Page 1

VS1MD User Manual

6/07

Instruction Manual

MN760-3

Page 2

The information in this manual is subject to change without notice.

Safety Notice

This equipment contains voltages that may be as high as 1000 volts! Electrical shock can cause serious or

fatal injury. Only qualified personnel should attempt the start-up procedure or troubleshoot this equipment.

This equipment may be connected to other machines that have rotating parts or parts that are driven by this

equipment. Improper use can cause serious or fatal injury. Only qualified personnel should attempt the startup procedure or troubleshoot this equipment.

Precautions: Classifications of cautionary statements

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in injury

!

or death.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, could result in

!

damage to property.

Precautions

WARNING: Do not touch any circuit board, power device or electrical connection before you

!

first ensure that power has been disconnected and there is no high voltage present from this

equipment or other equipment to which it is connected. Electrical shock can cause serious or fatal

injury. Only qualified personnel should attempt the start-up procedure or troubleshoot this

equipment.

WARNING: Do not touch any circuit board, power device or electrical connection before you

!

first ensure that power has been disconnected and there is no high voltage present from this

equipment or other equipment to which it is connected. Electrical shock can cause serious or fatal

injury. Only qualified personnel should attempt the start-up procedure or troubleshoot this

equipment.

WARNING: Be sure that you are completely familiar with the safe operation of this equipment.

!

This equipment may be connected to other machines that have rotating parts or parts that are

controlled by this equipment. Improper use can cause serious or fatal injury. Only qualified

personnel should attempt the start-up procedure or troubleshoot this equipment.

WARNING: Do not use motor overload relays with an automatic reset feature. These are

!

dangerous since the process may injure someone if a sudden or unexpected automatic restart

occurs. If manual reset relays are not available, disable the automatic restart f eature using external

control wiring.

WARNING: Do not use motor overload relays with an automatic reset feature. These are

!

dangerous since the process may injure someone if a sudden or unexpected automatic restart

occurs. If manual reset relays are not available, disable the automatic restart f eature using external

control wiring.

WARNING: This unit has an automatic restart feature that will start the motor whenever input

!

power is applied and a RUN (FWD or REV) command is issued. If an automatic restart of the

motor could cause injury to personnel, the automatic restart feature of the VS1MSD should be

disabled.

WARNING: Be sure the system is properly grounded before applying power. Do not apply AC

!

power before you ensure that all grounding instructions have been followed. Electrical shock can

cause serious or fatal injury.

Page 3

WARNING: Do not remove cover for at least five (5) minutes after AC power is disconnected

!

to allow capacitors to discharge. Dangerous voltages are present inside the equipment. Electrical

shock can cause serious or fatal injury.

WARNING: Improper operation of control may cause violent motion of the motor shaft and driven

!

equipment. Be certain that unexpected motor shaft movement will not cause injury to personnel

or damage to equipment. Certain failure modes of the control can produce peak torque of several

times the rated motor torque.

WARNING: Motor circuit may have high voltage present whenever AC power is applied, even

!

when motor is not rotating. Electrical shock can cause serious or fatal injury.

WARNING: Dynamic brake resistors may generate enough heat to ignite combustible materials.

!

Keep all combustible materials and flammable vapors away from brake resistors.

WARNING: The motor shaft will rotate during the touting procedure. Be certain that unexpected

!

motor shaft movement will not cause injury to personnel or damage to equipment.

CAUTION: Disconnect motor leads (U, V & W) from control before you perform a “Megger” test

!

on the motor. Failure to disconnect motor from the control will result in extensive damage to the

control. The control is tested at the factory for high voltage / leakage resistance as part of

Underwriter Laboratory requirements.

CAUTION: Suitable for use on a circuit capable of delivering not more than the RMS

!

symmetrical short circuit amperes listed here at rated voltage.

Horsepower RMS Symmetrical Ampheres

1-30 5,000

CAUTION: Do not connect AC power to the Motor terminals U, V and W. Connecting AC power

!

to these terminals may result in damage to the control.

CAUTION: Baldor recommends not to use "Grounded Leg Delta" transformer power leads that

!

may create ground loops. Instead, we recommend using a four wire Wye.

CAUTION: Only Baldor cables should be used to connect the keypad and control. These are

!

special cables to protect the control and keypad. Damage associated with other cable types are

not covered by the Baldor warranty.

CAUTION: If an M-Contactor is installed, the control must be disabled for at least 200msec

!

before the M-Contactor is opened. If the M-Contactor is opened while the control is supplying

voltage and current to the motor, the control may be damaged. Before the control is enabled, the

M-Contactor must be closed for at least 200msec.

CAUTION: Use of power correction capacitors on the output of the drive can result in erratic

!

operation of the motor, nuisance tripping, and/or permanent damage to the drive. Remove power

correction capacitors before proceeding. Failure to observe this precaution could result in damage

to, or destruction of, the equipment.

-3

Page 4

-4 VS1MD AC Drive User Manual

Page 5

VS1MD ERRATA SHEET

1.1 Change from Main Source to 2nd Source

The function of parameters P46 and P47 has been changed. A digital input can now

select between the main control and speed setting selected in parameters P38 and

P40 and the secondary source set in parameters P46 and P47. A digital input

programmed in t1 to t8 must be set to “22” Exchange between second source and

drive.

1.2 Parameters

P46 Drive Start/Stop Source 2

Range: 0 to 3 (see table for P38)

Default: 0 = Keypad

Access: Configurable

See Also: P38, P47, t1 to t8

This parameter serves as an alternate control mode. It is selectable by

a digital input (t1 to t8) = “22” Exchange between second source and

drive.

P47 Frequency Setting Mode 2

Range: 1 to 7 (See table for P40)

Default: 1 = Keypad

Access: Configurable

See Also: P40, P47, t1 to t8

This parameter serves as an alternate speed reference mode. It is

selectable by a digital input (t1 to t8) = “22” Exchange between second

source and drive.

NOTE: Parameters P46 and P47 are only viewable when one of the t1 to t8

terminals is set equal to “22”.

t1-t8 Digital Input 1 define (I/O Terminal P1) to Digital Input 8 define (I/O

Terminal P8)

Range: 0 to 25

Default: t1 = 0, t2 = 1, t3 = 2, t4 = 3, t5 = 4, t6 = 5, t7 = 6, t8 = 7

Access: Configurable

See Also: n/a

Errata Sheet for the VS1MD Drive Installation & Operating Manual

Page 6

22 = Exchange between second source and drive: When the defined

input is turned ON, the values set in drv2 and Frq2 are used for control

and reference to the drive. Settings for drv2 and Frq2 can not be

changed while the digital input is closed. During the change over from

the Main Source to the 2nd source, the drive will stop if the control

source differs. To restart the drive, a new run command must be given.

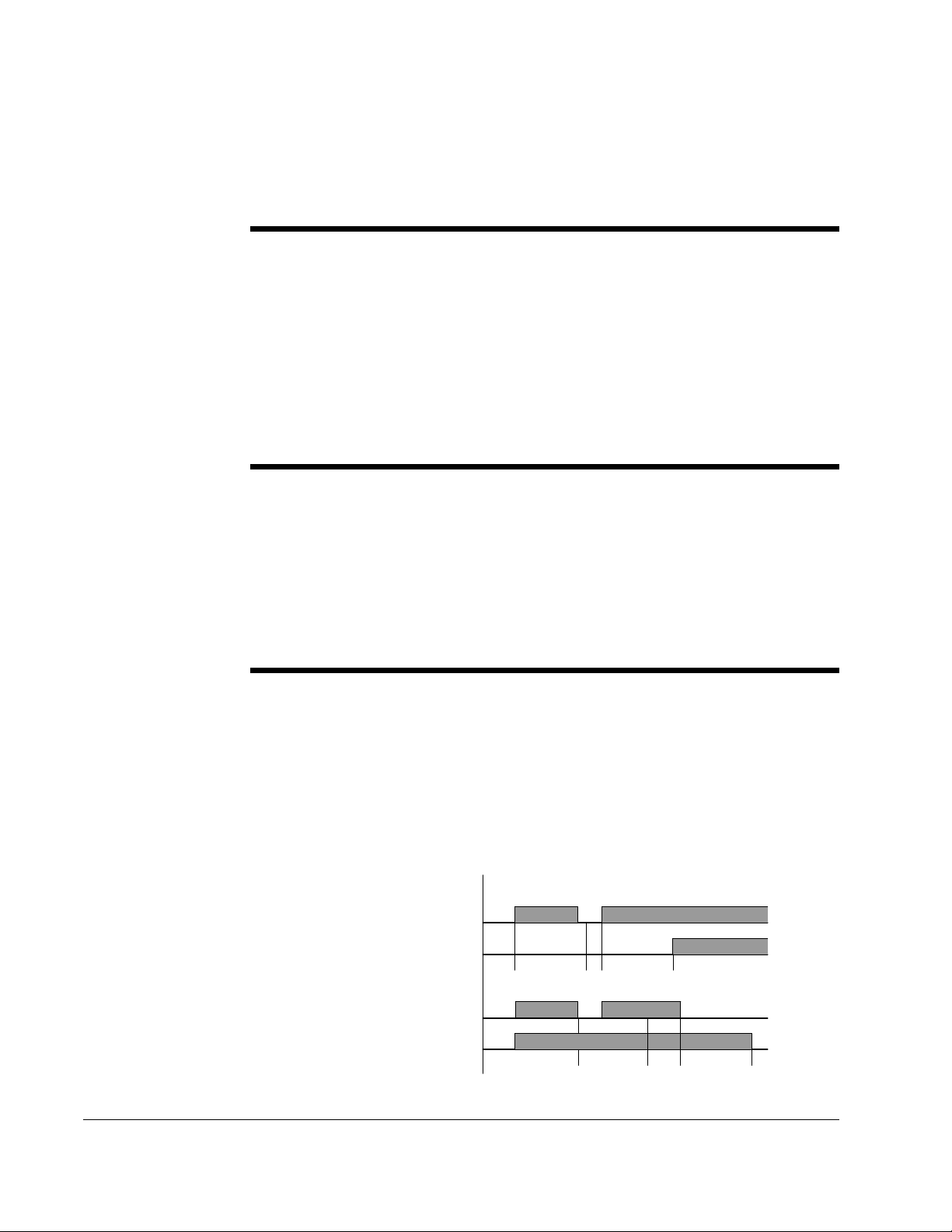

Digital/Relay Output On/Off Delay

A timer function has been implemented by adding four new software parameters.

Two are for the On Delay and two for the Off Delay timer to the digital outputs of the

VS1MD drive. Setting a value of greater than zero will begin the On, Off or both

timers when the condition set in t32 and t33 for the digital outputs is met.

In the case of the On delay timer, the actual output will not change state until the

time value set in t50 to t51 is met. The Condition set in t32 to t33 must be active

when the timer is reached for the output state to change.

In the case of the Off delay timer, once the output state is on, it will delay turning of f

after the Off delay value is reached on t52 to t53. When the Off delay time is

reached, the condition set in t32 to t33 must still be off.

t50

t51

t52

t53

Digital Output (MO) On Delay

Relay Output (3A - 3C) On Delay

Range: 0 to 3,600 Seconds

Default: 0

Access: Configurable

See Also: t32 and t33

Sets the on delay timer for the digital output.

Digital Output (MO) Off Delay

Relay Output (3A - 3C) Off Delay

Range: 0 to 3,600 Seconds

Default: 0

Access: Configurable

See Also: t32 and t33

Sets the off delay timer for the digital output.

MO or Relay State

Output

On De la y Tme On De la y Time

MO or Relay St ate

Output

Off Delay Time

Errata Sheet for the VS1MD Drive Installation & Operating Manual

Off Delay Time

Page 7

Chapter 1 Introduction

1.1 Getting Assistance from Baldor.......................................................................1-1

Chapter 2 Gene ral Information a n d Ratin gs

2.1 Identifying the Drive by Model Number ...........................................................2-1

2.2 VS1-MD Drive Ratings, Model Numbers a nd Frame Sizes.............................2-2

2.3 Storage Guid e li n e s............................................................................ ..............2-2

Chapter 3 Installing the Drive

3.1 General Requirements for the Installation Site................................................3-1

3.2 Mounting the Drive ..........................................................................................3-5

3.3 Watts Loss Data..............................................................................................3-6

Chapter 4 Power Wirin g

4.1 Grounding the Drive ........................................................................................4-1

4.2 Connecting Peripheral Devices to the VS1-MD Drive .....................................4-3

4.3 Power Termina l Wir ing........................................................ ............................4

4.4 Specifications for Power Terminal Block Wiring .............................................4-5

4.5 Recomme nded Breake rs.................................................................................4

4.6 Recommended AC Reactors...........................................................................4-6

Chapter 5 Control Wiring

5.1 Stop Circuit Requirements...............................................................................5-1

5.2 Motor Start/Stop Precautions ..........................................................................5-2

5.3 Terminal Wiring (Control I/O)...........................................................................5-3

5.4 Control Terminal Specifications.......................................................................5

5.5 Source/Sync for Input Control Wiring..............................................................5-5

5.6 I/O Wiring Recommendations..........................................................................5-6

5.7 Technical Specifications..................................................................................5-6

Table of Contents

Chapter 6 Using the Keypad

6.1 Keypad Component s.......................................................................................6-1

6.2 LED Descripti o ns.......... ................................................................... ................6-2

6.3 Key Descripti o n s.......................................... ....................................................6-2

6.4 About Parameters...................................................... ..... ....... .. .......... .. ..... .......6-3

6.5 How Parameters are Organized........... ...........................................................6-4

6.6 Moving Betwee n Para me te r Groups ................ ...............................................6-4

6.7 Changing Between Parameters Within a Group..............................................6-6

6.8 Modifying th e Valu e of a Para mete r.................................................. ..............6-8

6.9 Monitoring Display Parameters .....................................................................6-10

6.10 Reviewing the Fault Status in the Display Group..........................................6-11

6.11 Resetting the Parameters to Factory Default................................................6-12

Chapter 7 Parameter Description s

7.1 Overview..........................................................................................................7-1

7.2 Display Group Parameters..............................................................................7-2

7.3 Basic Group Par a mete r s..... ................................................................... .........7-5

7.4 Terminal Par a mter s.......................................................................................7-12

7.5 Function Gro up 1 Parame ters.................................................................... ...7-28

7.6 Function Gro up 2 Paramters.................................................................... .....7-40

Contents I

Page 8

Chapter 8 Customi z in g f or Y our Applicat io n

8.1 Frequency Mode.......... ...................................... ..............................................8-1

8.2 UP-Down..........................................................................................................8

8.3 3-Wire ..............................................................................................................8

8.4 PID Control.....................................................................................................8

8.5 Auto-tuning.....................................................................................................8-

8.6 Sensorless Ve cto r Co nt r o l........................................................... ..................8

8.7 Speed Search ...............................................................................................8

8.8 Self-Diagnostic Function................................................................ .......... ......8-17

8.9 Parameter Read/Write ...................................................................................8

8.10 Parameter Initialization / Lock........................................................................8-19

8.11 Multi-function Output Terminal (MO) and Relay (3AC) ..................................8

8.12 Accel/Dece l setting and V/F Control......... ..................................... ................8-27

8.13 Control Block Diagram...................................................................................8-28

8.14 Frequency and Drive Mode Setting................................................................8-29

Chapter 9 Trouble shooting

9.1 Verifying that DC Bus Capacitors are Discharged Before

Servicing the Drive..........................................................................................9-1

9.2 Determining Drive Status Using the STP/FLT LED..........................................9-2

9.3 Monitoring Drive Sta tu s Usi n g the Displ a y Parameters............................. ......9-2

9.4 Reviewing Fault Status of the Drive.................................................................9-3

9.5 Fault Codes......................................................................................................9-3

9.6 Fault Correction................................................................................................9-6

9.7 Overload Prote c tion .................................... .....................................................9-8

Appendix A Technical Specifications........................................................................................A-1

Appendix B Options & Kits

B.1 Remote Option...... ...................................... ....................................................B-1

B.2 Condui t Kit.......................................................................................................B-4

B.3 Breaking Resistor............................................................................................B-8

Appendix C RS485 Protocol

C.1 In troduction . ....................................................................................................C-1

C.2 Specifications ..................................................................................................C-2

C.3 Installation .......................................................................................................C-3

C.4 Operation ........................................................................................................C-3

C.5 Communication Protocol (MODMUS-RTU).....................................................C-4

C.6 Communication Protocol (LS BUS) .................................................................C-4

C.7 Troubleshooting ..............................................................................................C-7

II VS1MD User Manual

Page 9

This manual is intended for qualified electrical per so nnel fa mi liar wit h insta llin g,

programming, and maintaining AC Drives.

