Page 1

Vision Sensors & Lighting

THIRD EDITION

®

Page 2

New models to solve your toughest inspection challenges.

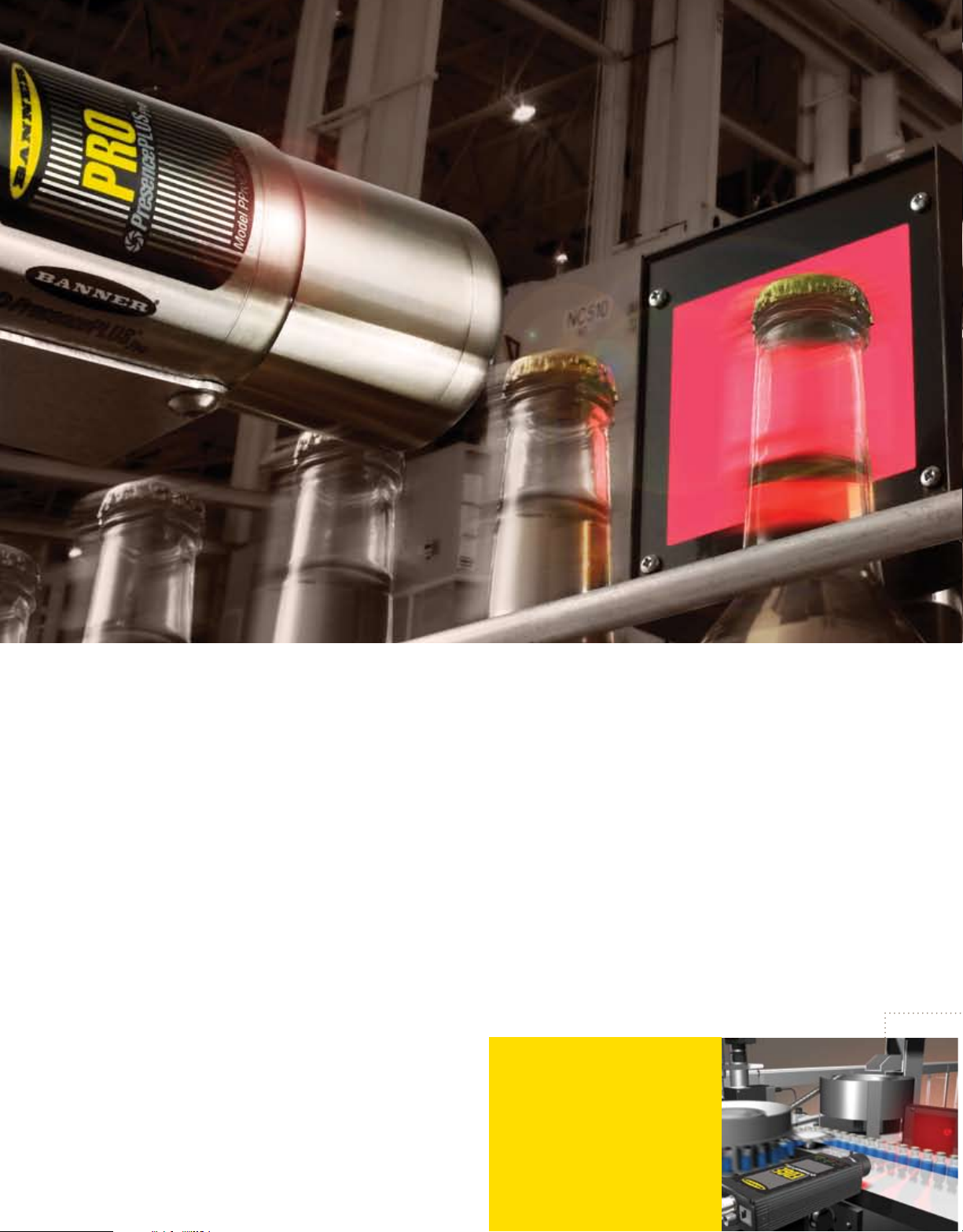

PresencePLUS® Pro & P4 COLOR

Ruggedized Pro Cameras & Lights

P4 OMNI

Offers color sensing in two

convenient packages.

Page 8

Delivers all the functionality

and features of advanced vision

into harsh IP68 environments.

Page 6

Bar Code Reading

Lighting

A compact, integrated vision

sensor with features for the

most demanding applications.

Page 16

Decodes 2D and 1D linear bar

codes in the toughest lowlight/low-contrast conditions.

Page 10

Offers a complete selection

of basic and specialty lighting

solutions to enhance vision

capabilities.

Page 30

2

Page 3

Contents

When the world thinks of sensors,

it thinks of Banner.

With more than 17,000 photoelectric,

ultrasonic and vision sensors, and safety

products available worldwide, Banner is the

most innovative, most experienced name in

sensors. For simple to complex applications,

Banner has more sensor solutions than any

other manufacturer.

The innovation leader with more

than 40 years of sensor development and

application expertise, Banner understands

the challenges of sensing in manufacturing

and process industries. Banner has more

than 3,000 factory and eld representatives

worldwide, as well as the largest force of

application engineers in the industry who

solve thousands of the most challenging

applications every year.

PresensePLUS Vision Sensing 4

Machine Vision Solutions 6

Color Analysis Solutions 8

ID, Bar Code and Traceability Solutions 10

PresensePLUS Software & Inspection 12

PresensePLUS Features Comparision 14

PresensePLUS Pro and P4 OMNI 16

P4 Dedicated-Function Sensors 18

Pro Sensors & Kits 20

P4 Sensors & Kits 22

Specications 24

Hookups & Dimensions 26

System Selection & Integration 28

Lighting Selection Guide 30

Lenses 39

Brackets 40

Monitors & Indicators 43

Cables & Cordsets 44

Interface Modules 46

Power Supplies 46

3

Page 4

OPPOSED

RETROREFLECTIVE

Advanced vision solutions from the number one name in sensors.

)PSJ[POUBM

'07

8PSLJOH

%JTUBODF

7FSUJDBM

'07

Vision sensing from the source you trust.

As the prefered brand of sensors worldwide, Banner

knows the challenges of the factory oor. That’s why we

designed our line of PresencePLUS® vision sensors from

the ground up, with advanced features, easier setup and

operation, rugged design, the most value of any vision

systems in the market and, most of all, Banner reliability

and support.

A complete solution.

From a single inspection point to plant-wide vision

integration, Banner oers complete vision solutions. Vision

sensing has two major elements: hardware—the camera,

controller, lighting and brackets; and software— the control

system, graphical user interface and image algorithms.

Banner provides all of the elements to successfully deploy

vision sensing in your facility.

Visual Inspection Process

1. Acquire an image of the part.

2. Analyze the image.

Determine if the inspection passes or fails, and report the

3.

results to the manufacturing line. The part then either passes

to the next process or is rejected and removed.

1. Sensor: The sensor contains the imager, microprocessor and

I/O. The imager has an array of tiny light-sensitive cells (pixels)

that convert the target into an image. The microprocessor

analyzes the image and makes determinations about it based

on user-determined tolerances and criteria. The sensor

exports the inspection results through some type of I/O,

such as discrete, Ethernet or serial.

The lens focuses the light onto the sensor’s

2. Lens:

imager. To determine the lens focal length for an

applications, specify the field of view and

working distance.

3. Light Source:

The light source is a critical

component of any vision inspection system. Lighting is

the most powerful tool for creating contrast to amplify

the feature of interest, while minimizing other features of the

part. Selecting the best light source depends on the shape,

surface texture, color and opacity of the part.

Opposed Mode

Proximity Mode

4

Part Light Source Lens Imager Sensor

Process the image,

make a decision

ACQUIRE ANALYZE DETERMINE

Output

Results

Backlight Ring Dome Directional Low-angle On-axis

Page 5

Aordable sensing technology

that’s easy to use.

The best value in vision.

• The best price-performance ratio brings full vision

capabilities to all sensor speciers.

• Simple, easy-to-use interface.

• Easy to justify cost for multiple applications.

• No software maintenance fees—free rmware &

PC software upgrades.

• Hundreds of lens and lighting options.

• Superior in-house manufacturing and quality.

The easiest-to-use vision sensors available.

• Easy, menu-driven, point and click interface.

• Remote TEACH input similar to a photoelectric sensor.

• Simple inspection changeovers.

• Live video display without a PC.

• User interface software that allows setup and

seamless operation in nine languages.

“ The substantially lower cost of

the Banner vision sensor makes

it feasible to set up more

inspection systems.”

–Major automotive manufacturer

“ One of the most benecial, yet

simple, advantages of the Banner

vision sensor was its TEACH tool.

This tool was extremely valuable

for eliminating guess work and

applying the statistical variation.”

–Automotive engineer

The best vision sensor performance.

• Inspection speeds faster than 10,000 parts per minute.

• Full 360° xture-free inspection.

• Locates inspection detail, regardless of orientation.

• Solves the most applications in your plant.

• Full suite of grayscale, color and binary vision tools.

More sensors, more solutions,

more customer support.

• Superior vision products from the leader in sensing.

• More than 17,000 photoelectric, ultrasonic and vision

sensors available worldwide.

• Experienced factory application engineers to solve your

most advanced sensing challenges.

• More than 3,000 trained factory and eld representatives

worldwide.

• Complete factory training, eld training and online training.

• Helps you achieve 100% quality inspection and zero

defect manufacturing.

“ The PresencePLUS® vision sensor

not only saved time and freed up

our quarantined product, it provided a level of documentation.”

–Metal stampings manufacturer

“ I appreciate the level of expertise

the eld rep showed with the

PresencePLUS sensors and how

he has helped me with other

dicult applications in the past.”

–Major consumer goods

manufacturer

5

Page 6

Machine vision made simple.

Robust inspection solutions. With more

advanced capabilities.

From simple verication to complex inspection,

Banner has the most powerful and aordable vision

systems and sensors, built to perform in high-speed

manufacturing and production environments. Banner

provides an alternative to costly, complex machine

vision systems with proven, easy-to-use and aordable

self-contained vision sensors for real-world applications.

Select the PresencePLUS® Pro which incorporates

remote cameras paired with powerful controller units

featuring 11 location, vision and analysis tools. Or,

choose the versatile new, self-contained PresencePLUS

Banner Machine Vision

P4 OMNI with easy TEACH setup. To deploy the precise

inspection capability where you need it, select from

four PresencePLUS P4 series vision sensors with dedicated

functionality.

Banner machine vision solutions are available in

standard resolution and high-resolution 1.3 megapixel

models for more detailed inspections, as well as sealed,

IP68-rated models for rugged industrial and washdown

environments. P4 models are available in both in-line

and right-angle congurations. These options, as well

as a complete selection of Banner lenses, lighting and

brackets, provide complete, high-speed inspection

capabilities in the vast majority of applications.

6

EXAMPLE APPLICATIONS

Page 7

Add inspection capabilities where you need them. PresencePLUS® Pro and P4

vision sensors integrate easily into existing production systems to provide new

levels of quality control, error proong and verication.

Vial Fill Level and Cap Seal Verication

To rapidly verify that vials are lled to the correct level and that caps are

correctly aligned, a high-speed PresencePLUS P4 EDGE vision sensor

locates the vial and veries the ll level and cap placement.

Food Packaging Error Proong

Each unit of pastry dough is inspected by a PresencePLUS

P4 AREA vision sensor to detect the presence of a frosting

packet—ensuring that one is included in each package.

Rivet Inspection

Following installation of a rivet into each corner of an

automobile steering wheel horn frame assembly, the

component passes beneath a PresencePLUS Pro vision

sensor to verify the presence and quality of each rivet.

