Page 1

PVA Pick-to-Light Array

Light screen for error-proofing of bin-picking operations

• Compact package, available in 4 lengths to fit many sizes and configurations of existing

parts bins

• Range up to 2 m (6.5 ft)

• Two-component system (asynchronous emitter and receiver) needs no sync wire or controller box.

• Emitters and receivers sold separately or in pairs for easy ordering.

• Two LEDs on each emitter and receiver indicate proper setup and system errors.

• Clearly visible green job indicator lights mounted on either side of emitter and receiver

housings; the light can be remotely controlled to initiate user action with a solid ON or

blinking condition

• Two frequency settings to prevent crosstalk in close-proximity, multiple-array installations

• Easy DIP-switch selection of light/dark operate, solid/flashing job light, A/B frequency,

and gate polarity for activating the job light indicator.

• Choose 2 m (6.5 ft) unterminated cable or 2 m (6.5 ft) cable with 4-pin Euro-style quickdisconnect connector.

• PNP or NPN receiver output, depending on model

• 12 to 30V dc operation

• Minimum resolution 35 mm (1.4 in)

• Wide beam pattern for easy alignment

• Heavy-duty protective brackets available

WARNING: Not To Be Used for Personnel Protection

Never use this device as a sensing device for personnel protection. Doing so could lead to serious

injury or death. This device does not include the self-checking redundant circuitry necessary to allow its

use in personnel safety applications. A sensor failure or malfunction can cause either an energized or deenergized sensor output condition.

Models

1

Model

PVA100N6 Emitter/Receiver Pair

PVA100N6R Receiver

PVA100P6 Emitter/Receiver Pair

PVA100P6R Receiver

NOTE: Additional models on the next page.

Description Array Length / # Beams Job Light Input

100 mm (4 in) Long, 5

Beams

2

Receiver Output

0V dc NPN (Sinking)PVA100N6E Emitter

+5 to 30V dc PNP (Sourcing)PVA100P6E Emitter

1

Only cabled models (2 m (6.5 ft) unterminated integral cable) are listed. For 2 m (6.5 ft) pigtail with Euro-style Quick-disconnect fitting, add "Q" to the model number (for example,

PVA100N6Q).

2

See Configuration on page 5

P/N 52088_web

Rev. E

5/1/2013

Page 2

PVA Pick-to-Light Array

3

Model

Description Array Length / # Beams Job Light Input

PVA225N6 Emitter/Receiver Pair

PVA225N6R Receiver

PVA225P6 Emitter/Receiver Pair

PVA225P6R Receiver

PVA300N6 Emitter/Receiver Pair

PVA300N6R Receiver

PVA300P6 Emitter/Receiver Pair

PVA300P6R Receiver

PVA375N6 Emitter/Receiver Pair

PVA375N6R Receiver

PVA375P6 Emitter/Receiver Pair

225 mm (9 in) Long, 5

Beams

300 mm (12 in) Long, 13

Beams

375 mm (15 in) Long, 16

Beams

4

Receiver Output

0V dc NPN (Sinking)PVA225N6E Emitter

+5 to 30V dc PNP (Sourcing)PVA225P6E Emitter

0V dc NPN (Sinking)PVA300N6E Emitter

+5 to 30V dc PNP (Sourcing)PVA300P6E Emitter

0V dc NPN (Sinking)PVA375N6E Emitter

+5 to 30V dc PNP (Sourcing)PVA375P6E Emitter

PVA375P6R Receiver

NOTE: Cable diameter is 3.3 mm (0.13 in) on all models.

Overview

The PVA Series Parts Verification Array is a simple, easy-to-use light screen suited to many part assembly and object detection applications.

The PVA has two components: an emitter and a receiver. The receiver's solid-state output interfaces to a system controller, which is preprogrammed by a supervisor for a specific sequence of tasks. Mounted so that the beams stretch across each bin in an assembler’s work

station, the PVA then signals the assembler (by means of easy-to-see job lights) which bins contain items to be picked in a given operation and in what order they should be picked.

