Page 1

STB Self-Checking Optical Touch Buttons

Datasheet

• Continuous internal self-checking operation

• Diverse-redundant microcontroller-based photoelectric touch

buttons

• Ergonomically designed to eliminate hand, wrist and arm

stresses associated with repeated switch operation; require no

physical pressure to operate

• High excess gain cuts through heavy contamination

• Immune to ambient light, EMI and RFI interference

• LED power, output and fault indicators

• Yellow field cover included

U.S. Patent(s) issued or pending

Model Cable

STBVP6

STBVP6Q

STBVP6Q5 4-Pin Euro-style QD

STBVR81

STBVR81Q 5-Pin Mini-style QD

STBVR81Q6 5-Pin Euro-style QD

Standard 2 m (6.5 ft) cable models are listed. To order the 9 m (30 ft) cable model, add suffix "W/30" to the cabled model

number. For example, STBVP6 W/30. Models with a QD connector require a mating cable.

4-wire 2 m (6.5 ft) integral

cable

4-Pin Mini-style QD

5-wire 2 m (6.5 ft) integral

cable

WARNING:

Not a Stand-Alone Safety Device. STB Series Touch Buttons are self-checking ergonomic actuating

devices, but are not, by themselves, safety devices. To be used in a safety application, two STBs must

be interfaced with a type IIIC two-hand-control module, such as the Banner AT-FM-10K, to meet all

relevant safety requirements of the appropriate standards (e.g., ISO13851 / EN574).

Supply

Voltage

10–30V dc

20–30V ac/dc

Output Type

Complementary

PNP

Two Individual

Complementary

Relays

DUO-TOUCH® SG

Compatibility

AT-FM-10K, AT-GM/HM-13A, and

AT-GM/HM-11KM Two-Hand

Control Modules, and SC22-3

Safety Controller

Important - Read This Before Proceeding

The user is responsible for satisfying all local, state, and national laws, rules, codes, and regulations relating to

the use of this product and its application. Banner Engineering Corp. has made every effort to provide complete

application, installation, operation, and maintenance instructions. Please direct any questions regarding the use or

installation of this product to the factory applications department at the telephone numbers or address found at http://

www.bannerengineering.com.

The user is responsible for making sure that all machine operators, maintenance personnel, electricians, and

supervisors are thoroughly familiar with and understand all instructions regarding the installation, maintenance, and use of

this product, and with the machinery it controls. The user and any personnel involved with the installation and use of this

product must be thoroughly familiar with all applicable standards, some of which are listed within the specifications.

Banner Engineering Corp. makes no claim regarding a specific recommendation of any organization, the accuracy or

effectiveness of any information provided, or the appropriateness of the provided information for a specific application.

