Baldor VS1SM, VS1SM80P5, VS1SM81, VS1SM82 Installation & Operating Manual

Installation & Operating Manual

VS1SM

Single Phase AC Drive

10/07 MN761

Any trademarks used in this manual are the property of their respective owners.

Important:

Be sure to check www.baldor.com for the latest software, firmware and drivers for your

VS1 product. Also, you can download the latest version of this manual in Adobe Acrobat

PDF format.

Table of Contents

MN761 Table of Contents i

Chapter 1

Introduction 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Getting Assistance from Baldor 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Safety Notice 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Quick Start 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2

General Information and Ratings 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Identify the Drive by Model Number 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Storage Guidelines 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 VS1SM Ratings, Model Numbers and Frame Sizes 2-1. . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3

Installing the Drive 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Receiving & Inspection 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 General Requirements for the Installation Site 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Operating Conditions 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 Minimum Mounting Clearances 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Mounting the Drive 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Protecting the Drive from Debris 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.2 Watts Loss Data 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Cover Removal 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4

Power Wiring 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Overview of Power Connections 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Power Disconnect 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Protective Devices 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Electrical Installation 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.1 Input Power Connections 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.1 Grounding Procedure 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2 Motor Connections 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Optional Dynamic Brake Hardware 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5

Control Wiring 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Control Wiring Overview 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Control Input Connections 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Control Output Connections 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 6

Using the Keypad 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Keypad Overview 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Parameter Groups 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 7

Parameter Descriptions 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Drive Group 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Function Group1 7-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Function Group2 7-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 I/O Group 7-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii Table of Contents MN761

Chapter 8

Customizing for Your Application 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 9

Troubleshooting 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 Periodic Maintenance 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Reviewing Fault Status of the Drive 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A

Technical Specifications A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B

Parameter Tables B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C

CE Guidelines C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.1 CE Declaration of Conformity C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2 EMC - Conformity and CE - Marking C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.3 EMC Installation Instructions C-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MN760 Quick Start 1-1

Chapter 1

Introduction

This manual is intended for qualified electrical personnel familiar with installing, programming, and

maintaining AC Drives. This manual contains information on:

S Installing and wiring the VS1SM drive

S Programming the drive

S Troubleshooting the drive

1.1 Getting Assistance from Baldor

For technical assistance, contact your Baldor District Office. Before calling, please review the

troubleshooting section of this manual and you will be asked for the drive model number or catalog

number that is located on the Nameplate.

1.2 Safety Notice

This equipment contains voltages that may be as high as 1000 volts! Electrical shock can cause serious

or fatal injury. Only qualified personnel should attempt the start-up procedure or troubleshoot this

equipment.

This equipment may be connected to other machines that have rotating parts or parts that are driven by

this equipment. Improper use can cause serious or fatal injury. Only qualified personnel should attempt

the start-up procedure or troubleshoot this equipment.

Precautions: Classifications of cautionary statements

WARNING: Do not touch any circuit board, power device or electrical connection before you first

ensure that power has been disconnected and there is no high voltage present from

this equipment or other equipment to which it is connected. Electrical shock can

cause serious or fatal injury. Only qualified personnel should attempt the start-up

procedure or troubleshoot this equipment.

WARNING: Be sure that you are completely familiar with the safe operation of this equipment.

This equipment may be connected to other machines that have rotating parts or

parts that are controlled by this equipment. Improper use can cause serious or fatal

injury. Only qualified personnel should attempt the start-up procedure or

troubleshoot this equipment.

WARNING: Do not use motor overload relays with an automatic reset feature. These are

dangerous since the process may injure someone if a sudden or unexpected

automatic restart occurs. If manual reset relays are not available, disable the

automatic restart feature using external control wiring.

WARNING: This unit has an automatic restart feature that will start the motor whenever input

power is applied and a RUN (FWD or REV) command is issued. If an automatic restart

of the motor could cause injury to personnel, the automatic restart feature of the

VS1MSD should be disabled.

WARNING: Be sure the system is properly grounded before applying power. Do not apply AC

power before you ensure that all grounding instructions have been followed.

Electrical shock can cause serious or fatal injury.

WARNING: Do not remove cover for at least five (5) minutes after AC power is disconnected to

allow capacitors to discharge. Dangerous voltages are present inside the equipment.

Electrical shock can cause serious or fatal injury.

WARNING: Motor circuit may have high voltage present whenever AC power is applied, even

when motor is not rotating. Electrical shock can cause serious or fatal injury.

Continued on next page

1-2 Quick Start MN760

WARNING: Improper operation of control may cause violent motion of the motor shaft and

driven

equipment. Be certain that unexpected motor shaft movement will not cause injury to

personnel or damage to equipment. Certain failure modes of the control can produce

peak torque of several times the rated motor torque.

WARNING: Dynamic brake resistors may generate enough heat to ignite combustible materials.

Keep all combustible materials and flammable vapors away from brake resistors.

WARNING: The motor shaft will rotate during the autotune procedure. Be certain that

unexpected motor shaft movement will not cause injury to personnel or damage to

equipment.

Caution: Disconnect motor leads (U, V and W) from control before you perform a “Dielectric

Withstand” test on the motor. Failure to disconnect motor from the control will result

in extensive damage to the control. The control is tested at the factory for high

voltage / leakage resistance as part of Underwriter Laboratory requirements.

Caution: Suitable for use on a circuit capable of delivering not more than the RMS

symmetrical short circuit amperes listed here at rated voltage.

Horsepower

RMS Symmetrical Amperes

1-50 5,000

51-200 10,000

201-400 18,000

401-600 30,000

601-900 42,000

Caution: Do not connect AC power to the Motor terminals U, V and W. Connecting AC power

to these terminals may result in damage to the control.

Caution: Baldor recommends not to use “Grounded Leg Delta” transformer power leads that

may create ground loops. Instead, we recommend using a four wire Wye.

Caution: If the DB hardware mounting is in any position other than vertical, the DB hardware

must be derated by 35% of its rated capacity.

Caution: Only Baldor cables should be used to connect the keypad and control. These are

special twisted pair cables to protect the control and keypad. Damage associated

with other cable types are not covered by the Baldor warranty.

Caution: If an M-Contactor is installed, the control must be disabled for at least 200msec

before the M-Contactor is opened. If the M-Contactor is opened while the control is

supplying voltage and current to the motor, the control may be damaged. Before the

control is enabled, the M-Contactor must be closed for at least 200msec.

Caution: Use of power correction capacitors on the output of the drive can result in erratic

operation of the motor, nuisance tripping, and/or permanent damage to the drive.

Remove power correction capacitors before proceeding. Failure to observe this

precaution could result in damage to, or destruction of, the equipment.

MN760 Quick Start 1-3

1.3 Quick Start Quick Start Guide is also available separately, see MS760.

Figure 1‐1 Power & Motor Terminal Locations

L1 L2 P P1 N U V W

Jumper Bar

VS1SM82/82-F, VS1SM83/83-F

L1 L2 P P1 N

UVW

Jumper Bar

VS1SM80P5/80P5-F, VS1SM81/81-F

Powerup Procedure Refer to Chapter 3, 4 and 5 for additional details.

1. Remove all power from the control.

2. Connect Power & Motor, See Figure 1‐1.

3. Connect input control wires and output wires, See Figure 1‐2.

4. Disconnect the motor from the load (including coupling or inertia wheels).

5. Turn power on. Be sure there are no faults.

6. Set the following parameters for the values displayed on the motor nameplate:

P30 Motor HP Select

P32 Motor Rated Current

P33 Pole Number

P34 Base Frequency

7. If external dynamic brake hardware is used, set the Level 2 Brake Adjust block “Resistor Ohms”

and “Resistor Watts” parameters.

WARNING: The motor shaft will rotate during this procedure. Be certain that unexpected motor

shaft movement will not cause injury to personnel or damage to equipment.

8. Set H41 =1 from using the Keypad. Perform each step including auto tune.

9. Remove all power from the control.

10. Couple the motor to its load.

11. Verify freedom of motion of motor shaft.

12. Verify the motor coupling is tight without backlash.

13. Verify the holding brakes if any, are properly adjusted to fully release and set to the desired torque.

14. Turn power on. Be sure no errors are displayed.

15. Run the drive from the keypad.

16. Select and program additional parameters to suit your application, see Chapter 8.

The control is now ready for use the in keypad mode. If a different operating mode is desired, refer to

Chapter 7 Parameter Descriptions and Chapter 8 Customizing for your Application.

