Page 1

SM30 Series 30 mm Barrel Sensor

Opposed-Mode Infrared Photoelectric Sensors for Especially Demanding Applications

• Stainless steel or plastic barrel models

• Very high excess gain; 150 m (500 ft) sensing range; 880 nm Infrared LED

• Positive sealing eliminates even capillary leakage; lens is quad-ring sealed; exceeds

NEMA 6P (IP67) ratings – ideal for equipment wash-down environments

• EZ-BEAM® technology provides reliable sensing without the need for adjustment

• Modulation frequency “A” is standard; frequencies “B” and “C” also available for

preventing crosstalk in multiple-sensor applications (emitter and opposed receiver

frequencies must match)

• AC- and DC-operated receiver models available; emitters feature Universal voltage

• Range for all models: 150 m (500 ft). See page 3 for performance curves.

Modulation Frequency*

A B C

Housing Cable**

Emitter Models

SMA30PEL SMA30PELB SMA30PELC

SMA30PELQD SMA30PELQDB SMA30PELQDC 3-pin Mini-style QD†

SMA30SEL SMA30SELB SMA30SELC

SMA30SELQD SMA30SELQDB SMA30SELQDC 3-pin Mini-style QD†

Plastic

Stainless

Steel

2 m (6.5') 2-wire Cable

2 m (6.5') 3-wire Cable

DC Receivers

SM30PRL SM30PRLB SM30PRLC

SM30PRLQD SM30PRLQDB SM30PRLQDC 4-pin Mini-style QD

SM30SRL SM30SRLB SM30SRLC

SM30SRLQD SM30SRLQDB SM30SRLQDC 4-pin Mini-style QD

Plastic

Stainless

Steel

2 m (6.5') 4-wire Cable

2 m (6.5') 4-wire Cable

AC Receivers

SM2A30PRL SM2A30PRLB SM2A30PRLC

SM2A30PRLQD SM2A30PRLQDB SM2A30PRLQDC 3-pin Mini-style QD†

SM2A30SRL SM2A30SRLB SM2A30SRLC

SM2A30SRLQD SM2A30SRLQDB SM2A30SRLQDC 3-pin Mini-style QD†

SM2A30PRLNC SM2A30PRLNCB SM2A30PRLNCC

SM2A30PRLNCQD SM2A30PRLNCQDB SM2A30PRLNCQDC 3-pin Mini-style QD†

SM2A30SRLNC SM2A30SRLNCB SM2A30SRLNCC

SM2A30SRLNCQD SM2A30SRLNCQDB SM2A30SRLNCQDC 3-pin Mini-style QD†

Plastic

Stainless

Steel

Plastic

Stainless

Steel

2 m (6.5') 2-wire Cable

2 m (6.5') 3-wire Cable

2 m (6.5') 2-wire Cable

2 m (6.5') 3-wire Cable

Supply

Power

Universal:

12 to 240V ac,

10 to 30V dc

10 to 30V dc

24 to 240V ac

Output Type

–

Bi-Modal™

NPN or PNP

SPST

Solid-state,

L.O.

SPST

Solid-state,

D.O.

* Any emitter and receiver shown here can be used together, if they have the same modulation frequency.

** Standard 2 m (6.5 ft) cable and integral QD models are listed. A model with a QD connector requires a mating cable; see page 4. To order the 9 m (30 ft) cable: add

suffix “W/30” following the Frequency suffix of any cable model (e.g., SM30PRLBW/30).

† AC models with QD require SM30CC model cables; see page 4.

WARNING . . . Not To Be Used for Personnel Protection

Never use these products for personnel protection. Doing so could lead to serious injury or death. These devices do NOT include the self-checking redundant circuitry

necessary to allow their use in personnel safety applications. A device failure or malfunction can cause either an energized or de-energized output condition. Consult your

current Banner Safety Products catalog for safety products that meet OSHA, ANSI, and IEC standards for personnel protection.