Applicable U.S. Standards

ANSI B11 Standards for Machine Tools Safety

P/N 64136 Rev. C 4 December 2013

Page 2

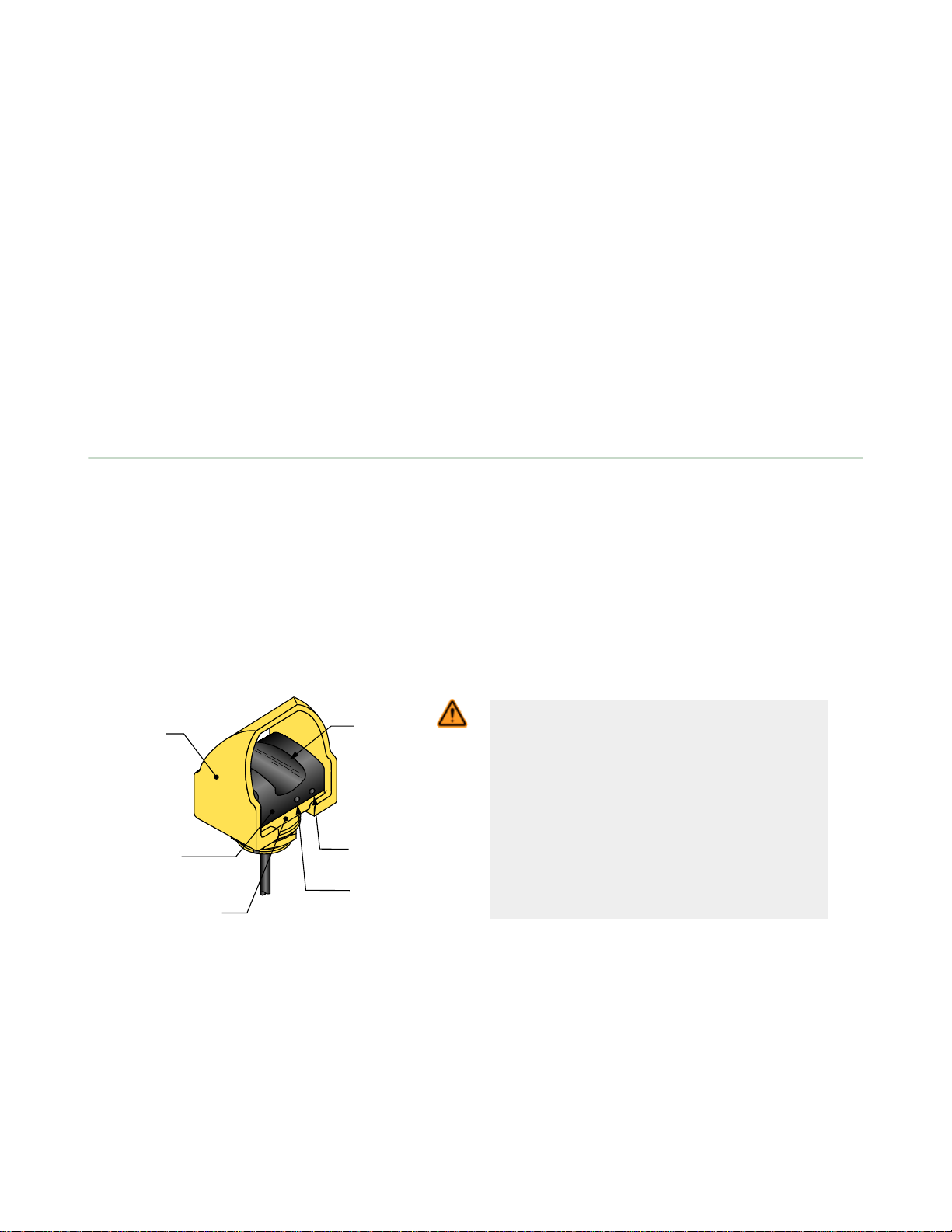

Yellow

Polypropylene

Field Cover

Black Polyetherimide

Output

Fault

LED

Power

ON/OFF

LED

Switch

"Touch Area"

(yoke)

Yellow Fiber

Reinforced PBT Base

STB Self-Checking Optical Touch Buttons

Contact: Safety Director, AMT – The Association for Manufacturing Technology, 7901 Westpark Drive, McLean, VA 22102,

Tel.: 703-893-2900

ANSI NFPA 79 Electrical Standard for Industrial Machinery

Contact: National Fire Protection Association, 1 Batterymarch Park, P.O. Box 9101, Quincy, MA 02269-9101, Tel.:

800-344-3555

ANSI/RIA R15.06 Safety Requirements for Industrial Robots and Robot Systems

Contact: Robotic Industries Association, 900 Victors Way, P.O. Box 3724, Ann Arbor, MI 48106, Tel.: 734-994-6088

Applicable International Standards

ISO 12100-1 & -2 (EN 292-1 & -2) Safety of Machinery – Basic Concepts, General Principles for Design

IEC 60204-1 Electrical Equipment of Machines Part 1: General Requirements

ISO 13849-1 (EN 954-1) Safety-Related Parts of Control Systems

ISO 13856-1 (EN1760-1), Safety of Machinery – Pressure-Sensitive Protective Devices

Contact: Global Engineering Documents, 15 Inverness Way East, Englewood, CO 80112-5704, Tel.: 800-854- 7179

Overview

STB Self-Checking Optical Touch Buttons are touch-activated photoelectric devices designed to replace capacitive touch

switches and mechanical push buttons. Their outputs activate while a finger is in the “touch area” (yoke) of the switch,

interrupting the button’s infrared sensing beam.

Banner STB Series buttons are ergonomically designed to eliminate the hand, wrist, and arm stresses associated with

mechanical push buttons. They require absolutely no physical pressure to operate. LED indicators light when power is on

and outputs are activated.