1-4 Quick Start MN760

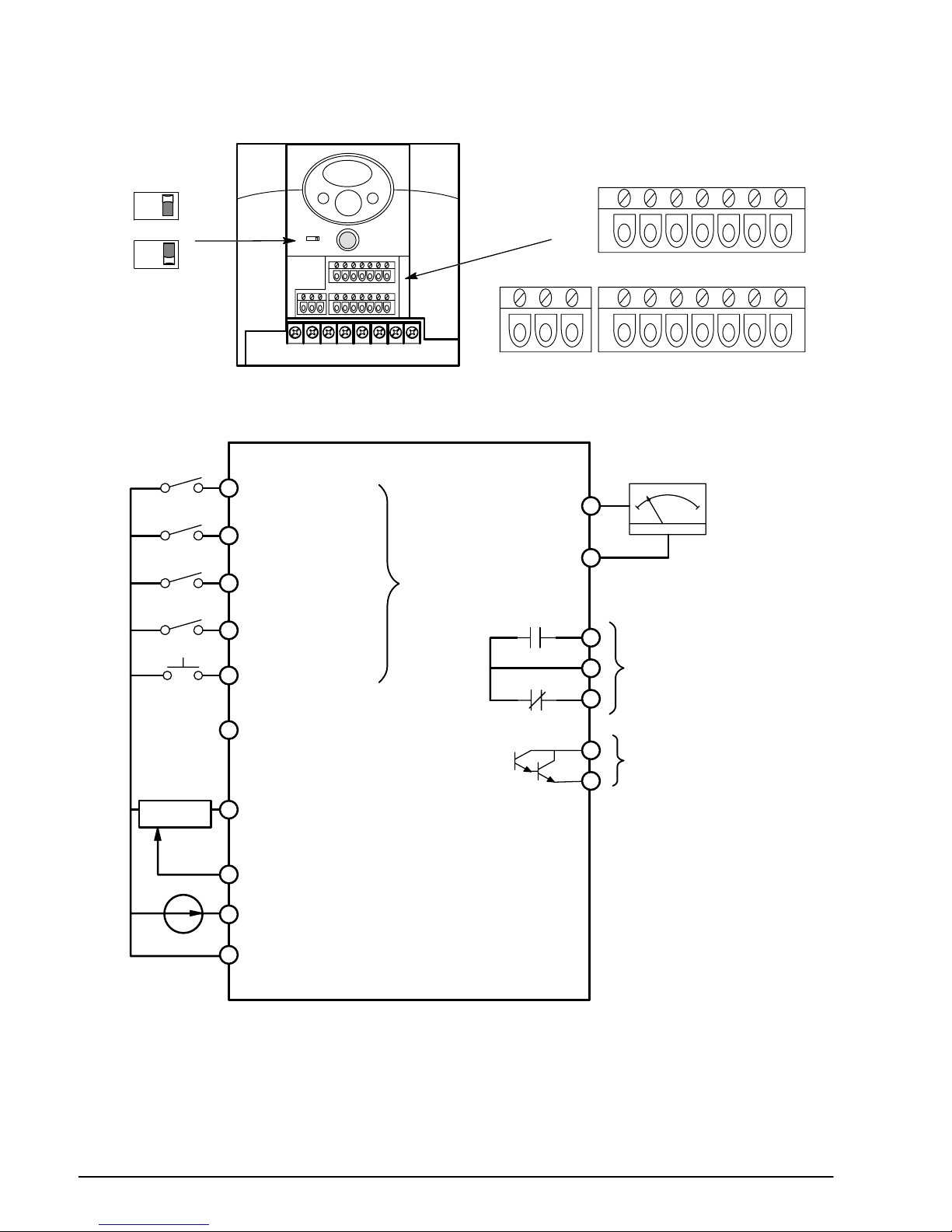

Figure 1‐2 Input/Output Connections

Control I/O Terminal Strip

P4

P5 VR V1 CM I AM

30A30B30C MOEXTGP24 P1 P2 CM P3

See MN761 for

Tightening Torques

NP

N

PN

P

Set the NPN/PNP switch

for desired mode.

NPN Mode

PNP Mode

OR

Shown with NPN Digital Input Connections

Tightening Torque = 3.5 lb-in (0.4Nm)

Forward Run

Speed signal input (0-10VDC )

Speed signal input (0-20mA)

P1

P2

P3

P4

P5

P24

VR

VI

I

CM

Reverse Run

Output Inhibit

Jog Operation

Fault Reset

PNP 24VDC Output

Common

VS1SM

Digital

Inputs

AM

CM

30A

30B

30C

MO

EXTG

Relay Output

Digital Output

Analog Output

(0-10VDC)

Tightening Torque =

3.5 lb-in (0.4Nm)

MN761 General Information and Ratings 2-1

Chapter 2

General Information and Ratings

The VS1SM is a variable frequency PWM drive capable of operating in open- loop, V/Hz (volts per

hertz) mode and in a sensorless vector control (SVC) mode. This chapter contains information

about the VS1SM drive, including how to identify the drive.

2.1 Identify the Drive by Model Number

Each drive can be identified by its model number, as shown in Figure 2‐1. The model number is on

the shipping label and the drive nameplate. The model number includes the drive and any options.

Figure 2‐1 Drive Identification

VS1 family SM (Sub-Micro)

for Single Phase Power Applications

VS1 SM 8 0P5

Voltage Code

8= 230VAC, 1PH

Horse Power Rating

OP5=0.5HP

1 = 1HP

2 = 2HP

3 = 3HP

V/Hz and Open Loop Vector Control -F

EMC Filter:

F = Filter

blank = No Filter

2.2 Storage Guidelines

If you need to store the drive, follow these recommendations to prolong drive life and performance:

1. Storage ambient temperature is -20°C to 65°C.

2. Storage Humidity range 10% to 90% RH non-condensing.

3. Do not expose to corrosive atmosphere.

2.3 VS1SM Ratings, Model Numbers and Frame Sizes

Table 2‐1 has drive ratings for each VS1SM Model.

Table 2‐1

Catalog No.

Input

Volt

Frame

Size

Output Watts Loss

HP KW Amps Watts

VS1SM80P5 230 A 0.5 0.4 2.5 7

VS1SM81 230 A 1 0.75 5.0 25

VS1SM82 230 B 2 1.5 8.0 48

VS1SM83 230 B 3 2.2 12.0 73

2-2 General Information and Ratings MN761

MN761 Installing the Drive 3-1

Chapter 3

Installing the Drive

This chapter provides information that must be considered when planning a VS1SM drive

installation and provides drive mounting information and installation site requirements.

3.1 Receiving & Inspection

When you receive your control, there are several things you should do immediately.

1. Observe the condition of the shipping container and report any damage immediately to the

commercial carrier that delivered your control.

2. Remove the control from the shipping container and remove all packing materials from the control.

The container and packing materials may be retained for future shipment.

3. Verify that the part number of the control you received is the same as the part number listed on

your purchase order.

4. Inspect the control for external physical damage that may have been sustained during shipment

and report any damage immediately to the commercial carrier that delivered your control.

5. If the control is to be stored for several weeks before use, be sure that it is stored in a location that

conforms to published storage humidity and temperature specifications stated in this manual.

3.2 General Requirements for the Installation Site

It is important to ensure that the drives environment and operating conditions are satisfactory.

The area behind the drive must be kept clear of all control and power wiring. Power connections may

create electromagnetic fields that may interfere with control wiring or components when run in close

proximity to the drive.

Read the recommendations in the following sections before continuing with the drive installation.

3.2.1 Operating Conditions

Before deciding on an installation site, consider the following guidelines:

S Protect the cooling fan by avoiding dust or metallic particles.

S Do not expose the drive to a corrosive atmosphere.

S Protect the drive from moisture and direct sunlight.

S Verify that the drive location will meet the environmental conditions specified in Table 3‐1.

Table 3‐1 - Ambient Temperatures and Mounting Clearances

Ambient Temperature

Enclosure Rating Minimum Mounting Clearances

Minimum Maximum

14°F (-10°C)

104°F (40 °C) IP20/Open Type 2 in (50mm)

104°F (40 °C) IP20/NEMA 1 2 in (50mm)

104°F (40 °C) Side-by-Side 2 in (50mm)

3.2.2 Minimum Mounting Clearances

Be sure to provide proper top, bottom and side clearance (2” minimum each side).

3.3 Mounting the Drive

Mount the drive upright on a flat, vertical, non combustible and level surface.

Refer to Figure 3‐3 for mounting hole locations.

3.3.1 Protecting the Drive from Debris

The drive must be protected from debris falling through the drive vents during installation and operation.

The drive is designed to operate in IP20/NEMA1 Type installations.

3-2 Installing the Drive MN761

3.3.2 Watts Loss Data

Refer to Table 2‐1 for watts loss data.

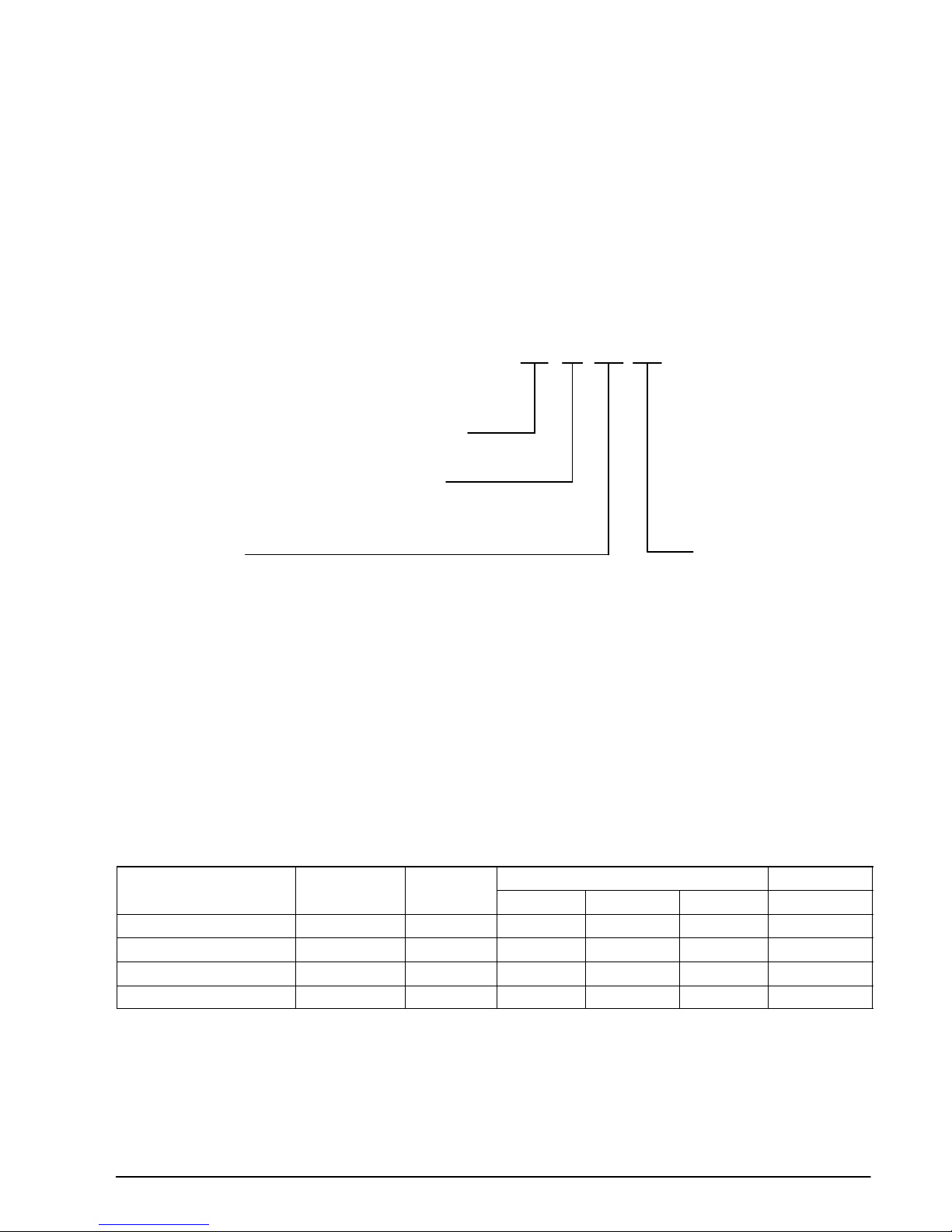

3.3 Cover Removal

To connect power and signal wires, the cover must be removed.

Remove the cover as shown in Figure 3‐2.

