Page 1

PRESENTS YOUR

BALDOR GENERATORS

3815 OREGON STREET OSHKOSH WI 54902

PHONE: 920–236–4200 FAX: 920–236–4219

REVISED/EFFECTIVE MAY 1, 2003 C:\ISO9001\FORMS\SPSG–002–48msw

FORM#: S–PSG–002–48

Page 2

TOWABLES

OPERATOR’S MANUAL

Table of Contents

ACCESSORIES AND EQUIPMENT WITH THIS GENERATOR SET INCLUDES:

ITEM PAGE

SAFETY RECOMMENDATIONS: These recommendations must be read and followed 1

to safely operate your generator set.

VOLTAGE RATINGS: This informational page describes features and specifications for 7

all Towable Units.

ELECTRICAL CONNECTION INFORMATION: This information explains how to interface 9

your generator with the AC loads and other standard and optional accessories.

CONTROL PANEL: This includes a drawing of the control panel and a description of 11

the components associated with it.

PRE–START PROCEDURE: This described a pre–start check that should be performed 14

prior to initial start–up.

OPERATION GUIDE: Information on how to start, stop, and operate the generator set 15

is included here. Included also is information in regards to the operation of the

genset/ engine control device and the different fault shutdown circuits designed to

protect the generator set from potential engine operational problems.

TROUBLESHOOTING GUIDE: Included in this guide are basic instructions to help 18

troubleshoot most problems with your generator set. For more troubleshooting

help please contact the service department at Baldor Generators

HIGHWAY TRAILER: This includes information in regards to safe operation, proper 23

utilization, and recommended guidelines for using and operating the trailer.

BALDOR GENERATORS W ARRANTIES: this details the warranty provided by Baldor 27

Generators for coverage for electrical generator end of the generator set.

OTHER MANUALS AND ACCESSORIES THAT SHOULD ACCOMPANY YOUR TOWABLE

GENERATOR:

ENGINE OPERATOR’S MANUAL: This operator’s manual includes information in regards to

the operation and maintenance of the engine utilized in this generator set.

AC GENERATOR, ACCESSORIES, AND LOAD CONNECTION DIAGRAMS / ENGINE

CONTROLS, ACCESSORIES, AND REMOTE CONNECTION DIAGRAMS: These diagrams contain in-

formation in regards to the internal wiring of the generator set, specifically the AC and

Engine Control circuits. These diagrams will also include information for any optional AC

or DC powered accessories that are included.

PARTS LIST: This is a listing of all parts used by Baldor Generators to build this specific generator set.

Page 3

Page 4

SAFETY WARNINGS

z Place protective covers and guards over the rotating parts, if rotating parts such as the drive shaft, pulley,

belt, etc. are left exposed, they are potentially hazardous.

z When cleaning, repairing or inspecting, make sure all moving parts have stopped.

z Prior to working on the generator set, disconnect the spark plug and battery to prevent accidental starting.

z Use only original equipment or authorized replacement parts. Use of correct parts will assure the operator

of the safety integrity that was designed into the unit.

z Unauthorized modifications to the generator set may impair the function and/or safety of the unit.

z Do not operate the generator set without a muffler. Inspect periodically and replace if necessary.

z Do not touch the hot exhaust components or the high voltage spark plug and coil terminals. While Spark

Plug Voltages are not normally lethal, an involuntary jerk of the hand caused by a hot surface or by

an electrical shock can result in injury.

z Repair of electrical generating equipment requires specialized skills. Repair personnel must have a

thorough understanding of generator and small engine repair procedures.

z Never inhale exhaust gases. They contain carbon monoxide; a colorless, odorless and extremely

dangerous gas that can cause unconsciousness or death. Symptoms of carbon monoxide poisoning

can include: dizziness, nausea, headaches, sleepiness, vomiting or incoherency. If you or anyone else

experiences any of these symptoms, get out into the fresh air immediately. Shut the unit down and

do not operate it until it has been inspected and, if necessary, repaired.

z Never Operate the generator set indoors or in a poorly ventilated area such as a tunnel or cave.

z CALIFORNIA PROPOSITION 65 WARNING: engine exhaust from this product contains chemicals known

to the state of California to cause cancer, birth defects or other reproductive harm.

z Know how to stop the engine quickly and understand the operation of all controls.

Revised: 8/13/02 Page 1 of 4 FORM#: S–PSG–001–3

Effective: 2/27/98 C:\ISO9001\FORMS\SPSG0013.msw.bbk

1

Page 5

SAFETY WARNINGS

z Never permit anyone to operate the generator set without proper instructions.

z Never allow children to operate the generator set.

z Children and pets must be kept away from the area of operation due to the possibility of burns from hot

engine components or injury from any equipment the generator set is powering.

z Always wear eye protection and Hearing protection when working near the generator set.

z Operate the generator set only with the guards, shields and other safety items in place and working

properly.

z Do not put hands, feet, tools or other objects near rotating parts.

z Use reasonable care when moving or lifting the unit. The generator set may move around inside the wrap

frame creating ”Pinch Points”.

z Do not run the generator set while it is being moved.

z Do not support the generator set from the top of the wrap frame.

z Do not operate the generator set while under the influence of alcohol, drugs or medication.

z When transporting or using a generator set with the wheel option, secure the unit to prevent it from moving

around.

z Do not tamper with or change the engine speed as it has been preset at the factory for proper operation.

z Keep hands and face away from the carburetor when the air cleaner is being moved. A sudden backfire

can cause serious burns.

z Be careful of hot parts. The muffler and other generator parts become very hot while the engine is running.

z Do not ”jump start” the generator set.

z Sulfuric acid can cause severe injury and can give off gases, which are corrosive and potentially explosive.

Avoid contact with skin, eyes, and clothing. In case of contact, flush area immediately with water.

z When transporting a generator set, secure it to prevent it from moving or shifting.

z Know how to stop the engine quickly and understand the operation of all controls.

z Do not operate electrical equipment while standing in water, on wet ground or with wet hands or shoes.

z Use extreme caution when working on electrical components. Potentially dangerous voltage is present

when the engine is running.

Revised: 8/13/02 Page 2 of 4 FORM#: S–PSG–001–3

Effective: 2/27/98 C:\ISO9001\FORMS\SPSG0013.msw.bbk

2

Page 6

SAFETY WARNINGS

z Always treat the electrical circuits as if they were energized.

z Disconnect all leads plugged into the unit Prior to working on it.

z Have the electrical circuits serviced only by qualified technicians.

z Inspect wiring frequently and replace frayed, broken or poor leads.

z Do not connect this unit to any building’s electrical system unless you utilize an approved transfer switch or

the main service entrance switch has been disconnected and locked open.

z Circuit overload protection must be provided in accordance with national electrical codes and local

regulations.

z Check GFCI Receptacles monthly by using the ”Test” and ”Reset” buttons designed into them.

z Depending on your application it may be mandatory to ground or not ground this unit to earth ground.

Comply with local electrical codes.

```` FOR GASOLINE OR DIESEL POWERED GENERATOR SETS ````

z Operate the generator set on a level surface. If the generator set is tilted, fuel spillage may result.

z Handle fuel with care. It is highly flammable. Use only clean, properly marked and approved safety

containers for refueling and storing fuel.

z Stop the engine and allow it to cool before refueling.

z Do not overfill the fuel tank. Only fill the tank to within 1/2” of the top of the tank to allow space for fuel

expansion.

z If fuel is spilled, wipe it up carefully and wait until the fuel has dried before starting the engine.

z Make sure the fuel cap is properly closed after refueling.

z Never operate the generator set while smoking.

z Never operate the generator set near an open flame.

z Never store the generator set with fuel in the tank indoors or in an enclosed, poorly ventilated enclosure

where fuel fumes may reach an open flame, electrical spark or pilot light as on a furnace, water heater,

clothes dryer, etc.

z When transporting over long distances or rough roads, drain the fuel tank to prevent leakage and spillage.

Revised: 8/13/02 Page 3 of 4 FORM#: S–PSG–001–3

Effective: 2/27/98 C:\ISO9001\FORMS\SPSG0013.msw.bbk

3

Page 7

SAFETY WARNINGS

```` FOR GASOLINE OR DIESEL POWERED GENERATOR SETS ````

z Check all fuel supply piping and their connections on a monthly basis for fuel leaks.

z Use only approved piping and componentry in your fuel supply system.

z A professional, experienced technician should only install the fuel supply system.

z Do not run the fuel line up against any sharp objects.

z Comply with NFPA regulations and your local codes in regard to shut–off valves, regulators, etc. and any

other recommendations or requirements they may have.

z Keep the generator set at least three feet away from buildings or other structures.

z Keep the generator set away from flammable and other hazardous materials (trash, rags, lubricants,

explosives, paints, etc.)

z Keep the generator set free of grass, leaves and excessive grease and oils.

z Allow the generator set to cool before transporting it or storing it indoors.

z Have fire extinguisher accessible and nearby while operating the generator set.

z This generator set must not be used on or near any forest covered brush covered or grass covered land

unless the engine’s exhaust system is equipped with a spark arrester and it must be maintained

in effective working order by the operator.

z Operation inside an enclosed compartment or building is a potential fire hazard and should not be done

unless approval is obtained from Baldor Generators. Engine/Generator overheating can cause severe

damage due to restricted, obstructed or improper air–flow that is necessary for the proper cooling of the

unit.

z Hot exhaust gases being discharged by the engine must never be directed toward anything that could

catch fire or explode.

Revised: 8/13/02 Page 4 of 4 FORM#: S–PSG–001–3

Effective: 2/27/98 C:\ISO9001\FORMS\SPSG0013.msw.bbk

4

Page 8

FORWARD

This manual contains the information you need to safely and efficiently operate your generator

set. During the preparation of this manual every effort was made to ensure the accuracy of its

contents.

Never operate this generator set without first carefully reading this manual and observing all the

safety warnings it presents. While safety is built into every Baldor Pow’R Gard generator set,

careless or improper operation could possibly result in mechanical failure, property damage, severe injury or death.

Note that this manual covers only very basic information in regards to the engine. A separate

owner’s manual for the engine is supplied with this unit for your use. Please refer to this manual

for information relative to engine operation, maintenance, recommendations and additional

safety warnings.

As soon as you receive your generator set, inspect it closely for shipping damage. If you find

some damage, notify the transportation company immediately and file a freight damage claim.

Think of this manual as a tool to help you get the most out of your generator set. We strongly

suggest that you keep this manual with your generator set and refer to it when questions arise

in regards to its operation.

Baldor Generators, formerly Pow’R Gard Generator Corporation has been in business since

1965. The generator sets we manufacture have earned the reputation of being of high quality

and a dependable product. We take pride in this fact and continue to keep our quality standards

high on our list of priorities. We are also constantly researching new technological ideas to determine if they could be used to make our generator sets even better.

