Page 1

NATIONAL

SmartVap

TM

REFRIGERATION

PROGRAM SPECIFICATIONS

AND OPERATING

INSTRUCTIONS

1079817

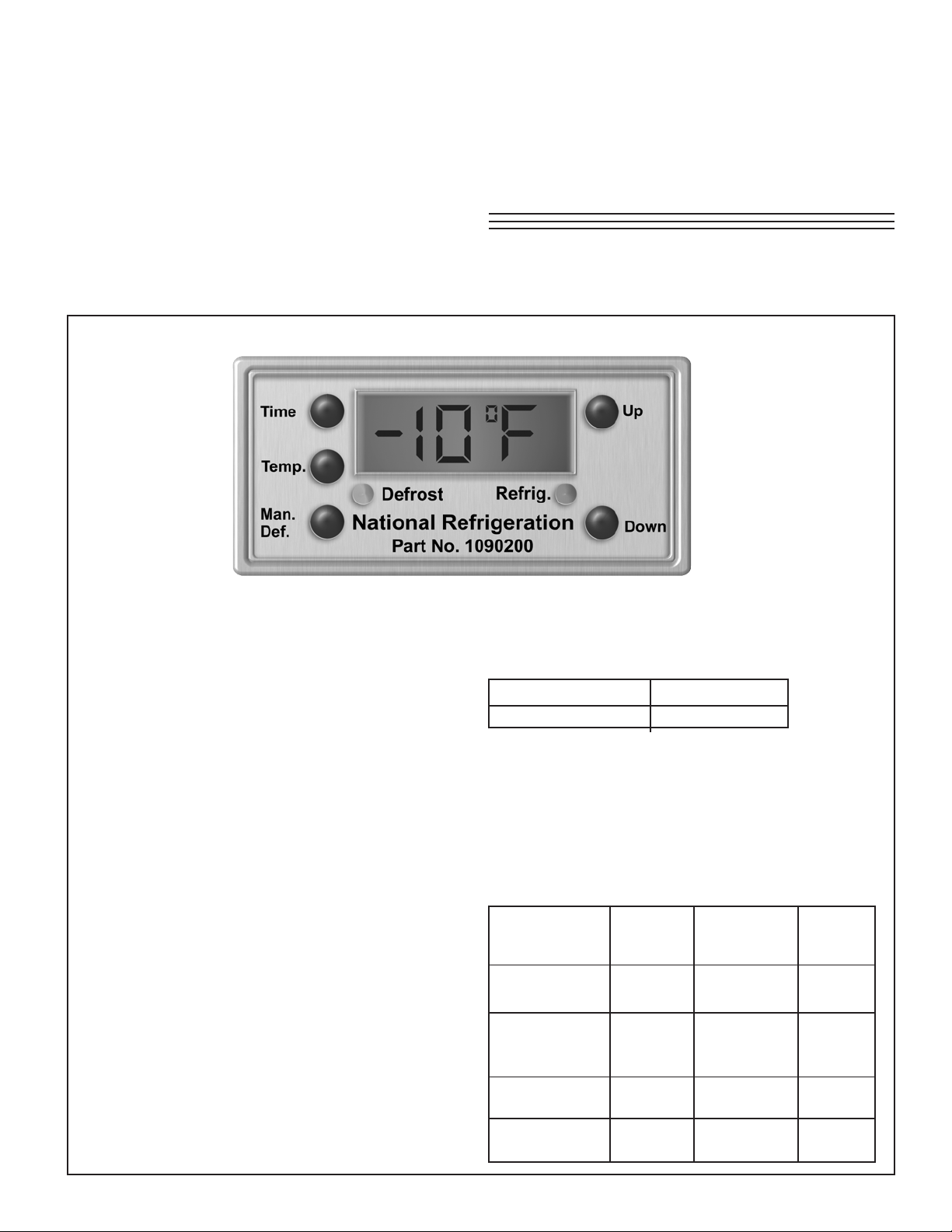

Electronic Room Thermostat & Defrost Control

Electronically

Controlled System

Model: (Part # 1090200)

Electrical Power: 115/1/60, 208-230/1/60

Factory Settings:

This Defrost/Temperature control has been

COMPLETELY pre-set at the factory for Electric

Defrost mode. Room temperature default

factory setting is –10ºF. Simply re-adjust if

different room temperature setting is required.

