Page 1

1-800-24 BALLY

Bally Refrigerated Boxes, Inc.

www.ballyrefboxes.com

Modular Buildings

Installation Manual

1. Introduction 2

2. Marking Installation Area 2

3. Speed-Lok Operation 2

4. 'Z' Base Trim 3

5. Less Floor Walk-Ins 3

6. Floor Panel Installation 4

7. With-Floor Installation 4

8. Door Panel Installation 4

9. Multi-Compartment Walk-Ins 5

10. Interior Steel 5

11. Shear Plates 5

12. Batten Strips 5

13. High Wind Securing 6

14. Outdoor Considerations 6

15. Door Rain Shield 6

16. Wall Standards 6

17. Panel Penetrations 7

18. Prevent Vapor Leaks 7

19. Grounding 8

20. Broken or Stripped Locks 8

REV: 1/2013 Instruction Manual IM-238-94 2013 © Bally Refrigerated Boxes, Inc. 1

Page 2

1. Introduction

A. When the building is delivered, make sure you have the right equipment

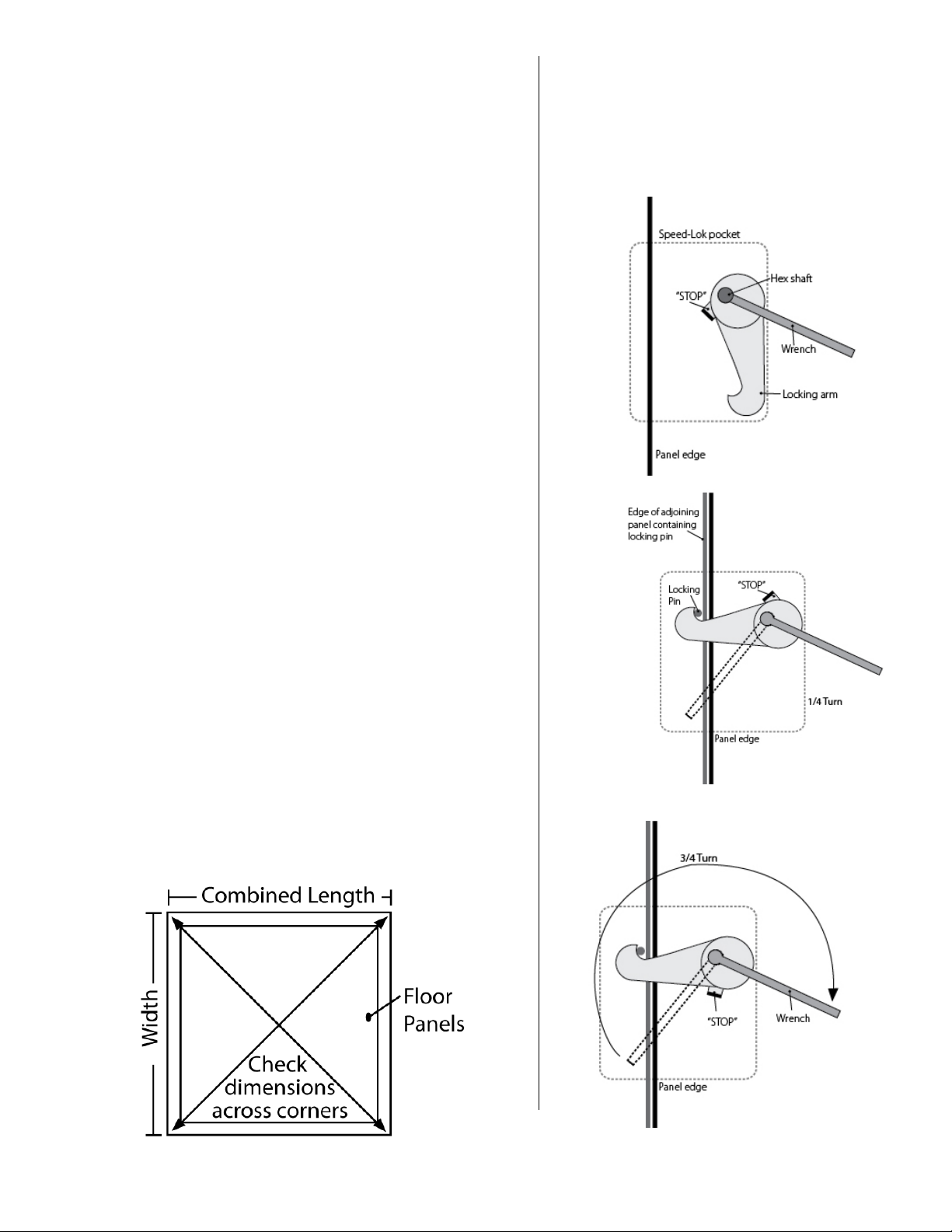

3. Speed-Lok Operation

Before attempting to erect panels, familiarize

Figure 3

Figure 2

Figure 1

and manpower on hand to unload the truck. A forklift or high jack can

be helpful if the shipment includes heavy steel or refrigeration

equipment. The carrier typically imposes time constraints on unloading

your box, and in all situations one person is not enough.

B. As you are unloading look for any freight damage; all products left our

factory in perfect condition. Once the Bill of Landing was signed by the

carrier, safe delivery became their responsibility and the equipment

became your property. Check the packing list and make sure that all

component parts are accounted for. Before signing the Bill of Landing,

inspect all items. If any damage is noted or the number of pieces

received does not agree with the invoice, do not accept shipment

without notation by the carrier’s agent on the Freight Bill. If damage or

shortage is discovered when unpacking leave material and request an

