Page 1

BSC Series 2000/ 3000

Servo Control

7/92

Installation & Operating Manual

Page 2

C O N T E N T S

1.0 Specifications ............................... 1

1.1 Usage Definitions ....................... 1

1.2 Identification .............................. 1

1.3 Features ..................................... 1

1.4 Declaration of Conformity .......... 2

1.5 EMC Conformity and CE Marking 2

1.5.1 EMC Installation Instructions ..... 2

1.5.2 Specifications add components .. 3

1.5.2.1 Mains Filters .............................. 3

1.5.2.2 Connection Cables ..................... 4

1.5.2.3 Screen Connections .................... 4

1.5.2.4 Connectors ................................ 4

1.5.2.5 PG-Cable Glands ....................... 5

1.6 Technical Data ........................... 5

1.6.1 Power Section ............................ 5

1.6.2 24VDC Input ............................. 6

1.6.3 Velocity Controller .................... 6

1.6.4 Mechanical Section .................... 6

1.6.5 Environmental Section ............... 7

2.0 Installation Recommendations .... 7

2.1 Mechanical Installation ............... 7

2.2 Electrical Installation .................. 8

3.0 Interconnection Diagram ............. 9

4.0 BSC Wiring .............................. 10

4.1 Power Wiring ............................. 10

4.1.1 Power Supply ............................. 10

4.1.2 24VDC Connection .................... 10

4.1.3 Motor Wiring ............................. 10

4.2 Control- and Signal Wiring ......... 11

4.2.1 Control Inputs ............................ 11

4.2.2 Control Outputs ......................... 12

4.2.3 Command Input ......................... 13

4.2.4 Encoder Output ......................... 13

4.2.5 Resolver ..................................... 13

4.3 Minimum Wiring Diagram .......... 14

5.0 Dimensions ................................... 16

6.0 System Set Up Procedure ............ 18

6.1 Presets ....................................... 18

6.1.1 Potentiometer Preset .................. 18

6.1.2 DIP-Switches Settings ................ 18

6.2 System Set Up Step by Step ....... 19

6.3 System Tuning ........................... 20

7.0 Status Monitor ............................. 22

8.0 Testsignals .................................... 23

9.0 Identity Modul ............................. 23

9.1 Component Functions ................ 23

9.2 Component Layout .................... 24

10.0 I/O Hardware Description ........... 24

10.1 Input Signals .............................. 25

10.2 Output Signals ........................... 26

10.3 Encoder Output ......................... 27

10.3.1 Encoder Signals ......................... 27

10.4 Resolver ..................................... 28

Page 3

1

L

1.0 Specification

1.1 Usage Definitions

The amplifiers of the series BSC2000/3000 are electrical equipment for industrial power installations. They are designed for

machine applications, which need variable speed controlled three-phase A.C. motors.

This product is only for use in industrial applications as described in norms EN 60204 and VDE 0160. This means use

BSC2000/3000 in stationary groundbased applications only. It is not meant for use in home appliances, medical technics,

cars, ships or airplanes.

Before the BSC is put into operation, please contact your Electric-Supply-Company for special operating conditions.

1.2 Identification

BSC x x xx - xx

24 - External 24VDC-I nput

{

MR - Multiresolvercard

15

25

Nomin al C urrent (Amps)

35

{

45

1.3 Features

A BSC is an analog 1 axis amplifier with integrated power stage.

It provides the following features:

POWER SECTION:

• 3 respectively 4 output current versions (15/25/35/45A)

available.

• Ratio peak : nominal current = 2:1.

Both values independently adjustable.

• All BSC amplifiers are short circuit proof and require

no minimum load.

CONTROL I/O Section:

• 5 opto isolated control inputs for dedicated amplifier

functions

• Diagnostic display on front panel

GENERAL:

• Protection class IP20 (acc. to DIN40 050 / IEC144)

• Cooling: self-ventilation

20 : Series 2000

{

30 : Series 3000

BALDOR-SERVO-CONTRO

• Output power up to 30kVA

• Brushless-servomotors (2 to 8 poles) can be connected.