This manual contains information on:

• Installing and wiring the VS1MD drive

• Programming the drive

• Troubleshooting the drive

1.1 Getting Assistance from Baldor

For technical assistance, call 1-864-284-5444. Before calling, please review the

troubleshooting section of this manual and check the Baldor Drives website at

www.reliance.com/vsdrives for additional information. When you call technical

support, you will be asked for the drive model num ber or catalog number and this

instruction manual number.

CHAPTER 1

Introduction

Introduction 1-1

Page 10

1-2 VS1MD AC Drive User Manual

Page 11

CHAPTER 2

General Information and Ratings

The VS1MD is a variable frequency PWM drive capable of operating in open-loop,

volts-per-hertz mode and in a sensorless vector control (SVC) mode.

This chapter contains information about the VS1MD drive, including how to identify

the drive.

2.1 Identifying the Drive by Model Number

Each drive can be identified by its model number, as shown in figure 2.1. The model

number is on the shipping label and the drive nameplate. The model number includes

the drive and any options.

Drive model numbers for the VS1MD drive are provided in table 2.1.

VS1 MD 4 10

HP

0P5 = 0.5HP

1 = 1HP

2 = 2HP

3 = 3HP

5 = 5HP

7 = 7.5 HP

10 = 10HP

Voltage:

2 = 230V

4 = 460V

Family

MD = Microdrive

Figure 2.1 – Identifying the Drive by Model Number

General Information and Ratings 2-1

Page 12

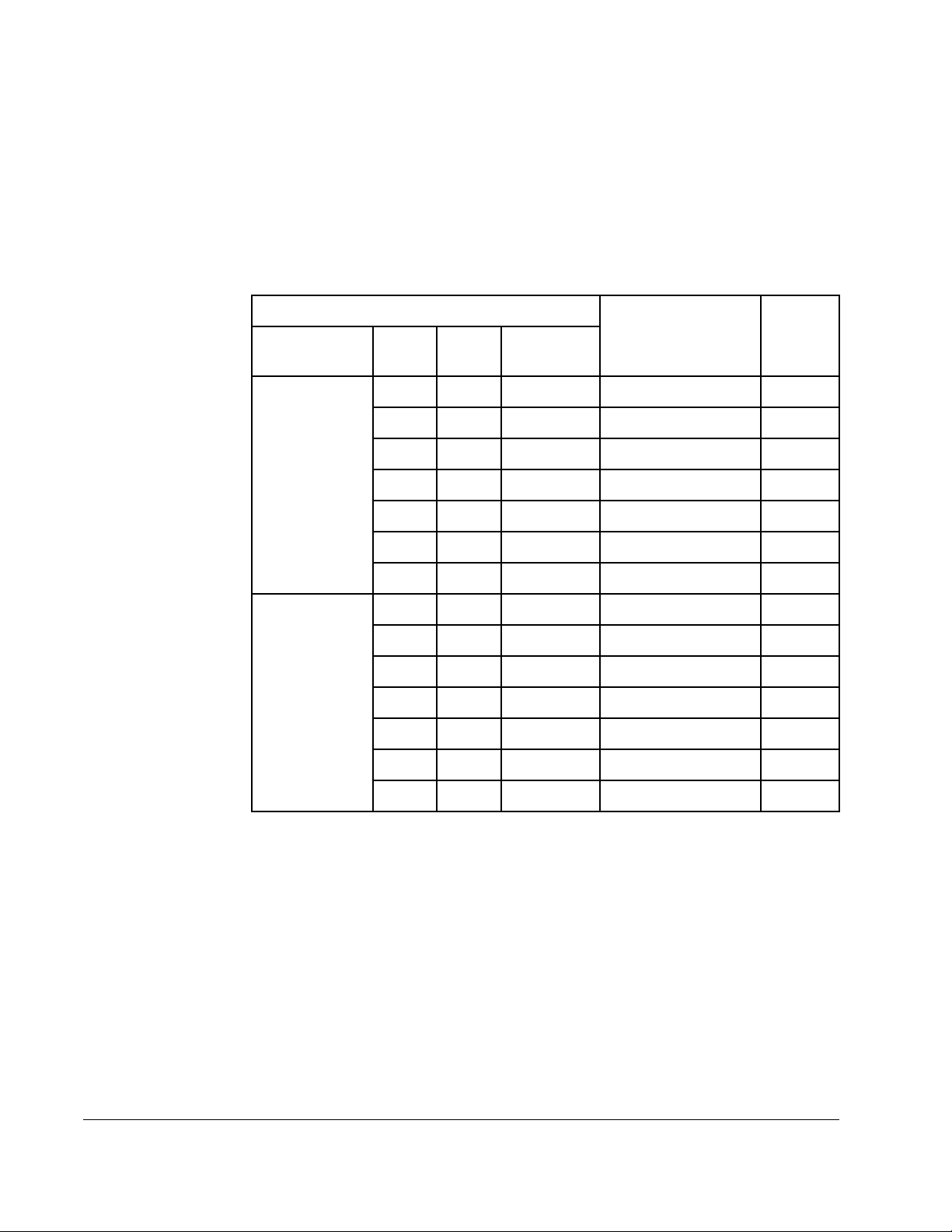

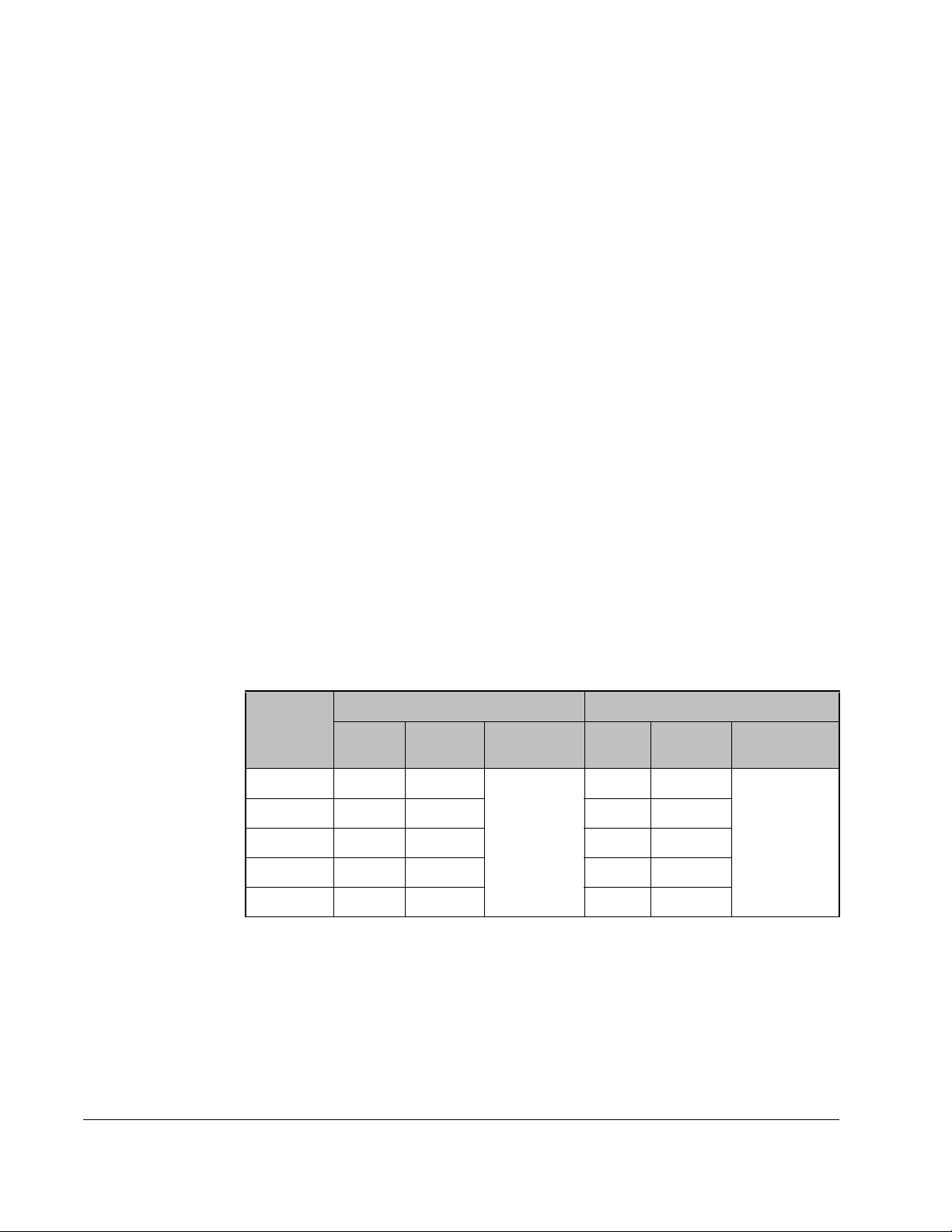

2.2 VS1MD Drive Ratings, Model Numbers and Frame

Sizes

Similar VS1MD drive sizes are grouped into frame sizes to simplify re-ordering and

dimensioning. Refer to figures 3.2 through 3.5 for the dimensions of each frame size.

Table 2.1 provides VS1MD drive ratings, model numbers and frame sizes.

Table 2.1 – Drive Ratings, Model Numbers and Frame Sizes

Drive Ratings Model Number Fram e

Input Voltage kW HP Output

Current

0.4 0.5 2.5 VS1MD20P5 A

0.75 1.0 4.5 VS1MD21 A

200-230V

3-Phase

1.5 2.0 8.0 VS1MD22 B

2.2 3.0 12.0 VS1MD23 C

3.7 5.0 17.0 VS1MD25 C

5.5 7.5 24.0 VS1MD27 D

Size

7.5 10 32.0 VS1MD210 D

0.4 0.5 1.25 VS1MD40P5 A

0.75 1.0 2.5 VS1MD41 A

380-480V

3-Phase

1.5 2.0 4.0 VS1MD42 B

2.2 3.0 6.0 VS1MD43 C

3.7 5.0 8.0 VS1MD45 C

5.5 7.5 12.0 VS1MD47 D

7.5 10.0 16.0 VS1MD410 D

2.3 Storage Guidelines

If you need to store the drive, follow these recommendations to prolong drive life and

performance:

• Store the drive within an ambient temperature range of -40

• Store the drive within a relative humidity range of 0% to 90%, non-condensing.

Do not expose the drive to a corrosive atmosphere.

o

to +70 Co.

2-2 VS1MD AC Drive User Manual

Page 13

CHAPTER 3

Installing the Drive

This chapter provides information that must be considered when planning a VS1MD

drive installation and provides drive mounting information and installation site

requirements.

ATTENTION: Only qualified electical personnel familiar with the

construction and operation of this equipment and the hazards involved

!

should install, adjust, operate, or service this equipment. Read and

understand this manual and other applicable manuals in their entirety

before proceeding. Failure to observe this precaution could result in

severe bodily injury or loss of life.

ATTENTION: Use of power correction capacitors on the output of

the drive can result in erratic operation of the motor, nuisance tripping,

and/or permanent damage to the drive. Remove power correction

capacitors before proceeding. Failure to observe this precaution could

result in damage to, or destruction of, the equipment.

ATTENTION: The user is responsible for conforming with all

applicable local, national, and international codes. Failure to observe

this precaution could result in damage to, or destruction of, the

equipment.

3.1 General Requirements for the Installation Site

It is important to properly plan before installing a VS1MD to ensure that the drive’s

environment and operating conditions are satisfactory.

The area behind the drive must be kept clear of all control and power wiring. Power

connections may create electromagnetic fields that may interfere with control wiring or

components when run in close proximity to the drive.

Read the recommendations in the following sections before continuing with the drive

installation.

Inst alling the Drive 3-1

Page 14

3.1.1 Operating Conditions

Before deciding on an installation site, consider the following guidelines:

• Protect the cooling fan by avoiding dust or metallic particles.

• Do not expose the drive to a corrosive atmosphere.

• Protect the drive from moisture and direct sunlight.

• Verify that the drive location will meet the environmental conditions specified in table

3.1.

