Page 1

Tier 2/3 Towable Generators

(Trailer and Skid Mounted)

(Diesel Liquid Cooled)

TS25, 35, 45, 60, 80, 130, 175, 250 and 400

Installation & Operating Manual

8/06 MN2417

Page 2

WARNING:

CALIFORNIA PROPOSITION 65 WARNING:

Engine exhaust from this product contains chemicals known

to the state of California to cause cancer, birth defects and

other reproductive harm.

WARNING:

CALIFORNIA PROPOSITION 65 WARNING:

Battery posts, terminals and related accessories are known to

the state of California to cause cancer, birth defects and other

reproductive harm.

Page 3

Table of Contents

Section 1

Product Safety Information 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Notice 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Responsibility 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IMPORTANT SAFETY INSTRUCTIONS 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Caution Statements 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 2

General Information 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 3

Receiving & Installation 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiving & Inspection 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lifting the Generator 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Location 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Secure the Generator 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hot Exhaust Gasses 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Connections 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Connections 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Connections 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Engine Oil and Battery Type 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Post Installation Checks 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 4

Operation 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Towing the Generator 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting the Proper Towing Equipment 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safe Driving Tips 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Checks 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Towing Instructions 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lug Nut Tightness 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trailer Setup 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Voltage Selection 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pre−Start Procedure 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Procedures 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Engine Controller Description 4-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarms 4-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inputs and Outputs 4-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Inputs 4-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setpoints 4-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 5

Troubleshooting and Maintenance 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Problems and Solutions 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A

Wiring Diagrams A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Diagrams A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents iMN2417

Page 4

ii Table of Contents MN2417

Page 5

Section 1

Product Safety Information

Safety Notice Be sure that you are completely familiar with the safe operation of this equipment. This

equipment may be connected to other machines that have rotating parts or parts that are

controlled by this equipment. Improper use can cause serious or fatal injury. Always

disconnect all electrical loads before starting the generator.

Installation and repair procedures require specialized skills with electrical generating equipment

and liquid cooled engine systems. Any person that installs or repairs this generator must have

these specialized skills to ensure that this generating unit is safe to operate. Seek expert advise

for repairs or any questions you may have about the safe installation and operation.

The precaution statements are general guidelines for the safe use and operation of this

generator. It is not practical to list all unsafe conditions. Therefore, if you use a procedure that is

not recommended in this manual you must determine if it is safe for the operator and all

personnel in the proximity to the generator and connected loads. If there is any question of the

safety of a procedure please seek expert advise before starting or stopping the generator.

This equipment contains high voltages. Electrical shock can cause serious or fatal injury. Only

qualified personnel should attempt the start−up procedure or troubleshoot this equipment.

This equipment may be connected to other machines that have rotating parts or parts that are

driven by this equipment. Improper use can cause serious or fatal injury. Only qualified

personnel should attempt the start−up procedure or troubleshoot this equipment.

− System documentation must be available to anyone that operates this equipment at all

times.

− Keep non-qualified personnel at a safe distance from this equipment.

− Only qualified personnel familiar with the safe installation, operation and maintenance

of this device should attempt start-up or operating procedures.

− Always stop engine before making or removing any connections.

− Always stop engine and allow it to cool before refueling.

Responsibility When your generator is delivered, it becomes the responsibility of the owner/operator of the

generator set to prevent unsafe conditions and operation of the equipment. Some

responsibilities include (but are not limited to) the following:

1. It is the responsibility of the owner/operator of this generator to ensure that this

equipment is correctly and safely installed.

2. It is the responsibility of the owner/operator of this generator to ensure that this

equipment, when installed fully complies with all federal, state and local codes.

3. It is the responsibility of the owner/operator of this generator to ensure that any person

operating this equipment has been properly trained.

4. It is the responsibility of the owner/operator of this generator to ensure that any person

operating this equipment has access to all manuals and information required for the

safe use and operation of this equipment.

5. It is the responsibility of the owner/operator of this generator to ensure that it is properly

maintained and safety inspected at regular scheduled intervals.

6. It is the responsibility of the owner/operator of this generator to ensure that any person

who has not been trained on the safe use of this equipment does not have access to

this equipment.

Read This Manual Thoroughly

If you do not understand any concept, any procedure, any safety warning statement, any safety

caution statement or any portion of this manual, seek expert advise. Make sure you understand

the information in this manual so that you can safely enjoy the full use of this generator.

Product Safety Information 1-1MN2417

Page 6

Symbols

This symbol is shown throughout the manual to indicate a connection to ground reference point.

Indicates a potentially hazardous situation which, if not avoided, could result in injury or death.

Indicates a potentially hazardous situation which, if not avoided, could result in injury or death.

Precaution Statements Used In This Manual

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in injury or

Caution: Indicates a potentially hazardous situation which, if not avoided, could result in damage to

Note: Additional information that is not critical to the installation or operation.

There are three classifications of precautionary statements used in this manual. The most critical

is a WARNING statement, then the Caution statement and the least critical is the Note

statement. The usage of each statement is as follows:

death.

property.

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS − This manual contains important instructions for the generator that

should be followed during installation, operation and maintenance of the generator.

For ease of reading, the Warning statements are divided into four categories: Operation, Burn, Installation,

and Maintenance.

Operation

WARNING: Never allow a person to ride in or on a trailer that is being towed. All states prohibit

passengers in towed vehicles. A person can fall off and be struck be another vehicle or run

over by the towed trailer. Failure to observe this warning can result in death.

WARNING: Before using a tow vehicle with a trailer mounted generator, verify that the vehicle is designed

for the load. Using a vehicle that is too small is very dangerous. Be certain that it can handle

the M.G.T.W. (Maximum Gross Trailer Weight) and the tongue weight for safe towing and

braking.

WARNING: For a new trailer, the wheel lug nuts should be tightened to the proper torque specification

before use, after 25 miles of operation and every 100 miles of operation thereafter. Failure to

check the lug nuts for proper tightness can result in an accident due to a wheel falling from

the trailer.

WARNING: Never operate a trailer or tow vehicle that has a loose, missing or broken lug nut. The trailer

is designed for safe operation with all lug nuts installed and all at the proper torque rating.

Operating the trailer with one or more broken or missing lug nuts greatly increases the load

on the remaining nuts and can cause failure of the remaining nuts that can result in an

accident due to a wheel falling from the trailer.

WARNING: Never operate this generator in a manner other than as described in this manual. Operation

in any manner not described in this manual should be considered unsafe and should not be

attempted. Never start the engine unless you have first verified that the installation and

operation of the generator are as described in this manual.

WARNING: Be sure that you are completely familiar with the safe operation of this equipment. This

equipment may be connected to other machines that have rotating parts or parts that are

controlled by this equipment. Improper use can cause serious or fatal injury.

WARNING: Exhaust fumes/gases are extremely dangerous and can cause severe illness or death. Never

breath exhaust fumes produced by a running engine. Only run the engine outdoors where

ventilation is plentiful. Exhaust gases contain carbon monoxide, a colorless, odorless and

extremely dangerous gas that can cause unconsciousness or death. Symptoms of carbon

monoxide poisoning include: dizziness, nausea, headaches, sleepiness, vomiting or

incoherence. If you or anyone else experiences these symptoms, get out into fresh air

immediately. Stop the engine and do not restart the engine until it has been inspected and if

necessary repaired or reinstalled in a well ventilated area.

WARNING: When operating this generator remain alert at all times. Never operate machinery when

physically or mentally fatigued, or while under the influence of alcohol, drugs or medication.

Continued on next page.

1-2 Product Safety Information MN2417

Page 7

Operation Warning Statements Continued

WARNING: Over crank indication can mean a loss of crank disconnect signal during the previous run

period. Attempting to restart the engine with no crank disconnect signal can destroy the

starter motor, which can cause serious personal injury.

WARNING: Hot exhaust gasses must never be directed toward anything that may catch fire or explode.

WARNING: This generator must not be used on or near any forest covered, brush covered, or grass

covered land unless the engine’s exhaust system is equipped with a spark arrestor. The

spark arrestor must be maintained in effective working order by the operator.

WARNING: Never operate the generator set indoors or in a poorly ventilated area such as a tunnel or cave.

Exhaust fumes are extremely dangerous to all personnel that are in or in contact with that area.

WARNING: Keep generator at least three feet away from buildings and other structures.

WARNING: Keep generator away from flammable or hazardous materials (trash, rags, lubricants,

explosives, paints etc.) and grass or leaf build up.

WARNING: Some parts of this generator rotate during operation. Rotating parts can present extreme

danger if clothing or body extremities are caught by the rotating part and can cause serious

or fatal injury. Never touch a part of the generator until the engine has been stopped and all

rotating parts are completely stopped. Also, disconnect the battery terminals to prevent

accidental engine rotation during servicing.

WARNING: Never move a generator set that is running. Loads should be connected and position secure

before starting the engine. Hazards are caused by moving a generator set that is running.

WARNING: Never connect or disconnect loads during operation. Always connect load circuits before

starting the engine and use external branch disconnects etc. to switch loads On/Off.

WARNING: High voltage is present whenever engine is running. Electrical shock can cause serious or

fatal injury. Never operate electrical equipment while standing in water, on wet ground or with

wet hands, feet or shoes or while barefoot.

WARNING: High voltage is present whenever the engine is running. Electrical shock can cause serious

or fatal injury. Always stop engine before connecting or disconnecting power cords or

external devices.

WARNING: Be sure that you understand how to stop the engine quickly in case of an emergency situation.

Become familiar with the controls and safety systems provided with this generator set.

WARNING: Always wear safety glasses with side shields and hearing protection when working near the

generator.

WARNING: Improper operation may cause violent motion of connected equipment. Be certain that

unexpected movement will not cause injury to personnel or damage to equipment.

WARNING: Never permit anyone to operate the generator without proper instructions. Be sure to keep a

copy of this manual with the generator so that all users can be properly informed of its safe

operation.

WARNING: Never allow children or pets to be in the area where the generator is running. The generator

and the equipment being powered by the generator may cause injury or death.

WARNING: Never operate the generator unless all guards, covers, shields and other safety items are

properly installed.

WARNING: Do not put hands, feet, tools clothing or other objects near rotating parts such as drive shaft,

pulley, belt etc. Rotating parts cause extremely dangerous situations because they can catch

loose clothing or extremities and cause serious or fatal injury.

WARNING: Never operate the engine when the air cleaner is removed. An engine backfire can cause

serious burns.

WARNING: Never “jump start” a generator to start the engine. If the battery charge is insufficient to start

the engine, charge or replace the battery and try to restart. Jump starting a battery can cause

the battery to explode and cause severe injury or death to anyone in the area.

WARNING: Do not smoke near generator during operation or when close to fuel source. LPG and natural

gas fuels are flammable and can cause fire, explosions, injury or death.

WARNING: Keep a fire extinguisher near the generator while generator is in use. An extinguisher rated

“ABC” by the National Fire Protection Association is appropriate.

Continued on next page.

MN2417

Product Safety Information 1-3

Page 8

Warning Statements Continued

Burn

WARNING: Parts of this generator are extremely hot during and after operation. To prevent severe burns,

do not touch any part of the generator until you have first determined if the part is hot. Wear

protective clothing and after use allow sufficient time for parts to cool before touching any

part of the generator.

WARNING: Do not touch the hot exhaust parts. In addition to a sever burn, the sudden involuntary jerk of

the hand or body part caused by contact with high voltage or a hot surface can result in injury

to yourself or others.

WARNING: Engine coolant is under pressure and is near the boiling point of water when engine is hot.

Do not open the coolant system until the engine has completely cooled. Hot coolant can

cause severe burns and other injuries. When engine is cool, coolant level can be checked.

Installation

WARNING: Disconnect the battery’s ground terminal before working in the vicinity of the battery or

battery wires. Contact with the battery can result in electrical shock when a tool accidently

touches the positive battery terminal or wire. The risk of such shock is reduced when the

ground lead is removed during installation and maintenance.

WARNING: Installation and repair procedures requires specialized skills with electrical generating

equipment and small engine systems. Any person that installs or performs repairs must have

these specialized skills to ensure that the generator set is safe to operate. Seek expert advise

for installation or repairs.

WARNING: Be sure all wiring complies with the National Electrical Code (NEC) and all regional and local

codes or CE Compliance. Improper wiring may cause a hazardous condition and exposure to

electrical hazards can cause serious injury or death.

WARNING: Be sure the system is properly grounded before applying power. Do not apply AC power

before you ensure that grounds are connected. Electrical shock can cause serious or fatal

injury. NEC requires that the frame and exposed conductive surfaces (metal parts) be

connected to an approved earth ground. Local codes may also require proper grounding of

generator systems.

WARNING: Place protective covers over all rotating parts such as drive shaft, pulley, belt etc. Rotating

parts cause extremely dangerous situations because they can catch loose clothing or

extremities and cause serious or fatal injury.

WARNING: Unauthorized modification of a generator set may make the unit unsafe for operation or may

impair the operation of the unit. Never start a generator set that has been modified or tampered

with. Be sure that all covers and guards are properly installed and that the unit is safe before

starting the engine. If you are unsure, seek expert advise before starting the engine.