As the assembler reaches into each bin, the system senses if the correct part has been taken, then signals the next bin in the sequence.

The system may be wired to signal an alarm for the assembler and/or a supervisor in the event an incorrect part is selected.

The major benefit of a PVA-driven system is increased efficiency, due to simplified job training, increased quality control (no skipped

components), and reduced rework and inspections. The PVA speeds the resumption of work after breaks and other distractions. And it is

ideal for multilingual workplaces where communication may be an issue.

3

Only cabled models (2 m (6.5 ft) unterminated integral cable) are listed. For 2 m (6.5 ft) pigtail with Euro-style Quick-disconnect fitting, add "Q" to the model number (for example,

PVA100N6Q).

4

See Configuration on page 5

2 www.bannerengineering.com - tel: 763-544-3164 P/N 52088_web

Rev. E

Page 3

MODE

Emitter

Receiver

Receiver

Emitter

MODE

MODE

Emitter

Receiver

MODE

Receiver

Emitter

Receiver

Emitter

MODE

MODE

Emitter

Receiver

0

0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

25020015010050

Sensor Separation – Y

(Meters)

Horizontal Misalignment

Vertical Misalignment

Maximum Off-axis Distance – X

(Millimeters)

X

Y

X

Y

PVA Pick-to-Light Array

Installation

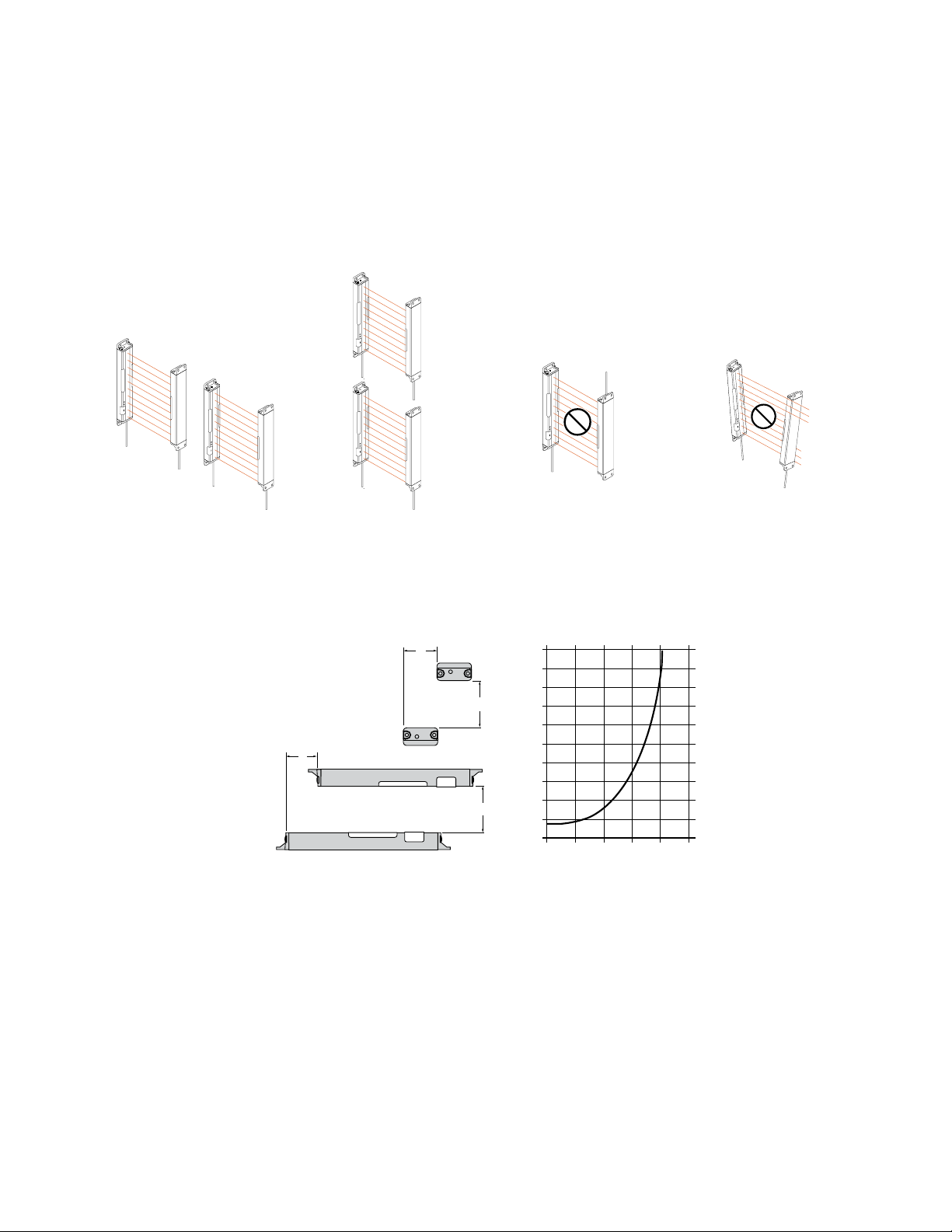

Multiple sensor pairs located farther than the sensor's effective maximum range (approximately 2 m or 6.5 ft) from one another are unlikely to cause crosstalk problems. However, when multiple sensor pairs are mounted in a confined area, take care to avoid crosstalk between them. To avoid crosstalk:

• Alternate the relative position of adjacent emitter/receiver pairs.

• Alternate the Frequency configuration of adjacent pairs.

Mount emitter and receiver pairs parallel, with both cable ends pointing the same direction.

Figure 1. Example—Correct Positions

Figure 3. Maximum Off-Axis Misalignment

Cable ends pointing in opposite directions

Figure 2. Example—Incorrect Positions

Non-parallel orientation

P/N 52088_web