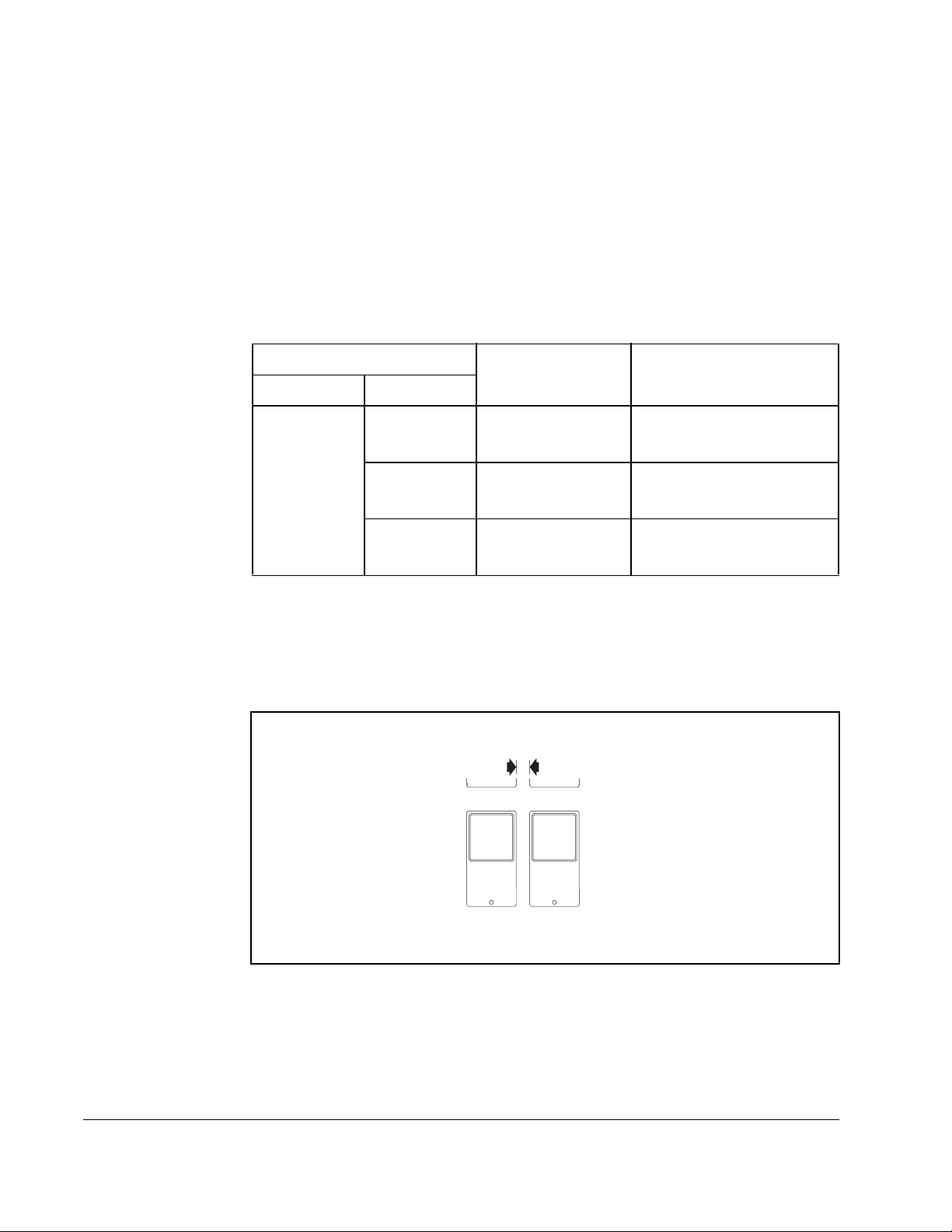

Table 3.1 – Ambient Temperatures and Mounting Clearances

Ambient Temperature Enclosure Rating Minimum Mounting

Minimum Maximum

Clearances

-10

(14

o

C

o

F)

o

50

(122

o

40

(104

o

50

(122

C

o

F)

C

o

F)

C

o

F)

IP20/Open Type 5 cm

IP20/NEMA 1 5 cm

Side-by-Side 5 cm

3.1.2 Minimum Mounting Clearances

Refer to figur e 3.1 f or the mi nimum mou nting cl earances. Refer to sec tion 3 .1 f or dr ive mount ing

dimensions.

5 cm

(1.0 in)

Figure 3.1 – Mini mum Mounting Clea rances

3-2 VS1MD AC Drive User Manual

Page 15

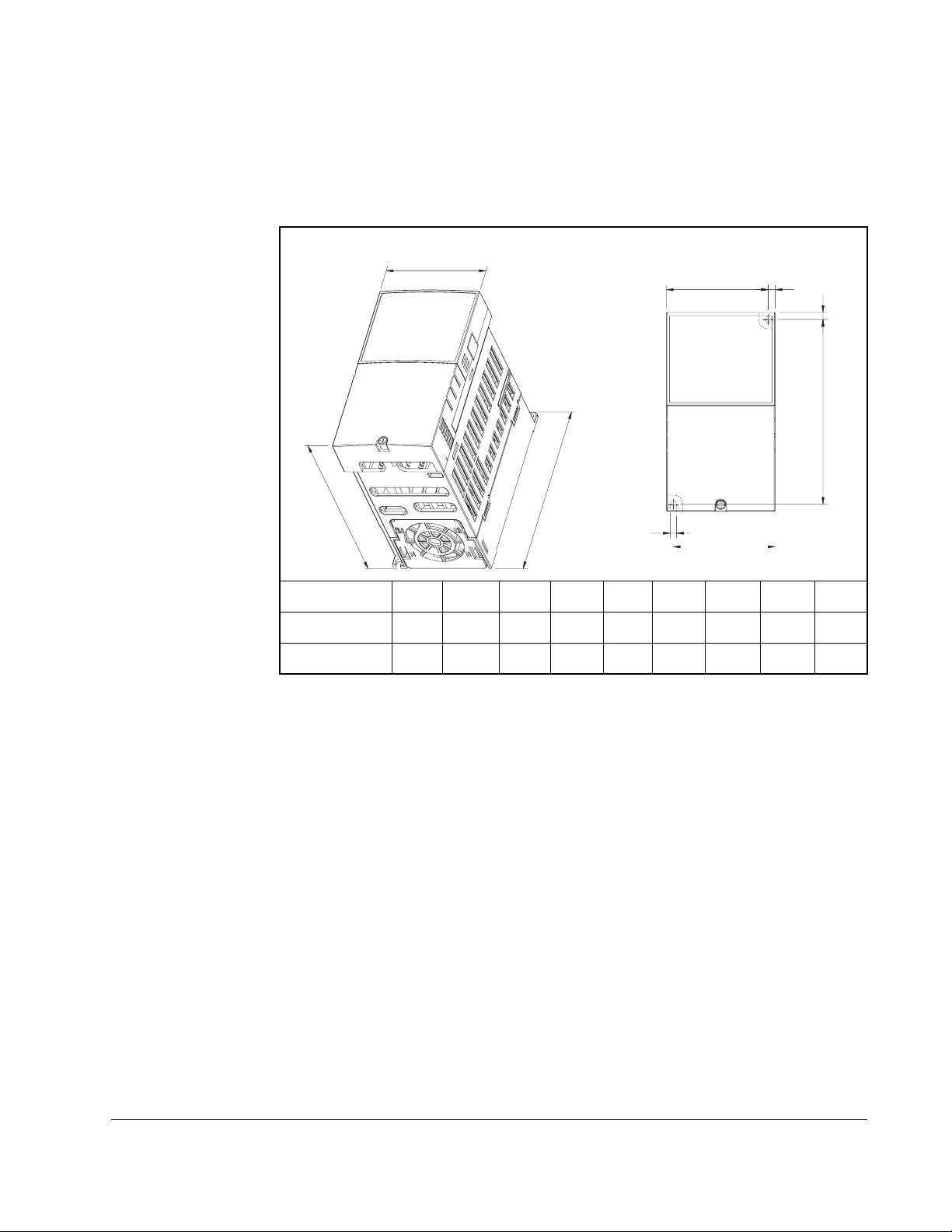

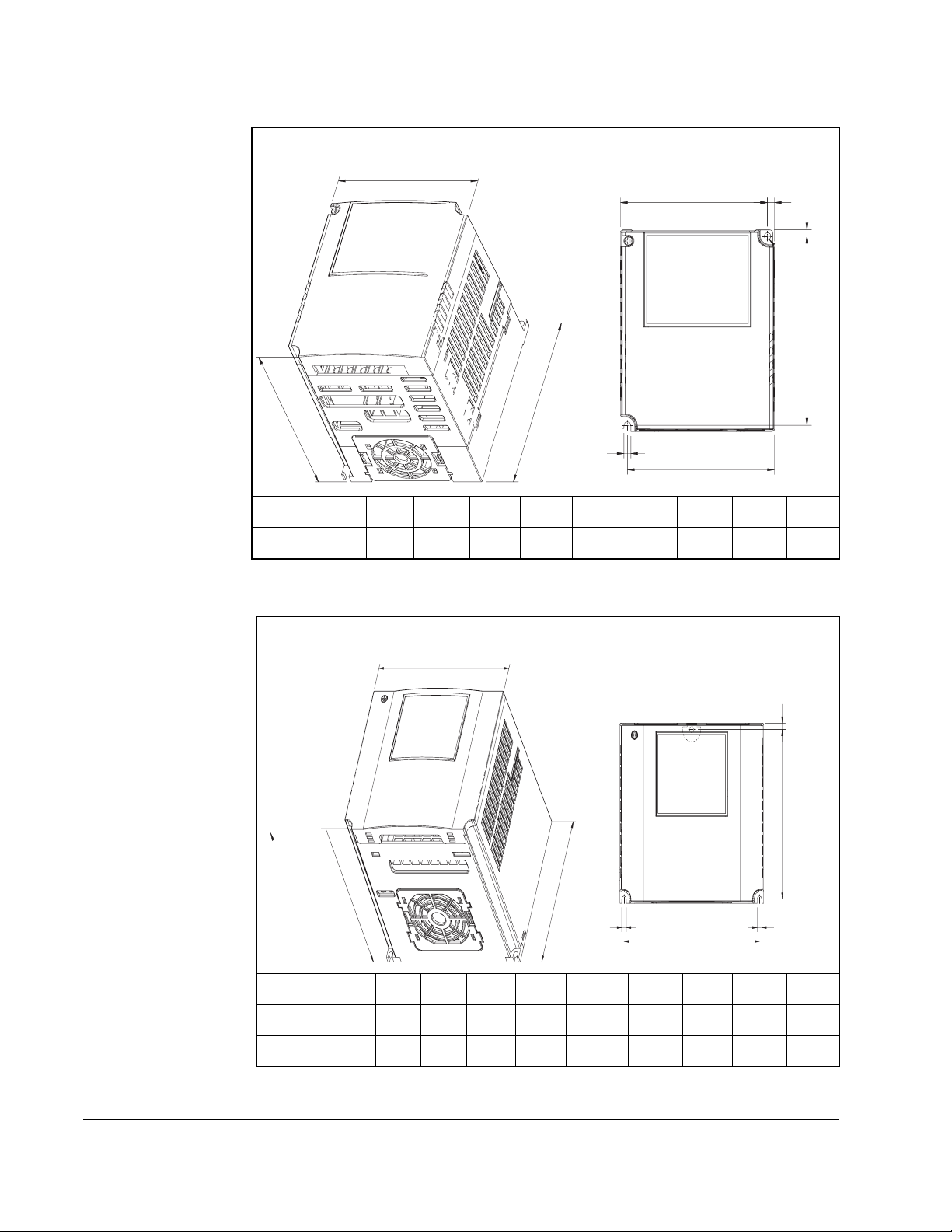

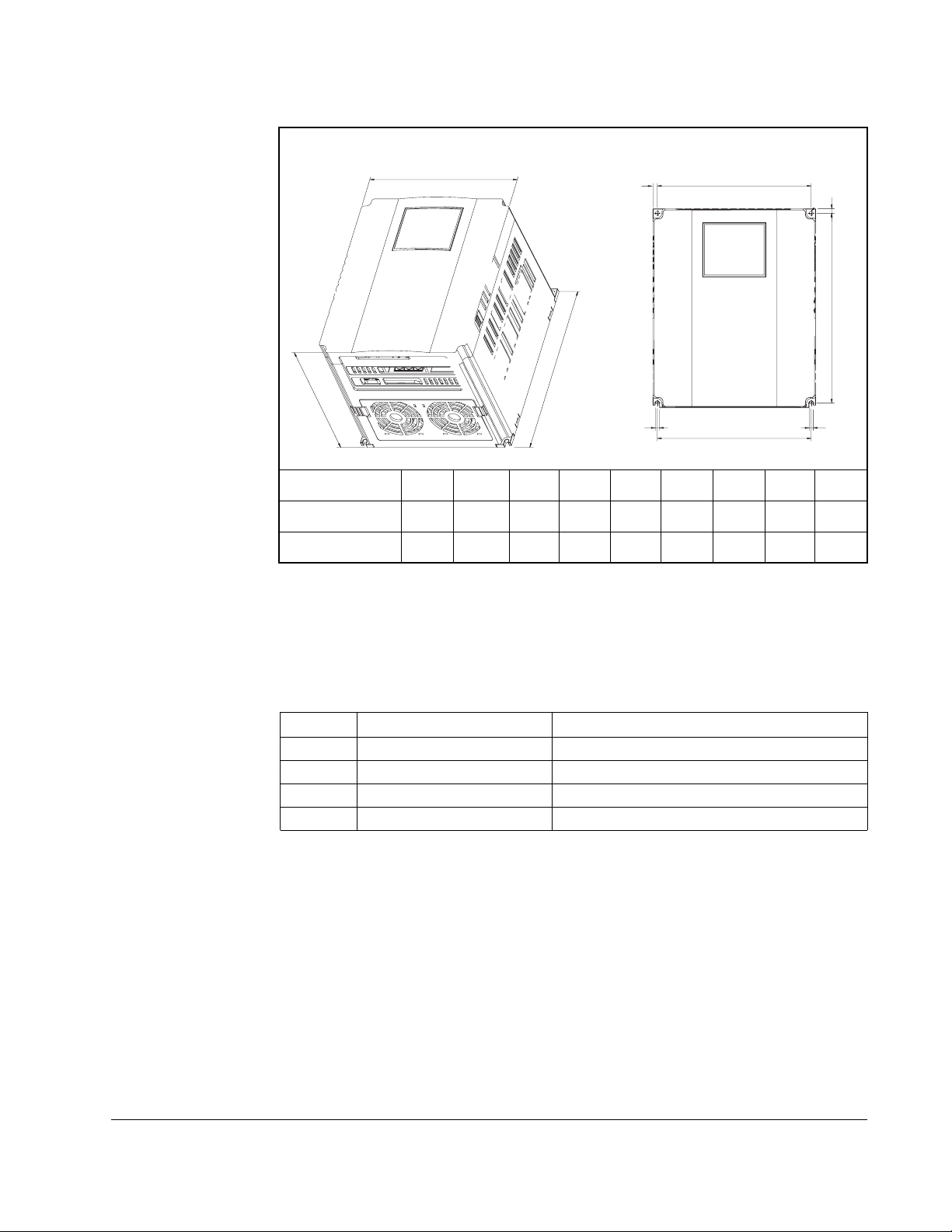

3.1.3 Mounting Dimensions for the VS1MD Drive

Overall dimens ions and weights are illustrated in figures 3.2, 3.3, 3.4 and 3.5 as an aid to

calculating the total area required by the VS1-MD drive. Dimensions are in millimeters. Weights

are in kilograms. See table 2.1 for drive ra tings by frame.

