Page 1

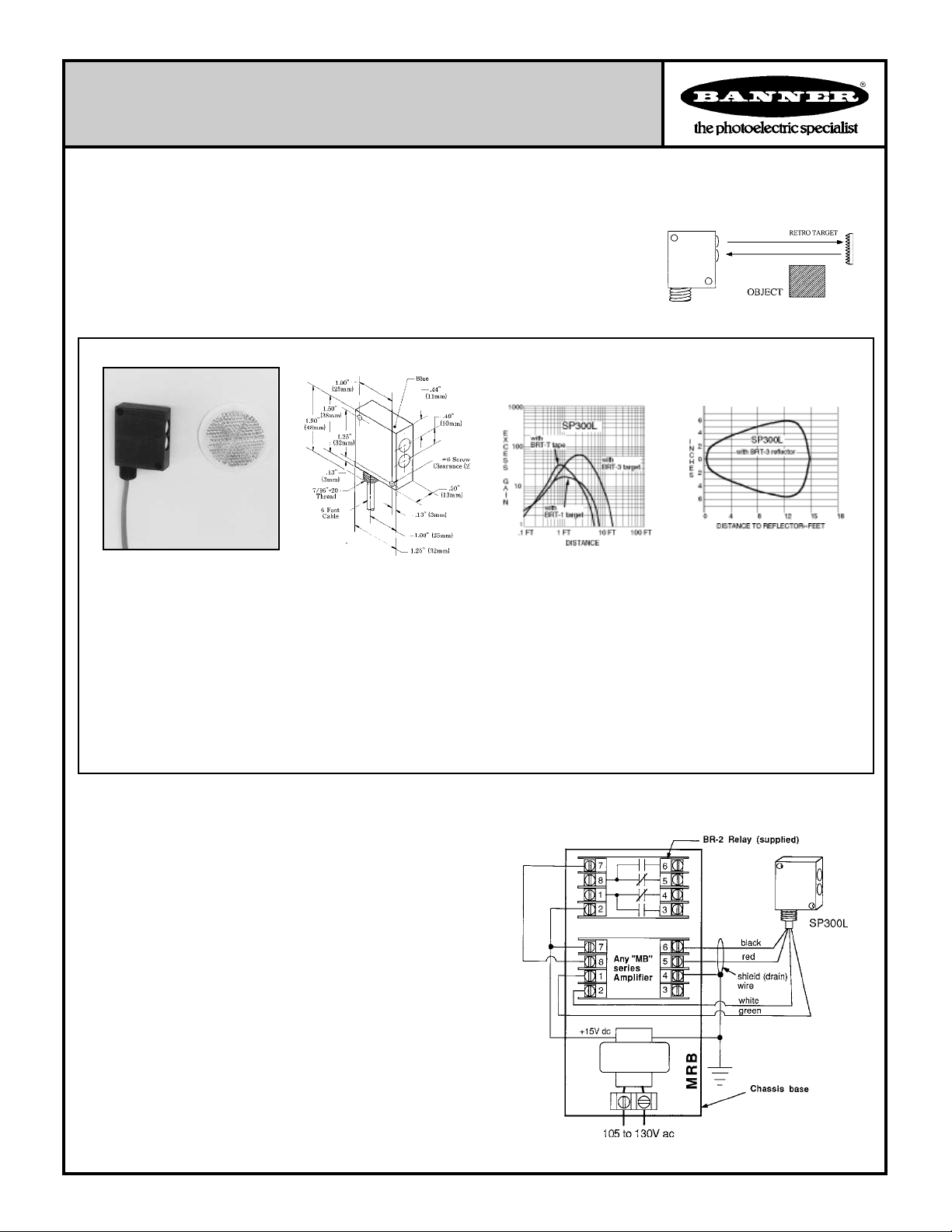

SP300L

Model SP300L is a rugged, totally encapsulated infrared remote retroreective sensor with a range of up to 15' (minimum range 6").

The SP300L is fully encapsulated and is supplied with 6 feet of 4-conductor PVC-covered cable. Units may be washed down without

damage.

This sensor is designed for use with Banner MICRO-AMP® system MA3-4 and MA3-4P

modulated ampliers, MAXI-AMP™ system CM Series modulated ampliers, and MB Series

ampliers.

Application Note: if the object being sensed is shiny, the SP300L should be mounted at an angle

of 10 degrees or more to that surface in order to eliminate false signals ("proxing"). For best

results, use the SP300L with the model BRT-3 3" diameter corner-cube retroreector (see excess

gain curve).

Retroreective Mode Remote Sensor

Specications, SP300L

RANGE: up to 15 feet with BRT-3 reector (minimum range 6")

RESPONSE SPEED: a function of the amplier (see below)

OPERATING TEMPERATURE: -40 to +80° C (-40 to +176°

F)

EMITTER CHARACTERISTICS: infrared LED, 940nm

CONSTRUCTION: totally encapsulated, hermetically sealed

lenses. Anodized aluminum housing; NEMA 1, 3, 4, 12, and 13.