Thank you for purchasing your Baldor Pow’R Gard Generator Set.

Effective: February 26, 1998

Revised 2/01/02

Form#: S–CSD–003–7 C:\ISO9001\FORMS\SCSD0037.MSW

5

Page 9

Effective: February 26, 1998

Revised 2/01/02

Form#: S–CSD–003–7 C:\ISO9001\FORMS\SCSD0037.MSW

6

Page 10

Features & Specifications

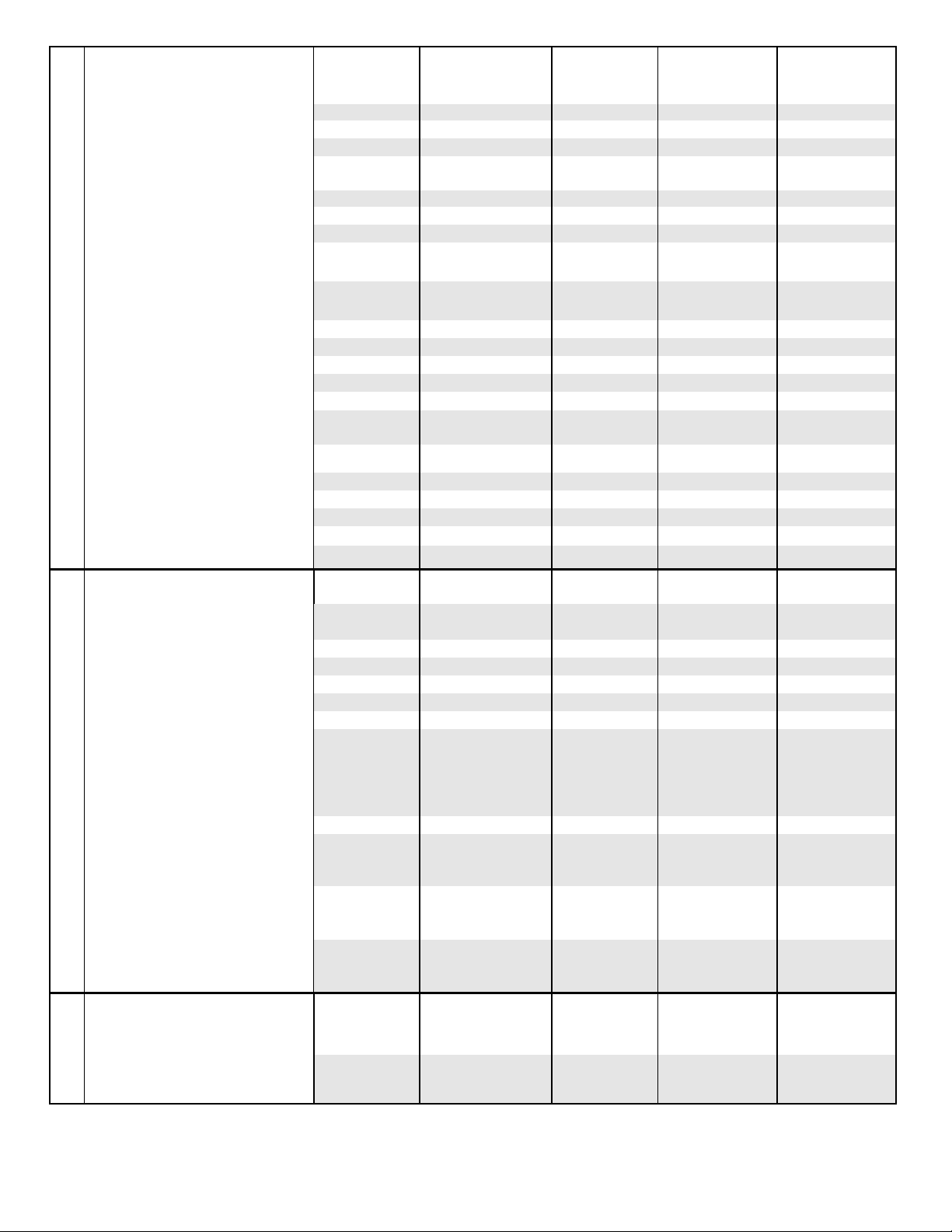

Model TS25 TS45 TS80 TS130 TS175

Standby output– 1500C Rise

G

G

E

(KVA/KW):

3 PH @ 480 Volt 25/20 48/38 81/65 134/107 175/140

3 PH @ 208/240 Volt 25/20 46/37 72/58 131/105 169/135

1 PH @ 240 Volt 18/18 27/27 45/45 70/70 80/80

Continuous Output–

1250C Rise (KVA/KW):

3 PH @ 480 Volt 23/18 44/35 75/60 121/97 169/135

3 PH @ 208/240 Volt 23/18 44/35 69/55 119/95 156/125

1 PH @ 240 Volt 18/18 25/25 43/43 66/66 75/75

Voltage – 3 PH Adjustable 208/220/240/

N

E

Voltage – 1 PH Adjustable 120/127/139/

R

A

T

O

R

E

N

G

I

N

E

Amperage (Continuous):

3 PH 480 Volt 27.1 52.6 90.2 145.8 203.0

3 PH 208 Volt 62.5 121.4 190.8 329.6 433.7

3 PH 240 Volt 54.1 105.3 165.4 285.7 375.9

1 PH 240 Volt/120 Volt 75.0/150.0 104.2/208.3 179.2/358.3 275/550 312.5/625.0

Receptacles:

120 Volt, 15 Amp GFCI 4 6 6 6 6

120/240 Volt, 50 Amp,

CS6369 Twistlock

Voltage Regulation 1/2% 1/2% 1/2% 1/2% 1/2% 1/2%

Power Factor – 3 Phase 0.8 0.8 0.8 .08 .08

Total Harmonic Distortion <5% <5% <5% <5% <5%

Engine Make/Model Isuzu

Fuel Consumption (GPH):

Approx. Run Time (Hrs.):

Battery Recommendation Min. Cold

(Battery not included)

Frequency 50 or 60 Hertz 50 or 60 Hertz 50 or 60 Hertz 50 or 60 Hertz 50 or 60 Hertz

Insulation Class F Class F Class F Class F Class F

Design Water Cooled

Starting System 12 VDC 12 VDC 12 VDC 12 VDC 12 VDC

Displacement (cid) 133.0 264.2 276.0 414.0 498.0

Cylinders 4 4 4 6 6

HP @ Rated Speed 34.5 64.0 100.0 166.0 211.0

RPM 1800 1800 1800 1800 1800

Safety Shutdowns:

High Temperature Std. Std. Std. Std. Std.

Low Oil Std. Std. Std. Std. Std.

Overspeed Std. Std. Std. Std. Std.

Overcrank Std. Std. Std. Std. Std.

Fuel Capacity 50 80 80 160 160

1/2 Load 1.3 2.0 2.7 4.2 5.6

Full Load 2.0 3.4 4.9 8.1 10.5

1/2 Load 38 40 30 38 29

Full Load 25 24 16 20 15

Cranking Amps

416/440/460/480

240/254/277

2 3 3 3 3

4LE

4 Cycle Diesel

750 900 900 (2) 750 (2) 750

208/220/240/

416/440/460/480

120/127/139/

240/254/277

Isuzu

4BG1

Water Cooled

4 Cycle Diesel

208/220/240/

416/440/460/480

120/127/139/

240/254/277

John Deere

TO4045T

Water Cooled

4 Cycle Diesel

208/220/240/

416/440/460/480

120/127/139/

240/254/277

John Deere

TO6068

Water Cooled

4 Cycle Diesel

208/220/240/

416/440/460/480

120/127/139/

240/254/277

John Deere

RG6081T

Water Cooled

4 Cycle Diesel

Dimensions (L x W x H):

With Trailer 123” x 62” x 70” 139” x 60” x 81” 139” x 60” x 81” 163” x 66” x 94” 163” x 66” x 94”

Without Trailer 74” x 38” x 52” 84” x 38” x 61” 84” x 38” x 61” 108” x 42” x 74” 108” x 42” x 74”

Weight (Lbs.):

Without Fuel 2265 3540 3848 5600 6200

Without Fuel & Trailer 1790 2829 3053 4610 5205

7

Page 11

8

Page 12

SWITCHABLE

ELECTRICAL CONNECTION INFORMATION

WARNING: High voltage may be present at receptacles and load studs while engine is

operating – DANGER of electrical shock is present. Use extreme care.

LOAD RECEPTACLES

1. Voltage is present in 120/240 volt switch position only.

2. Load wires may be brought into receptacle compartment through access door at control station.

HARD WIRE LOAD TERMINAL BLOCK

1. Voltage available at load block is outlined in chart below.

2. Cables must be brought into load block compartment through access hole in base of trailer.

3. Opening load block door will cause load disconnect to trip.

4. Do not start engine with load turned “on”. Allow engine to come up to speed and warm up (1).

5. If left unattended, lock all doors to prevent tampering or injury.

AVAILABLE VOLTAGE:

SWITCH POSITION

277/480 1–2–3 = 480 VAC, 3 Phase

1–N, 2–N, 3–N = 277 VAC, 1 Phase

120/240 1–2–3 = 240 VAC, 3 Phase

2–3 = 240 VAC, 1 Phase

2–N, 3–N = 120 VAC, 1 Phase

1–N = 180 – 200 VAC, Wild Leg

120/208 1–2–3 = 208 VAC, 3 Phase

2–3 = 208 VAC, 1 Phase

1–N, 2–N, 3–N = 120 VAC, 1 Phase

STUD

NOTE: To prevent damage to loads and generator, select voltage switch position prior to starting

engine.

NOTE: Upon switching voltage selector switch, adjust voltage and adjust rheostat (located on engine

control panel) for proper voltage.

Revised: October 3, 2002 D:\ISO9001\FORMS\MSW’98bbk

Effective: April 23, 1999

Form#: S–PSG–001–15

9

Page 13

CONNECTION INFORMATION

Your new Baldor Generator has all interconnecting wiring terminated at a junction box. All wiring will be

clearly labeled as being load; remote start contacts and AC input terminals and are to be connected as

described below.

Load – These connections are rated and sized according to the KW of the generator. Proper lead

wire from these points to the automatic transfer switch (or load switching device) is mandatory.

See enclosed transfer switch information for corresponding generator input terminals.

Remote Start Contacts – This two–wire connection, once connected to an appropriate switch,

will start the generator and perform as described in the remote start/stop literature. These

contacts are connected to the “Engine Start Contacts” of the automatic transfer switch.

A Two Pole normally open, closed to operate switch may also be used to start the generator.

AC Input – These connections are for units with float type battery chargers or engine block

heater combinations. A Constant supply of 120 volts AC (or as specified) is needed at these

terminals to power these devices.

NOTE: Power is not required when the unit is in operation. Internal battery charging and radiant heat

during operation eliminate the need for these devices.