inspection by the carrier. Keep all documents and information so you

can file you claim properly with the carrier. The Bill of Landing, Freight

Bill, and the original invoice are need to file a claim, and must be filed

within the first six months from the date of shipment.

C. Use extreme caution when unpacking to prevent damage to panels and

other equipment. Pay close attention to hardware affixed to the door

and door-frame. Do not lift the door by its Hardware or the Light Base.

Do not drop panels or slide over unfinished surfaces. Keep panels dry

and out of direct sunlight. The protective plastic coating on the panels

may be removed before or after the installation depending on the timing

of construction schedules.

D. The most important requirement for installation of this Walk-In is to have

a level floor. If the floor is level the process will be very smooth.

Otherwise, it’s impossible to make sure that the panels will align correctly

and be plumb and level. Use a laser level or transit to identify the high

spots on the floor. Whenever Walk-Ins are to be installed where concrete

is curing or tile is being set, it is important to provide adequate

ventilation. Concrete and tile grout release hydrogen while curing,

which can damage the finish.

2. Marking Installation Perimeter

The most important requirement is that the Modular Building is installed

over a complete and level floor. This will ensure that the vertical panels

will align correctly and be plumb. Locate and mark the outside

perimeter on the surface where the Modular Building will be installed.

Check marked area for squareness by measuring across the corners.

yourself with the operation of the locks Figures 1, 2,

and 3. On Bally panels, locks will always be on the

left turning in clockwise rotation. If for any reason

you have to unlock a panel, refer to Section 19.