1. Gently press in the area labeled Cover Release shown in Figure 3‐2.

2. Slide the cover downward about 3/8 in (10mm) and lift off the Main Cover.

3. The Power Terminal Cover can then be removed by lifting it from the control.

Figure 3‐2 Cover Removal

Cover

Release

Main

Cover

Power

Terminal

Cover

Lift Cover

Slide

Cover

Power &

Motor

Ground

Size B

Size A

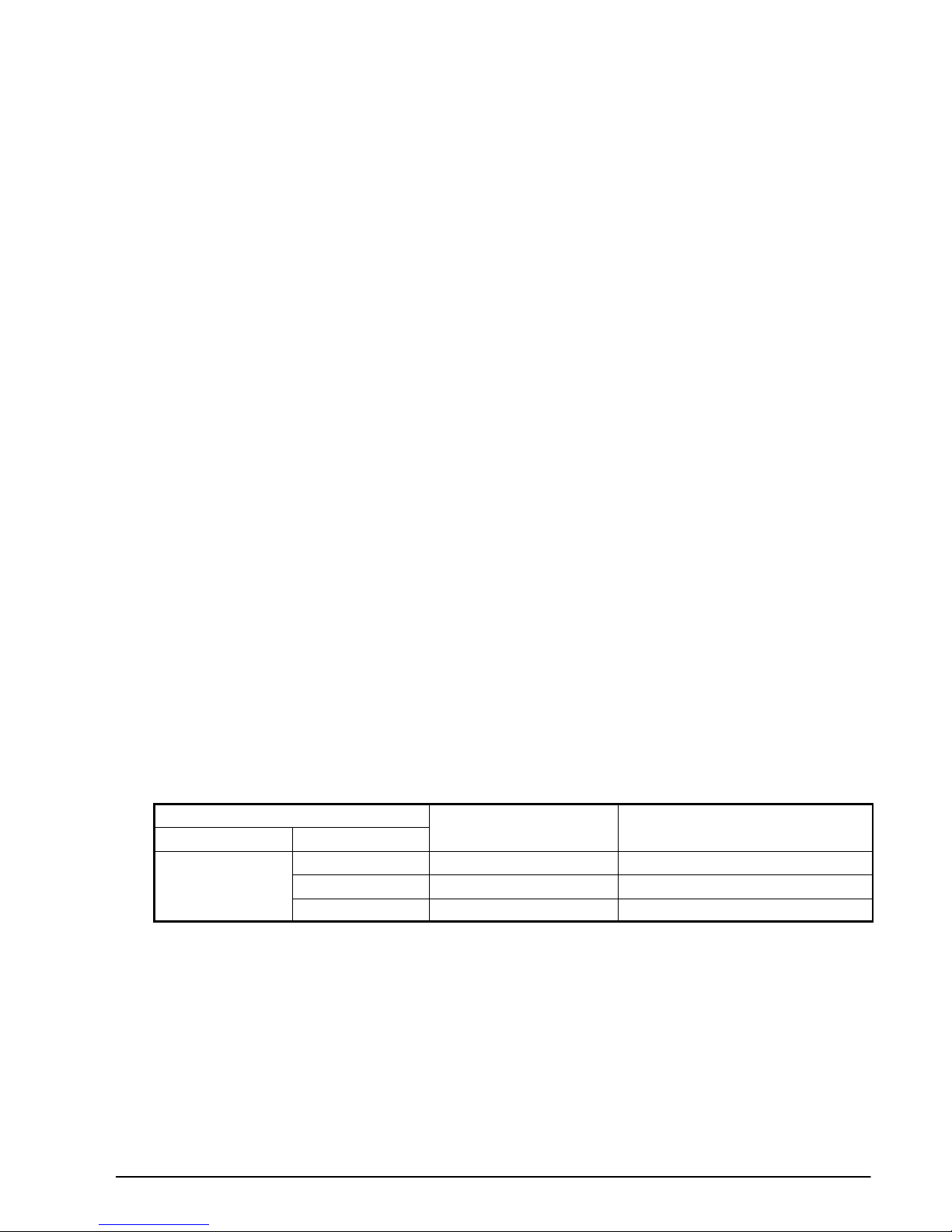

Figure 3‐3 Mounting Hole Locations

B1

B2

B

A1

A

C

Table 3‐2 Drive Dimensions and Weights

Size

Catalog

Number

Dimensions inches(mm)

Weight

Outside Mounting

Height (A) Width (B) Depth (C) Height (A1) Width (B1) Width (B2) lb (kg)

A VS1SM80P5 5.63 (143) 3.11 (79) 5.64 (143) 2.66 (67.5) 5.35(135.9) N/A 1.92 (0.87)

A VS1SM80P5- F 5.63 (143) 3.11 (79) 5.64 (143) 2.66 (67.5) 5.35(135.9) N/A 2.09(0.95)

A VS1SM81 5.63 (143) 3.11 (79) 5.64 (143) 2.66 (67.5) 5.35(135.9) N/A 1.96 (0.89)

A VS1SM81-F 5.63 (143) 3.11 (79) 5.64 (143) 2.66 (67.5) 5.35(135.9) N/A 2.14(0.97)

B VS1SM82 5.63 (143) 6.14 (156) 5.64 (143) 5.34 (135) 5.43 (138) 2.71 (68.8) 3.95 (1.79)

B VS1SM82-F 5.63 (143) 6.14 (156) 5.64 (143) 5.34 (135) 5.43 (138) 2.71 (68.8) 4.28(1.94)

B VS1SM83 5.63 (143) 6.14 (156) 5.64 (143) 5.34 (135) 5.43 (138) 2.71 (68.8) 4.08 (1.85)

B VS1SM83-F 5.63 (143) 6.14 (156) 5.64 (143) 5.34 (135) 5.43 (138) 2.71 (68.8) 4.41(2.0)

MN761 Power Wiring 4-1

Chapter 4

Power Wiring

4.1 Overview of Power Connections

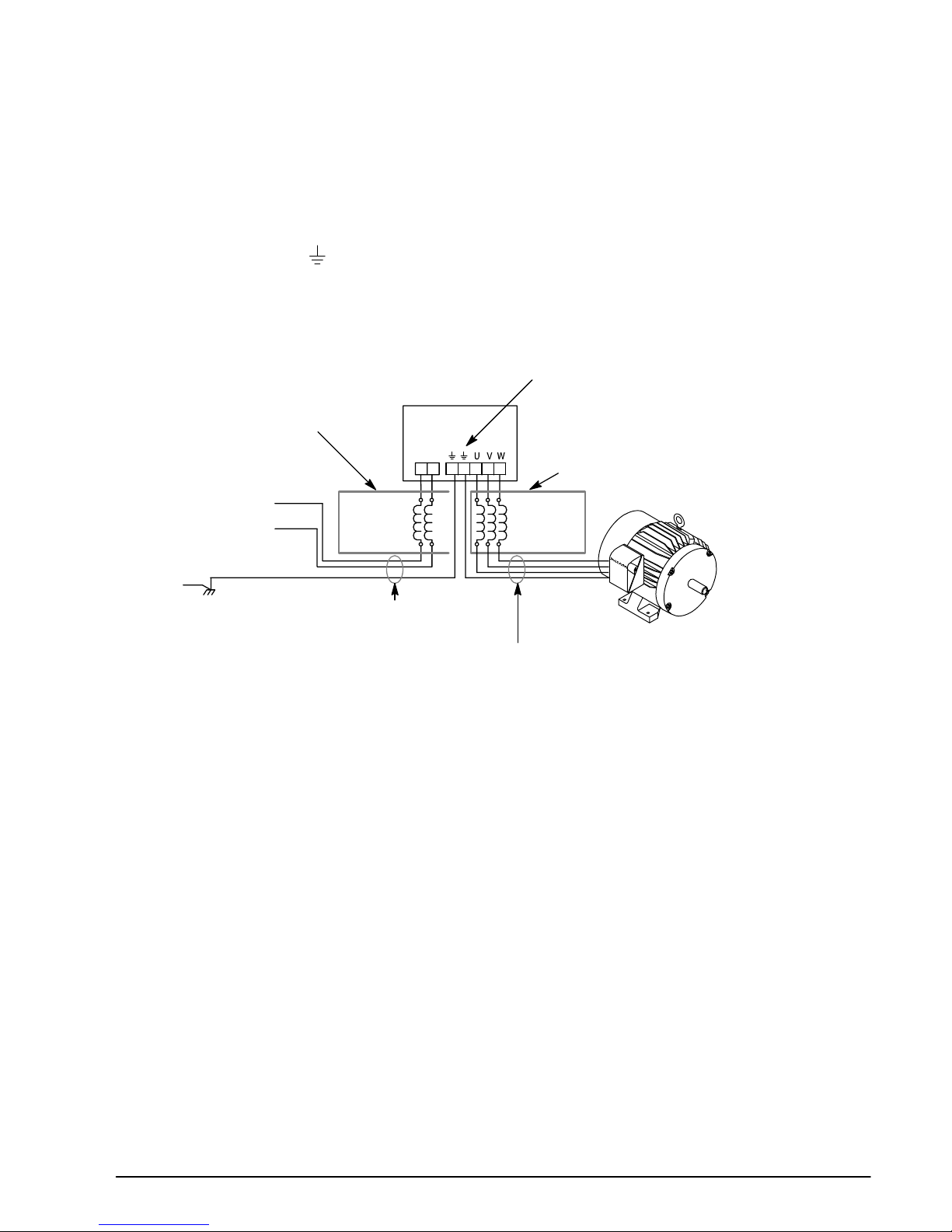

The recommended grounding method is shown in Figure 4‐1.

Safety Ground - (G)

This is the safety ground for the drive that is required by code. One of these points must be connected to

adjacent building steel (girder, joist), a floor ground rod, or bus bar. Grounding points must comply with

national and local industrial safety regulations and/or electrical codes.

Figure 4‐1 Recommended System Grounding

AC Main

Supply

Safety

Ground

Driven Earth

Ground Rod

(Plant Ground)

Four Wire

“Wye”

L1

L2

Optional

Line

Reactor

Optional

Load

Reactor

Route all 4 wires L1, L2, L3 and Earth

(Ground) together in conduit or cable.

Route all 4 wires U, V, W and Motor Ground together in conduit or cable.

Connect all wires (including motor ground) inside the motor terminal box.

Ground per NEC

and Local codes.

Note: Wiring shown for clarity of grounding

method only. Not representative of

actual terminal block location.

Note: A load reactor is recommended

and must be purchased separately.

Note: A line reactor is recommended and

must be purchased separately.

Drive

See recommended tightening torques in Table 4‐1.

L1

L2

Motor Ground

The motor ground must be connected to one of the ground terminals on the drive.

Shield Termination

Either of the safety ground terminals located on the power terminal block provides a grounding point for

the motor cable shield. The motor cable shield connected to one of these terminals (drive end) should

also be connected to the motor frame (motor end). Use a shield terminating or EMI clamp to connect the

shield to the safety ground terminal. The NEMA 1/IP30 Kit may be used with a cable clamp for a

grounding point for the cable shield.

