Totally encapsulated, non-metallic enclosure. Black

polysulfone or red polycarbonate upper housing (see

Application Note below); translucent white polycarbonate base. Electronics fully epoxy-encapsulated.

Operating Conditions

–20° to +50° C (–4° to +122° F)

90% @ +55º C max. relative humidity (non-condens-

ing)

Application Notes

Environmental considerations for models with polysulfone upper housings: The polysulfone upper housing

will become brittle with prolonged exposure to outdoor

sunlight. Window glass effectively filters longer wavelength ultraviolet light and provides excellent protection

from sunlight. Avoid contact with strong alkalis. Clean

periodically using mild soap solution and a soft cloth.

Environmental considerations for models with polycarbonate upper housings: Avoid prolonged exposure to

hot water and moist high-temperature environments

above 66° C (150° F). Avoid contact with aromatic hydrocarbons (such as xylene and toluene), halogenated

hydrocarbons and strong alkalis. Clean periodically using mild soap solution and a soft cloth.

Certifications

4 www.bannerengineering.com - tel: 763-544-3164 P/N 067570 Rev. C

Page 5

max. torque 4.5 Nm (40 lbf in)

59.9 mm

(2.36")

27.9 mm

(1.10")

43.2 mm

(1.70")

35.0 mm

(1.38")

22.1 mm

(0.87")

15.2 mm

(0.60")

22.1 mm

(0.87")

M30 External Threads

Jam Nut, Lock Ring, and

Seal Washers are Supplied

NPSM

Internal Threads

VTBP6 VTBP6

44 Typ.

ø 14.5

M12 x 1

2

3

4

1

VTB Pick-to-Light Optical Touch Button

Dimensions

Accessories

Quick Disconnect (QD) Cables

Use the 4-pin Euro-style cordsets with the one-color job light models.

4-Pin Threaded M12/Euro-Style Cordsets

Model Length Style Dimensions Pinout

MQDC-406 1.83 m (6 ft)

MQDC-415 4.57 m (15 ft)

MQDC-430 9.14 m (30 ft)

MQDC-450 15.2 m (50 ft)

P/N 067570 Rev. C www.bannerengineering.com - tel: 763-544-3164 5

Straight

1 = Brown

2 = White

3 = Blue

4 = Black

Page 6

32 Typ.

[1.26"]

30 Typ.

[1.18"]

ø 14.5 [0.57"]

M12 x 1

44 Typ.

ø 14.5

M12 x 1

2

3

4

1

5

32 Typ.

[1.26"]

30 Typ.

[1.18"]

ø 14.5 [0.57"]

M12 x 1

45

61

69

A

B

C

70

57

A

B

C

57

VTB Pick-to-Light Optical Touch Button

4-Pin Threaded M12/Euro-Style Cordsets

Model Length Style Dimensions Pinout

MQDC-406RA 1.83 m (6 ft)

MQDC-415RA 4.57 m (15 ft)

MQDC-430RA 9.14 m (30 ft)

Right-Angle

MQDC-450RA 15.2 m (50 ft)

Use the 5-pin Euro-style cordsets with the two-color job light models.

5-Pin Threaded M12/Euro-Style Cordsets (Single Ended)

Model Length Style Dimensions Pinout (Female)

MQDC1-501.5 0.50 m (1.5 ft)

MQDC1-506 1.83 m (6 ft)

Straight

MQDC1-515 4.57 m (15 ft)

MQDC1-530 9.14 m (30 ft)

MQDC1-506RA 1.83 m (6 ft)

1 = Brown

2 = White

3 = Blue

MQDC1-515RA 4.57 m (15 ft)

4 = Black

5 = Gray

Right-Angle

MQDC1-530RA 9.14 m (30 ft)

Brackets

SMB30A

• Right-angle bracket with

curved slot for versatile

orientation

• Clearance for M6 (¼ in)

hardware

• Mounting hole for 30 mm

sensor

• 12-ga. stainless steel

Hole center spacing: A to B=40

Hole size: A=ø 6.3, B= 27.1 x 6.3, C=ø 30.5

6 www.bannerengineering.com - tel: 763-544-3164 P/N 067570 Rev. C

SMB30MM

• 12-ga. stainless steel

bracket with curved

mounting slots for versatile

orientation

• Clearance for M6 (¼ in)

hardware

• Mounting hole for 30 mm

sensor

Hole center spacing: A = 51, A to B = 25.4

Hole size: A = 42.6 x 7, B = ø 6.4, C = ø 30.1

Page 7

45

93

A

C

B

53

48

45

A

C

B

67

58

29

B

A

A

B

68.9

36.3

83.2

OTC Series

Field Cover

51.0 mm

(2.0")