Rev. E

www.bannerengineering.com - tel: 763-544-3164 3

Page 4

MODE

bn

wh

+

-

bu

12-30V dc

Job Light

Enable*

bn

wh

+

-

bk

bu

12-30V dc

Job Light

Enable*

bn

bu

-

+

bk

wh

12-30V dc

Job Light

Enable*

Load

bn

bu

-

+

bk

wh

12-30V dc

Job Light

Enable*

Load

PVA Pick-to-Light Array

Mounting

The wide beam pattern of PVA emitters and receivers simplifies their alignment. M4 stainless

steel fasteners and two stainless steel brackets are included with each sensor.

Mount each emitter and its corresponding receiver parallel to one another in the same plane, with

their cable ends pointing the same direction, and their tops and bottoms aligned.

1. From a common point of reference, make measurements to locate the emitter and receiver

in the same plane with their midpoints directly opposite each other.

2. Mount the included brackets to the top and bottom of each sensor, as shown.

3. Mount the emitter and receiver in their brackets, being careful to position the red lenses of

the two units directly facing each other. (Remember, the cable ends of both sensors must

point in the same direction to ensure proper sensing.)

4. Measure from one or more reference planes (for example, the building or bin floor) to the

same point(s) on the emitter and receiver to verify their mechanical alignment. (If the sensors are mounted exactly vertical or horizontal, a carpenter’s level may be helpful. A

straightedge or a string extended between the sensors may also be helpful.)

5. Also check “by eye” for line-of-sight alignment.

6. Make any necessary final mechanical adjustments, and hand-tighten the bracket hardware.

7. After the electrical hookup is complete, check for beam alignment. If necessary, re-align the

emitter and receiver at that time.

Figure 4. PVA Mounting Hard-

ware

Hookups

All models feature integral 2 m (6.5 ft) long, 3.3 mm (0.13 inch) dia. PVC-jacketed cables. Models whose model numbers end in “Q” are

terminated with quick-disconnect (QD) Euro-style 4-pin connectors; other models have unterminated ends.