If desired, clock can be set to display the

current time (24 hour mode)

to retain all other factory settings initially , and

re-adjust accordingly later, if required.

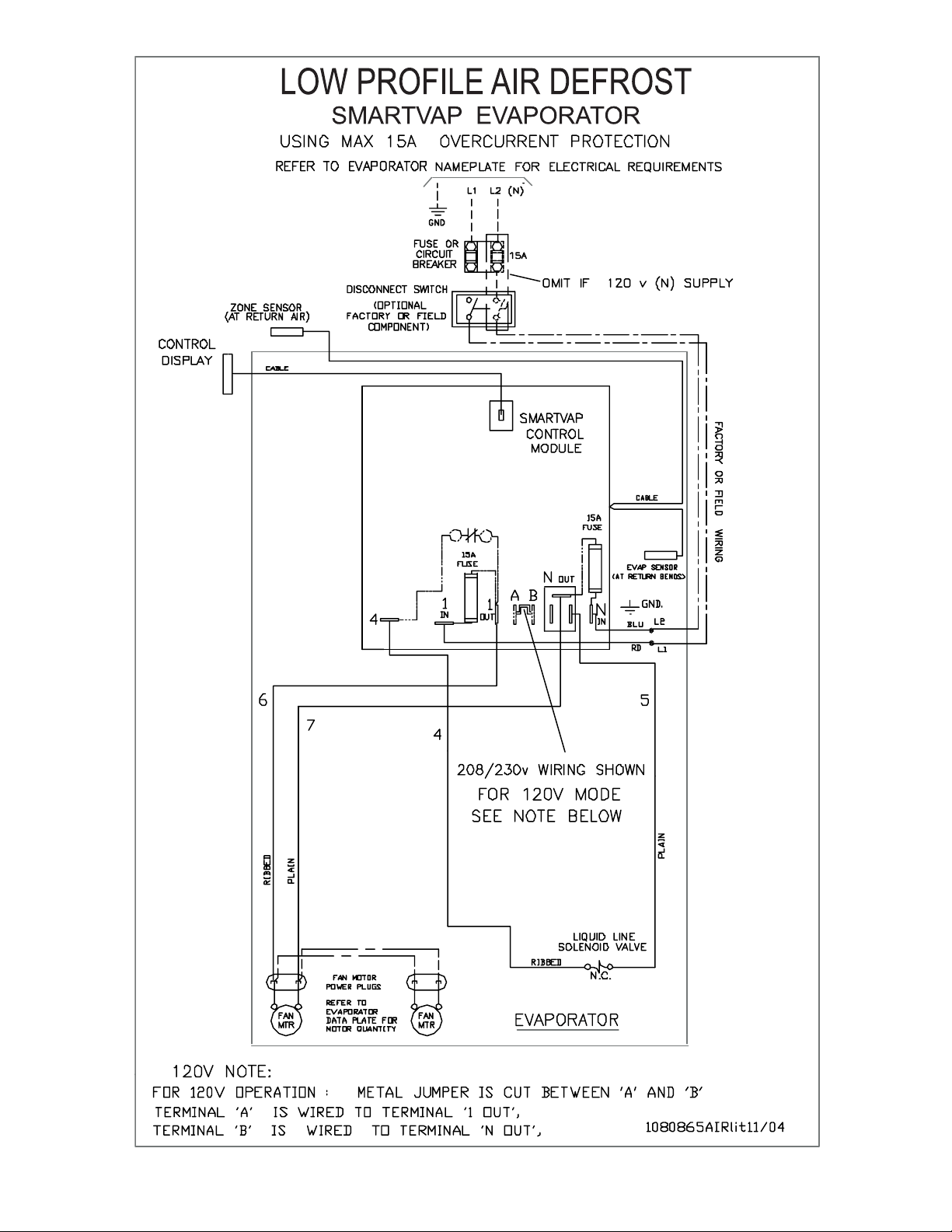

Also refer to control wiring diagrams on

following pages.

