Page 1

D11 Expert Series

Low-cost TEACH-mode sensors for use with plastic fiber optics

• Low-cost, 10 to 30V dc, self-contained, TEACH-mode sensors for use with all Banner

plastic fiber optics

• Compact 11 mm-wide housing designed for DIN rail mounting; also mounts to other

surfaces using the supplied mounting bracket

• Easy push-button TEACH-mode programming automatically adjusts sensitivity to optimal setting

• D11E sensors are designed for low-contrast sensing applications (sensitivity set to just

above the “dark” condition)

• D11E2 series sensors set the switching point midway between the “dark” and “light”

conditions to ignore subtle changes, such as web flutter

• Fast, 200 microsecond (0.2 millisecond) output response; a 40 millisecond output pulse

stretcher also may be programmed

• Models available with NPN (sinking) or PNP (sourcing) output

• Output may be programmed for either light operate (“LO”) or dark operate (“DO”)

• Separate input allows remote programming by an external device, such as a switch or

Models available with integral 2 m (6.5 ft)

cable or Pico-style quick-disconnect (QD)

connector; 9 m (30 ft) cables are also

available

a process controller

• LED status indications for power ON, output state, received signal strength, and sensing contrast

Models

D11EN6FP

D11EN6FPQ 4-pin Pico QD

D11EP6FP 2 m (6.5 ft)

D11EP6FPQ 4-pin Pico QD

D11E2N6FP

D11E2N6FPQ 4-pin Pico QD

D11E2P6FP 2 m (6.5 ft)

D11E2P6FPQ 4-pin Pico QD

Switching Threshold Setting

Just above the “dark” condition

Midway between “dark” and

“light” conditions

Cable Output Type

2 m (6.5 ft)

2 m (6.5 ft)

NPN (sinking)

PNP (sourcing)

NPN (sinking)

PNP (sourcing)

Maximum Range (Diffuse mode performance

based on 90% reflectance white test card)

Range varies by sensing mode and fiber optics used:

• PIT46U fibers, opposed mode: 180 mm (7.1")

• PIT26U fibers, opposed mode: 50 mm (2.0")

• PBT46U fiber, diffuse mode: 50 mm (2.0")

• PBT26U fiber, diffuse mode: 10 mm (0.4")

Standard 2 m (6.5 ft) cable models are listed. To order the 9 m (30 ft) cable model, add suffix "W/30" to the cabled model number. For

example, D11EN6FP W/30. Models with a QD connector require a mating cable. (See Accessories).

WARNING: Not To Be Used for Personnel Protection

Never use this device as a sensing device for personnel protection. Doing so could lead to serious

injury or death. This device does not include the self-checking redundant circuitry necessary to allow its

use in personnel safety applications. A sensor failure or malfunction can cause either an energized or deenergized sensor output condition.

1

Specifications

Supply Voltage and Current

10 to 30V dc (10% maximum ripple) at less than 45

mA, exclusive of load

1

Opposed-mode range may be extended using optional lenses (see catalog for available lenses).

P/N 44279 Rev. C 8/6/2013

Required Fiber Optic Cable

PI or PB Series plastic fibers

Page 2

1

2

3

4

D11 Expert Series

Supply Protection Circuitry

Protected against reverse polarity and transient voltages

Output Configuration

One (SPST) NPN (sinking) or PNP (sourcing) opencollector transistor, depending on model; programmable for light or dark operate

Output Rating

150 mA maximum

Off-state leakage current: <5 microamps at 30V dc

On-state saturation voltage: <1V at 10 mA dc; <1.5V at

150 mA dc

Output Protection Circuitry

Protected against false pulse on power-up and continuous overload or short-circuit

Output Response Time

200 microseconds (0.2 milliseconds) ON and OFF (40

milliseconds OFF when pulse stretcher is programmed). NOTE: 100 millisecond delay on power-up; output is non-conducting during this time

Output Timing Functions

ON/OFF (no delay) or fixed 40 millisecond OFF-delay

pulse stretcher; selected by push button

Operating Temperature

–10 to +55 ºC (–14 to +131 ºF)

Maximum relative humidity 90% at 50ºC (non-condens-

ing)

Certifications

Sensing Beam

Visible red, 680 nm

Repeatability

66 microseconds

Adjustments

Push button TEACH mode sensitivity setting (see

TEACH mode, page 2); remote TEACH mode input is

provided

Indicators

Three LEDs: Green, Yellow and Red

Green LED lights for dc power ON and flashes when

ready to register sensing condition during TEACH

mode: 1 Hz when waiting to learn first sensing condition; 2 Hz when waiting to learn second sensing condition; 4 Hz when output is overloaded.

