Page 1

Q45U Ultrasonic Sensors with Analog Outputs (Long Range)

Piezoelectric proximity mode sensors with push-button programming of sensing window limits

• Ultrasonic proximity detection from 0.25 to 3.0 m (9.8 to 118 inches)

• Push-button TEACH-mode programming of sensing window limits

• Digital filtering for exceptional immunity to electrical and acoustic “noise”

• Selectable 0 to 10V dc voltage sourcing or 4 to 20 mA current sourcing analog outputs

• Selectable output slope: positive or negative with increasing target distance

• Wide operating temperature range of –25 to +70 °C; all models include temperature compensation

• Rugged design for use in demanding sensing environments; rated IEC IP67,

NEMA 6P

• Choose models with integral 2 m (6.5 ft) or 9 m (30 ft) cable, or with Mini-style or

Euro-style quick-disconnect fitting

• Input for remote TEACH-mode programming of window limits

Models

Q45ULIU64BCR

Q45ULIU64BCRQ 5-Pin Mini-style QD

Q45ULIU64BCRQ6 5-Pin Euro-style QD

Standard 2 m (6.5 ft) cable models are listed. To order the 9 m (30 ft) cable model, add suffix "W/30" to the cabled model number. For

example, Q45ULIU64BCR W/30. Models with a QD connector require a mating cable.

Temperature

Compensation

Yes

WARNING: Not To Be Used for Personnel Protection

Never use this device as a sensing device for personnel protection. Doing so could lead to serious

injury or death. This device does not include the self-checking redundant circuitry necessary to allow its

use in personnel safety applications. A sensor failure or malfunction can cause either an energized or deenergized sensor output condition.

Cable Supply Voltage Output Type Response Time

2 m (6.5 ft)

15–24V dc

Selectable 0–10V dc or 4–

20 mA sourcing

Adjustable from 80

milliseconds to 2.56

seconds

Temperature Compensation

All models listed above feature temperature compensation. An increase in air temperature shifts both sensing window limits closer to the

sensor. Conversely, a decrease in air temperature shifts both limits further away from the sensor. The shift is approximately 3.5% of the

limit distance for a 20 °C change in temperature.

Temperature compensated models maintain the position of both sensing window limits to within 1% of each limit distance over the 0 to

+50 °C range, and to within 2.5% over the full operating range of from –25 to +70 °C.

Setting the Near and Far Sensing Limits

The Q45U features a single push button for programming of sensing window near and far limits. For more information, refer to Program-

ming the Window Limits on page 4.

Status Indicators

Status indicator LEDs are visible through the transparent, o-ring sealed acrylic top cover. Indicator function in the Run mode is, as follows:

P/N 48456 Rev. E 8/21/2013

Page 2

Limits

N

1 2 3 4 5

3

4

5

1

2

7

Resp.

Speed

+

–

6

1ON2 3 4

Q45U Ultrasonic Sensors with Analog Outputs (Long Range)

• The green LED is solid when power is applied to the sensor and flashes to indicate a current output fault.

• The red LED is solid when an echo is received and flashes at a rate proportional to echo strength.

• The amber LED is solid when the target is within the operating window limits.

The 5-segment moving dot LED indicator displays the relative position of the target within the programmed sensing window. LED #1

flashes when the target is closer than the near limit. LED #5 flashes when the target is beyond the far limit.

1 - Push button for programming sensing window limits

2 - 5-segment target position indicator (N = near)

3 - Green POWER indicator LED

4 - Red SIGNAL indicator LED

5 - Amber OUTPUT indicator LED

6 - Response adjustment

7 - Slots for removing inner cover

Figure 1. Analog Q45U Features

Output Response Settings

Important: Remove power before making any internal adjustments.

Using the two slots shown in Figure 1. Analog Q45U Features on page 2, a small flat-blade screwdriver may be used to lift up and

remove the black inner cover to expose the 4-position DIP switch. Use these DIP switches to program the output slope, output mode,

loss of echo, and min./max. output value default.

