BNI EIP-502-105-R015

BNI EIP-508-105-R015

EtherNet/IP™ IP67 modules

User's Guide

www.balluff.com

1

Table of Contents

1 Notes 3

1.1. Structure of the guide 3

1.2. Typographical Conventions 3

Enumerations 3

Actions 3

Syntax 3

Cross-references 3

1.3. Symbols 3

1.4. Abbreviations 3

1.5. Deviating views 3

2 Safety 4

2.1. Intended Use 4

2.3. General Safety Notes 4

2.4. Resistance to Aggressive Substances 4

Dangerous Voltage 4

3 First Steps 5

3.1. Module Overview 5

3.2. Mechanical Connection 6

3.3. Electrical Connection 6

Power Supply 6

Grounding 6

Ethernet IP Interface 6

I/O Port 7

IO-Link Port 7

Port 7

4 Technical Data 8

4.1. Dimensions 8

4.2. Mechanical Data 8

4.3. Operating Conditions 8

4.4. Electrical Data 8

4.5. Ethernet 9

4.6. Function Indicators 9

Module Status 9

Port 10

5 Integration 11

5.1. Integration in Rockwell RS Logix 5000 11

5.2. Address Specifications 15

5.3. Data Configuration 15

5.4. Configuration Data 15

Module Configuration BNI EIP-502-105-XXX 16

Module Configuration BNI EIP-508-105-XXX 16

Module Configuration BNI EIP-507-005-Z040, BNI EIP-527-005-Z040 16

Module Configuration BNI EIP-508-XXX-XXXX-C06 16

IO-Link Port Configuration 17

Cycle Settings 18

Validation Settings 18

Parameter Server 19

Upload Flag on the IO-Link Device 19

6 Configuration via Explicit Messages 20

QuickConnect 20

Rockwell Automation Products that are Compatible with QuickConnect 21

Balluff Network Interface EtherNet/IP™

www.balluff.com

2

Example with Rockwell Components 22

PLC Program 23

Fault State 26

Enable/Disable Fault State 26

Fault State Action 26

IO-Link Device Parameterization 27

Read IO-Link Parameter 27

Write IO-Link Parameter 29

7 Process Data 30

7.1. Process Data Inputs 30

Standard Input Data 30

IO-Link Input Data 31

7.2. Process Data Outputs 32

Standard Output Data 32

IO-Link Output Data 32

8 Display 33

8.1. General 33

8.2. Address Specifications 33

8.3. Control and Display 33

8.4. Display Information 33

8.5. Design and Symbols 34

8.6. Startup 34

8.7. Main Menu 34

8.8. IP Setup 35

8.9. Network Config 35

8.10. Edit mode 36

8.11. Module Information 37

8.12. General Information 37

9 Web Server 38

9.1. General 38

9.2. Navigation / Info 39

9.3. Login/Logout 40

9.4. "Home" dialog 41

9.5. "Ports" dialog 43

No appropriate IODD uploaded 43

Appropriate IODD uploaded 44

9.6. "IODD" dialog 46

9.7. "Config" dialog 47

9.8. "Log" dialog 49

10 Appendix 51

10.1. Scope of Delivery 51

10.2. Order Number 51

10.3. Ordering Information 51

Notes 52

www.balluff.com

3

1 Notes

1.1. Structure of the

guide

This guide is arranged so that one chapter builds upon the other.

Chapter 2: Basic safety instructions

Chapter 3: Main steps for installing the device

………

1.2. Typographical

Conventions

The following typographical conventions are used in this manual.

Enumerations

Enumeration is shown in the form of bulleted lists.

• Entry 1,

• Entry 2

Actions

Action instructions are indicated by a preceding triangle. The result of an action is indicated

by an arrow.

Action instruction 1.

Result of action.

Action instruction 2.

Actions can also be indicated as numbers in parentheses.

(1) Step 1

(2) Step 2

Syntax

Numbers:

Decimal numbers are shown without additional information (e.g. 123),

Hexadecimal numbers are shown with the additional indicator hex (e.g., 00

hex

) or the prefix

"0x" (e.g., 0x00).

Cross-references

Cross-references indicate where additional information on the topic is located.

1.3. Symbols

Note

This symbol indicates general notes.

Attention!

This symbol indicates a security notice which most be observed.

1.4. Abbreviations

BNI Balluff Network Interface

I Standard input port

EIP EtherNet/IP™

EMC Electromagnetic compatibility

FE Function ground

O Standard output port

1.5. Deviating views

Product views and illustrations in this manual may differ from the actual product. They are

intended only as illustrative material.

Balluff Network Interface EtherNet/IP™

www.balluff.com

4

2 Safety

2.1. Intended Use

The BNI EIP-… is a decentralized IO-Link, input and output module for connecting to the

EtherNet/IP™ network.

2.2. Installation and

Startup

Attention!

Installation and startup are to be performed by trained technical personnel only.

Skilled specialists are people who are familiar with the work such as installation

and the operation of the product and have the necessary qualifications for these

tasks. Any damage resulting from unauthorized tampering or improper use shall

void warranty and liability claims against the manufacturer. The operator is

responsible for ensuring that the valid safety and accident prevention regulations

are observed in specific individual cases.

2.3. General Safety

Notes

Commissioning and inspection

Before commissioning, carefully read the User's Guide.

The system must not be used in applications in which the safety of persons depends on the

function of the device.

Intended use

Warranty and liability claims against the manufacturer shall be rendered void by damage

from:

• Unauthorized tampering

• Improper use

• Use, installation or handling contrary to the instructions provided in this User's

Guide.

Obligations of the owner/operator

The device is a piece of equipment in accordance with EMC Class A. This device can

produce RF noise. The owner/operator must take appropriate precautionary measures

against this for its use. The device may be used only with a power supply approved for this.

Only approved cables may be connected.

Malfunctions

In the event of defects and device malfunctions that cannot be rectified, the device must be

taken out of operation and protected against unauthorized use.

Intended use is ensured only when the housing is fully installed.

2.4. Resistance to

Aggressive

Substances

Attention!

The BNI modules always have good chemical and oil resistance. When used in

aggressive media (such as chemicals, oils, lubricants and coolants, each in a high

concentration (i.e. too little water content)), the material must first be checked for

resistance in the particular application. No defect claims may be asserted in the

event of a failure or damage to the BNI modules caused by such aggressive

media.

Dangerous

Voltage

Attention!

Before working on the device, switch off its power supply.

Note

In the interest of continuous improvement of the product,

Balluff GmbH reserves the right to change the technical data of the product and

the content of these instructions at any time without notice.