Note: Af ter power - up, allow 15 seconds for

display to activate

. It is recommended

Electric Defrost Mode Program

Default DISPLAY shows actual room (zone)

temperature:

Display shows: Range:

“-10ºF” -45ºF to 99ºF

Note: To gain access to control buttons, pry

up cover (use slot at bottom of cover)

“Time” Button Functions

To view TIME settings (in sequence listed below),

push and release the “Time” button

To adjust settings, hold down the “Time” button

while pushing “Up” or “Down” buttons.

Display Adjustment Factory

Function Shows: Range: Default

Setting:

24 hour time

of day

Number of

defrosts per “nd / 04” nd01 to 12 nd / 04

day (24 hrs)

First defrost “def 01 / 00:00 to

start time 09:00” 24:00

Maximum

defrost duration 2 hours

“24:00”

“defd / 35”

00:00 to

24:00

1 min. to

NA

09:00

35 min.

Page 2

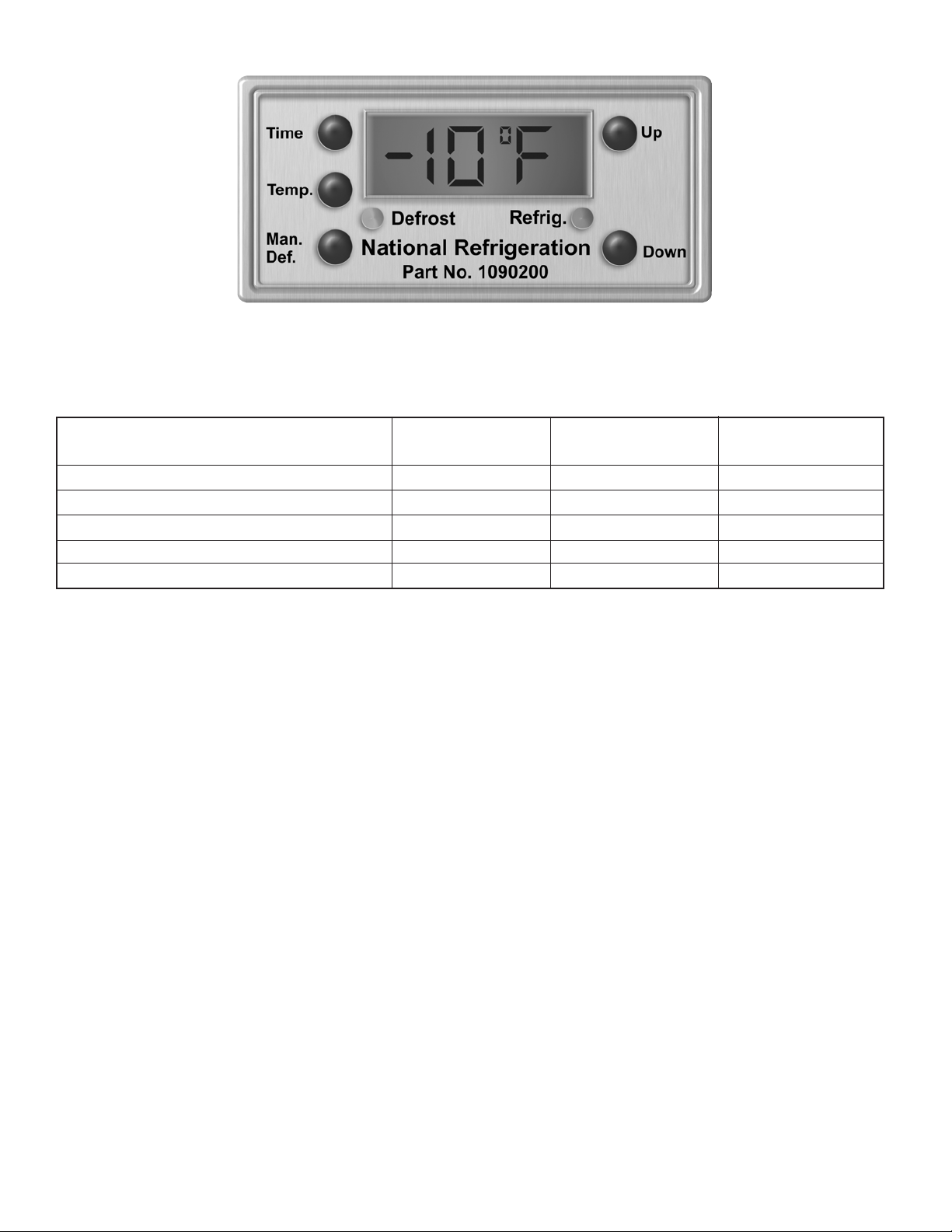

“Temp” Button Functions

To view TEMP settings (in sequence listed below), push and release the “Temp” button.

To adjust settings, hold down the “T emp” button while pushing “Up” or “Down” buttons.

Function Display Adjustment Factory Default

Shows: Range: Setting:

Temp (zone) set point cut -in “SPº / -10ºF” -40 to 99ºF -10ºF

T emp (zone) set point differential* “difº / 04ºF” 2 to 25ºF 4ºF*

T emp (evap) actual temperature “Evap” / actual ºF NA NA

Fan delay temp (fans cut-in) set point “Fdº / 25ºF” 15 to 30ºF 25ºF

Defrost termination temp cut -in set point “dtº / 55ºF” 40 to 70ºF 55ºF

* CAUTION: “Cut-Out” = “Cut-In” - “Diff”

Increasing this factory difº value will result in longer compressor running times and colder room temperature. Decreasing this factory difº value

will result in short compressor running on/off cycles.