DIP Switch Function Settings

1 Output slope On = Output value increases with distance

Off* = Output value decreases with distance

2 Output mode On = Current output enabled

Off* = Voltage output enabled

3 Loss of echo On = Min - Max Mode

4 Min-Max On* = Default to maximum output value

Off* = Hold Mode

Off = Default to minimum output value

* Factory default setting.

2 www.bannerengineering.com - tel: 763-544-3164 P/N 48456 Rev. E

Figure 2. DIP Switches for Q45U Sensors

Page 3

0

Near

Window

Far

Window

10

Target Position

Analog Output (V dc)

Positive

Slope

Voltage/Current-Sourcing Models

4

20

Analog Output (mA)

Q45U Ultrasonic Sensors with Analog Outputs (Long Range)

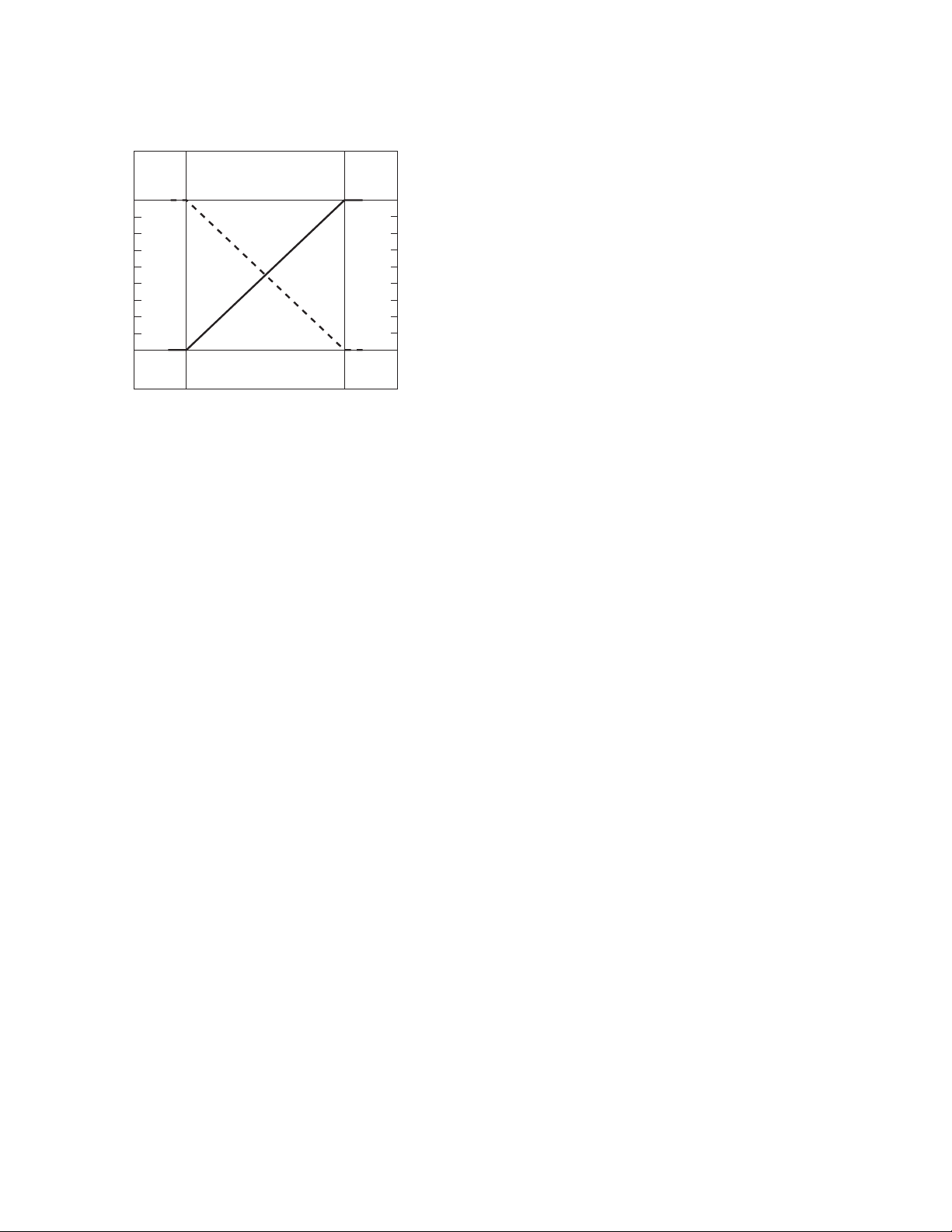

DIP Switch 1: Output Slope Select

Figure 3. Output as a function of target position

On = Direct = Output value (voltage or current) increases with increasing distance of the target from the sensor