All models are immune to EMI, RFI, and ambient light interference. STBs have a black polyetherimide upper housing and

yellow PBT base. The 30 mm threaded base on all models provides easy mounting and easy retrofitting into existing

applications. Rugged yellow polypropylene (TP) field covers are supplied with all models to prevent inadvertent switch

actuation due to objects (such as loose clothing or debris) which might accidentally block the sensing beam. The

polypropylene material is capable of absorbing high impact (even at low temperatures) and is highly resistant to abrasion

and to damage by most chemicals.

WARNING: Point-of-Operation Guarding

When properly installed, a two-hand control

device provides protection only for the hands of

the machine operator. It may be necessary to

install additional safeguarding, such as safety

light screens, additional two-hand controls, and/or

hard guards, to protect all individuals from

hazardous machinery.

Failure to properly guard hazardous

machinery can result in a dangerous

condition which could lead to serious injury

or death.

Figure 1. STB Touch Button features

STB Self-Checking Optical Touch Buttons are very similar to the proven and popular OTB Series buttons. The dualmicrocontroller internal design of the new buttons, however, allows the hookup to a Banner DUO-TOUCH SG Two-HandControl Safety Module, or other two-hand-control designed to meet Type IIIC requirements per ISO 13851 (EN 574)

(requiring 1 normally open and 1 normally closed contact per input channel). These microcontrollers perform a continuous

self-check. The emitter is continuously pulsed, and receiver response is checked accordingly by the microcontrollers. STB

Series Touch Buttons are designed to immediately detect any internal component failure, go into a lockout mode, and

indicate the failure with a flashing green Fault LED.

2 www.bannerengineering.com - tel: 763-544-3164 P/N 64136 Rev. C

Page 3

STB Self-Checking Optical Touch Buttons

The STB outputs are not monitored by the STB circuitry, and have no external device monitoring feedback. Output

monitoring must be accomplished by using an external device, such as a Type IIIC Two-Hand-Control module.

STB Series Touch Button LED Indicators

Power On (green): Solid when power is applied

Output, Fault (green): Solid when button is activated

Off when button is not activated

Flashing when a fault condition is detected

STB Series Self-Checking Touch Buttons were designed primarily to provide the self-checking function required in controlreliable machine cycle initiation applications. STBs also are suitable for use anywhere mechanical push buttons or the

original OTB Touch Buttons are used.

Both the solid-state and relay-output versions have complementary outputs and can be connected to switch power to

equipment as long as the STB’s switching voltage and current limits are not exceeded.

STBs must be connected to a type IIIC Two-Hand-Control circuit module, in most cases, when used to initiate potentially

dangerous machine cycles.

Installation

OSHA and ANSI require that the hand controls be mounted to protect them from accidental or unintentional operation. Use

shields, covers, rings, collars, dividers, or similar protection to prevent accidental switch actuation and to discourage use of

forearms or elbows. European standard ISO 13851 (EN 574) includes a detailed discussion of approaches to protection of

hand controls. The hand controls must be arranged far enough apart so that the operator cannot operate both hand

controls by the use of one arm. Typically, this distance is not less than 550 mm (21.7") in a straight line, but using guards

or alternate mounting arrangement can allow shorter distances, per ISO 13851 (EN574). This standard also recommends

that hand controls be arranged on a horizontal (or nearly horizontal) surface that is 1,100 mm (43.3") above the floor.

Consider ergonomic principles to avoid unnecessary fatigue in the installation of the hand controls. Install the touch

buttons at a height and in a location that will be comfortable for the user.See ISO 13851 (EN574) Two-Hand Control, ANSI

B11.TR1—Ergonomic Guidelines, and EN894— Safety of Machinery—Ergonomic Requirements—Control Actuators for

further information.