NOTE: It is recommended that units utilizing an automatic transfer switch with adjustable time delays

have the initial adjustments made prior to start–up.

Factory recommendations are; allow a 2 second delay on start–up, 15–second delay on emergency to

normal.

Revised: March 20,2001 D:\ISO9001\FORMS\MSW’98bbk

Effective: April 23, 1999

Form#: S–PSG–001–19

10

Page 14

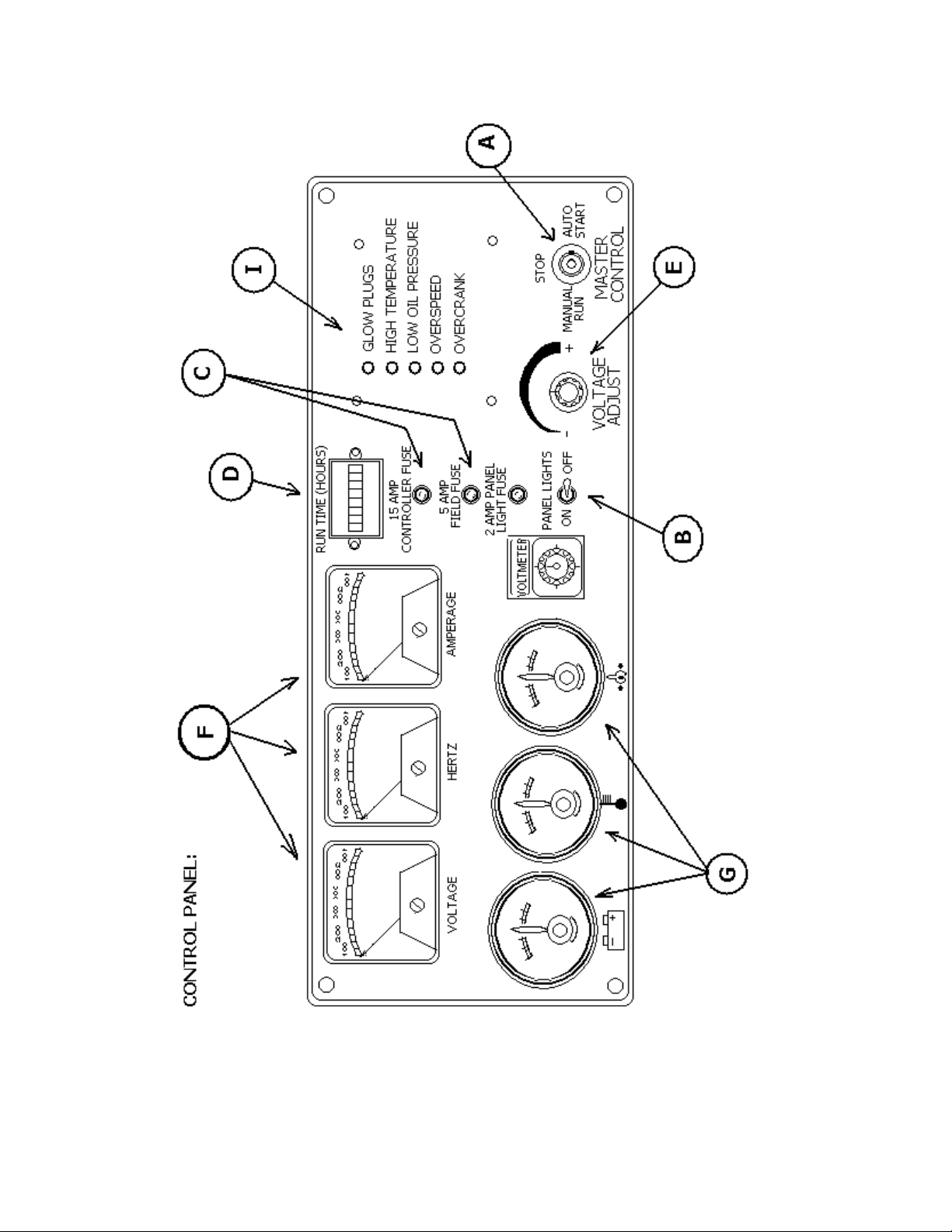

CONTROL PANEL OPERATION

AND FUNCTION

A. MASTER CONTROL SWITCH – This switch controls the starting and stopping of the engine via

the engine control logic circuitry.

With this switch in the “Manual” mode, the engine will start and run immediately after a

10 – 20 second time delay.

CAUTION: Please note that once the engine has been told to start, the gen set

should be treated as though it is operational, even though the start

delay has not yet allowed the engine to crank.

With this switch in the “Automatic” mode, the engine can be started and stopped from a remote

contact. (Standard switch, transfer switch, etc.) There is a time delay, to cool down, of 60–90

seconds when the unit is shut down from the remote contacts while the Master Control Switch is in

the “Automatic Mode.

With this switch in the “Off” position, the engine will immediately stop. The position must also be

utilized to clear fault shut–down conditions.

B. PANEL LIGHTS – By turning on the panel light switch, the panel lights will be energized and will

illuminate the control panel. The fuse next to the switch is to protect this circuit from damage due to

excessive current.

C. FIELD AND CONTROLLER FUSES – These fuses protect the internal workings of the generator

set.

D. GAUGES – These gauges monitor some of the more critical operating parameters of the engine as

well as the run time of the generator set.

The Voltmeter displays the charging rate that is currently being produced by the engine’s alternator to

facilitate the charging of the battery. This gauge should normally be above 12.5V whenever the unit is

running. If you ever notice the gauge is reading below 12V while the engine is running please contact

the service department at Baldor Generators.

The Temperature Gauge monitors and displays the operating temperature of the engines coolant. The

point at which a fault shut–down will occur is approximately 230°F.

The Oil Pressure Gauge displays and monitors the current operating pressure of the engine’s oil

system. The trip point at which a fault shutdown will occur is approximately 15 PSI or below.

Fuel level is checked by the owner or is usually a separately supplied fuel tank.

The Hour Meter accumulates and displays the total running time of the generator set.

11

Page 15

E. VOLTAGE ADJUST – The rheostat allows the user to “fine tune” the generator set’s voltage

output. It is normally used to adjust output voltage after switching the output of the generator set to a

different voltage.

F. METERS – These meters monitor and display the current operating parameters of the generator set.

The Voltmeter monitors and displays the current operating AC output of the generator set.

The Hertz Meter monitors and displays the current operating frequency of the generator set.

The ammeter monitors and displays the amount of current that is being delivered by the generator set.

This meter works in conjunction with the Voltmeter Switch (Item G) in determining which output leg

to monitor.

G. AMMETER SWITCH – The switch allows the user to switch between L1, L2 and L3 to monitor the

current in each output leg of the generator.

H. PANEL LIGHT – By turning on the panel light switch, the panel lights (Not pictured on diagram)

will be energized and will illuminate the control panel.

I – SYSTEM FAULT INDICATORS – These lights will come on when a fault condition or a warning

condition develops.

The “Low Oil Pressure” light will come on when the engine’s oil pressure drops below 15 PSI. This

condition will trigger a fault shut–down and the unit will stop.

The “Over–crank” light will come on when the engine has failed to start after four attempted crank

cycles. Each crank cycle consists of a 12 second time period followed by a 12 second rest time

period.

The “Over–speed” light will come on when the engine’s operating speed rises above it’s normal

operating parameters. This condition will trigger a fault shut–down and the engine will stop.

High Temperature light will come on when the engine’s operating temperature exceeds the safety

set–point.

12

Page 16

13

Page 17

OPERATION – PRE–START PROCEDURE

1. Fill system fuel tank with clean, fresh diesel fuel.

CAUTION: Wipe up any and all fuel spillage.

2. Fill engine crankcase to full mark with clean, fresh lubricating oil per attached engine operating guide.

3. Radiator coolant should be checked at the beginning of each day and filled in compliance with the engine

manufacturer’s guidelines.

4. Secure the generator for operation.

Skid mounted – the power generating system should be mounted to a smooth,

hard surface suitable for supporting the system under all stress conditions.

Trailer mounted – block wheels to prevent accidental movement.

Adequate clearance must be provided for access doors to fully open.

NOTE: The generating system exhaust also exits radiator end. When

positioning a generator system ensure position does not cause a

concentration of toxic emissions.

14

Page 18

OPERATION – STARTING

1. Conduct ‘Pre–start Procedures.

2. Switch the generator set to the applicable voltage setting.

3. Connect the load(s) to the circuit breaker.

WARNING: High voltage is present when the generator set is running.

4. Move the ‘Master Control Switch” to the appropriate position.

5. Adjust the voltage if necessary by turning the voltage adjustment knob located on the control panel.

15

Page 19

OPERATION

The prime mover utilized in this power generating system is controlled via an engine control module.

Starting is accomplished by commanding the control to ”start” the engine. This command can be

given by a number of controls.

? The operator control mounted on the front panel.

? The remote controls via the transfer switch or remote start terminal closure.

Initially, the system may be started and operated by placing the operator control in the ”manual/run”

position. To cease operation, return the switch to the ”off” position.

NOTE: Clear unit of all loose objects and perform all ”pre–start” procedures before operating

generator system.

ENGINE CONTROL MODULE:

The engine control module (ECM) is a microprocessor– based module that monitors the control and

safety inputs and provides all the required START and STOP functions automatically.

The following front panel controls and instruments are wired into the microprocessor through the

ECM terminal blocks:

1. Run–Off–Auto Switch

a. * ”Run” – run position causes the generator set to start and run immediately.

b. * ”Auto” – auto position allows unit to be controlled via any remote single–pole ”dry” contact

(transfer switch, etc.). Contact closure causes the unit to start and run, while contact opening causes

unit to shut down after a preset cool down period.

c. ”Off” – unit operation is terminated.

* – units equipped with Isuzu engines may have a time delay glow plug cycle before starting.

2. Lamp Test

Push button energizes all alarm lights simultaneously. This feature is disabled with the

run–stop–auto switch in the ”stop” position, and has no other effect on unit operation.

SAFETY INPUTS

1. Low Oil Pressure Shutdown – (LOP)

Monitoring of oil pressure begins for a preset time after unit starts and remains in effect until

unit is shut down (except as noted in ”loss of frequency input” below). The LOP signal is derived

from an oil pressure switch gauge mounted on the control panel

2. High Temperature Shutdown – (HT)

The engine temperature monitoring begins immediately with the start signal. However, if engine

temperature is excessive prior to start (i.e., heat soak after shutdown), the unit is permitted to

start.

The high temperature condition is permitted to exist for up to 60 seconds after the unit is running

before shutdown when alarm occurs. If the excessive temperature condition is corrected within

that time period, the HT circuit reverts to normal monitoring. The HT signal is derived from a

monitoring device located on the prime mover.