When shielded cable is used for control and signal wiring, the shield should be grounded at the drive end

only, never at both ends.

RFI Filter Grounding

Using single-phase drives with integral filter, or an external filter with any drive rating, may result in

relatively high ground leakage currents. Therefore, the filter must only be used in installations with

grounded AC supply systems and be permanently installed and solidly grounded (bonded) to the building

power distribution ground.

Ensure that the incoming supply neutral is solidly connected (bonded) to the same building power

distribution ground. Grounding must not rely on flexible cables and should not include any form of plug or

socket that would permit inadvertent disconnection. Some local codes may require redundant ground

connections. The integrity of all connections should be checked periodically.

4-2 Power Wiring MN761

4.2 Power Disconnect

A power disconnect should be installed between the input power service and the drive for a fail safe

method to disconnect power. The drive will remain in a powered‐up condition until all input power is

removed from the drive and the internal bus voltage is depleted.

4.3 Protective Devices

Recommended fuse sizes are based on the following:

115% of maximum continuous current for time delay.

150% of maximum continuous current for Fast or Very Fast action.

Note: These recommendations do not consider harmonic currents or ambient temperatures greater than

45°C.

Be sure a suitable input power protection device is installed. Use the recommended fuses and wire sizes

shown in Table 4‐1 is based on the use of copper conductor wire rated at 75 °C. The table is specified

for NEMA B motors.

Fast Action Fuses: 240VAC, Buss® KTN; 460VAC, Buss® KTS

Very Fast Action: 240VAC, Buss® JJN; 460VAC, Buss® JJS

Semiconductor 240VAC, Ferraz Shawmut A50QS

Buss® is a trademark of Cooper Industries, Inc.

4.4 Electrical Installation

All interconnection wires between the drive, AC power source, motor, host control and any operator

interface stations should be in metal conduits or shielded cable must be used. Use listed closed loop

connectors that are of appropriate size for wire gauge being used. Connectors are to be installed using

crimp tool specified by the manufacturer of the connector. Only class 1 wiring should be used.

Table 4‐1 Fuse & Wire Size and Terminal Tightening Torque Specifications

Catalog Number

Input Fuse (Amps) Wire Gauge Tightening Torque

Fast Acting (UL) AWG mm

2

lb-in Nm

VS1SM80PF, VS1SM80P5-F 10A 14 2.5 9 4.5

VS1SM81, VS1SM81-F 20A 14 2.5 9 4.5

VS1SM82, VS1SM82-F 30A 12 4.0 15 1.7

VS1SM83, VS1SM83-F 40A 12 4.0 15 1.7

Note: Wire sizes based on 75°C copper wire. Fuses based on 45°C ambient, max continuous output and no

harmonic current.

4.4.1 Input Power Connections

All cables must be shielded and the shields must be grounded at the enclosure cable entrance.

1. Connect the line L1, L2 to the Power Terminal Strip, Figure 4‐3.

2. Connect the motor leads to U, V and W terminals, Figure 4‐2.

3. Connect motor ground to the ground terminal located in the opening at the rear of the drive by

the fan (see Figure 3‐2 for location).

MN761 Power Wiring 4-3

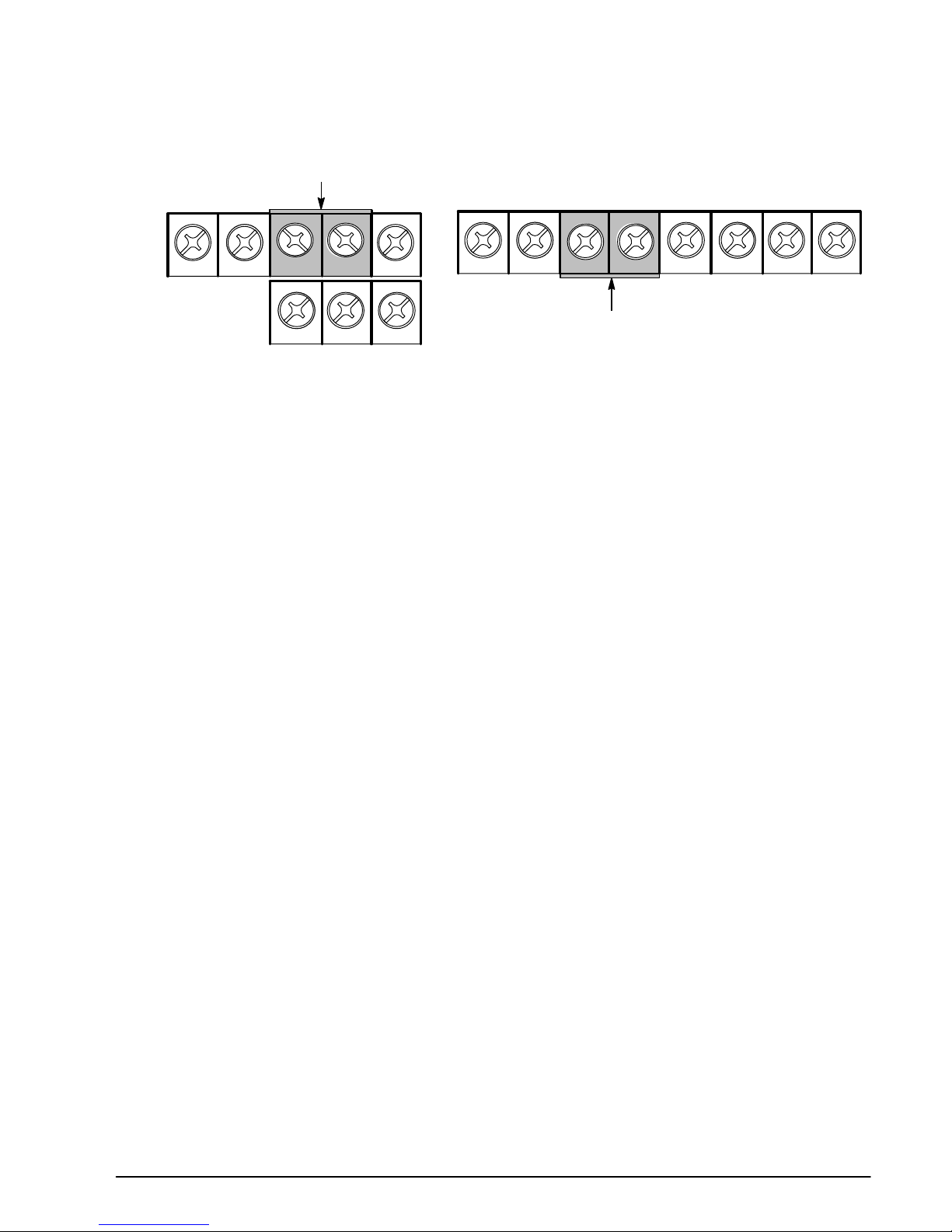

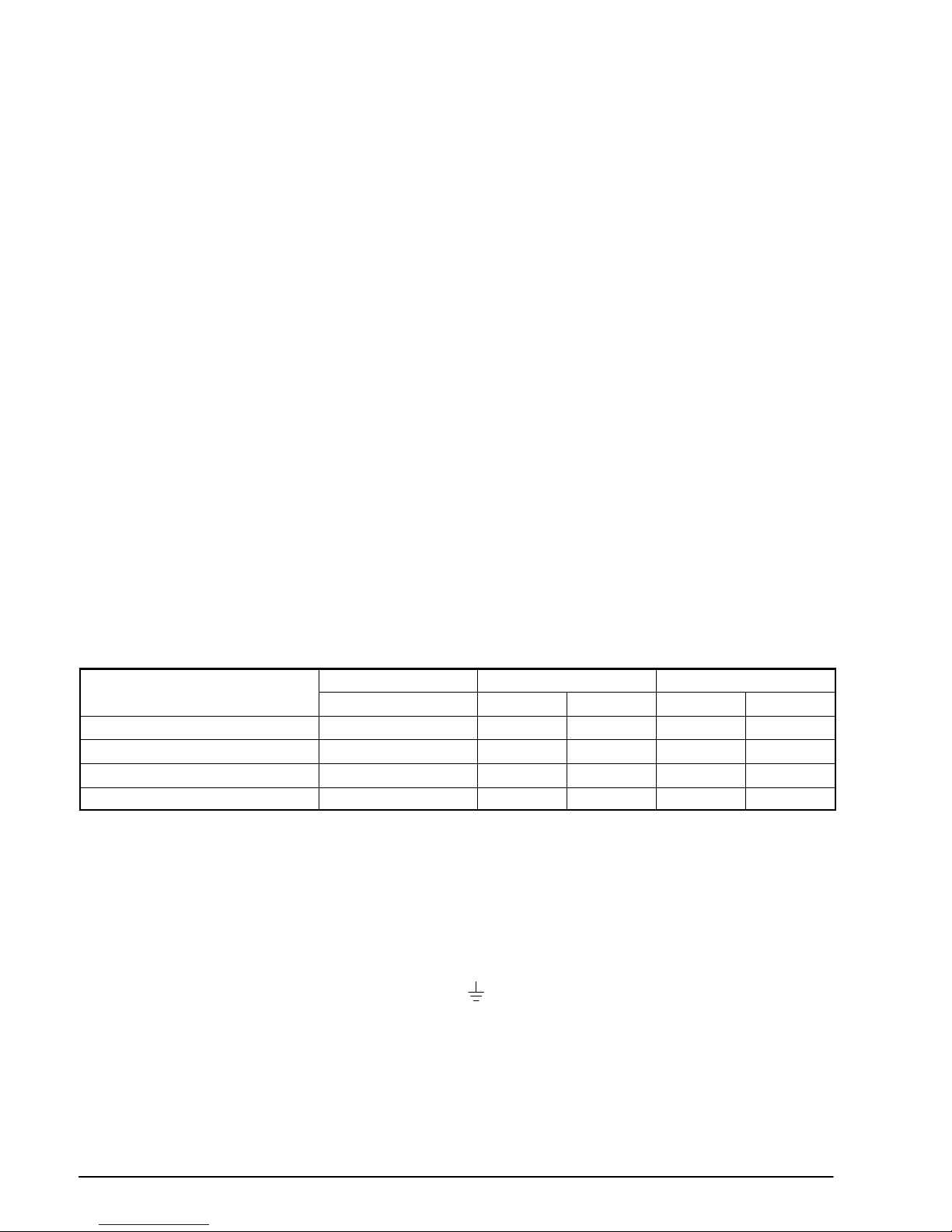

Figure 4‐2 Power Terminal Locations

NPN

PNP

Power Terminal Strip

L1 L2 P P1 N U V W

Jumper Bar

VS1SM82/82-F, VS1SM83/83-F

L1 L2 P P1 N

UVW

Jumper Bar

VS1SM80P5/80P5-F, VS1SM81/81-F

See Recommended Tightening

Torques in table 4‐1.