A high-resolution PresencePLUS P4 EDGE 1.3 vision sensor combines with

a laser line to inspect the beveled gum wedge of continuously extruded

rubber. The laser line bends at the bevel, allowing a cost-eective twodimensional vision sensor to perform a three-dimensional measurement.

Stamped Metal Pin Inspection

To verify the quantity, pitch and straightness of connector

pins on a stamped metal subassembly, the high-resolution

PresencePLUS P4 OMNI 1.3 vision sensor counts the number of

connector pins, simultaneously detecting irregular gaps that

indicate pins are bent or missing.

Page 8

Color Vision Sophistication. Banner Simplicity. Banner’s PresencePLUS® Pro COLOR

and P4 COLOR vision sensors combine with the comprehensive suite of PresencePLUS

inspection tools to deliver an easy-to-apply, color-based vision inspection solution of

extraordinary sophistication for signicantly less than comparable systems.

8

Page 9

Color Solutions

Unlimited color spectrum analysis

for your most challenging applications.

For inspection features best examined by spectral analysis, Banner offers

solutions designed to meet your requirements and fit your machinery. The new onepiece PresencePLUS® P4 COLOR OMNI and the compact PresencePLUS® Pro COLOR

sensor with a separate DIN-mountable controller offer two powerful platforms for

color vision applications—with all of the robust inspection tools and capabilities of

their gray scale counterparts.

PresencePLUS Pro COLOR and P4 COLOR OMNI vision sensors inspect unlimited

color variations visible in the camera’s field of view. Shape and color data can be

combined to identify minute variations and color consistency can be monitored within

a taught range of acceptable color.

Combining intuitive PresencePLUS software, remote TEACH for rapid configuration

and a precision 752 x 480 pixel resolution color CMOS imager, PresencePLUS Pro

COLOR and P4 COLOR OMNI vision sensors inspect for a specific color or color range

taught to the sensor with the Color Match tool. All models include the powerful suite

of gray scale vision tools—including Locate, Pattern Find and Count, Geometric Find

and Count, Edge, Object, Blob and Average Gray Scale—that deliver extraordinary

precision and versatility, for the most demanding inspections.

EXAMPLE APPLICATIONS

Candy Color Inspection

A PresencePLUS P4 COLOR OMNI mounted above a conveyor inspects each

box of 12 chocolates, making sure each paper nest contains the correct type,

based on color. It rejects boxes that have the wrong chocolate in a nest, are

missing product or have damaged product.

Color Inspection and Vericatio

A PresencePLUS Pro COLOR vision sensor veries that pour spouts inserted

into detergent bottles are present, fully inserted and of the correct color to

match the bottle. The IP68 sealed housing protects the sensor and light

from liquids.

Automotive Fuse Box Error Proong

To verify that fuses of the specied amperage are placed in the correct location

in an automotive fuse box assembly, a PresencePLUS Pro COLOR vision sensor

using a Banner White Area Light provides fast and easy error proong.

Comprehensive Blister Pack Inspection

Tightened federal regulations require critical quality controls in pharmaceutical packaging. A PresencePLUS Pro COLOR vision sensor under a Banner

Tubular Fluorescent Light inspects blister packs to ensure each blister

contains the correct tablet, veries each tablet is unbroken, and detects

empty blisters or those containing foreign matter.

Cap and Fill Inspectio

As glass bottles pass on a high-speed conveyor, a PresencePLUS P4 COLOR

OMNI conrms each bottle is completely lled, while verifying the stopper

is fully inserted and is the correct color. Dual Banner Area Lights bracket

directly to the sensor to create the optimum contrast for the inspection.

n

n

9

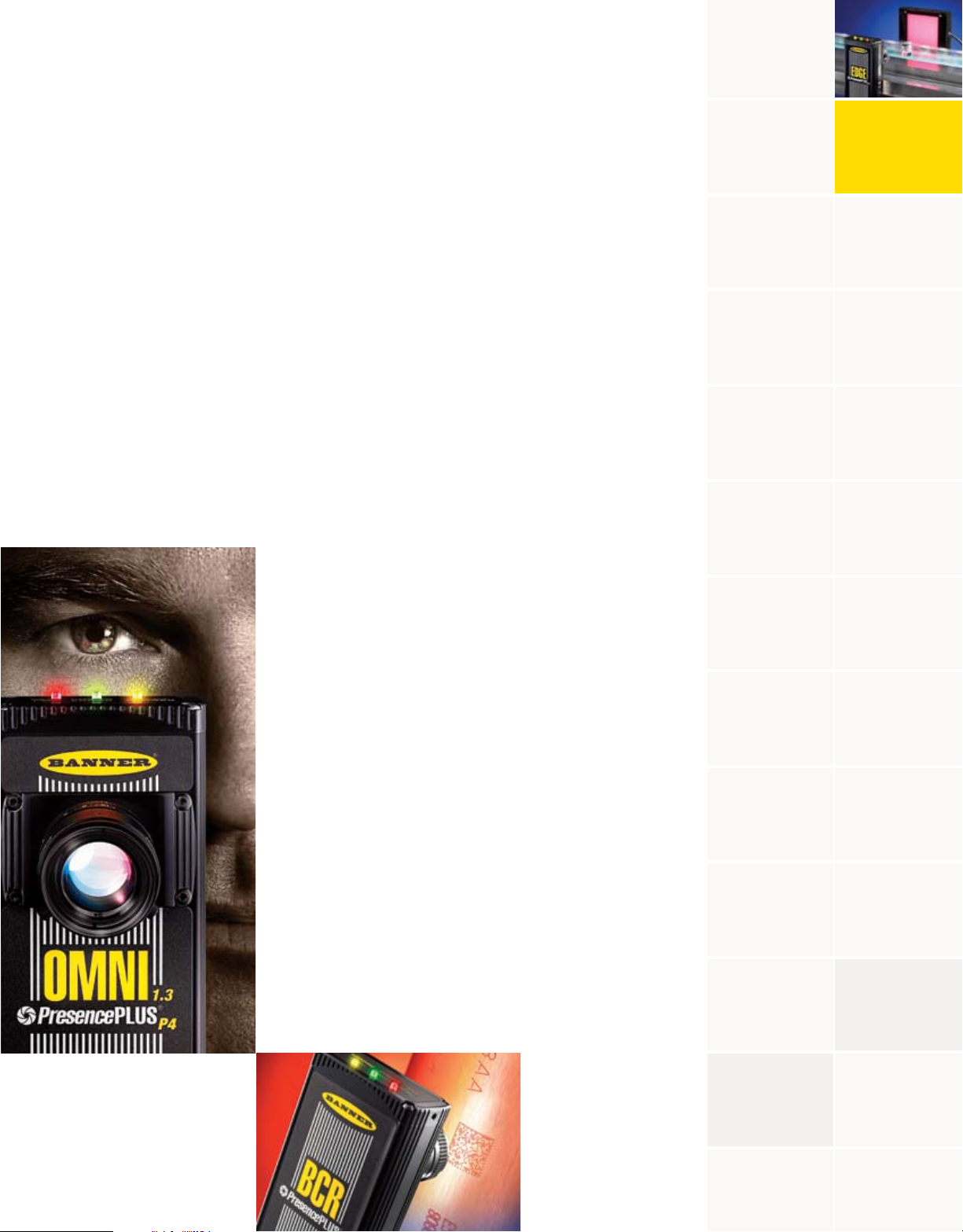

Page 10

ID, Bar Code and Traceability Solutions

EXAMPLE APPLICATIONS

Accurately reads and grades 2D and 1D bar codes.

A traceability program is only as successful as the vision sensor that reads 2D or

1D bar codes under plant conditions. That’s why major manufacturers depend on the

industry’s most reliable sensor expert for their vision needs. Banner’s PresencePLUS® Pro

and P4 OMNI with optional bar code reading software offer tremendous power and

flexibility, for accurate high-speed bar code reading in the toughest environments.

The PresencePLUS® P4 BCR and high-resolution BCR 1.3 vision sensors have been

developed from the ground up for the most robust 2D and 1D linear bar code reading

capabilities—even when conditions and codes are less than ideal.

Whether for production traceability of direct-marked manufactured components or

to verify product lots for consumer goods, Banner PresencePLUS sensors are engineered

to oer the highest read rates in low contrast/poor visibility conditions, or where marked

or formed bar codes have degraded. The BCR is “taught” the correct codes, either with

the sensor itself or over an industrial Ethernet network (EIP or Modbus TCP/IP). Banner’s

dedicated BCR solutions keep lines moving by reading despite problems such as low

contrast, shadows, orientation, surface variations or marking variables resulting from

degraded etching, stamping or printing.

BCR models read 2D Data Matrix ECC200 and 1D linear bar codes such as

Code 39, Code 128, Codabar, Interleaved 2 of 5, EAN-8 and EAN-13 (supports UPC-A),

UPC-E and Postnet. High-resolution BCR 1.3 models (1280 x 1024 pixels) feature 1.3

megapixel imaging that reads and grades smaller bar codes, or allows larger fields of

view. Codes and code grades can be communicated using the BCR’s serial port.

2D Stamped Bar Code Verication

Manufacturing lots can be tracked for quality assurance using a PresencePLUS Pro

bar code reader to detect and verify a subtle 2D bar code stamped into metal

parts. Advanced 2D capabilities and a Banner Low-Angle Ring Light facilitate

detection of bar codes subject to stamping quality variables.

Simultaneous Verication of Two Bar Code

The high-resolution PresencePLUS P4 BCR 1.3 delivers an extended eld of view to

read 1D linear and 2D bar codes simultaneously to verify components in an

assembly are correctly paired. Strobed ring lighting and 1.3 megapixel resolution

provide increased image repeat rates for accurate reading at full line speed.

Large Area Verication for Sorting and Die Protection

The dies in tire presses suer costly damage if the press tries to stamp tread into an

unstamped, or green, tire of the wrong size. To direct each tire to the correct press

at production line speeds, a series of six high-resolution PresencePLUS P4 BCR 1.3

vision sensors sort green tires based on bar code data printed on a label on the

tire’s bead, regardless of position or orientation.

Miniature Bar Code Vericatio

The advanced functionality of the PresencePLUS P4 BCR reads and veries

miniaturized symbology, such as 2D bar codes, on small electronic components.

A Banner Backlight through the semi-transparent circuit membrane optimizes

contrast of the code for optimal reading conditions at high line speeds.

Pharmaceutical Product ID and Lot Contro

Federal pharmaceutical product identication and lot control requirements are

both stringent and evolving. The PresencePLUS Pro gives you the power and

exibility to future-proof inspection, verication and tracking capabilities.

n

s

l

10

Page 11

Part traceability using direct-marked 2D Data Matrix bar codes

demands extraordinary levels of reliable performance from code

reading tools. With a proven foundation of industrial sensor reliability,

Banner’s PresencePLUS® P4 BCR sensors handle the toughest 2D and

1D bar code reading chores at the highest throughput rates.