16

Page 20

3. Over–speed Adjustment – (OS) – Over Frequency

Over–speed protection is provided by a frequency sensing network within the controller. The trip

point of the frequency network is adjustable via a rheostat located on the top of the controller at

the right hand side. Clockwise (CW) rotation increases the trip frequency and, thereby, raises the

shutdown speed.

CRANKING CONTROL

1. Over–crank Protection

This feature provides a preset second crank cycle. Failure of the engine to start by the end of the

crank period results in an ”Over–crank” shutdown and alarm indication.

2. Cranking Disconnect Adjustment (CDS Adjustment)

The cranking disconnect signal is obtained by a frequency network within the controller. The trip

point of the frequency network is not adjustable.

LOSS OF FREQUENCY

Internal protection against loss of frequency input to the cranking disconnect circuit is programmed in

after the unit has started normally. In the event the frequency goes to zero (engine runs out of fuel,

frequency signal source fails, etc.) the LOP shutdown circuit is bypassed and a 12–second wait

period is initiated. If frequency returns within this time period, LOP monitoring resumes and operation

continues normally. If frequency has not returned at the end of this time period, the engine oil

pressure status is observed to determine whether the engine is actually running or stopped. If the

engine has stopped (i.e., air in fuel, etc.), the cranking cycle will begin in an effort to restart the

engine. If the engine has not stopped (loss of input signal, etc.), the unit is shutdown with an

”Over–crank” indication and alarm.

WARNING: Over–crank indication can mean a loss of crank–disconnect signal during the

previous run period. Attempting to restart the engine with no crank–disconnect signal can

destroy the starter motor, which can cause serious personal injury.

This is of particular note since the tendency is to pursue only cranking and start related faults. The

cranking disconnect signal source is a key component in this system and must be checked out

thoroughly whenever an ”Over–crank” shutdown occurs.

NOTE: The controller does not provide protection against loss of signal during start–up. A

shutdown with alarm, due to any of the above conditions, will prevent any subsequent

operation of the generator set. The run–stop–auto selector switch on the control panel

must be momentarily placed in the stop position to reset these functions.

CAUTION: If a dead battery is suspected, remove controller fuse, charge battery (or replace), and

then attempting starting. Damage to engine control may result from jump starting.

17

Page 21

TROUBLESHOOTING – GENERATOR

As with any machine, trouble may develop in electrical generators. It may be due to long service

or neglect of regular maintenance. Servicing, and checking. Should trouble develop, the following instructions will be helpful in tracing the cause and making repairs.

SPEED DEVIATIONS:

The generator speed should be maintained at rated nameplate speed. The frequency and volt-

age of the generator output depends on speed. If the generator runs slower than rated speed,

the voltage will drop off.

NO VOLTAGE

CAUSE

Loss of residual magnetism in Flash Field.

exciter field poles.

Open in stator windings Check for continuity in windings. Return to factory

Open or short in rotating rectifiers. Check rectifiers.

Short Circuited. Clear lead to restore voltage build–up.

Open in alternator field Check for continuity and return rotor to factory for

Shorted exciter armature Check for short and replace if faulty.

Shorted leads between exciter Test and repair

armature and generator field.

LOW VOLTAGE

CAUSE

CHECK AND REMEDY

for repair if open

repair if field coils are open.

CHECK AND REMEDY

Excessive load. Reduce load. With 3 phase generators, the load on

each leg should be as evenly balanced as possible

and should not exceed the rated current on any leg.

Low Speed. Check engine for malfunction or system for over-

load.

Line loss. Increase size of line lead wire.

18

Page 22

LOW VOLTAGE (Continued)

CAUSE

CHECK AND REMEDY

High resistance connections– Make better connection electrically and

Connections will be warm or hot mechanically.

Shorted field. Test field coils for possible short by checking resist-

ance with an ohmmeter or resistance bridge. Return rotor assembly to factory for repair if alternator

field coils are shorted.

Low power factor Reduce inductive (motor) load. Some AC motors

Draw approximately the same current regardless of

load. Do not use motors of larger horsepower rating

than is necessary to carry the mechanical load.

FLUCTUATING VOLTAGE

(May be indicated by flickering lights.)

CAUSE

CHECK AND REMEDY

Irregular speed of engine. Check engine for malfunction or load for fluctuation.

Fluctuating speed. Stabilize load. The addition of a lamp load (resist-

ance load) may compensate partially for load

changes caused by intermittent motor operation.

Do not overload.

Loose terminal or load connections. Make better connection mechanically and electri-

cally.

Defective bearing causing uneven air gap. Replace worn bearing.

HIGH VOLTAGE

CAUSE

CHECK AND REMEDY

Excessive speed. Check engine for malfunction.

OVERHEATING

CAUSE

CHECK AND REMEDY

Generator overloaded. Reduce load. (Check with ammeter and compare

with nameplate rating.)

Clogged ventilating screens. Clean air passages.

19

Page 23

OVERHEATING (continued)

CAUSE

CHECK AND REMEDY

High room temperature. Improve ventilation.

Insufficient circulation. Provide cross–ventilation.

Low power factory. Reduce inductive loads or install power factor im-

provement capacitors.

Unbalanced load The load on each leg should be as evenly balanced

as possible and should not exceed the rated cur-

rent on any leg.

Dry bearing. Replace bearing.

MECHANICAL NOISE

CAUSE

CHECK AND REMEDY

Defective bearing. Replace bearing.

Rotor scrubbing on stator. Bad bearing; replace. Bent shaft, return to factory.

Loosen end bell, tighten; loose drive discs, tighten.

Loose laminations. Return to factory.

Loose or misaligned coupling. Tighten or align.

GENERATOR FRAME PRODUCES SHOCK WHEN TOUCHED

CAUSE

CHECK AND REMEDY

Static charge. Ground generator frame.

Grounded armature or field coil. Return to factory for repair.

20

Page 24

TROUBLESHOOTING – ENGINE

CODE LIST OF POSSIBLE CAUSES

1. Battery capacity low. 33. Piston rings not free or are worn or broken.

2. Bad electrical connections. 34. Valve stems and/or guide worn.

3. Fault in starter motor. 35.West type air cleaner too full or wrong oil used.

4. Fault in starter motor. 36. Crankshaft bearings worn or damaged..

5. Wrong grade of lubricating oil. 37. Not enough lubricating oil in the pump.

6. Low engine speed from starter motor. 38. Gauge not correct.

7. Stop control fault. 39. Lubricating oil pump worn.

8. Restriction in fuel lift pipe. 40. Relief valve not free to close.

9. Fault in fuel lift pump. 41. Relief valve not free to open.

10. Dirty fuel filter element. 42. Relief valve spring broken.

11. Restriction in air filter or induction system. 43. Fault in suction pipe of lubricating oil pump.

12. Air in fuel system. 44. Dirty lubricating oil filter element.

13. Fault in fuel injection pump. 45. Piston damaged.

14. Fault in atomizers or not correct type. 46. Piston height not correct.

15. Cold start equipment not used correctly. 47. Fan damaged.

16. Fault in cold start equipment. 48. Fault in engine mounting (housing).

17. Broken fuel injection pump drive. 49. Flywheel housing or flywheel not aligned

18. Fuel injection pump timing not correct. correctly.

19. Valve timing not correct. 50. Fault in thermostat or wrong type.

20. Bad compression. 51. Restriction in coolant passages.

21. restriction in fuel tank vent. 52. Water pump drive belt loose.

22. Type or grade of fuel not correct. 53. Restriction in radiator.

23. Restriction of engine speed control movement. 54. Fault in water pump.

24. Restriction in exhaust pipe. 55. Restriction in breather pipe.

25. Cylinder head gasket leaks. 56. Damaged valve stem oil seals (where used).

26. Engine temperature too high. 57. Not enough coolant in system.

27. Engine temperature too low. 58. Restriction in sump strainer.

28. Valve tip clearances not correct. 59. Valve spring broken.

29. Valves not free. 60. Fault in exhaust or vacuum pipe leakage.

30. Wrong high pressure pipes. 61. Turbo charger impeller damage, or dirty impeller.

31. Worn cylinder bores. 62. Turbo charger lubricating oil seal leaks.

32. Valves and seats do not seal correctly. 63. Induction system leaks (turbo charged engines.)

21

Page 25

22

Page 26

MMAAGGNNAAPPLLUUSS GGEENNEERRAATTOOR

R

228800 ---- 443300 FFrraamme

IInnssttaallllaattiioonn,, OOppeerraattiioonn aanndd MMaaiinntteennaanncce

MMaannuuaal

l

e

e

MMaarraatthhoonn EElleeccttrriic

AA SSuubbssiiddiiaarryy ooff RReeggaall--BBeellooiitt CCoorrpp.

110000 EEaasstt RRaannddoollpphh SSttrreeeet

PP..OO.. BBooxx 8800003

WWaauussaauu,, WWII 5544440022--8800003

PPhhoonnee:: ((771155)) 667755 3333111

FFaaxx:: ((771155)) 667755 6633661

c

t

3

3

1

1

.

Page 27

TTAABBLLEE OOFF CCOONNTTEENNTTS

S

SSAAFFEETTY

RREECCEEIIVVIINNGG AANNDD SSTTOORRAAGGE

PPRRIINNCCIIPPLLEESS OOFF OOPPEERRAATTIIOON

IINNSSTTAALLLLAATTIIOON

Y..............................................................................................................................................................................................44

E.........................................................................................................................................................44

UUNNPPAACCKKIINNGG AANNDD HHAANNDDLLIINNG

SSTTOORRAAGGE

E........................................................................................................................................................................................44

G...................................................................................................................................................44

N ......................................................................................................................................................55

A

M

AAGGNNA

FFIIGGUURREE 11 ---- M

FFIIGGUURREE 22 ---- T

V

OOLLTTAAGGEE

V

T

R

EEGGUULLAATTIIOON

R

MMOOTTOORR SSTTAARRTTIINNG

PPLLUUSS C

YYPPIICCAALL

M

AAGGNNA

M

N

.....................................................................................................................................................................66

G.......................................................................................................................................................................66

PPAARRAALLLLEELL OOPPEERRAATTIIOON

NNOONNLLIINNEEAARR LLOOAADDIINNG

G................................................................................................................................................................66

C

N ..............................................................................................................................................................66

IIRRCCUUIITT

A

PPLLUUSS L

D

IIAAGGRRAAM

D

L

AAYYOOUUTT

N................................................................................................................................................................................66

PPRREEPPAARRAATTIIOONN FFOORR UUSSE

GGEENNEERRAATTOORR MMOOUUNNTTIINNG

SSiinnggllee BBeeaarriinngg UUnniittss.