Off* = Inverse = Output value decreases with increasing distance

of the target from the sensor

DIP Switch 2: Output Mode Select

On = The 4 to 20 mA current output (white wire) is enabled

Off* = The 0 to 10V dc voltage output (black wire) is enabled

This switch configures the D/A driver to use either the current output or the voltage output driver. This output function can only be set with

the power to the sensor turned off.

DIP Switch 3: Loss of Echo Mode Select

On = Min - Max Mode

Off* = Hold Mode

This switch determines the output response to the loss of echo. The “Hold Mode” (Switch 3 Off*) maintains the output at the value

present at the time of echo loss. The “Min - Max Mode” (Switch 3 On) drives the output to either the minimum value (0V or 4 mA or the

maximum value (10V or 20 mA) when the echo is lost. Minimum or maximum value is selected by DIP switch 4.

DIP Switch 4: Min-Max Default

On* = Default to maximum output value at loss of echo

Off = Default to minimum output value at loss of echo

Switch 4 selects the output response to loss of echo when “Min - Max Mode” is selected by DIP switch 3.

Response Speed Adjustments

The speed of the output response is set using the single-turn potentiometer. There are six values for response speed, which relate directly to the number of sensing cycles over which the output value is averaged. The response value is set by aligning the slot of the potentiometer with one of the marked positions.

P/N 48456 Rev. E www.bannerengineering.com - tel: 763-544-3164 3

Page 4

1

2

3 4

5

6

+

–

Position Response Speed Potentiometer Positions

Q45U Ultrasonic Sensors with Analog Outputs (Long Range)

1 80 milliseconds (2 cycles)

2 160 milliseconds (4 cycles)

3 320 milliseconds (8 cycles)

4 640 milliseconds (16 cycles)

5 1.28 seconds (32 cycles)

6 2.56 seconds (64 cycles)

This example shows the potentiometer set at position number 4. There

Figure 4. Response adjustment positions

are no numbers on the actual product label.

Programming the Window Limits

Use the “Limits” push button, located under the transparent top cover, to program the near and the far limits. The near limit may be set as

close as 250 mm (9.8 inches) and the far limit may be set as far as 3.0 m (118 inches) from the transducer face. Minimum window width

is 25 mm (1 inch). Whenever possible, use the actual target to be sensed when setting the window limits. The following procedure begins

with the sensor in Run mode.

Step Description LED Indicator Status

1 Access Limit Programming Mode. Push and hold until the

green indicator LED turns off (approximately 2 seconds).

2 Set the First Limit (Near or Far). Place the target at the

first limit and press the push button for less than 2 seconds.

Green: Goes off

Amber: Solid on to indicate ready for teaching first limit

Red: Flashes to indicate strength of echo or is off if no target is

present

Green: Remains off

Amber: Flashes at 2 Hz to indicate ready for teaching second

limit

Red: Solid on for a moment, then resumes flashing to indicate

strength of echo

3 Set the Second Limit (Far or Near). Place the target at the

second limit and press the push button for less than 2 seconds

Notes Regarding Window Limit Programming

1. Either the near or far limit may be programmed, first.

2. There is a 2-minute time-out for programming of the first limit. The sensor will return to Run mode with the previously programmed

limits. There is no time-out between programming of the first and second limit.

3. The programming sequence may be cancelled at any time by pressing and holding the push button for ≥ 2 seconds. The sensor

returns to Run mode with the previously programmed limits.