W

H

W1

A

A

H1

D

B

W1

Frame Size A HP W W1 H H1 D A B kg

230V/460V 0.5 70 65.5 128 119 130 4.5 4.0 0.76

230V/460V 1.0 70 65.5 128 119 130 4.5 4.0 0.77

Figure 3.2 – Drive Dimensions and Weights Frame A

Inst alling the Drive 3-3

Page 16

W

W1

A

H1

H

D

B

W1

Frame Size B HP W W1 H H1 D A B kg

230V/460V 2.0 100 95.5 128 120 130 4.5 4.5 1.12

Figure 3.3 – Drive Dimensions and Weights Frame B

A

W

A

H1

D

Frame Size C HP W W1 H H1 D A B kg

230V/460V 3.0 140 132 128 120.5 155 4.5 4.5 1.84

230V/460V 5.0 140 132 128 120.5 155 4.5 4.5 1.89

Figure 3.4 – Drive Dimensions and Weights Frame C

H

B

W1

B

3-4 VS1MD AC Drive User Manual

Page 17

W

A

W

H1

H

D

B

B

W1

Frame Size D HP W W1 H H1 D A B kg

230V/460V 7.5 180 170 220 210 170 5.0 4.5 3.66

230V/460V 10.0 180 170 2 20 210 170 5.0 4.5 3.66

Figure 3.5 – Drive Dimens ions and Weights Frame D

A

3.2 Mounting the Drive

Mount the drive upright on a flat, vertical, and level surface.

Table 3.1 – Mounting Speci fications

Frame Screw Size Screw Torque

A M3.5 (#6-32) 0.67 - 0.97 N-m (6 - 8 in-lb)

B M4 (#8-32) 1.56 - 1.96 N-m (14 -17 in-lb)

C M4 (#8-32) 1.56 - 1.96 N-m (14 -17 in-lb)

D M4 (#8-32) 1.56 - 1.96 N-m (14 -17 in-lb)

3.2.1 Protecting the Drive from Debris

The drive must be protected from debris falling through the vents in the top of the drive

during installation and operation. The drive is designed to operate in IP20/Open Type

application mounted in a protective enclosure. A conduit kit is available as an option

which provides a top panel to block the top vents and prevent debris from entering the

drive.

Inst alling the Drive 3-5

Page 18

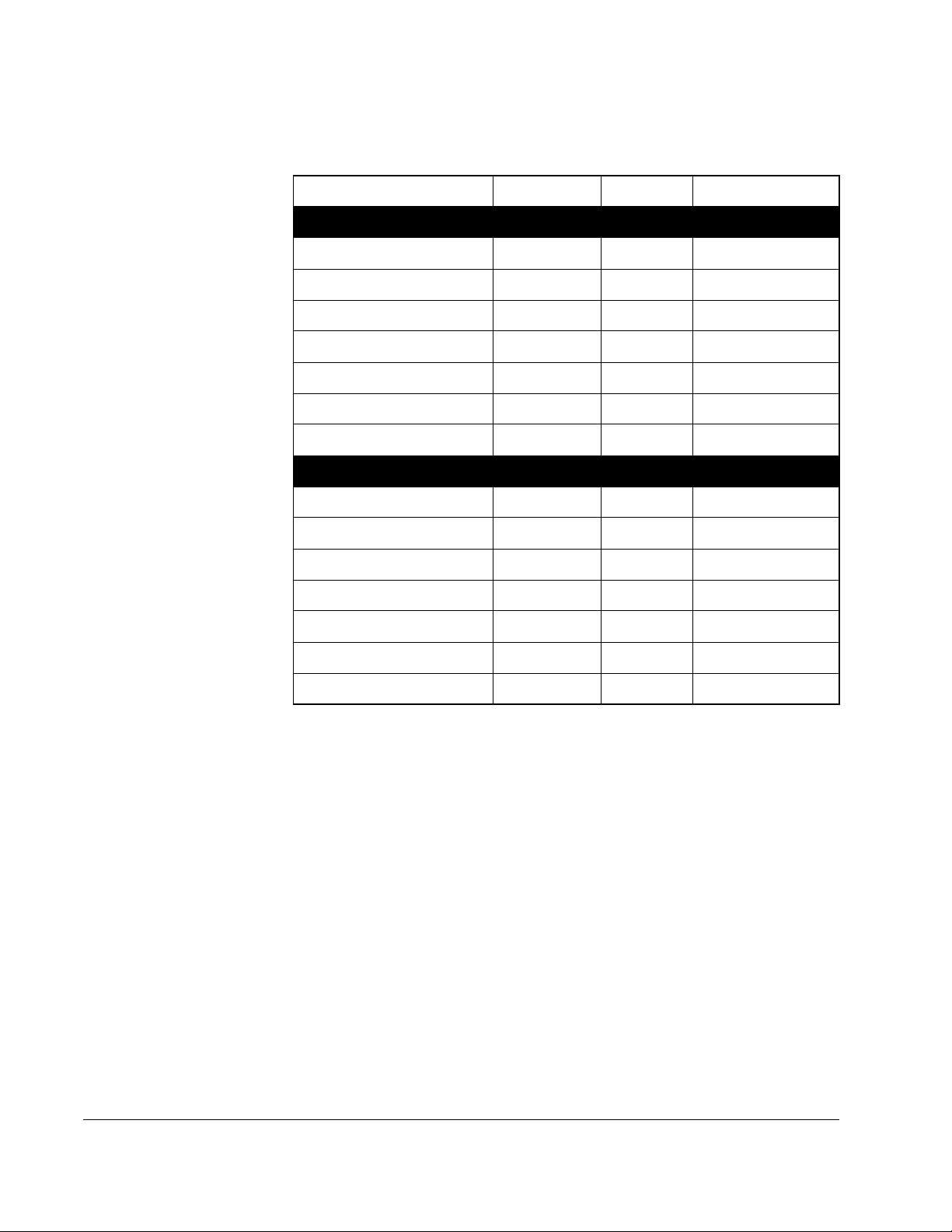

3.3 Watts L oss Data

Model # HP Fr ame Wat ts Loss

VS1MD20P5 0.5 A 13

VS1MD21 1.0 A 28

VS1MD22 2.0 B 18

VS1MD23 3.0 C 56

VS1MD25 5.0 C 98

VS1MD27 7.5 D 73

VS1MD210 10.0 D 70

VS1MD40P5 0.5 A 9

VS1MD41 1.0 A 22

VS1MD42 2.0 B 32

Table 3.2 – Watts Loss Data

230 Volts

460 Volts

VS1MD43 3.0 C 47

VS1MD45 5.0 C 94

VS1MD47 7.5 D 84

VS1MD410 10.0 D 113

3-6 VS1MD AC Drive User Manual

Page 19

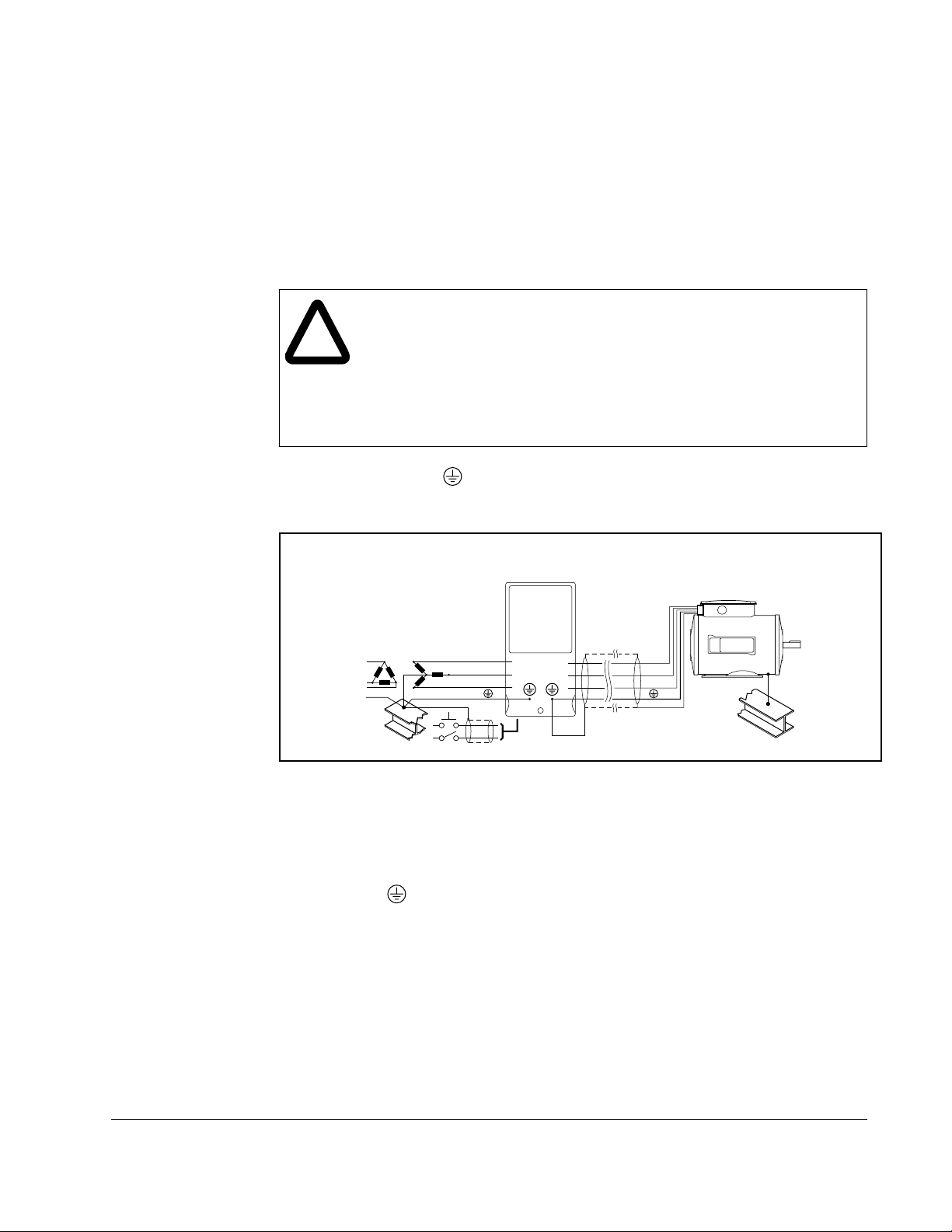

4.1 Grounding the Drive

ATTENTION:T he following information is merely a guide for proper

installation. Baldor Electric Company cannot assume responsibility for

!

The drive Safety Ground - must be connected to system ground. Ground impedance must

conform to the requirements of national and local indust ri al safety regulations and/or electrical

codes. The integr ity of all ground conne cti ons should be periodically checked.

the compliance or the noncompliance to any code, national, local or

otherwise for the proper installation of this drive or associated equipment.

A hazard of personal injury and/or equipment damage exists if codes are

ignored during installation.

ATTENTION:Use the dedicated ground terminal to ground the drive. Do

not use the screw in the case or chassis, etc for grounding.

CHAPTER 4

Power Wiring

R

S

T

SHLD

Figure 4.1 – Typical Grounding

Ground Fault Monitoring

If a system ground fault monitor is to be used, only Type B devices should be used to

avoid nuisance tripping.

Safety Ground -

This is the safety ground for the drive that i s requi red by code. One of these points must be

connected to adjacent building steel (girder, joist), a floor ground rod, or bus bar. Grounding

points must comply with national and loc al i ndustrial safet y regulations and/or electrical codes.

Motor Ground

The motor ground must be connected to one of the ground terminals on the drive.

U

V

W

Power Wiring 4-1

Page 20

Shield Terminat io n - SH L D

Either of the safety ground termi nals provides a grounding point for the motor cable shiel d. The

motor cable shield connected to o ne of these term inal s (drive end) sho uld al so be connect ed to

the motor frame (motor end). Use a shield terminating or EMI clamp to connect the shield to the

safety ground te rminal.

When shielded cable is used for control and signal wiri ng, t he shield should be grounded at

the source end only, not at the drive end.

4.1.1 RFI Filter Grou nding

Using drives with RFI fi lter s may resul t in relat ivel y high gr ound leak age cu rrent s. The refor e, the

filter must only be used in installations with grounded AC supply systems and be

permanently installed and solidly grounded (bonded) to the buildi ng power distribution

ground.

Ensure that the incom ing supply neutral is solidly connected (b onded) to the same building

power distribution ground. Groundi ng m ust not rely on flexible cables and should not include

any form of plug or sock et that would permit inadvertent disconnection. Some local codes may

require redundant ground connections. The integrity of all connections should be periodically

checked.

4.1.2 Grounding Procedure

Step 1. Remove the front cover.

Step 2. Connect the Grounding wire to the ground terminal through the opening for

ground terminal. Enter the screw driver from vertical to the terminal and

secure the screw tightly.

4.1.3 Grounding Guidelines

200V Class 400V Class

Inverter

capacity

0.5 HP 3.5 mm

1.0 HP 3.5 mm

2.0 HP 3.5 mm

3.0 HP 3.5 mm

7.5 HP 5.5 mm

Wire

size

2

2

2

2

2

Terminal

screw

M3 Type 3 2 mm

M3 2 mm

M3 2 mm

M3 2 mm

M4 3.5 mm

Table 4.1 – Grounding G uidelines

Grounding

method

Wire

size

2

2

2

2

2

Terminal

screw

Grounding

method

M3 Special Type 3

M3

M3

M3

M4

4-2 VS1MD AC Drive User Manual

Page 21

4.2 Connecting Peripheral Devi ces to the VS1MD Drive

ATTENTION:Appropria te peripheral devices must be selected and

correct connections made to ensure proper operation. You must read and

understand this manual thoroughly before proceeding. Failure to observe

!

this precaution could result in damage to, or destruction of, the equipment.