E .............................................................................................................................................................66

G...........................................................................................................................................................77

. ...................................................................................................................................................................77

TTwwoo BBeeaarriinngg GGeenneerraattoorrss ---- DDiirreecctt DDrriivve

TTwwoo BBeeaarriinngg UUnniittss ---- BBeelltt DDrriivveen

EENNDD PPLLAAYY TTEESSTTIINNG

TTOORRSSIIOONNAALL VVIIBBRRAATTIIOON

G.....................................................................................................................................................................77

N.............................................................................................................................................................77

n.................................................................................................................................................77

EENNVVIIRROONNMMEENNTTAALL CCOONNSSIIDDEERRAATTIIOONNS

M

...............................................................................................................................55

D

D

IIAAGGRRAAM

M

.................................................................................................................55

e .....................................................................................................................................77

S.....................................................................................................................................88

WWIIRRIINNGG CCOONNNNEECCTTIIOONNS

OOPPEERRAATTIIOON

N....................................................................................................................................................................................1111

PPRREE--SSTTAARRTT IINNSSPPEECCTTIIOON

SSTTAARRTT--UUP

P.....................................................................................................................................................................................1111

SSHHUUTTDDOOWWNN PPRROOCCEEDDUURRE

MMAAIINNTTEENNAANNCCE

E .............................................................................................................................................................................1122

DDRRYYIINNGG WWIINNDDIINNGGS

SSppaaccee HHeeaatteerrs

FFoorrcceedd AAiir

TTEESSTTIINNG

G..........................................................................................................................................................................................1133

V

V

C

C

C

C

I

I

I

IISSUUAALL

I

OONNSSTTAANNTT

OONNTTIINNUUIITTYY

NNSSUULLAATTIIOONN

DDIIOODDEE TTEESSTTIINNG

SSEERRVVIICCE

E..........................................................................................................................................................................................1144

GGEENNEERRAAL

s.............................................................................................................................................................................1133

r ..................................................................................................................................................................................1133

NNSSPPEECCTTIIOON

E

XXCCIITTAATTIIOONN

E

R

EESSIISSTTAANNCCEE

// R

T

............................................................................................................................................................................1144

T

EESST

T

G..........................................................................................................................................................................1144

L .....................................................................................................................................................................................1144

FFIIEELLDD FFLLAASSHHIINNG

B

EEAARRIINNGG

B

R

EEMMOOVVAAL

R

S................................................................................................................................................................88

N ..........................................................................................................................................................1111

E.........................................................................................................................................................1122

S ...................................................................................................................................................................1133

N

........................................................................................................................................................................1133

T

.........................................................................................................................................................1133

T

EESST

T

T

.....................................................................................................................................................1133

T

EESST

T

G........................................................................................................................................................................1144

L

........................................................................................................................................................................1155

OOppppoossiittee DDrriivvee EEnndd BBeeaarriinngg BBrraacckkeett RReemmoovvaall.

DDrriivvee EEnndd BBeeaarriinngg BBrraacckkeett RReemmoovvaall,

TTwwoo BBeeaarriinngg UUnniittss.

BBEEAARRIINNGG RREEPPLLAACCEEMMEENNT

R

EECCTTIIFFIIEERR

R

D

IIOODDEE

D

A

SSSSEEMMBBLLYY

A

R

EEPPLLAACCEEMMEENNT

R

......................................................................................................................................................................1155

T ........................................................................................................................................................1155

R

R

T

.....................................................................................................................................................................1155

EEMMOOVVAAL

L

....................................................................................................................................................1155

..........................................................................................................................1155

, ........................................................................................................................................1155

2

2

Page 28

RREETTUURRNNEEDD GGOOOODDS

S ......................................................................................................................................................................1166

TTRROOUUBBLLEESSHHOOOOTTIINNG

GGEENNEERRAATTOORR PPRROODDUUCCEESS NNOO VVOOLLTTAAGGE

GGEENNEERRAATTOORR PPRROODDUUCCEESS LLOOWW VVOOLLTTAAGGEE,, NNOO LLOOAAD

GGEENNEERRAATTOORR PPRROODDUUCCEESS LLOOWW VVOOLLTTAAGGEE WWHHEENN LLOOAADD AAPPPPLLIIEED

GGEENNEERRAATTOORR PPRROODDUUCCEESS FFLLUUCCTTUUAATTIINNGG VVOOLLTTAAGGE

GGEENNEERRAATTOORR PPRROODDUUCCEESS HHIIGGHH VVOOLLTTAAGGE

GGEENNEERRAATTOORR BBUUIILLDDSS VVOOLLTTAAGGEE FFRROOMM SSTTAARRTTUUPP,, TTHHEENN GGOOEESS TTOO LLOOWW ((RREESSIIDDUUAALL)) VVOOLLTTAAGGE

GGEENNEERRAATTOORR IISS OOVVEERRHHEEAATTIINNG

GGEENNEERRAATTOORR PPRROODDUUCCEESS MMEECCHHAANNIICCAALL NNOOIISSE

EEQQUUIIPPMMEENNTT RRUUNNSS NNOORRMMAALLLLYY OONN UUTTIILLIITTYY PPOOWWEERR,, BBUUTT WWIILLLL NNOOTT RRUUNN OONN GGEENNEERRAATTOOR

SSPPEECCIIFFIICCAATTIIOONNS

PPAARRTTSS LLIISSTT –– SSIINNGGLLEE BBEEAARRIINNG

TTyyppiiccaall GGeenneerraattoorr CCrroossss SSeeccttiioon

PPAARRTTSS LLIISSTT –– DDUUAALL BBEEAARRIINNG

TTyyppiiccaall GGeenneerraattoorr CCrroossss SSeeccttiioon

G...................................................................................................................................................................1166

E................................................................................................................................1177

D.........................................................................................................1177

D ..................................................................................1188

E..........................................................................................................1188

E............................................................................................................................1188

G..............................................................................................................................................1199

E ..................................................................................................................1199

S..........................................................................................................................................................................2200

G...............................................................................................................................................2211

n ...............................................................................................................................................2211

G..................................................................................................................................................2222

n ...............................................................................................................................................2222

E...........................1199

R.................................1199

3

3

Page 29

SSAAFFEETTY

Y

WWhheenn iinn ddoouubbtt,, aasskk.. QQuueessttiioonnss aarree mmuucchh eeaassiieerr ttoo hhaannddlle

tthhaann mmiissttaakkeess ccaauusseedd bbyy aa mmiissuunnddeerrssttaannddiinngg ooff tthhe

iinnffoorrmmaattiioonn pprreesseenntteedd iinn tthhiiss mmaannuuaall.

.

e

e

PPLLEEAASSEE RREEMMEEMMBBEERR SSAAFFEETTYY FFIIRRSSTT..

ooff tthhee iinnssttrruuccttiioonnss oorr pprroocceedduurreess ccoonnttaaiinneedd hheerreeiinn,, sseeeek

qquuaalliiffiieedd hheellpp bbeeffoorree ccoonnttiinnuuiinngg.

TThhiiss sseerrvviiccee mmaannuuaall eemmpphhaassiizzeess tthhee ssaaffeettyy pprreeccaauuttiioonns

nneecceessssaarryy dduurriinngg tthhee iinnssttaallllaattiioonn,, ooppeerraattiioonn,, aannd

mmaaiinntteennaannccee ooff yyoouurr MMaaggnnaaPPLLUUSS ggeenneerraattoorr.. EEaacchh sseeccttiioon

ooff tthhiiss mmaannuuaall hhaass ccaauuttiioonn aanndd wwaarrnniinngg mmeessssaaggeess.. TThheesse

mmeessssaaggeess aarree ffoorr yyoouurr ssaaffeettyy,, aanndd tthhee ssaaffeettyy ooff tthhe

eeqquuiippmmeenntt iinnvvoollvveedd.. IIff aannyy ooff tthheessee ccaauuttiioonnss oorr wwaarrnniinnggss iis

nnoott rreeaaddiillyy uunnddeerrssttoooodd,, sseeeekk ccllaarriiffiiccaattiioonn ffrroomm qquuaalliiffiieed

ppeerrssoonnnneell bbeeffoorree pprroocceeeeddiinngg.

BBeeffoorree aannyy sseerrvviiccee wwoorrkk iiss ddoonnee,, ddiissccoonnnneecctt aallll ppoowweer

ssoouurrcceess aanndd lloocckk oouutt aallll ccoonnttrroollss ttoo pprreevveenntt aann uunneexxppeecctteed

ssttaarrtt--uupp ooff tthhee ggeenneerraattoorr sseett ddrriivveerr.. PPrrooppeerr ggrroouunnddiinng

((eeaarrtthhiinngg)) ooff tthhee ggeenneerraattoorr ffrraammee aanndd ddiissttrriibbuuttiioonn ssyysstteemm iin

ccoommpplliiaannccee wwiitthh llooccaall aanndd nnaattiioonnaall eelleeccttrriiccaall ccooddeess aannd

ssppeecciiffiicc ssiittee rreeqquuiirreemmeennttss mmuusstt bbee pprroovviiddeedd.. TThheessee ssaaffeetty

pprreeccaauuttiioonnss aarree nneecceessssaarryy ttoo pprreevveenntt ppootteennttiiaall sseerriioouus

ppeerrssoonnaall iinnjjuurryy,, oorr eevveenn ddeeaatthh.

TThhee hhaazzaarrddss aassssoocciiaatteedd wwiitthh lliiffttiinngg oorr mmoovviinngg yyoouur

MMaaggnnaaPPLLUUSS ggeenneerraattoorr aarree ppooiinntteedd oouutt iinn tthhee iinnssttaallllaattiioonn aannd

mmaaiinntteennaannccee sseeccttiioonnss.. IInnccoorrrreecctt lliiffttiinngg oorr mmoovviinngg ccaann rreessuullt

iinn ppeerrssoonnaall iinnjjuurryy oorr ddaammaaggee ttoo tthhee uunniitt.

PPrriioorr ttoo ssttaarrtt--uupp ooff tthhee uunniitt eennssuurree tthhaatt aallll ggeenneerraattoorr lleeaadds

aarree pprrooppeerrllyy ccoonnnneecctteedd ttoo tthhee ggeenneerraattoorr lliinnkk bbooaarrdd llooccaatteed

iinnssiiddee tthhee ccoonnnneeccttiioonn bbooxx.. AAllwwaayyss aassssuummee tthhaatt tthheerree wwiillll bbe

vvoollttaaggee pprreesseenntt aatt tthhee ggeenneerraattoorr tteerrmmiinnaallss wwhheenneevveerr tthhe

ggeenneerraattoorr''ss sshhaafftt iiss rroottaattiinng

RReessiidduuaall vvoollttaaggee iiss pprreesseenntt aatt tthhee ggeenneerraattoorr tteerrmmiinnaallss aanndd aat

tthhee aauuttoommaattiicc vvoollttaaggee rreegguullaattoorr ppaanneell ccoonnnneeccttiioonnss eevveenn wwiitth

tthhee rreegguullaattoorr ffuussee rreemmoovveedd.. CCaauuttiioonn mmuusstt bbee eexxeerrcciisseedd,, oor

sseerriioouuss iinnjjuurryy oorr ddeeaatthh ccaann rreessuulltt.