REV: 1/2013 Instruction Manual IM-238-94 2013 © Bally Refrigerated Boxes, Inc. 2

Page 3

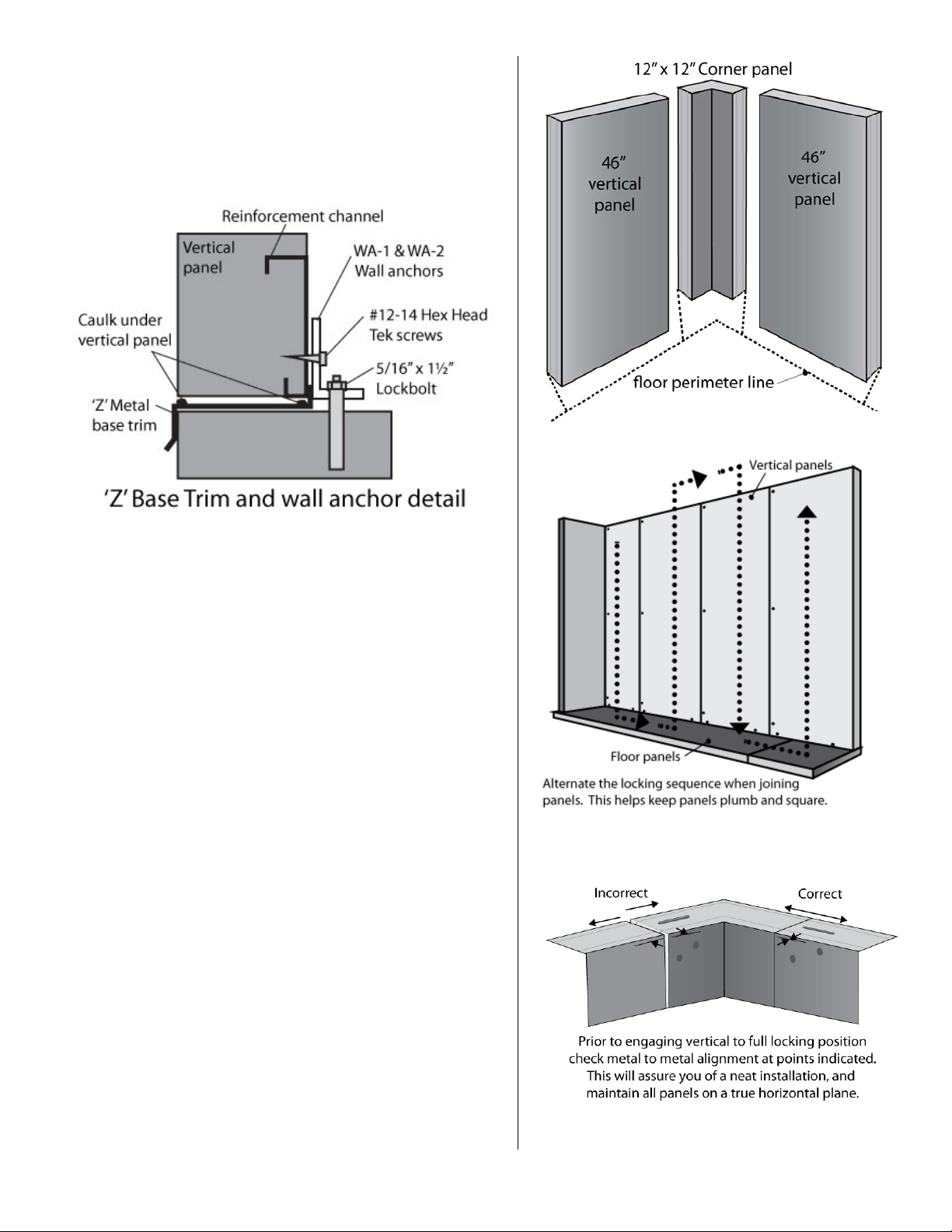

4. "Z' Base Trim (Optional)

'Z' Base trim is installed along bottom edges of Modular Building that

Figure 7

Figure 4

Figure 6

Figure 5

are flush with concrete pad. 'Z' Base trim is outlined and installed on

concrete pad before the placement of vertical panels. 'Z' Base trim

should be secured to concrete pad by installer. Vertical panels will be

secured with wall anchors after Modular Building erection. Apply

caulk along exterior and interior seam along vertical panels and 'Z'

base trim. See Figure 4.