(Feedback: 2-pole resolver)

• Power wiring via terminal screws (max. wiring diameter

10mm²/AWG7)

• Wiring of control inputs and outputs via plug type

screw connection (max. wiring diameter 1,5mm²/

AWG15) or SUB-D connector

• Isolation classification according to DIN 0110 with

overvoltage category II

• Contamination level 2

Page 4

2

1.4 Declaration of Conformity

Herewith we declare, that our products are components only and not ready for immediate or instant use within the meaning

of "Safety law of appliance", "EMC Law" or "Machine directive".

The final mode of operation is defined only by the insertion into the user´s construction.

It is the responsibility of the user to verify that his construction is in accordance with existing regulations.

It is prohibited by law to put the machine into operation before verifying that the machine is in accordance with EC directive

89/392 and 921/368.

The supplier declares product conformity with the following standards:

DIN VDE 0160 / 05.88 Electronic equipment for use in electrical power installations

DIN VDE 0100 Erection of power installations with nominal voltages up to 1000V

DIN IEC 326 Part 1 / 10.90 Design and use of printed boards

DIN VDE 0110 Part 1-2 / 01.89 Dimensioning of clearance and creepage distances

DIN VDE 0110 Part 20 / 08.90

EN 60529 / 10.91 Degrees of protection provided by enclosures

1.5 EMC - Conformity and CE - Marking

The application of EMC conformal component and partly systems relieves the observance of EMC Guidelines and the

guaranty of conformity for the manufacturer of machines. Therefore all standard components and partly systems will be

tested according to the requirements of EMC regulation. Those tests will be executed by a competent and indepen-dent

institution. The conformity of the products will be confirmed by a declaration of conformity from the European Community.

The installation instructions refer to elimination of radio interference as well as to immunity from noise for BALDOR Drive

Systems.

Thereby the user is informed about the EMC critical parts. The examples don´t show the complete possibilities of cabinet

components or constructions.

Guidelines for EMC Conformity

⇒ Machine Guideline (89/392/EWG) - Machine Safety Law

Application since 01.01.95

⇒ EMV Guideline (89/336/EWG) - EMC Law

Applicade 01.01.96 on

⇒ Low Voltage Guideline (73/23/EWG) - Machine Safety Law

Applicade 01.01.97 on

1.5.1 EMC Installation Instructions

To ensure electromagnetical compatibility (EMC) at hostile environment inside the cabinet following instructions are to be

observed for construction. Only the implementation of following provisions enables the reduction of interference down to

required values.

For the Drives Technology following key points are to be considered:

- Grounding

- Screening

- Filtering

Page 5

3

Furthermore the relevant chapters of the Installation manual for the controllers have to be observed.

For installation of the drives system the starting point is the installation into a cabinet.

For construction of a cabinet the following installation instructions have to be considered:

A) All metal conducting parts of a cabinet are to be connected arealy and conductable.Eventually

the connections should be placed with an earthing strap at a central grounding point .

B) Signal lines and Power Cables are to be connected separately. (Avoid interaction space)

C) The screen connection of the signal lines and the power cables has to be ensued on a screen linequaranteeing

enough space. This screen line also has to be conductable and connected to

the remaining housing parts.

D) The cable to the regeneration resistor has to be screened. The screen connection should be on

both sides.

E) The mounting of the mains filter has to be situated at the input of the cabinet or behind the transformer. The

filter is to connect on ground (cabinet housing, mounting plate etc.).

F) Wiring has to be conducted bundled and close to the cabinet housing or at the mounting line.

The unused leads of a cable have to be connected on one side with ground.

G) In case of worse potential balance between the screen connections a compensating leak with at least

10mm2 (AWG) has to be provided parallely in addition to reduction of the screen current.

1)

Grounding in general describes all metal parts which can be connected to a protective conductor, e.g. housing of

switch cabinet, motor housing, fundament grounder.

1)

1)

1.5.2 Specifications and Additional Components

1.5.2.1 Mains Filter

Following results are desired through the application of mains filters:

The electronic system should be protected from high frequency interferences which could enter via the mains cable

(immunity from noise) and vice versa the mains cable may not transmit interferences from the electro-nic systems to

the adjoining components (elimination of radio interference).

In the main line a mains input filter has to be provided between transformer and controller

(In case of direct connecton this has to be in front of the controller).

To choose the fitting mains filter types following points have to be considered:

1. The need of power of the connected controller. Thereby the capacity an d the ability of peak phase current has to be

considered.

