Page 1

Q25 Sensors – ac-Voltage Series

P

Self-contained ac-operated sensors

Features

• Featuring EZ-BEAM® technology for reliable sensing without the need for

adjustments

• Rectangular 25 mm plastic housing with 18 mm threaded mounting base in

opposed, retroreflective or fixed-field modes

• Completely epoxy-encapsulated to provide superior durability, even in harsh

sensing environments to IP69K

• Innovative dual-indicator system takes the guesswork out of sensor performance

monitoring

• 20 to 250V ac (3-wire hookup); SPST solid-state switch output, maximum

load 300 mA

Models

Sensing Mode Range LED Output Model*

Opposed

Polarized

Retroreflective

Fixed-Field

20 m (66')

2 m (79")

25 mm (1") cutoff

50 mm (2") cutoff

100 mm (4") cutoff

Infrared

950 nm

Visible Red

680 nm

Infrared

880 nm

–

LO

DO

LO

DO

LO

DO

LO

DO

LO

DO

Q253E

Q25AW3R

Q25RW3R

Q25AW3LP

Q25RW3LP

Q25AW3FF25

Q25RW3FF25

Q25AW3FF50

Q25RW3FF50

Q25AW3FF100

Q25RW3FF100

* Standard 2 m (6.5') cable models are listed.

• 9 m (30') cable: add suffix “W/30” (e.g., Q253E W/30).

• 4-pin Micro-style QD models:

add suffix “Q1” (e.g., Q253EQ1). A model with a QD connector requires a mating cable. (See page 7.)

WARNING . . . Not To Be Used for Personnel Protection

Never use these products as sensing devices for personnel protection. Doing so could lead to serious injury or death.

These sensors do NOT include the self-checking redundant circuitry necessary to allow their use in personnel safety

applications. A sensor failure or malfunction can cause either an energized or de-energized sensor output condition.

Consult your current Banner Safety Products catalog for safety products which meet OSHA, ANSI and IEC standards for

personnel protection.