www.balluff.com

5

3 First Steps

3.1. Module Overview

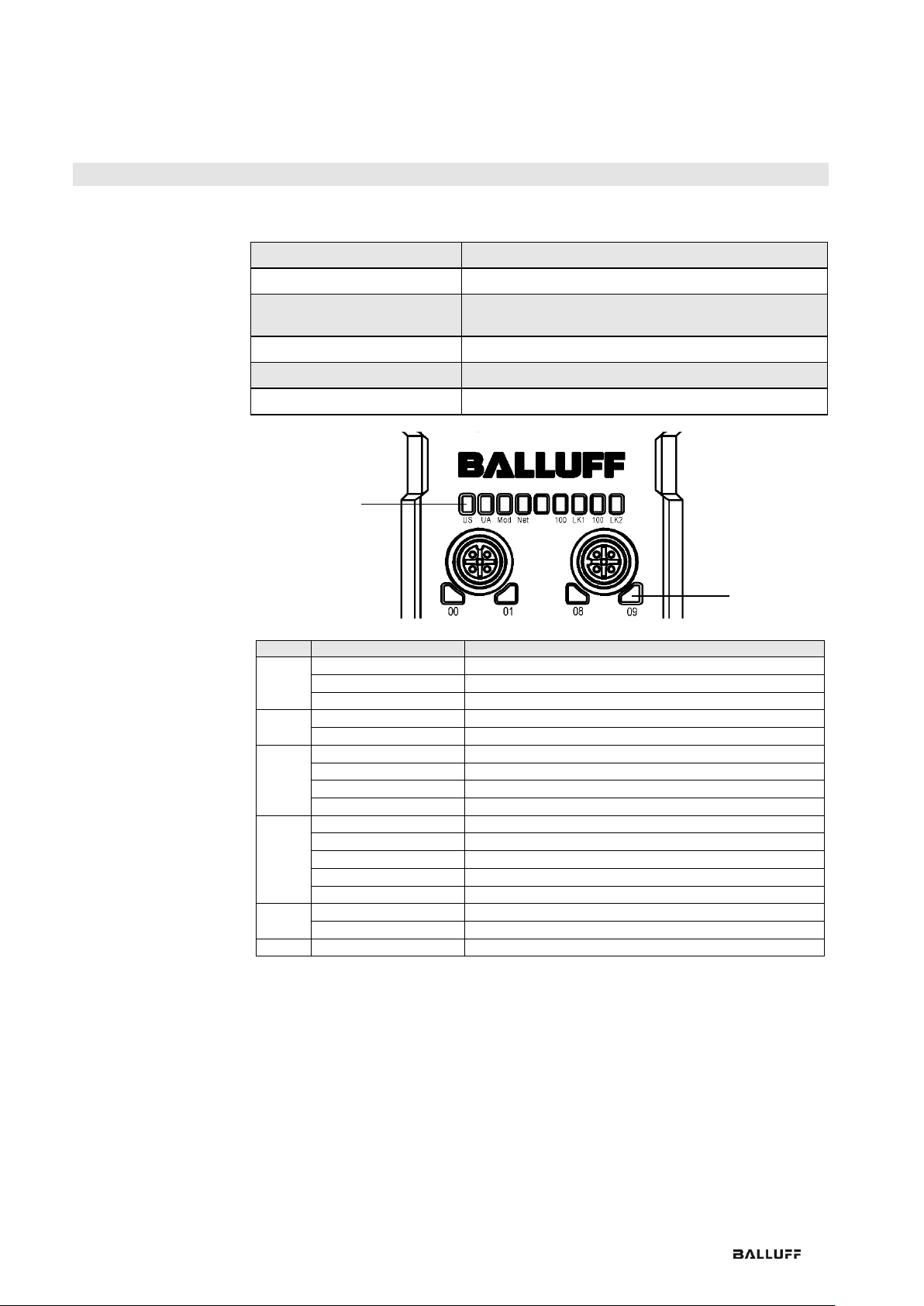

Figure – Overview: BNI EIP-508-105-R015

1 Mounting hole

2 EtherNet/IP™ port 2

3 Display

4 Power supply, input

5 Status LED: communication / module

6 Port 08 / 09 (IO-Link, standard I/O)

7 Pin/port LED: signal status

8 Port 10 / 11 (IO-Link, standard I/O)

9 Port 12 / 13 (IO-Link, standard I/O)

10 Port 14 / 15 (IO-Link, standard I/O)

11 Port 06 / 07 (IO-Link, standard I/O)

12 Port 04 / 05 (IO-Link, standard I/O)

13 Port 02 / 03 (IO-Link, standard I/O)

14 Port 00 / 01 (IO-Link, standard I/O)

15 Power supply, output

16 EtherNet/IP™ port 1

17 Ground connection

1 6 2 3 12

11

13

14

15

17

8

10

7 9 16 5 4

1

Balluff Network Interface EtherNet/IP™

www.balluff.com

6

3 First Steps

3.2. Mechanical

Connection

The module is secured by means of two M6 screws and two washers.

Insulation support is available separately.

3.3. Electrical

Connection

Power Supply

IN

7/8”, male

OUT

7/8” female

Pin

Function

Description

1

+24 V

Actuator supply

2

+24 V

Module / sensor supply

3

0 V

GND module / sensor and actuator supply

4

Note

Where possible, use a separate power source to supply the sensor/bus and

actuator with power.

Total current < 9 A The total current of all modules must not exceed 9 A even in

the case of series connection of the actuator supply.

Grounding

Note

The functional ground connection between housing and machine must have a

low impedance and be as short as possible.

Ethernet IP

Interface

M12, D-coded, female

Pin

Function

1

Tx+

Transmit Data +

2

Rx+

Receive Data +

3

Tx-

Transmit Data -

4

Rx-

Receive Data -

www.balluff.com

7

3 First Steps

I/O Port

M12, A-coded, female

Pin

Function

1

+24 V, 200 mA

2

Input/output 2A

3

GND

4

Input/output 2A

5

FE

Note

For the digital sensor inputs, refer to guideline on inputs EN 61131-2, Type 2.

Note

The total current of the module must not exceed 9 A.

Note

Unused I/O ports must be provided with cover caps to comply with degree of

protection IP67.

IO-Link Port

M12, A-coded, female

Pin

Function

1

+24 V, 1.6 A

2

Input/output 2A

3

GND

4

IO-Link/input/output 2A

5

n.a.

Port

Port

00/01, 02/03, 08/09, 10/11

04/05, 06/07, 12/13, 14/15

BNI EIP-502-105-R015

IN / OUT

IN / OUT / IO-Link

BNI EIP-508-105-R015

IN / OUT / IO-Link

Balluff Network Interface EtherNet/IP™

www.balluff.com

8

4 Technical Data

4.1. Dimensions

4.2. Mechanical Data

Housing material

Plastic housing, resistant (Fortron 6165 A6 black)

Enclosure rating per IEC 60529

IP 67 (only when plugged-in and threaded-in)

Supply voltage

7/8" 4-pin, connector / female

Input ports / output ports

M12, A-coded (8x female)

Dimensions (W x H x D in mm)

68 x 226 x 42.9

Type of mounting

Screw mounting with 2 mounting holes

Ground strap installation

M4

Weight

Approx. 670 gr.

4.3. Operating

Conditions

Operating temperature T

a

Storage temperature

-5 °C ... 70 °C

-25 °C ... 70 °C

EMC

- Immunity

- Emission

EMC Directive 2004/108/EEC

- EN 61000-6-2

- EN 61000-6-4

Shock/vibration

EN 60068-2-6, EN 60068-2-27

EN 60068-2-29, EN 60068-2-64

4.4. Electrical Data

Supply voltage

18...30.2 V DC, in accordance with EN 61131-2

Ripple

< 1%

Input current at 24 V

130 mA

www.balluff.com

9

4 Technical Data

4.5. Ethernet

Ethernet IP port

2 x 10Base/100Base Tx

Connection for Ethernet IP port

M12, D-coded, female

Cable types in accordance with

IEEE 802.3

Shielded, twisted pair min. STP CAT 5/ STP CAT 5e

Data transmission rate

10/100 Mbps

Max. cable length

100 m

Flow control

Half-duplex/full-duplex (IEEE 802.33x pause)

4.6. Function

Indicators

Module Status

LED

Display

Description

UA

Green

Output power OK

Red, flashing

Low output power (< 18V)

Red

No output power (< 11V)

US

Green

Input power OK

Red, flashing

Low input power (< 18V)

Mod

Green, flashing

Incorrect or no configuration of the module

Green

Module is working

Red, flashing

Fixed bus clock is not possible

Red-green, flashing

Initial sequence

Netw

ork

Off

Module has no IP address

Green, flashing

Module has IP, but no connection established

Green

Connection established

Red, flashing

Connection timeout

Red-green, flashing

Initial sequence

100

Off

Bus clock: 10 Mbps

Yellow

Bus clock: 100 Mbps

LNK

Green

Data transfer

Status LEDs

Port LEDs

Balluff Network Interface EtherNet/IP™

www.balluff.com

10

4 Technical Data

Port

Each port has two bicolored LEDs for displaying the I/O statuses.