2. The required or prevailing mains impedance.

This table shows the corresponding mains filter types for 3 phase input:

Type

FN 351 - 8 - 29

FN 351 - 16

FN 351 - 25

FN 351 - 36

FN 351 - 50 - 29

FN 351 - 80 - 29

FN 351 - 110 - 29

Rated Voltage

[V]

3x 440 8 16 8.0 1.8 24667

3x 440 16 16 9.0 1.8 24668

3x 440 25 170 9.0 3.0 24669

3x 440 36 170 10.5 3.0 24670

3x 440 50 190 12.5 3.1 24671

3x 440 80 210 26.0 9.5 24672

3x 440 110 210 28.0 9.5 24673

Rated Current

(at 40°C)

[A]

Leakage

Current

[mA]

Power

Losses

[W]

Weight

[kg]

BALDOR

-

ID-No

Page 6

1.5.2.2 Connection Cables

All cables have to be screened.

Motorcable and Signalcable

Motorcable 4 x 1.0 mm2 21599

Motorcable 4 x 2.5 mm2 21364

Motorcable 4 x 6.0 mm2 21597

Resolvercable 3 x [2 x 0.14 mm2] 19413

Regen Resistorcable 3 x 2.5 mm2 11302

1.5.2.3 Screen Connection

4

BALDOR

ID - No.

5mm Rail Wiring Diameter

10mm Rail

for T- and double T-profile

1.5.2.4 Connectors

Connection Designation BALDOR - ID -No.

for Motorcable

Plug

Socket

for Resolvercable

Plug

Socket

Connector

Housing

Siemens Clamp Siemens -No.

2

1.5 - 16 mm

1.5 - 35 mm

16 - 70 mm

16 - 120 mm

Wiring Diameter

95 - 300 mm

CONN SET FEM

CONN SET MALE

CONN SET FEM

CONN SET MALE

for BSC with EMC-Regulation

connector X2 with housing

2

2

2

2

8US19 21 -2AA00

8US19 41 -2AA00

2 x 4 pole

2 x 4 pole

12/6 pole

12/6 pole

25043A

25049A

-2AB00

-2AD00

-2AC00

24654A

24656A

24655A

24657A

Page 7

1.5.2.5 PG - Cable Glands

PG Cable Gland Cable Dimensions Designation BALDOR

PG 9

PG 13.5

PG 21

4 - 8 mm

Resolvercable

BALDOR ID-No.19413

6 - 12 mm

Motorcable

BALDOR ID-No. 21599

13 - 18 mm

Motorcable

BALDOR ID-No. 21364

1.6 Technical Data

All values at T

= 40 °C, if not otherwise specified.

amb

1.6.1 Power Section

5

ID - No.

SCREWING 24658

SCREWING 24659

SCREWING 24660

General Unit BSC

2015

Nominal DC-Bus-Voltage

Uin (BPS) = 230V

Nominal DC-Bus-Voltage

Uin (BPS) = 400V

Nominal DC-Bus-Voltage

Uin (BPS) = 460V

DC-Bus-Voltage

absolute min./max.

Output Voltage Line/Line

fundamental wave; @V

Nominal Phase Current (±10%) A

Peak Phase Current (±10%)

1.5s ±0.5s

Nominal Output Power kVA 6.5 10.8 15.1 19.5 13.0 21.6 30.3

Efficiency % > 95

Min. Load Inductance μH 200

DC-Bus (nom.)

VDC 320 -

VDC - 560

VDC - 650

VDC 0 ... 350 0 ... 740

V

0 ... 250 0 ... 500

RMS

15 25 35 45 15 25 35

RMS

A

30 50 70 90 30 50 70

RMS

BSC

2025

BSC

2035

BSC

2045

BSC

3015

BSC

3025

BSC

3035

Output Frequency Hz 0 ... 500

Nominal Switching Frequency kHz 8.5

Page 8

6

1.6.2 24V

24V-Input Unit BSC2000 BSC3000

DC

Input

Input Voltage Range

absolute min./max.