11

Page 12

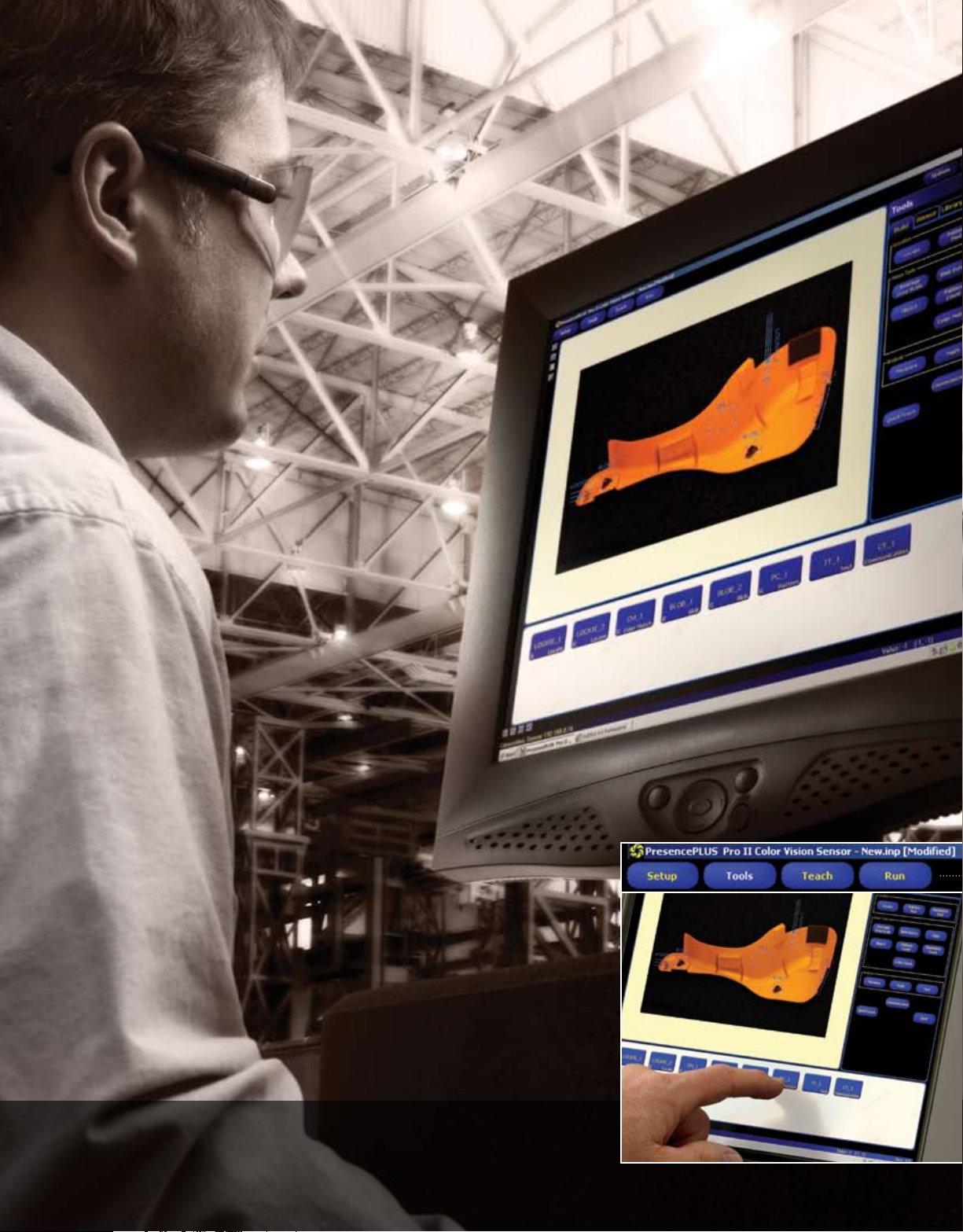

Setting up an application is easy. Advanced PresencePLUS® software

oers point-and-click setup without any knowledge of programming

languages. Set up an inspection by simply illuminating the target,

focusing the camera and selecting the features to analyze.

12

Page 13

Software and Tools

9

Languages

Powerful Inspection Tools.

One Advanced Software Platform.

Fullling the capabilities of powerful PresencePLUS® vision

sensor hardware requires an equally advanced software solution.

One that operates seamlessly across all Banner vision products.

One that provides a common, intuitive graphical interface. One

so advanced, it can literally teach itself your vision challenge.

Banner’s versatile PresencePLUS software does just that.

Now conguring sophisticated vision applications is faster and

easier than ever before, while common applications are virtually

plug-and-play.

Features:

• Seamless functionality across the entire Pro and P4 vision

sensor series.

• Remote TEACH input similar to a photoelectric sensor

self-learns the inspection tolerances of your application.

• Easy, menu-driven, point-and-click interface on a PC.

• Simple push-button inspection changeovers.

• Live video display without a PC.

• ActiveX utilities for exporting inspections, images and results.

• Direct connectivity to EtherNet/IP and Modbus TCP

industrial networks.

• In nine languages including English, Simplied Chinese,

Traditional Chinese, French, German, Japanese, Portuguese

and Spanish with translated text, buttons, commands and

icons in the respective language.

• Operates on Microsoft Windows® operating systems.

• Free web download or CD-ROM; includes all Banner vision

sensor manuals, troubleshooting guides, and lens and

lighting selection guides.

• Free rmware and software upgrades.

PresencePLUS Software Operation

3-point click-and-go Intuitive, wizard-like graphics walk the operator through adjusting the sensor position, selecting the features

to inspect, operating the sensor and monitoring its outputs.

Setup Dynamically view the sensor image, adjust the lighting

position and intensity, and then focus the lens to maximize contrast

between target features and the background.

PresencePLUS: A Comprehensive Suite

of Inspection and Analysis Tools.

LOCATION TOOLS compensate for translational and

rotational movement.

Locate Determines translation and rotation

by detecting relative movement of edges

Pattern Find Determines translation and rotation

by detecting relative movement of a pattern

GEO Find Determines translation and rotation

movement of a part up to 360° by detecting

relative movement of a pattern

VISION TOOLS

Color Match Inspects for matching hue

and intensity

Average Gray Scale Determines the gray scale

intensity value of an area

Blob Determines the presence, connectivity, size

and location of selected features

Edge Determines the presence, number, classification

and location of edges

Object Determines the presence, number,

classification, size and location of objects

Pattern Count Determines the presence, number

and location of pattern(s)

GEO Count Detects the presence and location of a

target pattern in any orientation

Bar Code Finds, decodes and grades advanced 2D

and 1D linear bar codes

ANALYSIS TOOLS

of the vision tools.

Measure Measures distance and angles between

two prescribed points or lines

Math Performs arithmetic functions on any tool

or constant

analyze the image.

measure and evaluate the results

COMMON

Tools Highlight the features to inspect while selecting tools and

lters to maximize robust operation. Choose criteria and margins

for good or failed outputs. Select data or images to communicate

through the Ethernet or serial ports.

Run Operate inspections and sensor outputs while viewing

images or exploring the detailed, comprehensive inspection

results. Select the inspection to run. Log any inspection to archive

its images and results.