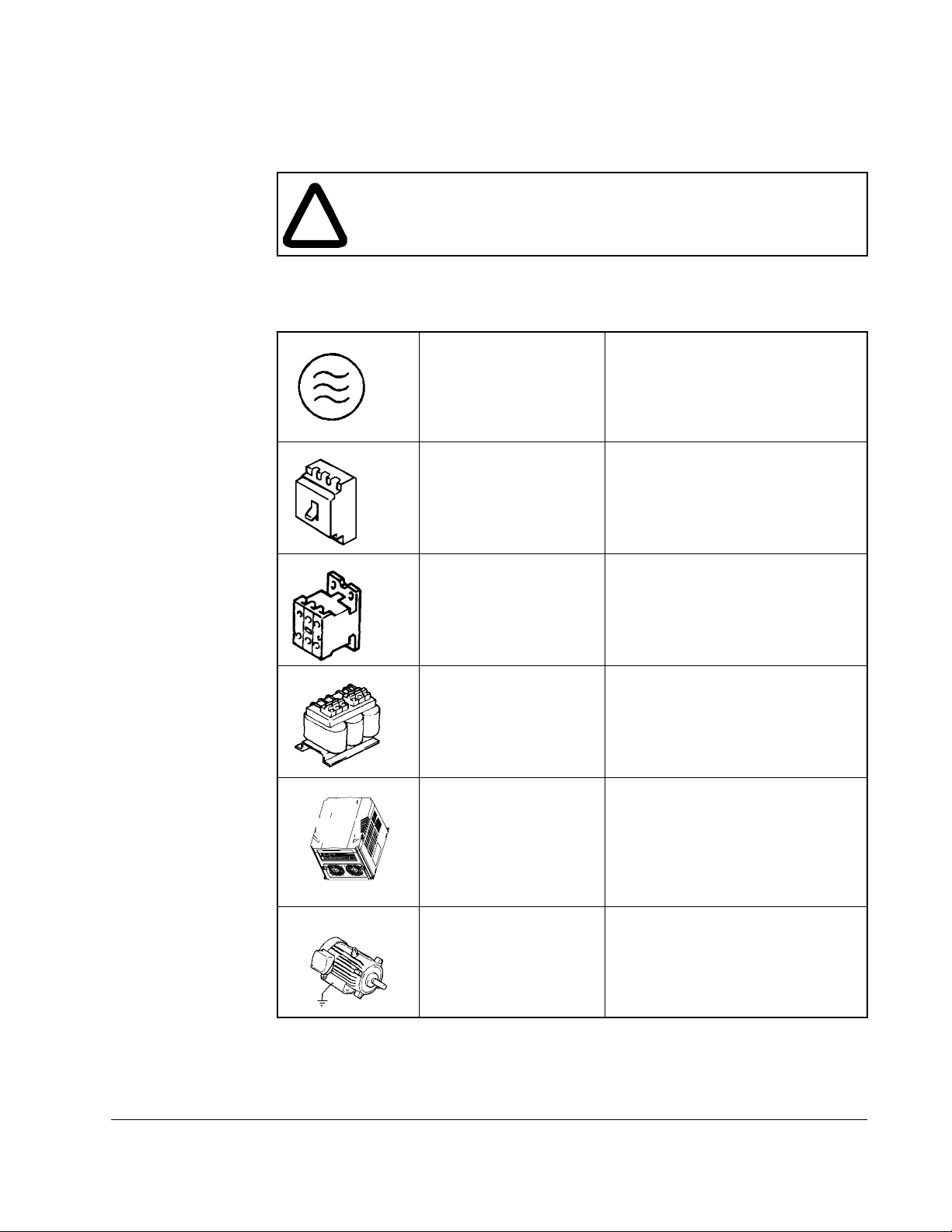

The following devices are required to operate the VS1MD drive.

Table 4.2 – Peripheral Devices for the VS1MD Drive

AC Source Supply Use a power supply within the

permissible range for the drive’s

input power rating.

MCCB or Earth leakage

circuit breaker (ELB)

Magnetic Contactor Install a magnetic contactor if

Reactors Reactors must be used when the

Installation and wiring To ensure optimal operation and

Select circuit breakers with care. A

large inrush current may flow in the

converter when power is turned on.

necessary. When installed, do not

use the contactor for the purpose of

starting or stopping.

power factor needs to be improved

or the drive is installed within 10 m

of a large power supply system

(1000kVA or more).

life span of the drive, install it in an

approriate place with proper

orientation and clearances.

Incorrect terminal wiring can result

in damage to the equipment.

To motor Do not connect a power factor

capacitor , surge suppresor , or radio

noise filter to the output side of the

drive.

Power Wiring 4-3

Page 22

4.3 Power Terminal Wiring

3KDVH$&

9ROWDJHLQSXW

5DWHGLQSXW

9 ROWDJH

5HVL VW R U

0RWRU

'%

5

AC Line

6

Voltage

input

7

DB

%

%

reistor

connect

terminal

8

Motor

connect

9

terminal

:

Ground

*

5

ion

6

7

ion

*

Figu re 4.2 – Power Terminal Wi ring

% %

8

9

:

*

4-4 VS1MD AC Drive User Manual

Page 23

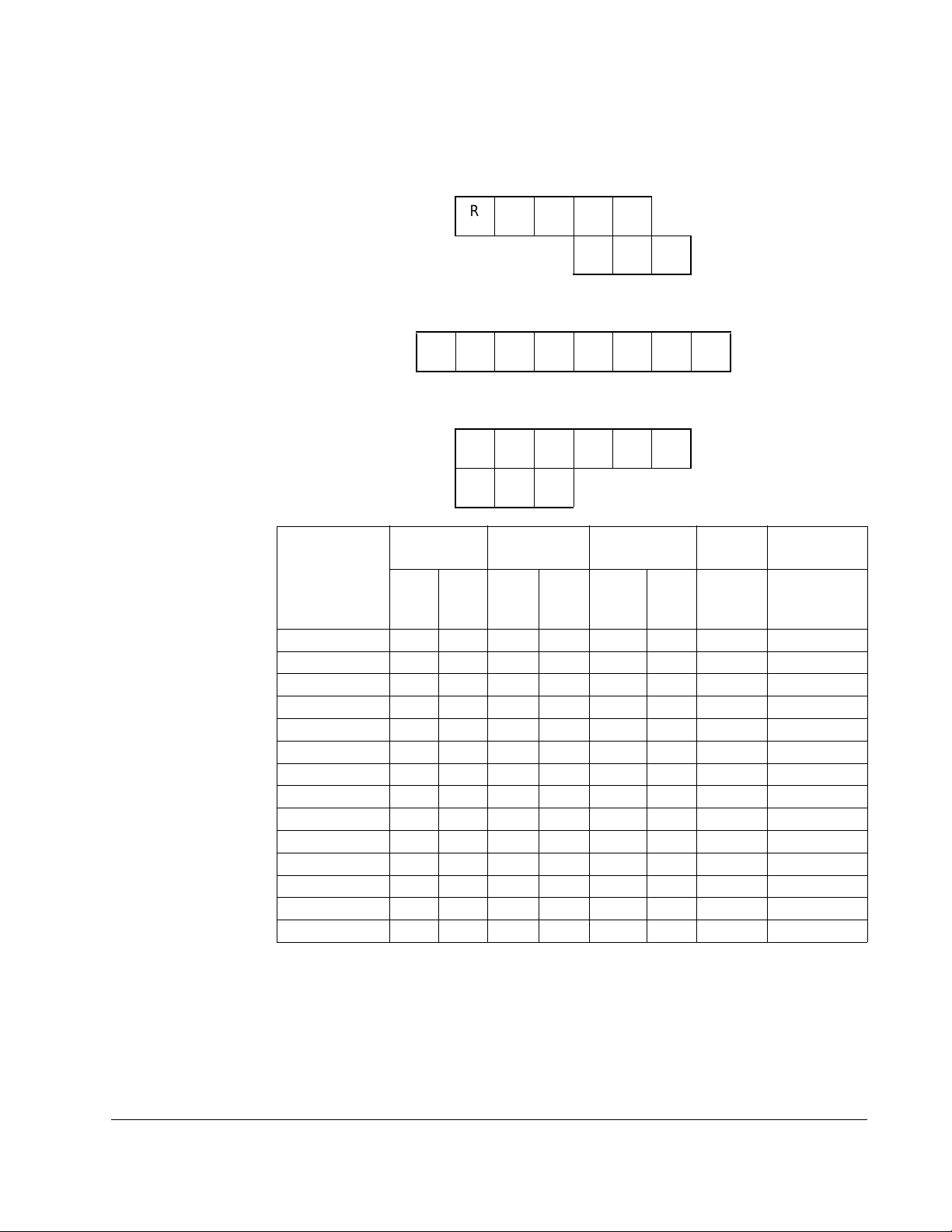

4.4 Specifications for Power Terminal Block Wiring

VS1MD20P5, VS1MD21, VS1MD40P5, VS1MD41, VS1MD22, VS1MD42

RSTB1B2

UVW

VS1MD23, VS1MD43, VS1MD25, VS1MD45

RSTB1B2UVW

VS1MD27, VS1MD210, VS1MD47, VS1MD41 0

B1 B2 U V W

RST

Model

Number

VS1MD20P5

VS1MD21

VS1MD22

VS1MD23

VS1MD25

VS1MD27

VS1MD10

VS1MD40P5

VS1MD41

VS1MD42

VS1MD43

VS1MD45

VS1MD47

VS1MD410

R,S,T

wire size

2

AWG

mm

2 14 2 14 3.5 12 M3.5 10/ 8.7

2 14 2 14 3.5 12 M3.5 10/ 8.7

2 14 2 14 3.5 12 M3.5 10/ 8.7

2 14 2 14 3.5 12 M4 15/13

3.5 12 3.5 12 3.5 12 M4 15/13

5.5 10 5.5 10 5.5 10 M5 32/28

8 8 8 8 5.5 10 M5 32/28

2 14 2 14 2 14 M3.5 10/8.7

2 14 2 14 2 14 M3.5 10/8.7

2 14 2 14 2 14 M4 15/13

2 14 2 14 2 14 M4 15/13

2 14 2 14 2 14 M4 15/13

3.5 12 2 14 3.5 12 M5 32/28

3.5 12 3.5 12 3.5 12 M5 32/28

U, V, W

wire size

2

mm

AWG

Ground Wire Screw

size

2

mm

AWG Terminal

Screw

Size

Terminal

torque

Screw

Torque

(Kgf.cm/lb-in)

* Strip the sheaths of the wire insulation 7mm when a ring terminal is not used for

power connection.

Power Wiring 4-5

Page 24

4.5 Recommended Breakers

Table 4.3 – Circuit Brea ker Ratings by Model Number

Model Breaker Model Breaker

Current[A] Voltage[V] Current[A] Voltage[V]

VS1MD20P5

VS1MD21 30 230

VS1MD22 30 230

VS1MD23 30 230

VS1MD25 30 230

VS1MD27 50 230

VS1MD10 60 230

30 230

VS1MD40P5 30 460

VS1MD41 30 460

VS1MD42 30 460

VS1MD43 30 460

VS1MD45 30 460

VS1MD47 30 460

VS1MD410 30 460

4.6 Recommended Fuses and AC Reactors

Model External fuse AC reactor

Current[A] Voltage[V]

VS1MD20P5

VS1MD21 10 A 500 2.13mH, 5.7A

VS1MD22 15 A 500 1.20mH, 10A

VS1MD23 25 A 500 0. 88m H,14A

VS1MD25 40 A 500 0.56mH, 20A

VS1MD27 40 A 500 0.39mH, 30A

VS1MD210 50 A 500 0.28mH, 40A

VS1MD40P5 5 A 500 18.0mH, 1.3A

VS1MD41 10 A 500 8.63mH, 2.8A

VS1MD42 10 A 500 4.81mH, 4.8A

VS1MD43 10 A 500 3.23mH, 7.5A

VS1MD45 20 A 500 2.34mH, 10A

VS1MD47 20 A 500 1.22mH, 15A

VS1MD4100 30 A 500 1.14mH, 20A

10 A 500 4.20mH, 3.5A

ATTENTION:Suitable For Use On A Circuit Capable Of Delivering

Not More Then 65,000 RMS Symmetrical Amperes. 240V drives

!

4-6 VS1MD AC Drive User Manual

or 480V drives Volts Maximum

ATTENTION:Use Class H or K5 UL Listed Input Fuse and UL

Listed Breaker Only. See the table above for the voltage and current

rating of the fuse and the breaker.

Page 25

4.7 Reflected Wave Protection

When more than one motor is connected to one inverter, total wiring length should be

less than 200m (656ft). Do not use a 3-wire cable for long distances. Due to increased

leakage capacitance between wires, over-current protective feature may operate or

equipment connected to the output side may malfunction. In case of long wire length,

lower carrier frequency or contact Baldor for recommendations.

Table 4.4 – Wire Length Recommendations

Length Between Inverter and Motor Allowable Carrier Frequency

Up to 50 meters Less than 15 kHz

Up to 100 meters Less than 5 kHz

More than 100 meters Less than 2.5 kHZ

Power Wiring 4-7

Page 26

4-8 VS1MD AC Drive User Manual

Page 27

CHAPTER 5

Control Wiring

This chapter describes how to wire the signal and I/O terminal strip for stop, speed

feedback, and remote control signals.

ATTENTION:Apply the rated torque to terminal screws. Loose screws

can cause short circuit and malfunction. Tightening the screws too much

!

can damage the terminals and cause short circuit and malfunction.

ATTENTION:Make sure the input power is off before wiring.

ATTENTION:After power supply is switched off following operation, wait

at least 10 minutes after LED keypad display is off before you start

working on it.

ATTENTION:Applying input power supply to the output terminals U, V

and W causes internal inverter damage.

ATTENTION:Use ring terminals with insulated caps when wiring the

input power and motor wiring.

ATTENTION:Do not leave wire fragments inside the inverter. Wire

fragments can cause faults, breakdowns and malfunctions.

ATTENTION:When more than one motor is connected to one inverter,

total wiring length should be less than 200m (656ft). Do not use a 3-wire

cable for long distances. Due to increased leakage capacitance between

wires, over-current protective feature may operate or equipment

connected to the output side may malfunction. In case of long wire

length, lower carrier frequency or contact Baldor for recommendations.

ATTENTION:Never short B1 and B2 terminals. Shorting terminals may

cause internal inverter damage.

ATTENTION:Do not install a power factor capacitor, surge suppressor

or RFI filter in the output side of the inverter. Doing so may damage

these components.

5.1 Stop Circuit Requirements

ATTENTION:You must provide an external, hardwired emergency

stop circuit outside of the drive circuitry. This circuit must disable the

!

In addition to the operational stop, you must provide a hardwired emergency stop

external to the drive. The emergency stop circuit must contain only hardwired

electromechanical components. Operation of the emergency stop must not depend on

electronic logic (hardware or software) or on the communication of commands over an

electronic network or link. Note that the hardwired emergency stop you install can be

used at any time to stop the drive.

Control Wiring 5-1

system in case of improper operation. Uncontrolled machine

operation can result if this procedure is not followed. Failure to observe

this precaution could result in bodily injury.

Page 28

5.2 Motor Start/Stop Precautions

ATTENTION:A contactor or other device that routinely disconnects and

reapplies the AC line to the drive to start and stop the motor can cause

!