max. V

Input Current; @ 28VDC A

Surge Current at Power On

@ 28VDC; @ 100ms

Ripple

= ±10%

VDC

1.6

RMS

A

2.5

RMS

20 ... 29

1.6.3 Velocity Controller

Preamplifier Unit BSC2000 BSC3000

Command Input VDC 0 .. ±10

Drift (velocity controller) rpm/K 0.4

Balance (velocity controller) rpm typ. 8 ; adjustable to 0

Resolverfeedback Unit BSC2000 BSC3000

Resolution bit 12

Encoder-Simulation ppr 250 / 500 / 1000 / 1024

Signal 5V TTL ; A;A/; B;B/; C;C/

Reference Pulse available; non adjustable

1.6.4 Mechanical Section

Mechanical Unit BSC2000 BSC3000

Mounting - Bookstyle or Thru the Wall

Dimensions mm 105 x 357 x 328 / 140 x 357 x 328 1)

Weight kg 8.5 / 9.5 1)

1) : BSC2045/3035

Page 9

7

1.6.5 Environmental Section

Environmental Unit BSC2000 BSC3000

Operating Temperature Range °C +5 ... +45

Storage Temperature Range °C -25 ... +70

Humidity % 10 ... 90; not condensating; according to DIN40 040, Class F

Class of Protection (Enclosure) - IP20; according to DIN40 050 / IEC 144

Max. Installation Altitude / M.S.L. m 1000

Shock - 10G; according to DIN IEC 68-2-6/29

Vibration - 1G; 10 ... 150 Hz; according to DIN IEC 68-2-6/29

Legend:

This is an INFORMATION sign.

If this information is read, installation and / or

amplifier operating problems can be avoided

in advance.

This sign means ATTENTION.

In all cases it must be read and taken into

account.

Non-observance can cause dangerous situations

for equipment and personnel.

2.0 Installation Recommendations

2.1 Mechanical Installation

- For installation of your system use a cabinet with a protection class that suits your environmental conditions.

- As cooling air freely enters the unit, the environment must be free from corrosive chemical substances, oil, vapour,

steam, metal particles and dust.

- Make sure that cooling is provided.

- Make sure that the top of the unit is covered during installation to prevent particles from falling into the unit.

- Keep DC-bus links as short as possible. Therefore always mount BSC2000/3000-combinations side by side.

- Mount all BSC vertical (Terminal blocks to the top).

- Use BSC2000/3000 in stationary groundbased applications only.

Page 10

2.2 Electrical Installation

8

Page 11

3.0 Interconnection Diagram

9

Content of delivery: mating connector to X1 - 4 and X10. Order-no´s for mating connectors (spare part or completion):

X2: #16000 (20 pole, female); X3: #20506 (8 pole, female); X4: #17934 (10 pole, female); X5: #16215 (9 pole, male)

Connector X4 is reserved for option Multi-Resolver (Absolute positioning). For interconnection diagram refer to manual

Multi-Resolver.

Page 12

10

4.0 BSC Wiring

In chapter 4.3 you will find the typical (minimum) wiring of the system . The following pages show some special

applications and the typical wiring in more detail.

This chapter is valid for all BSC versions.

ATTENTION: For the system set up (chapter 6) it is nessesary to wire the system step by step.

It is recommended to follow the system set up procedure, especiallly for users who are not

very familar with the BSC amplifier series.

4.1 Power Wiring

4.1.1 Power Supply

The BSC amplifier will be supplied from a BPS with the DC-bus voltage. The connection between BSC and BPS must be as

short as possible. The wiring can be done with copper bars (#23176).

Wiring Power Supply:

Chapter 4.3 shows the wiring in detail

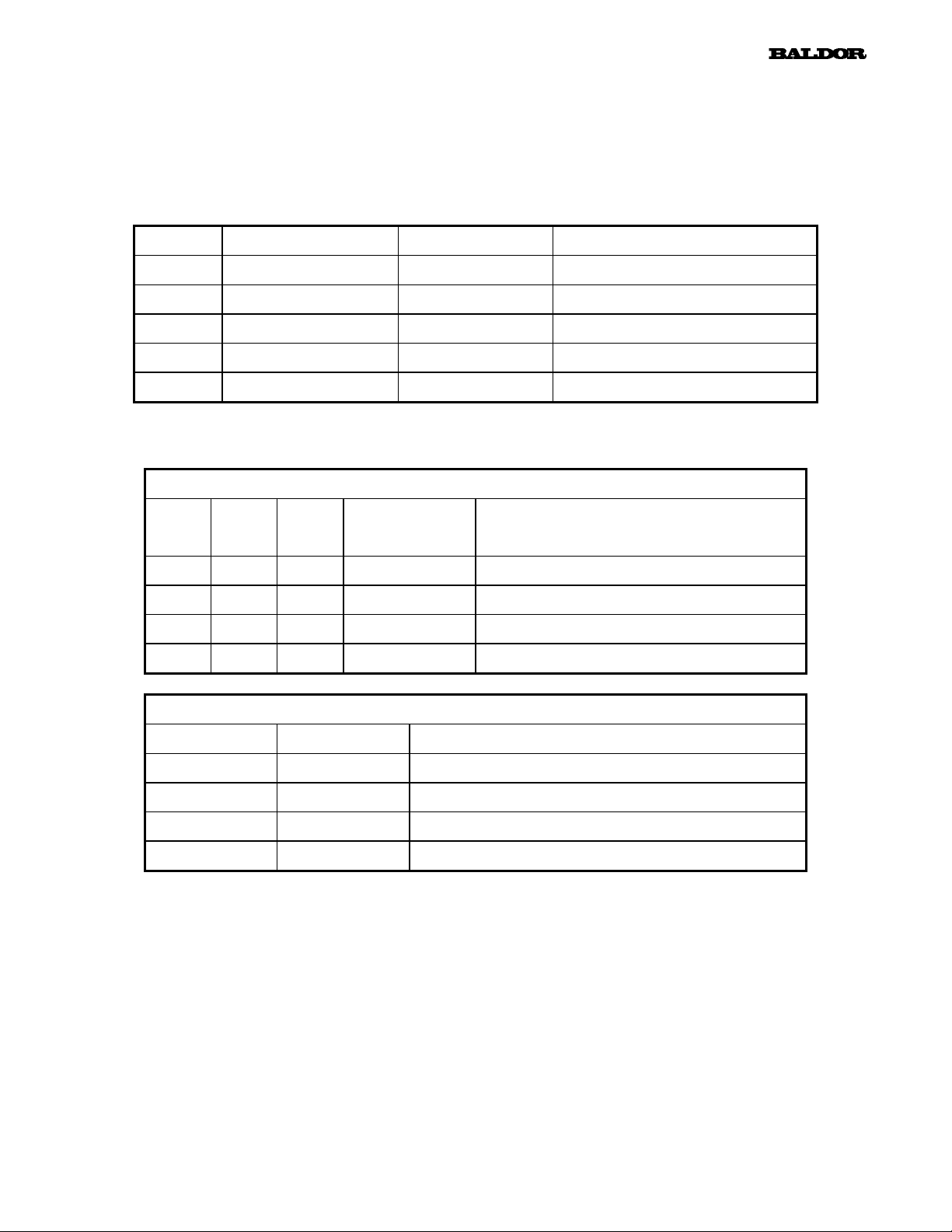

4.1.2 24V

A BSC2000/3000 needs an external 24V control supply. This voltage supplies the amplifiers control circuits.

The advantage is, if main power is switched off, control circuits are still supplied and position information gets not lost.

This supply must be linked to BSC connector X10 (Pin 1 and 2). The BPS2000/3000 provide the needed 24V output. This

output is for that purpose and has the same denotation on BPS.

If the BSC is not supplied with the BPS, an external power supply must be connected to connector X10.

The external power supply must fullfil certain specifications (see chapter 1.6.2).

Wiring 24VDC-option:

- Connection

DC

1) The shown BPS, can be replaced by an external 24V-power-supply.

The amount of connected BSC´s (n) which can be connected to one BPS, is "5"

(refer to BPS2000/3000 manual)

2) The wiring of X10 pin 3 and 4 is nessesary for proper BSC operation. For details please refer to chapter

4.2.1.

4.1.3 Motor Wiring

The motor must be connected to the following terminals:

U Phase U

V Phase V

W Phase W

Page 13

A wiring example is shown in chapter 4.3.

11

4.2 Control- and Signal Wiring

This chapter is valid for all BSC versions.

The wiring of the control in- and outputs can be achieved with one cable only unlike shown in the pictures below.