Printed in USA 01/05 P/N 121517

Page 2

3ENSING

!XIS

2

2

%

R1

R2

Lenses

Object

A

Object B

or

Background

Sensing

Range

Cutoff

Distance

E

Receiver

Elements

Near

Detector

Far

Detector

Emitter

Object is sensed if amount of light at R1

is greater than the amount of light at R2

Q25 Sensors – ac-Voltage Series

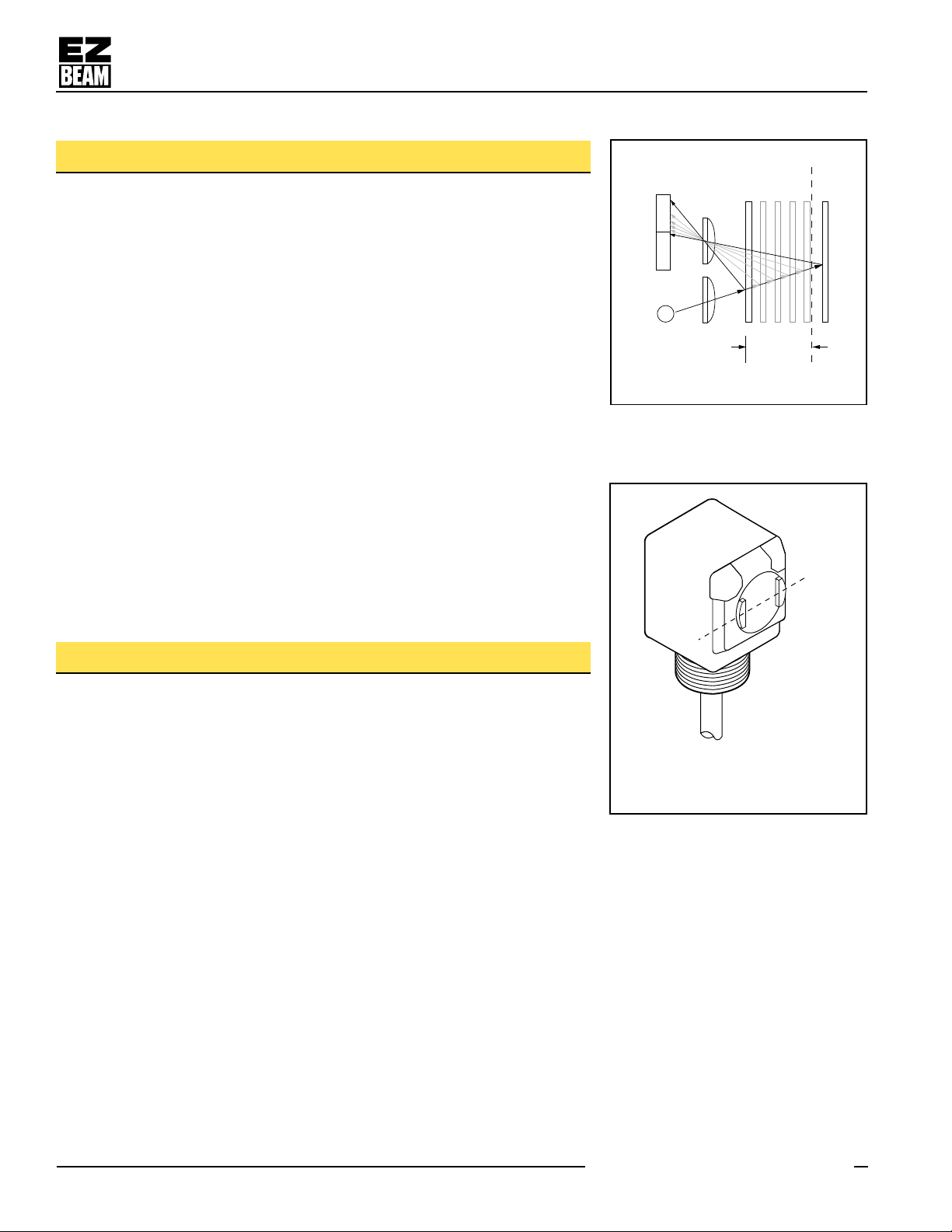

Fixed-Field Mode Overview

Q25 Series self-contained fixed-field sensors are small, powerful, infrared diffuse mode

sensors with far-limit cutoff (a type of background suppression). Their high excess gain

and fixed-field technology allow them to detect objects of low reflectivity, while ignoring

background surfaces.

The cutoff distance is fixed. Backgrounds and background objects must always be placed

beyond the cutoff distance.

Fixed-Field Sensing – Theory of Operation

The Q25FF compares the reflections of its emitted light beam (E) from an object back to the

sensor’s two differently aimed detectors, R1 and R2 (see Figure 1). If the near detector (R1)

light signal is stronger than the far detector (R2) light signal (see object A, closer than the

cutoff distance), the sensor responds to the object. If the far detector (R2) light signal is

stronger than the near detector (R1) light signal (see object B, beyond the cutoff distance),

the sensor ignores the object.

The cutoff distance for model Q25FF sensors is fixed at 25, 50 or 100 millimeters (1", 2",

or 4"). Objects lying beyond the cutoff distance usually are ignored, even if they are highly

reflective. However, it is possible to falsely detect a background object, under certain

conditions (see Background Reflectivity and Placement).

In the drawings and discussion on these pages, the letters E, R1, and R2 identify how the

sensor’s three optical elements (Emitter “E”, Near Detector “R1”, and Far Detector “R2”)

line up across the face of the sensor. The location of these elements defines the sensing

axis (see Figure 2). The sensing axis becomes important in certain situations, such as those

illustrated in Figures 5 and 6.

Figure 1. Fixed-field concept

Sensor Setup

Sensing Reliability

For highest sensitivity, position the target object for sensing at or near the point of

maximum excess gain. The excess gain curves for these products are shown on page 5.