Display

Status

Description

I/O port

Off

I/O status

The status of the input or output pins is 0

Yellow

I/O status

The status of the input or output pins is 1

Red,

flashing

Short-circuit

Short-circuit between pin 1 and 3

Red

Short-circuit

Short-circuit at dedicated pin

IO-Link port

Green

IO-Link

IO-Link communication active

Green,

flashing

IO-Link

No IO-Link communication

Green,

rapidly

flashing

IO-Link

IO-Link pre-operate during data storage

Red

Short-circuit

Short-circuit at pin 4

Red,

flashing

quickly

IO-Link

Validation failed /

Data storage failed /

Wrong device for data storage

www.balluff.com

11

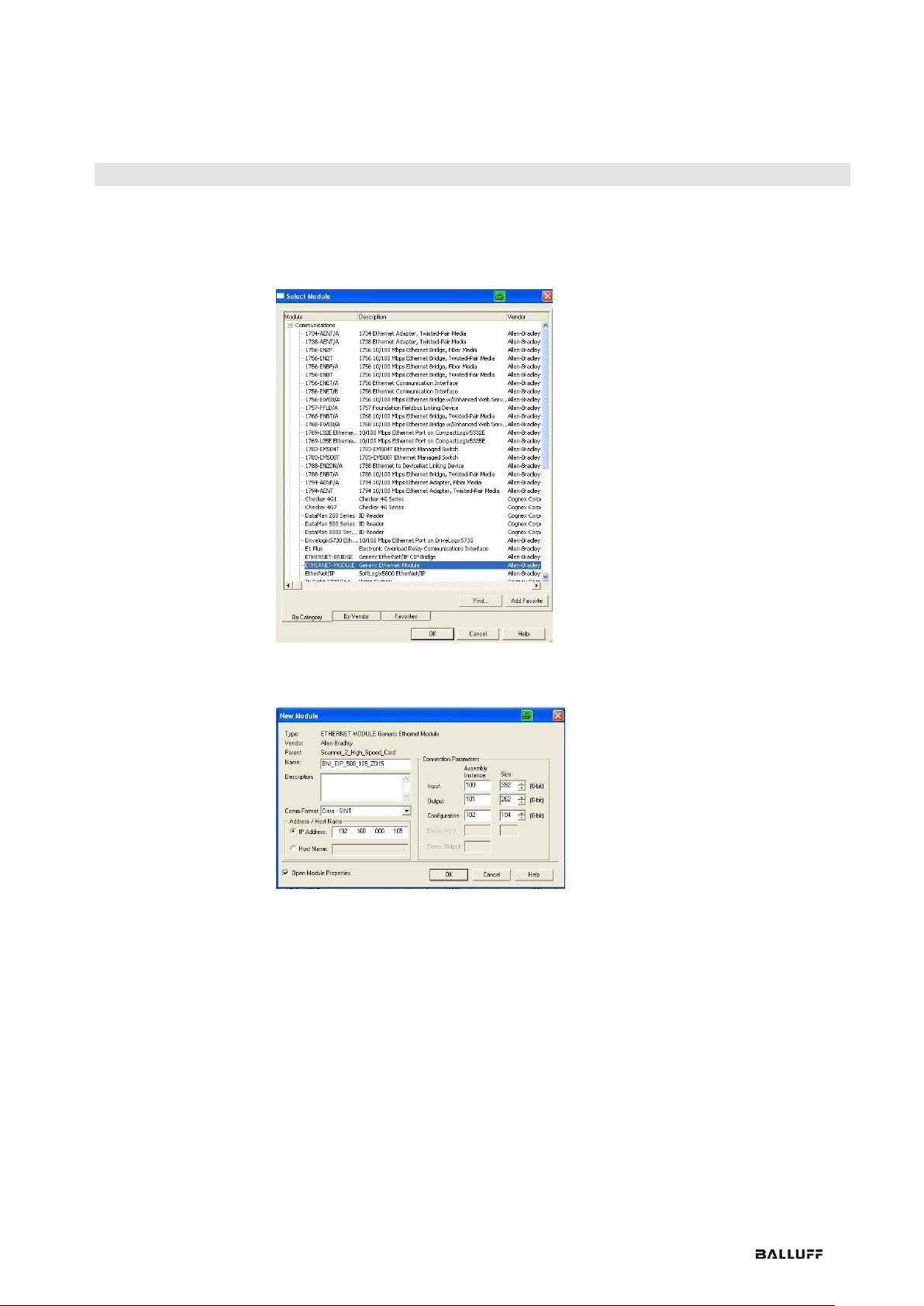

5 Integration

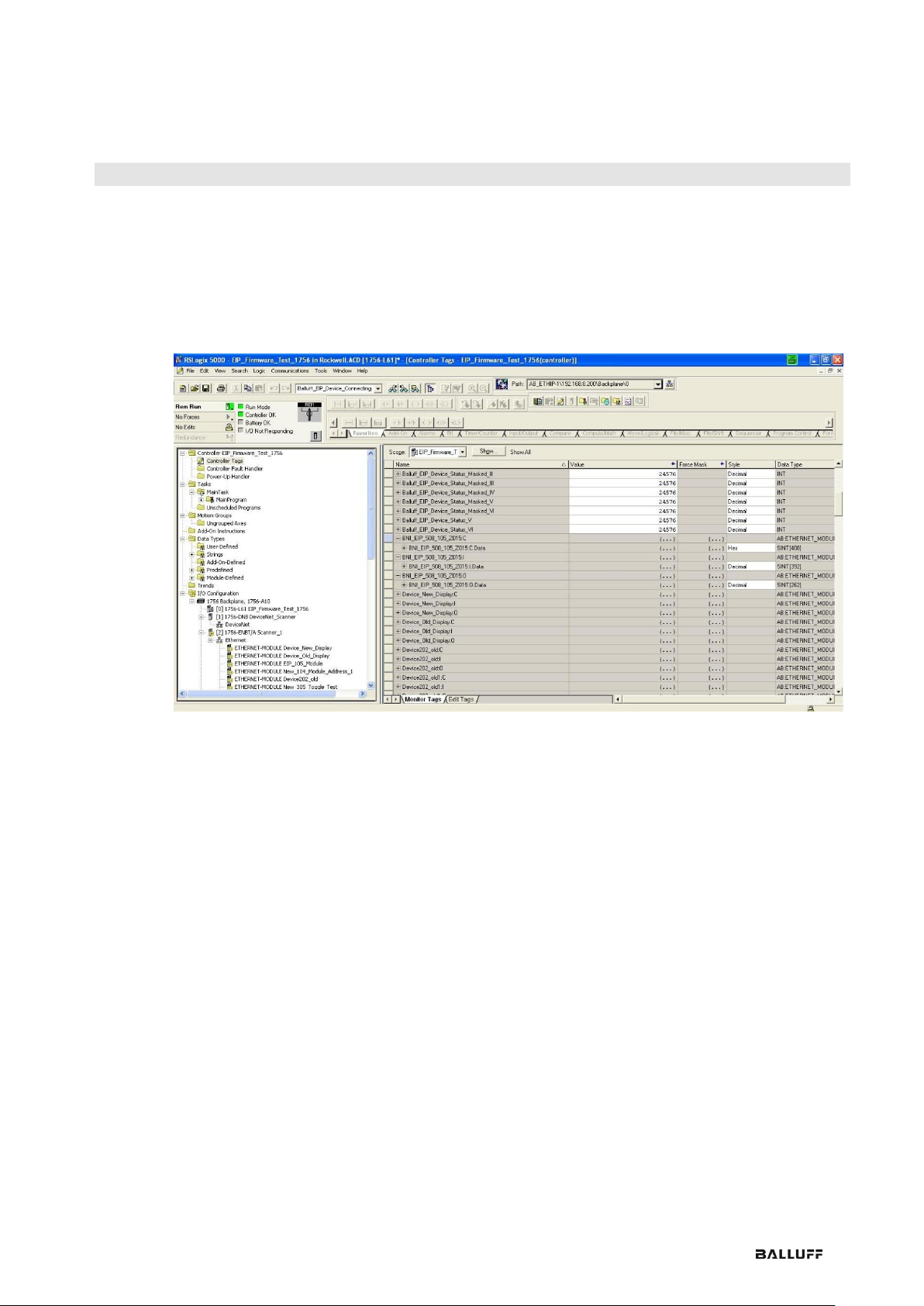

5.1. Integration in

Rockwell RS

Logix 5000

Here you see an example of how the module can be integrated into a Rockwell RS Logix

5000:

First go offline

Right-click Ethernet (on the correct scanner card)

Select a new module

Balluff Network Interface EtherNet/IP™

www.balluff.com

12

5 Integration

Then select the general Ethernet module as the ETHERNET module in the communication

path

Now enter a user-defined tag name to select the general format Data-SINT, to enter the IP

address of the module and to enter the correct connection parameters.

www.balluff.com

13

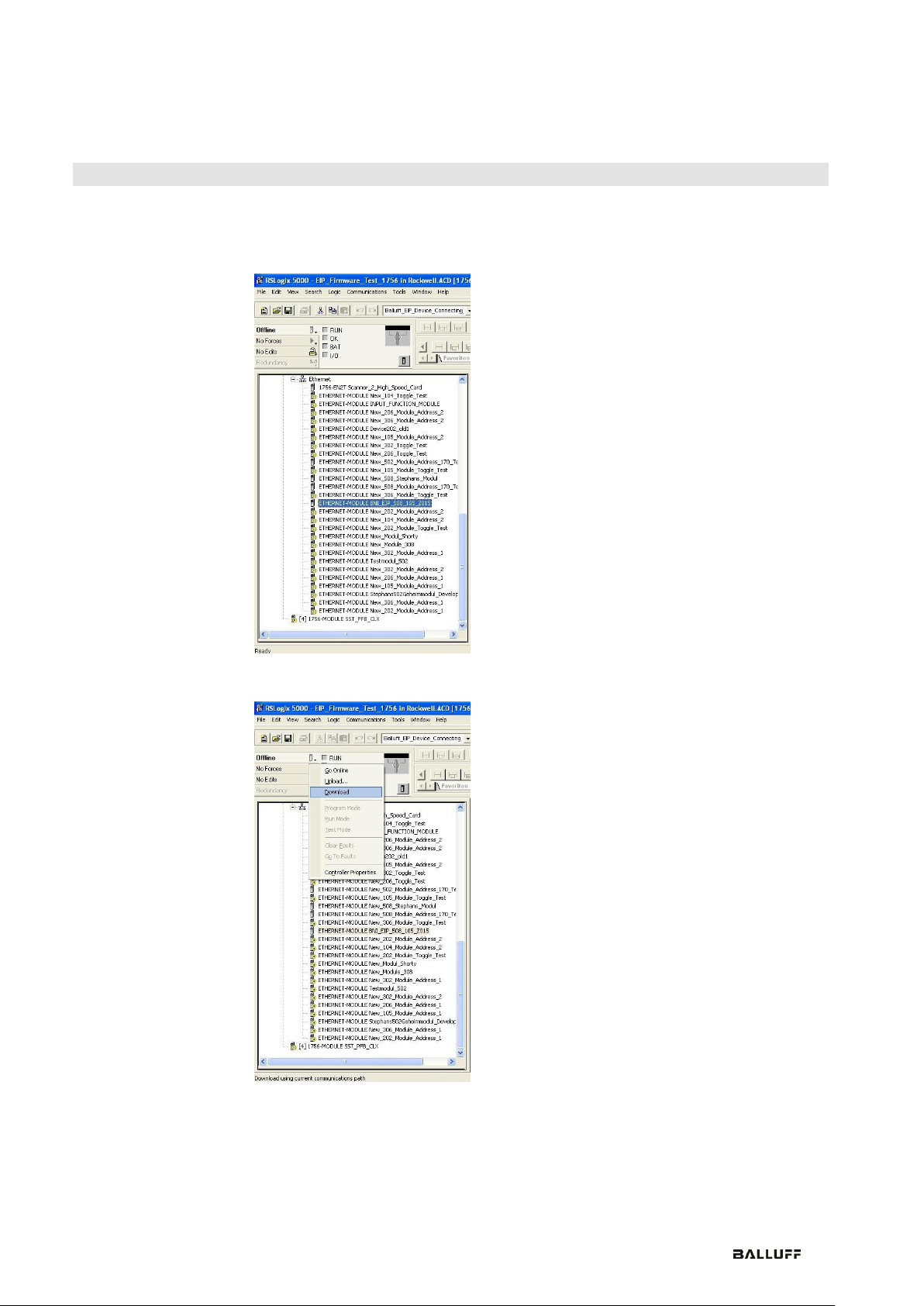

5 Integration

The new module and corresponding controller tags are generated automatically.

Then download the configuration

Balluff Network Interface EtherNet/IP™

www.balluff.com

14

5 Integration

When the download is done, you can observe and control the tags using the Controller Tags option. Make

sure you select the correct tag name, which you configured beforehand.

The input, output and configuration data for this is described on the following pages.

You can use these tags for the programming, too.

www.balluff.com

15

5 Integration