WARNING: When moving the generator, use reasonable caution. Be careful where you place fingers and

toes to prevent injury “Pinch Points”. Never try to lift a generator without a hoist or lift means

because they are heavy and bodily injury may result.

Warning: Never connect this generator to the electrical system of any building unless a licensed

electrician has installed an approved transfer switch. The national electrical code (NEC)

requires that connection of a generator to any electrical circuit normally powered by means of

an electric utility must be connected by means of approved transfer switch equipment to

isolate the electrical circuit from the utility distribution system when the generator is

operating. Failure to isolate the electrical circuits by such means may result in injury or death

to utility power workers due to backfeed of electrical energy onto the utility lines.

WARNING: Circuit overload protection must be provided in accordance with the National Electrical Code

and local regulations.

WARNING: Check Ground Fault Circuit Interrupt (GFCI) receptacles monthly by using the “Test” and

“Reset” buttons.

WARNING: Only a professional experienced technician should install a fuel supply system. Diesel, LPG and

natural gas fuels are flammable and can cause fire, explosions, injury or death. Fuel supply lines

should be kept away from sharp objects to prevent rupture. Comply with all NFPA regulations

and local codes for shut−off valves, regulators, fuel line type, connectors etc.

WARNING: Have electrical circuits and wiring installed and checked by licensed electrician or qualified

technician. Electrical shock can cause serious or fatal injury.

Continued on next page.

1-4 Product Safety Information

MN2417

Page 9

Warning Statements Continued

WARNING: Incorrect installation of this generator set could result in property damage, injury or death.

Connection of the generator to its fuel source must be done by a qualified professional

technician or contractor.

WARNING: Never stand under or close to an object that is being hoisted or lift into position. Accidents

happen and if the object falls or tips over you or someone else could be crushed by the

weight of the object causing severe injury or death to to yourself or others. Always remain a

safe distance from the object and always wear protective head gear (hard hat).

Maintenance

WARNING: Before servicing the generator set, be sure to disconnect the battery terminals to prevent

accidental engine rotation or starting.

WARNING: Before cleaning, inspecting, repairing or performing any maintenance to the generator set,

always be sure the engine has stopped and that all rotating parts have also stopped. After

stopping, certain components are still extremely hot so be careful not to get burned.

WARNING: Before servicing the generator set, be sure to disconnect the glow plugs or spark plug wires

and the battery terminals to prevent accidental engine rotation or starting.

WARNING: Engine coolant is under pressure and is near the boiling point of water when engine is hot.

Do not open the coolant system until the engine has completely cooled. Hot coolant can

cause severe burns and other injuries. When engine is cool, coolant level can be checked.

WARNING: Inspect all wiring frequently and replace any damaged, broken or frayed wiring or wires with

damaged insulation immediately. Electrical shock can cause serious or fatal injury.

WARNING: Disconnect all electrical wires and load devices from generator power outlets before servicing

the generator. Electrical shock can cause serious or fatal injury. Always treat electrical

circuits as if they are energized.

WARNING: Check all fuel supply piping, and their connections monthly for fuel leaks. Diesel, LPG and

natural gas fuels are flammable and can cause fire, explosions, injury or death. If a leak is

found, replace only with approved pipe or components.

WARNING: A battery presents a risk of fire and explosion because they generate hydrogen gas.

Hydrogen gas is extremely explosive. Never jump start a battery, smoke in the area around

the battery or cause any spark to occur in the area around the battery.

WARNING: Do not mutilate the battery or dispose of a battery in a fire. The battery is capable of

exploding. If the battery explodes, electrolyte solution will be released in all directions.

Battery electrolyte solution is caustic and can cause severe burns and blindness. If

electrolyte contacts skin or eyes, immediately flush the area with water and seek medical

attention quickly.

WARNING: The battery electrolyte is a dilute sulfuric acid that is harmful to the skin and eyes. It is

electrically conductive and corrosive. If electrolyte contacts the skin, flush the area

immediately with water and wash it off using soap and water. If electrolyte contacts the eyes,

immediately flush the eye thoroughly with water and seek medical attention quickly.

WARNING: A battery presents a risk of electrical shock hazard and high short circuit current. Electrical

shock can cause serious or fatal injury. Never wear jewelry, watch or any metal objects when

in the area around the battery.

MN2417

Continued on next page.

Product Safety Information 1-5

Page 10

Caution Statements

Caution: Avoid installing the generator set beside heat generating equipment, or directly below water

or steam pipes or in the vicinity of corrosive substances or vapors, metal particles and dust.

Heat can cause engine problems to develop and unwanted substances can cause rust or

generator failure over time.

Caution: Do not apply high voltage to windings (do not start the generator) in a moisture−saturated

condition. Moisture can cause insulation breakdown, making it necessary to repair the

generator and consequent expense and loss of time.

Caution: Use only original equipment or authorized replacement parts. Using the correct parts will

assure continued safe operation as designed.

Caution: Do not support the generator from the top of the frame or enclosure.

Caution: Do not tamper with or change the engine speed. Engine speed is factory set to produce the

correct voltage and output frequency.

Caution: Never operate the engine without a muffler. The engine is designed to have the correct

exhaust components installed and operating without these components can present a fire

hazard, cause excessive exhaust gases and cause damage to engine. Inspect muffler

periodically and replace if necessary.

Caution: The Programmable Output Contacts selection must agree with the external control wiring

prior to energizing the controller. Failure to do so may cause severe equipment damage.

Caution: If a dead battery is suspected, remove the controller fuse, charge battery (or replace), and

then attempting starting. Damage to engine control may result from jump starting.

Caution: This generator must have a battery installed for operation. The battery is used during starting

and during operation. If engine operation is attempted while the battery is removed, damage

to the engine’s electrical components may result.

Caution: Large “Engine Compartment Doors” on each side of enclosure must remain closed during

operation. If doors remain open, engine will overhead due to insufficient air flow around

engine.

1-6 Product Safety Information

MN2417

Page 11

Section 2

General Information

Thank you for purchasing your Baldor Generator Set. This manual contains information you need to safely and efficiently

install and operate your generator set. During the preparation of this manual every effort was made to ensure the

accuracy of its contents. This manual describes only very basic engine information. A separate owner’s manual for the

engine is supplied with this unit for your use. Please refer to the engine manual for information relative to engine

operation, maintenance, recommendations and additional safety warnings.

Copyright Baldor 2006. All rights reserved.

This manual is copyrighted and all rights are reserved. This document may not, in whole or in part, be copied or

reproduced in any form without the prior written consent of Baldor Electric Company, Inc.

Baldor Generators have earned the reputation of being high quality and dependable. We take pride in this fact and

continue to keep our quality standards high on our list of priorities. We are also constantly researching new technological

ideas to determine if they could be used to make our generator sets even better.

Baldor makes no representations or warranties with respect to the contents hereof and specifically disclaims any implied

warranties of fitness for any particular purpose. The information in this document is subject to change without notice.

Baldor assumes no responsibility for any errors that may appear in this document.

Limited Warranty

Baldor will replace or repair free of charge any part or parts of the generator of their manufacture that are defective in

workmanship and materials for a period of time as set forth in the Warranty Period chart below. All Baldor products

requiring warranty service shall be transported or shipped freight pre−paid to a Baldor Generator repair facility.

Notification of the defect or problem, a description of the manner in which the Baldor generator is used, and the name,

address and telephone number of the customer requiring warranty service must be included. Baldor is not responsible for

removal and shipment of the Baldor product to the service center or for the reinstallation of the Baldor product upon its

return to the customer, or any incidental or consequential damages resulting from the defect, removal, reinstallation,

shipment or otherwise. Problems with Baldor products can be due to improper maintenance, faulty installation,

non−Baldor additions or modifications, or other problems not due to defects in Baldor workmanship or materials. If a

Baldor Generator repair facility determines that the problem with a Baldor product is not due to defects in Baldor

workmanship or materials, then the customer will be responsible for the cost of any necessary repairs. Genset engines

are covered under the engine manufacturers warranty. Proper engine maintenance is required. Any request for engine

warranty or repair should be made directly with the engine manufacturers warranty center. See engine manufacturers

data for applicable engine warranty periods and location of repair centers. This Limited Warranty and Service Policy

represents Baldor’s sole and exclusive warranty obligation with respect to Baldor products. Baldor’s liability to a customer

or any other person shall not exceed Baldor’s sales price of the applicable Baldor product. BALDOR DISCLAIMS ALL

OTHER EXPRESSED AND IMPLIED WARRANTIES INCLUDING THE IMPLIED WARRANTIES OF FITNESS FOR A

PARTICULAR PURPOSE AND MERCHANTABILITY.

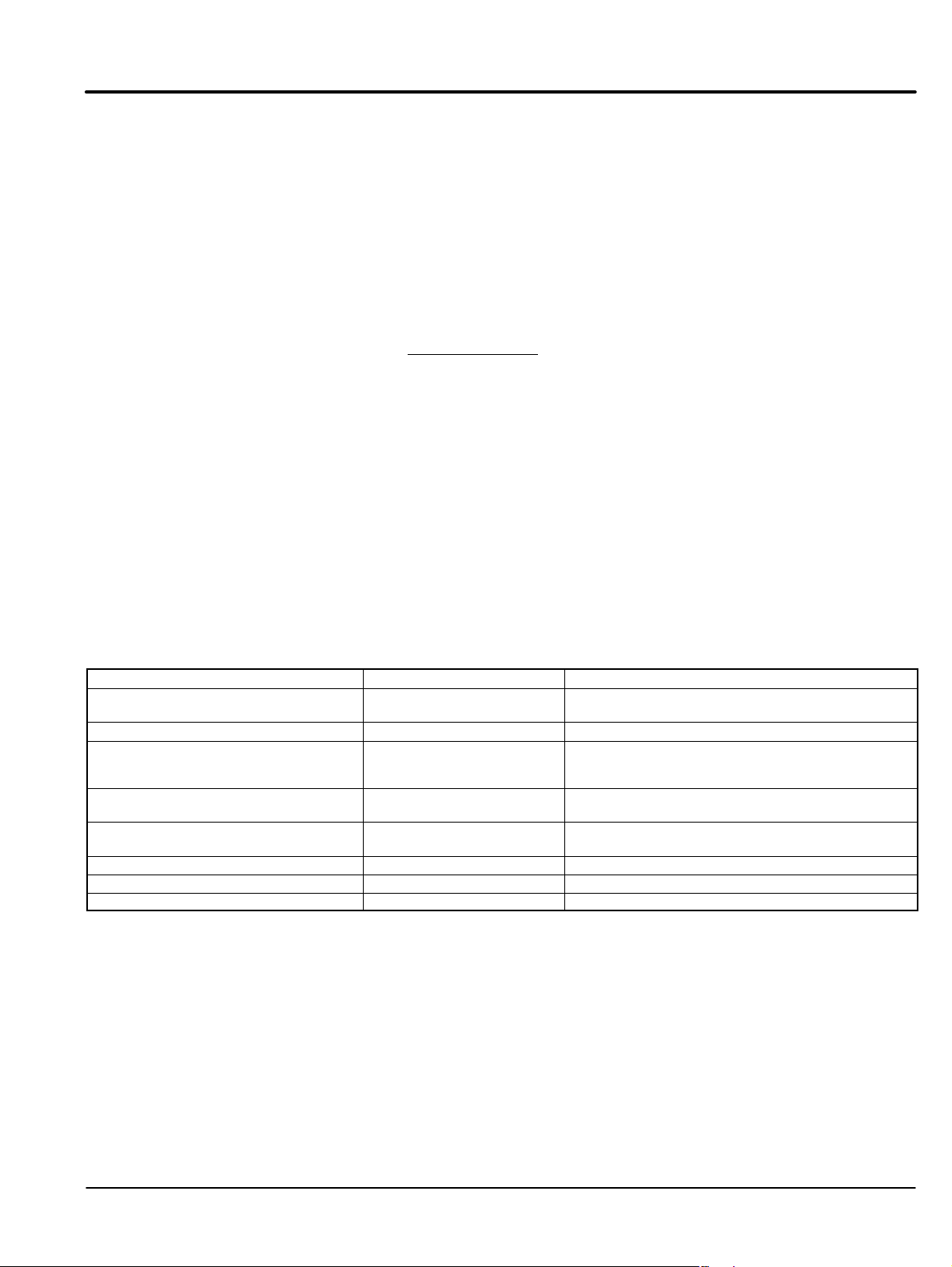

Warranty Period

Generator Series Labor* Parts

Portable Products (Premier, Powerchief,

3600 RPM Standby Systems

1800 RPM Standby Systems

(Some AE Models, DLC, GLC)

Industrial Standby Systems 1 Year or 1,000 Hours 2 Years or 1,000 Hours

Industrial Prime Power Systems 1 Year or 1,000 Hours 1 Year or 1,000 Hours

DG Series)

Towable Products (TS) 1 Year or 3,000 Hours 3 Years or 3,000 Hours

POW’R LITE Light Towers 1 Year or 3,000 Hours 3 Years or 3,000 Hours

1 Year or 1,000 Hours 3 Years or 1,000 Hours

(Some AE Models)

1 Year or 3,000 Hours 3 Years or 3,000 Hours

International 1 Year or 1,000 Hours 1 Year or 1,000 Hours

1 Year 3 Years

Light Fixture, Lamps and Ballasts are excluded

from any warranty coverage

*For products covered under labor coverage, travel expenses will be allowed up to 7 hours straight labor or 300 miles,

whichever occurs first, and only applies to permanently wired and mounted products (AE, DLC, GLC, IDLC).