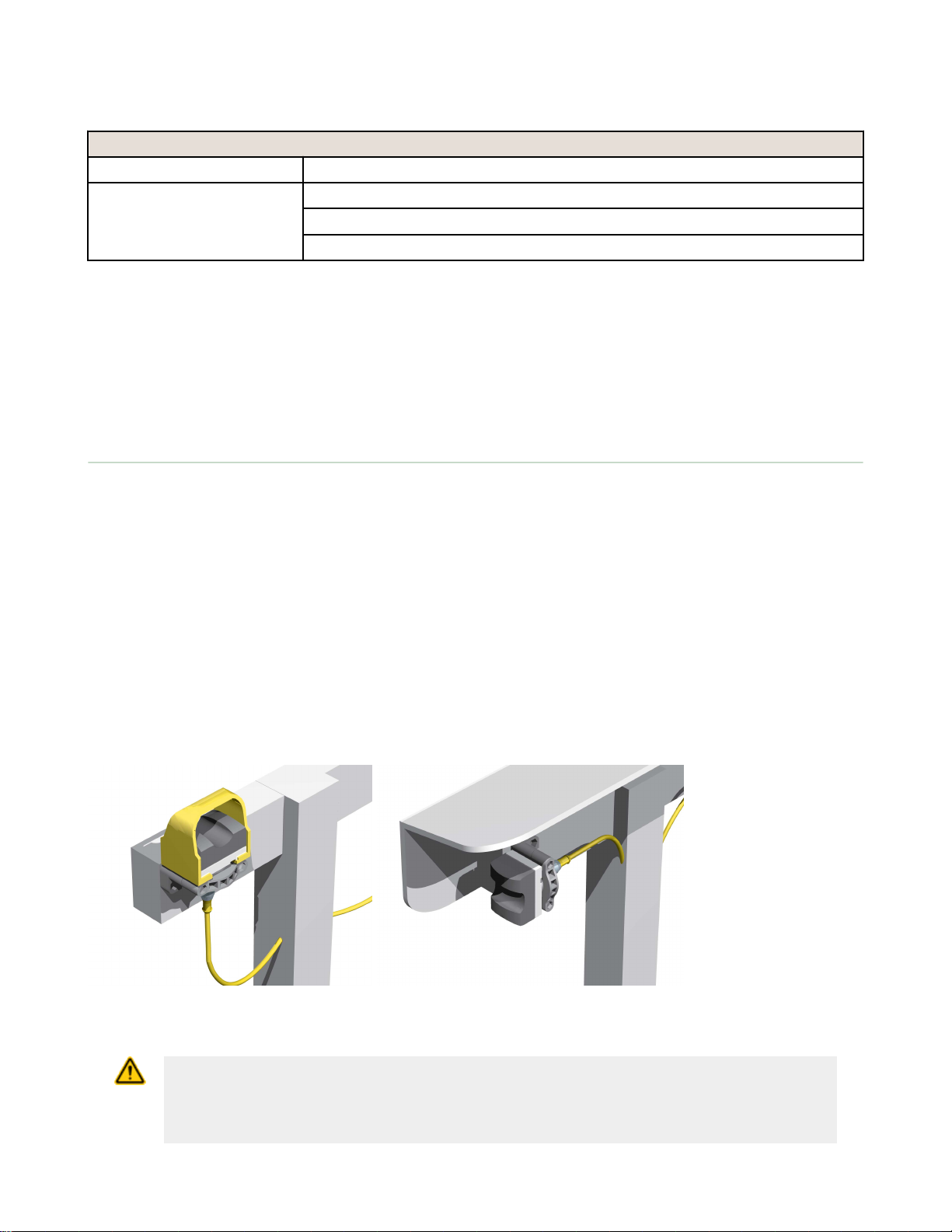

The following figure shows two methods for mounting the touch buttons, to prevent accidental switch actuation. When

mounting them on top of the control bar, the protective field covers should be in place, as shown; or for added protection,

mount the touch buttons sideways under and/or behind a protective hood, rather than on top of the bar, removing the

field covers. This side mount prevents an object from being left in the path of the beam, intentionally bypassing the

safeguard. In addition, shields, covers, rings, collars, dividers, or similar protection may be used to prevent accidental

switch actuation.

Figure 2. Protect STB touch buttons to prevent defeat or inadvertent actuation

CAUTION: Install Hand Controls to Prevent Accidental Actuation

Total protection for the two-hand control system from defeat is not possible. However, the user is

required by U.S. and International standards to arrange and protect hand controls to

minimize the possibility of defeat or accidental actuation.

P/N 64136 Rev. C www.bannerengineering.com - tel: 763-544-3164 3

Page 4

STB Self-Checking Optical Touch Buttons

CAUTION: Hand Controls

The environment in which hand controls are installed must not adversely affect the means of

actuation. Severe contamination or other environmental influences may cause slow response or false

On conditions of mechanical or ergonomic buttons. This may result in exposure to a hazard.