User Interface

across all Banner Vision products

Test Evaluates results of selected vision and analysis

tools to determine whether an inspection passes or

fails; performs logical operations; and activates outputs

Communication Sends image or results of selected

location, vision and analysis tools over the Ethernet

or RS-232 serial communication ports to industrial

Ethernet or PC networks

FREE Software & Firmware

UPGRADES

13

Page 14

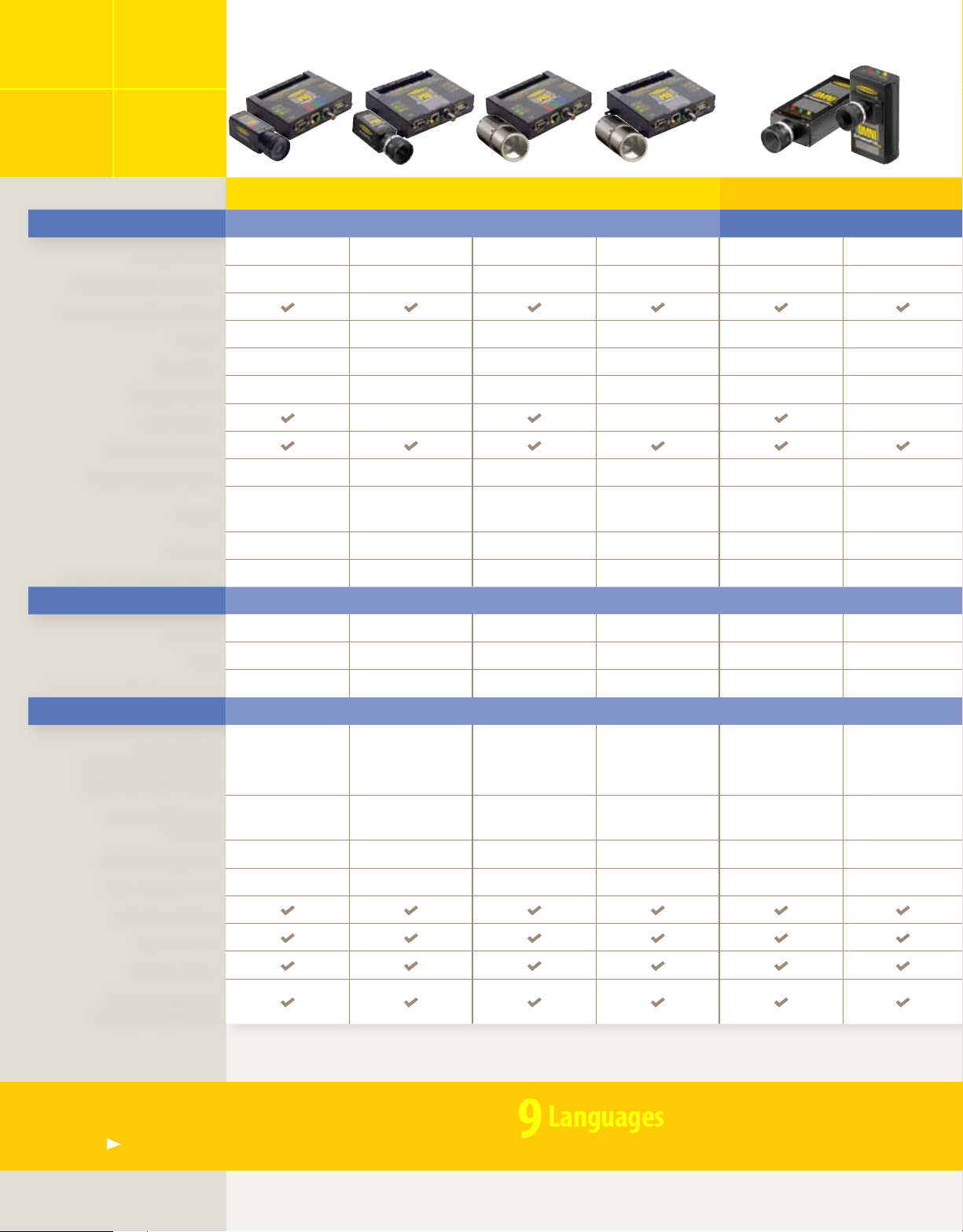

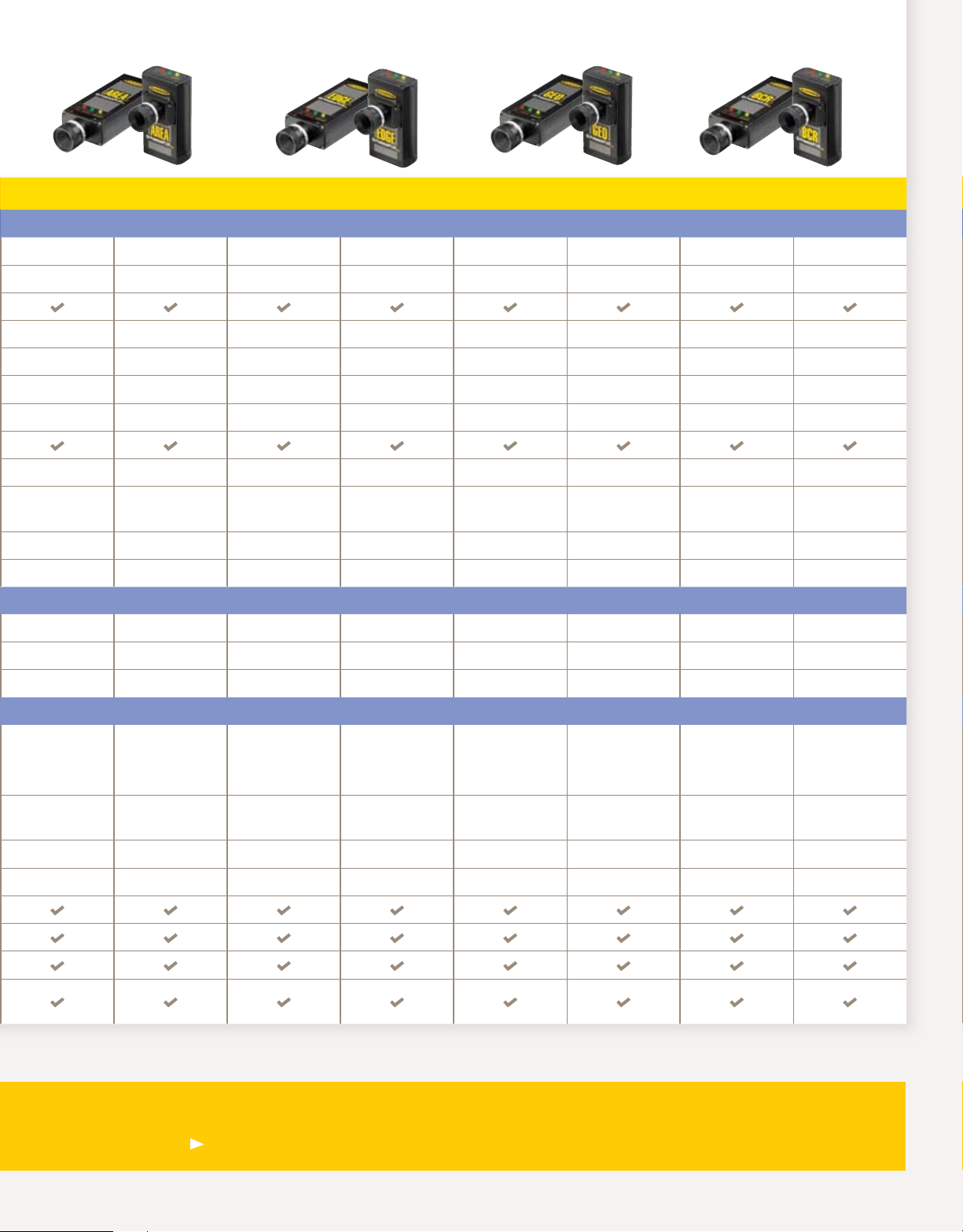

PresencePLUS® Pro & P4 General-Purpose Sensors PresencePLUS® P4 Dedicated-Function Sensors

9

Languages

PROII PROII 1.3 IP68 PROII IP68 PROII 1.3 OMNI OMNI 1.3 AREA AREA 1.3 EDGE EDGE 1.3 GEO GEO 1.3 BCR BCR 1.3

Hardware

Integrated I/O 14 14 14 14 7 7 7 7 7 7 7 7 7 7

Interchangeable Lenses C-mount C-mount C-mount C-mount C-mount C-mount C-mount C-mount C-mount C-mount C-mount C-mount C-mount C-mount

Interchangeable Lighting

Imager CCD CMOS CCD CMOS CCD CMOS CMOS CMOS CMOS CMOS CMOS CMOS CCD CMOS

Resolution 640 x 480 1280 x 1024 640 x 480 1280 x 1024 640 x 480 1280 x 1024 128 x 100 1280 x 1024 128 x 100 1280 x 1024 128 x 100 1280 x 1024 640 x 480 1280 x 1024

Imager Speed 48 fps 18 fps 48 fps 18 fps 48 fps 27 fps 500 fps 27 fps 500 fps 27 fps 500 fps 27 fps 48 fps 27 fps

Color Models

Live Video Output

Power Requirements 10-30V dc 10-30V dc 10-30V dc 10-30V dc 10-30V dc 10-30V dc 10-30V dc 10-30V dc 10-30V dc 10-30V dc 10-30V dc 10-30V dc 10-30V dc 10-30V dc

Trigger

Memory 64 MB 64 MB 64 MB 64 MB 32 MB 32 MB 8 MB 32 MB 8 MB 32 MB 8 MB 32 MB 8 MB 32 MB

Inspection Storage (Max.) 999 999 999 999 999 999 500 999 500 999 500 999 400 999

Communications

Ethernet 10/100 10/100 10/100 10/100 10/100 10/100 10/100 10/100 10/100 10/100 10/100 10/100 10/100 10/100

Serial RS-232 RS-232 RS-232 RS-232 RS-232 RS-232 RS-232 RS-232 RS-232 RS-232 RS-232 RS-232 RS-232 RS-232

Internal or

External

Internal or

External

Page 20 Page 22 Page 23

Internal or

External

Internal or

External

Internal or

External

Internal or

External

Programmable Discrete I/O 6 6 6 6 4 4 4 4 4 4 4 4 4 4

Programming/Interface

User Interface

Languages Supported

(English, German, Japanese, Chinese,

Spanish, French, Italian, Portugese)

Industrial Ethernet

Protocols

Software Upgrades Free Free Free Free Free Free Free Free Free Free Free Free Free Free

Runs without a PC Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

ActiveX Interface

Quick TEACH

Remote Teach

External Inspection

Storage & Operations

9 9 9 9 9 9 9 9 9 9 9 9 9 9

EthnerNet/IP &

Modbus TCP/IP

EthnerNet/IP &

Modbus TCP/IP

EthnerNet/IP &

Modbus TCP/IP

EthnerNet/IP &

Modbus TCP/IP

EthnerNet/IP &

Modbus TCP/IP

EthnerNet/IP &

Modbus TCP/IP

14

COMMON

User Interface

across all Banner Vision products

Page 15

Internal or

External

Internal or

External

Internal or

External

Internal or

External

Internal or

External

Internal or

External

Internal or

External

Internal or

External

EthnerNet/IP &

Modbus TCP/IP

EthnerNet/IP &

Modbus TCP/IP

EthnerNet/IP &

Modbus TCP/IP

EthnerNet/IP &

Modbus TCP/IP

EthnerNet/IP &

Modbus TCP/IP

EthnerNet/IP &

Modbus TCP/IP

EthnerNet/IP &

Modbus TCP/IP

EthnerNet/IP &

Modbus TCP/IP

FREE Software & Firmware UPGRADES

15

Page 16

Pro and P4 General-Purpose Sensors

Aordable full-feature vision sensor solutions.

No compromises.

PresencePLUS® Pro Series

• Full-featured; compact camera with

separate DIN-mountable controller

• Convenient 20-pin removable

terminal block

• Six bicolor bright LED indicators

• Fourteen configurable discrete I/O

(NPN/PNP)

II Models

PRO

PresencePLUS Pro

640 X 480 resolution CCD

PresencePLUS Pro COLOR

752 X 480 resolution CMOS

PresencePLUS Pro 1.3

1280 X 1024 resolution CMOS

PresencePLUS Pro sealed cameras

Rugged, IP68 housing

The PresencePLUS® Pro and PresencePLUS® P4 OMNI vision sensors deliver

professional, image-based inspection capabilities to your factory oor—at an

unprecedented price. Banner has transformed costly, complex machine vision systems

into easy-to-use, workhorse sensors that solve real-world applications. Now you can

quickly integrate inspection capabilities anywhere you need them, at a cost that’s easy

to justify and provides immediate ROI. Banner innovation has revolutionized vision

inspection by consolidating a host of powerful features into two advanced hardware

platforms, available in standard, color, high-resolution and IP68 sealed models.

PresencePLUS Series Features:

• Universal software with three-step, point-and-click setup.

• Ethernet, serial and flexible discrete I/O in the same full-featured sensor.

• Direct connectivity for all I/O to EtherNet/IP and Modbus TCP.

• ActiveX connectivity to create custom operator control software with objectoriented programming.

• Real-time video output for direct connection to a conventional monitor without a PC.

• Remote and Quick TEACH with a single reference image or custom setup.

• Color, IP68 housing and high-resolution 1.3 megapixel models.

• Complete suite of location, inspection, analysis and geometric tools; all can be

used simultaneously for inspecting multiple features and complex applications.

• Multiple inspection routines, stored and accessed without a PC.

PresencePLUS® P4 OMNI Series

• Full featured; economical one-piece

design

• Seven configurable discrete I/O

(NPN/PNP)

• Three bicolor bright LED indicators

• In-line or rightangle housing

P4 OMNI Models

PresencePLUS P4 OMNI

640 X 480 resolution CCD

PresencePLUS P4 OMNI COLOR

752 X 480 resolution CMOS

PresencePLUS P4 OMNI 1.3

1280 X 1024 resolution CMOS

• Microsoft Windows® compatible OS with intuitive Wizard-like setup procedure

and common graphical interface; supports nine languages.

• Complete selection of lenses, lighting, brackets and accessories.

• 10 to 30V dc operation.

16

Page 17

Comprehensive vision capabilities in an aordable, easy-to-use sensor. Banner’s

PresencePLUS® general-purpose vision sensors oer location, vision and analysis tools

that can be used together to solve nearly any inspection challenge.

17

Page 18

Solve specic inspection challenges. Banner’s PresencePLUS® P4 series of

dedicated-function vision sensors delivers the performance and ease of use

you need in a aordable, practical solution for any size manufacturer.

18

Page 19

P4 Dedicated-Function Sensors

Robust, aordable vision solutions solve specic

inspection challenges.

In the past, machine vision was practical only for complex, mission-critical inspection

applications at considerable expense. Banner’s PresencePLUS® vision sensors changed

everything, bringing high-performance inspection capabilities with ease-of-use and

aordability—priced for general industry. Now, Banner revolutionizes vision again,

with a family of four powerful, aordable vision sensors dedicated to solving the most

common inspection challenges. PresencePLUS® P4 series dedicated-function sensors

oer just the tools you need, in a price-performance breakthrough that simplifies vision

inspection and makes it practical.