5. Installation of Less-Floor Walk-Ins

A. After you have checked that the building floor is level, use a transient

or builders level to find the highest point on the perimeter. Position

the first 12 x 12 corner to be level with the high point. Begin at

corner and align panels at the top. See Figure 5.

B. Position a vertical panel to the right and left of the corner panel (as

per Plan View) and flush with the perimeter line. See Figure 7. Once

these panels have been aligned properly, fully engage all vertical-tovertical locks.

C. Level these panels to the perimeter high point and check for plumb

with a 48” spirit level. (Panels over 10’ in height should be checked

for plumb with a plumb bob.)

D. As each panel is installed, check to make sure it’s plumb and level. If

the panel is not plumb, shim to adjust for plumb. Making the same

check down the panel’s leading edge shows whether it’s level along

the top or not. If not adjust accordingly.

E. Continue installing vertical panels in the same manner, periodically

checking to make sure that panels remain plumb and level. See

Figure 6. (staggered locking sequence).

F. When enough vertical panels are set to accept the installation of the

first ceiling and end panel, begin assembly of the ceiling panels. See

Section 7 for method of installing remaining vertical and ceiling

panels.

G. With installation complete, caulk the bases of the vertical panels

where they meet the concrete floor.

REV: 1/2013 Instruction Manual IM-238-94 2013 © Bally Refrigerated Boxes, Inc. 3

Page 4

6. Floor Panel Installation

A. Make sure the floor is level. The entire area beneath the Walk-In floor should be

7. With-Floor Installation

Begin by erecting the 12” x 12” vertical

ed to one another.

F. When all walls and ceiling panels are in

place, lock all vertical panels to floor panels.

8. Door Installation

hinge at a time and do not loosen hinge base screws while door is open.

covered with a heavy polyethylene vapor barrier to prevent possible damage by

moisture.

B. Check drawings for any special panel configuration, then place a 23½” wide

floor end panel along the most logical starting point (usually the furthest corner,

if to a building wall if possible). Be sure the panel is a floor panel. All floor

panels have extra-heavy gauge metal on the interior for extra strength. Again,

make sure panel is level to high point of concrete slab.

C. Set the first floor panel section in place, then install the next panel and align.

Leveling occurs every time a new panel is installed. Remember to level to the

high point of the concrete slab.

D. Install shims (such as cedar shakes) under corners and cross panel joints as

needed to ensure proper support and levelness of panels. Be sure the shims are

not more than 23” apart at any given point under the panel. Place additional

shims, equally spaced, along the door frame area. This is done in order to

support the panels properly and eliminate any potential sagging.

E. Continue to install floor panels as per Plan View, locking each panel to its

adjoining panel. Make sure to keep ends or panels even with one another.

Continue until all floor panels are assembled. Again check them for levelness

and sqaureness. (Adjust if necessary.)

F. Check bottom section of door to be used to insure the proper door is being in

the proper location. Doors are specifically located by the floor plan drawing

which is enclosed with the installation instructions. A freezer door may have a

different stepplate condition than a cooler door. Follow the suffix 01 – 02 that

corresponds to the drawing.

G. If structural steel is required it should be located and installed before installing

further.

A. Determine the critical areas to find a starting

point. On smaller Walk-Ins the most critical

area is the door location. This section of the

Walk-In must be perfectly plumb and square

to insure proper operation of the door.

B.

corner panel at a convenient corner, if the

Walk-In is being installed near a building

start at a corner nearest that. Note that the

Speed-Lok holes must always be on the lefthand side when facing the interior of the

panel.

C. Next, erect the vertical panels called for by

the panel view to the right and left of the

corner panel. Make sure to align the tops of

the panels. This will help to insure that the

panels remain plumb and level. Lock these

panels together and check to make sure the

lock is engaged in the pin box properly. Be

sure the proper metal finish is exposed

where specified on the plan view.