Two-Hand Control Safety Distance (Minimum Distance)

Both hand controls must be located far enough away from the nearest hazard point that the operator cannot reach the

hazard with a hand or other body part before the hazardous motion ceases. This is the “separation distance” (“safety

distance”), and may be calculated as follows.

WARNING: Location of Touch Button Controls

Hand controls must be mounted a safe distance from moving machine parts, as determined

by the appropriate standard. It must not be possible for the operator or other non-qualified persons

to relocate them. Failure to establish and maintain the required safety distance may result in

serious injury or death.

U.S. Applications

The Safety Distance formula, as provided in ANSI B11.19:

Part-Revolution Clutch Machinery (the machine and its controls allow the machine to stop motion during the

hazardous portion of the machine cycle)

Ds = K x (Ts + Tr + Th)

For Full-Revolution Clutch Machinery (the machine and its controls are designed to complete a full machine cycle)

Ds = K x (Tm + Tr + Th)

4 www.bannerengineering.com - tel: 763-544-3164 P/N 64136 Rev. C

Page 5

STB Self-Checking Optical Touch Buttons

U.S. Applications

D

s

the Safety Distance (in inches)

K

the OSHA/ANSI recommended hand-speed constant (in inches per second), in most cases is calculated at 63

in/sec, but may vary between 63 to 100 in/sec based on the application circumstances

not a conclusive determination; consider all factors, including the physical ability of the operator, when

determining the value of K to be used

T

h

the response time of the slowest hand control from the time when a hand disengages that control until the

switch opens

Th is usually insignificant for purely mechanical switches. However, Th should be considered for safety distance

calculation when using electronic or electromechanical (powered) hand controls. For Banner Self-checking

Touch Buttons (STBs) the response time is 0.02 seconds

T

m

the maximum time (in seconds) the machine takes to cease all motion after it has been tripped. For full

revolution clutch presses with only one engaging point, Tm is equal to the time necessary for one and one-half

revolutions of the crankshaft. For full revolution clutch presses with more than one engaging point, Tm is be

calculated as follows:

Tm = (1/2 + 1/N) x T

cy

N = number of clutch engaging points per revolution

Tcy = time (in seconds) necessary to complete one revolution of the crankshaft

T

r

the response time of the Safety Controller as measured from the time a stop signal from either hand control.

The default Safety Controller response is 0.0xx seconds, plus any additional closed-to-open debounce time. If

the debounce time is adjusted, the time in excess of xx ms (default closed-to-open debounce time) must be

added to the stated response (see Specifications).

T

s

the overall stop time of the machine (in seconds) from the initial stop signal to the final ceasing of all motion,

including stop times of all relevant control elements and measured at maximum machine velocity

Ts is usually measured by a stop-time measuring device. If the specified machine stop time is used, add at

least 20% as a safety factor to account for brake system deterioration. If the stop-time of the two redundant

machine control elements is unequal, the slower of the two times must be used for calculating the separation

distance

European Applications

The Minimum Distance Formula, as provided in ISO 13855:

S = (K x T) + C

S

the Minimum Distance (in millimeters)

K

the ISO 13855 recommended hand-speed constant (in millimeters per second), in most cases is calculated at

1600 mm/sec, but may vary between 1600 to 2500 mm/sec based on the application circumstances

not a conclusive determination; consider all factors, including the physical ability of the operator, when

determining the value of K to be used.

T

the overall machine stopping response time (in seconds), from the physical initiation of the safety device to the

final ceasing of all motion

C

the added distance due to the depth penetration factor equals 250 mm, per ISO 13855. The ISO 13855 C

factor may be reduced to 0 if the risk of encroachment is eliminated, but the safety distance must always be

100 mm or greater

Example Separation Distance Calculation

The following example illustrates the use of the formula to calculate separation distance for a part-revolution clutch

machine. This example uses 0.50 seconds as a typical value for Ts and 0.035 seconds for Tr and 0.020 seconds for Th:

P/N 64136 Rev. C www.bannerengineering.com - tel: 763-544-3164 5

Page 6

1

3

2

5

4

Supply Voltage*

(see Specifications)

N.C.