Figure 4‐3 Input Power Connections

L1 L2

L1 L2

Earth

* Optional components not provided with control.

Baldor

Control

Note 1

Note 3

Notes:

1. See “Protective Devices” described

previously in this section.

2. Use same gauge wire for Earth ground

as is used for L1 and L2.

3. Metal conduit should be used. Connect

conduits so the use of a Reactor or RC

Device does not interrupt EMI/RFI

shielding.

Note 2

*Fuses

See Recommended Tightening Torques in table 4‐1.

See Figure 3‐2

for ground location.

N

N

4-4 Power Wiring MN761

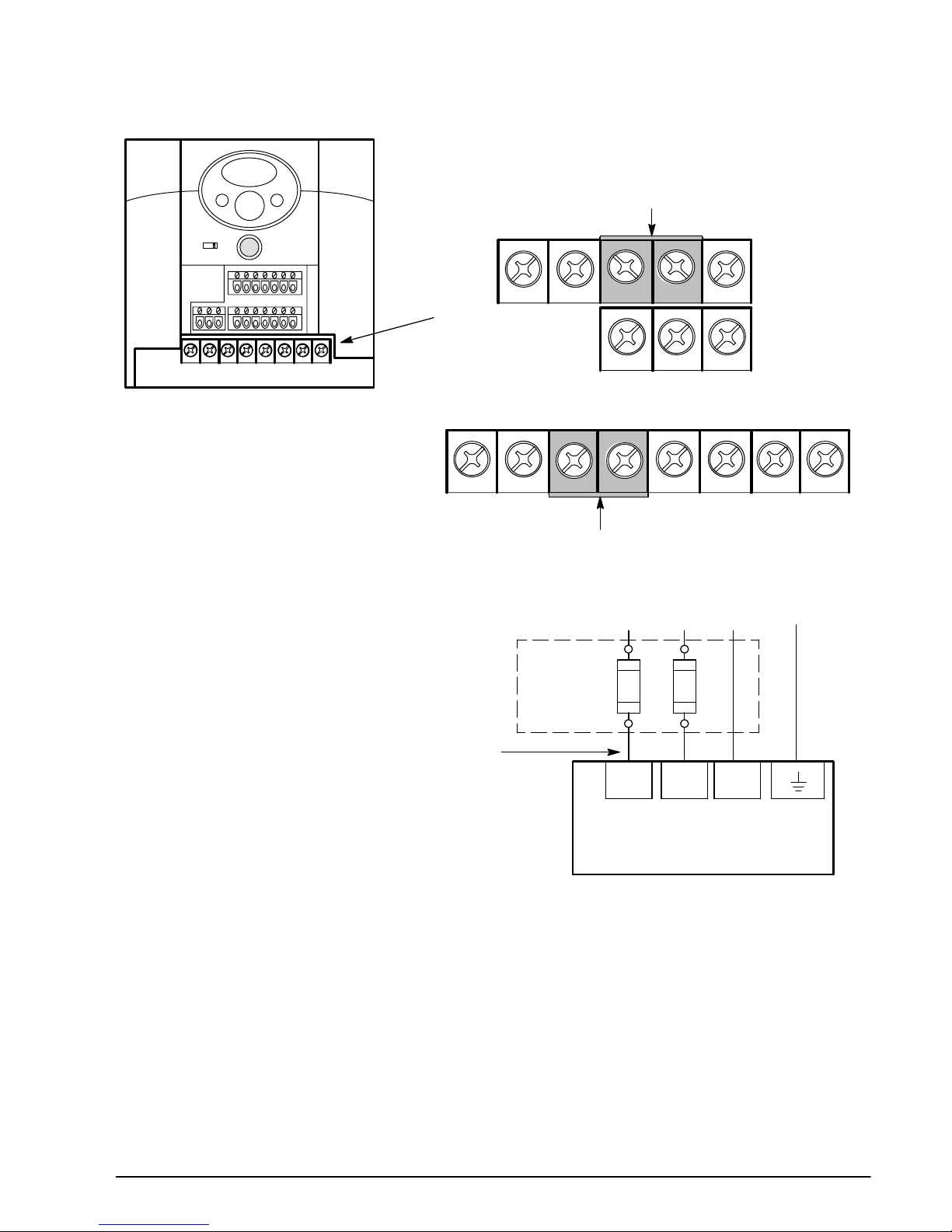

Figure 4‐4 Motor Connections

* Optional components not

provided with control.

Baldor Control

Notes:

1. Metal conduit should be used. Connect

conduits so the use of Load Reactor or RC

Device does not interrupt EMI/RFI shielding.

2. See Line/Load Reactors described

previously in this section.

3. Use same gauge wire for ground as for U, V

and W.

* AC Motor

Note 1

*Optional

Load

Reactor

Note 1

A1 B1 C1

A2 B2 C2

UVW

U

VW

G

Note 3

Note 2

See Recommended Tightening

Torques in table 4‐1.

See Figure 3‐2 for ground location.

4.4.1 Grounding Procedure

1. Remove covers. Cover removal is described in Chapter 3 of this manual.

2. Connect the power ground wire to the ground terminal G (see Figure 3‐2).

3. Connect the motor ground wire to the ground terminal G (see Figure 3‐2).

4.4.2 Motor Connections

All cables must be shielded and the shields must be grounded at the enclosure cable entrance.

1. Remove covers. Cover removal is described in Chapter 3 of this manual.

2. Connect the Motor leads to terminals U, V and W (see Figure 4‐2 for location).

Long Motor Leads

The wire leads that connect the motor to the control are critical in terms of sizing, shielding and the cable

characteristics. Short cable runs are usually trouble free but fault-monitoring circuitry can produce

numerous faults when long cables (over 100 feet) are used.

100+ ft (30m). Baldor recommends adding an optional load reactor to the output of the control.

250+ ft (75m). Baldor recommends adding an optional load reactor and common mode choke to the

control.

The load reactor and/or common mode choke should be placed in close physical proximity to the control.

Unexpected faults may occur due to excessive charging current required for motor cable capacitance.

If you use long motor leads and experience unexpected trips due to current overload conditions and are

not sure how to correctly size and connect the optional load reactors, please contact your Baldor

representative. Baldor is always glad to assist.

4.5 Optional Dynamic Brake Hardware

Refer to MN763DB for DB resistor connections.

Dynamic Brake (DB) Hardware must be installed on a flat, non‐flammable, vertical surface for effective

cooling and operation.

MN761 Control Wiring 5-1

Chapter 5

Control Wiring

5.1 Control Wiring Overview

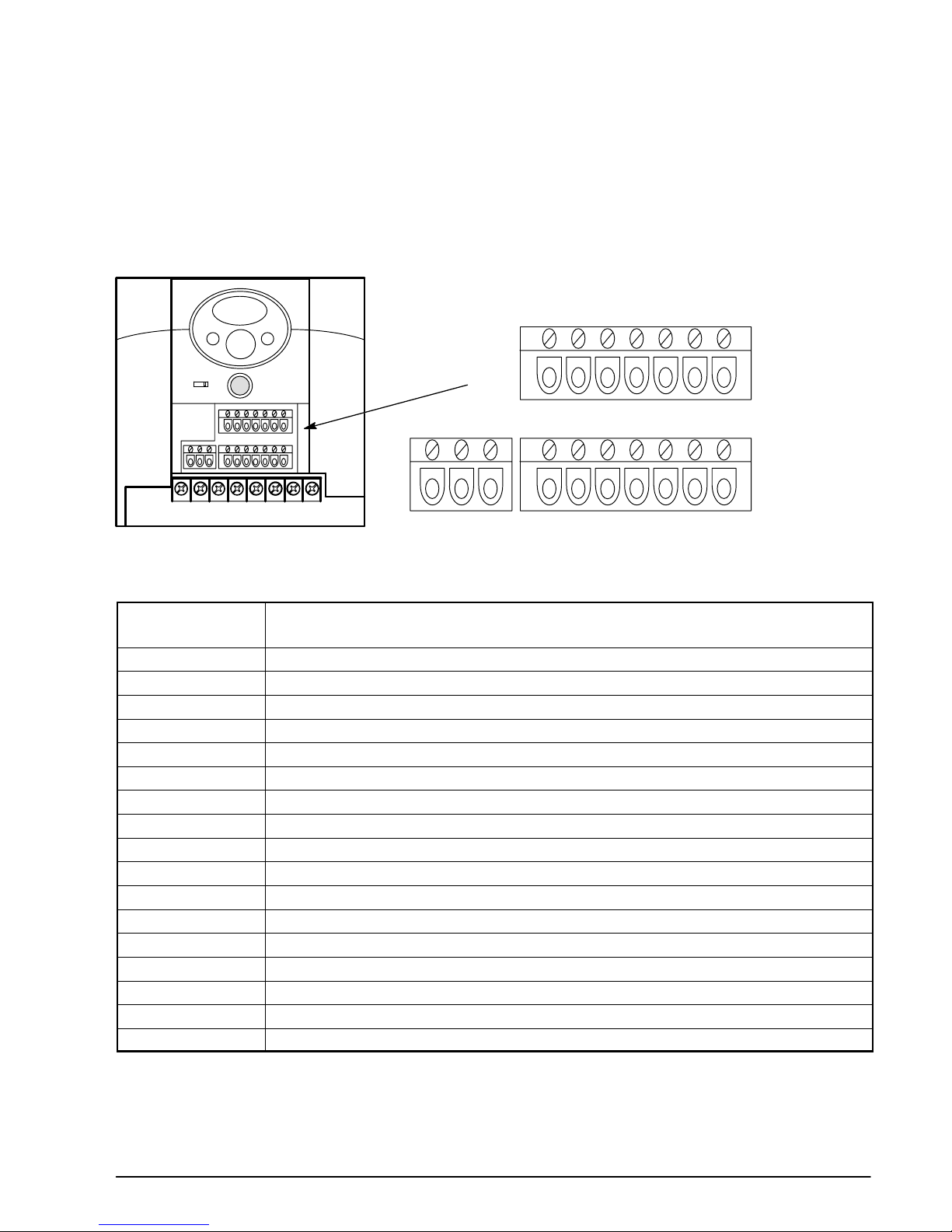

Analog and digital inputs and output terminals are shown in Figure 5‐1 and described in Table 5‐1.

