Page 1

1-800-24 BALLY

www.mortuarycoolers.com

Installation Manual

Mortuary Cooler Systems

1. Installation Preparation 2

2. Establishing Mortuary Perimeter 3

3. Vertical Panel Assembly 3

4. Installing Door Panel 4

5. Installing Ceiling Panels 4

6. Anchoring Mortuary Cooler 4

7. Caulking Mortuary Cooler 5

8. Installing Refrigeration Unit 5

9. Installing SaniTray Rack and Tray 5

10. Installing Telescoping Tray 6

Assembly of a 6 or 9 Body Cooler 7

REV: 6/2014 IM-418-11 © 2014 Bally Refrigerated Boxes, Inc. 1

Page 2

Please read this instruction and any other installation material provided before starting the assembly of Bally

Figure 1

Figure 2

Figure 3

Mortuary Cooler. A plan showing the proper locations of panels is enclosed.

1. Installation Preparation

A. When the building is delivered, make sure you have the right equipment and manpower on hand to unload the

truck. A forklift or high jack can be helpful if the shipment includes heavy steel or refrigeration equipment. The

carrier typically imposes time constraints on unloading your box, and in all situations one person is not enough.

B. As you are unloading look for any freight damage; all products left our factory in perfect condition. Once the Bill of

Landing was signed by the carrier, safe delivery became their responsibility and the equipment became your

property. Check the packing list and make sure that all component parts are accounted for. Before signing the Bill

of Landing, inspect all items. If any damage is noted or the number of pieces received does not agree with the

invoice, do not accept shipment without notation by the carrier’s agent on the Freight Bill. If damage or shortage

is discovered when unpacking leave material and request an inspection by the carrier. Keep all documents and

information so you can file you claim properly with the carrier. The Bill of Landing, Freight Bill, and the original

invoice, are need to file a claim, and must be filed within the first six months from the date of shipment.

Do not substitute hardware or other materials supplied. If there are questions or missing components,

call the Bally Mortuary Sales Department at 1-800/24BALLY (1-800-242-2559)

C. Use extreme caution when unpacking to prevent damage to panels and other equipment. Pay close attention to

hardware affixed to the door and door-frame. Do not lift the door by its Hardware or the Light Base. Do not drop

panels or slide over unfinished surfaces. Keep panels dry and out of direct sunlight. The protective plastic coating

on the panels may be removed before or after the installation depending on the timing of construction schedules.

D. Check the packing list and make sure that all components are included in the shipment.

E. The most important requirement for o successful assembly is that the floor is level so that the panels will align

correctly and be plumb. Have a plumb line and level available during the installation and check panel plumbness

and levelness frequently.