CABLE: sensors are supplied with 6' 4-wire PVC-covered cable.

30' cables are available by special order.

Hookup to MB Series Ampliers

Banner remote sensors will connect to any MB series amplier. The

model MRB chassis (shown) has octal sockets for the amplier and a

BR-2 relay (supplied) and provides power for the sensors and amplier. Up to four sensor pairs may be connected to one amplier for

light-operated OR or dark operated AND operation. In multiple-sensor

hookups, receivers are wired in parallel and emitters are connected in

series (see example for CM Series modules, next page).

Several MB series ampliers are available. Each provides a different

output logic function. Chassis models with additional octal sockets

are also available. Other types of output devices, including solid state

relays, may be ordered (see Banner catalog).

EXCESS GAIN CURVE

BEAM PATTERN

Wiring rules:

1) Avoid running remote sensor cables in wireways together with

power-carrying conductors.

2) Avoid running remote sensor cables through areas of known ex-

treme electrical interference (electrical "noise").

3) Always use shielded cables and only connect the shield ("drain")

wire at the amplier.

4) When splicing, never combine emitter and receiver wires into a

common cable. (The result will be electrical "crosstalk" within the

cable, which causes a "lock-on" condition of the amplier.)

Specications, MB Series Ampliers

POWER SUPPLY REQUIREMENT: 12-18V dc at less than 100mA,

exclusive of load.

OUTPUT CONFIGURATION: open collector NPN transistor; maximum

on-state current 250mA, maximum off-state leakage current 100 microamps.

RESPONSE SPEED: 1 millisecond ON and OFF.

MAXIMUM SENSOR LEAD LENGTH: 100 feet (30m) maximum;

use separate shielded cables for emitter and receiver.

OPERATING TEMPERATURE RANGE: 0 to +50°C (+32 to +122° F).