Figure 5‐1 Control Wiring Terminal Identification

Control I/O Terminal Strip

P4 P5 VR V1 CM

I

AM

30A 30B 30C MO EXTGP24 P1 P2 CM P3

Tightening Torque =

3.5 lb-in (0.4Nm)

See Table 4‐1 for

Tightening Torques

NPN

PNP

Table 5‐1 I/O Connection Description

Connector

Terminal

Signal Description

P1 Forward Run

P2 Reverse Run

P3 Output Inhibit

P4 Fault Reset

P5 Jog Operation

P24 Internal 24VDC power (powers P1-P5 inputs)

VR 12V power supply for speed reference potentiometer

V1 0-10VDC Analog Input Terminal

I

0-20mA Analog Input Terminal

CM Internal 24V common (return for P1-P5 and AM inputs)

AM 0-10VDC Analog Output Terminal

CM Common for Analog Output

MO Digital Output (Open Collector)

EXTG Digital Common for MO

30A Relay Output - A Contact

30B Relay Output - B Contact

30C Common - 30A, 30B Contacts

5-2 Control Wiring MN761

5.2 Control Input Connections

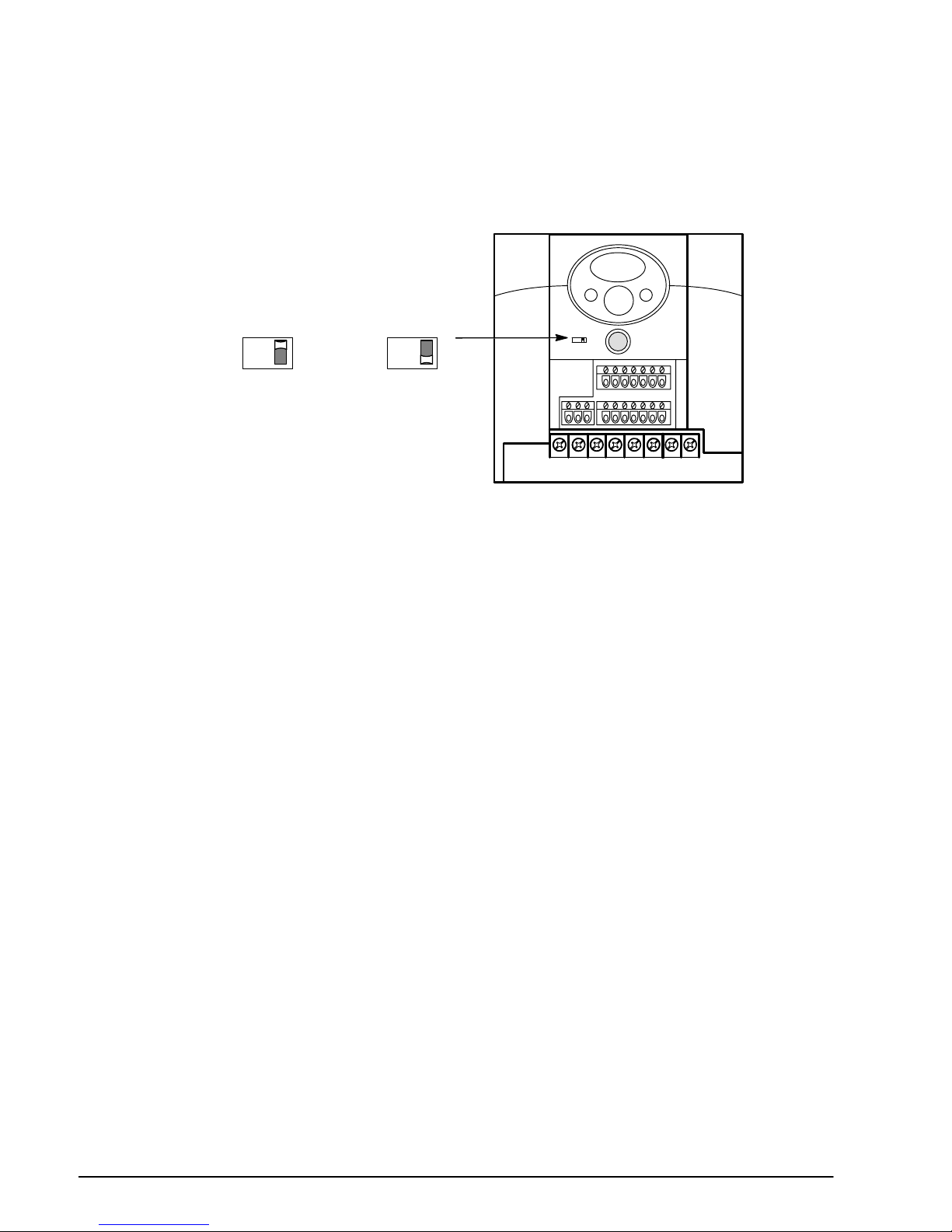

Determine if you will use NPN (factory setting) or PNP connections. NPN/PNP settings are shown in

Figure 5‐2. For NPN, CM (Common or ground) is used to switch the input signals. For PNP, P24

(+24VDC output) is used to switch the input signals.

Figure 5‐2 NPN/PNP Mode

Set the NPN/PNP switch for desired mode.

NPN Mode

PNP Mode

OR

See Table 4‐1 for Tightening

Torques

NPN

PNP

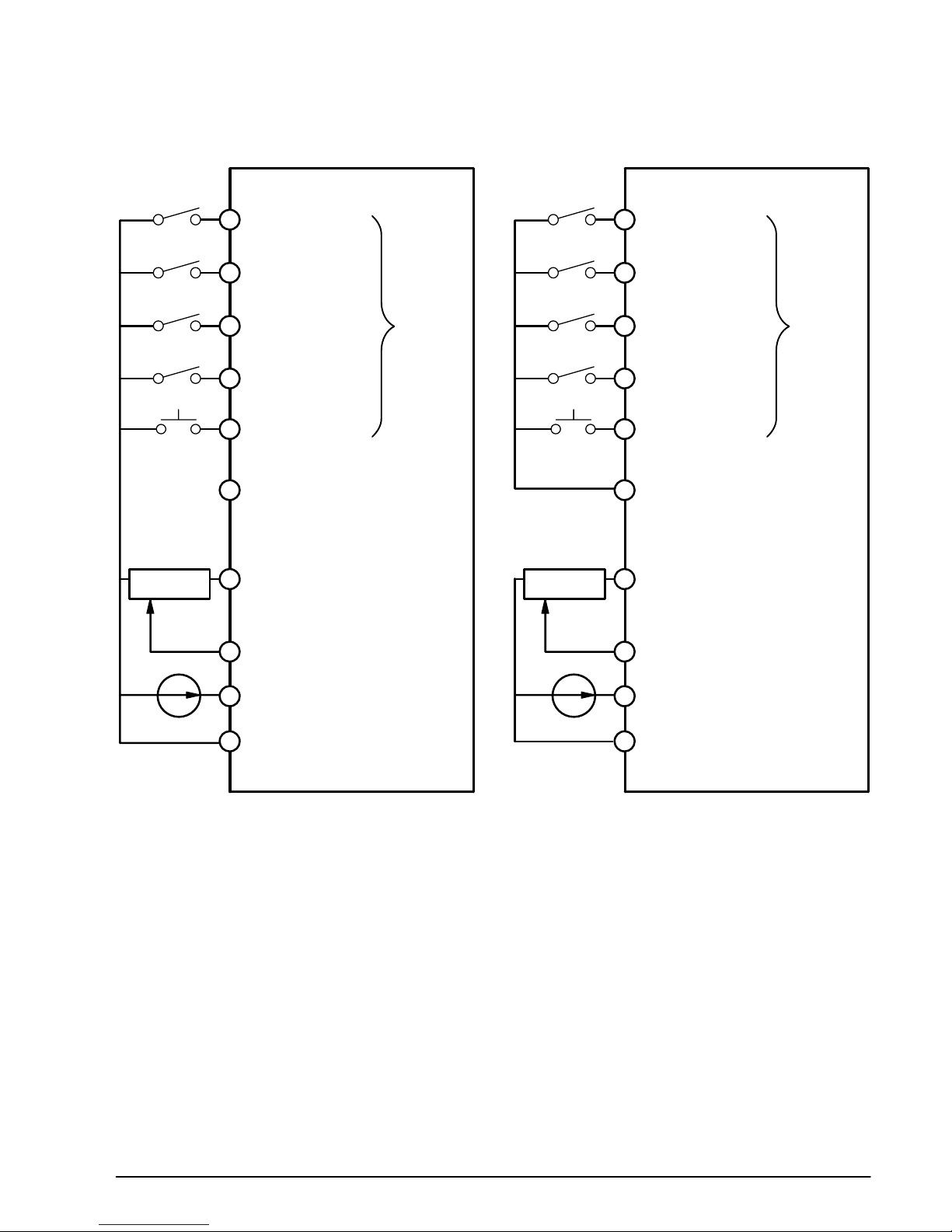

Input connections are shown in Figure 5‐3

1. For NPN Connections Connect the Digital Inputs to one pole of a switch and the other switch pole

to CM. An active low at P1 - P5 will activate the inputs.

For PNP Connections1 Connect the Digital Inputs to one pole of a switch and the other switch

pole to P24. An active High at P1 - P5 will activate the inputs.

2. The speed Command input can be wither a Voltage (0-10VDC) or a Current (0-20mA) input.

For Voltage input, either an external potentiometer or an external voltage reference can be used.

a. For an External reference voltage input, connect the 0-10VDC input to the VI terminal.

Connect the reference from the external source to the CM terminal.

b. For an external potentiometer, connect the pot as shown, one end to VR terminal, the wiper to

VI terminal and the other end to CM terminal.

For Current input, connect the 0-20mA source to the I terminal, the reference to CM terminal.