5.2. Address

Specifications

These settings are factory-set.

IP-Adresse: 192.168.1.1

Subnetmaske: 255.255.255.0

Gatewayadresse: 192.168.1.1

5.3. Data

Configuration

Please enter the following values in the control system. They describe the data sizes of the

input, output and configuration data.

Instanc ID

Data length

502

508

507

527

508-C06

Input

100

200

392

196

196

128

Output

101

134

262

130

128

86

CONFIG

102

98

194

98

98

0

5.4. Configuration

Data

The following tables show an allocation of the configuration data sequence. The standard

values specified below describe a configuration with the IO-Link function at Pin 4 and

standard I/O functions at Pin 2 and 4 of each port. The input and output functions of the

configured standard I/O ports are set via the process data.

BNI EIP-502-105-XXXX, BNI EIP-507-005-Z040, BNI EIP-527-005-Z040

Byte

Slot

Module part

Description

0…1

1

Module

General configuration for the entire module

2…25

2

IO-Link port 0

Configuration of IO-Link port 0

26…49

3

IO-Link port 1

Configuration of IO-Link port 1

50…73

4

IO-Link port 2

Configuration of IO-Link port 2

74…97

5

IO-Link port 3

Configuration of IO-Link port 3

BNI EIP-508-105-XXXX

Byte

Slot

Module part

Description

0…1

1

Module

General configuration for the entire module

2…25

2

IO-Link port 0

Configuration of IO-Link port 0

26…49

3

IO-Link port 1

Configuration of IO-Link port 1

50…73

4

IO-Link port 2

Configuration of IO-Link port 2

74…97

5

IO-Link port 3

Configuration of IO-Link port 3

98…121

6

IO-Link port 4

Configuration of IO-Link port 4

122…145

7

IO-Link port 5

Configuration of IO-Link port 5

146…169

8

IO-Link port 6

Configuration of IO-Link port 6

170…193

9

IO-Link port 7

Configuration of IO-Link port 7

Note

The BNI EIP-508-XXX-XXXX-C06 has no configuration data. These are fixed

and can not be changed.