Yellow LED lights for output ON (conducting).

Red LED is Banner’s patented Alignment Indicating

Device (AID™, U.S. patent #4356393) which lights

whenever the sensor “sees” a light condition and superimposes a pulse rate which is proportional to the

strength of the received light signal (the stronger the

signal, the faster the pulse rate).

Construction

Black ABS flame retardant housing with acrylic cover

Stainless steel M3 x 0.5 hardware for use with ABS

mounting bracket (supplied)

Environmental Rating

IEC IP54; NEMA 2

Connections

2 m (6.5 ft) or 9 m (30 ft) attached cable, or 4-pin Picostyle quick-disconnect fitting; Cables for QD models

are purchased separately

Run Mode

Run mode is the normal operation of the D11 Expert series. The LED indicators operate in Run mode, as follows:

Indicator LED Color Function

1 Signal Strength

(SIG)

2 Output Amber Follows the action of the output:

3 Power ON Green Solid when power is applied.

2 www.bannerengineering.com - tel: 763-544-3164 P/N 44279 Rev. C

4 Button n/a Programming push button

Red Lights when the sensor "sees" its modulated light source

and pulses at a rate proportional to the received light signal

strength.

• On when the output is energized

• Off when the output is de-energized

Flashes at approximately 4 Hz to indicate the output is overloaded

Page 3

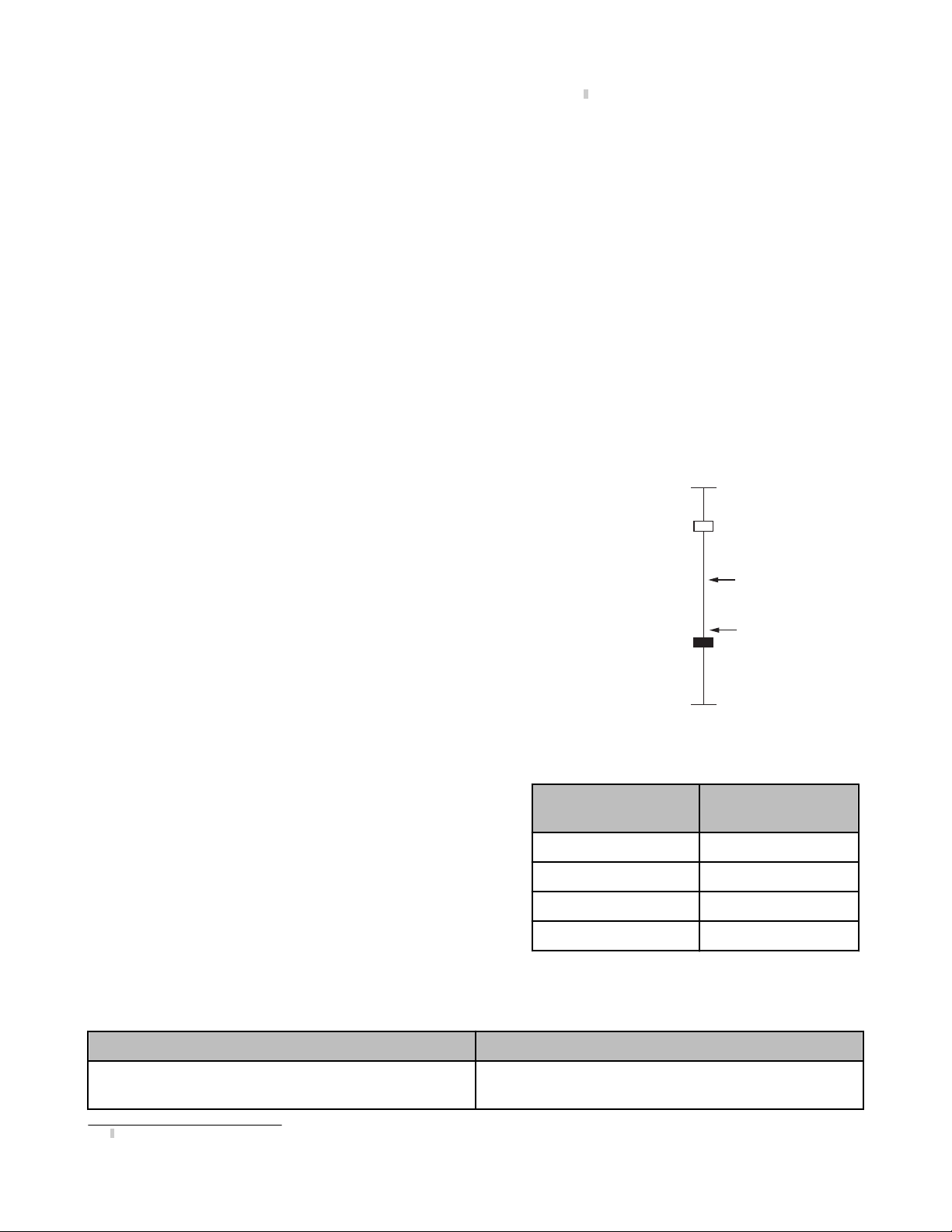

Max. Light Signal

Threshold for

D11E2 (e.g. = 1x)

Light Sensing

Condition

Threshold for

D11E (e.g. = 1x)

Min. Light Signal

Dark Sensing

Condition

D11 Expert Series

2

The Signal Strength indicator is Banner’s exclusive AID™ (Alignment Indicating Device

). This feature simplifies accurate alignment

during TEACH mode and provides a means of signaling when maintenance is needed during Run mode. When the pulse rate is slow,

clean the fiber sensing ends and check the alignment.

Maximum Sensitivity/Factory Defaults

The sensors are factory-programmed for maximum sensitivity. This default setting may be easily recalled by holding the push button for

two or more seconds to enter TEACH mode, and then clicking the push button four times in a row.

The default program also is set for light operate output and pulse stretcher OFF, push button enabled.

Perform the following procedures to program your own settings.

TEACH Mode

Sensitivity is automatically set (and optimized) by “teaching” the sensor the “light” and “dark” conditions. This is accomplished in TEACH

mode. TEACH mode requires that each of the two sensing conditions be presented to the fiber optics; when the push button is clicked,