They show excess gain vs. sensing distance for sensors with 25 mm, 50 mm, and 100 mm

(1", 2", and 4") cutoffs. Maximum excess gain for the 25 mm models occurs at a lens-toobject distance of about 7 mm; for 50 mm models, at about 10 mm; and for the 100 mm

models, at about 20 mm. Sensing at or near this distance will make maximum use of

each sensor’s available sensing power. The background must be placed beyond the cutoff

distance. (Note that the reflectivity of the background surface also may affect the cutoff

distance.) Following these two guidelines will improve sensing reliability.

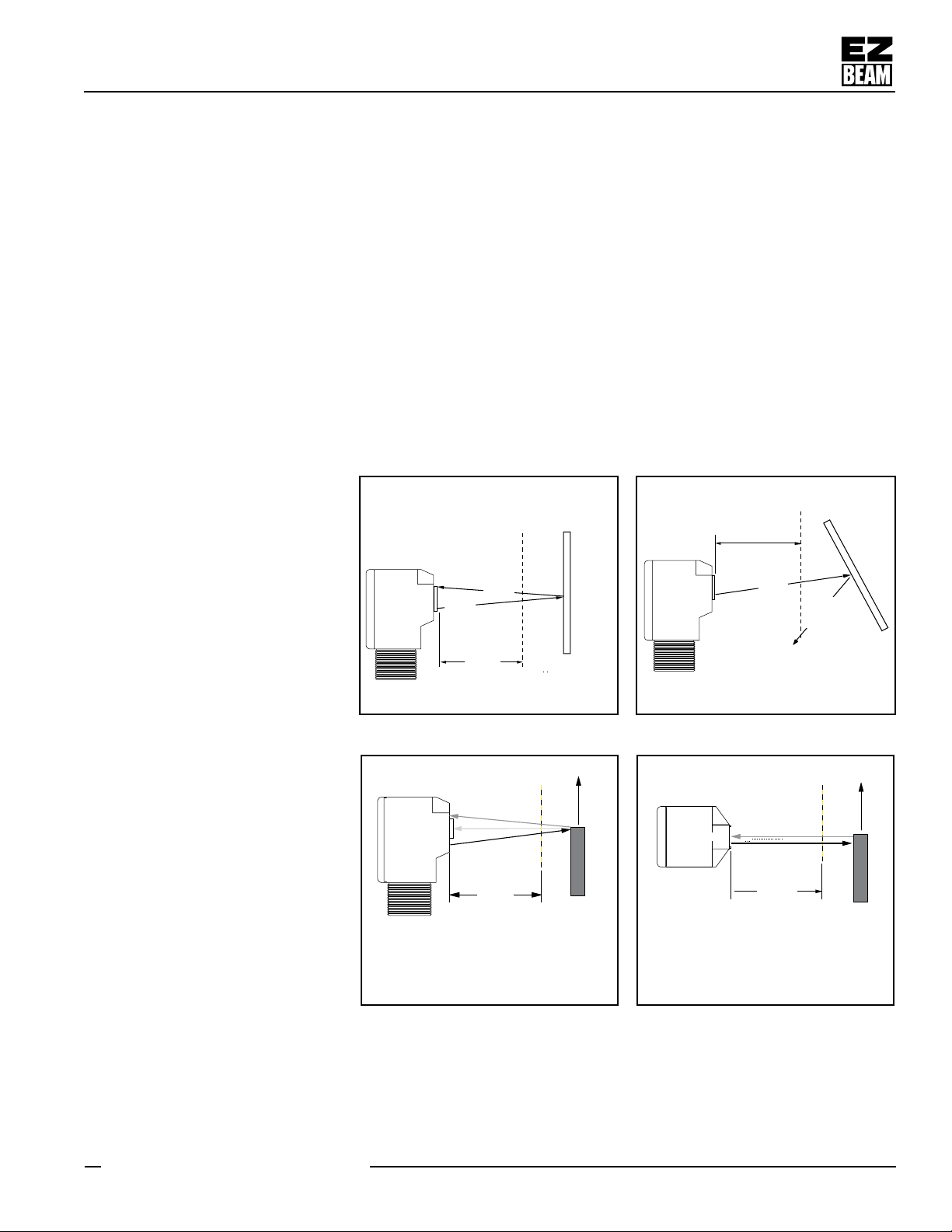

Background Reflectivity and Placement

Avoid mirror-like backgrounds that produce specular reflections. False sensor response will