F. The vertical and door panels are pre-numbered and must be positioned as depicted in the Plan View.

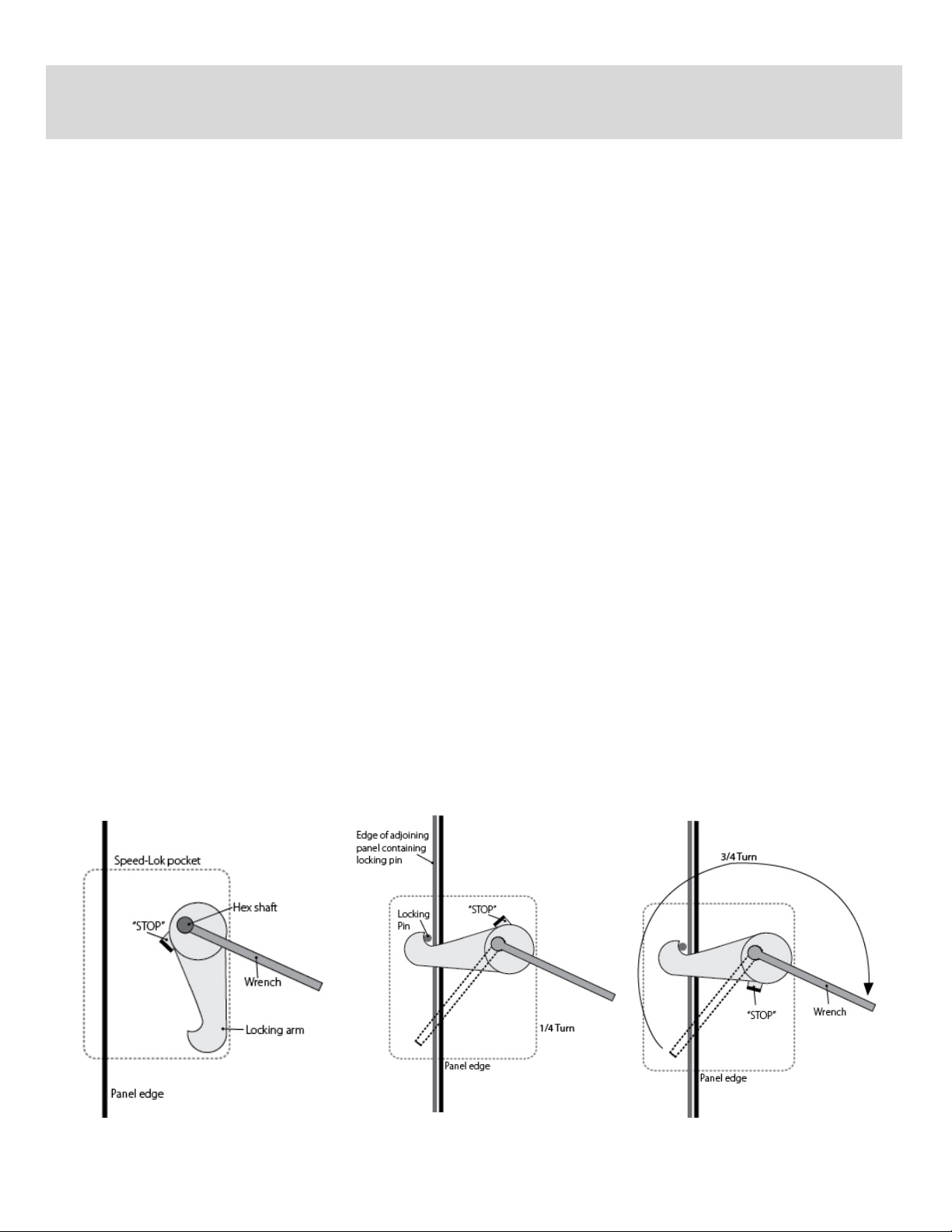

G. Familiarize yourself with the operation of the Speed-Loks. Study the figures and perform o few trial locks before

actual assembly. Speed-Loks are accessed from the interior of Mortuary Cooler. Turn Speed-Lok wrench clockwise

to engage the locking arm. See Figures 1, 2 and 3.

REV: 6/2014 IM-418-11 © 2014 Bally Refrigerated Boxes, Inc. 2

Page 3

Establishing Mortuary Cooler Perimeter

Figure 4:

Check Perimeter Outline

Figure 5:

Check Floor level

Figure 6:

Position Vertical Panels

A. The following instructions cover the erection of Mortuary Coolers that do not include Bally floor panels and

are shipped unassembled.

B. Mark the outside perimeter of the Mortuary Cooler on the building floor. Check the marked area for

squareness by measuring the distance across the corners as shown in Figure 4. Check floor for levelness. If

floor is not level, the panels will need to be shimmed to maintain the height of the highest point of floor.

Determine the highest point of floor using o 48" spirit level. If needed, establish a level string to help set

vertical panels. See Figure 5.

Vertical Panel Assembly

A. Position the first corner panel (#1) so the

outside of the panel is flush with the

perimeter line. If necessary, shim corner panel

to be level with the highest point of floor.

B. Position the center back vertical panel (#2) to

the corner panel and lock the adjoining side

Speed-Loks. Shim the second panel if

necessary for it to be plumb and level with

the corner panel. Ensure that the tops of the

panels are even. Insert Speed-Lok wrench

into access hole and turn clockwise until the

Speed-Lok locking arm stops. If Speed-Lok

was fully open, the wrench should make one

complete turn. See Figure 6 and 7.

C. Position the next rear corner panel and lock to

previously installed vertical panel. Check

panels for plumbness and levelness.

D. Proceed to position and lock the side vertical

panels as numbered. Check each vertical

panel for plumb and level when installed.

REV: 6/2014 IM-418-11 © 2014 Bally Refrigerated Boxes, Inc. 3

Page 4

Figure 7:

Lock Verticals Even at Top

Figure 8:

Mortuary Cooler Anchoring

Installing Door Panel

A. Remove the steel-shipping strap mounted at

the bottom of door panel opening. Position

door panel and align with vertical panels

previously installed.