The outputs can be wired. But there is no need for BSC operation.

4.2.1 Control Inputs

The control inputs below are optoisolated. The ground return for all inputs is "CREF", connector X2.14.

Control Input Function:

Signalname Connector Switch Position / Function

Pin closed open

ENABLE X2.9 Amplifier enabled Amplifier disabled

EMStop X2.10 Amplifier is active Motor decellerates with torque to velocity 0

CWLimit X2.11 Clockwise direction of rotation enabled Clockwise direction of rotation disabled

CCWLimit X2.12 Counterclockwise direction of rotation

enabled

CurrentC X2.13 Current Mode active Velocity Mode active

A wiring proposal for the control inputs above you will find in chapter 4.3. The hardware description of the optoisola-

ted input is show in chapter 10.1.

About CurrentC (X2.13):

It is not permitted to activate or deactivate the input during amplifier is operating. The controller behavior

is completely different. The input should be fixed wired.

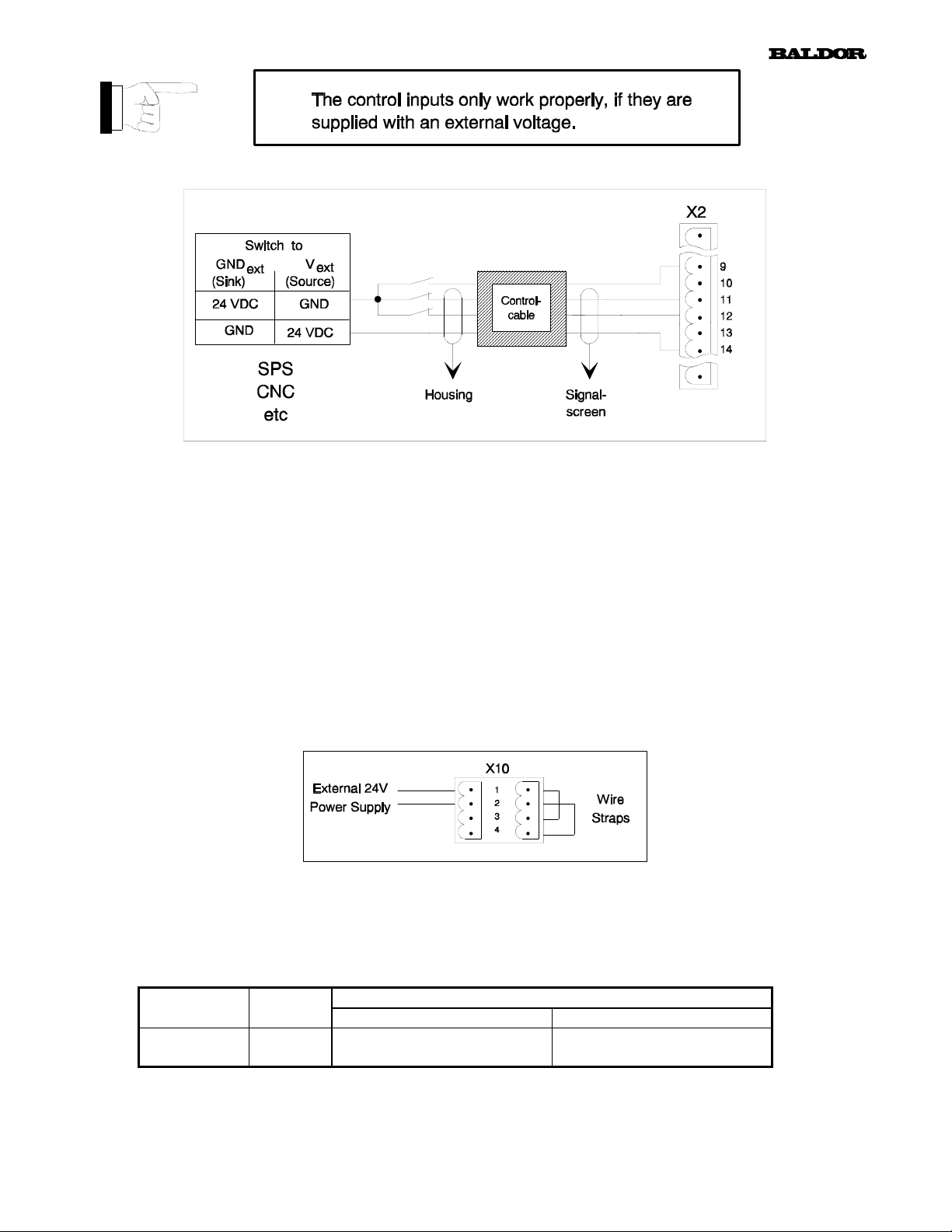

Functional example of control inputs:

The wiring of the control inputs is also shown in chapter 4.3 .