69.0 mm

(2.7")

74.0 mm

(2.9")

VTB Pick-to-Light Optical Touch Button

SMBAMS30P

• Flat SMBAMS series

bracket

• 30 mm hole for mounting

sensors

• Articulation slots for 90°+

rotation

• 12-ga. 300 series stainless

steel

Hole center spacing: A=26.0, A to B=13.0

Hole size: A=26.8 x 7.0, B=ø 6.5, C=ø 31.0

SMB30SC

• Swivel bracket with 30 mm

mounting hole for sensor

• Black reinforced thermoplastic polyester

• Stainless steel mounting

and swivel locking hardware included

Hole center spacing: A=ø 50.8

Hole size: A=ø 7.0, B=ø 30.0

SMBAMS30RA

• Right-angle SMBAMS series bracket

• 30 mm hole for mounting

sensors

• Articulation slots for 90°+

rotation

• 12-ga. (2.6 mm) cold-rolled steel

Hole center spacing: A=26.0, A to B=13.0

Hole size: A=26.8 x 7.0, B=ø 6.5, C=ø 31.0

SMB30FA

• Swivel bracket with tilt and

pan movement for precise

adjustment

• Mounting hole for 30 mm

sensor

• 12-ga. 304 stainless steel

• Easy sensor mounting to

extrude rail T-slot

• Metric and inch size bolt

available

Bolt thread: SMB30FA, A= 3/8 - 16 x 2 in; SMB30FAM10, A=

M10 - 1.5 x 50

Hole size: B= ø 30.1

Field Covers

Field covers are designed to prevent inadvertent activation of optical touch buttons by objects that accidentally block the sensing beam.

Field covers are constructed of rugged polypropylene and are highly resistant to abrasion and to damage by most chemicals. A variety of

colors is available, allowing color-coding when multiple touch buttons are used. Note that when a field cover is used, it also blocks a

portion of the job light.

Model Description

OTC-1-BK Black cover

OTC-1-GN Green cover

OTC-1-RD Red cover

OTC-1-YW Yellow cover

Banner Engineering Corp Limited Warranty

Banner Engineering Corp. warrants its products to be free from defects in material and workmanship for one year following the date of

shipment. Banner Engineering Corp. will repair or replace, free of charge, any product of its manufacture which, at the time it is returned

to the factory, is found to have been defective during the warranty period. This warranty does not cover damage or liability for misuse,

abuse, or the improper application or installation of the Banner product.

P/N 067570 Rev. C www.bannerengineering.com - tel: 763-544-3164 7

Page 8

VTB Pick-to-Light Optical Touch Button

THIS LIMITED WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES WHETHER EXPRESS OR IMPLIED (INCLUDING, WITHOUT LIMITATION, ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE), AND

WHETHER ARISING UNDER COURSE OF PERFORMANCE, COURSE OF DEALING OR TRADE USAGE.

This Warranty is exclusive and limited to repair or, at the discretion of Banner Engineering Corp., replacement. IN NO EVENT SHALL

BANNER ENGINEERING CORP. BE LIABLE TO BUYER OR ANY OTHER PERSON OR ENTITY FOR ANY EXTRA COSTS, EXPENSES, LOSSES, LOSS OF PROFITS, OR ANY INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES RESULTING FROM ANY

PRODUCT DEFECT OR FROM THE USE OR INABILITY TO USE THE PRODUCT, WHETHER ARISING IN CONTRACT OR WARRANTY, STATUTE, TORT, STRICT LIABILITY, NEGLIGENCE, OR OTHERWISE.

Banner Engineering Corp. reserves the right to change, modify or improve the design of the product without assuming any obligations or

liabilities relating to any product previously manufactured by Banner Engineering Corp.

www.bannerengineering.com - tel: 763-544-3164

Loading...

Loading...