Important points to remember about I/O wiring:

• Always use copper wire.

• Wire with an insulation rating of 600V or greater is recommended.

• Control and signal wires should be separated from power wires by at least 0.3

meters (1 foot).

drive hardware damage. The drive is designed to use control input

signals that will start and stop the motor. If used, the input device must

not exceed one operation per minute or drive damage can occur. Failure

to observe this precaution can result in damage to, or destruction of,

equipment.

ATTENTION:The drive start/stop control circuitry includes solid-state

components. If hazards due to accidental contact with moving

machinery or unintentional flow of liquid, gas or solids exist, an

additional hardwired stop circuit may be required to remove the AC line

to the drive. When the AC line is removed, there will be a loss of any

inherent regenerative braking effect that might be present - the motor

will coast to a st op . A n a ux iliary brakin g method may b e required.

Important: I/O terminals labeled “Common” are not referenced to the safety ground

terminal and are designed to greatly reduce common mode interference.

ATTENTION:Driving the 4-20 mA analog input from a voltage source

could cause component damage. Verify proper configuration prior to

!

applying input signals.

5-2 VS1MD AC Drive User Manual

Page 29

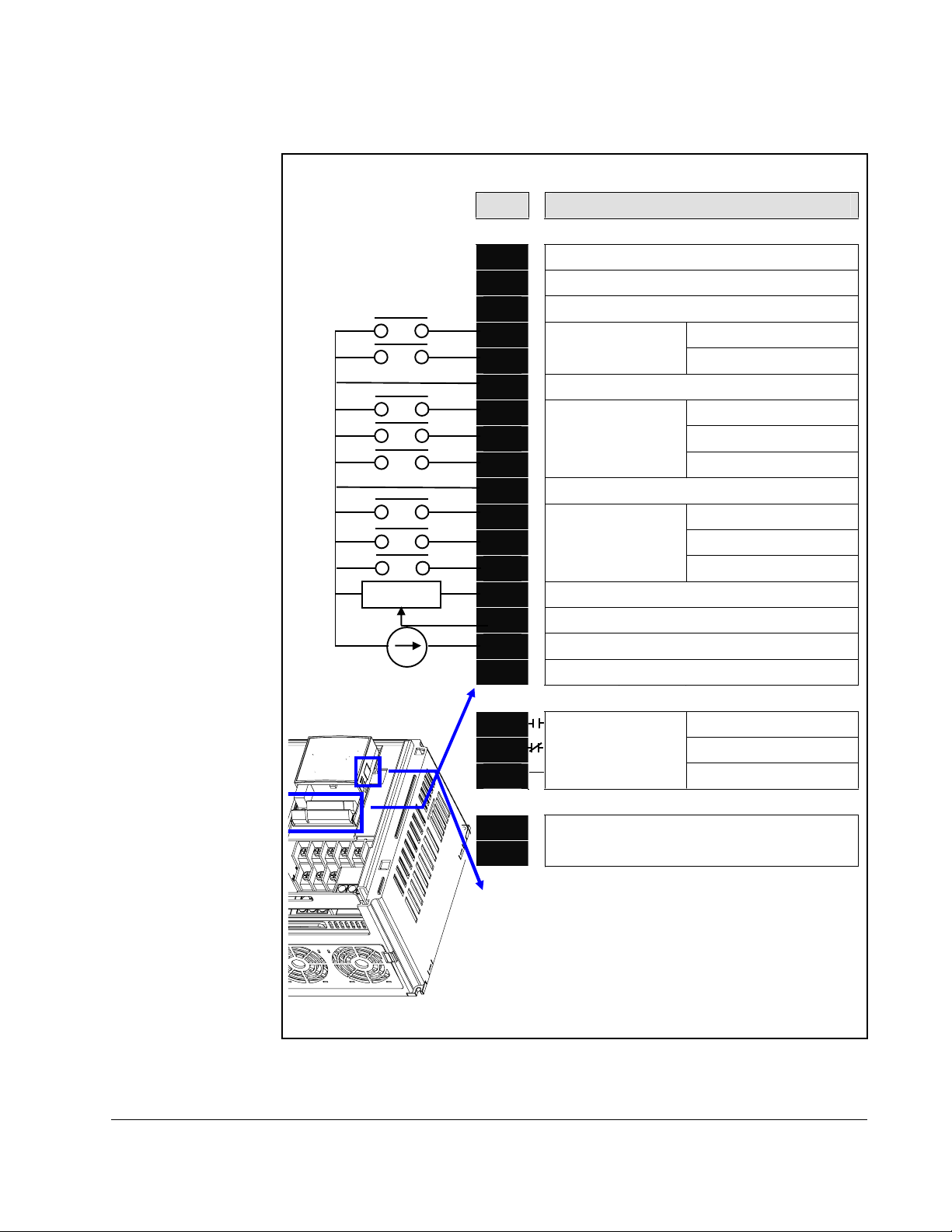

5.3 Terminal Wiring (Control I/O)

T/M Description

MO Multi-function open collector output

MG MO Common

24 24V output

P1 FX: F orw ard run

P2

CM Input signal common

P3 BX: Stop

P4 RST: Trip reset

P5

CM Input signal common

P6

P7

P8

VR 10V power supply for potentiometer

V1 Freq. Setting Voltage signal input: -0~10V

G

I Freq. Setting Current signal input: 0~20mA

AM Multi-function analog output signal: 0~10V

MF input terminal

(factory setting)

MF input terminal

(factory setting)

MF input terminal

(factory setting)

RX: Reverse run

JOG: Jog operation

Preset Speed Input 1

Preset Speed Input 2

Preset Speed Input 3

3A A contact output N.O.

3B B contact output N.C.

3C

S+

S-

Multi-function relay

output terminal

A/B contact common

RS485 communication terminal

# For connection to Remote Option or

parameter copying

Control Wiring 5-3

Page 30

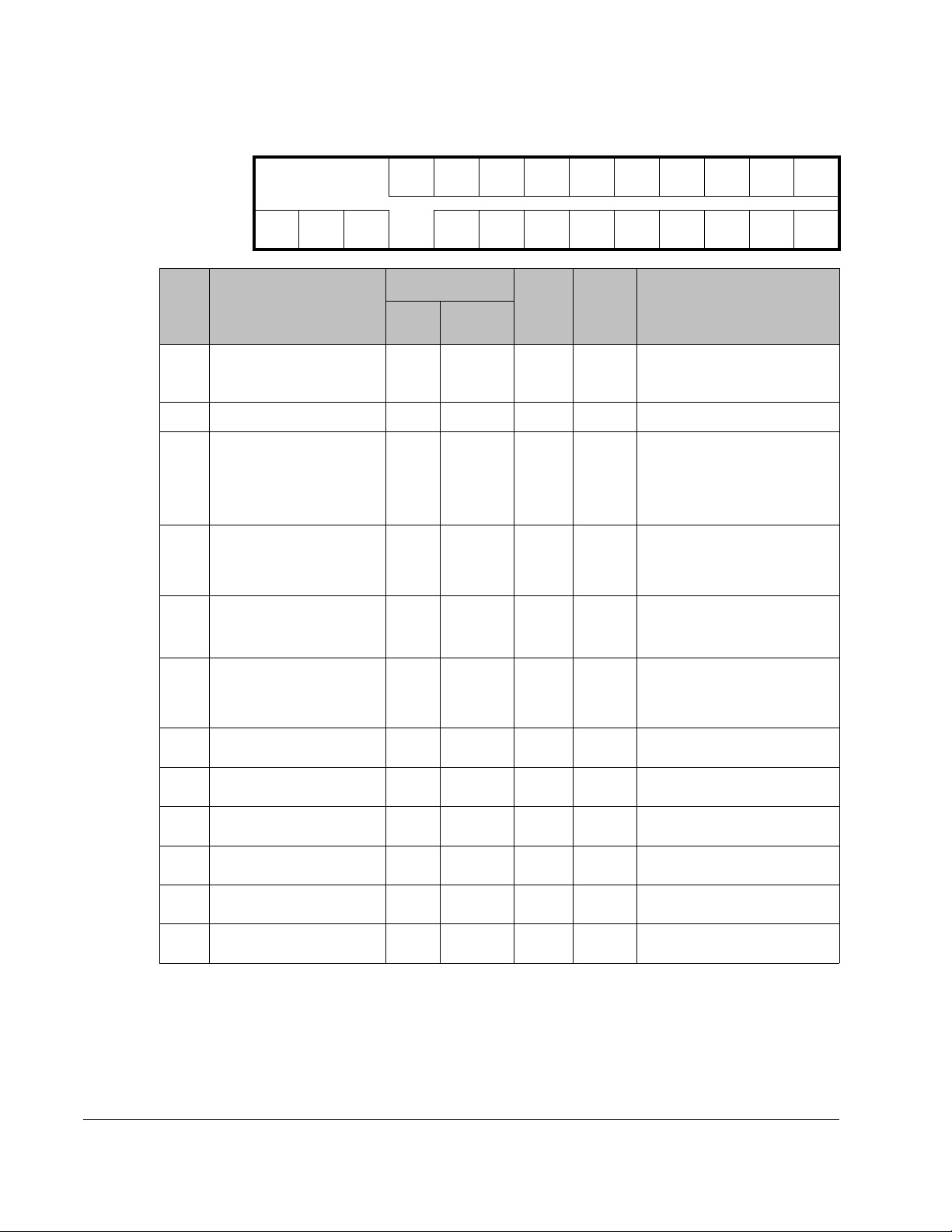

5.4 Control Terminal Specificati ons

MO MG 24 P1 P2 CM P3 P4 S- S+

3A 3B 3C P5 CM P6 P7 P8 VR V1 I AM

T/M Terminal Description

P1

Multi-fu nction d igital input

to

P8

CM Common Terminal 1.0 1.5 M2.6 0.4

VR Power supply for external

V1 Input terminal f or Voltage

I Input terminal for Current

AM Multi-function analog

MO Multi-function terminal for

MG Ground terminal for

24 24V External Power

3A Multi-function relay

3B Multi-function relay

3C Common for

T/M 1-8

speed potentiometer

operation

operation

output termin al

open collector output

external power supply

Supply

output A contact N.O.

output B contact N.C.

Multi-function relays

Wire size[m m2]

solid

wire

1.0 1.5 M2.6 0.4

1.0 1.5 M2.6 0.4

1.0 1.5 M2.6 0.4

1.0 1.5 M2.6 0.4

1.0 1.5 M2.6 0.4

1.0 1.5 M2.6 0.4

1.0 1.5 M2.6 0.4

1.0 1.5 M2.6 0.4

1.0 1.5 M2.6 0.4

1.0 1.5 M2.6 0.4

1.0 1.5 M2.6 0.4

stranded

Screw

size

Torque

[Nm]

Specification

Output Voltage: 12 V

Max output current: 10mA

Potentiometer: 1 - 5 kohm

Max input voltage:

-12V - +12V input

0 - 20 mA input

Internal Resister: 250 ohm

Max output voltage: 11 V

Max output current:

100mA

Below DC 26V, 100mA

Max output current:

100mA

Below AC 250V, 1A

Below DC 30V, 1A

5-4 VS1MD AC Drive User Manual

Page 31

5.5 Source/Sync for Input Control Wiring

1. When using DC 24V inside inverter [Source]

SW S8

SW S8

S8

CM

RG

P1

CM

(inside inverter)

2. When using external DC 24V [Sink ]

SW S8

S8

DC24V

CM

P1

CM

( ins i de inv e rt e r)

RG

Source

(NPN)

DC 24 V

CPU

RG

CM

Sink (PNP)

DC 24 V

CPU

R

CM

Control Wiring 5-5

Page 32

5.6 I/O Wiring Recommendations

Table 5.1 – Recommended Control and Sign al Wire

Wire Type(s) Description

Belden 8760/9460

(or equiv.)

Belden 8770

(or equiv.)

1

If the wires are short and contained within a cabinet that has no sensitive circuits,

0.8 mm

0.8 mm

only.

2

(18AWG), twisted pair, 100% shield with drain.

2

(18AWG), 3 conductor, shielded for remote pot

the use of shielded wire may not be necessary, but is always recommended .

Table 5.2 – I/O Terminal Block Specifications

Maximum Wire Size1

2

1.3 mm

1

Maximum / minimum that the terminal block will accept. These are not

(16 AWG) 0.13 mm2 (26 AWG)

Minimum Wire Size

1

0.5 to 0.8 Nm

(4.4 in-lb to 7 in-lb)

recommendations.

5.6.1 Maximum Control Wire Length Recommendations

1

Minimum

Insulation

Rating

300 V

75° C

(167° F)

Torque

Do not exceed control wiring length of 30 meters (100 feet). Control signal cable

length is highly dependent on electrical environment and installation practices. To

improve noise immunity, the I/O terminal block Common must be connected to ground

termi n al/protective e a r th .

5.7 Technical Specifications

Please see Appendix A - Technical Specifications for detailed electrical information.

5-6 VS1MD AC Drive User Manual

Page 33

Factory-default parameter values allow the drive to be controlled from the integral

keypad. No programming is required to start, stop, change direction, or control speed

directly from the integral keypad.

This chapter provides an overview of the integrated keypad and how to use it to

program the VS1MD drive.

6.1 Keypad Components

CHAPTER 6

Using the Keypad

1

2

Refer to table 6.1 for the LED descriptions noted by

6.1.1 Display Descript ion

The alpha-numeric display indicates the following:

• Operational Values (such as Output Frequency)

3

4

➊ through ➍ and table 6.2 for key definitions.

• Parameter Numbers

• Parameter Values

• Fault Codes

Using the Keypad 6-1

Page 34

6.2 LED Descriptions

Refer to figure 6.1 for the location of the LEDs described in table 6.1.

No. LED LED State Description

PROG Steady Red (On) Indicates the drive is in programming mode.

➊

(Off) Indicates the drive is in operational Mode.

RUN Steady Red (On) Indicates the drive is running at commanded speed.

➋

Flashing Red Indicates dri ve is accelerating or decelerating to new

(Off) Drive is not running.

FWD Steady Red (On) Indicates the drive is in forward operation.

➌

(Off) Indicates the drive is in reverse operation.

STP/FLT Steady Red (On) Indicates the drive is in a stopped position.

➍

Flashing Red Indicates the drive is faulted.

(Off) Drive is running.

6.3 Key Descriptions

Table 6.1 – LED D escriptions

speed setting.

Refer to figure 6.1 for the location of the keys described in table 6.2.

Table 6.2 – Key Descriptions

Key Name Description

Run Key

• Starts the drive.

• Active when the input mode is programmed for

keypad control.

St op Key

• Stop s the drive in programmed stop mode.