.

.

.

,

g

,

aanndd pprroocceeeedd aaccccoorrddiinnggllyy.

.

IIff yyoouu aarree nnoott ssuurre

.

e

k

s

d

n

e

e

s

d

r

d

g

n

d

y

s

r

d

t

s

d

e

e

.

t

h

r

RREECCEEIIVVIINNGG AANNDD SSTTOORRAAGGE

RREECCEEIIVVIINNGG AANNDD SSTTOORRAAGGE

UUppoonn rreecceeiipptt ooff tthhee ggeenneerraattoorr,, iitt iiss rreeccoommmmeennddeedd tthhaatt iitt bbe

ccaarreeffuullllyy eexxaammiinneedd ffoorr ppoossssiibbllee sshhiippppiinngg ddaammaaggee.. TThhe

ggeenneerraattoorr wwaass ggiivveenn ttoo tthhee ffrreeiigghhtt ccaarrrriieerr iinn ggoooodd ccoonnddiittiioonn;

tthhuuss,, tthhee ccaarrrriieerr iiss rreessppoonnssiibbllee ffoorr tthhee pprroodduucctt ffrroomm tthhe

ffaaccttoorryy ddoocckk ttoo tthhee ddeessttiinnaattiioonn.. AAnnyy ddaammaaggee sshhoouulldd bbe

nnootteedd oonn tthhee ffrreeiigghhtt bbiillll bbeeffoorree aacccceeppttiinngg tthhee sshhiippmmeenntt.. AAnny

ccllaaiimmss ffoorr ddaammaaggee mmuusstt bbee pprroommppttllyy ffiilleedd wwiitthh tthhee ddeelliivveerriinng

.

ccaarrrriieerr.

UUNNPPAACCKKIINNGG AANNDD HHAANNDDLLIINNG

CCaarreeffuullllyy rreeaadd aallll iinnssttrruuccttiioonn ttaaggss sshhiippppeedd wwiitthh tthhee uunniitt.

WWhheenn lliiffttiinngg,, aattttaacchh aann oovveerrhheeaadd ccrraannee ttoo tthhee lliiffttiinngg lluugg((ss)) oon

tthhee ggeenneerraattoorr ffrraammee.. AAppppllyy lliiffttiinngg ffoorrcceess iinn aa vveerrttiiccaal

ddiirreeccttiioonn.. WWhheenn ttrraannssppoorrttiinngg ssiinnggllee bbeeaarriinngg ggeenneerraattoorrss,, tthhe

ggeenneerraattoorr’’ss rroottoorr mmuusstt bbee aaddeeqquuaatteellyy ssuuppppoorrtteedd ttoo pprreevveennt

ddaammaaggee.

.

E

TTHHE

LLIIFFTTIINNG

NNOOT

R

TTHHE

E

D

T

LLIIFFT

AASSSSEEMMBBLLY

GGEENNEERRAATTOORR.. PPEERRSSOONNAAL

DDEESSIIGGNNEED

O

DDO

DDRRIIVVEER

N

OON

EEQQUUIIPPMMEENNT

G

LLUUGG ((SS)

O

TTO

SSUUPPPPOORRT

T

T

DDAAMMAAGGE

WWAARRNNIINNG

)

A

A

CCOOMMPPLLEETTE

Y

Y

BBY

E

MMAAY

N

OON

TTHHE

T

TTHHE

MMEEAANNS

Y

RREESSUULLTT.

G

E

E

E

S

E

E

G

GGEENNEERRAATTOOR

GGEENNEERRAATTOOR

GGEENNEERRAATTOOR

OOF

F

LLIIFFTTIINNG

L

IINNJJUURRY

.

G

R

AARRE

R

OONNLLYY.

R

AANND

LLUUGG ((SS)

Y

OOR

e

e

;

e

e

y

g

.

n

l

e

t

E

.

D

)

R

TThhiiss mmaannuuaall iiss nnoott iinntteennddeedd ttoo bbee aa ssuubbssttiittuuttee ffoorr pprrooppeerrlly

ttrraaiinneedd ppeerrssoonnnneell.. IInnssttaallllaattiioonn aanndd rreeppaaiirrss sshhoouulldd oonnllyy bbe

aatttteemmpptteedd bbyy qquuaalliiffiieedd,, ttrraaiinneedd ppeeooppllee.. TThhee ccaauuttiioonnss aannd

wwaarrnniinnggss ppooiinntt oouutt kknnoowwnn ccoonnddiittiioonnss aanndd ssiittuuaattiioonnss tthhaatt aarre

ppootteennttiiaallllyy hhaazzaarrddoouuss.. EEaacchh iinnssttaallllaattiioonn mmaayy wweellll ccrreeaattee iitts

oowwnn sseett ooff hhaazzaarrdds

s

y

e

d

e

s

SSTTOORRAAGGE

IInn tthhee eevveenntt tthhaatt tthhee ggeenneerraattoorr iiss nnoott iimmmmeeddiiaatteellyy iinnssttaalllleed

oonn iittss pprriimmee mmoovveerr,, iitt iiss rreeccoommmmeennddeedd tthhaatt tthhee uunniitt bbee ssttoorreed

iinnddoooorrss iinn aa cclleeaann,, ddrryy aarreeaa,, wwhhiicchh iiss nnoott ssuubbjjeecctt ttoo rraappiid

cchhaannggeess iinn tteemmppeerraattuurree aanndd hhuummiiddiittyy.. IIff tthhee ggeenneerraattoorr iis

ssttoorreedd ffoorr aa lloonngg ppeerriioodd ooff ttiimmee,, tthhee ggeenneerraattoorr sshhoouulldd bbe

tteesstteedd,, cclleeaanneedd aanndd ddrriieedd aass rreeqquuiirreedd bbeeffoorree bbeeiinngg ppuutt iinntto

sseerrvviiccee.. SSeeee tthhee mmaaiinntteennaannccee sseeccttiioonn ooff tthhiiss mmaannuuaall ffoor

ffuurrtthheerr iinnffoorrmmaattiioonn.. IIff tthhee uunniitt hhaass bbeeeenn ssttoorreedd iinn aann aarreea

wwhheerree iitt hhaass bbeeeenn ssuubbjjeecctt ttoo vviibbrraattiioonn,, iitt iiss rreeccoommmmeennddeed

tthhaatt tthhee bbeeaarriinngg((ss)) bbee iinnssppeecctteedd aanndd rreeppllaacceedd aass nneecceessssaarryy.

4

4

E

d

d

d

s

e

o

r

a

d

.

Page 30

PPRRIINNCCIIPPLLEESS OOFF OOPPEERRAATTIIOON

N

PMG (optional)

PMG Field

(rotor)

N

S

PMG

Armature

(stator)

PMG Input Power (optional)

(1 phase, 300/250 hertz)

Exciter Field

(stator)

(+)

DC

(in)

(-)

Exciter Armature

3 Phase AC (out)

Exciter Field Power

(DC out)

FFIIGGUURREE 11 ---- MMaaggnnaaPPLLUUSS CCiirrccuuiitt DDiiaaggrraam

Rotating Assembly

(rotor)

m

Rotating Rectifier Assembly

3 Phase -- Full Bridge

Automatic

Voltage

Regulator

Main Field

(rotor)

(+)

DC

(in)

(-)

Input Power -- Single Phase

(shunt powered regulator)

Sensing Input -- Single Phase

3 phase (optional)

Main Armature

3 Phase AC (out)

(stator)

L

1

L

2

L

3

FFIIGGUURREE 22 ---- TTyyppiiccaall MMaaggnnaaPPLLUUSS LLaayyoouutt DDiiaaggrraam

m

5

5

Page 31

PPRRIINNCCIIPPLLEE OOFF OOPPEERRAATTIIOON

MMaaggnnaaPPLLUUSS ggeenneerraattoorrss aarree aa bbrruusshhlleessss,, sseellff eexxcciitteedd,, aannd

eexxtteerrnnaallllyy vvoollttaaggee rreegguullaatteedd,, ssyynncchhrroonnoouuss AACC ggeenneerraattoorr.

TThhee ggeenneerraattoorr iiss mmaaddee uupp ooff ssiixx mmaajjoorr ccoommppoonneennttss:: mmaaiin

ssttaattoorr ((aarrmmaattuurree)),, mmaaiinn rroottoorr ((ffiieelldd)),, eexxcciitteerr ssttaattoorr ((ffiieelldd)),

eexxcciitteerr rroottoorr ((aarrmmaattuurree)),, rreeccttiiffiieerr aasssseemmbbllyy,, aanndd vvoollttaagge

rreegguullaattoorr.. IInn uunnddeerrssttaannddiinngg tthhee aabboovvee tteerrmmiinnoollooggyy,, nnoottee tthhe

ffoolllloowwiinngg:: ssttaattoorrss aarree ssttaattiioonnaarryy,, rroottoorrss rroottaattee,, aa ffiieelldd iiss aan

eelleeccttrriiccaall iinnppuutt,, aanndd aann aarrmmaattuurree iiss aann eelleeccttrriiccaall oouuttppuutt.

TThheessee ssyysstteemm ccoommppoonneennttss aarree eelleeccttrriiccaallllyy iinntteerrccoonnnneecctteedd aas

sshhoowwnn iinn ffiigguurree 11 aanndd pphhyyssiiccaallllyy llooccaatteedd aass sshhoowwnn iin

.

ffiigguurree 22.

N

ggeenneerraattoorrss ggeenneerraallllyy ssuuppppllyy ..33 ttoo ..44 hhoorrsseeppoowweerr ppeer

ggeenneerraattoorr kkWW iinn mmoottoorr ssttaarrttiinngg ccaappaabbiilliittyy.. FFoorr ssppeecciiffiicc ddaatta

ccoonnttaacctt MMaarraatthhoonn EElleeccttrriicc.

d

.

n

,

e

e

n

.

s

n

PPAARRAALLLLEELL OOPPEERRAATTIIOON

AAllll MMaaggnnaaPPlluuss ggeenneerraattoorrss aarree bbuuiilltt wwiitthh 22//33 ppiittcchh mmaaiinn ssttaattoor

wwiinnddiinnggss aanndd ffuullll aammoorrttiisssseeuurr ((ddaammppeerr)) wwiinnddiinnggss.. TThheesse

ffeeaattuurreess mmaakkee tthhee MMaaggnnaaPPlluuss ggeenneerraattoorrss ssuuiittaabbllee ffoorr ppaarraalllleel

ooppeerraattiioonn wwhheenn eeqquuiippppeedd wwiitthh tthhee pprrooppeerr vvoollttaaggee rreegguullaattoorrs

aanndd vvoollttaaggee rreegguullaattoorr aacccceessssoorriieess.. CCoonnssuulltt wwiitthh tthhee ffaaccttoorry

ffoorr ffuurrtthheerr iinnffoorrmmaattiioonn rreellaattiivvee ttoo ppaarraalllleell ooppeerraattiioonnss.