Printed in USA Apr 2013 P/N 03541 Rev. E

Page 2

SM30 Series 30 mm Barrel Sensor

Specifications

Supply Voltage and Current

Supply Protection Circuitry

Output Configuration

Output Rating

Output Protection Circuitry

Output Response Time

Repeatability

Indicators

Construction

Environmental Rating

Connections

Operating Conditions

Certifications

Emitters: 12 to 240V ac (50/60 Hz) or 10-30V dc at 20 mA, 10% maximum ripple

DC Receivers: 10 to 30V dc at 10 mA maximum (exclusive of load); 10% maximum ripple

AC Receivers: 24 to 240V ac (50/60 Hz)

Protected against reverse polarity and transient voltages

DC Receivers: Bi-Modal™ output (PNP sourcing or NPN sinking). Selection of light/dark operate and sourcing or

sinking configuration dependent on hookup.

AC Receivers: SPST solid-state switch; light operate (LO) or dark operate (DO) dependent on model.

DC Receivers: 250 mA continuous

Output saturation voltage (PNP & NPN configuration) < 1 volt at 10 mA and < 2 volts at 250 mA

Off-state leakage current < 10 microamps

AC Receivers: Maximum steady-state load capability is 500 mA

Inrush capability: 10 amps for 1 second (non-repeating)

Off-state leakage: current < 1.7 mA rms

On-state voltage drop: < 3.5 volts rms across a 500 mA load; < 5 volts rms across a 15 mA load

Outputs of dc receivers are short circuit protected

10 milliseconds on/off

“A” frequency models: 1 ms

“B” frequency models: 1.5 ms

“C” frequency models: 2.3 ms

Internal red LED, visible through the lens or from side of the sensor.

Emitters: Red “Power ON” indicator LED

DC Receivers: Lights whenever receiver sees its modulated light source

AC Receivers: Lights whenever receiver’s output is conducting

Fully epoxy-encapsulated tubular threaded housing, positive sealed at both ends, quad-ring sealed acrylic lens.

Plastic models: 30 mm diameter thermoplastic polyester housing and jam nuts.

Stainless Steel models: 30 mm diameter 303 stainless steel housing and jam nuts.

Exceeds NEMA 6P and IEC IP67 standards

PVC-jacketed 2 m or 9 m cables or Mini-style quick-disconnect (QD) fitting are available. QD cables are ordered

separately. See page 4.

Temperature: -40° to +70° C (-40° to +158° F)

Relative humidity: 90% at 50° C (non-condensing)