You must save the purchase receipt. Proof of purchase, date, serial number and model number will be required for all

portable and Towable products to qualify for any warranty consideration.

A start−up inspection form/warranty registration must be completed in its entirety and submitted to Baldor Generators

within 30 days of start−up to qualify for any warranty consideration, excluding: Portables, Towables and Light Towers.

General Information 2-1MN2417

Page 12

2-2 General Information MN2417

Page 13

Section 3

Receiving & Installation

Receiving & Inspection When you receive your generator, there are several things you should do immediately.

1. Observe the condition of the shipping container and report any damage immediately to

the commercial carrier that delivered your system.

2. Verify that the part number of the system you received is the same as the part number

listed on your purchase order.

3. If the system is to be stored for several weeks before use, be sure that it is stored in a

location that conforms to published storage temperature and humidity specifications.

WARNING: Never stand under or close to an object that is being hoisted or lift into position. Accidents

happen and if the object falls or tips over you or someone else could be crushed by the

weight of the object causing severe injury or death to to yourself or others. Always remain a

safe distance from the object and always wear protective head gear (hard hat).

Lifting the Generator When lift or hoist equipment is used to lift the generator and move it to position, be careful not

to contact overhead wires or other obstacles. Be sure the lift or hoist equipment has appropriate

capacity and tires for the terrain to avoid becoming stuck or tipping over. If the shipping pallet is intact,

use a fork lift to move the generator. If the shipping pallet has been removed, use the “Lift Point”

hole at the top of the generator, Figure 3-1.

The lift point is designed only for the weight of the generator and factory trailer. Do not lift by these

points if the generator is mounted to a trailer that has been modified from the factory specifications

for stock units. Please consult Baldor for custom designs.

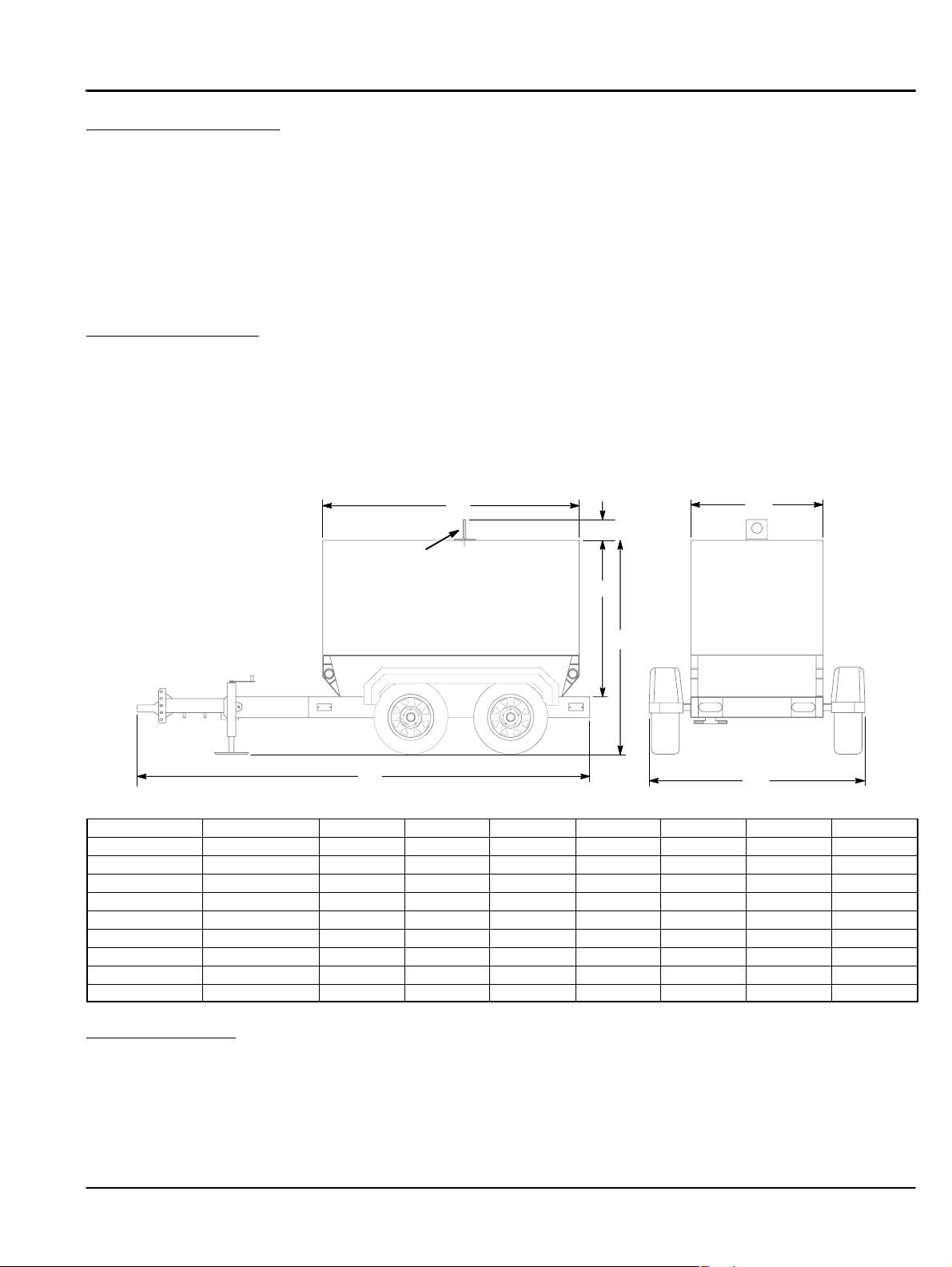

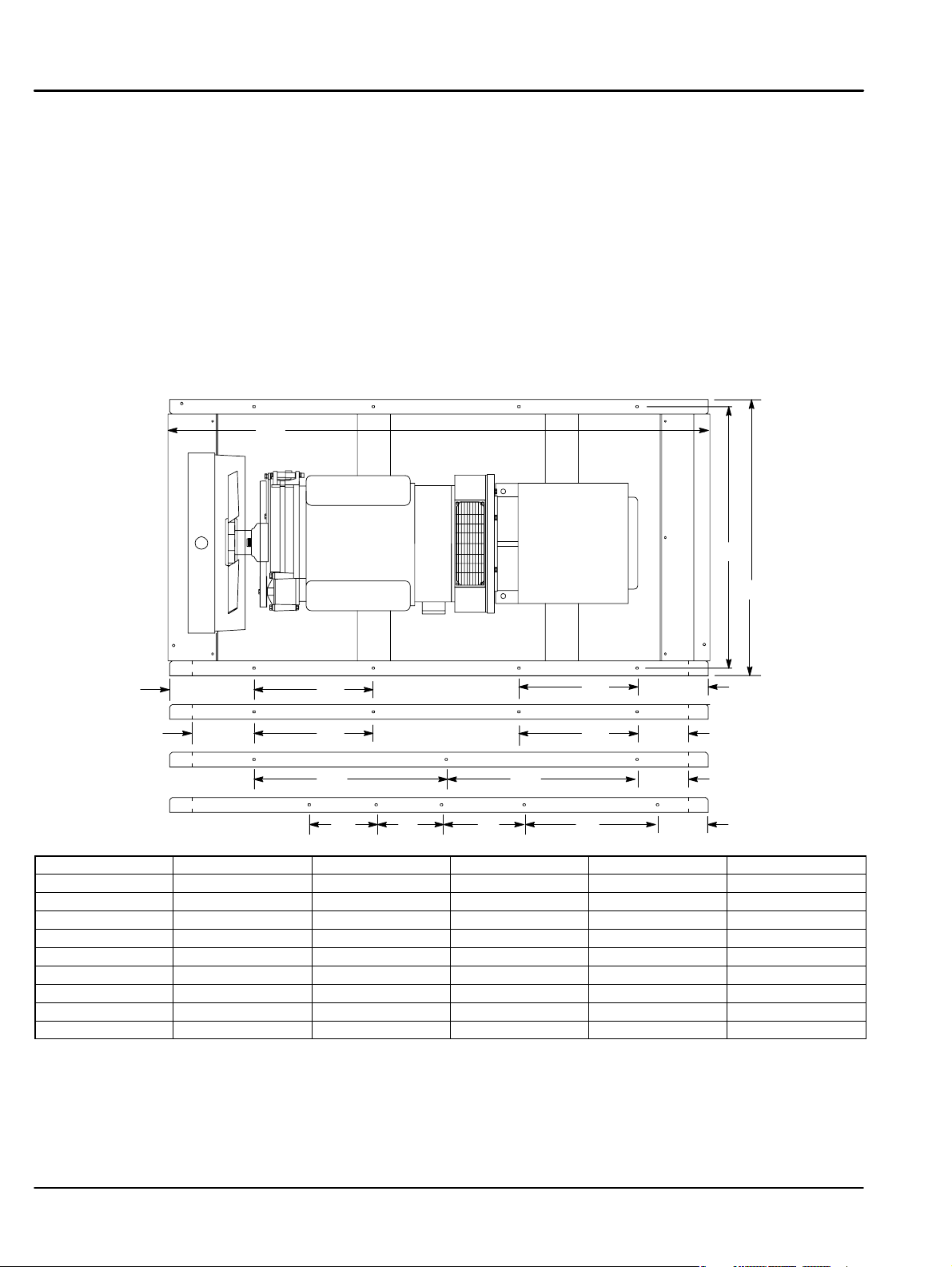

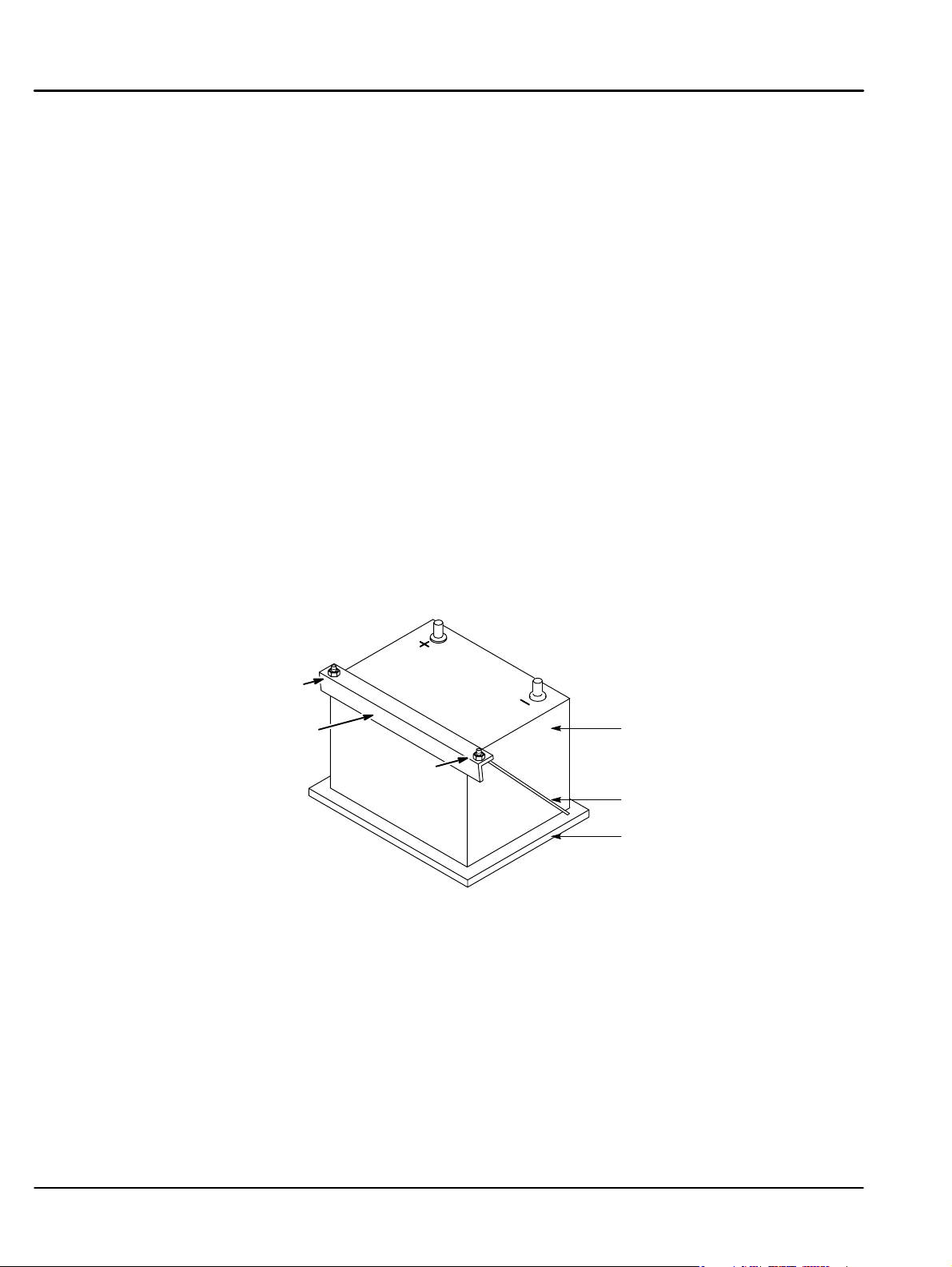

Figure 3-1 Generator Lifting

B1

A2

Lift Point

A1

A

B

C1

C

Table 3-1 Mounting Dimensions

Generator No. of Axles A A1 A2 B B1 C C1

TS25 1 67 47.5 5.5 130 74 62 38

TS35 1 67 47.5 5.5 130 74 62 38

TS45 2 82 60 5.5 146 84 62 38

TS60 2 82 60 5.5 146 84 62 38

TS80 2 76 55 5.5 146 84 62 38

TS130 2 88 68 6 180 118 75 42

TS175 2 88 68 6 180 118 75 42

TS250 2 102 76 7 218 159 82 54

TS400 2 126 93 5.22 251 195 98 66

Physical Location The mounting location of the system is important. It should be installed in an area that is

protected from direct harmful gases or liquids, dust, metallic particles, shock and vibration.