.

N

.

r

a

r

e

l

s

y

TThhee ggeenneerraattoorr’’ss eexxcciitteerr ccoonnssiissttss ooff aa ssttaattiioonnaarryy ffiieelldd aanndd a

rroottaattiinngg aarrmmaattuurree.. TThhee ssttaattiioonnaarryy ffiieelldd ((eexxcciitteerr ssttaattoorr)) iis

ddeessiiggnneedd ttoo bbee tthhee pprriimmaarryy ssoouurrccee ooff tthhee ggeenneerraattoorr’’ss rreessiidduuaal

mmaaggnneettiissmm.. TThhiiss rreessiidduuaall mmaaggnneettiissmm aalllloowwss tthhee eexxcciitteerr rroottoor

((aarrmmaattuurree)) ttoo pprroodduuccee AACC vvoollttaaggee eevveenn wwhheenn tthhee eexxcciitteer

ssttaattoorr ((ffiieelldd)) iiss nnoott ppoowweerreedd.. TThhiiss AACC vvoollttaaggee iiss rreeccttiiffiieedd tto

DDCC bbyy tthhee rroottaattiinngg rreeccttiiffiieerr aasssseemmbbllyy aanndd ffeedd ddiirreeccttllyy ttoo tthhe

mmaaiinn rroottoorr ((ffiieelldd)).. AAss tthhee ggeenneerraattoorr sshhaafftt ccoonnttiinnuueess ttoo rroottaattee,

tthhee mmaaiinn rroottoorr ((ffiieelldd)) iinndduucceess aa vvoollttaaggee iinnttoo tthhee ggeenneerraattoorr''s

mmaaiinn ssttaattoorr ((aarrmmaattuurree)).. AAtt rraatteedd ssppeeeedd,, tthhee mmaaiinn ssttaattoorr’’s

vvoollttaaggee pprroodduucceedd bbyy tthhee rreessiidduuaall mmaaggnneettiissmm ooff tthhee eexxcciitteer

aalllloowwss tthhee aauuttoommaattiicc vvoollttaaggee rreegguullaattoorr ttoo ffuunnccttiioonn.. TThhe

rreegguullaattoorr pprroovviiddeess vvoollttaaggee ttoo tthhee eexxcciitteerr rreessuullttiinngg iinn aa bbuuiilldduupp ooff ggeenneerraattoorr tteerrmmiinnaall vvoollttaaggee.. TThhiiss ssyysstteemm ooff uussiinng

rreessiidduuaall mmaaggnneettiissmm eelliimmiinnaatteess tthhee nneeeedd ffoorr aa ssppeecciiaall ffiieelld

ffllaasshhiinngg cciirrccuuiitt iinn tthhee rreegguullaattoorr.. AAfftteerr tthhee ggeenneerraattoorr hhaas

eessttaabblliisshheedd tthhee iinniittiiaall rreessiidduuaall vvoollttaaggee,, tthhee rreegguullaattoorr pprroovviiddees

aa ccoonnttrroolllleedd DDCC ffiieelldd vvoollttaaggee ttoo tthhee eexxcciitteerr ssttaattoorr rreessuullttiinngg iin

aa ccoonnttrroolllleedd ggeenneerraattoorr tteerrmmiinnaall vvoollttaaggee.

VVoollttaaggee RReegguullaattiioon

IInn tthhee ssttaannddaarrdd ccoonnffiigguurraattiioonn ((sshhuunntt eexxcciitteedd)),, tthhee aauuttoommaattiic

vvoollttaaggee rreegguullaattoorr rreecceeiivveess bbootthh iittss iinnppuutt ppoowweerr aanndd vvoollttaagge

sseennssiinngg ffrroomm tthhee ggeenneerraattoorr''ss oouuttppuutt tteerrmmiinnaallss ((SSeeee FFiigguurree 11)).

WWiitthh tthhee ooppttiioonnaall PPMMGG ccoonnffiigguurraattiioonn,, tthhee rreegguullaattoorr rreecceeiivvees

iinnppuutt ppoowweerr ffrroomm tthhee PPMMGG.. TThhee rreegguullaattoorr aauuttoommaattiiccaalllly

mmoonniittoorrss tthhee ggeenneerraattoorr''ss oouuttppuutt vvoollttaaggee aaggaaiinnsstt aann iinntteerrnnaal

rreeffeerreennccee sseett ppooiinntt aanndd pprroovviiddeess tthhee nneecceessssaarryy DDCC oouuttppuut

vvoollttaaggee ttoo tthhee eexxcciitteerr ffiieelldd rreeqquuiirreedd ttoo mmaaiinnttaaiinn ccoonnssttaannt

ggeenneerraattoorr tteerrmmiinnaall vvoollttaaggee.. AAddjjuussttiinngg tthhee rreegguullaattoorr''s

rreeffeerreennccee sseett ppooiinntt cchhaannggeess tthhee ggeenneerraattoorr''ss tteerrmmiinnaall vvoollttaaggee.

CCoonnssuulltt tthhee rreegguullaattoorr mmaannuuaall ffoorr ssppeecciiffiicc aaddjjuussttmmeenntt aannd

ooppeerraattiinngg iinnssttrruuccttiioonnss.

n

.

.

a

s

l

r

r

o

e

,

s

s

r

e

-

g

d

s

s

n

NNOONNLLIINNEEAARR LLOOAADDIINNG

SSoolliidd ssttaattee eelleeccttrroonniicc ccoonnttrrooll ddeevviicceess ((vvaarriiaabbllee ffrreeqquueennccy

ddrriivveess,, pprreecciissiioonn mmoottoorr ccoonnttrroollss,, bbaatttteerryy cchhaarrggeerrss,, eettcc..)) uuttiilliizze

eelleeccttrroonniicc sswwiittcchhiinngg cciirrccuuiittss ((tthhyyrriissttoorrss,, SSCCRRss,, DDiiooddeess,, eettcc..)).

TThheessee sswwiittcchhiinngg cciirrccuuiittss iinnttrroodduuccee hhiigghh ffrreeqquueennccyy hhaarrmmoonniiccss,

wwhhiicchh ddiissttoorrtt tthhee nnoorrmmaall wwaavveeffoorrmm ooff tthhee ggeenneerraattoorr.. TThhiis

ccrreeaatteess aaddddiittiioonnaall hheeaatt iinn tthhee ggeenneerraattoorr wwiinnddiinnggss aanndd mmaay

ccaauussee tthhee ggeenneerraattoorr ttoo oovveerr--hheeaatt.. PPrroobblleemmss tthhaatt ccaann ooccccuur

aarree nnoott lliimmiitteedd ttoo tthhee ggeenneerraattoorr.. PPoooorr wwaavvee sshhaappee mmaay

aaddvveerrsseellyy eeffffeecctt vvaarriioouuss llooaaddss ccoonnnneecctteedd ttoo tthhee ggeenneerraattoorr.

CCoonnssuulltt MMaarraatthhoonn EElleeccttrriicc ffoorr ffuurrtthheerr iinnffoorrmmaattiioonn rreellaattiivvee tto

nnoonnlliinneeaarr llooaaddss.

IINNSSTTAALLLLAATTIIOON

.

N

PPRREEPPAARRAATTIIOONN FFOORR UUSSE

c

e

.

s

y

l

t

t

s

.

d

AAlltthhoouugghh tthhee ggeenneerraattoorr hhaass bbeeeenn ccaarreeffuullllyy iinnssppeecctteedd aannd

tteesstteedd iinn ooppeerraattiioonn pprriioorr ttoo sshhiippmmeenntt ffrroomm tthhee ffaaccttoorryy,, iitt iis

rreeccoommmmeennddeedd tthhaatt tthhee ggeenneerraattoorr bbee tthhoorroouugghhllyy iinnssppeecctteedd.

CChheecckk aallll bboollttss ffoorr ttiigghhttnneessss aanndd eexxaammiinnee tthhee iinnssuullaattiioonn oon

lleeaadd wwiirreess ffoorr cchhaaffiinngg pprriioorr ttoo pprroocceeeeddiinngg wwiitthh iinnssttaallllaattiioonn.

RReemmoovvee aallll sshhiippppiinngg ttaappeess,, bbaaggss,, sskkiiddss aanndd rroottoorr ssuuppppoorrt

bblloocckkiinngg.. FFoorr ttwwoo bbeeaarriinngg uunniittss,, rroottaattee tthhee sshhaafftt bbyy hhaanndd tto

eennssuurree tthhaatt iitt rroottaatteess ssmmooootthhllyy wwiitthhoouutt bbiinnddiinngg.

G

y

e

.

,

s

y

r

y

.

o

E

d

s

.

n

.

t

o

.

MMOOTTOORR SSTTAARRTTIINNG

WWhheenn aa mmoottoorr iiss ssttaarrtteedd,, tthhee mmoottoorr ddrraawwss aa llaarrggee ssuurrggee oof

ccuurrrreenntt.. TThhiiss ssttaarrttiinngg ccuurrrreenntt iiss eeqquuiivvaalleenntt ttoo tthhee mmoottoorrs

lloocckkeedd rroottoorr oorr ssttaallll ccuurrrreenntt aanndd iiss 55 ttoo 1100 ttiimmeess'' nnoorrmmaall ffuulll

llooaadd ccuurrrreenntt.. WWhheenn tthhee ggeenneerraattoorr ssuupppplliieess tthhiiss iinn--rruusshh oof

ssttaarrttiinngg ccuurrrreenntt,, tthhee ggeenneerraattoorr vvoollttaaggee ddiippss tteemmppoorraarriillyy.. IIf

tthhee mmoottoorr iiss ttoooo llaarrggee ffoorr tthhee ggeenneerraattoorr,, tthhee ggeenneerraattoorr’’s

vvoollttaaggee ddiippss ggrreeaatteerr tthhaann 3300 ppeerrcceenntt.. TThhiiss mmaayy rreessuulltt iinn tthhe

mmoottoorr ssttaarrtteerr ddee--eenneerrggiizziinngg oorr tthhee mmoottoorr ssttaalllliinngg.. MMaaggnnaaPPlluus

G

f

s

l

f

f

s

e

s

6

6

Page 32

WWAARRNNIINNG

DDIISSAABBLLEE AANNDD LLOOCCKKOOUUTT AANNYY EENNGGIINNEE CCRRAANNKKIINNG

DDEEVVIICCEESS BBEEFFOORREE AATTTTEEMMPPTTIINNGG TTOO IINNSSTTAALLLL OOR

SSEERRVVIICCEE TTHHEE GGEENNEERRAATTOORR.. FFOORR EELLEECCTTRRIIC

SSTTAARRTT SSEETTSS,, DDIISSCCOONNNNEECCTT TTHHEE CCRRAANNKKIINNG

BBAATTTTEERRYY.. FFOORR AAIIRR SSTTAARRTT,, DDIISSCCOONNNNEECCTT TTHHEE AAIIR

SSUUPPPPLLYY.. FFOORR MMOOTTOORR GGEENNEERRAATTOORR SSEETTSS,, OOPPEEN

TTHHEE PPOOWWEERR SSUUPPPPLLYY TTOO TTHHEE DDRRIIVVEE MMOOTTOORR.