Emitter with Unterminated Cable

Receiver with NPN (Sinking) Output Receiver with PNP (Sourcing) Output

Wiring is functionally identical for cabled and quick-disconnect receiver models.

* See Configuration on page 5 for job light enable input requirements.

Emitter with 4-Pin Euro QD

NOTE: Blue wire (dc common) is internally connected to emitter and receiver housings.

4 www.bannerengineering.com - tel: 763-544-3164 P/N 52088_web

Rev. E

Page 5

1 2 3 4

O

F

F

O

N

ON

OFF

Example Shown:

Switch #1 OFF

Switch #2 ON

Switch #3 OFF

Switch #4 ON

PVA Pick-to-Light Array

Configuration

PVA configuration is accomplished using the DIP switches on the emitter and receiver as shown. When setting the DIP switches, use the

supplied plastic screwdriver to avoid damaging the switches or causing a short circuit.

Cover Removal Cover Replacement

Insert a fingernail or small screwdriver into

the slot; apply gentle pressure, angling

To replace the switch cover, align one edge of the cover with the edge of the sensor

housing opening. Then press the front corners into place.

away from the sensor lens. The cover will

remain tethered to the sensor housing.

The switches determine four status operating modes:

• A/B frequency (to avoid crosstalk from multiple pairs of sensors)

• Light/dark operate

• Solid/flashing job light (depending on assembler and/or supervisor preference)

• Gate polarity

PVA Configuration DIP Switch Settings

*default settings

Switch Emitter Receiver

5

1

*ON = Frequency A

OFF = Frequency B

2

3

No function ON = Light operate

*ON = Job light steady

OFF = Job light flashes

*ON = Frequency A

OFF = Frequency B

*OFF = Dark operate

*ON = Job light steady

OFF = Job light flashes

Figure 5. Configuration DIP switch setting posi-

tions

5

Both emitter and receiver must be set to the same frequency in order to operate.

P/N 52088_web

Rev. E

4

Job light control input: connect the white wire of the emitter and

receiver as follows:

Models PVA...P6

ON = Job light ON for +5 to 30V dc (27K input impedance)

*OFF = Job light ON for 0 to 2V dc/open circuit

Models PVA...N6

ON = Job light ON for +5 to 30V dc/open circuit

*OFF = Job light ON for 0 to 2V dc (10K input impedance)

www.bannerengineering.com - tel: 763-544-3164 5

Page 6

MODE

Status Indicator #1

Status Indicator #2

PVA Pick-to-Light Array

Status Indicators/Troubleshooting

Figure 6. Status indicators

Emitter Indicator Condition Description

#1 OFF Frequency A selected (Emitter/Receiver Switch #1 both ON)

Steady Red Frequency B selected (Emitter/Receiver Switch #1 both OFF)

#2 Steady Green Power is ON and system is OK

OFF Power is OFF

Flashing Green 2x/sec Emitter Failure (remove and reapply power)

Receiver Indicator Condition Description

#1 Steady Yellow Output is active (change Switch #2 to Light Operate to turn the yellow indicator ON

when the system is clear)

OFF Output is inactive (change Switch #2 to Dark Operate to turn the yellow indicator

ON when the system is blocked)

#2 Steady Green Power is ON and system is OK

OFF Power is OFF

Flashing Green 1x/sec Receiver Failure (remove and reapply power)

6 www.bannerengineering.com - tel: 763-544-3164 P/N 52088_web

Rev. E

Page 7

PVA Pick-to-Light Array

Specifications

Supply Voltage and Current

12 to 30V dc (10% max. ripple) at less than 62 mA for

the emitter and 50 mA for the receiver (exclusive of

load)

Supply Protection Circuitry

Protected against reverse polarity

Sensing Range

2 m (6.5 ft) with 2x excess gain remaining

Sensing Height

100 mm (3.9 in), 225 mm (8.9 in), 300 mm (11.8 in), or

375 mm (14.8 in), depending on emitter and receiver

models

Beam Spacing

25.0 mm (0.98 in)