It should be installed in an outdoor location so the exhaust fumes are vented to the atmosphere.

When the Generator is installed outdoors

The factory installed enclosure is designed to keep out undesirable weather elements while

providing cooling and ventilation.

Receiving & Installation 3-1MN2417

Page 14

Several other factors should be carefully evaluated when selecting a location for installation:

1. For effective cooling and maintenance, the system should be mounted on a flat,

smooth, noncombustible level surface. A concrete pad is ideal and provides a secure

installation.

2. Installation should prevent water levels from reaching the generator. Drainage must be

adequate to keep concrete pad free from standing water.

3. Installation should prevent obstructions by buildup of leaves, grass, sand, snow, etc. If

these items pose a problem, consider building a small fence or other break to protect

the unit from accumulation of debris.

4. Installation should place the generator as close as possible to the transfer switch.

5. At least forty−eight (48) inches clearance must be provided on all sides for air flow.

6. Access must be provided to allow the enclosure covers to be opened or removed for

service and maintenance.

7. Maximum Ambient temperature is 122°F (50°C).

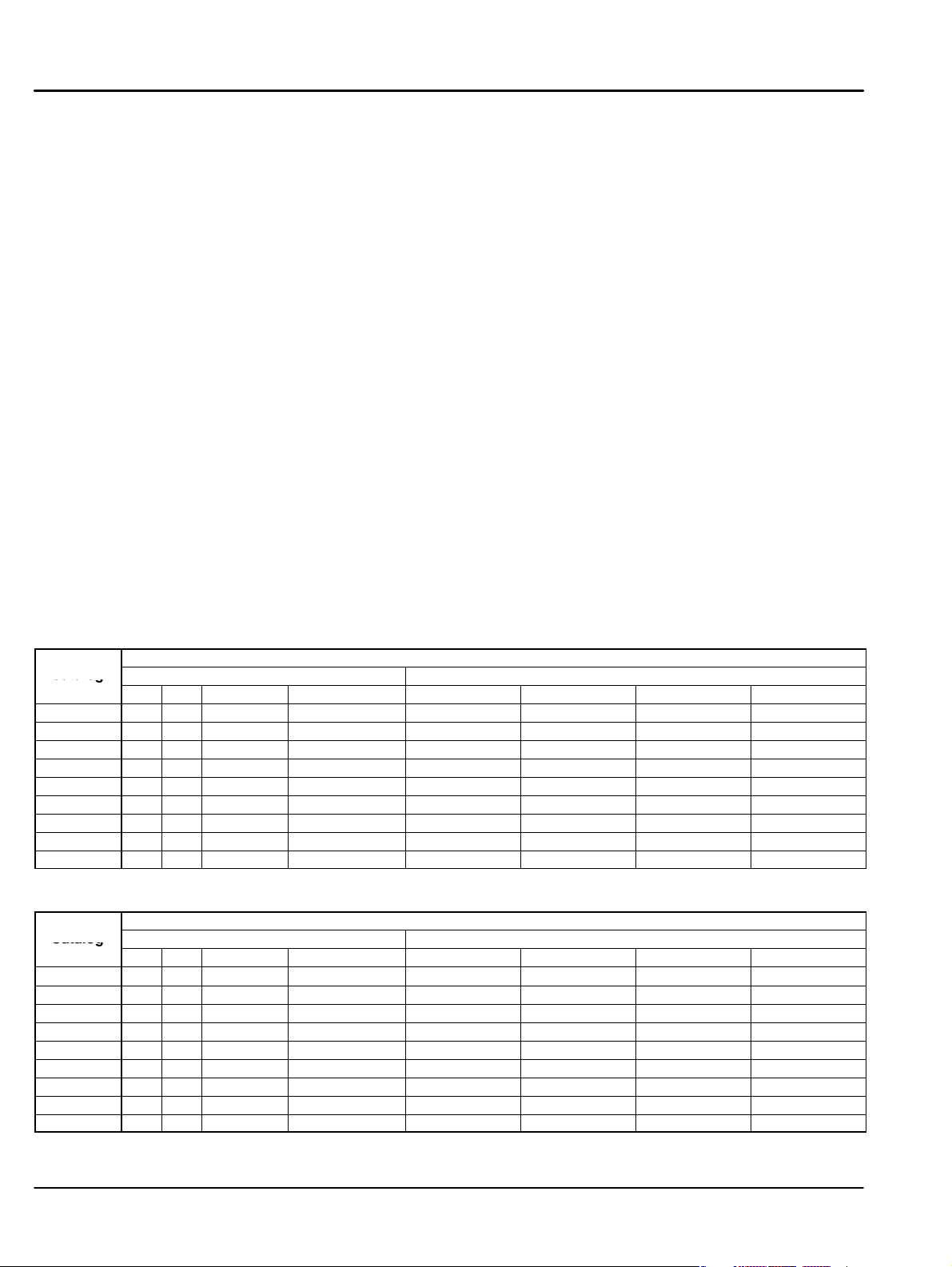

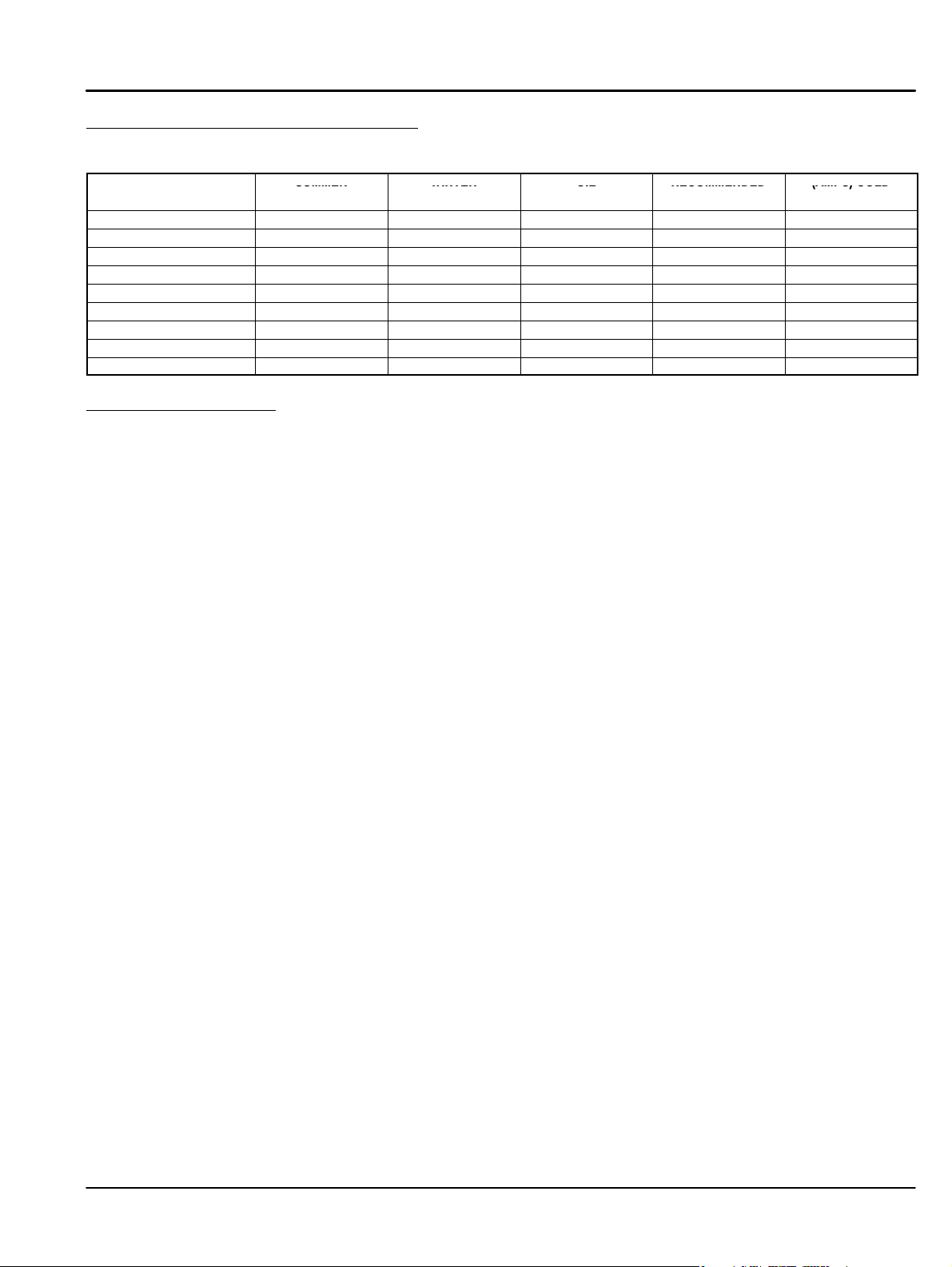

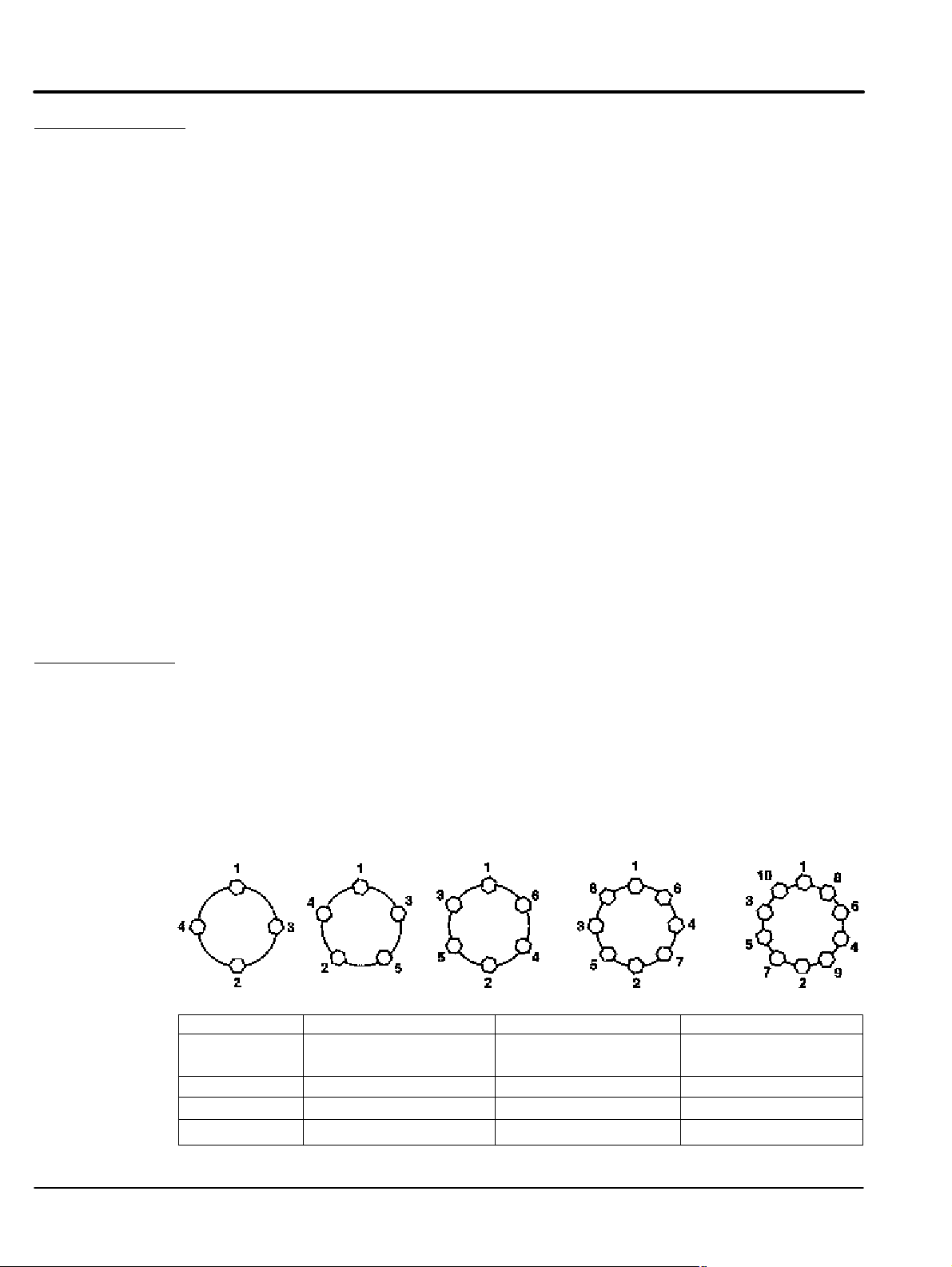

Figure 3-2 Generator Mounting (Skid)