Balluff Network Interface EtherNet/IP™

www.balluff.com

16

5 Integration

Module

Configuration

BNI EIP-502-105XXX

Byte

Bit

Description

7 6 5 4 3 2 1

0

0

P3

P2 - -

Port function

0x00: Standard I/O

0x01: IO-Link

1

P7

P6 - -

Module

Configuration

BNI EIP-508-105XXX

Byte

Bit

Description

7 6 5 4 3 2 1

0

0

P3

P2

P1

P0

Port function

0x00: Standard I/O

0x01: IO-Link

1

P7

P6

P5

P4

Module

Configuration

BNI EIP-507-005Z040, BNI EIP527-005-Z040

Byte

Bit

Description

7 6 5 4 3 2 1

0

0

P3

P2

P1

P0

Port function

0x00: Standard I/O

0x01: IO-Link

1

Reserved

Module

Configuration BNI

EIP-508-XXXXXXX-C06

The IO-Link ports are always activated.

www.balluff.com

17

5 Integration

IO-Link Port

Configuration

Byte

Bit

Description

7 6 5 4 3 2 1

0

2

Basic

Time

Cycle time

3

Validation type

Validation type

0 No validation

1 compatible (VID + DID)

2 Identical (VID + DID + SerNum)

4

Vendor ID 1

Vendor ID

5

Vendor ID 2

6

Device ID 1

Device ID

7

Device ID 2

8

Device ID 3

9

Serial number 1

Serial number

… … 24

Serial number 16

25

Parameter server

Parameter server

0x8X Enable

0x0X Disable

0x40 Delete

0xX1 Enable upload

0xX2 Disable download

…

The data of the other IO-Link ports is structured identically and described in the following.

For the BNI EIP-508-xxx-xxxx-C06 these data are not adjustable.

Balluff Network Interface EtherNet/IP™

www.balluff.com

18

Cycle Settings

This parameter can be used to influence the IO-Link communication speed. Calculated

using the multiplier and the time base, the IO-Link cycle time can be increased.

The time base is described in Table B3. The multiplier is entered in decimal form from

0…63.

Bit

Description

7 6 5 4 3 2 1

0

Time

base

Multiplier

Bit 0 to 5: Multiplier

These bits contain a 6-bit multiplier for the

calculation of MasterCycleTime or MinCycle

Time. Permissible values for the multiplier

are

0 to 63.

Bit 6 to 7: Time Base

These bits specify the time base for the

calculation of MasterCycleTime or

MinCycleTime.

Possible values of MasterCycleTime and MiniCycleTime

Time base

encoding

Time base

value

Calculation

Cycle time

00

0.1 ms

Multiplier x time base

0.4 ms to 6.3 ms

01

0.4 ms

6.4 ms + multiplier x time base

6.4 ms to 31.6 ms

10

1.6 ms

32.0 ms + multiplier x time base

32.0 ms to 132.8 ms

11

Reserved

Reserved

Reserved

NOTE: The value 0.4 results from the minimum possible transmission time according to

A.3.7.

Validation

Settings

No validation: validation deactivated, every device will be accepted.

Compatibility: manufacturer ID and device ID are compared to the IO-Link device data.

Identity: manufacturer ID and device ID and serial number are compared to the

IO-Link device data. The IO-Link communication is only started if there is a match.

www.balluff.com

19

5 Integration

Parameter Server

Enable: data management functions enabled, parameter data and identification data of the

IO-Link device are stored permanently.

Disable: data management functions disabled, stored parameter data and identification

data of the IO-Link device remain stored.

Deleted: data management functions disabled, stored parameter data and identification

data of the IO-Link device are deleted.

Enable upload:

If only the upload is enabled, the master always starts an upload of the parameter data. In

this case, the upload is independent of the upload flag of the IO-Link device. If no data is

stored in the Master Port, an upload likewise takes place. (e.g. after deleting the data or

before the first data upload)

Enable download:

If only the download is enabled, the master always starts a download of the parameter data.

In this case, the download is likewise independent of the upload flag of the IO-Link device.

If no data is stored in the Master Port, however, an upload takes place first. (e.g. after

deleting the data or before the first data upload)

Enable upload and download:

If the upload and download are enabled, different parameter sets are distinguished

depending on the upload flag of the IO-Link device.

If no parameter data is stored in the IO-Link master port, an initial upload takes place. (e.g.

after deleting the data or before the first data upload)

If the upload flag is set on the IO-Link device, an upload of the parameter data always takes

place.

If no upload flag is set and parameter data has already been stored, a download of the

parameter data always takes place.

Note

After the upload of the parameter data, the vendor ID and device ID of the

connected IO-Link device are also still saved until the data records are deleted.

When the connected IO-Link device is started, a validation takes place. Thus, only

an IO-Link device of the same type can be used for the data management.

If an IO-Link device of a different type is to be used, the contents of the parameter

server must be deleted.

The data storage is supported only by IO-Link devices with IO-Link Revision 1.1.

Upload Flag on

the IO-Link

Device

The upload flag is needed to overwrite already saved data in the parameter server with new

parameter data of the same IO-Link device.

To enable the upload flag of an IO-Link device,

the data value 0x05 must be entered in the index 0x02, subindex 0.

(For information about configuration via IO-Link, refer to the "Web Server" chapter under

"Device Properties" or the "Configuration via Explicit Messages" chapter

under "IO-Link Device Parameterization")

Balluff Network Interface EtherNet/IP™

www.balluff.com

20

6 Configuration via Explicit Messages

QuickConnect

The QuickConnect function makes it faster to boot up and integrate the BNI EIP-50x-105X015 modules.

Enabling QuickConnect automatically takes over all necessary port properties on the module:

Static IP address

Ports at 100 Mbps full-duplex

Auto-negotiation disabled

Auto MDI-X disabled

Prepared for linear topology

You can configure QuickConnect via the following

class instance attribute of the explicit messages:

Class

Instance

Attribute

Value

245 (0xF5)

1 (0x01)

12 (0x0C)

0: disabled (default)

1: enabled

Note

For QuickConnect to be enabled, ACD (Address Conflict Detection) must also be

enabled. This is switched on by default.

The ACD can be reviewed and changed using the following class instance attributes of the

explicit messages:

Class

Instance

Attribute

Value

245 (0xF5)

1 (0x01)

10 (0x0A)

0: disabled

1: enabled(default)

www.balluff.com

21

6 Configuration via Explicit Messages

Rockwell

Automation

Products that

are Compatible

with

QuickConnect

Source:

Allen-Bradley Ethernet/IP QuickConnect Application Technique

Page 13

Balluff Network Interface EtherNet/IP™

www.balluff.com

22

6 Configuration via Explicit Messages

Example with

Rockwell

Components

Source:

Allen-Bradley Ethernet/IP QuickConnect Application Technique, Page 12

Please also note the following:

Direct connection between PLC and QuickConnect slave with crossover cable

Slave-to-slave connection using patch cable

For setting up the topology, only the linear topology with a maximum of 20 modules

on the tool side is permitted.

If needed, only one managed switch may be used between the PLC and Ethernet/IP

slave.