the sensor samples the sensing condition and registers it into memory. After the second sensing condition is registered, the D11 Expert

automatically sets the sensitivity to the optimum value for the application, and then returns to Run mode.

NOTE: There is a period of a few seconds at the end of TEACH mode, before Run mode begins.

Light or Dark Operate Selection

The two sensing conditions may be presented in either order: the light condition first,

and then the dark condition, or vice versa. The condition presented first is the condition for which the output energizes. (In other words, the output will be light operated if

the light condition is TEACH condition #1, or the output will be dark operated if the

dark condition is TEACH condition #1.)

D11E sensors automatically set to a point just above the “dark” condition for the best

performance in low contrast sensing applications; D11E2 sensors automatically set to

a point midway between the “dark” and “light” conditions, to ignore subtle changes,

such as web flutter.

Contrast Indication

When the push button is clicked to teach the second sensing condition, the

three LED indicators flash simultaneously to indicate relative sensing contrast. (Contrast is the difference in light level between the two sensing conditions.)

Higher contrast allows higher sensitivity level, and resulting higher excess

gain. A high contrast level is directly related to sensing reliability, and is

more forgiving of subtle changes in sensing conditions. The contrast display

at the end of TEACH mode is shown.

No. of flashes at end of

TEACH mode

1 Unacceptable

2 Low

3 Moderate

4 High

Relative Contrast

NOTE: If the relative contrast level is unacceptable (1 flash), the program

will return to TEACH condition #1.

TEACH Mode Programming

Action Indicator Status

Push and hold the button for more than 2 seconds. Green LED: Flashes at 1 Hz

2

U.S. Patent #4356393

P/N 44279 Rev. C www.bannerengineering.com - tel: 763-544-3164 3

Amber LED: Off

Page 4

bn

bu

−

+

bk

wh

Load

10-30V dc

Load

Remote programming

switch (normally open)

bn

bu

−

+

bk

wh

Load

10-30V dc

Load

Remote programming

switch (normally open)

D11 Expert Series

Action Indicator Status

Red LED: Pulses to indicate relative received signal strength

TEACH Condition #1

Present the first sensing condition to the sensor and single-click

the button.

This condition corresponds to the sensor output ON state.

TEACH Condition #2

Present the second sensing condition to the sensor and singleclick the button.

This condition corresponds to the sensor output OFF state.