A

B1

Holes each side

TS250 only

(4 Holes)

TS130/175 only

(4 Holes)

TS25/45/80 only

(3 Holes)

TS400 only

(6 Holes)

TA0000C10

BA0236A00

BA0236A02

10.85401−G10

A2A1

A2A1

212427

A2 A1

A2 A1

A1A2 A2

Table 3-2 Mounting Dimensions

Generator A A1 A2 B B1

TS25 74 8.12 23.81 38 36

TS35 74 8.38 28.56 38 36

TS45 84 8.38 28.56 38 36

TS60 84 8.38 28.56 38 36

TS80 84 8.38 28.56 38 36

TS130 118 16.57 26.57 42 40

TS175 118 16.57 26.57 42 40

TS250 159 18.00 40.00 54 52

TS400 195 12.00 See Figure 3-2 66 63

Secure the Generator (Skid Mount only)

Six mounting bolts (eight for TS130/175/250) in the base frame secure the generator to the

shipping pallet. Remove these bolts, lift the generator and remove the shipping pallet. Secure

the generator to the concrete pad using anchor hardware (not provided) in the base frame

mounting holes (holes are 0.66” diameter). See Figure 3-2 and Table 3-2. Anchor bolts must be

long enough to extend through the generator mounting frame.

B

A148

3-2 Receiving & Installation MN2417

Page 15

Hot Exhaust Gasses

WARNING: Exhaust fumes/gases are extremely dangerous and can cause severe illness or death. Never

breath exhaust fumes produced by a running engine. Only run the engine outdoors where

ventilation is plentiful. Exhaust gases contain carbon monoxide, a colorless, odorless and

extremely dangerous gas that can cause unconsciousness or death. Symptoms of carbon

monoxide poisoning include: dizziness, nausea, headaches, sleepiness, vomiting or

incoherence. If you or anyone else experiences these symptoms, get out into fresh air

immediately. Stop the engine and do not restart the engine until it has been inspected and if

necessary repaired or reinstalled in a well ventilated area.

WARNING: Hot exhaust gasses must never be directed toward anything that may catch fire or explode.

Exhaust must always be directed away from living areas or buildings that are occupied by people

or animals. Never allow exhaust gases to be directed towards any openings or air entry routes

(doors, windows, vents, etc...) of an occupied building.

The direction of the discharged hot air and hot exhaust gases is important as they have the

potential to create brown spots on the lawn or shrubs. In extreme cases this extremely hot air

could cause dried grass, shrubs, trees or other debris to ignite.

It is also recommended that an exhaust rain cap be used whenever it is possible that rain could

get into the system. This will help to prevent corrosion and damage to the exhaust system and

engine.

Installation The generator is completely assembled, tested and adjusted at the factory before it is shipped.

The procedures presented in this manual are suggestions and it is the responsibility of the

Owner/Operator to arrange for these procedures to be performed by licensed contractors

according to all applicable codes including local codes for your Municipality/City/County and

State. External connections required at the time of installation are:

1. Electrical Connections − power wiring (optional transfer switch) and control wiring.

2. Ground Connection.

After installation, the post installation checks must be performed prior to starting the engine.

After these checks have been performed and the system operation is verified to be good, refer to

Section 5 Maintenance for periodic checks that must be performed at scheduled intervals to

ensure continued operation with minimal problems.

WARNING: Disconnect the battery’s ground terminal before working in the vicinity of the battery or

battery wires. Contact with the battery can result in electrical shock when a tool accidently

touches the positive battery terminal or wire. The risk of such shock is reduced when the

ground lead is removed during installation and maintenance.

Fuel Connections

External fuel connections are not required. A self contained fuel tank is located within the base

of the generator set.

MN2417

Receiving & Installation 3-3

Page 16

Electrical Connections Class 1 wiring methods must be used for field wiring connections to terminals of a class 2

Generator

Catalog

Generator

Catalog

circuit. It is the responsibility of the owner/operator to arrange for these procedures to be

performed by a licensed electrical contractor and ensure conformance to all applicable codes

including local codes peculiar to your municipality/city/county and state. Wire size and insulation

type should be as required by NEC (National Electrical Code) and local codes.

Warning: Never connect this generator to the electrical system of any building unless a licensed

electrician has installed an approved transfer switch. The national electrical code (NEC)

requires that connection of a generator to any electrical circuit normally powered by means of

an electric utility must be connected by means of approved transfer switch equipment to

isolate the electrical circuit from the utility distribution system when the generator is

operating. Failure to isolate the electrical circuits by such means may result in injury or death

to utility power workers due to backfeed of electrical energy onto the utility lines.

Warning: Incorrect installation of this generator set could result in property damage, injury or death.

Connection of the generator to its fuel source must be done by a qualified professional

technician or contractor.

WARNING: Be sure the system is properly grounded before applying power. Do not apply AC power before

you ensure that grounds are connected. Electrical shock can cause serious or fatal injury. NEC

requires that the frame and exposed conductive surfaces (metal parts) be connected to an

approved earth ground. Local codes may also require proper grounding of generator systems.

Intended Use The intended purpose of this generator set is to provide electrical power when the main utility power

supply is interrupted. Therefore, it is important that all the wiring that connects the generator set with

your house, transfer switch, distribution box, battery charger, etc. be properly installed.

Protection Single Phase circuit protection is provided within the generator. The power output connections

are rated and sized according to the KW of the generator. Proper lead wire from these points to

the automatic transfer switch (or load switching device) is mandatory. See transfer switch

information for corresponding generator input terminals.

Three phase circuit protection is provided by the generator. When connecting the generator

output to an electrical load, a UL listed circuit breaker with the appropriate ratings shall be

provided within 25 feet of the Genset. Use only copper wires.

Table 3-3 Standby Power Ratings

Generator

Catalog

No.

TS25 18 18 240/120 75/2x75 25/25/25 20/20/20 208/240/480 69/60/30

TS35 25 25 240/120 104/2x104 37/37/37 30/30/30 208/240/480 104/90/45

TS45 27 27 240/120 112/x2112 46/46/48 37/37/38 208/240/480 128/111/57

TS60 43 43 240/120 179/2x179 60/60/61 48/48/49 208/240/480 166/144/73

TS80 45 45 240/120 187/2x187 72/72/81 58/58/65 208/240/480 201/174/97

TS130 70 70 240/120 291/2x291 131/131/134 105/105/107 208/240/480 364/315/160

TS175 100 100 240/120 416/2x416 169/169/175 135/135/140 208/240/480 468/405/210

TS250 175 175 240/120 729/2x729 250/250/250 200/200/200 208/240/480 693/601/300

TS400 250 250 240/120 1041/2x1041 400/400/400 320/320/320 208/240/480 1110/962/481

* Example 2x75 means 2 lines (Line to Neutral) of 120V @ 75 amps each.

kVA kW Volts Amps * kVA kW Volts Amps

1 Phase 3 Phase

Electrical Load Capacity Standby Power Ratings

Table 3-4 Prime Power Ratings

Generator

Catalog

No.

TS25 18 18 240/120 75/2x75 23/23/23 18/18/18 208/240/480 62/54/27

TS35 22 22 240/120 91/2x91 33/33/33 27/27/27 208/240/480 93/81/40

TS45 25 25 240/120 104/2x104 44/44/44 35/35/35 208/240/480 121/105/52

TS60 40 40 240/120 166/2x166 56/56/56 45/45/45 208/240/480 156/135/67

TS80 43 43 240/120 179/2x179 69/69/75 55/55/60 208/240/480 190/165/90

TS130 66 66 240/120 275/2x275 119/119/121 95/95/97 208/240/480 329/285/145

TS175 95 95 240/120 395/2x395 156/156/159 125/125/127 208/240/480 433/375/190

TS250 160 160 240/120 666/2x666 227/227/227 180/180/180 208/240/480 624/541/270

TS400 240 240 240/120 1000/2x1000 365/365/365 292/292/292 208/240/480 1013/878/439

* Example 2x75 means 2 lines (Line to Neutral) of 75 amps each.

kVA kW Volts Amps * kVA kW Volts Amps

1 Phase 3 Phase

Electrical Load Capacity Prime Power Ratings

3-4 Receiving & Installation

MN2417

Page 17

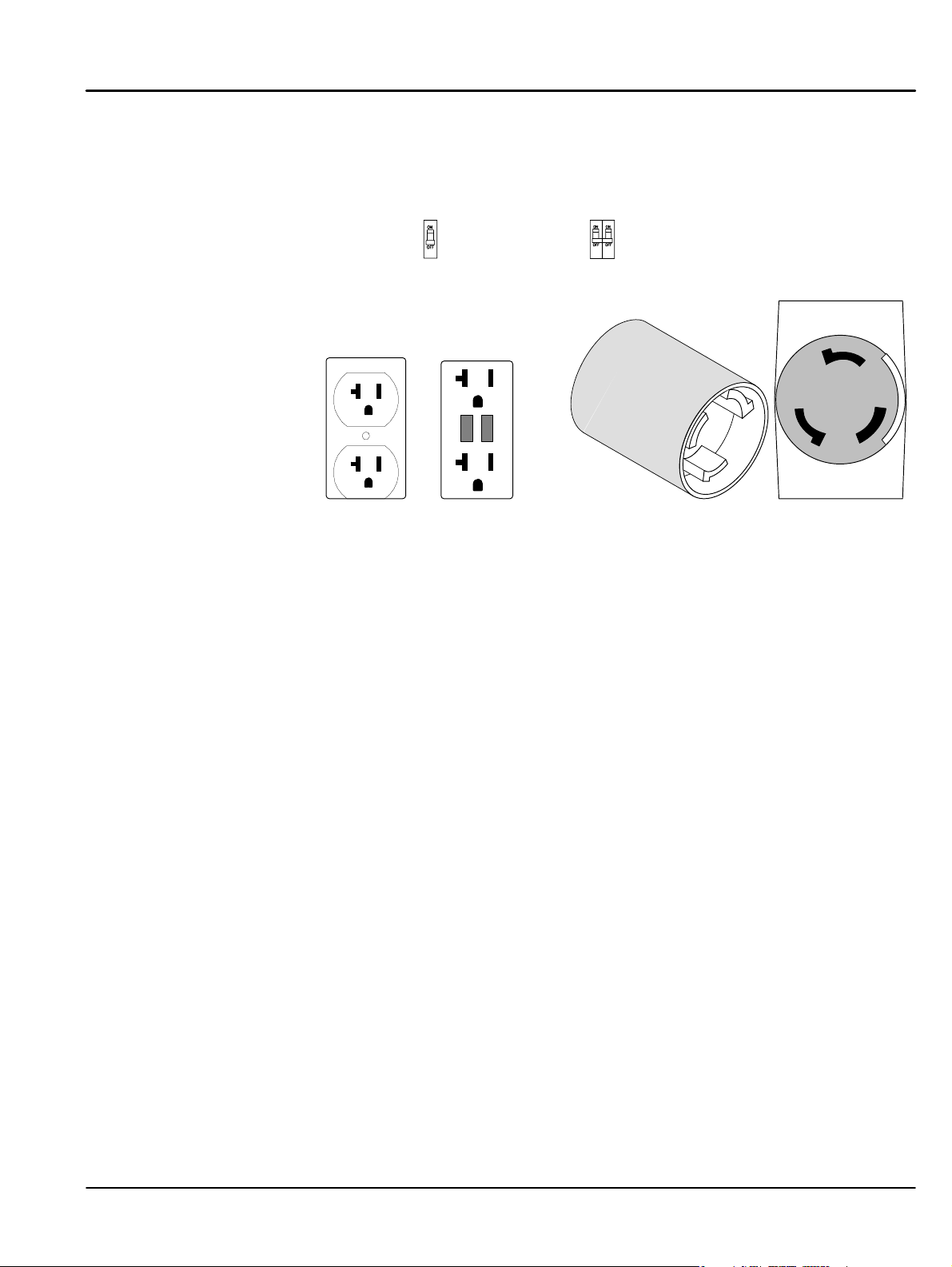

Single Phase Connections

Single phase connections are made at load receptacles located by the operator panel, see

Figure 3-3. Simply open the rear panel access door and make the connections. When the panel

door is closed, the connections are weather tight.