4. During limit programming, the 5-segment moving dot indicator displays the relative target position between 0 and 4.0 m (the maximum recommended far limit position is 3.0 m (118 inches)).

5. If the target is positioned between 3.0 m (118 inches) and 4.0 m, the 5th segment of the moving dot indicator flashes to indicate

that a valid echo is received, but the target is beyond the recommended 3.0 m (118 inches) maximum far limit.

6. If a limit is rejected during either programming step, the sensor will revert to the first limit programming step (Step 2 in programming

chart). This will be indicated by Green - off, Red - flashing to indicate signal strength, and Amber - solid on.

7. If both limits are accepted, the sensor will return to Run mode, which is indicated by the solid on Green LED.

4 www.bannerengineering.com - tel: 763-544-3164 P/N 48456 Rev. E

Green: Remains off, then comes on solid (returns to Run mode)

Amber: Solid on for a moment, then is either on or off to indicate output state (returns to Run mode)

Red: Solid on for a moment, then resumes flashing to indicate

strength of echo (returns to Run mode)

Page 5

Q45U Ultrasonic Sensors with Analog Outputs (Long Range)

8. If the target is held at the same position for programming of both limits, the sensor will establish a 50 mm-wide sensing window,

centered on the target position.

Specifications

Proximity Mode Range

Near limit: 250 mm (9.8 inches) min

Far limit: 3.0 m (118 inches) max

The far limit may be extended as far as 3.9 m for good

acoustical targets (hard surfaces with area > 100 cm²)

Supply Voltage and Current

15 to 24V dc (10% maximum ripple) at 100 mA, exclusive of load

Supply Protection Circuitry

Protected against reverse polarity and transient voltages

Indicators

Three status LEDs:

Green solid = power to sensor is ON

Green flashing = current output fault detected (indi-

cates that the 4-20 mA current path to ground has

been opened)

Amber solid = target is sensed within the window limits

(Amber LED also indicates programming status during

setup mode)

Red flashing = indicates relative strength of received

echo

5-segment moving dot LED indicates the position of the

target within the sensing window

Construction

Molded PBT thermoplastic polyester housing, o-ring

sealed transparent acrylic top cover, and stainless

steel hardware. Q45U sensors are designed to withstand 1200 psi washdown. The base of cabled models

has a 1/2"-14NPS internal conduit thread

Connections

2 m (6.5 ft) or 9 m (30 ft) attached cable, or 5-pin Ministyle or 5-pin Euro-style quick-disconnect fitting

Output Configuration

One voltage sourcing and one current sourcing; one or

the other output is enabled by internal programming

switch #2. Output function may be programmed by a 4position DIP switch located on top of the sensor, beneath the transparent o-ring sealed acrylic cover.

Output Rating

Voltage sourcing: 0 to 10V dc, 10 mA maximum

Current sourcing: 4 to 20 mA, 1 to 500 ohm impedance

Output Protection Circuitry

Both outputs are protected against continuous overload

and short circuit

Performance Specifications

Sensing Repeatability: ±0.1% of the measured distance (±0.50 mm minimum)

Sensing Resolution: 0.50 mm (0.02 in)

Analog Output Resolutions: 2 mV, 3 μA

Environmental Rating

Leakproof design is rated IEC IP67; NEMA 6P

Operating Temperature

Temperature: –25 to +70 °C (–13 to +158 °F)

Maximum relative humidity: 100%

Vibration and Mechanical Shock

All models meet Mil. Std. 202F requirements. Method

201A (Vibration: 10 to 60Hz max., double amplitude

0.06-inch, maximum acceleration 10G). Method 213B

conditions H & I (Shock: 75G with unit operating; 100G

for nonoperation). Also meets IEC 947-5-2 requirements: 30G, 11 ms duration, half sine wave

Application Notes

Minimum target size: 50 mm x 50 mm aluminum plate

at 3.0 m (118")

Remote Programming the Window Limits

Connect the yellow wire of the Analog Q45U to a switch or process controller for remote programming of the sensing window limits. The

programming procedure is the same as for the push button. A remote programming input is generated when +5 to 24V dc is applied to

the yellow wire. The timing diagrams, below, define the required input pulses.