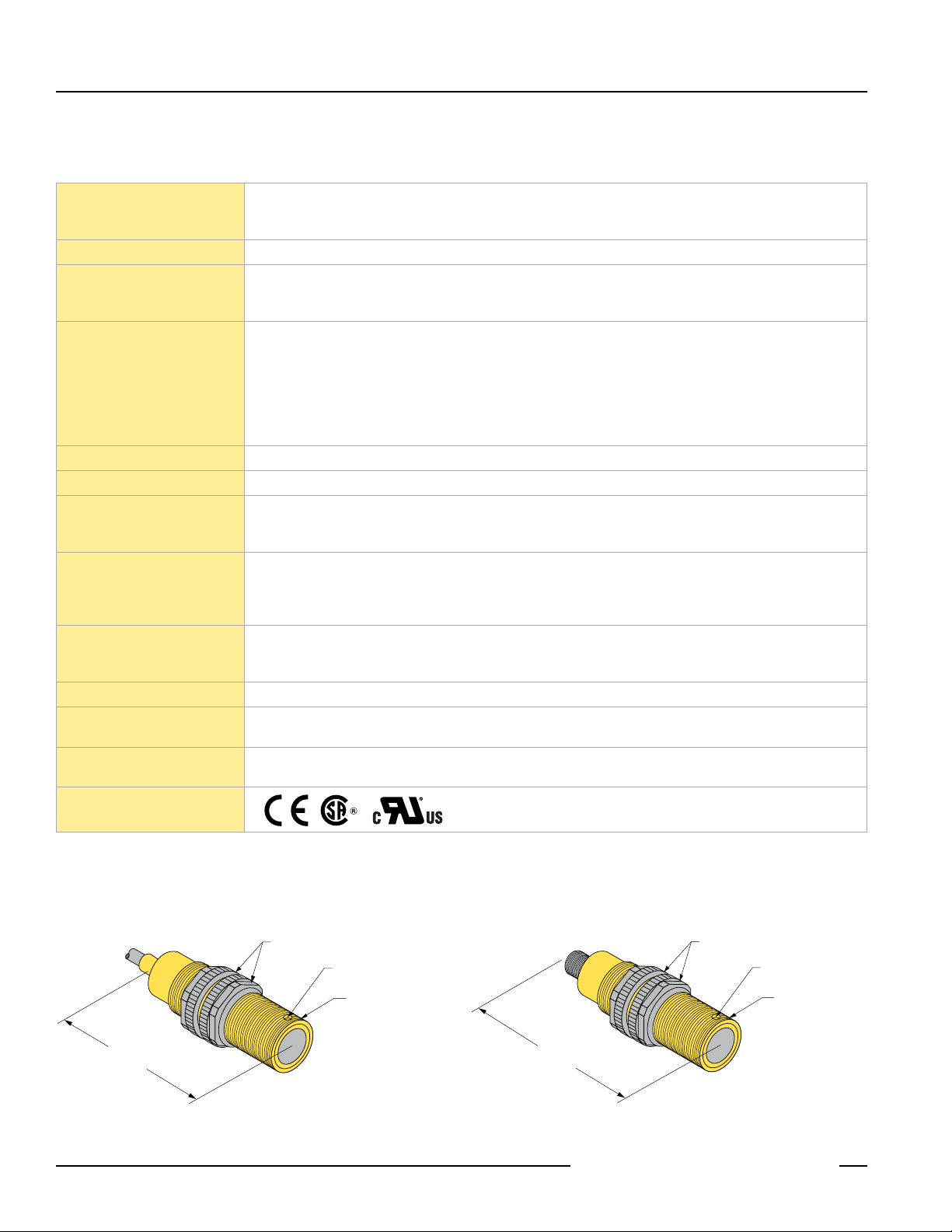

Dimensions

Cabled Models QD Models

Jam Nuts

102 mm

(4.0")

2 P/N 03541 Rev. E

(2 Provided)

Alignment

Indicator (Receivers)

M30 x 1.5

Thread

Jam Nuts

(2 Provided)

114 mm

(4.5")

Banner Engineering Corp. • Minneapolis, MN U.S.A

www.bannerengineering.com • Tel: 763.544.3164

Alignment

Indicator (Receivers)

M30 x 1.5

Thread

Page 3

Performance Curves

Excess Gain Curve Beam Pattern

100000

10000

E

X

C

1000

E

S

S

100

G

A

I

N

10

1

1 m

10 m

3.3 ft

33 ft

DISTANCE

Hookups

SM30 Series

Opposed Mode

100 m

330 ft

1000 m

3300 ft

1500 mm

1000 mm

500 mm

500 mm

1000 mm

1500 mm

SM30 Series 30 mm Barrel Sensor

SM30 Series

Opposed Mode

0

180 m

135 m

90 m

45 m

0

150 ft

300 ft

450 ft

600 ft

DISTANCE

60 in

40 in

20 in

0

20 in

40 in

60 in

225 m

750 ft

bn

bu

gn*

10-30V dc or

12-240V ac

Emitters – QDEmitters – Cabled AC Receivers – Cabled

rd/bk

rd/wh

gn*

10-30V dc or

12-240V ac

bn

bu

gn*

Load

24-240V ac

AC Receivers – QD

NOTE: AC emitters are not polarity-sensitive when powered by dc voltage. For QD

emitters, use SM30CC model cables listed on page 4 in order to match cable

colors.