B. Door panel is considerably heavier than vertical

panels and needs to be handled by at least (2)

able-bodied personnel. Ensure that door

panel is plumb and level and lock the

adjoining Speed-Loks. Shim door panel if

needed. If door panel is not installed plumb

and level, the door will not operate properly.

Installing Ceiling Panels

A. The Mortuary Cooler ceiling is made up of (2) ceiling panels that are locked together at the factory. Unlocking the

ceiling panels will damage the refrigeration unit opening.

B. Place ceiling panels on top of Mortuary as shown on the plan view. Align the edges with the vertical panels and

lock top Speed-Loks.

Anchoring Mortuary Cooler

A. Vertical panels are mounted to the building

floor using continuous angle, concrete anchors

and self-drilling metal (TEK) screws.

B. Angles are shipped in stock lengths and must

be cut before installation. Calculate angle

length by measuring inside of wall panels and

subtract 4 ". Angles will start 2" from each end

wall. See Figure 8.

C. Set angle along bottom of vertical panels with

larger holes on floor and mark concrete anchor

holes with a builders crayon or similar method.

D. Drill ¼” hole 2" deep in concrete at marked

locations. Set angles back in place and install

concrete anchors. Install self-drilling metal

screws (TEK) through upright leg of angle

through predrilled holes.

REV: 6/2014 IM-418-11 © 2014 Bally Refrigerated Boxes, Inc. 4

Page 5

Caulking Mortuary Cooler

Installing Refrigeration Unit

Figure 9:

Clamp Detail for Body Tray Racks

Figure 10:

Assembly of Body Tray Rack

A. Make final checks of Mortuary Cooler panels for

a square and plumb installation. Add or

remove shims as needed.

B. Caulk bottom of the exterior and interior of wall

panels using a silicone sealant that is mildew

and waterproof.

Ensure that refrigeration unit is not stored or moved from horizontal.

Installing SaniTray Rack and Tray

A. The SaniTray cross members and side rails on the

1-3 body cooler are identical.

B. Position cross members within vertical channel

slots with the ball bearing side facing up and the

open side facing to the rear. Install clamps halves

and hardware and tighten when cross member is

level and at desired height. See Figure 9 and 10.

C. The guide channels are marked left and right and

top, middle (if there is a third tier) and bottom.

These must be positioned as marked. It will be

easier to adjust and secure guide channels if

bottom guide channels are mounted first and

then the next immediate levels.

D. Position bottom level guide channels with the

open ends facing inwards. Install mounting

hardware loosely and slide body tray fully into

Mortuary Cooler. Align body tray within guide

channel adjustment to slide straight out of

Mortuary Cooler. Tighten hardware for guide

channels. Guide channels should fit loosely

against body tray. Remove body tray out the way

before installing next row of guide channels.

A. Refrigeration unit is positioned as shown on plan view.

Use the listed weights of refrigeration units to determine

the method of lifting. The end of the refrigeration unit

that is opposite of the bottom vent is the heavier end

containing the compressor. Cardboard placed on top of

Mortuary Cooler will help slide refrigeration unit into

place and protect exterior finish.

REV: 6/2014 IM-418-11 © 2014 Bally Refrigerated Boxes, Inc. 5

Page 6

Figure 12:

Installing the Telescoping Body Tray Assembly

Figure 11:

angle.

Proper order in which the clamps should be attached.

Figure 13:

1. With the back and two sidewalls erected and fastened together, place the

telescoping tray assembly into the partially constructed box. See Figure 11.

Insure that the ends of each cross brace are inserted into the vertical

struts. See Figure11a.

2. Raise and suspend the assembly to the desired height with temporary

supports. See Figure12.

3. At this time, securely fasten the cross braces to the supports struts with the

furnished clamps. See Figure 13.

Figure 11a:

Assembly tray inserted

into the vertical struts.

Telescoping tray

inserted at a 45°

Cross braces attached to

struts with clamps.

See Figure 9 on pg 5.

REV: 6/2014 IM-418-11 © 2014 Bally Refrigerated Boxes, Inc. 6

View of raised tray

assembly on

temporary supports.

Loading...

Loading...