Bally Refrigerated Boxes IM-268-11 Installation Manual

Pre-Engineered Walk-In Coolers and Freezers

Installation Manual

Part One: The Bally Walk-In

1. Preparation for Installing the Walk-In ___________________________________________________ 3

2. Operation of the Bally Speed-Lok _____________________________________________________ 3

Part Two: Installation

1. Positioning ______________________________________________________________________ 4

2. Walk-Ins with Screeds ______________________________________________________________ 4

3. Installing Less-Floor Walk-Ins _________________________________________________________ 4

4. Door Installation __________________________________________________________________ 5

5. Installing With-Floor Walk-Ins ________________________________________________________ 5

6. Vertical and Ceiling Panel Installation __________________________________________________ 5

7. Installing Multi-Compartment Walk-Ins _________________________________________________ 6

Part Three: Other Important Information

1. Preventing Vapor Leaks _____________________________________________________________ 6

2. Partition Wall Caulking _____________________________________________________________ 7

3. Air Gap Circulation Recommendation _________________________________________________ 7

4. Making holes for Refrigeration Tubing and Electrical Lines __________________________________ 7

5. Making Electrical Connections to Entrance Doors and Vapor-proof Lights ______________________ 7

Part Four: Completing the Bally Installation

Completing Installation of the Walk-In ___________________________________________________ 9

1-800-24BALLY | sales@ballync.com

UPDATED: 4/2015 Instruction Manual IM-268-11 2015© Bally Refrigerated Boxes, Inc. 1

Miscellaneous Box #1 with the orange sticker

contains all the information you will need.

• Before attempting to install the Bally Walk-In, review these instructions and any others supplied

with the shipment.

• For future reference, make sure there is a record of the original order number and a list of all se-

rial numbers for the Walk-In and refrigeration systems.

• A plan view showing the proper layout of panels is enclosed with other documents as well as this

manual. Make sure you are using the “As-Built” drawings as opposed to any previously supplied

“Proposal” drawings.

• Before placing any panel into position, check the plan view for location.

1. Installation Preparation

A. When the building is delivered, make sure you have the right equipment and manpower on hand to unload the truck. A fork-

lift or high jack can be helpful if the shipment includes heavy steel or refrigeration equipment. The carrier typically imposes

time constraints on unloading your box, and in all situations one person is not enough.

B. As you are unloading look for any freight damage; all products left our factory in perfect condition. Once the Bill of Landing

was signed by the carrier, safe delivery became their responsibility and the equipment became your property. Check the

packing list and make sure that all component parts are accounted for. Before signing the Bill of Landing, inspect all items.

If any damage is noted or the number of pieces received does not agree with the invoice, do not accept shipment without

notation by the carrier’s agent on the Freight Bill. If damage or shortage is discovered when unpacking leave material and

request an inspection by the carrier. Keep all documents and information so you can le you claim properly with the carrier.

The Bill of Landing, Freight Bill, and the original invoice, are needed to le a claim, and must be led within one week of the

date of shipment.

C. Use extreme caution when unpacking to prevent damage to panels and other equipment. Pay close attention to hardware

axed to the door and door-frame. Do not lift the door by its Hardware or the Light Base. Do not drop panels or slide over

unnished surfaces. Keep panels dry and out of direct sunlight.

D. The protective plastic coating on the panels may be removed before or after the installation depending on the timing of

construction schedules. The protective plastic on the bottom of the oor panels must be removed prior to setting the oors

in place. In all cases, ALL plastic must be removed before the nal completion of the installation. This includes all unexposed

areas and all surfaces under membrane roofs.

E. The most important requirement for installation of this Walk-In is to have a level oor. If the oor is level the process will be

very smooth. Otherwise, it’s impossible to make sure that the panels will align correctly and be plumb and level. Use a laser

level or transit to identify the high spots on the oor. Whenever Walk-Ins are to be installed where concrete is curing or tile is

being set, it is important to provide adequate ventilation. Concrete and tile grout release hydrogen while curing, which can

damage the panel nishes, especially any type of Aluminum nish.