Output Pulse Stretcher

A 40 millisecond pulse stretcher (OFF-delay) may be enabled for applications where a very short sensing event might be missed because

of the response of the load or input connected to the sensor output. Turn the pulse stretcher ON or OFF using the following procedure.

Action Indicator Status

Push and hold the button for more than 2 seconds. Green LED: Flashes at 1 Hz

Pulse Stretcher

Double-click the button to display status.

Single-click the button to toggle pulse stretcher ON or OFF

3

Green: Flashes at 2 Hz

Yellow: OFF

Red: Pulses to indicate relative received signal strength.

Green, Yellow, and Red indicators flash simultaneously one to four

times to indicate relative sensing contrast (see chart above).

After a few seconds, the sensor returns to RUN mode.

Amber LED: Off

Red LED: Pulses to indicate relative received signal strength

Pulse Stretcher ON

Green: Off

Amber: Off

Red: Solid on

Double-click the button to save the configuration and return to Run

mode.

Hookup Diagrams

Sensors with NPN (Sinking) Outputs Sensors with PNP (Sourcing) Outputs

Figure 1. Cabled Hookup

Pulse Stretcher OFF

Green: Off

Amber: Off

Red: Double-flash

See Run Mode on page 2

Figure 2. Cabled Hookup

3

The sensor returns to RUN mode if the first TEACH condition is not registered within 20 seconds. TEACH mode may be cancelled before either condition #1 or #2 by pressing the push

button for more than 2 seconds.

4 www.bannerengineering.com - tel: 763-544-3164 P/N 44279 Rev. C

Page 5

bn

bu

−

+

bk

wh

Load

10-30V dc

Load

Remote programming

switch (normally open)

bn

bu

−

+

bk

wh

Load

10-30V dc

Load

Remote programming

switch (normally open)

ø 9.0

32 Typ.

4

3

1

2

ø 10.9

29 Typ.

15 Typ.

Programming

Push Button

Power Indicator

Output Indicator

Signal Strength Indicator

ø 1.0 mm (0.04")

Plastic Fiber Emitter Port

ø 1.0 mm (0.04")

Plastic Fiber Receiver Port

Mounting Bracket

(Included)

35.0 mm

(1.38")

17.6 mm

(0.69")

64.1 mm

(2.53")

11.0 mm

(0.43")

29.0 mm

(1.14")

Slide Up

to Release

Fibers

Slide Up

to Release

Fibers

D11 Expert Series

Sensors with NPN (Sinking) Outputs Sensors with PNP (Sourcing) Outputs

Figure 3. Quick Disconnect Hookup

Figure 4. Quick Disconnect Hookup

Accessories

4-Pin Snap-on M8/Pico-Style Cordsets

Model Length Style Dimensions Pinout

PKG4-2 2.00 m (6.56 ft) Straight

PKW4Z-2 2.00 m (6.56 ft) Right-Angle

Dimensions

1 = Brown

2 = White

3 = Blue

4 = Black

Plastic Fiber Installation:

1. Cut fiber ends per instructions included with the fibers. Slide the fiber gripper up (open). For 0.25 mm or 0.5 mm diameter fibers,

insert the adapter (shown below) into the ports as far as it will go.

2. All sizes plastic fibers: Insert the prepared plastic fiber sensor ends gently into the ports as far as they will go.

P/N 44279 Rev. C www.bannerengineering.com - tel: 763-544-3164 5

Figure 5. Cabled Models

Page 6

Programming

Push Button

Power Indicator

Output Indicator

Signal Strength Indicator

ø 1.0 mm (0.04")

Plastic Fiber Emitter Port

ø 1.0 mm (0.04")

Plastic Fiber Receiver Port

Mounting Bracket

(Included)

35.0 mm

(1.38")

17.6 mm

(0.69")

64.1 mm

(2.53")

79.0 mm

(3.11")

11.0 mm

(0.43")

29.0 mm

(1.14")

Slide Up

to Release

Fibers

DIN Rail

35.0 mm

(1.38")

25.1 mm

(0.99")

30.2 mm

(1.19")

5.0 mm

(0.20")

9.9 mm

(0.39")

2 x C’sink

ø 7.9 mm (0.31")

3.2 mm (0.13") deep

ø4.4 (0.18") thru

2 x ø 3.25 mm

(0.128")

2 x 3.5 mm

(0.14")

5.5 mm

(0.22")

11.0 mm

(0.44")

25.6 mm

(1.01")

9.6 mm

(0.38")

2.5 mm

(0.10")

8.6 mm

(0.34")

4.8 mm

(0.19")

2 x ø 3.18 mm

(0.125")

D11 Expert Series

3. Slide the fiber gripper back down to lock.

A fiber adaptor is included for use with 0.25 mm (0.01") or 0.5 mm (0.02") diameter fibers.