occur if a background surface reflects the sensor’s light more strongly to the near detector,

or “sensing” detector (R1) than to the far detector, or “cutoff” detector (R2). The result

is a false ON condition (Figure 3). To cure this problem, use a diffusely reflective (matte)

background, or angle either the sensor or the background (in any plane) so the background

does not reflect light back to the sensor (see Figure 4). Position the background as far

beyond the cutoff distance as possible.

An object beyond the cutoff distance, either stationary (and when positioned as shown in

Figure 5), or moving past the face of the sensor in a direction perpendicular to the sensing

axis, can cause unwanted triggering of the sensor if more light is reflected to the near detector than to the far detector. The problem is easily remedied by rotating the sensor 90° (Figure

6). The object then reflects the R1 and R2 fields equally, resulting in no false triggering. A

better solution, if possible, may be to reposition the object or the sensor.

2 P/N 121517

As a general rule, the most reliable

sensing of an object approaching from the

side occurs when the line of approach is

parallel to the sensing axis.

Figure 2. Fixed-field sensing axis

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 3

1&&

%

2

2

%%MITTER

2.EAR$ETECTOR

2&AR$ETECTOR

&IXED

3ENSING

&IELD

3TRONG

$IRECT

2EFLECTION

TO2

#OREOF

%MITTED

"EAM

#UTOFF

$ISTANCE

2EFLECTIVE

"ACKGROUND

2 .EAR$ETECTOR

2 &AR$ETECTOR

% %MITTER

%

2

2

2EFLECTIVE

"ACKGROUND

OR

-OVING/BJECT

&IXED

3ENSING

&IELD

#UTOFF

$ISTANCE

1&&

22%

2 .EAR$ETECTOR

2 &AR$ETECTOR

% %MITTER

1&&

&IXED

3ENSING

&IELD

#UTOFF

$ISTANCE

2EFLECTIVE

"ACKGROUND

OR

-OVING/BJECT

%

2

2

1&&

%%MITTER

2.EAR$ETECTOR

2&AR$ETECTOR

&IXED3ENSING&IELD

3TRONG$IRECT

2EFLECTION

!WAY

&ROM3ENSOR

#OREOF

%MITTED

"EAM

#UTOFF

$ISTANCE

2EFLECTIVE

"ACKGROUND

Q25 Sensors – ac-Voltage Series

Color Sensitivity

The effects of object reflectivity on cutoff distance, though small, may be important for

some applications. It is expected that at any given cutoff setting, the actual cutoff distance

for lower reflectance targets will be slightly shorter than for higher reflectance targets (see

Figure-of-Merit information on page 5). This behavior is known as color sensitivity.

For example, an excess gain of 1 (see page 5) for an object that reflects 1/10 as much light

as the 90% white card is represented by the horizontal graph line at excess gain = 10. An

object of this reflectivity results in a far limit cutoff of approximately 20 mm (0.8") for the

25 mm (1") cutoff model for example; thus 20 mm represents the cutoff for this sensor and

target.

These excess gain curves were generated using a white test card of 90% reflectance.

Objects with reflectivity of less than 90% reflect less light back to the sensor, and thus

require proportionately more excess gain in order to be sensed with the same reliability as

more reflective objects. When sensing an object of very low reflectivity, it may be especially

important to sense it at or near the distance of maximum excess gain.

Figure 3. Reflective background – problem Figure 4. Reflective background – solution

A reflective background object in this position or

moving across the sensor face in this axis and

direction may cause false sensor response.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

P/N 121517 3

Figure 5. Object beyond cutoff – problem Figure 6. Object beyond cutoff – solution

A reflective background object in this position or

moving across the sensor face in this axis will be

ignored.