To trigger the QuickConnect sequence, an electrical lock signal is required that

reads in the supply voltage of the QuickConnect slaves via the controller.

www.balluff.com

23

6 Configuration via Explicit Messages

PLC Program

Source:

Allen-Bradley Ethernet/IP QuickConnect Application Technique, Page 29

Balluff Network Interface EtherNet/IP™

www.balluff.com

24

6 Configuration via Explicit Messages

Source:

Allen-Bradley Ethernet/IP QuickConnect Application Technique, Page 30

www.balluff.com

25

6 Configuration via Explicit Messages

Source:

Allen-Bradley Ethernet/IP QuickConnect Application Technique, Page 31

Balluff Network Interface EtherNet/IP™

www.balluff.com

26

6 Configuration via Explicit Messages

Source:

Allen-Bradley Ethernet/IP QuickConnect Application Technique, Page 32

Fault State

A safe state that the port is to take on in the case of a loss of bus communication can be

predefined for each output on the port pins.

The fault state settings can be configured using the following class instance attributes of the

explicit messages.

Enable/Disable

Fault State

Class

Instance

Attribute

Value

9 (0x09)

1 – m

6

0: Fault state disabled

1: Fault state enabled

Fault State

Action

Class

Instance

Attribute

Value

9 (0x09)

1 – m

5

0: Output on

1: Hold last state

m: Number of outputs

Note

The fault state settings are stored only temporarily in the module. They are deleted

after a power reset.

To ensure a long-term fault state configuration, the configuration has to be

programmed via the PLC so that the settings are transferred to the module again

when the system is restarted.

www.balluff.com

27

6 Configuration via Explicit Messages

IO-Link Device

Parameterization

There are two options for configuring an IO-Link device connected to the IO-Link port.

Configuration via the web server

refer to the "Web Server" chapter under "Device Properties"

Configuration via explicit messages

The following example describes how Rockwell RSLogix 5000 devices can be used to

configure an IO-Link device via explicit messages.

For this purpose, the "MSG" components in the PLC program are used.

Read IO-Link

Parameter

Service Code

Class

Instance

Attribute

0x32

0x96

1 - n

0x03

(Read Parameter)

n: Number of ports

Source Length must correspond to at least the read parameters, but a larger value can also

be entered. (In this example, 100 bytes)

As the Source Element (Write) and as the Destination Element (Read),

create one SINT[100] array each and select the first line[0].

Balluff Network Interface EtherNet/IP™

www.balluff.com

28

6 Configuration via Explicit Messages

In the Source Element Array (Write), enter which index is to be read.

In this example, this is index 0x4E.

Destination Array (Read) shows the read-out value.

In case of a configuration error, the error code is likewise displayed there.

In the "Communication" window, you have to select the Ethernet module

on which the configuration is to take place.

www.balluff.com

29

6 Configuration via Explicit Messages

Write IO-Link

Parameter

Service Code

Class

Instance

Attribute

0x32

0x96

1 - n

0x02

(Write

Parameter)

n: Number of the ports

Source Element and Destination Element are to be selected so they are identical to the

previous example, "Read IO-Link parameter".

The Source Length must be exactly the same length as the parameter data to be written.

In this example, index 0x4E, subindex 0,

value 0x02 is written in Source Element Array (Write).

In case of a configuration error, an error code appears in Destination Element Array (Read).

In the "Communication" window, you likewise have to select the Ethernet module

on which the configuration is to take place.

Note

The explicit messages functions are implemented in accordance with the

Volume 1: Common Industrial Protocol Specification and

Volume 2: Ethernet/IP Adaption of CIP.

Balluff Network Interface EtherNet/IP™

www.balluff.com

30

7 Process Data

7.1. Process Data

Inputs

The input data size is 200 bytes. Take a look at the tables below for the allocation of the

process data inputs.

BNI EIP-502-105-R015

Byte

Module part

Description

0…7

Standard I/O ports

Process data inputs at the standard inputs

8…55

IO-Link port 1

Process data inputs at IO-Link port 1

56…103

IO-Link port 2

Process data inputs at IO-Link port 2

104…151

IO-Link port 3

Process data inputs at IO-Link port 3

152…199

IO-Link port 4

Process data inputs at IO-Link port 4

BNI EIP-508-105-R015

Byte

Module part

Description

0…7

Standard I/O ports

Process data inputs at the standard inputs

8…55

IO-Link Port 0

Process data inputs at IO-Link port 0

56…103

IO-Link port 1

Process data inputs at IO-Link port 1

104…151

IO-Link port 2

Process data inputs at IO-Link port 2

152…199

IO-Link port 3

Process data inputs at IO-Link port 3

200…247

IO-Link port 4

Process data inputs at IO-Link port 4

248…295

IO-Link port 5

Process data inputs at IO-Link port 5

296…343

IO-Link port 6

Process data inputs at IO-Link port 6

344…391

IO-Link port 7

Process data inputs at IO-Link port 7

Standard Input

Data

BNI EIP-502-105-R015 and BNI EIP-508-105-R015

Byte

Bit

Description

7 6 5 4 3 2 1

0

0

I32

I34

I22

I24

I12

I14

I02

I04

Input data

I04 Input at port 0, pin 4

The result is 0 only if the port is

configured as an IO-Link port.

1

I72

I74

I62

I64

I52

I54

I42

I44

2

S3

S2

S1

S0

Short-circuit status

Short-circuit between pin 1 and 3

at the registered port

3

S7

S6

S5

S4

4

O32

O34

O22

O24

O12

O14

O02

O04

Overload status

O04 Overload at port 0, pin 4

Only if the port is configured as an

output.

5

O72

O74

O62

O64

O52

O54

O42

O44

6 0 0 0 0 0 NA

PS

PA

Status of the power supply

NV: No actuator power supply

PS: Power supply for sensor

PA: Power supply for actuator

7 0 0 0 0 0 0 0 0

Reserved

www.balluff.com

31

7 Process Data

IO-Link Input Data

BNI EIP-502-105-R015 and BNI EIP-508-105-R015

Byte

Bit

Description

7 6 5 4 3 2 1

0

8

…

39

IO-Link port 0 input data

40 0 0 0 0 0 0

DC

IOL

IO-Link status

IOL: Port in IO-Link mode

DC: Device connected

0: Reserved

41

SC 0 0 0 0

PDI

DF

VF

IO-Link error

VF: Validation failed

SC: IO-Link short-circuit

DF: Data storage validation failed

PDI: Process data invalid

42

Vendor ID 1

Vendor ID

43

Vendor ID 2

44

Device ID 1

Device ID

45

Device ID 2

46

Device ID 3

47

Mode

Type

0

Event 1

Mode:

0: Reserved

1: Event single shot

2: Event disappears

3: Event appears

Type:

0: Reserved

1: Notification

2: Warning

3: Error

48

Event code high

49

Event code low

50

Mode

Type

0

Event 2

51

Event code high

52

Event code low

53

Mode

Type

0

Event 3

54

Event code high

55

Event code low

…

The data of the other IO-Link ports are structured identically and described in the following.

Balluff Network Interface EtherNet/IP™

www.balluff.com

32

7 Process Data

7.2. Process Data

Outputs

The output data size is 134 bytes. Take a look at the tables below for the allocation of the

process data outputs.

BNI EIP-502-105-R015

Byte

Module part

Description

0…5

Standard I/O ports

Process data outputs at the standard inputs

6…37

IO-Link port 1

Process data outputs at IO-Link port 1

38…69

IO-Link port 2

Process data outputs at IO-Link port 2

70…101

IO-Link port 3

Process data outputs at IO-Link port 3

102…133

IO-Link port 4

Process data outputs at IO-Link port 4

BNI EIP-508-105-R015

Byte

Module part

Description

0…5

Standard I/O ports

Process data outputs at the standard inputs

6…37

IO-Link Port 0

Process data output at IO-Link port 0

38…69

IO-Link port 1

Process data output at IO-Link port 1

70…101

IO-Link port 2

Process data output at IO-Link port 2

102…133

IO-Link port 3

Process data output at IO-Link port 3

134…165

IO-Link port 4

Process data output at IO-Link port 4

166…197

IO-Link port 5

Process data output at IO-Link port 5

198…229

IO-Link port 6

Process data output at IO-Link port 6

230…261

IO-Link port 7

Process data output at IO-Link port 7

Standard Output

Data

Byte

Bit

Description

7 6 5 4 3 2 1

0

0

O32

O34

O22

O24

O12

O14

O02

O04

Output data

O04 Output at port 0, pin 4

To use this function at an IOLink port, the port has to be

configured as an output.