C

N.O.

* NOTE: Connection of dc power is without regard to polarity.

3

1

4

2

10-30V dc

–

+

Load

Load

A

1

K

1

K

2

Inputs Inputs

MPCE

Feedback

A

2

A

1

A

2

A

1

A

2

Machine

Control

Circuit

Two-Hand Control

Type IIIC

MPCE 1MPCE

2

STB Self-Checking Optical Touch Buttons

K = 63" per second,

Ts = 0.50 seconds (measured by a stop-time measuring device)

Tr = 0.035 seconds

Th = 0.020 seconds

Ds = K × (Ts + Tr + Th)

= 63" (0.50 + 0.035 + 0.020)

= 35"

In this example, both hand controls must be located no closer than 35" from the nearest hazard point.

Hookup Diagrams

Cabled models only are shown. Quick-disconnect wiring is functionally identical. Connection of dc power is without regard

to polarity.

Electromechanical Relay Output Models

PNP (Sourcing) Solid-State Output Models Wiring Key

1 = Brown

2 = White

3 = Blue

4 = Black

5 = Gray or Yellow

Wiring Key

1 = Two-Hand Control Type IIIC

Module

2 = Inputs

3 = MPCE feedback

4 = Machine control circuit

Figure 3. Generic interface of a relay-output STB Touch Button to a type IIIC two-hand-control

6 www.bannerengineering.com - tel: 763-544-3164 P/N 64136 Rev. C

module

Page 7

Solid-State

10-30V dc

V+ V+

bn

bl

bn

bl

yl

wh

bu

wh

bu

Micro-

Controller

1

Relay

20-30V ac/dc

V+ V+

Micro-

Controller

2

Micro-

Controller

1

Micro-

Controller

2

K

1

K1K

2

K

2

A

1

+ –

A

2

STB Self-Checking Optical Touch Buttons

WARNING:

Safety Systems Used for Two-Hand-Control. In a two-hand-control/trip system that incorporates STB

Touch Buttons as the actuation devices and functions as a safeguard, the anti-tiedown and simultaneity

monitoring functions should not be performed by a nonsafety-related device (e.g., a PLC or PC). Per

OSHA 29CFR1910.211(d)(62), the “safety system must...operate together as a unit, such that a single

failure or single operating error will not cause injury to personnel due to point-of-operation hazards.”

Refer to the appropriate standard to determine the requirements of a two hand-control/trip system

when used for safeguarding.

Figure 4. STB Touch Button block diagrams

Repairs

Contact Banner Engineering for troubleshooting of this device. Do not attempt any repairs to this Banner device; it

contains no field-replaceable components. If the device or a device component is determined to be defective by a

Banner Applications Engineer, they will advise you of Banner's RMA (Return Merchandise Authorization) procedure.

Important: If instructed to return the device, pack it with care. Damage that occurs in return shipping

is not covered by warranty.

Specifications

Supply Voltage and Current

STBVP6 models: 10 to 30 V dc @ 75 mA, typical

STBVR81 models: 20 to 30 V ac/dc or 20 to 30 V ac (peak-to-peak value), (50/60 Hz ±5%) @ 75 mA

Supply Protection Circuitry

Protected against reverse polarity and transient voltages

Output Configuration

STBVP6 models: Complementary PNP (sourcing) open-collector transistors

STBVR81 models: Complementary electromechanical relays

P/N 64136 Rev. C www.bannerengineering.com - tel: 763-544-3164 7

Page 8

STB Self-Checking Optical Touch Buttons

Output Rating

STBVP6 models (solid-state outputs):

Max. load: 150 mA

On-state max. output voltage (no load): +V(supply) − 1.5 V

Off-state leakage current: < 1 μA

STBVR81 models (electromechanical relays):

Max. switching voltage: 125 V dc/150 V ac

Max. switching current: 1 A @ 24 V dc; 0.4 A @ 125 V ac (resistive loads)

Max. resistive power: 24 W dc/50 VA ac

Mechanical life of relays: 10^9 cycles

Electrical life of relays: 1.5 x 10^5 cycles at 1 amp, 24 V resistive

Output Protection Circuitry

All models protected against false pulse on power-up. Models with solid-state outputs have overload and shortcircuit protection.