Page 4

Q25 Sensors – ac-Voltage Series

Specifications

Supply Voltage and

Current

Supply Protection

Circuitry

Output Configuration

Output Rating 300 mA maximum (continuous)

Output Protection

Circuitry

Output Response Time Opposed mode: 16 milliseconds ON, 8 milliseconds OFF

Repeatability Opposed mode: 2 milliseconds

Indicators

Construction

Environmental Rating

Connections

Operating Conditions Temperature: -40° to +70° C (-40° to +158° F)

Vibration and Mechanical

Shock

Certifications

20 to 250V ac (50/60 Hz)

Average current: 20 mA

Peak current: 200 mA @ 20V ac, 500 mA @ 120V ac, 750 mA @ 250V ac

Protected against transient voltages

SPST solid-state ac switch; three-wire hookup; light operate or dark operate, depending on model

Light Operate: Output conducts when sensor sees its own (or the emitter’s) modulated light

Dark Operate: Output conducts when the sensor sees dark

Fixed-Field models: derate 5 mA/°C above +50° C (122° F)

Inrush capability: 1 amp for 20 milliseconds, non-repetitive

OFF-state leakage current: < 100 microamps

ON-state saturation voltage: 3V @ 300 mA ac; 2V @ 15 mA ac

Protected against false pulse on power-up

Other models: 16 milliseconds ON and OFF

NOTE: 100 millisecond delay on power-up

Other models: 4 milliseconds

Repeatability and response are independent of signal strength

Two LEDs (Green and Yellow)

Green ON steady:

Yellow ON steady: sensor sees light

Yellow flashing: excess gain marginal (1 to 1.5x) in light condition

PBT polyester housing; polycarbonate (opposed-mode) or acrylic lens

Leakproof design rated NEMA 6P, DIN 40050 (IP69K)

2 m (6.5') attached cable or 4-pin Micro-style quick-disconnect fitting

Maximum relative humidity: 90% at 50° C (non-condensing)

All models meet Mil. Std. 202F requirements. Method 201A (Vibration; frequency 10 to 60 Hz, max., double

amplitude 0.06" acceleration 10G). Method 213B conditions H&I (Shock: 75G with unit operating; 100G for

non-operation)

power to sensor is ON

; outputs do not conduct during this time.

4 P/N 121517

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 5

25 m

(82')

20 m

(66')

15 m

(49')

10 m

(32')

5 m

(16')

0

0

500 mm

1000 mm

1500 mm

500 mm

1000 mm

1500 mm

0

20"

40"

60"

20"

40"

60"

DISTANCE

Q25 Series

Opposed Mode

2.5 m

(8.0')

2.0 m

(6.4')

1.5 m

(4.8')

1.0 m

(3.2')

0.5 m

(1.6')

0

0

50 mm

100 mm

150 mm

50 mm

100 mm

150 mm

0

2"

4"

6"

2"

4"

6"

DISTANCE

Q25 Series

Polarized Retro

with BRT-3 Reflector

1

10

100

1 m

(3.3')

10 m

(33')

100 m

(330')

0.1 m

(0.33')

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

Q25 Series

Opposed Mode

1

10

100

0.1 m

(0.33')

1 m

(3.3')

10 m

(33')

0.01 m

(0.033')

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

Q25 Series

Polarized Retro

with BRT-3 Reflector

1

10

100

1 mm

(0.04")

10 mm

(0.4")

100 mm

(4")

0.1 mm

(0.004")

E

X

C

E

S

S

G

A

I

N

DISTANCE

1000

Q25 Series

Fixed-field mode

with 25 mm far

limit cutoff

1

10

100

1 mm

(0.04")

10 mm

(0.4")

100 mm

(4")

0.1 mm

(0.004")

E

X

C

E

S

S

G

A

I

N

DISTANCE

1000

Q25 Series

Fixed-field mode

with 50 mm far

limit cutoff

1

10

100

1 mm

(0.04")

10 mm

(0.4")

100 mm

(4")

0.1 mm

(0.004")

E

X

C

E

S

S

G

A

I

N

DISTANCE

1000

Q25 Series

Fixed-field mode

with 100 mm far

limit cutoff

Q25 Sensors – ac-Voltage Series

Performance Curves

Excess Gain Beam Pattern

OpposedPolarized Retro

††

††

Performance based on use of a model BRT-3 retroreflector (3" diameter).