PresencePLUS P4 Dedicated-Function Sensors:

•

Four models with Locate, Measure, Math, Test, Communications and specific vision tools

• High-performance vision inspections in self-contained in-line or right-angle

housing styles that fit in the palm of your hand

• Standardized GUI supports nine languages

• Remote TEACH function for inspection changeovers without a PC

• Connects directly to real-time video display without a PC

• Communicates over Ethernet, configurable discrete I/O and RS-232 serial lines

• Provides direct connectivity to EtherNet/IP and Modbus TCP industrial networks

• ActiveX utilities for custom operator controls

• Available with a variety of mounting brackets, lenses and lighting accessories

PresencePLUS P4 AREA

• Uses Blob and Gray Scale tools for

basic inspections of defined areas

• High-speed analysis up to 10,000

parts per minute

• Standard resolution: 128 X 100

• High-resolution: 1280 X 1024

PresencePLUS P4 GEO

• Uses GEO Count tool to detect

presence, location and rotation of

a target pattern (360°)

• Standard resolution: 128 X 100

• High-resolution: 1280 X 1024

PresencePLUS P4 AREA and AREA 1.3:

• Inspects presence and size of defined areas using Blob and Gray Scale tools to

capture and analyze images and render pass-fail judgements

• Ideal for high-speed quality control, such as sorting, assembly error proofing, feature

identification and counting, orientation confirmation, process control, complete

case inspection and flaw detection

PresencePLUS P4 GEO and GEO 1.3:

• Performs 360° fixture-free inspections using GEO Count tool to detect the presence

and location of a pattern, regardless of product orientation or position in the sensor’s

field of view

• Ideal for part identification and orientation, pre-packaging assembly verification,

error proofing and label verification

PresencePLUS P4 EDGE and EDGE 1.3:

• Measures multiple edges of a product using Edge and Object tools to gauge height,

width, location and edges of selected areas

• Ideal for part identification and orientation, assembly verification, error proofing,

label verification, quality control sorting and measuring applications

PresencePLUS P4 BCR and BCR 1.3:

• Reads and decodes 2D and 1D linear bar codes; grades codes using industry

standard metrics

•

Reads Data Matrix (ECC200) and standard linear codes including Code 39, Code 128,

Codabar, Interleaved 2 of 5, EAN-8, EAN-13 (supports UPC-A), UPC-E and Postnet

• High-resolution model reads and grades smaller bar codes in larger fields of view

PresencePLUS P4 EDGE

• Uses Edge and Object tools to

validate height, width, location

and edges

• High-speed analysis faster than

10,000 parts per minute

• Standard resolution: 128 X 100

• High-resolution: 1280 X 1024

PresencePLUS P4 BCR

• Finds and decodes 2D and 1D linear

bar codes

• Industry standard bar code metrics

and grading

• Standard resolution: 640 X 480

• High-resolution: 1280 X 1024

19

Page 20

Controllers

PresencePLUS

®

Pro Sensors

• A full-featured vision sensor for advanced inspections

• Compact camera with separate DIN mountable controller

• A complete suite of location, inspection, analysis and geometric tools

• Color, IP68 housing and high-resolution models

Model Number:

Vision Tools:

Resolution:

Cameras Model Number Model Number Model Number Ring Light Window

PPRO CTL P PROC TLBCR PPROC TL1.3 P PROCTL1.3B CR PPR OCT LC PP ROCTLCBCR

PRO

PRO

II

Gray Scale

640 x 480 1280 x 1024 752 x 480

PPROCAM PPROCAM1.3 PPROCAMC — —

PPROCAMSC-G PPROCAM1.3SC-G PPROCAMCSC-G

PPROCAMSC-P PPROCAM1.3SC-P PPROCAMCSC-P Plastic

PPROCAMSR-G PPROCAM1.3SR-G

PPROCAMSR-P PPROCAM1.3SR-P Plastic

PPROCAMSI-G PPROCAM1.3SI-G

PPROCAMSI-P PPROCAM1.3SI-P Plastic

II

Gray Scale with

Bar Code

PRO

II

Gray Scale

PRO

II

Gray Scale with

Bar Code

COLOR PRO

COLOR PRO

II

with Bar Code

— Red

— Infrared

II

(No Light)

Cover

Glass

Glass

Glass

20

20

Pro

Sealed Pro Cameras Cameras

PPROCAMSB-G PPROCAM1.3SB-G

PPROCAMSB-P PPROCAM1.3SB-P Plastic

PPROCAMSG-G PPROCAM1.3SG-G

PPROCAMSG-P PPROCAM1.3SG-P Plastic

PPROCAMSW-G PPROCAM1.3SW-G PPROCAMCSW-G

PPROCAMSW-P PPROCAM1.3SW-P PPROCAMCSW-P Plastic

More information online at bannerengineering.com

Glass

— Blue

Glass

— Green

Glass

White

Page 21

Pro Basic Kit Model Key

Basic kits include a controller, camera, camera-to-controller cordset, CD-ROM and quick start guide.

Camera-to-Controller Cordset

Controller and Camera Cordset Length Style

P P __ K 0 6

Blank = PPROCTL Controller & PPROCAM Camera

1.3 = PPROCTL1.3 Controller & PPROCAM1.3 Camera

B = PPROCTLBCR Controller & PPROCAM Camera

1.3B = PPROCTL1.3BCR Controller & PPROCAM1.3 Camera

C = PPROCTLC Controller & PPROCAMC Camera

CB = PPROCTLCBCR Controller & PPROCA MC Camera

06 = 2 m

23 = 7 m

Blank = Straight

R = Right-Angle

H = High-Flex

RH = Right-Angle, High-Flex

Sealed Pro Basic Kit Model Key

Basic kits include a controller, sealed camera with cover or ring light, camera, camera-to-controller cordset,

ring light power cable, CD-ROM and quick start guide.

Sealed Cordset/Cable

Controller and Sealed Camera Ring Light Window Length

P P __ K S R — G — 13

Blank = PPROCTL Controller & PPROCAMS Camera

1.3 = PPROCTL1.3 Controller & PPROCAM1.3 S Camera

B = PPROCTLBCR Controller & PPROCAMS Camera

1.3B = PPROCTL1.3BCR Controller & PPROCAM1.3S Camera

C = PPROCTLC Controller & PPROCAMCS Camera

CB = PPROCTLCBCR Controller & PPROCA MCS Camera

C = Cover (no Light)

W = White

R = Red*

G = Green*

B = Blue*

I = Infrared*

G = Glass

P = Plastic

13 = 4 m

23 = 7 m

* Not recommended for color applications

More information online at bannerengineering.com

21

21

Page 22

P4

Sensors with

OMNI Tool Set

PresencePLUS

®

P4 General-Purpose Sensors

• Full-featured vision sensors for advanced inspections

• One-piece in-line or right-angle housings

• Color and high-resolution models

Model Number Vision Tools Housing Resolution

P4OR

P4OI

P4O1.3R

P4O1.3I

P4OBR

P4OBI

P4O1.3BR

P4O1.3BI

OMNI

Gray Scale

OMNI

Gray Scale

with Bar Code

Right-Angle

In-Line

Right-Angle

In-Line

Right-Angle

In-Line

Right-Angle

In-Line

640 x 480

1280 x 1024

640 x 480

1280 x 1024

P4COR

COLOR OMNI

P4COI

P4COBR

COLOR OMNI

with Bar Code

P4COBI

P4

with OMNI Tool Set Basic Kits

Basic kits include a sensor, bracket, cable, CD-ROM and quick start guide.

Additional Cable

Sensor Tools Resolution Tools Housing Length

P 4 0 R K 0 6

Blank = Standard Version

1.3 = 1.3 Megapixel Resolution

O = OMNI Gray Scale

CO = COLOR OMNI

Right-Angle

In-Line

Right-Angle

In-Line

RK = Right-Angle Kit

IK = In-Line Kit

B = Bar Code Reader

752 x 480

752 x 480

06 = 2 m

23 = 7 m

32 = 10 m

50 = 16 m

75 = 23 m

22

22

More information online at bannerengineering.com

Page 23

PresencePLUS

®

P4 Dedicated-Function Sensors

• Family of four vision sensors for specific inspection challenges

• One-piece in-line or right-angle housings

• High-resolution 1.3 megapixel models for more detailed inspections and increased field of view

P4

Sensors with

Simplified Tool Set

Model Number Vision Tools Housing Resolution

P4AR

P4AI

P4A1.3R

P4A1.3I

P4GR

P4GI

P4G1.3R

P4G1.3I

P4ER

P4EI

P4E1.3R

P4E1.3I

P4BCR

P4BCI

P4BC1.3R

P4BC1.3I

AREA

Blob & Gray Scale

GEO

Count & Find

EDGE

Edge & Object

BCR

Bar Code Reader

Right-Angle

In-Line

Right-Angle

In-Line

Right-Angle

In-Line

Right-Angle

In-Line

Right-Angle

In-Line

Right-Angle

In-Line

Right-Angle

In-Line

Right-Angle

In-Line

128 x 100

1280 x 1024

128 x 100

1280 x 1024

128 x 100

1280 x 1024

640 x 480

1280 x 1024

P4

with Simplified Tool Set Basic Kits

Basic kits include a sensor, bracket, cable, CD-ROM and quick start guide.

Cable

Sensor Tools Resolution Housing Length

P 4 A R K 0 6

A = AREA

G = GEO

E = EDGE

BC = BCR

Blank = Standard Version

1.3 = 1.3 Megapixel Resolution

RK = Right-Angle Kit

IK = In-Line Kit

06 = 2 m

23 = 7 m

32 = 10 m

50 = 16 m

75 = 23 m

More information online at bannerengineering.com

23

23

Page 24

Supply Voltage and Current

Supply Protection Circuitry

Memory

Input/Output Configuration

Output Rating

Input Specifications

Indicators

Display Options

Discrete I/O

Communications

Construction

Weight

Environmental Rating

Operating Temperature

Relative Humidity

PresencePLUS

PresencePLUS®Pro Controller Specifications

PPROCTL& PPROCTLBCR: 10 to 30V dc @ less than 1.5 A (exclusive of load)

PPROCTL1.3, PPROCTL1.3BCR, PPROCTLC & PPROCTLCBCR: 10 to 30V dc @ less than 1.2 A (exclusive of load)

Protected against reverse polarity and transient voltages

Storage: 64 MB Inspections (jobs): 999 max.

NPN (sinking) or PNP (sourcing) software selectable

150 mA max. each output

OFF-state leakage current: less than 100 µA ON-state saturation voltage: NPN—less than 1V @ 150 mA

NPN: ON—less than 3V PNP: ON—greater than (+V-2)V @ 1 mA max.

OFF-state voltage—greater than 10V @ 4 mA max. OFF-state voltage—less than 3V @ 6 mA max.

6 LED indicators: Trigger, Ready, Power, Pass, Fail, Error

PC or NTSC video (uses 9 m max. BNC cable)

1 Trigger IN (pin 3), 1 Strobe OUT (pin 4), 1 Remote TEACH IN (pin 6), 6 Programmable I/O (pins 9-14)

1 Product Change IN (pin 15), 4 Product Select IN (pins 16-19)

1 RJ-45 Ethernet-connection for running PresencePLUS Pro software and/or output inspection results

1 RS-232 DB-9 port for running PresencePLUS Pro software and/or output inspection results

Steel with black zinc plating

0.55 kg

IEC IP20; NEMA 1

0° to +50° C

90% (non-condensing)

®

Pro Specifications

PNP—greater than V+ -2V

Imager Resolution

Pixel Size

Imager Size

Levels of Gray Scale or Color

Exposure Time

Acquisition

Interface

Lens Mount

Construction

Max. Cable Length

Weight

Environmental Rating

Operating Temperature

Relative Humidity

PresencePLUS®Pro Camera Specifications

PPROCAM & PPROCAMS: 640 x 480 pixels

PPROCAM1.3 & PPROCAM1.3S: 1280 x 1024 pixels

PPROCAMC & PPROCAMCS: 752 x 480 pixels

PPROCAM & PPROCAMS: 7.4 x 7.4 µm

PPROCAM1.3 & PPROCAM1.3S: 6.7 x 6.7 µm

PPROCAMC & PPROCAMCS: 6.0 x 6.0 µm

PPROCAM & PPROCAMS: 4.8 x 3.6 mm, 6 mm diagonal (1/3 inch CCD)

PPROCAM1.3 & PPROCAM1.3S: 8.6 x 6.9 mm, 11 mm diagonal (2/3 inch CMOS)

PPROCAMC & PPROCAMCS: 4.5 x 2.9 mm, 5.4 mm diagonal (1/3 inch CMOS)

PPROCAM, PPROCAM1.3, PPROCAMS & PPROCAM1.3S: 256 Grayscale

PPROCAMC & PPROCAMCS: 256 Red, Green and Blue

PPROCAM & PPROCAMS: 0.10 to 2830 milliseconds

PPROCAM1.3 & PPROCAM1.3S: 0.10 to 1670 milliseconds

PPROCAMC & PPROCAMCS: 0.10 to 1040 milliseconds

PPROCAM & PPROCAMS: 48 frames per second max.