Single phase power is

always available.

Figure 3-3 Receptacle Panel (Single Phase)

Circuit Breakers (Single or Double pole)

Single pole breaker

for 120VAC outlets

Reset

Test

Double pole breaker

for 240VAC outlets

CS6365N

Circuit Breakers provides protection on some

units. To reset a breaker, place it in the OFF

then the ON position.

(GOLD)

X

X

CS6369

125/250V

50A

Y

W

G

(GOLD)

Y

(SILVER)

W

STD Outlet

120V, 20A

GFI Outlet

120V, 20A

240V, 50A

MN2417

Receiving & Installation 3-5

Page 18

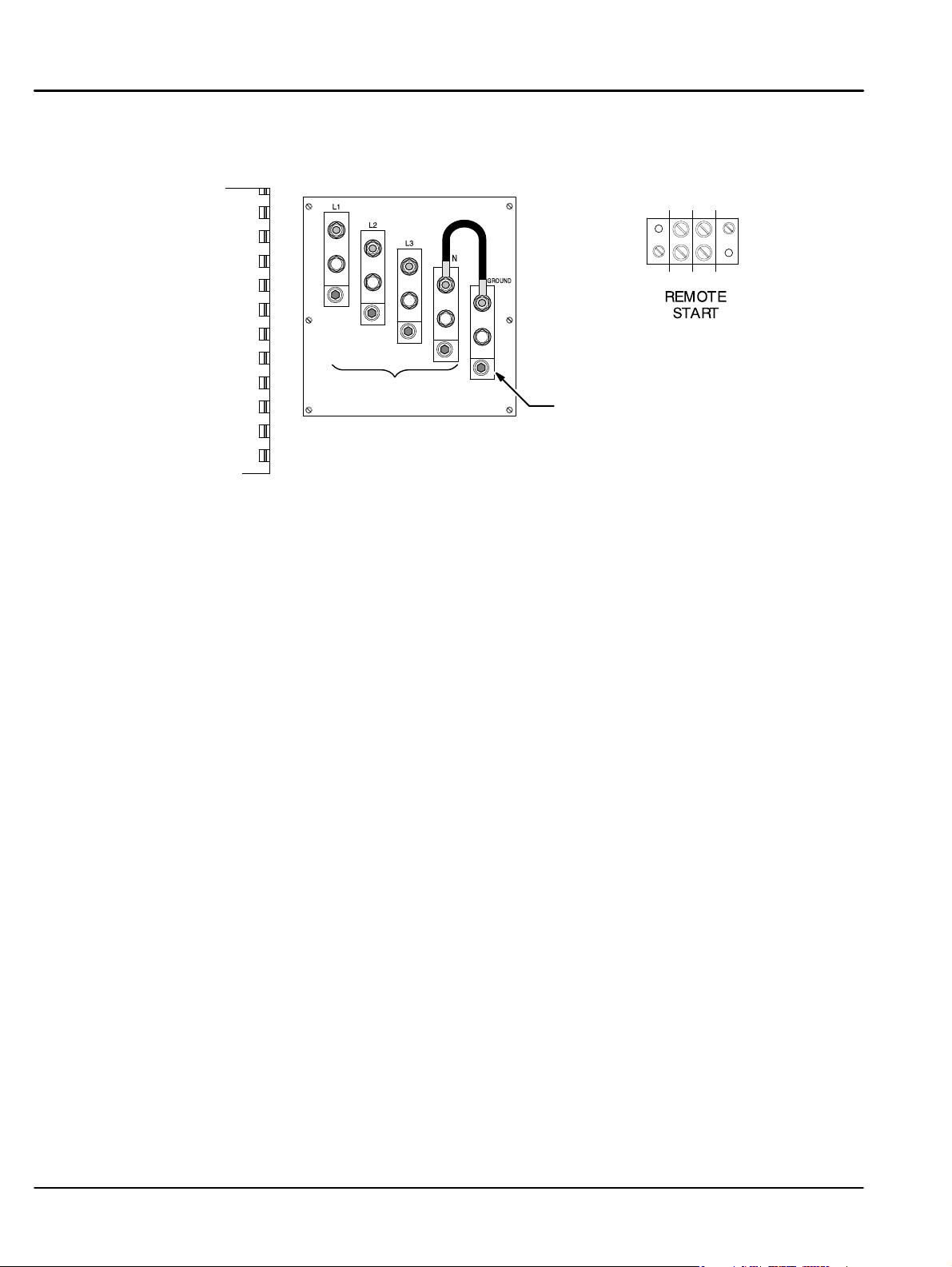

Three Phase Connections

Three phase connections are made at L1, L2, L3 and N connections shown in Figure 3-4.

For power to be applied to these

terminals, the Output Voltage Selector

Switch must be in the 120/208V,

120/240V or 277/480V positions.

Figure 3-4 Three Phase and Remote Start Connections

RR1 RR2

Remote Start Connections

Customer Connections

L1, L2, L3 and N

Earth Ground Connection

(Connect to Driven Earth Ground Rod)

Transfer Switch Considerations

The following are general considerations for the safe use of a transfer switch:

1. The transfer switch should be located inside the building near the main breaker box or

the disconnect box.

2. The transfer switch must be kept away from any location that might allow water to get

on it.

3. If the transfer switch is mounted outside, it must be protected from the environment and

it’s elements.

4. Do not mount the transfer switch on the generator set.

5. Do not mount the transfer switch where flammable liquids or vapors are present.

Remote Start Contacts

This two−wire connection will start and stop the generator, when properly connected to a remote

start contact, shown in Figure 3-4. These contacts RR1 and RR2 are connected to the “Engine

Start Contacts” of the automatic transfer switch. A two pole normally open, closed to operate

switch may also be used to start the generator.

Shore Power Use extension cord with appropriately sized conductors to connect the optional “Shore Power”

receptacle to 120VAC (240VAC for TS400) single phase utility power. This powers battery

chargers, block heaters etc. when the generator is not in operation. A single phase 20 amp

breaker is provided for circuit protection.

AC Input These connections are for units with float type battery charger or engine block heater. A

constant supply of 120 volts AC (or as specified) is needed at these terminals to power these

devices when generator is not operating.

Note: Power is not required when the unit is in operation. Internal battery charging and radiant

heat during operation eliminate the need for these devices.

Battery Charger Considerations

1. Mount the battery charger inside the generator enclosure as close to the battery as is

reasonably possible.

2. Do not mount the battery charger where flammable liquids or vapors are present.

When the battery is charging it produces explosive gasses.

General Wiring Considerations

1. When routing the interface wiring, do not route it up against anything that could cut or

chafe the wiring. do not route the wire up against any hot or potentially hot object.

2. Make sure that all the electrical components (generator set, transfer switch, battery

charger, etc.) share a common ground.

3. Check with your local building inspector to determine what you must do to comply with

the local regulations for grounding of this type of permanent installation.

3-6 Receiving & Installation

MN2417

Page 19

Frame Ground Connection

WARNING: Be sure the system is properly grounded before applying power. Do not apply AC power

before you ensure that grounds are connected. Electrical shock can cause serious or fatal

injury. NEC requires that the frame and exposed conductive surfaces (metal parts) be

connected to an approved earth ground. Local codes may also require proper grounding of

generator systems.

It is important for safety reasons that the Generator set, transfer switch and battery charger share

a common Ground and neutral.

The NEC requires that the frame and exposed metal surfaces be at local ground reference

potential to avoid electrical shock hazard. A local ground reference may require a driven earth

ground conductor at the generator installation site. Make the ground connection as shown in

Figure 3-4. Use the appropriate size wire as required by NEC and local codes.

1. Open the enclosure electrical access panel door.

2. Connect the ground wire to the “earth ground connection” terminal shown in Figure 3-4.

This is the local ground reference to ground the generator enclosure and frame.

Battery Connections The generator is shipped with no battery installed.

Caution: This generator must have a battery installed for operation. The battery is used during starting

and during operation. If engine operation is attempted while the battery is removed, damage

to the engine’s electrical components may result.

WARNING: Installation and servicing of batteries is to be performed or supervised by personnel

knowledgeable of batteries and the required precautions. Keep unauthorized personnel away

from batteries.

WARNING: Do not dispose of battery or batteries in a fire. The battery is capable of exploding. If the

battery explodes, electrolyte solution will be released in all directions. Battery electrolyte

solution is caustic and can cause severe burns and blindness. If electrolyte contacts skin or

eyes, immediately flush the area with water and seek medical attention quickly.

WARNING: Do not mutilate the battery . The battery contains electrolyte solution which is caustic and

can cause severe burns and blindness. If electrolyte contacts skin or eyes, immediately flush

the area with water and seek medical attention quickly.

WARNING: A battery presents a risk of electrical shock hazard and high short circuit current. The

following precautions are to be followed when working on batteries:

1. Remove watches, rings, necklaces and all other metal objects.

2. Use tools with insulated handles.

3. Wear safety goggles, rubber gloves and boots.

WARNING: The battery electrolyte is a dilute sulfuric acid that is harmful to the skin and eyes. It is

electrically conductive and corrosive. The following precautions are to be followed when

working on batteries:

1. Wear full eye protection (safety glasses or goggles) and protective clothing.

2. Where electrolyte contacts the skin, flush the area immediately with water and wash it

off using soap and water.

3. Where electrolyte contacts the eyes, immediately flush the eye thoroughly with water

and seek medical attention quickly.

4. Spilled electrolyte is to be washed down with an acid neutralizing agent. A common

practice is to use a solution of one pound (500 grams) bicarbonate of soda to one

gallon (four liters) of water. the bicarbonate solution is to be added until evidence of

reaction (foaming) has ceased. The resulting liquid is to be flushed with water and the

area dried.

MN2417

Receiving & Installation 3-7

Page 20

WARNING: A battery presents a risk of fire because they generate hydrogen gas. Hydrogen gas is

extremely explosive. Never jump start a battery, smoke in the area around the battery or

cause any spark to occur in the area around the battery. The following precautions are to be

followed when working on batteries:

1. Do not smoke when near batteries.

2. Do not cause flame or spark in battery area.

3. Discharge static electricity from body before touching batteries by first touching a

grounded metal surface.

WARNING: Disconnect the battery’s ground terminal before working in the vicinity of the battery or

battery wires. Contact with the battery can result in electrical shock when a tool accidently

touches the positive battery terminal or wire. The risk of such shock is reduced when the

ground lead is removed during installation and maintenance.