Actual sensing range may be more or less than specified, depending on the

efficiency and reflective area of the retroreflector used.

Performance based on use of a 90% reflectance white test card.

Ø 10 mm spot size @ 8 mm focus

Ø 10 mm spot size @ 25 mm cutoff

†

Using 18% gray test card: Cutoff

distance will be 95% of value shown.

†

Using 6% black test card: Cutoff

distance will be 90% of value shown.

Fixed-Field – 25 mm

Excess Gain

Ø 10 mm spot size @ 10 mm focus

Ø 10 mm spot size @ 50 mm cutoff

†

Using 18% gray test card: Cutoff

distance will be 90% of value shown.

†

Using 6% black test card: Cutoff

distance will be 85% of value shown.

Fixed-Field – 50 mm

Ø 10 mm spot size @ 20 mm focus

Ø 10 mm spot size @ 100 mm cutoff

†

Using 18% gray test card: Cutoff

distance will be 85% of value shown.

†

Using 6% black test card: Cutoff

distance will be 75% of value shown.

Fixed-Field – 100 mm

†

Focus and spot sizes are typical.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

P/N 121517 5

Page 6

bn

bu

bk

20-250V ac

Load

12.7 mm

(0.50")

Green LED

Power Indicator

Yellow LED

Output Indicator

25.0 mm

(0.98")

35.0 mm

(1.38")

30.0 mm*

(1.18")

12.4 mm

(0.49")

(Jam Nut Supplied)

Lens Centerline

15.2 mm

(0.60")

M18 x 1 Thread

2 m (6.5') Cable

*Fixed-field models = 31.0 mm (1.22")

20-250V ac

No Connection

rd/wh

rd/bk

rd

gn

bn

bu

20-250V ac

20-250V ac

No Connection

Load

rd/wh

rd

rd/bk

gn

Q25 Sensors – ac-Voltage Series

Dimensions

Cabled Models

Cabled Emitters

QD Models

Hookups

QD Emitters

(4-pin Micro-Style)

All Other Cabled Models

All Other QD Models

(4-pin Micro-Style)

6 P/N 121517

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 7

ø 1/2-20UNF-2B

ø15 mm

(0.6")

44 mm max.

(1.7")

38 mm max.

(1.5")

1/2-20UNF-2B

ø 15 mm

(0.6")

38 mm max.

(1.5")

Green Wire

Red/Black

Wire

Red/White

Wire

Red Wire

Q25 Sensors – ac-Voltage Series

Quick-Disconnect (QD) Cables

Style Model Length Dimensions Pinout

4-pin

Micro-style

Straight

4-pin

Micro-style

Right-angle

MQAC-406

MQAC-415

MQAC-430

MQAC-406RA

MQAC-415RA

MQAC-430RA

2 m (6.5')

5 m (15')

9 m (30')

2 m (6.5')

5 m (15')

9 m (30')

WARRANTY: Banner Engineering Corp. warrants its products to be free from defects for

one year. Banner Engineering Corp. will repair or replace, free of charge, any product of its

manufacture found to be defective at the time it is returned to the factory during the warranty

P/N 121517

Banner Engineering Corp., 9714 Tenth Ave. No., Minneapolis, MN USA 55441 • Phone: 763.544.3164 • www.bannerengineering.com • Email: sensors@bannerengineering.com

period. This warranty does not cover damage or liability for the improper application of

Banner products. This warranty is in lieu of any other warranty either expressed or implied.

Loading...

Loading...