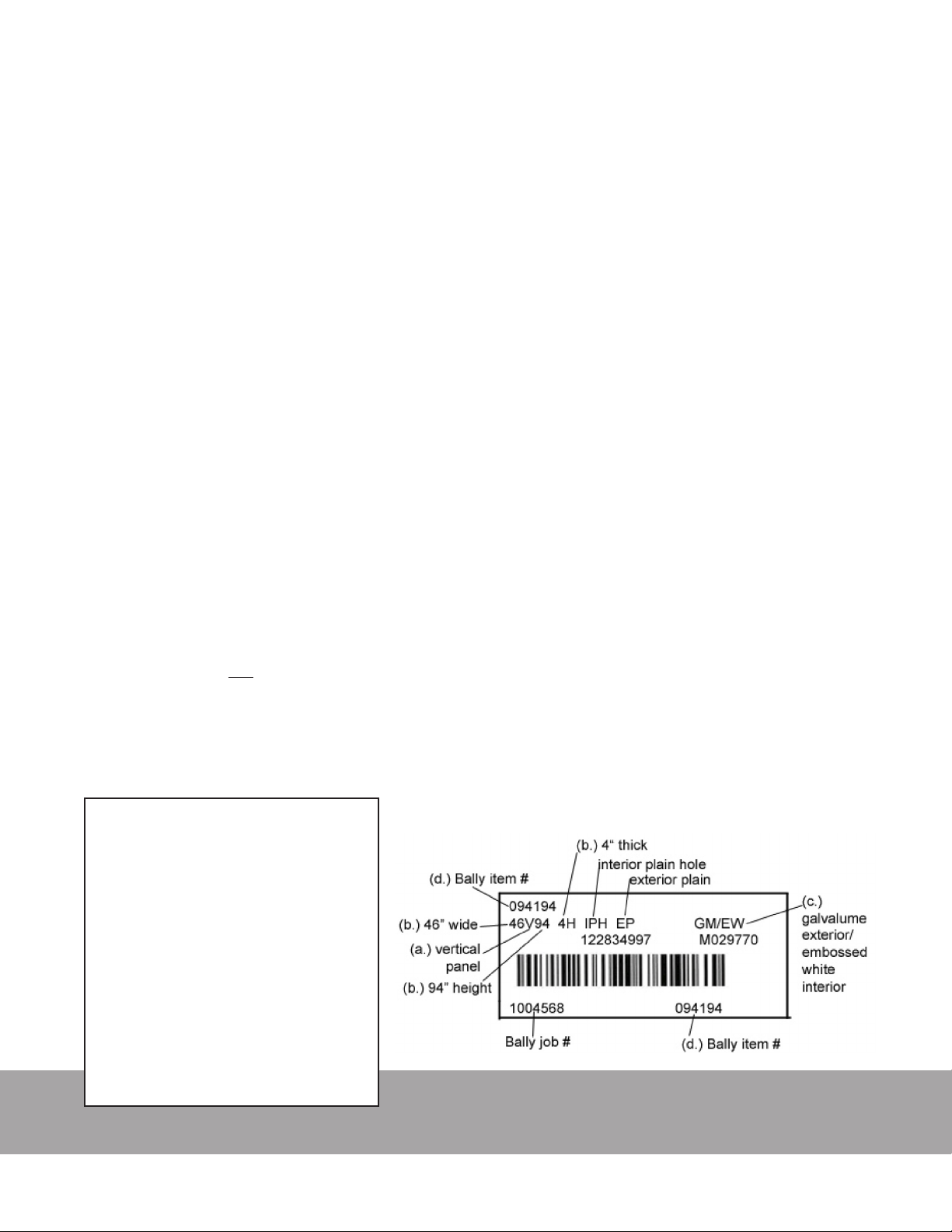

Bally identies panels with

barcode labels that specify:

a. Panel type:

FLR- Floor

CLG- Ceiling

V- Vertical

VC- Vertical corner

BKR- Breaker

b. Panel dimensions

c. Panel nishes

Listed Exterior/Interior

d. Bally Part# and Serial#

For immediate service, call Bally’s Parts and Service Hotline toll-free: 1-800-344-9302

UPDATED: 4/2015 Instruction Manual IM-268-11 2015© Bally Refrigerated Boxes, Inc. 2