D. When enough vertical panels have been set

to allow installation of the first ceiling panel,

install the panel walls in an order that will

allow a ceiling section to be installed before

proceeding with more panel walls. The

ceilings should be fasten

When two or three ceiling panels are in

place, lock the first ceiling end panel to the

vertical panels to prevent shifting.

Door sections are held down through the

threshold plate. Drill through thresholds’

pre-drilled holes into floor. Secure to floor

with screws provided. See Figure 8.

A. When erecting a door panel for an installation on a concrete floor and without Bally floor panels, it is necessary to provide a cutout in

the concrete floor for all freezer applications so that the heater channel may be inserted to prevent icing. Doors intended for Coolers

are simply set on top of the concrete.

If your door sticks out at the top your frame is not plumb; you’ll need to move the bottom frame in or out to correct this problem.

•

If the gap at the top of the door is inconsistent your frame is not level and the door latch may not work properly. Shim the low side

•

of the frame to level it with the high side.

B. Caulk and seal any gaps under panels or door to floor. Apply base trim as per plan view. For outdoor installation it is recommended

that all exterior panel joints be caulked during installation.

C. Troubleshooting: Check if door panel is square and plumb with 48" spirit level. To adjust door panel, loosen side, top and bottom

Speed-Loks and tap with wood block and hammer. Adjust either interior or exterior of door panel. If Modular Building door is

installed properly, no shimming is required. Shimming should only be used in conditions were the existing floor is very uneven or in

cases of poor installation. Check if door cap is toed out at top or bottom within door panel. Loosen the hinge base screws on door

panel and install shims at diagonally opposite end of door cap that is toed out. Do not loosen hinge base screws of more than (1)

REV: 1/2013 Instruction Manual IM-238-94 2013 © Bally Refrigerated Boxes, Inc. 4

Page 5

9. Multi-Compartment Walk-Ins

should always be on the colder compartment side, usually the freezer.

Shear plate locations are described on the

plan view of the Modular Building. Shear

Batten strip locations are described on the

y. Tekscrew centers should be

lateral steel. Install lateral steel as shown on plan view details.

Tekscrews through RA-1 tabs to secure to interior steel.

A. The most common arrangement for a Walk-In is a two compartment

Cooler/Freezer combination. Installation of panels in this situation is the same as

described above. The use of a “Breaker” or “Tee” panel is used to separate the

different compartments. These panels will be either 23” or 46”; typically the

verticals are the opposite of the ceilings and floors.

B. The Partition Wall will have at least two special panels referred to as P-1 and P-2.

The panel widths are either 7.6” or 9.1” and are marked with a special blue sticker

that corresponds to the drawing. The P-2 panels are double tongued (hook

pockets on both sides) which allows for final locking of the partition wall.

C. In large multi-compartment Walk-Ins, (three compartments or more) it is very

important to control the alignment of the panels and make sure if there is any

growth in the vertical panels that they are growing at the same rate as the

ceiling and floors. A quick and accurate way to check for correct alignment is to

measure the distance from the edge of the ceiling to the nearest vertical panel

joint. This measurement must be 11½”; it must be maintained at every joint to

assure proper assembly of the Walk-In. In these instances we recommend that

after the floors are placed and leveled that the center most partition be the

starting point and to work toward either end of the box.

D. Look at the plan view and take special note of which side of the panels the

wrench hold are on.

If there is not a door in the partition wall the panels will lock to ceiling and floors in

either orientation. An error on the partition wall could cost many man hours to

correct. The entire box will most likely have to be taken down to correct this error

because condensation will occur. As a general rule of thumb, the wrench holes

10. Interior Steel

A. Interior steel framework is assembled before Modular Building assembly. Details

and layouts for interior steel are given on the plan view. Steel pieces are painted

primer and are numbered for identification.

B. Mark the exact outside perimeter as previously described. Check that outline is

square. See Section 3.

C. Using the plan view and base plate details, mark the positions of centerlines in

relation to perimeter. Once base plate locations are anchor bolt locations can be

determined using base plate details. See Figure 9.