• Always active.

• Rese t active faults .

Ent/Prog Key

• Accesses programming m enu and locks in

changed values.

• To enter programming mode, the Ent/Prog key

must be held in for 2 seconds.

• Holding the Ent/Prog key for 2 sec onds or mo re will

escape back to Control Reference Mode or back

out of a parameter edit f unction.

6-2 VS1MD AC Drive User Manual

Page 35

T able 6.2 – Key Descriptions (Continued)

Key Name Description

Speed

Reference

Keys

Operation Mode:

• Changes the commanded speed r eference.

• Only active when the input mode is programmed for

keypad control.

• The Up-Arrow increases the speed reference at a

controlled rate.

• The Down-Arrow decre ases the s peed r efere nce at

a controlled r ate.

• Holding either arrow for a set period of time will

increase the ref erence ramp rate.

Program Mode:

• Increment / Decrement parameter numbers or

parameter values

Direction

Keys

Operation Mode:

• Only active when the input mode is programmed for

keypad control.

• Direction keys are active only when operating in

reference command mode.

• Reverse may also be disabl ed by a parameter .

6.4 About Parameters

To program the drive for a specific application, you adjust the appropriate param eters. The

paramete rs ar e used to define character istics of the drive.

There are three types of parameters:

• Numbered List Parameters (Enumerated Parameters)

Numbered list param eters allow a selection from two or more options. Each item is

represented by a number.

Example: Start/Stop Source (P38)

• Bit Par a me ters

Bit parameters have individual bits associated with features or conditions. If the bit is 0, the

feature is off or the condition is false. If the bit is 1, the feature is on or the co ndition is true.

Example: Terminal Status Display (d7)

• Numeric Parameters

These parameters have a single numerical value (for example, 0.1 volts).

Example: Motor Rated Current (P32)

Program Mode:

• Cycle through the parameter groups or shift to

the next digit to be changed while in the

parameter edit mode.

Parameters are al so either configurable or tunable, or read-onl y.

Configurable p arameters can be adjusted or changed only while the drive is stopped.

Using the Keypad 6-3

Page 36

T unable parameters can be adjusted or changed whil e the dr ive is running or stopped.

Read-only parameters cannot be adjusted.

6.5 How Parameters are Organized

Parameters are organized into five Parameter Groups:

• The Display Parameter Group (dnn) contains parameters for the display of basic

drive information.

• The Programming Parameter Group (Pnn) contains the most commonly used

parameters for startup and operation.

• The T erminal Parameter Group (tnn) contains a linear list of input and output control

parameters.

• Function Group 1 Parameters (Fnn) contains a linear list of advanced motor control

parameters.

• Function Group 2 Parameters (Hnn) contains a linear list of advanced motor profile

parameters.

6.6 Moving Between Parameter Groups

Use the following procedure to enter the programming mode and to move between

groups:

Table 6.3 – Moving Betwee n Parameter Group s

Procedure Sample Display

Step 1. When the drive first powers up, the display will

indicate the value of the “Power ON Display,” which

is defined in Parameter H72. The default “Power On

Display” is the commanded frequency.

Step 2. Press and hold down the ENTER key for at least two

seconds to change the drive from the operation

mode to the programming mode.The “PROG” LED

will illuminate indicating that the drive is in

programming mode. The drive will display the first

parameter of the “Display” group.

Step 3. Press the right arrow key to change to the

“Parameters Group”.

Step 4. Press the right arrow key to change to the “Terminal

Group”.

6-4 VS1MD AC Drive User Manual

Page 37

Table 6.3 – Moving Between Paramet er Group s

Procedure Sample Display

Step 5. Press the right arrow key to change to “Function

Group 1”.

Step 6. Press the right arrow key to change to “Function

Group 2”.

Step 7. Press the right arrow key to change to “Display”

group.

Step 8. Press and hold down the ENTER key for at least two

seconds to change the drive from the programming

mode back to operation mode.The “PROG” LED will

go out indicating that the drive is in operation mode.

The drive will display the default “Power On Display”.

Note that the above can be execute in reverse order by using the left arrow key

instead of the right arrow key.

Y ou can only move between groups while the first parameter of the group is displayed.

Pressing the left or right arrow while displaying any parameter other than the first

parameter of the group returns to the first parameter of the group.

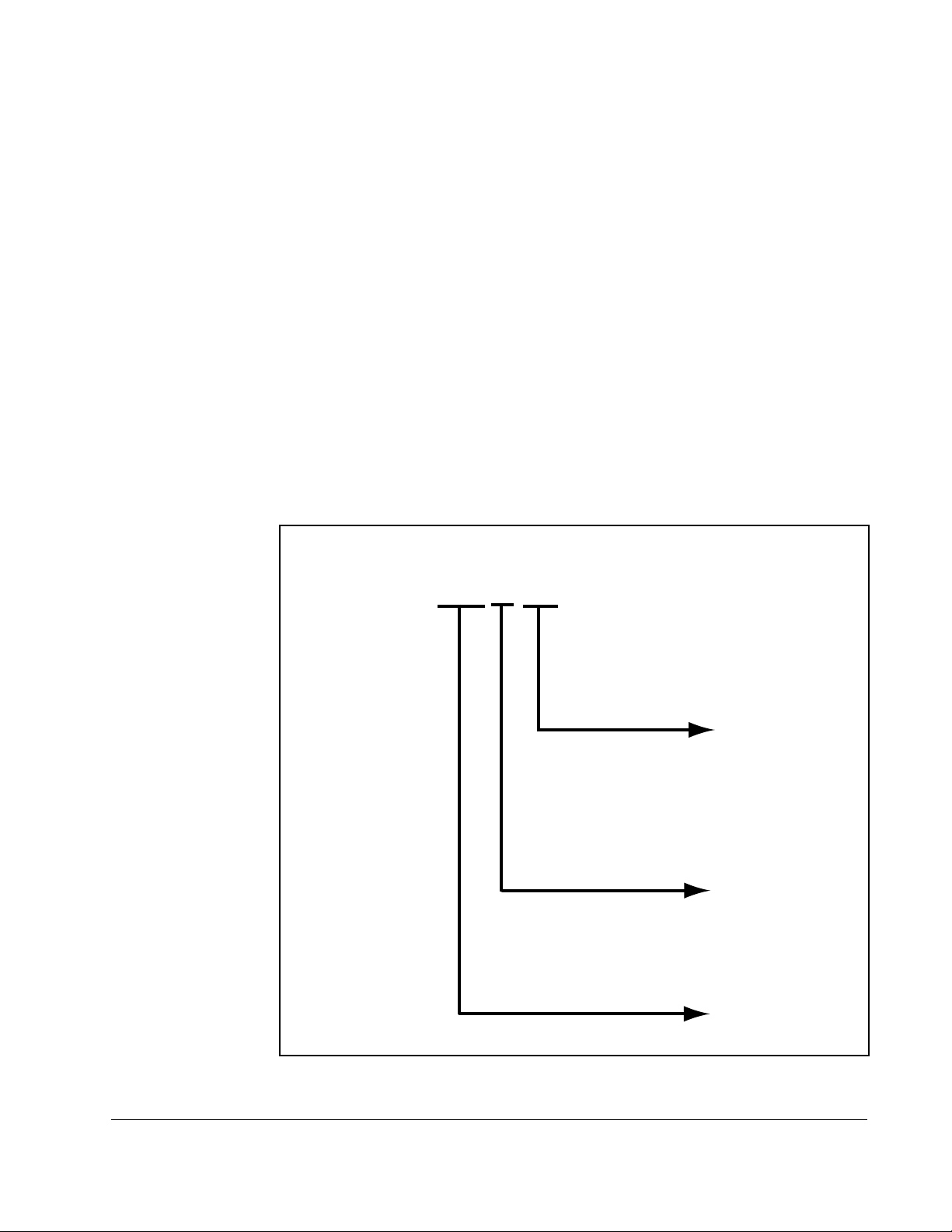

Pressing the

up or down

Terminal group

arrow mo ves

you within a

group of

parame ters

Function Group 1

Function Group 2

Pressing the

left or righ t

arrow from

any parameter

returns you to

the firs t

parameter of

the grou p

Using the Keypad 6-5

Page 38

The below example indicates the steps needed to move from parameter F35 to

Function Group 2.

Table 6.4 – Moving from F35 to Func tion Group 2

Procedure Sample Display

Step 1. When a parameter other than the first in a group is

displayed, you must initially go to the first parameter

of the group prior to going to the next group. For this

example, parameter F35 of Function Group 1 is

currently displayed and you want to go to Function

Group 2 (H Parameters).

Step 2. Press the left or right arrow and parameter F0 will be

displayed.

Step 3. Press the right arrow key to change to “Function

Group 2”.

6.7 Changing Between Parameters Within a Group

Each group contains parameters arranged in a linear list. The list can be navigated

using the Up and Down arrows.

Table 6.5 – Changing Between Parameters Withing a G roup

Procedure Sample Display

Step 1. From the operation mode, press and hold down the

ENTER key for at least two seconds to change the

drive to the programming mode. The “PROG” LED

will illuminate indicating that the drive is in

programming mode. The drive will display the first

parameter of the “Display” group.

Step 2. Press the up arrow to display the next parameter.

Step 3. Press the up arrow again to display the next

parameter, continue until the desired parameter is

displayed.

Note that using the down arrow allows navigation through the parameters in

reverse order.

6-6 VS1MD AC Drive User Manual

Page 39

The first parameter of each group, with the exception of the “Display Group”, is a

special parameter called a “Jump Code”. The parameter can be used to jump to a

specific parameter within a group without having to scroll through the parameters

using the up and down arrows. Once the Jump Code is programmed, the drive will

save the setting for future use, but this can always be reprogrammed to jump to a

different parameter.

The following exam ple illustrates the use of a Jump Code to jump to parameter P38.

Table 6.6 – Using the Jump Code

Procedure Sample Display

Step 1. From the operation mode, press and hold down the

ENTER key for at least two seconds to change the

drive to the programming mode. The “PROG” LED

will illuminate indicating that the drive is in

programming mode. The drive will display the first

parameter of the “Display” group.

Step 2. Press the right arrow to change to the “Parameters”

group.

Step 3. Press the ENTER key to edit P0 (Jump Code).

Step 4. Press the UP arrow seven times until the display

indicates an “8”.

Step 5. Press the left arrow one time such that the next digit

is displayed. It will be displayed brighter than the

previous digit.

Step 6. Press the UP arrow three times such that the display

indicates the parameter number.

Step 7. Press the ENTER key to accept the value. The value

will be saved in the Jump Code (P0) for future use

and the desired parameter will immediately be

displayed.

Using the Keypad 6-7

Page 40

The following example shows how to use a previously stored Jump Code.

Table 6.7 – Using a Previ ously Stored Jump Code

Procedure Sample Display

Step 1. From the operation mode, press and hold down the

ENTER key for at least two seconds to change the

drive to the programming mode. The “PROG” LED

will illuminate indicating that the drive is in

programming mode. The drive will display the first

parameter of the “Display” group.

Step 2. Press the right arrow to change to the “Parameters”

group.

Step 3. Press the ENTER key to access the Jump Code.

Step 4. Press the ENTER key a second time and the desired

paramete r w ill b e d is played.

6.8 Modifying the Value of a Parameter

The parameters located in the Display group are read-only and can not be modified.

All other parameters (with a few exceptions) can be modified by the user. Some

parameters are configurable - meaning that the drive must be stopped before the

parameter can be modified, while others are tunable - meaning that the parameter can

be modified while the drive is stopped or running.

6-8 VS1MD AC Drive User Manual

Page 41

The following example shows how to modify the acceleration time located in

parameter P 4 1.

Table 6.8 – Modifying Parameter Values

Program Group

Step 1. From the operation mode, press and hold down the

ENTER key for at least two seconds to change the

drive to the programming mode. The “PROG” LED

will illuminate indicating that the drive is in

programming mode. The drive will display the first

parameter of the “Display” group.

Step 2. Press the right arrow key to change to the

“Parameters” group.

Step 3. Use the up arrow or the jump code to display the

acceleration time parameter P41.

Step 4. Momentarily press the ENTER key to begin the

parameter value edit mode. Notice that the tenths

digit is highlighted for editing. At this point you can

use the up arrow key to increment the value all the

way to the new setting (16.0 in this example) or

proceed with the following steps.

Step 5. Press the left arrow key to select the ones digit for

editing.

Step 6. Press the up arrow key to increment the ones digit

from a 5 to a 6.

Step 7. Press the left arrow key to select the tens digit for

editing.

Step 8. Press the up arrow key to increment the tens digit

from a 0 to a 1.

Using the Keypad 6-9

Page 42

Table 6.8 – Modifying Parameter Values

Step 9. Press the ENTER key to accept the value and the

display will begin to flash so that you can confirm the

entry.

Step 10. Press the ENTER key a second time to acknowledge

the entry. The display will revert to showing the

parameter number.

6.9 Monitoring Display Parameters

The Display group is a group that consists of read only values that can be monitored

by the user to diagnose the operation of the drive and motor. To monitor the motor

current, follow the below example.

Table 6.9 – Monitoring Display Parameters

Display Group

Step 1. From the operation mode, press and hold down the

ENTER key for at least 2 seconds to change the

drive to the programming mode. The “PROG” LED

will illuminate indicating that you are in the

programming mode. The drive will display the first

parameter of the “Display” group.

Step 2. Press the up arrow key twice to change to the

parameter d2 (Motor Current).

Step 3. Momentarily press the ENTER key to display the

motor current. The display will be updated in real

time.

Step 4. Press the ENTER key to return to the previous

display so that you can select a new parameter to

view.

6-10 VS1MD AC Drive User Manual

Page 43

6.10 Reviewing the Fault Status in the Display Group

When a fault is active, this is annunciated on the drive by flashing the STOP/FAULT

LED. This procedure is used to review the active fault as well as certain conditions at

the time the fault occurred.

Table 6.10 – Reviewing Fault Status in the Display Group

Over-

current

trip

Display Gr oup

STOP

RESET

Step 1. When an overcurrent condition has been detected by

the drive, a fault will be latched and the display will

show the condition.

Step 2. Press the ENTER key to see the frequency at which

the fault occurred. This example indicates that the

drive was outputting 30.00 Hz when the fault

occurred.

Step 3. Press the up arrow to view the output current during

the fault. This example indicates that the drive was

outputting 5.0 Amps when the fault occurred.

During

Accel

Current

Frequency

Step 4. Press the up arrow key again to view the operating

status of the drive when the fault occurred. This

example indicates that the drive was accelerating

when the fault occurred.

Step 5. Press the STOP/RESET button on the keypad to

reset the fault and the STOP/FAULT LED will

illuminate solid indicating that the fault is cleared and

that the drive is in the stopped condition. The display

will indicate that there is no longer a fault condition.