Output Response Time

20 milliseconds ON/OFF

Indicators

2 green LED indicators:

Power: ON – power applied

Output/fault: ON – button is activated; OFF – button is deactivated; Flashing – internal fault or blocked button

on power-up detected

Connections

PVC-jacketed 2 m (6.5') cables or QD fitting, depending on model; integral 9 m (30') cables are also available.

Accessory QD cables required for QD models.

STBVP6 models: 4-wire (4-pin Mini-style or Euro-style QD)

STBVR81 models: 5-wire (5-pin Mini-style or Euro-style QD)

Environmental Rating

Meets NEMA standards 1, 3, 4, 4X, 12 and 13; IEC IP66

Construction

Totally encapsulated, non-metallic enclosure. Black polyetherimide upper housing; fiber-reinforced PBT polyester

base. Electronics fully epoxy-encapsulated. Supplied with polypropylene (TP) field cover.

Ambient Light Immunity

Up to 100,000 lux

Applicable Agency Standards

(Used with an AT-FM-10K module or an SC22-3 Safety Controller) Analysis of measures for fault avoidance and

fault control according to SIL3 (IEC 61508 and IEC 62061) and Category 4 (EN ISO 13849-1) passes EMI/RFI test

levels as speCified in IEC61496 and IEC62061..

Operating Conditions

0 to 50 °C (32 to 122 °F)

90% @ 55 ºC max. relative humidity (non-condensing)

Application Notes

The polyetherimide upper housing will become brittle with prolonged exposure to outdoor sunlight. Window glass

effectively filters longer wavelength ultraviolet light and provides excellent protection from sunlight. Avoid contact

with strong alkalis, hydrocarbons and fuels. Clean periodically using mild soap solution and a soft cloth.

Two-Hand Control System Note

When the STBVP6 is used with Banner’s SC22-3 Safety Controller in a two-hand control system, the power supply

to the STBVP6 must be of the same voltage that is used to power the Safety Controller and they must have a

common supply ground.

Certifications

8 www.bannerengineering.com - tel: 763-544-3164 P/N 64136 Rev. C

Page 9

OUTPUT

FAULT

POWER

OUTPUT

FAULT

POWER

OUTPUT

FAULT

POWER

59.9 mm

(2.36")

27.9 mm

(1.10")

43.2 mm

(1.70")

35.0 mm

(1.38")

22.1 mm

(0.87")

22.1 mm

(0.87")

13.0 mm

(0.50")

15.2 mm

(0.60")

22.1 mm

(0.87")

M30 External Threads

Jam Nut, Lock Ring, and

Seal Washers are Supplied

Integral Cable

Mini-Style

Quick-Disconnect

Euro-Style

Quick-Disconnect

With

Field Cover

NPSM Internal Threads

69 mm

(2.7")

74.0 mm

(2.9")

51.0 mm

(2.0")

7/8-16UN-2B

ø 28 mm max.

(1.1")

61 mm max.

(2.4")

4

3

1

2

7/8-16UN-2B

ø 28 mm max.

(1.1")

61 mm max.

(2.4")

1

2

4

3

5

STB Self-Checking Optical Touch Buttons

Dimensions

Accessories

4-Pin Mini-Style Cordsets

Model Length Style Dimensions Pinout

MBCC-406 1.83 m (6 ft) Straight

MBCC-412 3.66 m (12 ft)

MBCC-430 9.14 m (30 ft)

5-Pin Mini-Style Cordsets

Model Length Style Dimensions Pinout

MBCC-506 1.83 m (6 ft)

MBCC-515 4.57 m (15 ft)

MBCC-530 9.14 m (30 ft)

P/N 64136 Rev. C www.bannerengineering.com - tel: 763-544-3164 9

Straight

1 = Brown

2 = White

3 = Blue

4 = Black

1 = Black

2 = Blue

3 = Yellow

4 = Brown

5 = White

Page 10

44 Typ.

ø 14.5

M12 x 1

2

3

4

1

44 Typ.

ø 14.5

M12 x 1

2

3

4

1

5

70

57

A

B

C

57

67

58

29

B

A

45

93

A

C

B

53

48

45

A

C

B

STB Self-Checking Optical Touch Buttons

4-Pin Threaded M12/Euro-Style Cordsets

Model Length Style Dimensions Pinout

MQDC-406 1.83 m (6 ft)