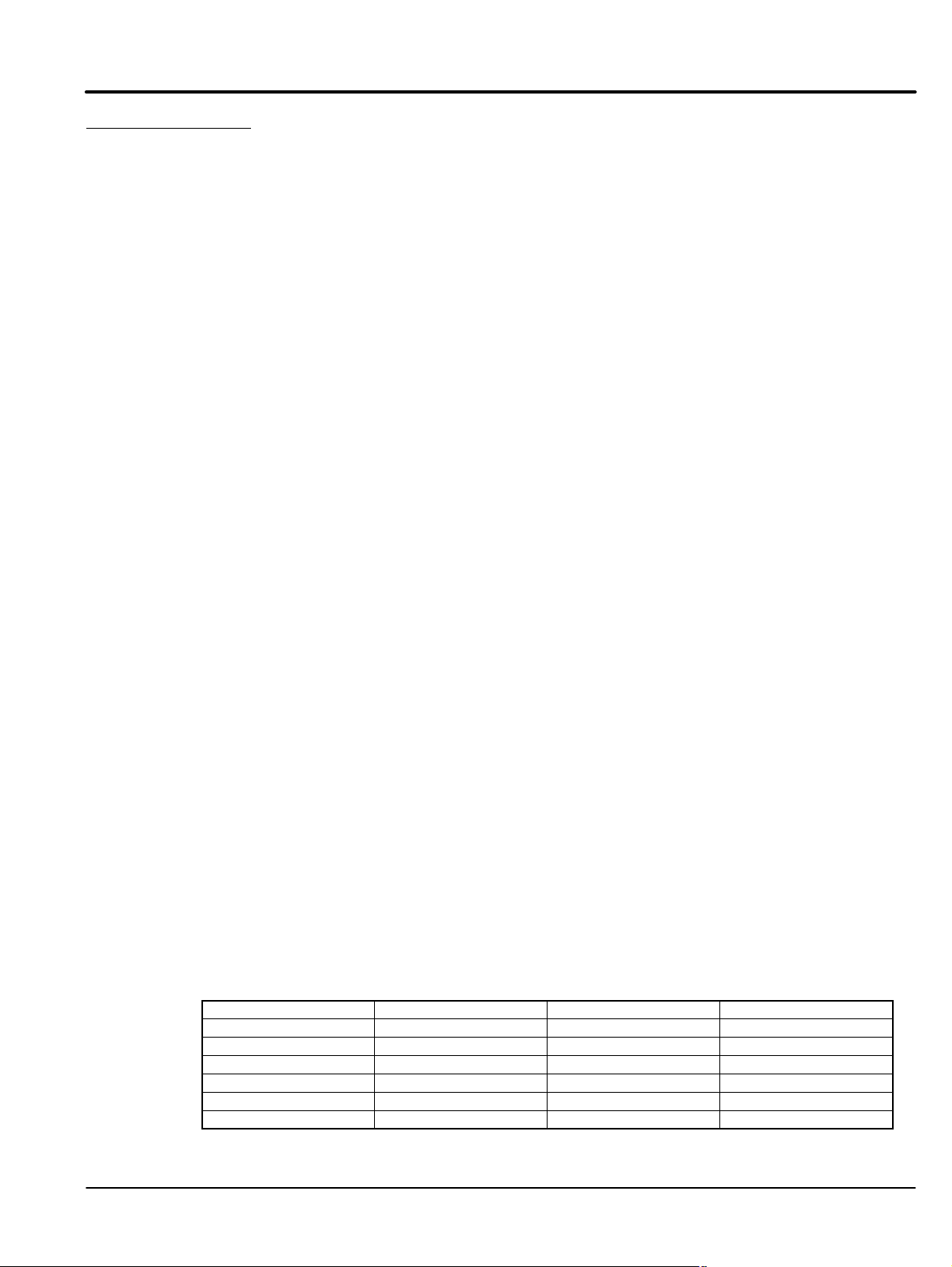

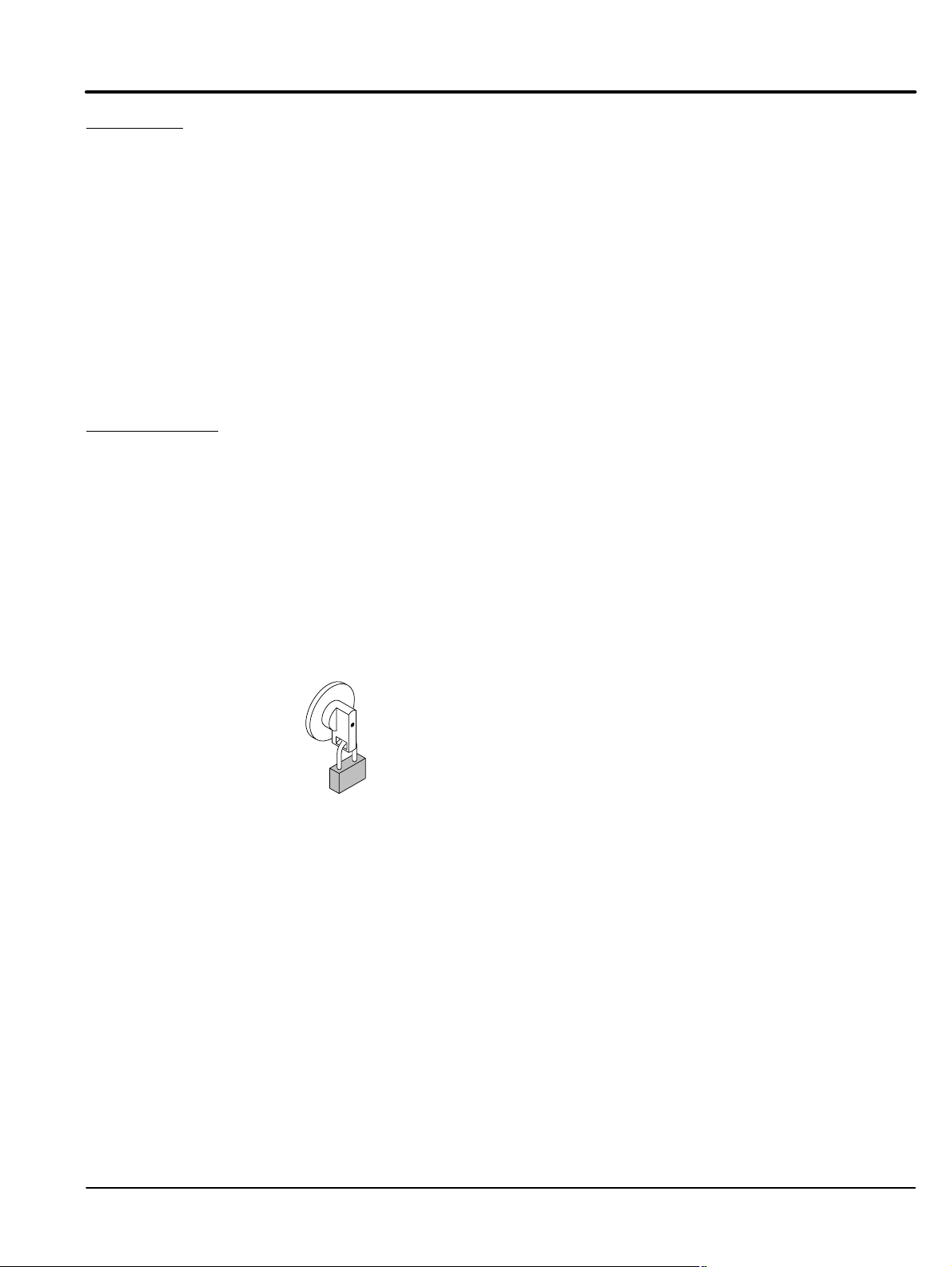

Procedure: The correct type battery must be installed in the battery compartment provided, see Table 3-5.

Installation and servicing of batteries is to be performed or supervised by personnel

knowledgeable of batteries and the required precautions.

Keep unauthorized personnel away from batteries.

1. Open access doors and locate battery tray.

2. Remove battery cables from the battery, the (−) negative first then the (+) positive.

3. Remove the Battery Hold Down Bar and Rods.

4. Remove the old battery and place the correct new battery (see Table 3-5) on the tray.

5. Install the Battery Hold Down Bar and Rods as shown in Figure 3-5.

a. Place the bent end of the Battery Hold Down Rod through the hole in the Battery Tray.

b. Place the threaded end of the Battery Hold Down Rod through the hole in the

Battery Hold Down Bar and secure with flat washer, lock washer and nut.

c. Repeat steps a and b for the other Battery Hold Down Rod.

Figure 3-5 Battery Installation

Washers & Nut

Battery Hold Down Bar

(Install away from terminals)

6. Connect the positive lead to the positive (+) battery terminal.

7. Connect the negative lead to the negative (−) battery terminal.

8. Do not lay tools or metal parts on top of batteries.

9. Connect charging source to the battery terminals.

10. Disconnect the battery’s ground terminal before working in the vicinity of the battery or

battery wires. Contact with the battery can result in electrical shock when a tool

accidently touches the positive battery terminal or wire. The risk of such shock is

reduced when the ground lead is removed during installation and maintenance.

The + and − terminals of your battery may

be different than shown. Be sure that the

Positive lead is connected to the positive

(+) terminal of your battery.

Battery

Washers & Nut

Battery Hold Down Rod

Battery Tray

3-8 Receiving & Installation

MN2417

Page 21

Recommended Engine Oil and Battery Type

MODEL

SUMMER

WINTER

OIL

RECOMMENDED

(AMPS) COLD

When replacing batteries, use only the recommended battery for your generator, see Table 3-5.

Table 3-5 Oil & Battery Recommendations

SUMMER WINTER OIL RECOMMENDED (AMPS) COLD

OIL

TS25 SAE. 20W/50 5W/30 8.6 QTS BCI Group 24 925

TS35 SAE. 20W/50 5W/30 8.5 QTS BCI Group 925

TS45 SAE. 20W/50 5W/30 11.8 QTS BCI Group 925

TS60 SAE. 20W/50 5W/30 11.8 QTS BCI Group 925

TS80 SAE. 20W/50 5W/30 14.0 QTS BCI Group 925

TS130 SAE. 20W/50 5W/30 18.0 QTS BCI Group (2) 750

TS175 SAE. 20W/50 5W/30 34.0 QTS BCI Group (2) 750

TS250 SAE. 20W/50 5W/30 34.0 QTS BCI Group (2) 750

TS400 SAE. 20W/50 5W/30 45.0 QTS BCI Group (2) 750

OIL

CAPACITY

BATTERY

CRANKING

Post Installation Checks

When the initial installation is complete, these checks must be performed before starting the

engine. These checks are not required before each start, only after the initial installation.

1. Generators that have been in transit or storage for long periods may be subjected to

extreme temperature and moisture changes. This can cause excessive condensation,

and the generator windings should be thoroughly dried before bringing the generator

up to full nameplate voltage. If this precaution is not taken, serious damage to the

generator can result.

Caution: Do not apply high voltage to windings (do not start the generator) in a moisture−saturated

condition. Moisture can cause insulation breakdown, making it necessary to return the

generator to the factory for repair, and consequent expense and loss of time.

Note: These precautions are especially necessary in locations such as seaboard installations and

other high humidity areas. Some installations will be in atmospheres that are much more

corrosive than others. Prevention of a failure is better than being forced to make a repair.

2. Verify that the transfer switch is in Utility Power mode. No power must be present at

the generator or transfer switch connections. Verify with a voltmeter.

3. Verify that the engine starting battery is disconnected so accidental starting is not possible.

4. Verify generator is securely mounted and anchored to cement pad (skid mount only).

5. Verify that proper clearance exists on all sides and top of enclosure.

6. Verify no debris (buildup of leaves, grass, sand, snow, etc.) is present.

7. Assure generator is a safe distance from any flammable or combustible material.

8. Verify that the three phase generator power (L1, L2, L3 and N) are properly connected

to the transfer switch.

9. Verify that the generator and transfer switch load are voltage compatible.

10. Verify that no load is connected to the circuit breaker and/or transfer switch.

11. Inspect the engine and generator and verify that there are no loose wires or

components. Tighten if necessary.

12. Verify that the ground conductor is of correct wire size and properly connected.

13. Verify engine oil level is full. Refer to engine manual if necessary.

14. Verify engine coolant level is full. Refer to engine manual if necessary.

15. Verify exhaust system to assure it is in properly connected and pointing away from

occupied living space, air entry routes (doors, windows, vents etc.) and combustible

materials.

MN2417

Receiving & Installation 3-9

Page 22

Post Installation Checks Continued

16. Place the voltage output selector switch in the appropriate position.

17. Verify all loads are disconnected.

18. Verify the Master Control is in the “Stop” position.

Connect the engine starting battery to the starter. Verify it is installed correctly.

19. Verify the fuel source is available.

20. Remove all tools, rags, etc. from inside the generator enclosure. Close all enclosure

doors and be sure no hands are inside the generator enclosure when it starts.

21. Start the generator.

22. The engine should begin to crank and start when the fuel moves to the engine. If the

engine fails to start, refer to Section 5 Troubleshooting.

23. With the engine running, several checks must be made:

a. Verify there are no fuel leaks. If a fuel leak is detected, stop the engine (set the

Master Control in the “Stop” position) immediately and repair the leak before

proceeding.

b. Verify there are no coolant or oil leaks. If a leak is detected, stop the engine (set

the Master Control in the “Stop” position) immediately and repair the leak before

proceeding.

c. Verify that operation is smooth. If squeals, vibrations or other abnormal sources of

noise exist, stop the engine (set the Master Control in the “Stop” position)

immediately and repair before proceeding.

d. Verify the correct voltage exists at the receptacles.

WARNING: Engine coolant is under pressure and is near the boiling point of water when engine is hot.

Do not open the coolant system until the engine has completely cooled. Hot coolant can

cause severe burns and other injuries. When engine is cool, coolant level can be checked.

24. After the operation checks are made, stop the engine (set the Master Control in the

“Stop” position) and wait 2 hours for the engine to cool. When the engine is cool,

check engine oil and coolant levels as instructed in the engine operation manual.

25. Close all enclosure covers. The post installation checks are now complete.

3-10 Receiving & Installation

MN2417

Page 23

Section 4

Operation

Towing the Generator

WARNING: Never allow a person to ride in or on a trailer that is being towed. All states prohibit

passengers in towed vehicles. A person can fall off and be struck be another vehicle or run

over by the towed trailer. Failure to observe this warning can result in death.

WARNING: Before using a tow vehicle with a trailer mounted generator, verify that the vehicle is designed

for the load. Using a vehicle that is too small is very dangerous. Be certain that it can handle

the M.G.V.W. (Maximum Gross Vehicle Weight) and the tongue weight for safe towing and

braking.

WARNING: For a new trailer, the wheel lug nuts should be tightened to the proper torque specification

before use, after 50 miles of operation, after 100 miles of operation and periodically thereafter.

Failure to check the lug nuts for proper tightness can result in an accident due to a wheel

falling from the trailer.

WARNING: Never operate a trailer or tow vehicle that has a loose, missing or broken lug nut. The trailer

is designed for safe operation with all lug nuts installed and all at the proper torque rating.

Operating the trailer with one or more broken or missing lug nuts greatly increases the load

on the remaining nuts and can cause failure of the remaining nuts that can result in an

accident due to a wheel falling from the trailer.