D. If the floor surface is considerably uneven, find the highest point of steel column

positions and level all other columns to this height using leveling grout or plates

11. Shear Plates

plates are installed over Speed-Lok locations

using 6 self-drilling Tekscrews provided by

Bally.

12. Batten Strips

plan view of the Modular Building. Batten

Strips are installed over vertical and/or

ceiling joints. Batten Strips are to cut length

and installed using Tekscrews provided by

Ball

approximately 2" from ends and 8" center to

center.

(Supplied by installer).

REV: 1/2013 Instruction Manual IM-238-94 2013 © Bally Refrigerated Boxes, Inc. 5

Note: Depending on architectural specifications, J-bolts can be

foamed into concrete when slab is poured or anchor bolts after

concrete slab is cured. Place all columns into position and

secure them to concrete slab. Plumb columns and position

When ceiling panels are assembled, install provided self-drilling

Page 6

13. High Wind Securing

The following high wind anchoring methods are suggestions and

Bally supplies door canopies for outdoor installations. It is

16. Wall Standards for Mounting Equipment

ion standard against vertical panel with one end

level. Mark hole locations with maker and drill using

Hold ceiling bracket in against ceiling panels and mark

screws and

Figure 11

are not inclusive of all possible anchoring methods. The type of

anchoring and the space between tie downs are dictated by local

building codes. All materials used are provided by building installer.

A. Anchor Bolt Through (For Modular Buildings with floors only):

Anchor bolts are located in concrete prior to Modular Building

installation. Anchor bolt locations should avoid floor panel

penetration limits and compression plates should be at least ½”

from interior of vertical panels.

B. Eye Bolt and Hold Down Cable: Anchor bolts are located in

concrete prior to Modular Building installation. Light Structural

Member determined by local building code advisory. Light

Structural Member should be placed as to not trap water.

Precautions should be taken to prevent Light Structural Member

from chafing exterior membrane roof.

C. Earth Anchor and Hold Down Cable: Earth Anchors can be

located after Modular Building installation. Installer should use

Anti-Flutter Padding to keep hold down cable from chafing

exterior roof. Distribution angle should be at least 18" to allow

hold down cable to migrate and allow ample load distribution.

14. Outdoor Considerations

All outdoor installations require some type of weather roof to cover

the top of Modular Building.

A. Aluminum Roofs are available for buildings that have a wall width

of 34' 7" or less. See Instruction Manual IM-276-90.

B. Membrane (polyvinyl sheet) Roofs are available as dictated by

building specifications. See Instructions for Membrane Roof.

Wall post locations are determined by customer equipment

arrangement within Modular building. Please note the

location limits shown. See Figure 10.

A. Posit

touching ceiling panels. Check standard plumb with 48"

3/32" drill. Do not punch holes. Install standard with #8½” screws. Install screws in all wall post mounting holes.

B. Temporarily install ceiling bracket with (2) clamps halves,

(1) 3/8" x 1¼" bolt and (1) 3/8" nut at top of standard.

the (4) mounting holes with marker. Drill 3/32" holes and

install ceiling bracket with (4) #8-½”

previously mentioned clamp. See Figure 11.

C. Ceiling panel exterior joints must be caulked with silicone or

other waterproof sealant after assembly. Floor panels must be

elevated above immediate area of installation. Concrete pads

must have drainage as shown in Bally floor detail on plan view.

Installation must not allow water to seep under Modular Building.

15. Door Canopy

recommended that canopy be installed over door opening to

prevent water damage and icing. Apply caulking to back of canopy

mounting flanges. Form fillet with caulking when canopy is mounted.

Install canopy centered and level over door opening with provided

self-drilling Tekscrews. Canopy height should be high enough to clear

door operation.