PPROCAM1.3 & PPROCAM1.3S: 18 frames per second max.

PPROCAMC & PPROCAMCS: 17 frames per second max.

LVDS

Standard C-mount (1 inch—32 UN)

PPROCAM, PPROCAM1.3 & PPROCAMC: black anodized aluminum

PPROCAMS, PPROCAM1.3S & PPROCAMCS: nickel-plated aluminum (Lens covers and ring lights are nickel-plated

aluminum with glass or polycarbonate window)

7 m

PPROCAM, PPROCAM1.3 & PPROCAMC: approx. 0.09 kg

PPROCAMS, PPROCAM1.3S & PPROCAMCS: approx. 0.28 kg

Camera only—0.28 g, Camera with cover—0.35 g, Camera with ring light—0.59 g

PPROCAM, PPROCAM1.3 & PPROCAMC: IEC IP20; NEMA 1

PPROCAMS, PPROCAM1.3S & PPROCAMCS: IEC IP68; NEMA 6P

0° to +50° C

PPROCAM, PPROCAM1.3 & PPROCAMC: 90% (non-condensing)

24

24

More information online at bannerengineering.com

Page 25

PresencePLUS

Supply Voltage and Current

Memory

Input/Output Configuration

Output Rating

Bicolor Status Indicators

Display Options

Discrete I/O

Communications

Imager Resolution

Pixel Size

Imager Size

Levels of Gray Scale

or Color

Exposure Time

Acquisition

Lens Mount

Construction

Weight

Environmental Rating

Operating Temperature

Relative Humidity

®

P4 Specifications

PresencePLUS®P4 Specifications

10 to 30V dc (24V dc ±10% if the sensor powers a light source)

OMNI, OMNI with BCR & BCR: less than 650 mA (exclusive of lights and I/O load)

AREA, GEO & EDGE: less than 500 mA (exclusive of lights and I/O load)

OMNI 1.3, OMNI 1.3 with BCR, COLOR OMNI, COLOR OMNI with BCR, AREA 1.3, GEO 1.3, EDGE 1.3 &

BCR 1.3: less than 550 mA (exclusive of lights and I/O load)

Storage: BCR—8 MB Inspection (jobs): 400 max.

AREA, GEO, EDGE—8 MB Inspection (jobs): 500 max.

All others—32 MB Inspection (jobs): 999 max.

NPN (sinking) or PNP (sourcing) software selectable

150 mA max. each output

OFF-state leakage current: less than 100 µA ON-state saturation voltage: NPN—less than 1V @ 150 mA max.

PASS/FAIL: Green ON steady—PASS Red ON steady—FAIL

POWER/ERROR: Green ON steady—POWER Red ON steady—ERROR

READY/TRIGGER: Green ON steady—READY Yellow ON steady—TRIGGER

PC or NTSC video (uses 9 m max. BNC cable)

1 Trigger IN

1 Strobe OUT

4 Programmable I/O

1 Product Change IN

1 Remote TEACH IN

1 RJ-45 10/100 Ethernet connection for running PresencePLUS P4 software and/or output inspection results

RS-232 flying leads

OMNI, OMNI with BCR & BCR: 640 x 480 pixels

OMNI 1.3, OMNI 1.3 with BCR, AREA 1.3, GEO 1.3, EDGE 1.3 & BCR 1.3: 1280 x 1024 pixels

AREA, GEO & EDGE: 128 x 100 pixels

COLOR OMNI & COLOR OMNI with BCR: 752 x 480 pixels

OMNI, OMNI with BCR & BCR: 7.4 x 7.4 µm

OMNI 1.3, OMNI 1.3 with BCR, AREA 1.3, GEO 1.3, EDGE 1.3 & BCR 1.3: 6.7 x 6.7 µm

AREA, GEO & EDGE: 20 x 20 µm

COLOR OMNI & COLOR OMNI 1.3: 6.0 x 6.0 µm

OMNI, OMNI with BCR & BCR: 4.8 x 3.6 mm, 6 mm diagonal (1/3 inch CCD)

OMNI 1.3, OMNI 1.3 with BCR, AREA 1.3, GEO 1.3, EDGE 1.3 & BCR 1.3: 8.6 x 6.9 mm, 11 mm diagonal (2/3 inch CMOS)

AREA, GEO & EDGE: 2.6 x 2.0 mm, 3.3 mm diagonal (1/5 inch CMOS)

COLOR OMNI & COLOR OMNI with BCR: 4.5 x 2.9 mm, 5.4 mm diagonal (1/3 inch CMOS)

OMNI, OMNI with BCR, OMNI 1.3, OMNI 1.3 with BCR, AREA, AREA 1.3, GEO, GEO 1.3, EDGE , EDGE 1.3,

BCR & BCR 1.3: 256 Grayscale

COLOR OMNI & COLOR OMNI with BCR: 256 Red, Green and Blue

OMNI, OMNI with BCR & BCR: 0.1 to 2830 milliseconds

OMNI 1.3, OMNI 1.3 with BCR, AREA 1.3, GEO 1.3, EDGE 1.3 & BCR 1.3: 0.1 to 1670 milliseconds

AREA, GEO & EDGE: 0.1 to 20.47 milliseconds

COLOR OMNI & COLOR OMNI with BCR: 0.1 to 1000 milliseconds

OMNI, OMNI with BCR & BCR: 48 frames per second max.

AREA, GEO & EDGE: 500 frames per second max.

OMNI 1.3, OMNI 1.3 with BCR, AREA 1.3, GEO 1.3, EDGE 1.3 & BCR 1.3: 27 frames per second max.

COLOR OMNI & COLOR OMNI with BCR: 17 frames per second max.

Standard C-mount (1 inch—32 UN)

Black anodized aluminum housing, glass lens

Approx. 0.29 kg

IEC IP20; NEMA 1

0° to +50° C

90% (non-condensing)

PNP—greater than V+ -2V

More information online at bannerengineering.com

25

25

Page 26

10-30V dc

Trigger IN

I/O 4

I/O 3

I/O 2

I/O 6

I/O 5

I/O 1

Chassis

Ground

NPN Outputs with NPN Inputs

†

–

+

1

2

9*

11*

10*

12*

19

3

6

16

15

18

17

4

20

Load

Load

13*

Load

14*

Load

Load

Load

Load

Product

Change IN

Product

Select 3 IN

Product

Select 2 IN

Product

Select 1 IN

Product

Select 0 IN

Strobe OUT

Remote TEACH IN

10-30V dc

Trigger IN

I/O 4

I/O 3

I/O 2

I/O 6

I/O 5

I/O 1

Chassis

Ground

PNP Outputs with PNP Inputs

†

–

+

1

2

9*

11*

10*

12*

19

3

6

16

15

18

17

4

20

Load

Load

13*

Load

14*

Load

Load

Load

Load

Product

Change IN

Product

Select 3 IN

Product

Select 2 IN

Product

Select 1 IN

Product

Select 0 IN

Strobe OUT

Remote TEACH IN

31.9 mm

133.3 mm

105.0 mm

30.0 mm

32.0 mm

78.2 mm

ø 52.5

127.3 mm

PresencePLUS

®

Pro Hookups & Dimensions

Pro Hookup Diagrams

NPN Outputs with NPN Inputs† PNP Outputs with PNP Inputs

†

Inputs can be either NPN or PNP.

* Can be independently configured as an output or input.

** Not used

†

Key

1 = Brown

2 = Blue

3 = Green

4 = Red

5 = Yellow**

6 = Yellow

7 = Yellow**

8 = Yellow**

9 = White*

10 = White*

11 = White*

12 = White*

13 = White*

14 = White*

15 = Green

16 = Green

17 = Green

18 = Green

19 = Green

20 = Green

26

26

Connection Points

12-pin QD to DB15 RJ45 Ethernet BNC Coaxial DB9 Serial

Camera-to-Controller Cordset Video Cordset Cordset

Cordset

Dimension Drawings

More information online at bannerengineering.com

Controller Models Camera Models

Detailed

Dimensions

(Shown with lens—sold seperately)

Terminal Diagram

Sealed Camera Models

(Shown with cover)

Page 27

66.8 mm

124.5 mm

34.4 mm

136.1 mm

34.3 mm

66.8 mm

66.8 mm

124.5 mm

34.4 mm

10-30V dc

RS-232

Transmit

Trigger IN

I/O 4

I/O 3

I/O 2

I/O 1

RS-232

Receive

RS-232

Ground

Chassis

Ground

PNP Outputs with PNP Inputs

†

–

+

12

11

5*

Shield

7*

6*

8*

4

3

2

10

9

1

Load

Load

Load

Load

Product

Change IN

Remote

TEACH IN

2

11

3

6

7

12

8

9

10

4

5

1

10-30V dc

RS-232

Transmit

RS-232

Receive

RS-232

Ground

Chassis

Ground

NPN Output with NPN Inputs

†

–

+

11

12

5*

Shield

7*

6*

8*

4

3

2

10

9

1

Load

Load

Load

Load

Trigger IN

Product

Change IN

Remote

TEACH IN

I/O 4

I/O 3

I/O 2

I/O 1

PresencePLUS

®

P4 Hookups & Dimensions

P4 Hookup Diagrams

NPN Outputs with NPN Inputs† PNP Outputs with PNP Inputs

†

Key

1 = Yellow

2 = Gray

3 = Orange

4 = Pink

5 = Black*

6 = Red*

7 = White*

8 = Light Blue*

9 = Purple

10 = Green

11 = Blue

12 = Brown

Shield = Bare Metal

†

Inputs can be either NPN or PNP.

* Can be independently configured as an output or input.

Connection Points Dimension Drawings

RJ45 Ethernet

Cordset

3-pin Pico QD Banner

Vision Light

12-pin QD Cable

More information online at bannerengineering.com

BNC Coaxial

Video Cordset

In-Line Sensor Models

(Shown with lens—sold separately)

12-Pin QD

Right-Angle Sensor Models

(Shown with lens—sold separately)

Detailed

Dimensions

27

27

Page 28

Light Lens Bracket/Enclosure Display/Indicators

See page 31 See page 39 See page 40 See page 43 See page 44 See page 46

• Maintenance free, rugged LED

lighting in red, green, blue,

white and infrared

• Ring lights, area lights,

backlights, on-axis lights and

speciality lights for tough-tolight objects

• Models for direct connection

to sensors or external

power supply

• 4-75 mm standard C-mount

lenses

• 3.5-75 mm high-performance

lenses for less image distortion

and greater depth of eld

• 8-50 mm megapixel lenses for

extraordinary resolution

• Focus locking on most models

28

28

Page 29

Comprehensive Vision Solutions.

Vision Sensing System Selection and Integration.

Banner Makes it Easy. And Aordable.

The processing power, sophisticated technology and innovation of compact, aordable Banner

PresencePLUS® vision sensors make possible high-speed inspection, measurement, sorting and quality

control capabilities that were once possible only with sensor arrays or costly, complex machine vision

systems. The exibility and low cost of PresencePLUS vision sensors let manufacturers place more sensors

in more inspection points to detect defective parts before they become rejected—and costly—assemblies

at the end of the production line.