MN761 Control Wiring 5-3

Figure 5‐3 Input Connections

Forward Run

Speed signal input

(0-10VDC )

Speed signal input (0-20mA)

P1

P2

P3

P4

P5

P24

VR

VI

I

CM

Reverse Run

Output Inhibit

Jog Operation

Fault Reset

Internal 10VDC

Power for Potentiometer

PNP 24VDC Output

Common

Shown with NPN Digital Input Connections

VS1SM

Tightening Torque = 3.5 lb-in (0.4Nm)

Digital

Inputs

Forward Run

Speed signal input

(0-10VDC )

Speed signal input (0-20mA)

P1

P2

P3

P4

P5

P24

VR

VI

I

CM

Reverse Run

Output Inhibit

Jog Operation

Fault Reset

Internal 10VDC

Power for Potentiometer

PNP 24VDC Output

Common

Shown with PNP Digital Input Connections

VS1SM

Digital

Inputs

5-4 Control Wiring MN761

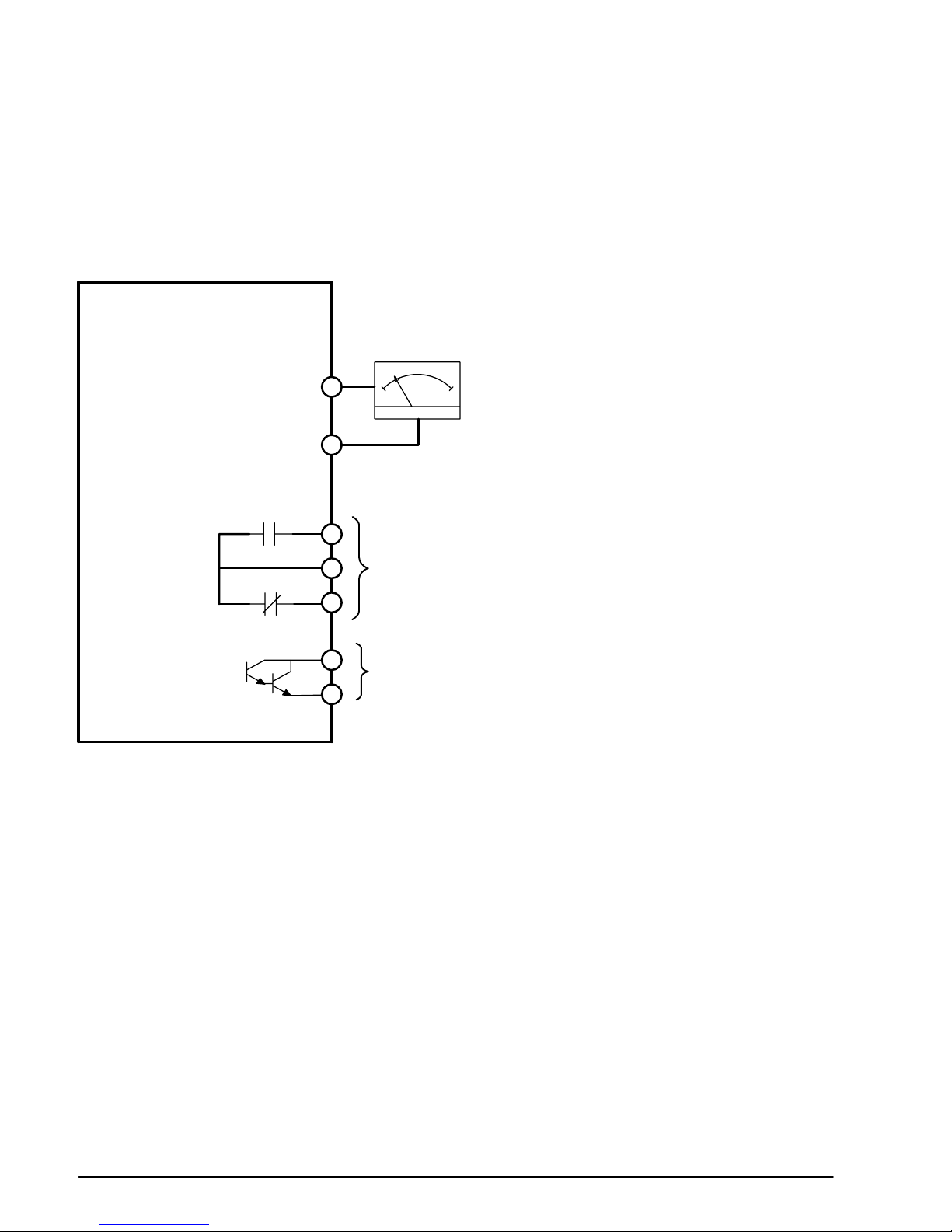

5.3 Control Output Connections

The Analog and Digital outputs are shown in Figure 5‐4.

1. Connect an external analog output device to AM terminal and it's reference to CM.

2. The normally Open and Closed relay outputs can be connected to an external device, terminal 30B

is the common terminal.

3. A multi-function open collector output can drive a digital load, connect to MO and EXTG.

Figure 5‐4 Output Connections

AM

CM

30A

30B

30C

MO

EXTG

VS1SM

Tightening Torque = 3.5 lb-in (0.4Nm)

Relay Output

Digital Output

Analog Output

(0-10VDC)

MN761 Using the Keypad 6-1

Chapter 6

Using the Keypad

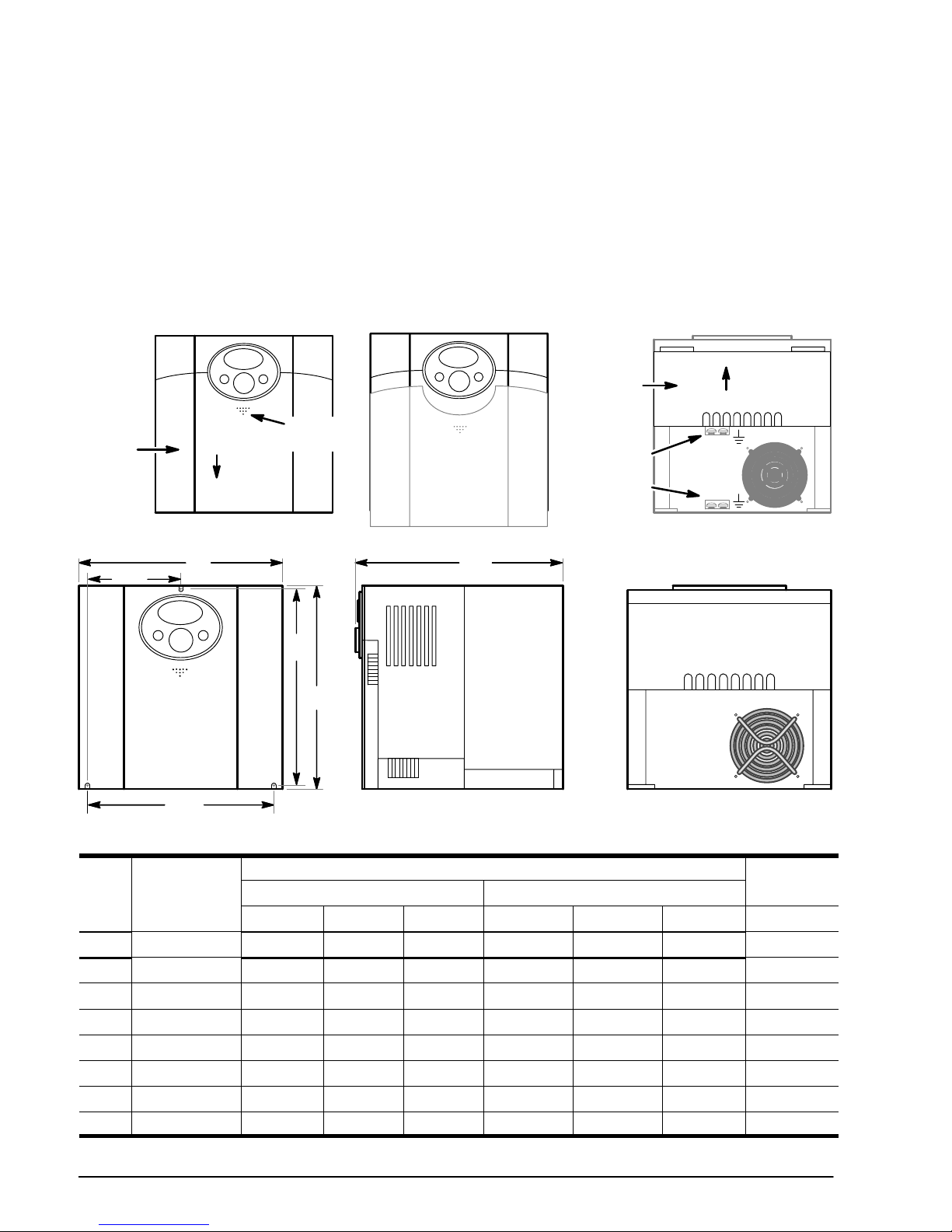

6.1 Keypad Overview

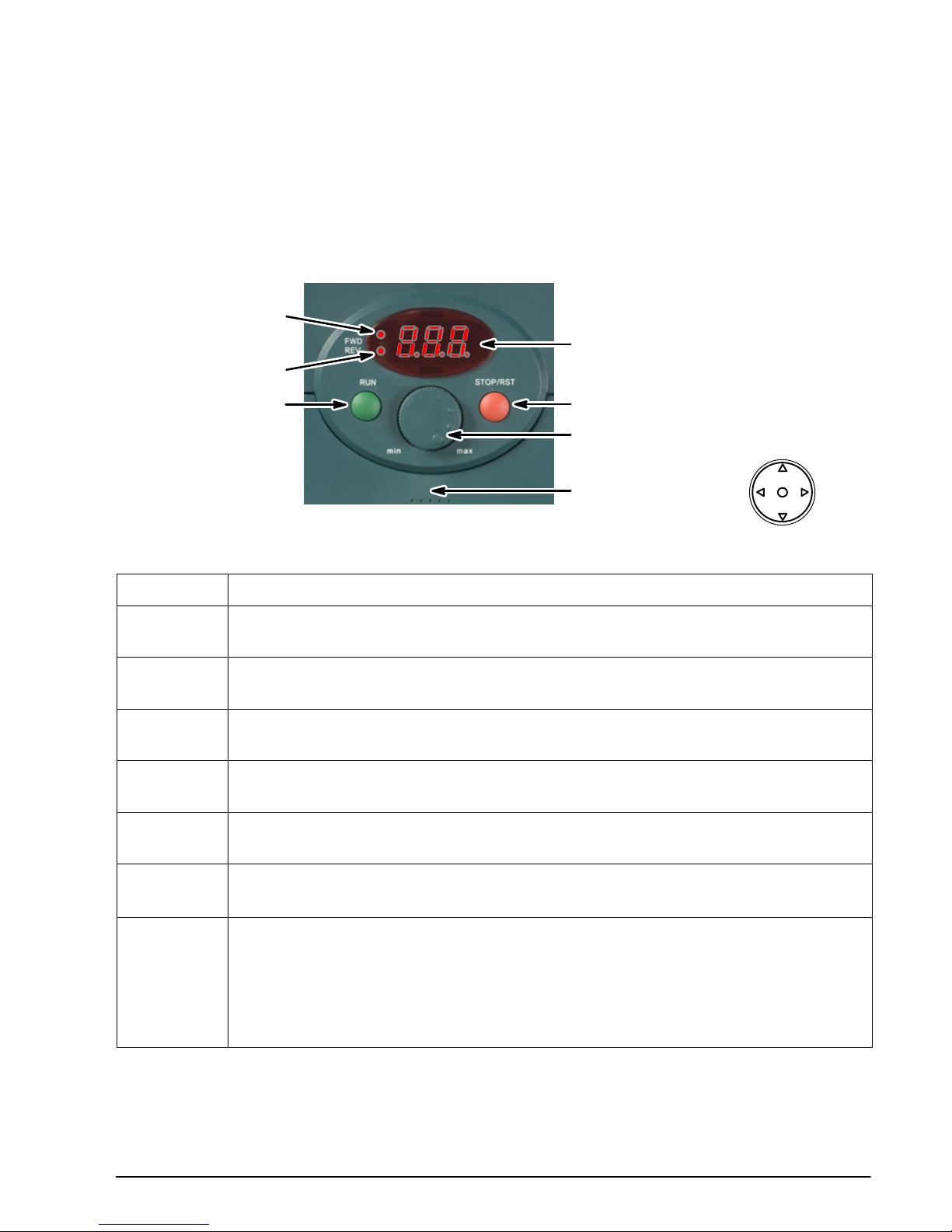

Operator controls are shown in Figure 6‐1 and described in Table 6‐1.