REV: 1/2013 Instruction Manual IM-238-94 2013 © Bally Refrigerated Boxes, Inc. 6

Page 7

17. Panel Penetrations

If penetrations in panels are needed, avoid the areas

18. Prevent Vapor Leaks

is installed settles. If the internal

across from the vapor leak which can make locating a leak

All wall penetrations should be sealed. This includes any

that are shown. Penetrations should be made as needed

by competent installer or mechanical service. If shaded

areas are avoided, urethane insulation can be easily

removed from opening. After equipment installation, fill

in hole with permagum caulk. See Figure 12.

Condensation in electrical junction boxes can be

eliminated by installing a seal-off fitting in conduit

where they pass through Modular Building walls.

A. Modular panels are square and dimensionally accurate so in most

installations they will seal effectively against vapor leaks. However

in some unusual cooler applications, minor vapor leaks may occur.

The leaks can occur if the panels follow slab variations or if the

building in which the Walk-In

temperature is cycled periodically, the expansion and contraction

of building materials will cause enough movement to allow some

vapor penetration.

B. Unfortunately, internal dripping does not always occur directly

troublesome. In order to avoid time-consuming search procedures,

caulk the exterior junction of three or more panel joints. Most leaks

caused by settlement will be at these points.

C.

protruding clips or hangers installed in panels joints.

D. Use either industrial-grade or silicone calking. When silicone is

used, sealed areas must be cut opened whenever the panels are to

be disassembled for relocation or enlargement.

REV: 1/2013 Instruction Manual IM-238-94 2013 © Bally Refrigerated Boxes, Inc. 7

Page 8

19. Grounding

Figure 13

Ensure that all protective plastic coating is removed from

panels.

A. Install Angled Batten strips along interior top of Vertical

panels using #8 3/4" Metal screws (Install Angled Batten

strips along interior bottom of Vertical panels if Modular

Building has Floor panels). Install Braided copper wire at

every Speed-Lok location for Ceiling end panels using #8

2-1 /2” Metal screws (Install wires at Speed-Lok locations

for Floor panels if equipped). Install Metal screws in line

with Speed-Lok holes and at least 3" from edge of panel.

B. If Modular Building does not have a Bally aluminum roof,

install exterior Batten strips using #B 3/4" Metal screws.

C. Install #8 2-1 /2" Metal screws at Speed-Lok locations on

both legs of Corner panels. Install Metal screws at the

same height of Speed-Loks and at least 3" from edge of

Corner panel.

20. Broken or stripped locks

A. The panel contained the lock must be slid away from adjacent

panels in order to obtain adequate working space. First check for

any obstructions (dirt, foam, etc) once you have unlocked a panel

reset the cam stop by turning the lock fully back to it’s original

position. If the hook is broken or stripped replacements can be

found in Miscellaneous Parts Box#1.

B. Position the lock wrench on the hex rod and turn clock-wise until

the locking arm protrudes. See Figure 13.

C. Place your hand near the bend in the wrench as shown in Figure

5 and use a lift-up motion. This will produce a clamping action

on the hex rod. While doing this, pull forward until the rod is free

of the panel. The locking arm will then drop free.

D. Hold the new locking arm in position. Make sure the hook of the

arm faces in the proper direction. See Figure 14

E. Insert the new hex rod into the lock hole. Care must be taken to

insert the notched end of the rod. The end to be inserted has a

notch located 1” from the end. This notch acts as a stop so the

rod will not be inserted too far.

F. Align the hex rod with the hex hold of the locking arm; gently tap

it until the notch stops against the locking arm.

G. Replace and refasten the panel in its original position.

1-800-24BALLY

ballysales@ballyrefboxes.com

Phone: 252.240.2829 | Fax: 252.240.0384

135 Little Nine Drive Morehead City, NC 28557

www.ballyrefboxes.com

REV: 1/2013 Instruction Manual IM-238-94 2013 © Bally Refrigerated Boxes, Inc. 8

Loading...

Loading...