1

O72

O74

O62

O64

O52

O54

O42

O44

2

R32

R34

R22

R24

R12

R14

R02

R04

Restart

Restart of the output after a

short-circuit is detected

3

R72

R74

R62

R64

R52

R54

R42

R44

4 0 0 0 0 0 0 0 0

Reserved

5 0 0 0 0 0 DL

GO

RO

Display control system

DL: Display disabled / PLC

lock

GO: Green display LED

illuminates

RO: Red display LED

illuminates

IO-Link Output

Data

Byte

Bit

Description

7 6 5 4 3 2 1

0

6…37

IO-Link port 0 output data

…

The data of the other IO-Link ports are structured identically and described in the

following.

www.balluff.com

33

8 Display

8.1. General

With the implemented display, the address is output directly to the devices BNI EIP…

The following address types are possible:

• IP address

• Subnet mask

• Gateway address

Each address is composed of 4 octets.

The display also shows information about the hardware and firmware update.

The display has a locking function that can be enabled from the control panel. If the lock is

set, no more editing can be done (see bit layout, Chapter 6.2 Standard output data).

8.2. Address

Specifications

IP address: 192.168.1.1

Subnet mask: 255.255.255.0

Gateway address: 192.168.1.1

8.3. Control and

Display

1 Display

2 Arrow key

3 Octet cursor

4 Address type cursor

5 "Set" key

6 LED

8.4. Display

Information

IP: IP address

SN: Subnet address

GW: Gateway address

3: First octet

2: Second octet

1: Third octet

0: Fourth octet

S

↑

IP

SN

GW

3 2 1 0

1 2 3

4

5

6

2

3

1

0

Cursor for selecting the address type

Cursor for selecting the octet

IP

SN

GW

Balluff Network Interface EtherNet/IP™

www.balluff.com

34

8 Display

8.5. Design and

Symbols

In the following flow charts, some symbols are used to describe the display functionality:

8.6. Startup

8.7. Main Menu

• Press the Set key briefly to scroll through the main menu.

• Press the arrow key to open the menu.

Current status

Switch

S

Condition: Briefly press the Set key

S

Condition: Press and hold the Set key (at least 3 seconds)

Condition: Briefly press the arrow key

IP

192 . 168 .

015 . 005

VERSION

H W : 1 . 0

S W : 1 . 0

Subnet

255 . 255 .

255 . 000

Gateway

000 . 000 .

000 . 000

Hardware and firmware update

Current IP

Current subnet mask

Current gateway address

BNI

EIP-508 105-R015

Module name

B A L L U F F

BALLUFF

Network

Config

Standard view

4th octet of the IP address

Menu: Network Config

Menu: IP Setup

Menu: Module Information

007

…

…

S

S

S

S

…

IP

SETUP

MODULE

INFO

www.balluff.com

35

8 Display

8.8. IP Setup

• Press and hold the Set key to call up the editing mode.

• The preferred value is configured by briefly pressing the arrow key.

8.9. Network Config

• Press and hold the Set key to call up the editing mode.

• The preferred value is configured by briefly pressing the arrow key.

• Press and hold the arrow key to call up the fast program mode.

• Briefly pressing the Set key saves the entered value and scrolls to the next octet.

The 4th octet represents the beginning of the editing process.

• The completely entered address is saved by briefly pressing the Set key when

editing the first octet. The entered value appears right afterwards in the IP overview

display.

• Manual changes to IP, subnet or gateway lead to an automatic change of the IP

setup to "static".

STATIC

DHCP

X FACTORY SETTING

STATIC

X DHCP

FACTORY SETTING

X STATIC

DHCP

FACTORY SETTING

S

S

S

S

Editing mode

X STATIC

DHCP

FACTORY SETTING

IP editing mode

IP

192.168.

015.005

Subnet

255.255.

255.000

Gateway

000.000.

000.000

Editing mode

Programming mode

005

015

168

192

S

S

S

S

S

Editing mode

Programming mode

000

255

255

255

S

S

S

S

S

Editing mode

Programming mode

000

000

000

000

S

S

S

S

S

Balluff Network Interface EtherNet/IP™

www.balluff.com

36

8 Display

8.10. Edit mode

• In the Network Configuration menu, select IP / Subnet or Gateway Address.

• Press the set button long to switch to edit mode.

• Press the arrow key briefly to change the number.

• Press the Set button briefly to move to the next position.

• After the last digit, press the set button briefly to move to the next octet of the address

or to accept the new number after the last octet.

Note

The module has to be restarted to work with the new configuration.

www.balluff.com

37

8 Display

8.11. Module

Information

• Briefly pressing the arrow key allows scrolling through the "Module information"

menu.

• The product name, module updates and Mac-ID are displayed as information.

8.12. General

Information

• Press and hold the arrow key to scroll quickly in editing mode.

• If no key is pressed for 10 seconds, the view reverts to the standard display (4th

octet of the IP address). Changes that have not been saved will be lost.

• Differences between the new configuration and the configuration with which the

module works are indicated by an unequal sign. In this case, the screen switches

to the standard display after 5 seconds.

• The display flashes in editing mode. The display flickers in fast scroll mode.

• If the module receives a single ping, the word "Ping" appears on the display for a

couple of seconds. Then the previous display returns. You can exit ping mode

sooner by briefly pressing the Set key.

• If the module receives two or more pings, the word "Ping" appears on the display.

You can exit the display only by briefly pressing the Set key. Then the display

before the ping returns.

• The LED function of the display LEDs can be set in a user-specific manner by

setting several bits in the process data outputs. (see bit layout, standard output

data)

• The plc lock function can also be used by setting a bit in the process data outputs.

(see bit layout, standard output data)

Note

You cannot select editing mode in the display if the plc lock is set in the process

data inputs by a bit (see bit layout, standard output data)

BNI

EIP-508105-R015

Version

SW: x.x

HW: x.x

MAC ID

XX : XX : XX :

XX : XX : XX

Balluff Network Interface EtherNet/IP™

www.balluff.com

38

9 Web Server

9.1. General

The BNI fieldbus module contains an integrated web server for retrieving detailed device

information and for configuring the device.

To use the web interface you must first ensure that the module has been correctly integrated

into your network. In addition the IP subnet of the BNI module must be accessible from the

PC on which the browser is running. Please use Internet Explorer 10 or newer as the browser;

older versions may result in display problems.

For open a connection with the web server, enter the IP address of the module in the address

line of the browser. The homepage then appears with the essential device information.

www.balluff.com

39

9 Web Server

9.2. Navigation / Info

The navigation bar is located in the upper area of the window, which allows you to switch

between the various dialogs of the web interface. To do this click on the corresponding icon.

When the "Info" tab is selected the following overview appears:

The "BALLUFF" logo at upper right links to the international Balluff homepage.

Balluff Network Interface EtherNet/IP™

www.balluff.com

40

9 Web Server

9.3. Login/Logout

To make configuration settings on the fieldbus module using the web interface, you must first

log in. Functionalities which cannot be used without logging in are indicated by the grayed out

buttons.