The 5 Way Button that is used for parameter setting is only accessible when the cover is removed.

Figure 6‐1 Operator Controls

Display

Stop/Reset Switch

Speed Adjustment

Potentiometer

Run Switch

FWD Run LED

REV Run LED

5 Way Button

(Must remove cover to access)

Table 6‐1 Key Descriptions

Item

Description

FWD FWD Run LED:

On during Forward Run.

REV REV Run LED:

On during Reverse Run.

DISPLAY 7 Segment LED Display:

Displays operation status and parameter information.

RUN Run Switch:

Press to issue a run command.

STOP/RST Stop / Reset Switch:

STOP: Stop the operation RST: Reset faults

POTENTIO-

METER

Speed Adjustment Potentiometer:

Adjusts the value of run frequency.

5 WAY

BUTTON

5 Way Button: (Not visible with cover on.)

Y Navigate parameter lists or increase parameter value.

B Navigate parameter lists or decrease parameter value.

" Navigate parameter groups or move cursor to the right to change the parameter value.

A Navigate parameter groups or move a cursor to the left to change the parameter value.

F Set the parameter value or save the changed parameter value (Enter).

6-2 Using the Keypad MN761

Figure 6‐2 Alpha-numeric LED Characters

1B L V

0A K U

2C M W

3D N X

4E O Y

5F P Z

7H R

8I S

9J T

6G Q

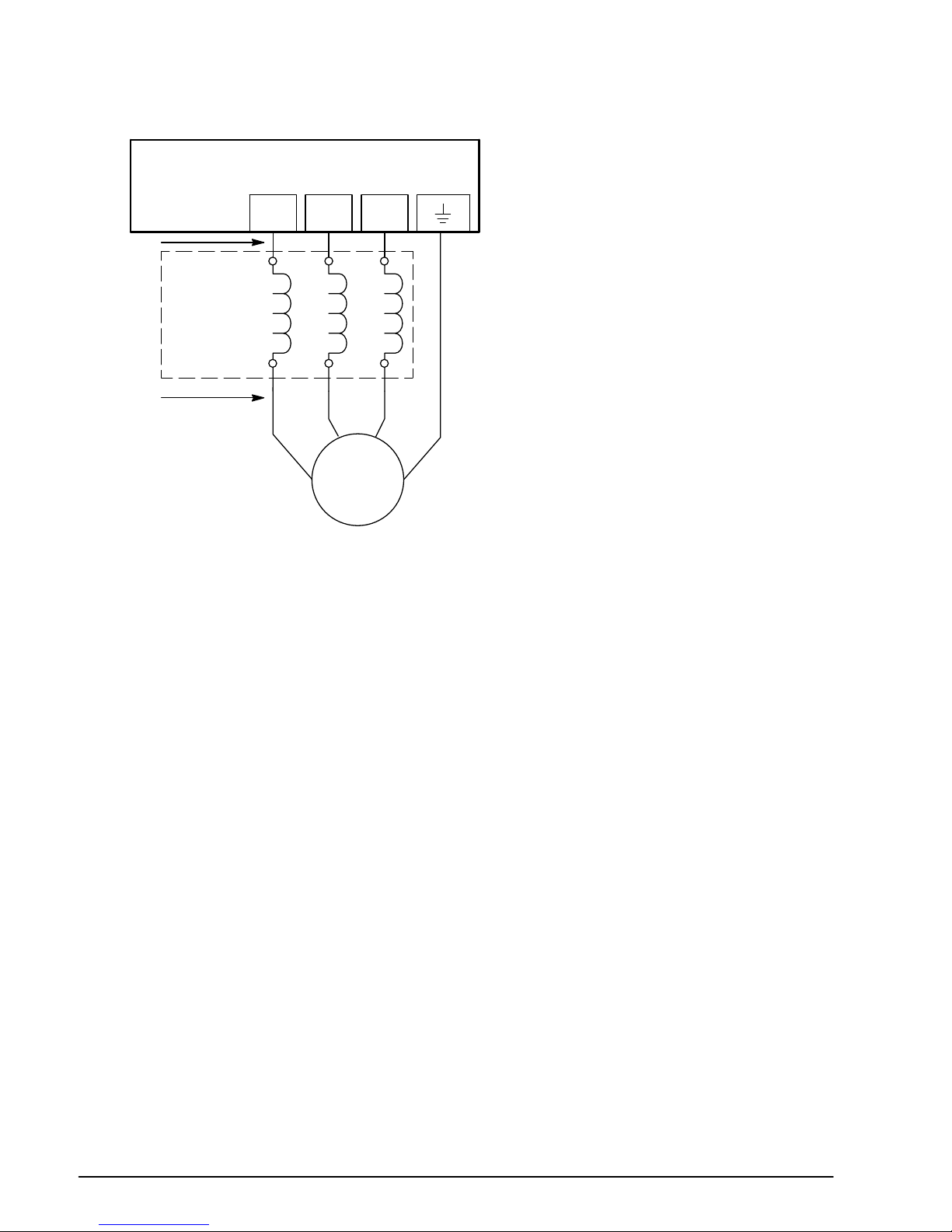

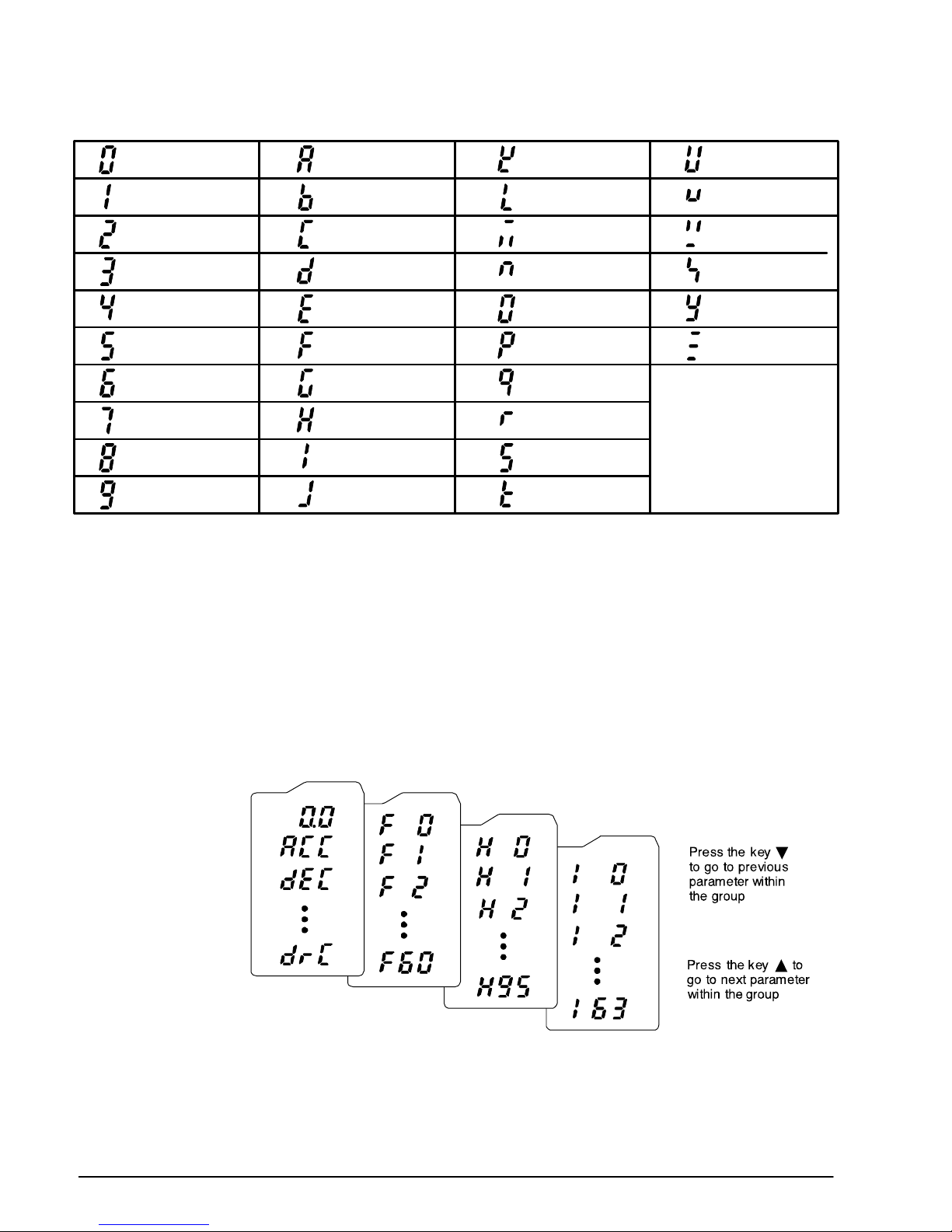

6.2 Parameter Groups

To access the parameter groups the cover must be removed to allow access to the 5 Way Button.

The 5 Way Button is used to navigate the parameters and examine or change values.

There are 4 parameter groups in VS1SM shown in Figure 6‐3.

Drive Group Basic start up parameters necessary to run the drive.

Function Group1 Basic function parameters to adjust output speed/voltage, minimum/maximum

speeds and braking.

Function Group2 Advanced function parameters.

I/O Group Parameters to configure the digital and analog I/O and to set preset speeds.

Figure 6‐3

I/O group

Fun ction

group 1

Drive group

Function

group 2

Press the " key to navigate to the next group. Press the A key to navigate to the previous group.

Loading...

Loading...