With Ethernet, serial and exible discrete I/O in every PresencePLUS sensor, Windows® based GUI

and easy-to-apply inspection tools, integrating a vision system into an existing manufacturing

environment no longer requires reconguration, wiring runs or signicant downtime.

PresencePLUS P4 dedicated-function vision sensors, with lenses and lighting, economically and

eectively solve a host of common inspection, measurement, identication and presence applications

with plug-and-play simplicity. High-resolution models oer 1.3 megapixel imaging for more detailed

inspections of large areas. For more complex or demanding applications, PresencePLUS P4 OMNI and

PresencePLUS Pro full-feature vision sensors oer additional location, vision and analysis tools and I/O—

plus color and sealed models. Combined with lighting options, highest quality optics and versatile

xturing solutions, there is a PresencePLUS vision sensor to handle your most demanding applications at

a fraction of the cost of a conventional machine vision system.

• A wide selection of specialized

brackets, xtures and mounting

systems

• Models for Pro and P4

sensors and Banner lighting

• Enclosures for sensors and lights

• Live video output for enhanced

inspection visibility during

setup and/or operation

• Black and white, or color

monitors for displaying images

• Indicators for clear indication of

part status

Cable

• Cables for sensors, cameras,

video, serial and Ethernet

connections

• Splitter cable for powering two

lights from one P4 sensor

• High-ex cables for robotic

applications

Interface Module

• Simplify wiring of P4 sensors in

an electrical panel

• Provide repeatable control of

strobed lights

• Interface between hardware

and PresencePLUS sensors

or lighting

More information online at bannerengineering.com

29

29

Page 30

3030

Page 31

PresencePLUS

An Illuminating Look at the Critical Role of Lighting

in Successful Vision Sensing.

®

Lighting Selection Guide

Ring Light (see page 32)

Mounts directly to the sensor for easy

setup and illuminates any object

directly in front of the sensor

No matter how powerful or robust a sensor is, successfully

meeting challenging vision applications relies heavily on matching

the vision sensor with appropriate lighting. Lighting sources,

geometry and techniques need to be optimized to the target’s

optical properties. While contrast is critical, target size, speed,

working distance, topography, color, and likelihood of defects are

among the other considerations.

The choices in lighting optics, color lters, diusers and

focusing elements are as varied as the choices of light sources,

which include LEDs, uorescents, lasers, and incandescent

halogens or xenons. Lighting is essential to any successful vision

sensing system.

Fortunately, Banner oers one of the industry’s most

extensive selection of lighting solutions for vision sensing, plus

the knowledge, personnel and experience to create an integrated

solution that delivers reliable performance at desired speeds.

Banner’s lighting selection and accessories provide single-source

convenience and support for matching a sensor and illumination.

For the most challenging applications, Banner engineers will work

with your sample parts to design an integrated optimal solution.

Backlight (see page 33)

Installs behind the target, directly

facing the sensor; has a highly

diused surface and uniform

brightness, with a lower intensity

than other lights

Area Light

Provides even illumination in a

concentrated area

Spot Light

Provides even illumination in a small

concentrated spot

Linear Array Light

Provides high-intensity illumination

of large areas, at long distances

Tubular Fluorescent Light

Features icker-free high-intensity

illumination of large areas

(see page 34)

(see page 35)

(see page 35)

(see page 35)

On-Axis Light

Provides collimated illumination in

same optical path as camera

Highly Diused Light

Softly illuminates from multiple

directions, minimizing glare

and shadows

Low-Angle Ring Light

Illuminates nearly perpendicular to the

direction of an inspection, enhancing

the contrast of surface features

Multi-Light (see page 37)

Has independently adjustable light

intensity on each axis

Structured Light

Uses laser emitter with extra bright

light for 3-dimensional sensing

(see page 36)

(see page 36)

(see page 37)

(see page 37)

31

31

Page 32

PresencePLUS

®

Ring Lights

• Brightly illuminates smaller objects

• Centers the light on the image

• Mounts directly to the camera

Presence

PLUS

LED Ring Lights

Voltage: 24V dc

Presence

PLUS

LED Ring Lights

Voltage: 24V dc

®

Pro

®

P4

†

Size

80 x 80 mm

62 x 62 mm

*For 9 m cable, add suf fix W/30 to the 2 m model number ( example, LEDRR80X80W W/30).

†

For replacement windows and diff users (see page 3 8).

†

Size

80 x 80 mm

62 x 62 mm

*Split ter cable available for powering two lights (s ee page 4 5).

†

For replacement windows and diff users (see page 3 8).

Model Description Connection* Data Sheet

LEDRR80X80W

LEDWR80X80W White

LEDBR80X80W Blue

LEDGR80X80W Green

LEDIR80X80W Infrared

LEDRR62X62W Red

LEDWR62X62W White

LEDBR62X62W Blue

LEDGR62X62W Green

LEDIR62X62W Infrared

Model Description Connection* Data Sheet

LEDRR80X80M

LEDWR80X80M

LEDBR80X80M

LEDGR80X80M Green

LEDIR80X80M Infrared

LEDRR62X62M Red

LEDWR62X62M White

LEDBR62X62M Blue

LEDGR62X62M Green

LEDIR62X62M Infrared

Red

Red

White

Blue

2 m 108626

2 m 108626

0.3 m Threaded

3-pin Pico

pigtail QD

0.3 m Threaded

3-pin Pico

pigtail QD

116941

116941

32

32

Sealed

Presence

PLUS

®

Pro

LED Ring Lights

Voltage: 24V dc

90 mm dia.

Specialty Ring Lights

100 mm dia.

RFLBB UV fluorescent ring lamp replacemen t bulb, RFLW 5100 fluoresc ent ring la mp re plac ement bulb.

NOTE: Spe cialty lights are not stocked and are non -returnable.

More information online at bannerengineering.com

Size Model Window Description Connection Data Sheet

LEDRR90S-P

LEDRR90S-G

LEDWR90S-P

LEDWR90S-G

LEDBR90S-P

LEDBR90S-G

LEDGR90S-P

LEDGR90S-G

LEDIR90S-P

LEDIR90S-G

Size Model Description Data Sheet

HFFW5100

HFFW5100A220

HFFBB

Plastic

Glass

Plastic

Glass

Plastic

Glass

Plastic

Glass

Plastic

Glass

Red

White

Blue

Green

Infrared

110V ac Fluorescent 115969

220V ac Fluorescent 115970

110V ac UV Fluorescent 115968

3-pin Pico QD 128842

Page 33

PresencePLUS

®

Backlights

• Determines the shape and size of target objects

• Provides the most robust lighting for measuring and gauging

• Highlights through-holes in target objects

LED Backlights

Voltage: 24V dc

Specialty

LED Backlights

Voltage: 12V dc

Illumination Area

70 x 70 mm

85 x 220 mm

* For 9 m cable, add suf fix W/30 to the 2 m model number ( example, LEDRB70X70W W/3 0). QD models can be

connected dire ctly to P4 sensors; splitt er cables available for powering two lights (see page 45).

†

For replacement windows and diff users (see page 3 8).

Illumination Area Model Description Connection* Data Sheet

50 x 50 mm

75 x 75 mm

100 x 100 mm

50 x 200 mm

100 x 200 mm

*Specialty lights are not stocked and are non-returnable; they require an external power supply (see page 46).

†

Model Description Connection* Data Sheet

LEDRB70X70W

LEDRB70X70M

LEDIB70X70W

LEDIB70X70M

LEDRB85X220W

LEDRB85X220M

LEDIB85X220W

LEDIB85X220M

LEDRB50X50N

LEDWB50X50N

LEDBB50X50N

LEDIB50X50N

LEDRB75X75N

LEDWB75X75N

LEDBB75X75N

LEDIB75X75N

LEDRB100X100N

LEDWB100X100N

LEDBB100X100N

LEDIB100X100N

LEDRB50X200N

LEDRB50X200N-H

LEDRB50X200N-NH

LEDRB100X200N

LEDIB100X200N

Red

Infrared

Red

Infrared

Red diffused

White diffused

Blue diffused

Infrared diffused

Red diffused

White diffused

Blue diffused

Infrared diffused

Red diffused

White diffused

Blue diffused

Infrared diffused

Red diffused 67429

Red diffused, high output

Red non-diffused, high output

Red diffused

Infrared diffused

2 m 115349

2 m Threaded

3-pin Pico pigtail QD

2 m 115349

2 m Threaded

3-pin Pico pigtail QD

2 m 115349

2 m Threaded

3-pin Pico pigtail QD

2 m 115349

2 m Threaded

3-pin Pico pigtail QD

1.8 m with 9-pin

D-sub connector

116947

116947

116947

116947

67426

67427

67428

67430

67431

More information online at bannerengineering.com

33

33

Page 34

®

Area Lights

Description

Red

White

Blue

Green

Infrared

Red

White

Blue

Green

Infrared

3-pin Pico pigtail QD

3-pin Pico pigtail QD

3-pin Pico pigtail QD

3-pin Pico pigtail QD

3-pin Pico pigtail QD

3-pin Pico pigtail QD

3-pin Pico pigtail QD

3-pin Pico pigtail QD

3-pin Pico pigtail QD

3-pin Pico pigtail QD

Connection*

2 m 115607

2 m Threaded

2 m 115607

2 m Threaded

2 m 115607

2 m Threaded

2 m 115607

2 m Threaded

2 m 115607

2 m Threaded

2 m 121779

2 m Threaded

2 m 121779

2 m Threaded

2 m 121779

2 m Threaded

2 m 121779

2 m Threaded

2 m 121779

2 m Threaded

Data Sheet

116949

116949

116949

116949

116949

121780

121780

121780

121780

121780

LED Area Lights

Voltage: 24V dc

PresencePLUS

• Illuminates specific surface angles

• Reflects glare from shiny surfaces away from camera

• Creates shadows to detect changes in depth

†

Size

80 x 80 mm

62 x 62 mm

* For 9 m cable, add suffix W /30 to the 2 m model number ( example, LEDRA80X80W W/30). QD models

can b e connected directly to P4 sensors; split ter cables available for powering t wo lights (see page 45).

†

For replacement windows and diff users (see page 3 8).

Model

LEDRA80X80W

LEDRA80X80M

LEDWA80X80W

LEDWA80X80M

LEDBA80X80W

LEDBA80X80M

LEDGA80X80W

LEDGA80X80M

LEDIA80X80W

LEDIA80X80M

LEDRA62X62W

LEDRA62X62M

LEDWA62X62W

LEDWA62X62M

LEDBA62X62W

LEDBA62X62M

LEDGA62X62W

LEDGA62X62M

LEDIA62X62W

LEDI A62X62M

34

34

Specialty

LED Area Lights

Voltage: 12V dc

More information online at bannerengineering.com

50 x 50 mm

75 x 75 mm

100 x 100 mm

*Specialt y lights are not s tocked and are non-returnable; they require an external power supply (see page 46) .