The picture by-stander shows the function and the two

wiring principles of the control inputs:

The two wiring versions are:

1) Switching to the external control input power supply.

The switch will be linked between the control input

(X2.x) and the external power supply (V

The ground return (GND

with CREF (X2.14).

2) Switch to the ground return of the external power

supply. The switch will be linked between the control

input and the external ground return (GND

The external power supply (V

wired with CREF (X2.14).

Voltage range of V

: +12 ... 29VDC

ext

) is permanetly wired

ext

) is permanently

ext

ext

).

ext

).

X2.x: "x" for connector pin,

e.g. x=9 → X2.9 = Enable-Input

Counterclockwise direction of rotation

disabled

Page 14

12

Control Input Wiring:

Control Input "±BPS Ready"

a) BSC with BPS2000/3000:

The BSC provide as default a control input "BPS Ready". If the BPS2000/3000 has an internal malfunction, the BPS will

disable the connected BSC amplifiers. The input is on connector X10 pin 3 and 4.

Under BPS fault condition, this input will be deactivated and the BSC will show the following state:

LED Ready = RED

Monitor = 2 (Undervoltage)

With this fault indication the BSC will be disabled.

b) BSC with external 24V Power Supply:

If the BSC is not operated with the BPS, an external power supply must be connected to connector X10 as shown below. In

that case, the control input "±BPS Ready" has no more function. Nevertheless the input must be wired. Without the wiring

below, the BSC will indicate fault condition like above (see a)).

4.2.2 Control Outputs

The BSC is equipped with a fault relais. The relais contact can be used to observe the amplifier status. The wiring of the fault

relais contact is optional and not nessesary for proper amplifier operation.

Control Output Function:

Signalname Connector Switch Position / Function

Pin closed open

FAULT+

FAULT -

Control Output Wiring:

see chapter 4.3

X2.15

X2.16

BSC happy

no fault indication

BSC not happy

fault indication / monitor

Page 15

13

4.2.3 Command Input

The BSC has an analog command input (±10V). The input can be wired in "single-ended" or in "differential mode".

Wiring of the command input:

4.2.4 Encoder Output

The BSC has an encoder output, which can be used for position- and/or velocity feedback for a superset controller.

The encoder output resolution (pulse per revolution; ppr) can be configured via software. The following binary resolu-tions

are available with the BSC20xx/30xx-Axx version:

250ppr 500ppr 1000ppr 1024ppr

Wiring of the encoder output:

A wiring proposal is shown in chapter 4.3.

It is strongly recommended to make the wire connection with twisted pairs and screened cable.

We recommend the use of the BALDOR encoder cable #13036.

4.2.5 Resolver

The resolver must be connected to connector X9.

Wiring of the resolver in- and outputs:

The wiring is shown in chapter 4.3.

We recommend the use of the special BALDOR resolver cable #19413.

Page 16

14

4.3 Minimum Wiring Diagram "The wiring proposal gives no warranty for

1) The power supply must be wired according to the BPS2000/3000 manual (#22705A)

2) Motorcable: # 21599: Wire diameter: 1.0mm² / AWG17 Cable outer diameter: (11.6 ±0.4)mm

# 21364: Wire diameter: 2.5mm² / AWG13 Cable outer diameter: (14.5 ±0.5)mm

# 21597: Wire diameter: 6.0mm² / AWG9 Cable outer diameter: (18.5 ±0.6)mm

3) Terminal box BSM 6R, BSM90A/90B/100A/100B

4) Connector BSM 63/80 Europe

5) The wiring diameter must fit to nominal BPS output current. The connection between BPS and the BSC ampli-

fiers must be as short as possible.