S Make sure the tow vehicle is able to tow the load. Vehicle brake capacity is extremely

critical and the tow vehicle must be able to handle the additional weight of the trailer

mounted generator. Radiator and transmission cooling must also be considered.

S Be sure hitch capacity is equal to or greater than the load when mounted on the

vehicle.

S Be sure the size and rating of the hitch ball is equal to or greater than the load.

S Make sure the safety chain(s) rating is equal to or greater than twice the maximum

gross vehicle weight rating of your trailer.

S It is illegal to transport passengers in any trailer.

S Reduce weight in car trunk and rear seat areas by the amount of tongue weight of your

trailer.

S Any alterations or changes made to the trailer void any express or implied warranties

on the trailer or towing equipment.

Selecting the Proper Towing Equipment

When selecting the proper towing equipment, the two most important factors that must be

considered are the M.G.V.W. (Maximum Gross Vehicle Weight) and the Tongue Weight (trailer

tongue weight at the hitch). The M.G.V.W. is the total weight of the trailer plus the payload in the

trailer. The tongue weight is the downward pressure exerted at the coupler. The easiest way to

measure the gross vehicle weight is to place the loaded trailer on a vehicle scale making sure

that the scales are supporting the entire weight of the loaded trailer.

The easiest method to measure tongue weight is to place the jack stand (trailer tongue) on a

scale making sure the trailer is level. The trailer tongue should be level and in its normal towing

position. Tongue weight should be 10% of trailer weight and not more than10% of M.G.V.W.

Tow Vehicle

Make sure the vehicle you are using to tow the trailer is capable of towing the weight. Check the

vehicle Owner’s Manual for towing capability of the towing vehicle or contact the vehicle

manufacturer for this information. Make sure the tow vehicle is able to tow the load. Vehicle

brake capacity is extremely critical and the tow vehicle must be able to handle the additional

weight of the trailer mounted generator. Radiator and transmission cooling must also be

considered. Seek expert advise to select the proper tow vehicle. Trailers with a gross vehicle

weight rating that exceeds 10,000 lbs require special consideration.

Table 4-1 Tow Hitch Capacity

Tow Vehicle Hitch Class Maximum Tow Capacity Maximum Tongue Weight

Compact Vehicle Sub Class I 1000 Lbs. 100 Lbs.

Compact Vehicle Class I 2000 Lbs. 200 Lbs.

Mid & Full Size Vehicle Class II 3500 Lbs. 300 Lbs.

3/4 Ton or larger Truck Class III 5000 Lbs. 500 Lbs.

1 Ton or larger Truck Class IV 10000 Lbs. 1000 Lbs.

Class 3−8 Vehicle Custom Engineered Custom Engineered Custom Engineered

Operation 4-1MN2417

Page 24

Selecting the Proper Towing Equipment Continued

Electrical Trailer Wiring

All trailers must have taillights, brake lights and turn signals connected to the towing vehicle’s

electrical system. It is also recommended that a heavy duty turn signal flasher and emergency

flasher (if separate) be installed since the trailer lights place an extra load on car flasher units.

Towing Heavy Trailer Loads

1. Trailer brakes. In all cases refer to your vehicle’s owner manual and the trailer

operating manual to be certain you have an adequate braking system to handle the

vehicle/trailer combination. Also, State and local requirements, road and weather

conditions and grade of road, etc. should be considered for trailer braking.

2. Additional equipment. The following items may be helpful for towing heavy loads. Consult

your vehicle’s owner manual or dealership for recommended towing accessories.

a. Overload Springs

b. Overload or air shocks

c. Transmission Oil Cooler

d. Engine Oil Cooler

e. Coolant recovery System

f. Heavy Duty Fan

g. Side View Mirrors

h. Sway Control

Safe Driving Tips 1. Loading Trailer. The trailer should be loaded so that the downward tongue weight is

approximately 10% of the gross vehicle weight. The trailer tongue should be level with

the tow vehicle coupling during towing. Adjust load, hitch and coupling as necessary to

ensure trailer tongue remains level during towing.

2. Following and stopping distance. The stopping distance is increased when towing a

trailer. A rule of thumb for the minimum distance that should be maintained between

you and the preceding car on dry pavement is one car and trailer length (2 car lengths)

for every 10 MPH you are traveling. The distance should be increased accordingly

depending on road and weather conditions. Avoid sudden stops if possible.

3. Passing. Accelerating and passing should be done slowly to allow extra distance for

passing. Signal well in advance when passing and returning to the proper lane. Allow for

the extra length of the trailer before changing lanes. Never change lanes abruptly as this

may cause the trailer to sway and push the tow vehicle into a “jack knife” condition.

4. Turning. Allow for the extra length of the trailer. Drive slightly beyond normal turning point

to avoid running over curbs and soft shoulders. Turning radius increases when towing.

5. Uphill and Downhill Grades. Reduce speed and use a lower transmission gear for

steep or long up or down hill grades. Maintain safe distance from other vehicles.

6. Parking.

S Avoid parking on uphill or downhill grades

S Place transmission in “PARK”

S Apply parking brake.

S Use wheel chocks.

S In a parking lot, avoid parking close to other vehicles. Turning radius is greater

and it may be impossible to get out of a parking space after a few other vehicles

have parked around your vehicle.

7. Trailer Sway. If trailer sway occurs, reduce speed. Apply trailer brakes rather than car

brakes to control sway. See step 1 and ensure trailer tongue remains level during

towing. If sway persists, seek expert advise.

8. Trailer Backing. Backing a trailer can be frustrating. The most important item to remember

is that the trailer will go in the opposite direction of the tow vehicle. It is helpful to have

another person help you back the trailer and watch for objects.

Turn the vehicle’s wheels to the right to make the trailer go left, and vice versa.

Put your hand at the bottom of the steering wheel. The trailer will go in the same direction

your hand moves (moving your hand to the right will cause the trailer to go right, and vice

versa). Sharp steering wheel corrections will cause the trailer to jackknife and may cause

damage to the rear of the tow vehicle or the front of the trailer.

4-2 Operation MN2417

Page 25

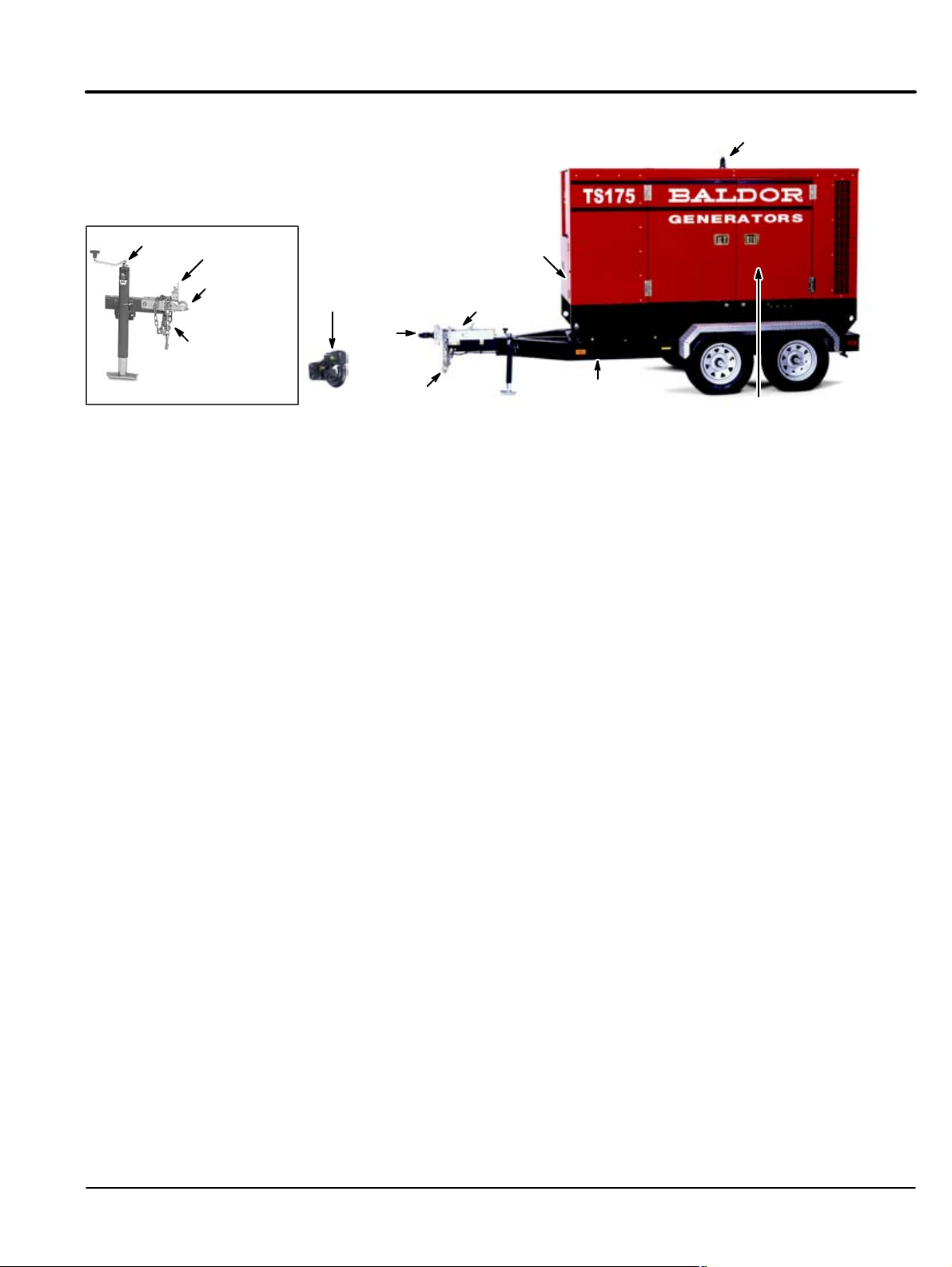

Figure 4-1 Trailer Component Identification

Lift Hook

Jack

Safety

Chains

Ball Coupler

Coupler Handle

Coupler

Tow Vehicle Mounted

Pintle Hook

Pintle

Safety

Chains

Battery

Compartment

Trailer Brake

Jack

Trailer

Single or

Double Axle

Engine

Compartment

Caution: Large “Engine Compartment Doors” on each side of enclosure must remain closed during

operation. If doors remain open, engine will overhead due to insufficient air flow around engine.

Safety Checks The following items should be checked before each use and once every 100 miles of towing:

1. Verify the tow vehicle is designed to tow the trailer before trailer is connected to the

vehicles hitch. Using a tow vehicle that is too small is very dangerous.

2. Verify the stop, tail and turn signals are working properly.

Replace damaged lenses, reflectors or bulbs.

3. Check wires for good connections and possible fraying or wearing of insulation.

4. Check and properly maintain the trailer, hitch, jack, ball and coupler.

5. Inspect hitch and ball for damage. Ball or hitch can be damaged in parking, hitting

curbs, dragging when crossing ditches or railroad tracks.

6. Check and properly tighten all bolts on trailer, hitch, ball and coupler (including trailer

wheels).

7. Check safety chains for wear and do not allow them to drag on ground or roadway.

8. Test breakaway system.

Hydraulic surge brake system, normally have a cable or chain connected to the tow

vehicle. In a break away condition, this cable or chain activates the master cylinder and

operates the brakes as the trailer stops.

An electric brake system, the emergency breakaway system has a battery, charger,

breakaway switch with a pull pin and cable connected to the tow vehicle. In a break

away condition, this cable operates the electric brakes (power provided by the brake

battery) as the trailer stops.

9. Check all generator mounting hardware for tightness.

10. Check tow vehicle tires for wear and proper inflation. (Check vehicle’s owner manual

for proper level of inflation of tires for towing a trailer).

11. Check trailer tires for wear and proper inflation. Replace only with a tire of the same

size and capacity ratings.

12. Carry emergency flares, reflectors and fire extinguisher.

13. Carry spare light bulbs and fuses.

14. Wheel bearings should be checked and regreased after the first 100 miles, and every

4000 miles thereafter or at least once a year. Wheel bearing grease or a good grade of

multi−purpose grease should be used for packing wheel bearings. If you don’t know

how to repack your wheel bearing, take your trailer to a service shop. Be sure to

properly tighten the axle nut and wheel nuts during assembly.

15. For proper tow vehicle maintenance while towing a trailer, check vehicle’s owner

manual and manufacturer’s specifications.

MN2417

Operation 4-3

Page 26

Towing Instructions See Figure 4-1 for component identification.

1. Be sure the generator is off.

2. Shut all enclosure doors and latch the locks.

3. Back the tow vehicle to within a few inches of the trailer coupler (Pintle or Ball).

4. Be sure the Coupler Handle is in the “UP” (open) position or the Pintle Hook is Open.

5. Adjust the trailer jack for the height of the hitch on the tow vehicle.

6. Back the tow vehicle so the trailer coupler is directly over the tow vehicle ball hitch or

the Pintle hook.

7. Lower the trailer so the trailer coupler rests securely on the ball hitch of the tow vehicle.

Move the Coupler Handle to the horizontal position and lock it in place to securely hold

the ball hitch of the tow vehicle.

OR