“Man. Def” (Manual Defrost)

Button Function

This will immediately START a manual defrost

cycle if in refrigeration mode. If already in a defrost

cycle, this will stop the defrost cycle if pushed a

second time. This will not affect or override any

normal defrost programming.

TESTING NOTE: The defrost cycle will not start if

the EVAP sensor temperature is at a temperature

higher than that of the Defrost Termination Set point

(55ºF). The evaporator must be at a colder

temperature.

Push and hold button for at least 5 seconds to

activate. Do not push this button on and off without

waiting at least 5 seconds between periods.

Loss of Power

In event of loss of power, all programmed settings

will remain as those at time of power loss. Clock

time will remain at time of power loss (similar to

a conventional defrost clock). When power is

restored, wait at least 15 seconds for display to

indicate the Zone temperature (default display)

Restore Original Factory Default

Settings

To restore unit to original factory default settings:

- Push “Up” and “Down” buttons simultaneously

and hold for at least 5 seconds until display “Ed”

steadily appears (1 second).

- Release Buttons.

The clock is now programmed for factory settings

on Electric Defrost mode.

For Air Defrost (Ad):

- Push “Up” and “Down” buttons simultaneously

and hold for at least 10 seconds until display “Ad”

appears (after “Ed” disappears).

- Release Buttons.

The clock is now programmed for factory settings

on Air Defrost mode.

- 2 -

Page 3

- 3 -

Page 4

- 4 -

Page 5

- 5 -

Page 6

Troubleshooting Guide

WARNING: These guidelines are intended only for qualified service personnel familiar with

troubleshooting procedures and high voltage.