FFAAIILLUURREE TTOO CCOOMMPPLLYY WWIITTHH TTHHEESSEE SSAAFFEETTY

PPRROOCCEEDDUURREESS CCOOUULLDD RREESSUULLTT IINN SSEEVVEERRE

PPEERRSSOONNAALL IINNJJUURRYY OORR EEQQUUIIPPMMEENNTT DDAAMMAAGGEE.

NNEEVVEERR ""BBAARR OOVVEERR"" TTHHEE EENNGGIINNEE GGEENNEERRAATTOOR

SSEETT UUSSIINNGG TTHHEE GGEENNEERRAATTOORR''SS FFAANN.. TTHHEE FFAANN IIS

NNOOTT DDEESSIIGGNNEEDD FFOORR TTHHIISS PPUURRPPOOSSEE.. BBAARRRRIINNG

OOVVEERR TTHHEE SSEETT WWIITTHH TTHHEE FFAANN CCOOUULLDD DDAAMMAAGGE

TTHHEE FFAANN AANNDD RREESSUULLTT IINN PPEERRSSOONNAALL IINNJJUURRYY OOR

EEQQUUIIPPMMEENNTT DDAAMMAAGGEE.

.

G

.

ddrriivveerr aanndd tthhee ggeenneerraattoorr''ss sshhaafftt.. AAlliiggnniinngg tthhee ggeenneerraattoorr aannd

iittss ddrriivveerr aass aaccccuurraatteellyy aass ppoossssiibbllee wwiillll rreedduuccee vviibbrraattiioonn,

iinnccrreeaasseess bbeeaarriinngg lliiffee,, aanndd eennssuurree mmiinniimmuumm ccoouupplliinngg wweeaarr.

G

R

C

G

R

N

.

Y

E

R

S

G

E

R

IItt mmaayy bbee nneecceessssaarryy ttoo sshhiimm tthhee ggeenneerraattoorr ffeeeett ffoorr pprrooppeer

ssuuppppoorrtt aanndd aalliiggnnmmeenntt.. SSeeccuurree tthhee ffeeeett ooff tthhee ggeenneerraattoorr wwiitth

ggrraaddee 55 oorr ggrreeaatteerr bboollttss tthhrroouugghh tthhee hhoolleess pprroovviiddeedd iinn tthhe

mmoouunnttiinngg ffeeeett.. CCoonnssuulltt tthhee ccoouupplliinngg mmaannuuffaaccttuurreerr''s

iinnssttrruuccttiioonnss ffoorr aalliiggnnmmeenntt ssppeecciiffiiccaattiioonnss aanndd pprroocceedduurreess.

GGEENNEERRAATTOORR MMOOUUNNTTIINNG

TTwwoo BBeeaarriinngg UUnniittss ---- BBeelltt DDrriivveen

TTwwoo bbeeaarriinngg MMaaggnnaaPPLLUUSS ggeenneerraattoorrss ccaann bbee bbeelltt ddrriivveen

pprroovviiddeedd bbeellttss aarree ssiizzeedd aanndd aapppplliieedd ccoorrrreeccttllyy.. PPlleeaassee rreeffeer

ttoo yyoouurr ssuupppplliieerr ooff bbeellttss aanndd sshheeaavveess ffoorr ccoorrrreecctt ssiizziinngg aannd

tteennssiioonniinngg ssppeecciiffiiccaattiioonnss.. AA bbeeaarriinngg lliiffee ccaallccuullaattiioonn sshhoouulld

bbee ppeerrffoorrmmeedd.. MMaarraatthhoonn EElleeccttrriicc rreeccoommmmeennddss aa mmiinniimmuum

BB--1100 lliiffee ooff 4400,,000000 hhoouurrss.. IIff ccoogg ttyyppee bbeellttss aarree uusseedd,, a

vviibbrraattiioonn mmaayy bbee iinnttrroodduucceedd wwhhiicchh ccoouulldd lleeaadd ttoo pprreemmaattuurre

ffaaiilluurree ooff tthhee bbeeaarriinnggss.

.

G

n

d

,

.

r

h

e

s

.

n

r

d

d

m

a

e

GGEENNEERRAATTOORR MMOOUUNNTTIINNG

SSiinnggllee BBeeaarriinngg UUnniittss.

SSiinnggllee bbeeaarriinngg uunniittss aarree pprroovviiddeedd wwiitthh aann SSAAEE ffllyywwhheeeel

hhoouussiinngg aaddaapptteerr ffllaannggee aanndd fflleexxiibbllee ddrriivvee ddiissccss.. CCoouupplliinngg tthhe

ggeenneerraattoorr''ss sshhaafftt ttoo tthhee eennggiinnee ffllyywwhheeeell iiss aaccccoommpplliisshheedd wwiitth

ssppeecciiaall sstteeeell ddrriivvee ddiissccss bboolltteedd ttoo tthhee sshhaafftt.. IInn aaddddiittiioonn ttoo tthhe

ddrriivvee ddiissccss,, tthheerree mmaayy bbee aa hhuubb ssppaacceerr,, ssppaacceerr ddiissccss,, oorr a

ccoommbbiinnaattiioonn ooff hhuubb ssppaacceerr aanndd ssppaacceerr ddiissccss iinnsseerrtteed

bbeettwweeeenn tthhee ddrriivvee ddiissccss aanndd tthhee sshhaafftt ttoo aacchhiieevvee tthhee pprrooppeer

sshhaafftt eexxtteennssiioonn ((""GG"" ddiimmeennssiioonn ppeerr SSAAEE JJ662200cc)).. HHoolleess aarre

pprroovviiddeedd iinn tthhee ppeerriipphheerryy ooff tthhee ccoouupplliinngg ddiissccss,, wwhhiicch

ccoorrrreessppoonndd ttoo ttaappppeedd hhoolleess iinn tthhee pprriimmee mmoovveerr''ss ffllyywwhheeeell.

TThhee oouuttssiiddee ddiiaammeetteerr ooff tthhee ddrriivvee ddiissccss ffiitt iinn aa rraabbbbeett iinn tthhe

ffllyywwhheeeell ssoo tthhaatt ccoonncceennttrriicciittyy iiss aassssuurreedd.

GGrraaddee 88 ppllaaccee bboollttss aanndd hhaarrddeenneedd wwaasshheerrss aarre

rreeccoommmmeennddeedd ttoo mmoouunntt tthhee ddrriivvee ddiissccss ttoo tthhee ffllyywwhheeeell.. DDO

NNOOTT UUSSEE SSPPLLIITT TTYYPPEE LLOOCCKK WWAASSHHEERRS

wwaasshheerrss wwhheenn bbiittiinngg iinnttoo tthhee ddrriivvee ddiisscc ccaauussee ssttrreessss rriisseerrss,

wwhhiicchh mmaayy rreessuulltt iinn tthhee ddiisscc ffrraaccttuurriinngg.

TThhee SSAAEE ffllyywwhheeeell hhoouussiinngg aaddaapptteerr rriinngg aanndd tthhee eennggiinne

ffllyywwhheeeell hhoouussiinngg aarree ddeessiiggnneedd ttoo mmaattcchh eeaacchh ootthheerr wwiitthh nno

ffuurrtthheerr aalliiggnnmmeenntt nneecceessssaarryy.. UUssee ggrraaddee 55 oorr ggrreeaatteer

mmoouunnttiinngg bboollttss.. MMaaggnnaaPPLLUUSS ggeenneerraattoorr ffrraammeess aarre

ccoonnssttrruucctteedd wwiitthh ttwwoo oorr tthhrreeee bboolltthhoolleess ppeerr ffoooott.. TThhee ffeeeet

sshhoouulldd bbee sshhiimmmmeedd wwhheerree nneecceessssaarryy ttoo oobbttaaiinn ssoolliidd ccoonnttaacct

wwiitthh tthhee ssuubb--bbaassee.. WWiitthh tthhee ffrraammee sseeccuurreellyy bboolltteedd ttoo tthhe

eennggiinnee ffllyywwhheeeell hhoouussiinngg,, tthheerree iiss nnoo ssiiddee tthhrruusstt oorr ppuullll oonn tthhe

ggeenneerraattoorr ffrraammee,, tthhuuss nnoo rreeaall nneeeedd ttoo sseeccuurree tthhee ffeeeett wwiitth

mmoorree tthhaann oonnee bboolltt ppeerr ffoooott.

.

GGEENNEERRAATTOORR MMOOUUNNTTIINNG

TTwwoo BBeeaarriinngg GGeenneerraattoorrss ---- DDiirreecctt DDrriivve

G

.

S

..

SSpplliitt lloocck

.

.

G

e

EENNDD PPLLAAYY TTEESSTTIINNG

l

e

h

e

a

d

r

e

h

.

e

e

O

k

,

RReeffeerr ttoo tthhee eennggiinnee mmaannuuaall ffoorr rreeccoommmmeennddeedd eennddppllaay

ssppeecciiffiiccaattiioonnss aanndd mmeeaassuurreemmeenntt pprroocceedduurreess.. IIff eennddppllaayy iis

nnoott ttoo ssppeecciiffiiccaattiioonn,, iitt iiss aann iinnddiiccaattiioonn tthhaatt tthhee ggeenneerraattoorr sshhaafft

iiss nnoott mmoovviinngg ffrreeeellyy iinn tthhee aasssseemmbbllyy,, aanndd nnoorrmmaall lliiffee ooff tthhe

tthhrruusstt bbeeaarriinngg ccoouulldd bbee iimmppaaiirreedd.. PPrroobbaabbllee ccaauusseess ooff tthhiis

pprroobblleemm aarree:

1

1

..IImmpprrooppeerr sseeaattiinngg ooff ddrriivvee ddiissccss iinn tthhee ffllyywwhheeeell rreessuullttiinngg iin

mmiissaalliiggnnmmeenntt.

.

22.

IImmpprrooppeerr mmaattiinngg ooff ggeenneerraattoorr ffrraammee ttoo eennggiinnee ffllyywwhheeeel

hhoouussiinngg rreessuullttiinngg iinn mmiissaalliiggnnmmeenntt.

.

33.

IImmpprrooppeerr ""GG"" ddiimmeennssiioonn ppeerr SSAAEE JJ662200cc oonn eeiitthheerr tthhe