The default password is:

BNI PNT-XXX-XXX-XXXX

"BNIPNT“

BNI EIP-XXX-XXX-XXXX

"BNIEIP“

BNI ECT-XXX-XXX-XXXX

"BNIECT“

The password cannot be changed!

After successfully logging in the dialogs are shown as follows:

Use the "Logout" button to log out again. After 5 minutes of no interaction with the Webserver

the user is automatically logged out.

Note

For security reasons the fieldbus module shows only one login at a time with

configuration access. Reading (without logging in) is however possible from multiple

PCs at the same time on the fieldbus module.

www.balluff.com

41

9 Web Server

9.4. "Home" dialog

Under "Home" you are given the essential information about the fieldbus itself and its network

activity. You are also shown whether the configuration block was enabled by the controller

(PLC).

Information is also shown about the current process data and the status of the module via

the corresponding LEDs. After selecting "LED Legend" a Help dialog appears which explains

the meaning of the LEDs.

If an IO-Link device is connected to one of the configured IO-Link terminals, some of the

device data will be displayed in addition to the module data in the form of a link. After selecting

one of these links the corresponding device dialog is opened.

Balluff Network Interface EtherNet/IP™

www.balluff.com

42

9 Web Server

PNT:

EIP:

www.balluff.com

43

9 Web Server

9.5. "Ports" dialog

The "Ports" dialog displays information and process data for the connected IO-Link devices.

Select the desired IO-Link Port in the image of the fieldbus module on the right side to see the

device data.

Note

The IO-Link device data are only displayed if the port is also

configured as an IO-Link port!

No appropriate

IODD uploaded

It is possible to read and write the configuration parameters of the IO-Link device via the

"Parameters" option. The parameter indexes and subindexes of the IO-Link device are

described in the corresponding separate user's guide (and follow the IO-Link conventions).

Under "Events" you can see whether a diagnostic event from the IO-Link device exists.

Under "Parameter Server Content" you can view the content of the parameter server if

parameter data is stored on the parameter server.

"Ports" dialog with direct parameter access

Balluff Network Interface EtherNet/IP™

www.balluff.com

44

9 Web Server

Appropriate IODD

uploaded

If an IODD appropriate to the IO-Link device connected to the currently selected port has

been uploaded (see "Dialog "IODD"), the normal dialog for "Process Data" and "Parameters"

is not displayed, but rather an expanded dialog.

Information from the IODD of the device is used so that the data can be better understood.

Thus in the following screenshot not only are the input data of the distance sensor displayed

as a hex number, but also interpreted and labeled under "Input".

Since the sensor has no parameters, none are displayed.

Dialog "Ports“: IODD interpretation and device image

www.balluff.com

45

9 Web Server

If the IODD of the IO-Link device on the currently selected port has parameters, these are

shown in table format (see following screenshot). In this example the parameters for the Balluff

Smart Light are shown.

The Smart Light is a signal light which can be used in three different modes. These modes can

be set using an IO-Link parameter. The parameter values and associated texts are stored in

the IODD.

This means "Operation Mode" can be read out and displayed ("Read" and "Read All" buttons)

or written to the device ("Write" button).

If subindexes have no buttons they cannot be individually processed but rather only the entire

index at once.

Note

Each changed value must be individually written by clicking on the "Write" button!

"Ports" dialog: Parameter list of an IO-Link device with uploaded IODD

Balluff Network Interface EtherNet/IP™

www.balluff.com

46

9 Web Server

9.6. "IODD" dialog

Using this dialog you can transfer IODDs (device description files for IO-Link devices) and the

associated device images to the fieldbus module, so that a detailed representation of the

connected IO-Link devices in the "Ports" dialog is possible.

When IO-Link devices are connected and IO-Link ports are activated, the dialog shows a table

with information about the IO-Link devices.

The fieldbus module file system supports only device names in "8+3" format, i.e. with a

restricted name length. Since IODD files are generally published with a long file name, these

must be renamed and given a shorter naming scheme on the PC before uploading to the

fieldbus module.

For this a help setting is provided in the dialog, with the associated required IODD file name

for the currently connected IO-Link devices shown in the bottom section of the list (column

IODD Filename).

Image files without IODD can also be uploaded; the images are still displayed in the "Ports"

dialog.

Using the "Delete" button you can delete IODDs and device images from the fieldbus when

needed.

Note

Before selecting the IODD it must be renamed on the PC to the file name which is

shown in the table in the "IODD Filename" column!

www.balluff.com

47

9 Web Server

9.7. "Config" dialog

The configuration page enables configuration of the module. You can change both the

module information texts and the port configuration.

The "Set Ports" action is not permanently stored in the device and is lost after the next reboot

or reset.

PNT / ECT:

Balluff Network Interface EtherNet/IP™

www.balluff.com

48

9 Web Server

EIP:

The parameter set “Module Configuration” on the left side is used by clicking "Save

Configuration" and permanently stored in the device.

The "Reboot" button reboots the device as if the power to the module had been turned off

and on again.

Clicking on "Factory Reset" deletes the configuration and log files saved in the device and

then performs a reboot, so that the device is restored to the default factory configuration as

on delivery.

www.balluff.com

49

9 Web Server

9.8. "Log" dialog

This dialog provides general service information about the device as well as a logging

function.

The upper table (see screenshot below) contains important information for all service

inquiries.

Note

If you have a detailed question about a specific situation, send us a screenshot of

this Website or print the site as a PDF.

Logging shows events which have occurred in chronological order. This provides a tool for

detailed troubleshooting in equipment.

Balluff Network Interface EtherNet/IP™

www.balluff.com

50

9 Web Server

Events are classified using the "Severity“ column:

Internal Error (Emergency, Alert, Critical)

The fieldbus module has detected a fault in itself (hardware or software) which should

not occur during normal operation. If this happens, the module must be serviced or

replaced.

External Error (Error, Warning)

The fieldbus module has detected what may be a non-permissible event which is

affecting the module from the outside. The system may require troubleshooting.

Event (Informational, Notice)

The fieldbus module has detected an important normal operating event and reports it. These

may include for example configuration actions over the web interface and other configuration

interfaces which are also recorded.

Clicking on "Set Module Time” sends the current browser time to the fieldbus module but

does not permanently store it. After a reset, reboot or loss of power the time begins to run

again from the year 2000.

Clicking on "Update Log” refreshes the display, and "Clear Log” deletes all entries. The log

entries are stored in a ring buffer.

www.balluff.com

51

10 Appendix

10.1. Scope of

Delivery

The BNI EIP comprises the following elements:

• IO-Link block

• 4x M12 dummy plugs

• Ground strap

• M4x6 screw

• 20 informational signs

10.2. Order Number

BNI EIP-50x-105-R015

Balluff Network Interface

Ethernet IP

Functions

502 = IP 67 IO-Link master module, 4 IO-Link ports

508 = IP 67 IO-Link master module, 8 IO-Link ports

Versions

105 = display version, 2-port switch

Mechanical version

R015 = plastic housing, resistant (Fortron 6165 A6 black)

Data transmission: 2 x M12x1 internal thread

Power supply: 7/8" external thread, 7/8" internal thread

Sensor connections: 8 x M12x1 internal thread

10.3. Ordering

Information

Product order code

Order code

BNI EIP-502-105-R015

BNI008Z

BNI EIP-508-105-R015

BNI008M

www.balluff.com

52

Notes

www.balluff.com

53

www.balluff.com

Balluff GmbH

Schurwaldstrasse 9

D-73765 Neuhausen a.d.F.

Germany

Phone +49 7158 173-0

Fax +49 7158 5010

balluff@balluff.de

No. 922508

-726 E 04.124053

Edition

D17 Replaces Edition

B17 Subject to modification

Loading...

Loading...