Sensing Resolution

35 mm (1.4 in) minimum diameter

Output Configuration

Receivers have one solid-state dc output, programmable for light or dark operate:

Models PVA...N6R have current sinking (NPN) opencollector transistor

Models PVA...P6R have current sourcing (PNP) opencollector transistor

Output Rating

150 mA maximum

OFF-state leakage current: less than 2 microamps

ON-state saturation voltage: less than 1V dc at 10

mA and less than 1.5V dc at 100 mA

Output Protection

Protected against false pulse on power-up and continuous overload or short circuit of output

Status Indicators

Emitter: Green—power ON/OFF; Red—frequency se-

lected

Receiver: Green—power ON/OFF; Yellow—output

state

Emitter and Receiver: Two highly visible job lights

turn ON and OFF in response to an external signal to

the white wire. Job lights may be configured for steady

or flashing green.

Construction

Black painted aluminum housing; acrylic lenses; PBT

end caps; thermoplastic elastomer programming switch

cover; stainless steel mounting brackets and hardware

Connections

Emitter: 3-conductor PVC-jacketed 2 m (6.5 ft) cable

which is either unterminated or terminated with a 4-pin

Euro-style quick-disconnect connector, depending on

model. Cable diameter is 3.3 mm (0.13 in).

Receiver: 4-conductor PVC-jacketed 2 m (6.5 ft) cable

which is either unterminated or terminated with a 4-pin

Euro-style quick-disconnect connector, depending on

model. Cable diameter is 3.3 mm (0.13 in).

Environmental Rating

NEMA 2; IEC IP62

Operating Temperature

0 °C to +50 °C (+32 °F +122 °F)

Maximum Off-axis Misalignment

See Figure 3. Maximum Off-Axis Misalignment on page

3

Certifications

Output Response Time

Sensor Size Standard With Crosstalk from Adjacent Units

100 mm 20 ms 30 ms

225 mm 40 ms 60 ms

300 mm 52 ms 78 ms

375 mm 64 ms 96 ms

P/N 52088_web

Rev. E

www.bannerengineering.com - tel: 763-544-3164 7

Page 8

MODE

Job Lights

15.0 mm

(0.59")

30.0 mm

(1.18")

Status Indicator 2

Status Indicator 1

Configuration Switch Cover

Cable

18.0 mm

(0.71")

ø4.45 mm

(0.175")

Beam 1Beam 2Beam 3

25.0 mm

(0.98")

25.0 mm

(0.98")

Beams Continue at

25.0 mm Spacing

15.0 mm

(0.59")

L2

71.8 mm

(2.83")

43.2 mm

(1.70")

L1

3.9 mm

(0.15")

40.6 mm

(1.60")

6.0 mm

(0.24")

6.0 mm

(0.24")

20.1 mm

(0.79")

18.0 mm

(0.71")

4 x ø4.6 mm

(0.18")

6.1 mm

(0.24")

2.0 mm

(0.08")

4 x R2.54

(0.10")

10.2 mm

(0.40")

10.2 mm

(0.40")

5.0 mm

(0.20")

5.0 mm

(0.20")

2 x 4.8 mm

(0.19")

22.9 mm

(0.90")

PVA Pick-to-Light Array

Dimensions

Emitter and Receiver

Model Number of Beams L

1

L

2

PVA100.. 5 130.0 mm (5.12 in) 137.8 mm (5.43 in)

PVA225.. 10 258.5 mm (10.18 in) 266.4 mm (10.49 in)

PVA300.. 13 333.5 mm (13.13 in) 341.4 mm (13.44 in)

PVA375.. 16 408.5 mm (16.09 in) 416.6 mm (16.40 in)

SMBPVA1 Standard Bracket (2 Included with PVA) Hardware Included with Each Sensor (kit part

number 50532)

Qty Description

4 Stainless steel Phillips panhead ma-

chine screws (M4 x 0.7 x 12)

4 Stainless steel hex nuts (M4 x 0.7)

4 Stainless steel lock washers (M4 x 0.7)

1 Plastic screwdriver (3.6 cm/1.4 in long)

8 www.bannerengineering.com - tel: 763-544-3164 P/N 52088_web

Rev. E

Page 9

44 Typ.

ø 14.5

M12 x 1

2

3

4

1

SMBPVA..A SMBPVA..ABSMBPVA..