*Connect green wire to earth ground whenever a stainless steel model is powered by ac voltage. (Cabled plastic models have no green wire.)

DC Receivers – NPN

wh

bu

bn

bk

10-30V dc

Load

wh

–

+

bu

bn

bk

Load

–

10-30V dc

+

DC Receivers – PNP

wh

bu

bn

bk

10-30V dc

Load

+

–

Light Operate Light OperateDark Operate Dark Operate

rd/bk

rd/wh

gn*

wh

bu

bn

bk

24-240V ac

Load

+

10-30V dc

–

Load

NOTE: Where QD hookups only are shown, cabled model hookups are functionally identical.

Banner Engineering Corp. • Minneapolis, MN U.S.A

www.bannerengineering.com • Tel: 763.544.3164

P/N 03541 Rev. E 3

Page 4

SM30 Series 30 mm Barrel Sensor

Male Pinout

Blue

Male Pinout

Quick-Disconnect (QD) Cables

Style Model Length Connector Use with Pinout

3-pin Mini-Style

SM30CC-306

SM30CC-312

MBCC-406

4-pin Mini-Style

MBCC-412

MBCC-430

Apertures

Model Description

Kit includes: a thread-on stainless steel housing, a flat

APG30S

glass lens, two quad-ring seals, plus 3 round and 3

slotted aperture disks

Mounting Brackets

SMB30A

• 30 mm, 12-gauge, stainless steel, right-angle bracket with a curved mounting slot for versatile orientation

• Clearance for M6 (1/4") hardware

2 m (6.5')

4 m (12')

2 m (6.5')

4 m (12')

9 m (30')

Straight

Emitters and

AC receivers

DC receivers

Green

Red/White

White Black

Brown

Red/Black

• 30 mm split clamp bracket

SMB30C

SMB30MM

SMB30SC

Banner Engineering Corp. warrants its products to be free from defects in material and workmanship for one year following the date of shipment. Banner Engineering Corp. will

repair or replace, free of charge, any product of its manufacture which, at the time it is returned to the factory, is found to have been defective during the warranty period. This

warranty does not cover damage or liability for misuse, abuse, or the improper application of the Banner product.

THIS LIMITED WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES WHETHER EXPRESS OR IMPLIED (INCLUDING, WITHOUT LIMITATION, ANY WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE), AND WHETHER ARISING UNDER COURSE OF PERFORMANCE, COURSE OF DEALING OR TRADE USAGE.

This Warranty is exclusive and limited to repair or, at the discretion of Banner Engineering Corp., replacement. IN NO EVENT SHALL BANNER ENGINEERING CORP. BE LIABLE

TO BUYER OR ANY OTHER PERSON OR ENTITY FOR ANY EXTRA COSTS, EXPENSES, LOSSES, LOSS OF PROFITS, OR ANY INCIDENTAL, CONSEQUENTIAL OR SPECIAL

DAMAGES RESULTING FROM ANY PRODUCT DEFECT OR FROM THE USE OR INABILITY TO USE THE PRODUCT, WHETHER ARISING IN CONTRACT OR WARRANTY, STATUTE,

TORT, STRICT LIABILITY, NEGLIGENCE, OR OTHERWISE.

Banner Engineering Corp. reserves the right to change, modify or improve the design of the product without assuming any obligations or liabilities relating to any product previously

manufactured by Banner Engineering Corp.

P/N 03541 Rev. E

Banner Engineering Corp., 9714 Tenth Ave. No., Minneapolis, MN USA 55441 • Phone: 763.544.3164 • www.bannerengineering.com • Email: sensors@bannerengineering.com

• Black reinforced thermoplastic polyester

• Includes stainless steel mounting hardware

• 30 mm, 12-gauge, stainless steel, right-angle bracket with curved mounting slots for versatile orientation

• Clearance for M6 (1/4") hardware

• 30 mm swivel bracket

• Black reinforced thermoplastic polyester

• Includes stainless steel mounting and swivel locking hardware

Loading...

Loading...