Printed in USA

P/N 03387C4B

Page 2

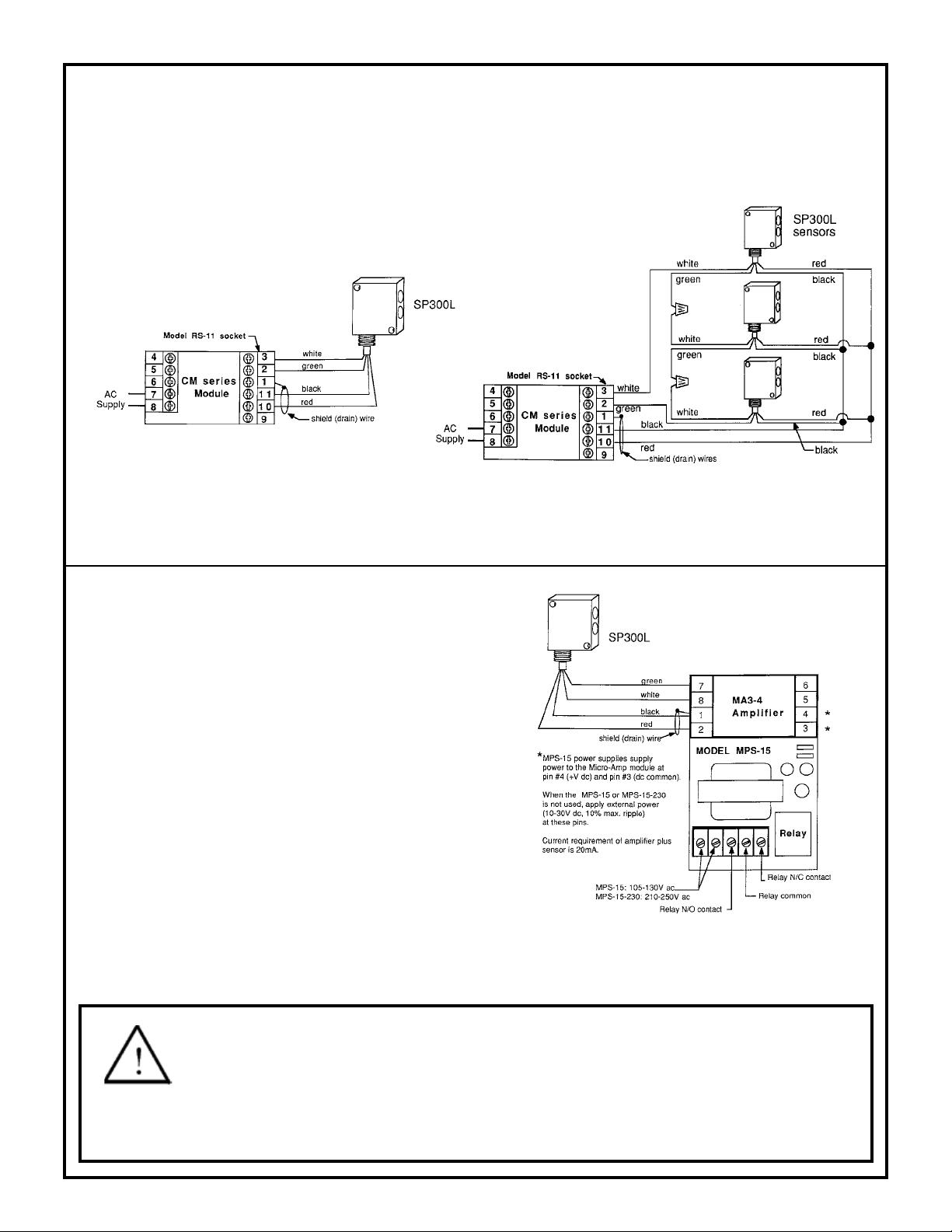

Hookup to MAXI-AMP™ CM Series Modules

CM Series modules combine power supply, modulated photoelectric

amplier, timing logic (CM5 models), and output relay in a single

compact module. Only an 11-pin relay socket (Banner model RS-11)

is needed to complete the system.

The CM Series contains models with or without programmable timing

logic and with either electromechanical or solid-state relay outputs. See

the Banner product catalog for further information.

Up to three sensors may be connected to each amplier. Light- operated

OR logic (input to module occurs whenever at least one receiver sees

"light") or dark-operated AND logic (input to module occurs when all

receivers simultaneously see "dark") is possible.

NOTE: to power the MAXI-AMP from a DC power supply, connect

+12 to 28V dc at ≥70mA to terminal #3 and DC common to terminal

#1. Make no connections to terminal #7 or #8.

To Multiple Sensors

To a Single Sensor

When wiring two sensors to one

MAXI-AMP, multiply excess gain

data (from excess gain curve) for

each sensor by 1/2; when wiring

three sensors to one MAXI-AMP,

multiply excess gain by 1/3.

Specications, MAXI-AMP CM Series Modules

RESPONSE SPEED: programmable for 10, 2, or 0.3 milliseconds (10 millisecond setting enhances noise rejection).

MAXIMUM SENSOR LEAD LENGTH: 50' (15m) maximum.

To avoid "cable crosstalk", use separate shielded cable for emitter and receiver, or order sensors with extended cable length.

OPERATING TEMPERATURE RANGE: 0 to +50 degrees C (+32 to +122 degrees F).

Hookup to MICRO-AMP® Modules

MICRO-AMP amplier module models MA3-4 and MA3-4P may

be used with this sensor. Model MA3-4 has complementary current

sinking outputs. Model MA3-4P has complementary current sourcing outputs.

Model MA3-4 (but not model MA3-4P) may be powered by the model

MPS-15 power supply, as shown in the hookup diagram (right). The

MPS-15 includes a socket for the MA3-4 and has a built-in SPDT

output relay (switchable by the MA3-4 module).

MICRO-AMP modules may also be mounted in a model RS8 wiring

socket and powered from a "remote" power supply. PVC mounting

track is available in 6" and 12" lengths to accommodate multiple MICRO-AMP system components.

NOTE: only one SP300L may be connected to each amplier.

Specications, MICRO-AMP MA3-4 & MA3-4P

POWER SUPPLY REQUIREMENT: 10-30V dc at less than 20mA; 10% maximum

ripple (obtainable from MPS-15 power supply--see above).

OUTPUT CONFIGURATION: model MA3-4 has two open-collector NPN (current sinking) transistor solid state switches, one normally open, one normally closed.

150mA max. each output. Model MA3-4P has two PNP (sourcing) outputs, 150mA

max. each.

RESPONSE SPEED: 1 millisecond ON and OFF.

MAXIMUM SENSOR LEAD LENGTH: 30' (9m).

OPERATING TEMPERATURE RANGE:

-40 to +70 degrees C (-40 to +158 degrees F).

WARNING These photoelectric presence sensors and ampliers do NOT include the self-checking redundant circuitry necessary

to allow their use in personnel safety applications. A sensor or amplier failure or malfunction can result in either an energized or a

de-energized sensor output condition.

Never use these products as sensing devices for personnel protection. Their use as safety devices may create an unsafe condition which

could lead to serious injury or death.

Only MACHINE-GUARD and PERIMETER-GUARD Systems, and other systems so designated, are designed to meet OSHA and ANSI machine safety

standards for point-of-operation guarding devices. No other Banner sensors or controls are designed to meet these standards, and they must NOT be used

as sensing devices for personnel protection.

Banner Engineering Corporation 9714 10th Ave. No., Minneapolis, MN 55441 Tel. (612) 544-3164 FAX (orders): (612) 544-3213 FAX (Applications): (612) 544-3573

Loading...

Loading...