Size Model Description Connec tion* Data Sheet

LEDRA50X50N

LEDWA50X50N

LEDBA50X50N

LEDIA50X50N

LEDRA75X75N Red

LEDWA75X75N

LEDBA75X75N

LEDIA75X75N

LEDRA100X100N

LEDWA100X100N White

LEDBA100X100N Blue

LEDIA100X100N Infrared

Red

White

Blue

Infrared

White

Blue

Infrared

Red

1.8 m with 9-pin

D-sub connector

67423

67424

67425

Page 35

PresencePLUS

®

Spot Lights

• Provides off-axis illumination of

small areas

• Withstands washdown (rated IP67)

Sealed LED Spot Lights

Voltage: 10 to 30V dc

®

PresencePLUS

Linear Array Lights

• Maintenance-free LED illumination of

large objects from far away

• Provides super high-intensity

illumination of large areas

• Withstands washdown (rated IP68)

Sealed LED Linear Array Lights

Voltage: 24V dc

Size Model Description Connection* Data Sheet

LEDRSW

LEDRSM

LEDWSW

30 mm

* For 9 m cable, add suf fix W/30 to the 2 m model number ( example, LEDRSW W/3 0) . QD models can be

connected dire ctly to P4 sensors; splitt er cables available for powering two lights (see page 45).

†

Length

12"

24"

* Split ter cable available for powering two lights (see page 4 5).

†

For replacement windows (see page 38).

LEDWSM

LEDBSW

LEDBSM

LEDGSW

LEDGSM

Model Window Description Connection* Data Sheet

LEDRLA290S-P

LEDRLA290S-G

LEDWLA290S-P

LEDWLA290S-G

LEDBLA 290S-P

LEDBLA 290S-G

LEDGLA 290S-P

LEDGLA 290S-G

LEDRLA580S-P

LEDRLA580S-G

LEDWLA580S-P

LEDWLA580S-G

LEDBLA 580S-P

LEDBLA 580S-G

LEDGLA 580S-P

LEDGLA 580S-G

White

Blue

Green

Plastic

Glass

Plastic

Glass

Plastic

Glass

Plastic

Glass

Plastic

Glass

Plastic

Glass

Plastic

Glass

Plastic

Glass

Red

Red

White

Blue

Green

Red

White

Blue

Green

2 m 122987

2 m Threaded

3-pin Pico pigtail QD

2 m 122987

2 m Threaded

3-pin Pico pigtail QD

2 m 122987

2 m Threaded

3-pin Pico pigtail QD

2 m 122987

2 m Threaded

3-pin Pico pigtail QD

0.15 m

Threaded

4-pin Euro

pigtail QD

0.15 m

Threaded

4-pin Euro

pigtail QD

122986

122986

122986

122986

127725

127725

®

PresencePLUS

• Provides easy, affordable, flicker-free

Tubular Lights

Length Model Voltage Ballast Data Sheet

illumination of large objects

• Uses waterproof housings (rated IP67)

with integrated mounting brackets

12"

Sealed Flourescent

Tubular Lights

Voltage: Varies

12"

14"

15"

15"

24"

36"

48"

12"

15"

24"

36"

48"

Note: Replacement bulbs available, contact factory for information. All models have louvers and integral mounting

flange; optional brackets are available for heavy-duty mounting (two brackets required for each light, see page 41).

More information online at bannerengineering.com

8"

8"

8"

8"

HFFW8DC

HFFW8AC110

HFFW8AC230

HFFW12DC

HFFW12AC

HFFW14DC

HFFW15AC110

HFFW15AC230

HFFW24AC

HFFW36 AC

HFFW48AC

HFFW8ACR

HFFW12ACR

HFFW15ACR

HFFW24ACR

HFFW36 ACR

HFFW48ACR

24V dc

110V ac

230V ac

24V dc

120 to 277V ac

24V dc

110V ac

230V ac

120 to 277V ac

120 to 277V ac

120 to 277V ac

120 to 277V ac

120 to 277V ac

120 to 277V ac

120 to 277V ac

120 to 277V ac

120 to 277V ac

Integral 115387

Remote 115387

35

35

Page 36

PresencePLUS® On-Axis Lights

• Provides more uniform illumination than a ring light

• Delivers collimated illumination in same optical path as camera

• Evenly illuminates on flat reflective material

LED On-Axis Lights

Voltage: 24V dc

Specialty

LED On-Axis Lights

Voltage: 12V dc

Size Model Description Connection* Data Sheet

LEDRO100W

LEDRO100M

LEDRO100W-D

LEDRO100M-D

LEDWO100W

LEDWO100M

LEDWO100W-D

LEDWO100M-D

100 x 100 mm

* For 9 m cable, add suffix W /30 to the 2 m model number ( example, LEDRO100 W W/ 30).

QD models c an be connected directly to P4 sensor s.

Size Model Description Connection* Data Sheet

25 mm dia.

50 mm dia.

75 mm dia.

* Specialt y lights are not stocked and are non- returnable; they require an external power supply ( see page 46).

LEDBO100W

LEDBO100M

LEDBO100W-D

LEDBO100M-D

LEDGO100W

LEDGO100M

LEDGO100W-D

LEDGO100M-D

LEDIO100W

LEDIO100M

LEDRO25N Red

LEDWO25N White

LEDBO25N Blue

LEDRO50N Red

LEDRO50N-D

LEDWO50N White

LEDBO50N Blue

LEDIO50N Infrared

LEDRO75N Red

LEDRO75N-H

LEDWO75N White

LEDBO75N Blue

Red

Red, w/dust cover

White

White, w/dust cover

Blue

Blue, w/dust cover

Green

Green, w/dust cover

Infrared

Red, w/dust cover

Red, high output

0.6 m Threaded 3-pin Pico pigtail QD

0.6 m Threaded 3-pin Pico pigtail QD

0.6 m Threaded 3-pin Pico pigtail QD

0.6 m Threaded 3-pin Pico pigtail QD

0.6 m Threaded 3-pin Pico pigtail QD

0.6 m Threaded 3-pin Pico pigtail QD

0.6 m Threaded 3-pin Pico pigtail QD

0.6 m Threaded 3-pin Pico pigtail QD

0.6 m Threaded 3-pin Pico pigtail QD

0.5 m with 9-pin D-sub connector 67437

2 m with 9-pin D-sub connector

0.5 m with 9-pin D-sub connector 67439

2 m

2 m

2 m

2 m

2 m

2 m

2 m

2 m

2 m

126059

67438

36

36

®

PresencePLUS

Highly Diffused Lights

• Minimizes glare and shadows • Illuminates curved surfaces softly and evenly • Minimizes texture

Specialty

LED Highly

Diffused Lights

Voltage: 12V dc

Size Model Description Connection* Data Sheet

150 mm dia.

25 mm dia.

75 mm dia.

* Specialt y lights are not stocked and are non- returnable; they require an external power supply ( see page 46).

LEDRD150N

LEDRS25N Red

LEDRS75N Red

LEDGS75N Green

Red, dome

More information online at bannerengineering.com

1.8 m with 9-pin

D-sub connector

0.5 m with 9-pin

D-sub connector

66955

67441

67442

Page 37

PresencePLUS

®

Low-Angle Ring Lights

• Highlights surface irregularities

• Highlights changes in elevation

• Illuminates from an angle nearly perpendicular to object

LED Low-Angle Ring Lights

Size Model Description Connection* Data Sheet

Voltage: 24V dc

150 mm dia.

* For 9 m cable, add suffix W /30 to the 2 m model number ( example, LEDRI150-3W W/ 30 ).

QD models c an be connected directly to P4 sensor s.

Specialty

LED Low-Angle Ring Lights

Voltage: 12V dc

PresencePLUS

®

Multi-Lights

Size Model Description Connection* Data Sheet

100 mm dia.

* Specialt y lights are not s tocked and are non-returnable; they require an external power supply (s ee page 4 6).

• Provides multiple lighting angles and highly diffused lighting

Specialty

LED Multi-Lights

Voltage: 12V dc

Size Model Description Connection* Data Sheet

50 mm dia.

75 mm dia.

150 mm dia.

200 mm dia.

NOTE: Spe cialty lights are not stocked and are non -returnable ; they require an external pow er supply (see page 46).

LEDRI150-3W

LEDII150-3M

LEDII150-3W

LEDII150-3M

LEDRI100N Red

LEDRM50N

LEDRM50N-H

LEDRM75N

LEDRC150N

LEDRC200N

2 m

Red

Infrared

Red low-angle & on-axis

Red low-angle & on-axis, high output

Red low-angle & on-axis 67436

Red low-angle & on-axis multi-light 67443

Red low-angle & on-axis multi-light 67444

2 m Threaded 3-pin

Pico pigtail QD

2 m

2 m Threaded 3-pin

Pico pigtail QD

1.8 m with 9-pin

D-sub connector

1.8 m with

9-pin D-sub

connector

127582

67432

67435

Laser Emitters for Structured Illumination

• Provides high-contrast illumination • Senses surface height differences • Provides 3D inspection with a 2D camera

QS18 Laser Emitters

Voltage: 10 to 30V dc

More information online at bannerengineering.com

Model Description Connection* Data Sheet

QS186LE212

* For 9 m cable, add suffix W/ 30 to the 2 m model number (example, QS186LE212 W/ 30).

Extra Bright Horizontal Line (Class 2) 2 m 109415

37

37

Page 38

PresencePLUS® Lighting Accessories

• Filters and diffusers for blocking light and improving lighting quality

• Window replacements for PresencePLUS Ring Lights, Area Lights,

Backlights and Linear Array Lights

Lighting Diffusers

Window Replacements

Model Description Use With

LEDRDW

LEDRCDW

LEDRDWS

LEDRCDWS

LEDADW

LEDADWS

Model Description Use With

LEDRCW

LEDRCWS

LEDAW

LEDAWS

LEDLA290SW-P

LEDLA580SW-P

LEDLA290SW-G

LEDLA580SW-G

LEDBW

LEDBIW

LEDBWL

LEDBIWL

White Diffusing Window Kit 80 x 80 mm Ring Lights

Clear Diffusing Window Kit 80 x 80 mm Ring Lights

White Diffusing Window Kit 62 x 62 mm Ring Lights

Clear Diffusing Window Kit 62 x 62 mm Ring Lights

White Diffusing Window Kit 80 x 80 mm Area Lights

White Diffusing Window Kit 62 x 62 mm Area Lights

80 x 80 mm Ring Lights

62 x 62 mm Ring Lights

Clear Plastic Window Replacement

Clear Glass Window Replacement

White Window Replacement

80 x 80 mm Area Lights

62 x 62 mm Area Lights

12" Sealed Linear Array Lights

24" Sealed Linear Array Lights

12" Sealed Linear Array Lights

24" Sealed Linear Array Lights

70 x 70 mm Red Backlights

70 x 70 mm Infrared Backlights

85 x 220 mm Red Backlights

85 x 220 mm Infrared Backlights

38

38

Filters

Choosing a Filter

More information online at bannerengineering.com

Model Color Description Data Sheet

FLTI

FLTB

FLTG

FLTR

LEDRRPFK

LEDRRPFKS

LEDAPFK

LEDAPFKS

LEDRPFK90

LEDFLTK

Infrared

(> 760 nm)

Blue

(400-525 nm)

Green

(400-575 nm)

Red

(> 600 nm)

— Polarizing filter kit for 80 x 80 Ring Lights 108945

— Polarizing filter kit for 62 x 62 Ring Lights 108945

—

— Polarizing filter kit for 62 x 62 Area Lights 113657

— Polarizing filter kit for Sealed Ring Lights 129871

—

High-pass filter blocks visible light and passes infrared

light. Included with all Banner Infrared light sources.

Band-pass filter improves quality by helping to reduce

ambient light; it passes blue and infrared light.

Band-pass filter improves quality by helping to reduce

ambient light; it passes green and infrared light.

High-pass filter improves quality by helping to reduce

ambient light; it passes red and infrared light

Polarizing filter kit for 80 x 80 Area Lights and 70 x 70

Backlights

Kit with a variety of filters, diffusers and window

replacements

115635

115634

113657

69461