Using the Keypad 6-11

Page 44

6.11 Resetting the Parameters to Factory Default

Follow the below procedure to reset the parameters to the factory default values:

Table 6.11 – Resetting Parameters to Factory Default

Function Group 2

Step 1. Navigate to the Function Group 2 (H Group).

Step 2. Press the ENTER key to edit the jump code. Modify

the jump code to be equal to 93.

Step 3. Press the ENTER key to jump to parameter H93.

Step 4. Press ENTER to display the current value of

parameter H93 (it will be 0 indicating that parameters

will not be reset).

Step 5. Press the up arrow key to change the value to a 1.

Step 6. Press the ENTER key to reset the drive parameters

to factory default. The display will revert back to

displaying the parameter number.

6-12 VS1MD AC Drive User Manual

Page 45

7.1 Overview

The following information is provided for each parameter listed in table 7.1 along with

its descripti on:

Parameter Numb er: Unique number assigned to each parameter.

Parameter Name: Unique nam e assig ned to each parameter.

LED Display: Display shown on LED screen when parameter is

Range: Predefined parameter limits or selections. Note that

Default: Factory default setting.

CHAPTER 7

P arameter Desc riptions

accessed.

a negative Hz value indicates reverse rotation.

Access:

• Read Only: Parameter value can not be modified

by user.

• Configurable: Parameter can only be modified

while drive is stopped.

• Tunable: Parameter can be modified while drive

is running or stopped.

Group: Menu group within which parameter is located.

See also: Associated parameters that may provide additional

or relate d in f or mation.

The parameters are presented in numerical order within each of the fivegroups

(Dispay, Basic Parameters, Terminal, Function Group 1, Function Group 2). Appendix

B contains a list of parameters by name cross-referenced to parameter number.

Parameter Descriptions 7-1

Page 46

7.2 Display Group Parameters

Parameters in this group are display only and can be used to monitor drive

conditions. To change th e active display for the drive, use parameter H72 - Power

On Display.

d0 Freq uency Comm and

Range: 0.0 to Frequency High Limit (P36) [Hz]

Default: Read Only

Displays the value of the active frequency command. The commanded

frequency is displayed even if the drive is not running.

d1 Motor R P M

Range: 0.0 Motor RPM (based on P33 Motor

Default: Read Only

Displays the output motor RPM. Motor RPM is scaled based on output

frequency present on terminals U, V and W based on the setting in P33

– Motor Poles.

Poles) [RPM]

d2 Output Current

Range: 0.0 to Motor Rated Current (P32) [Amps]

Default: Read Only

Displays the value of the output current present at terminals U, V and W.

d3 Output Voltage

Range: 0.0 to Drive Rated Voltage [volts]

Default: Read Only

Displays output voltage present at U, V, W.

d4 Outp ut Power

Range: 0.0 to (Drive Rated Power x 2) [kW]

Default: Read Only

Displays the value of the output power present at terminals U, V and W.

7-2 VS1MD AC Drive User Manual

Page 47

d5 Output Torqu e

Range: 0.0 to (Drive Rated Torque x 2) [kgf / M]

Default: Read Only

See Also: H36

Displays the value of the output torque present at terminals U, V and W.

Enter motor efficiency indicated on motor nameplate to H36 to display

correct torque.

d6 DC Li nk Voltage

Range: Based on Drive Rating [Volts DC]

Default: Read Only

Displays the present DC bus voltage level.

d7 Input Terminal status display

Range: See Figure Below

Default: Read Only

Displays the status of the input terminals P1~P8. An example is

shown below for when P1, P3, P4 are ON and P2, P5 are OFF.

33333333

d8 Output termina l status display

Range: See Figure Below

Default: Read Only

Displays the status of the Digital (MO) Output and the Relay

(3A~C) terminals. The following example is for when Digital

Output (MO) is ON and the Relay is OFF.

2 1

2 ))

21

2 ))

$&02

Parameter Descriptions 7-3

Page 48

d9 Software V ersion

Range: 1.0 to 99.9

Default: Read Only

Displays the Main Control Board software version.

nOn Current Fault Display

Range: See Chapter 9 - Troubleshooting for fault

Default: Read Only

See Also: H1-H6

Displays the types of faults, frequency and operating status at the time of

the last fault.

code description

Fault Types

Frequency

Current

Accel/

Decel

Information

Fault during Accel

Fault during Decel

Fault during constant run

Fault code history can be viewed in parameters H1 - H5. H6 is used to

clear the fault code history. For a complete description of fault codes,

refer to Chapter 9 - Troubleshooting.

7-4 VS1MD AC Drive User Manual

Page 49

7.3 Basic Program Group Parameters

The Basic Program Group (P) contains the parameters most commonly used in

start-up.

P0 Jump Code

Range: 30 -4 7

Default:

Access Tunable

Sets the code to jump directly to a specific parameter within the group.

P30 Motor HP Select

Range: 0.5

Default:

Access Configurable

See also:

30

= 0.5 HP

1

= 1 HP

2

= 2 HP

3

= 3 HP

5

= 5 HP

7.5

= 7.5 HP

10

= 10 HP

Preset based on drive rating.

P32 - P34

Sets the motor type connected to the drive output side.

P32 Motor Rated Current

Range: 0.5 - 50 Amps

Default:

Access Configurable

See Also:

Enter motor rated current on the nameplate.

P33 Pole Number

Range: 2, 4, 6, 8, 10, 12

Default:

Access Configurable

See Also:

Select number of motor poles

Preset based on drive rating

P30, P33, P34

4

P30, P32, P34

Parameter Descriptions 7-5

Page 50

P34 Base F requ enc y

Range: 30 - 400 [Hz]

Default:

60

Access Configurable

See Also:

P30, P33, F30-F38

The drive outputs its rated voltage to the motor at this frequency (enter motor

nameplate). See parameter F30 for custom V/Hz settings and V/Hz curve.

P35 Frequency Low Limit

Range: 0 - P36 [ Hz]

Default:

10.0

Access Configurable

See Also:

P36, F30-F38

Sets drive minimum steady state output frequency.

P36 Frequency High Limit

Range: 0 - 400 [Hz]

Default:

60.0

Access Configurable

See Also:

P35

Sets drive maximum steady state output frequency.

P37 Frequency Command

Range: 0 - 400 [Hz]

Default:

0.00

Access Tunable

This parameter manually sets the frequency that the drive is commanded to output.

Set the desired frequency and press ENTER/PROG to lock the value into memory. If

the drive is running, it will immediately accelerate or decelerate to this value once

enter is pressed. If the drive is not running, entering a value in P37 w ill pre-s et the

speed to accelerate to after a valid run command.

7-6 VS1MD AC Drive User Manual

Page 51

P38 Stop/Start Source

Range: 0

1

2

3

Default:

0 {Local OIM)

Access Configurable

See Also:

P40; t1 - t8

Sets the control used to start the drive.

0 Keypad Drive control for start, stop, forward and reverse are from

1Terminal

Operation

2 Drive is controlled from run terminal and directional

3 RS485

Communication

Terminal Operation Mode 1: (2-Wire or 3-Wire Control Fwd/Rev):

= Keypad

= Terminal Mode 1 (2 or 3- wire control for forward/reverse)

= Terminal Mode 2 (2 wire with direction switch)

= RS485 Communication

drive keypad.

Drive is controlled from run forward terminal and run

reverse terminal.

terminal.

Drive operation controlled using RS-485 communications

(see Appendix E).

• Select one digital input (t1~t8) = 0, run forward (FX).

• Select one digital input (t1~t8) = 1, run reverse (RX).

• To enable 3-Wire control select one digital input (t1~t8) = 17, 3-wire

operation.

• Drive stops when both inputs are off or when both inputs are on.

Drive Output

Forward

Digital In

(FX)

Reverse Digit al In (RX)

Parameter Descriptions 7-7

Page 52

P38 Stop/Start Source

Terminal Operation Mode 2: (2-Wire Control with Fwd/Rev Switch):

• Select one digital input (t1~t8) = 0, run forward (FX). Operates as a Run

Command

• Select one digital input (t1~t8) = 1, run reverse (RX). Operates as a

Direction Switch

• To enable 3-Wire control select one digital input (t1~t8) = 17, 3-wire

operation.

• Drive stops when both inputs are off or when both inputs are on.

Div e Output

Run Dig it al

In (FX)

(RX)

Dir ection Dig ital In (RX)

7-8 VS1MD AC Drive User Manual

Page 53

P39 Stop Type

Range: 0

Default:

Access Configurable

See Also:

Sets the active mode for all stop sources.

0 = Decelerate to Stop. Motor decelerates to 0 Hz and stops during the set

time.

)UHT

2SHUDWLQJ

FRPPDQG

= Decelerate to Stop (Ramp)

1

= DC Brake to Stop

2

= Coast to Stop

0

P38, P42, F8-F11

'HFHO

WLPH

1 = DC Brake to stop. See parameters F8 - F11 for further details.

2 = Coast to stop. Output frequency and voltage are shut down on a stop

command

)U HT 9ROWD JH

2SHUDWLQJ

FRPPDQG

Parameter Descriptions 7-9

Page 54

P40 Fre qu ency Setting Me thod

Range: 1

Default:

= Digi tal Keyp ad

2

= Analog V1 1: -10 - +10V

3

= Analog V1 2: 0 ~ +10 V

4

= Analog Te rmin al I: 0 - 20mA

5

= Analog Te rmin al V1 Mode 1+ Terminal I

6

= Analog Te rmin al V1 Mode 1+ Terminal I

7

= Analog RS485

1

Access Configurable

See Also:

t32-t33, F60

Sets the source of the speed reference to the drive.

1 = Keypad:Drive output frequency is set in the operation mode by pressing

the up/down keys. The drive immediately responds to the new setting

without pressing the enter key.

2 = Analog V1 Mode 1:Drive output frequency is set via a +/- 10V signal

applied to analog input terminal V1.

3 = Analog V1 Mode 2:Drive output frequency is set via a 4~20mA signal

applied to analog input terminal V1.

4 = Analog I:Drive output frequency is set via a 4~20mA signal applied to

analog input terminal I.

5 = Analog V1 Mode 1 + I:Drive output frequency is set via the sum of a

+/-10V signal applied to V1 and a 4~20mA signal applied to terminal I.

6 = Analog V1 Mode 2 + I:Drive output frequency is set via the sum of a

0~10V signal applied to V1 and a 4~20mA signal applied to terminal I.

7 = RS485:Drive output frequency is controlled via the RS485

communications port.

P41 Accel Time

P42 Decel Time

Range: 0 - 6,000 [sec]

Default:

Access Tunable

See Also:

Sets the Accel/Decel time of the drive. When using the multiple accel/decel

curves with preset speeds, this ramp serves as accel/decel time 0.

H71 can be used to scale the accel/decel units and H70 determines if the

time to accel/decel is relative to P35 (Frequency High Limit) or the delta

change of running frequency to set frequency.

P41 = 5.0, P42 = 10.0

P42, P36, H70, H71

7-10 VS1MD AC Drive User Manual

Page 55

P43 Preset Speed 1

P44 Preset Speed 2

P45 Preset Speed 3

Range: 0 - 400 [Hz]

Default:

P43 = 10, P44 = 20, P45 = 30

Access Tunable

See Also:

t1-t8, t10-t13

Provides an internal fixed speed command selectable by digital inputs.

P46 Drive Start/Stop Source 2

Range: 0 - 3 (see table for P38)

Default: 1 = Terminal Mo de 1

Access Configurable

See Also:

P38, t1-t8

Note: Only viewable when one of the t1-t8 terminals is set

for 22 and P38 = 3 (RS485 Communications).

When RS485 communica tions is used as the primary mode of controlling

the drive, this parameter serves as an alternate mode. It is selectable by a

digital input (t1-t8) = “22”.

P47 Frequency Setting Mo de 2

Range: 1-7 (see table for P40)

Default:

1 = Keypad

Access Configurable

See Also:

P40, P47, t1-t8

Note: Only viewable when one of the t1-t8 terminals is set

for 22 and P40 = 7 (RS485 Communications).

When RS485 communica tions is used as the primary mode of controlling

the drive, this parameter serves as an alternate mode. It is selectable by a

digital input (t1-t8) = “22”.

Parameter Descriptions 7-11

Page 56

7.4 Terminal Pa rameters

t0 Ju mp Code

Range: 0 - 81

Default: 0

Access Tunable

Sets the code to jump directly to a specfic parameter within the group.

t1 Digi tal Input 1 de fine ( I/O Termina l P1)

t2 Digi tal Input 2 de fine ( I/O Termina l P2)

t3 Digi tal Input 3 de fine ( I/O Termina l P3)

t4 Digi tal Input 4 de fine ( I/O Termina l P4)

t5 Digi tal Input 5 de fine ( I/O Termina l P5)

t6 Digi tal Input 6 de fine ( I/O Termina l P6)

t7 Digi tal Input 7 de fine ( I/O Termina l P7)

t8 Digi tal Input 8 de fine ( I/O Termina l P8)

Range: 0 =Forward Run Command

1 = Reverse Run Command

2 = Emergency Stop Trip

3 = Reset when a Fault occurs (RST)

4 = Jog Operation Command (2-wire only)

5 = Preset Speed Input - Bit 1

6 = Preset Speed Input - Bit 2

7 = Preset Speed Input - Bit 3

8 = Preset Speed Ramp - Bit 1

9 = Preset Speed Ramp - Bit 2

10 = Preset Speed Ramp - Bit 3

11 = DC Brake during start

12 = 2nd Motor Select

13 = Reserved

14 = Reserved

15 = Frequency increase (UP) Command

16 = Frequency decrease (DOWN) Command

17 = 3-wire operation

18 = External Trip: A Contact (EtA)

19 = External Trip: B Contact (EtB)

20 = Self-Diagnostic Function

21 = Exchange between PID operation and V/F operation

22 = Exchange between option (RS485) and Drive

23 = Analog Hold

24 = Accel/Decel Disable

25 = Up/Down Save Freq. Initialization

Default: t1 =0, t2 = 1 , t3 =2, t4=3, t5=4, t6=5, t7=6, t8=7

Access Tunable

Selects the function for the digital inputs.

7-12 VS1MD AC Drive User Manual

Page 57

0 = Forward Run (FX) Command: Select to define a digital input as a

forward run command in 2-wire or 3-wire control. For both 2-wire and

3-wire control, P38 – Drive Mode should be set to a 1 for normal operation.

For 3-wire control an additional terminal must be defined as 17 = 3-wire

operation.

1 = Reverse Run (RX) Command: Select to define a digital input as a

reverse run command in 2-wire or 3-wire control. For both 2-wire and