Figure 6. Quick Disconnect Models

Figure 7. DIN Rail Mounting

Remote Programming

Connect the D11 Expert's white wire to a remote switch for three sensor programming functions:

1. Disable or enable the push button

2. TEACH mode programming of sensitivity

6 www.bannerengineering.com - tel: 763-544-3164 P/N 44279 Rev. C

Figure 8. Mounting Bracket

Page 7

Single-Pulse

Input

Wait > 0.8 seconds before next input

0.04 sec T < 0.8 sec

T

Two-Pulse

Input

Wait > 0.8 seconds before next input

T

T

T

Four-Pulse

Input

Wait > 0.8 seconds before next input

T

T T T

T T T

D11 Expert Series

3. Enable or disable the 40- millisecond pulse stretcher.

Connect a remote programming switch between the

white wire and dc common (see Hookup Diagrams

on page 4). The switch may be either a normally

open contact, or an open-collector NPN transistor

with its emitter connected to dc common.

Program the sensor using a specified sequence of

input pulses. The duration of each pulse is defined

as: 0.04 seconds < T < 0.8 seconds.

The required spacing between adjacent pulses in a

sequence (e.g., a “double-pulse”) is: 0.04 < T < 0.8

seconds. The timing diagrams illustrate the input

requirements.

Figure 9. Timing Programs

Disable or Enable the Push Button

When remote programming is used exclusively, it may be beneficial to disable the push button on the D11E to increase the security of the

settings.

1. To disable the push button: Pulse the remote input four times.

2. To enable the push button at a later date: Pulse the input four times (again).

NOTE: The push button can be enabled and/or disabled via remote line only.

Set Sensitivity Via TEACH Mode

1. Present the first (output ON) sensing condition to the sensor and pulse the remote input once.

2. Present the second (output OFF) sensing condition to the sensor and pulse the remote input once. The three LED indicators flash

simultaneously one to four times to indicate relative sensing contrast. The sensor returns to RUN mode.

Enable or Disable the 40-millisecond Pulse Stretcher

1. Pulse the remote input two times. The status of the pulse stretcher is indicated by the red LED: ON if the pulse stretcher is ON, and

double-flash if the pulse stretcher is OFF.

2. Pulse the remote input once to toggle the pulse stretcher ON or OFF.

3. Pulse the remote input two times to save the setting and return to Run mode.

Banner Engineering Corp Limited Warranty

Banner Engineering Corp. warrants its products to be free from defects in material and workmanship for one year following the date of

shipment. Banner Engineering Corp. will repair or replace, free of charge, any product of its manufacture which, at the time it is returned

to the factory, is found to have been defective during the warranty period. This warranty does not cover damage or liability for misuse,

abuse, or the improper application or installation of the Banner product.

THIS LIMITED WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES WHETHER EXPRESS OR IMPLIED (INCLUDING, WITHOUT LIMITATION, ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE), AND

WHETHER ARISING UNDER COURSE OF PERFORMANCE, COURSE OF DEALING OR TRADE USAGE.

This Warranty is exclusive and limited to repair or, at the discretion of Banner Engineering Corp., replacement. IN NO EVENT SHALL

BANNER ENGINEERING CORP. BE LIABLE TO BUYER OR ANY OTHER PERSON OR ENTITY FOR ANY EXTRA COSTS, EXPENSES, LOSSES, LOSS OF PROFITS, OR ANY INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES RESULTING FROM ANY

P/N 44279 Rev. C www.bannerengineering.com - tel: 763-544-3164 7

Page 8

D11 Expert Series

PRODUCT DEFECT OR FROM THE USE OR INABILITY TO USE THE PRODUCT, WHETHER ARISING IN CONTRACT OR WARRANTY, STATUTE, TORT, STRICT LIABILITY, NEGLIGENCE, OR OTHERWISE.

Banner Engineering Corp. reserves the right to change, modify or improve the design of the product without assuming any obligations or

liabilities relating to any product previously manufactured by Banner Engineering Corp.

www.bannerengineering.com - tel: 763-544-3164

Loading...

Loading...