MQDC-415 4.57 m (15 ft)

MQDC-430 9.14 m (30 ft)

Straight

MQDC-450

15.2 m (50 ft)

1 = Brown

2 = White

3 = Blue

4 = Black

5-Pin Threaded M12/Euro-Style Cordsets (Single Ended)

Model Length Style Dimensions Pinout (Female)

MQDC1-501.5 0.50 m (1.5 ft)

MQDC1-506 1.83 m (6 ft)

MQDC1-515 4.57 m (15 ft)

Straight

1 = Brown

MQDC1-530

9.14 m (30 ft)

2 = White

3 = Blue

4 = Black

5 = Gray

SMB30MM

• 12-ga. stainless steel

bracket with curved

mounting slots for versatile

• Clearance for M6 (¼ in)

• Mounting hole for 30 mm

orientation

hardware

sensor

Hole center spacing: A = 51, A to B = 25.4

Hole size: A = 42.6 x 7, B = ø 6.4, C = ø 30.1

SMBAMS30P

• Flat SMBAMS series bracket

• 30 mm hole for mounting

• Articulation slots for 90°+

• 12-ga. 300 series stainless

sensors

rotation

steel

Hole center spacing: A=26.0, A to B=13.0

Hole size: A=26.8 x 7.0, B=ø 6.5, C=ø 31.0

Mounting Brackets

• Swivel bracket with 30 mm

• Black reinforced

• Stainless steel mounting and

• Right-angle SMBAMS series

• 30 mm hole for mounting

• Articulation slots for 90°+

• 12-ga. (2.6 mm) cold-rolled

SMB30SC

mounting hole for sensor

thermoplastic polyester

swivel locking hardware

included

Hole center spacing: A=ø 50.8

Hole size: A=ø 7.0, B=ø 30.0

SMBAMS30RA

bracket

sensors

rotation

steel

Hole center spacing: A=26.0, A to B=13.0

Hole size: A=26.8 x 7.0, B=ø 6.5, C=ø 31.0

10 www.bannerengineering.com - tel: 763-544-3164 P/N 64136 Rev. C

Page 11

45

61

69

A

B

C

STB Self-Checking Optical Touch Buttons

Mounting Brackets

• Right-angle bracket with

• Clearance for M6 (¼ in)

• Mounting hole for 30 mm

• 12-ga. stainless steel

SMB30A

curved slot for versatile

orientation

hardware

sensor

Hole center spacing: A to B=40

Hole size: A=ø 6.3, B= 27.1 x 6.3, C=ø 30.5

Banner Engineering Corp Limited Warranty

Banner Engineering Corp. warrants its products to be free from defects in material and workmanship for one year following

the date of shipment. Banner Engineering Corp. will repair or replace, free of charge, any product of its manufacture

which, at the time it is returned to the factory, is found to have been defective during the warranty period. This warranty

does not cover damage or liability for misuse, abuse, or the improper application or installation of the Banner product.

THIS LIMITED WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES WHETHER EXPRESS OR

IMPLIED (INCLUDING, WITHOUT LIMITATION, ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE), AND WHETHER ARISING UNDER COURSE OF PERFORMANCE, COURSE OF DEALING OR

TRADE USAGE.

This Warranty is exclusive and limited to repair or, at the discretion of Banner Engineering Corp., replacement. IN NO

EVENT SHALL BANNER ENGINEERING CORP. BE LIABLE TO BUYER OR ANY OTHER PERSON OR ENTITY FOR

ANY EXTRA COSTS, EXPENSES, LOSSES, LOSS OF PROFITS, OR ANY INCIDENTAL, CONSEQUENTIAL OR

SPECIAL DAMAGES RESULTING FROM ANY PRODUCT DEFECT OR FROM THE USE OR INABILITY TO USE THE

PRODUCT, WHETHER ARISING IN CONTRACT OR WARRANTY, STATUTE, TORT, STRICT LIABILITY,

NEGLIGENCE, OR OTHERWISE.

Banner Engineering Corp. reserves the right to change, modify or improve the design of the product without assuming any

obligations or liabilities relating to any product previously manufactured by Banner Engineering Corp.

www.bannerengineering.com - tel: 763-544-3164

Loading...

Loading...