H = +5 to 24V dc

L = <2V dc (or open circuit)

P/N 48456 Rev. E www.bannerengineering.com - tel: 763-544-3164 5

Page 6

Step 1

Access Limit

Programming Mode

Step 2

Set First Limit

(Near or Far)

Step 3

Set Second Limit

(Far or Near)

T T >2 sec

Wait >0.8 seconds

before next input

H

L

T

0.04 sec <T< 0.8 sec

Wait >2 seconds before next input

H

L

T

0.04 sec <T< 0.8 sec

H

L

Lateral Distance

Sensing Distance

4 in

8 in

12 in

16 in

4 in

8 in

12 in

16 in

100 mm

200 mm

300 mm

100 mm

00

200 mm

300 mm

400 mm

400 mm

0 500 mm

20 in

1000 mm

40 in

1500 mm

60 in

2000 mm

80 in

2500 mm

100 in

3000 mm

120 in

3500 mm

140 in

4000 mm

160 in

Lateral Distance

Sensing Distance

4 in

8 in

12 in

16 in

4 in

8 in

12 in

16 in

100 mm

200 mm

300 mm

100 mm

00

200 mm

300 mm

400 mm

400 mm

0 500 mm

20 in

1000 mm

40 in

1500 mm

60 in

2000 mm

80 in

2500 mm

100 in

3000 mm

120 in

3500 mm

140 in

4000 mm

160 in

Q45U Ultrasonic Sensors with Analog Outputs (Long Range)

Notes regarding remote window limit programming:

1. The push button is disabled during remote limit programming. (The remote programming input is disabled during push button pro-

2. Also see the notes regarding window limit programming.

Performance Curves

6 www.bannerengineering.com - tel: 763-544-3164 P/N 48456 Rev. E

Figure 5. Remote programming the window limits

gramming.)

Effective Beam with Plate Target (Typical) Effective Beam with Rod Target (Typical)

Page 7

bn

wh

bu

–

bk

ye or gy

15–24V dc

4 to 20mA

0 to 10V

Remote teach

(+5–24V dc)

Load

Load

+

shield

bn

wh

bu

–

bk

ye

4 to 20mA

0 to 10V

Remote teach

(+5–24V dc)

Load

Load

+

15–24V dc

shield

bn

wh

bu

–

bk

gy

4 to 20mA

0 to 10V

Remote teach

(+5–24V dc)

Load

Load

+

15–24V dc

shield

4

3

1

5

2

2

3

4

1

5

79.4 mm

(3.13")

44.5 mm

(1.75")

69.0 mm

(2.72")

87.6 mm

(3.45")

30.0 mm

(1.18")

Internal Thread: (1/2 NPSM)

External Thread: (M30 x 1.5)

ø6.1 mm (.24")

2 m (6.5') Cable

7.1 mm

(0.28")

4.5 mm (#10) Screw

Clearance (2)

50.3 mm

(1.98")

6.4 mm (0.25")

Transducer

Centerline

Transparent Cover (Gasketed)

View: Sensing Status

Output Load Status

Power

Open to Access:

Push Button for

Programming of Sensing

Window Limits

Hex Nut Supplied

14 mm (0.6")

15 mm (0.6")

Q45U Ultrasonic Sensors with Analog Outputs (Long Range)

Hookup Diagrams for Q45U Sensors with Analog Outputs

Sensor with Attached Cable Sensor with 5-pin Mini-style QD Sensor with 5-pin Euro-style QD

Banner Engineering Corp recommends the

shield wire be connected to earth ground or

dc common.

1 = brown

2 = white

3 = blue

4 = black

5 = yellow

1 = brown

2 = white

3 = blue

4 = black

5 = gray

Dimensions

Cabled Models 5-pin Mini-style QD Models 5-pin Euro-style QD Models

P/N 48456 Rev. E www.bannerengineering.com - tel: 763-544-3164 7

Page 8

7/8-16UN-2B

ø 28 mm max.

(1.1")

61 mm max.