35.6 mm

(1.40 in.)

19.3 mm

(0.76 in.)

L

35.6 mm

(1.40 in.)

19.3 mm

(0.76 in.)

L

35.6 mm

(1.40 in.)

19.3 mm

(0.76 in.)

L

PVA Pick-to-Light Array

Accessories

Cordsets

4-Pin Threaded M12/Euro-Style Cordsets

Model Length Style Dimensions Pinout

MQDC-406 1.83 m (6 ft)

MQDC-415 4.57 m (15 ft)

MQDC-430 9.14 m (30 ft)

MQDC-450 15.2 m (50 ft)

Brackets

NOTE: Standard SMBPVA1 mounting brackets are included with each PVA System. The following brackets

are in addition to the standard brackets.

SMBPVA2

• Set of 4 molded brackets

• Snaps onto standard 28

mm diameter pipe

• 2 required per sensor

Straight

1 = Brown

2 = White

3 = Blue

4 = Black

SMBPVA.., SMBPVA..A, SMBPVA..AB

• Protects sensor from impact

• Provides DIP-switch and/or indicator light exposure (depending on

model)

• Heavy-duty cold-rolled steel-zinc finish

Models DIP Switch Access Light Protected Length (L) Used With

SMBPVA5 Yes No

139.7 mm PVA100SMBPVA5A Yes Yes

SMBPVA5AB No Yes

SMBPVA10 Yes No

P/N 52088_web

Rev. E

SMBPVA10AB No Yes

www.bannerengineering.com - tel: 763-544-3164 9

268.2 mm PVA225SMBPVA10A Yes Yes

Page 10

PVA Pick-to-Light Array

Models DIP Switch Access Light Protected Length (L) Used With

SMBPVA13 Yes No

343.3 mm PVA300SMBPVA13A Yes Yes

SMBPVA13AB No Yes

SMBPVA16 Yes No

418.2 mm PVA375SMBPVA16A Yes Yes

SMBPVA16AB No Yes

Banner Engineering Corp Limited Warranty

Banner Engineering Corp. warrants its products to be free from defects in material and workmanship for one year following the date of

shipment. Banner Engineering Corp. will repair or replace, free of charge, any product of its manufacture which, at the time it is returned

to the factory, is found to have been defective during the warranty period. This warranty does not cover damage or liability for misuse,

abuse, or the improper application or installation of the Banner product.

THIS LIMITED WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES WHETHER EXPRESS OR IMPLIED (INCLUDING, WITHOUT LIMITATION, ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE), AND

WHETHER ARISING UNDER COURSE OF PERFORMANCE, COURSE OF DEALING OR TRADE USAGE.

This Warranty is exclusive and limited to repair or, at the discretion of Banner Engineering Corp., replacement. IN NO EVENT SHALL

BANNER ENGINEERING CORP. BE LIABLE TO BUYER OR ANY OTHER PERSON OR ENTITY FOR ANY EXTRA COSTS, EXPENSES, LOSSES, LOSS OF PROFITS, OR ANY INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES RESULTING FROM ANY

PRODUCT DEFECT OR FROM THE USE OR INABILITY TO USE THE PRODUCT, WHETHER ARISING IN CONTRACT OR WARRANTY, STATUTE, TORT, STRICT LIABILITY, NEGLIGENCE, OR OTHERWISE.

Banner Engineering Corp. reserves the right to change, modify or improve the design of the product without assuming any obligations or

liabilities relating to any product previously manufactured by Banner Engineering Corp.

Loading...

Loading...