Problem

SmartVapTM control display

does not power up and

display zone temperature

Evaporator fans do not start

(Display OK and powers up)

Possible Solutions

1. Check for voltage (200 to 240V) at 1 IN and N IN (see wiring schematic

for terminal locations)— If NONE, check for voltage at field connections L1

and L2 or back at main panel service entrance. (Note: 3 and 4 Fan models have

inline 20 or 25A fuses (type LPCC or CCMR). Reject type fuse MUST be used

and inserted with smaller diameter end into holder, large diameter in

cap. If fuse(s) are blown, check/repair wiring for short before replacing fuse(s).—

If all above VOLTAGE OK, check voltage at 1 OUT and N OUT. If NONE then

check both 15A ceramic fuses. If fuse(s) are blown check for wiring short before

replacing fuse(s). (250V Rated Type ABC or MDA 15A must be used).

2. If above voltage OK, then check phone cord and cable connection at

module end. (Ensure cable is snapped in) CAUTION: KEEP FINGERS AWAY

FROM POTENTIAL VOL T AGE (terminal 3) when checking.

3. Push and hold “Up” and “Down” Display buttons together for 5 — 10

seconds. This will re-boot & reprogram the electronic clock to factory settings.

Ensure “Ed” mode (Electric Defrost) is selected.

4. Contact Factory

1. Check to see if display indicates “Defrost” mode (Yellow LED on).

Evaporator fans are designed to be shut off during defrost and after a defrost

cycle fans will not re-start until temperature reaches 25ºF at “evap” sensor.

2. Check connection of orange jumper from C to 1 OUT. Check voltage at

C and N OUT

— If NONE, see fuse checks above on “Display” troubleshooting

— If OK, check voltage at F and N OUT, If OK check fan wiring and voltage

at plug (motor end).

3.Check fan delay temperature setting (Factory pre-set at 25ºF) and readjust higher if required.

4. If fan delay setting is OK, check sensor at rear of unit cooler in return

air stream (top left hand side -in front of fins) Is it tagged “ZONE”? If tagged

“Evap”, switch sensor locations. (Move “Evap” sensor to correct location at return

bends.)

5. Contact Factory

- 6 -

Page 7

Problem

Possible Solutions

Refrigeration cycle will

not start (Display OK and

powers up)

Defrost heaters do not energize (Display OK and powers

up)

Poor Refrigeration /

Defrosting Performance /

Drain Pan Ice Up Problems

1. Green LED light (indicates demand for refrigeration) must be on.

Box temperature must be higher than set point temperature. Check display

T emp Setting for “SP”.

2. Liquid line solenoid must be energized. Check solenoid coil with small

screwdriver to confirm there is magnetic force. If no force, check voltage at

terminal 4 and N OUT, check solenoid coil wire splices in conduit box.

3. Check, with gauges, condensing unit low-pressure control setting. Is it

adjusted low enough to cut-in?

4. Contact Factory

1. Y ellow LED light (indicates defrost cycle mode) must be on.

Defrost cycle will not start if “evap” sensor is above 55ºF. Ensure refrigeration

mode has run long enough to reduce “evap” sensor temperature below 55 ºF

2.Check for Voltage between terminal 3 and 1 IN. Check all heater wire

spade connections, splice connections and jumper connections.

3. Contact Factory

1. Refer to regular Evaporator or Condensing Unit instruction manual

troubleshooting sections.

2. Contact Factory

Contact the factory or your local Sales Representative for further information or assistance.

- 7 -

Page 8

NOTES

01/07/05

PROJECT INFORMATION

metsyS

rebmuNledoM pU-tratSfoetaD

rebmuNlaireS rotcartnoCecivreS

tnaregirfeRenohP

ylppuSlacirtcelExaF

NATIONAL REFRIGERATION

& AIR CONDITIONING CANADA CORP.

159 ROY BL VD., BRANTFORD, ONT ARIO, CANADA N3R 7K1

PHONE: 1-800-463-9517 (519)751-0444 FAX (519)753-1140

Due to National Refrigeration’s policy of continuous product improvement, we reserve the right to make changes without notice.

Loading...

Loading...