(2.4")

4

3

1

5

2

44 Typ.

ø 14.5

M12 x 1

2

3

4

1

5

32 Typ.

[1.26"]

30 Typ.

[1.18"]

ø 14.5 [0.57"]

M12 x 1

66

56

13

A

B

Q45U Ultrasonic Sensors with Analog Outputs (Long Range)

Accessories

5-Pin Mini-Style Cordsets with Shield

Model Length Style Dimensions Pinout (Female)

MBCC2-506 1.83 m (6 ft)

MBCC2-515 4.57 m (15 ft)

Straight

MBCC2-530 9.14 m (30 ft)

1 = Brown

2 = White

3 = Blue

4 = Black

5 = Yellow

5-Pin Threaded M12/Euro-Style Cordsets with Shield

Model Length Style Dimensions Pinout

MQDEC2-506 1.83 m (6 ft)

MQDEC2-515 4.57 m (15 ft)

Straight

MQDEC2-530 9.14 m (30 ft)

MQDEC2-550 15.2 m (50 ft)

MQDEC2-506RA 1.83 m (6 ft)

MQDEC2-515RA 4.57 m (15 ft)

MQDEC2-530RA 9.14 m (30 ft)

Right-Angle

1 = Brown

2 = White

3 = Blue

4 = Black

5 = Gray

MQDEC2-550RA 15.2 m (50 ft)

SMB30S

• Swivel bracket with 30 mm

mounting hole for sensor

• Adjustable captive swivel

ball

• Black reinforced thermo-

plastic polyester

• 30 mm split clamp, black

• Stainless steel mounting

• Mounting hole for 30 mm

SMB30C

PBT bracket

hardware included

sensor

• Stainless steel mounting

and swivel locking hard-

ware included

Hole center spacing: A=ø 45

Hole size: B=ø 27.2

Hole center spacing: A=ø ##.#

Hole size: A=ø #.#, B=ø ##.#

8 www.bannerengineering.com - tel: 763-544-3164 P/N 48456 Rev. E

Page 9

70

57

A

B

C

57

Q45U Ultrasonic Sensors with Analog Outputs (Long Range)

SMB30MM

• 12-ga. stainless steel

bracket with curved

mounting slots for versatile

orientation

• Clearance for M6 (¼ in)

hardware

• Mounting hole for 30 mm

sensor

Hole center spacing: A = 51, A to B = 25.4

Hole size: A = 42.6 x 7, B = ø 6.4, C = ø 30.1

Banner Engineering Corp Limited Warranty

Banner Engineering Corp. warrants its products to be free from defects in material and workmanship for one year following the date of

shipment. Banner Engineering Corp. will repair or replace, free of charge, any product of its manufacture which, at the time it is returned

to the factory, is found to have been defective during the warranty period. This warranty does not cover damage or liability for misuse,

abuse, or the improper application or installation of the Banner product.

THIS LIMITED WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES WHETHER EXPRESS OR IMPLIED (INCLUDING, WITHOUT LIMITATION, ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE), AND

WHETHER ARISING UNDER COURSE OF PERFORMANCE, COURSE OF DEALING OR TRADE USAGE.

This Warranty is exclusive and limited to repair or, at the discretion of Banner Engineering Corp., replacement. IN NO EVENT SHALL

BANNER ENGINEERING CORP. BE LIABLE TO BUYER OR ANY OTHER PERSON OR ENTITY FOR ANY EXTRA COSTS, EXPENSES, LOSSES, LOSS OF PROFITS, OR ANY INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES RESULTING FROM ANY

PRODUCT DEFECT OR FROM THE USE OR INABILITY TO USE THE PRODUCT, WHETHER ARISING IN CONTRACT OR WARRANTY, STATUTE, TORT, STRICT LIABILITY, NEGLIGENCE, OR OTHERWISE.

Banner Engineering Corp. reserves the right to change, modify or improve the design of the product without assuming any obligations or

liabilities relating to any product previously manufactured by Banner Engineering Corp.

www.bannerengineering.com - tel: 763-544-3164

Loading...

Loading...