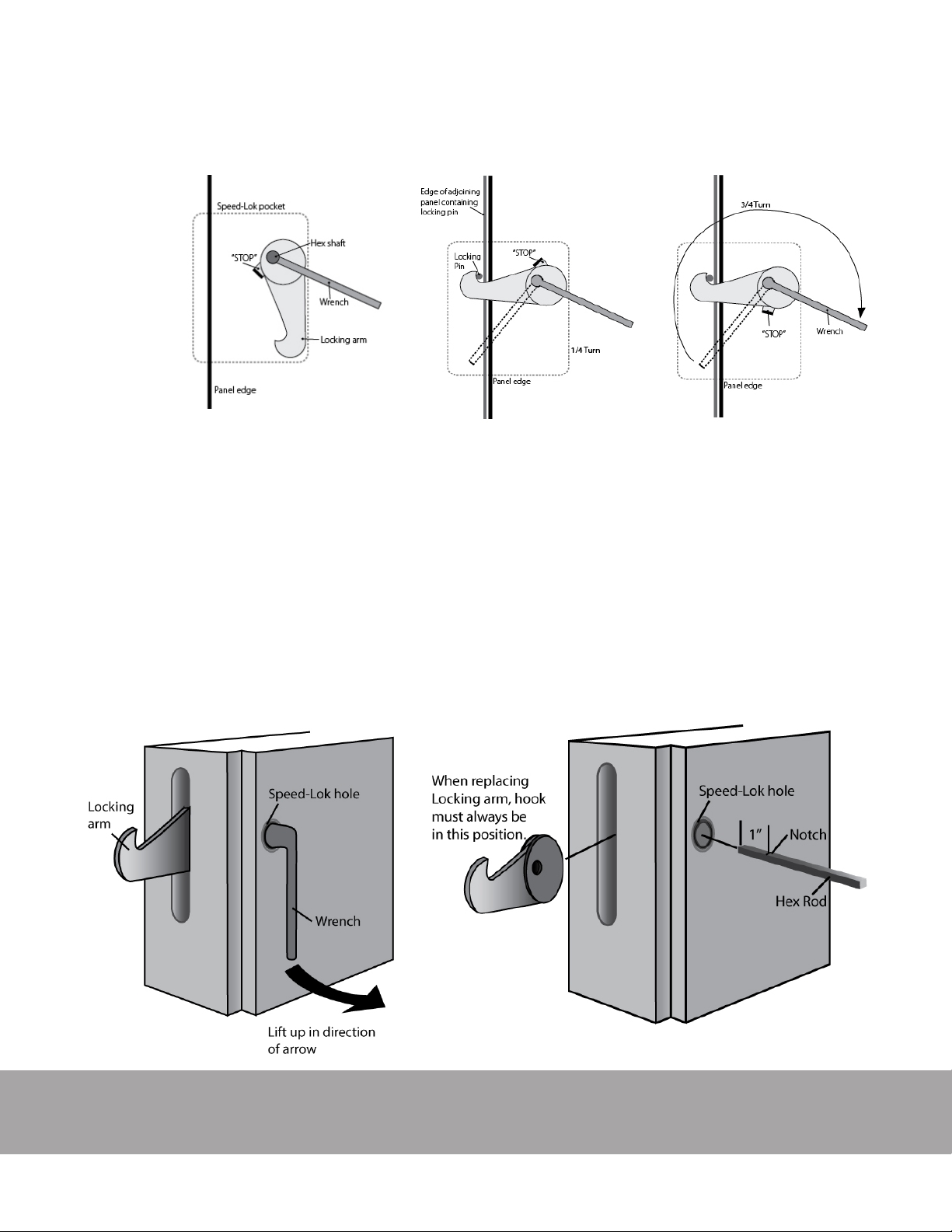

2. Operation of the Bally Speed-Lok:

A. Before attempting to erect panels, familiarize yourself with the operation of the locks Figures 2, 3, and 4. On Bally panels, locks

will always be on the left turning in clockwise rotation. If for any reason you have to unlock a panel, refer to Section B below.

Figure 1

B. Replacing broken or stripped locks

1. The panel contained the lock must be slid away from adjacent panels in order to obtain adequate working space. First check

for any obstructions (dirt, foam, etc.) once you have unlocked a panel reset the cam stop by turning the lock fully back to its

original position. If the hook is broken or stripped replacements can be found in Miscellaneous Parts Box#1.

2. Position the lock wrench on the hex rod and turn clock-wise until the locking arm protrudes.

3. Place your hand near the bend in the wrench and use a lift-up motion. This will produce a clamping action on the hex rod.

While doing this, pull forward until the rod is free of the panel. The locking arm will then drop free. See Figure 2.

4. Hold the new locking arm in position. Make sure the hook of the arm faces in the proper direction. See Figure 3.

5. Insert the new hex rod into the lock hole. Care must be taken to insert the notched end of the rod. The end to be inserted

has a notch located 1” from the end. This notch acts as a stop so the rod will not be inserted too far.

6. Align the hex rod with the hex hold of the locking arm; gently tap it until the notch stops against the locking arm.

7. Replace and refasten the panel in its original position.

Figure 2

Figure 3

Always refer to your Plan View when installing your Bally Walk-In Cooler or Freezer.

UPDATED: 4/2015 Instruction Manual IM-268-11 2015© Bally Refrigerated Boxes, Inc. 3

Loading...

Loading...