The wiring between BPS and BSC can be done with copper bars (ID-No.: #23176). Also wiring between BSC´s

can be done with copper bars. ID-No´s.: #23177 (105mm housing) #23179 (140mm housing)

# 21598: Wire diameter: 10mm² / AWG7 Cable outer diameter: (22.8 ±0.4)mm

Page 17

“Observance of valid EMI - standards"

15

6) If a very strong affect of EMI will be expected, it is recommended to connect the inside screens to DGND.

7) Resolvercable: #19413

8) Functional description of the control inputs see chapter 4.2.1. The control inputs must be supplied with an external

voltage source.

9) Control cable not available from BALDOR. Drawing shows the wiring principle only. Can be one or more cables

10) If the wiring is done like shown in the drawing, the motor rotates clock wise (view at motor shaft) with a positive

voltage on X1.1 referenced to X1.2.

11) Encodercable #13036, twisted and screened

ATTENTION: Please note also chapters 4.0. to 4.2.

Page 18

5.0 Dimensions

16

not scaled (dimensions in mm)

Page 19

17

not scaled (dimensions in mm)

1) Upper and lower fan housing brackets are not contents of delivery. They must be ordered seperately according table

below. The sets below contain both brackets and the screws.

BALDOR ID - Numbers

for Fan Housing Bracket Sets

BSC2015 / 2025 / 2035

BSC3015 / 3025

22570A

BSC2045

BSC3035

23098A

Page 20

18

6.0 System Set Up Procedure

6.1 Presets

Before applying power to the system, the following settings must be checked.

6.1.1 Potentiometer Preset

P1

P3

P4

P5

P6

Function adjustable from / to Presets ex factory

Reference Input gain 33 .. 100% Clockwise for max. input gain (100%)

Velocity feedback gain 33 .. 100% Clockwise for max. gain (100%)

Velocity Balance -110mV to +110mV Standstill at zero input command

Velocity loop gain 4.8 .. 100% Anti-clockwise for min. gain

Peak current 9 .. 100% Clockwise for max. current (100%)

6.1.2 DIP - Switch Settings

AS1-1 AS1-2 AS1-3 Number of

OFF OFF OFF 1 BSM 2 R

ON OFF OFF 2 *) BSM 63A / 80A / 80B

OFF ON OFF 3 BSM 6 R

ON ON OFF 4 BSM 90A / 90B / 100A / 100B

POLE PAIR SELECT

TYPE OF MOTORS

POLEPAIRS

ENCODER - SIMULATION

AS1-4 AS1-5 PULSES / REVOLUTION

OFF OFF 1024

ON OFF*) 1000

OFF ON 500

ON ON 250

*)

Ex factory

- DIP - Switch AS1-6

AS1-6 (ON) switches OFF the Integral- part of the velocity loop. This improves the transient response of the

controller in positioning mode. (ex factory OFF)

- Velocity or current mode select

Ex factory the amplifier is set to operate as a velocity controller. If you want to operate in current control mode,

connect 12..29 VDC to the input X2-13 (CurrentC) in reference to CGND.

Page 21

19

6.2 System Set Up Step by Step

With all initial settings completed (chapter 6.1), the set-up procedure can begin.

1. Before you connect the BSC amplifier to the BPS, the BPS must be wired and checked according to the manual

2. Now you can wire the BSC amplifier under observance of chapter 4.

It is not permitted to connect the motorcable yet. On the other hand the resolver must be linked to the motor.

3. Now switch ON the main power. The LED "READY" and the "MONITOR" must show the following:

LED "READY" = GREEN

MONITOR = "•" Decimal point on the lower right corner is illuminating

(Amplifier enabled)

Now switch off main power.

Page 22

20

4. Connect the motorcable. Switch ON the main power and activate the ENABLE-Input (X2.9); switch must be closed (see

chapter 4). The monitor will show the state:

MONITOR = "•" Decimal point on the lower right corner is illuminating

Now turn OFF the main power.

5. Now connect a variable DC- voltage (±10 VDC) to the reference input CMD+ (X2-1) and CMD- (X2-2) (see also chapter

4). Turn on the power supply. Apply a voltage between 0..+10 VDC: the motor will rotate clockwise. The DC-voltage level

corresponds with the speed and the polarity corresponds with the direction of the motion.

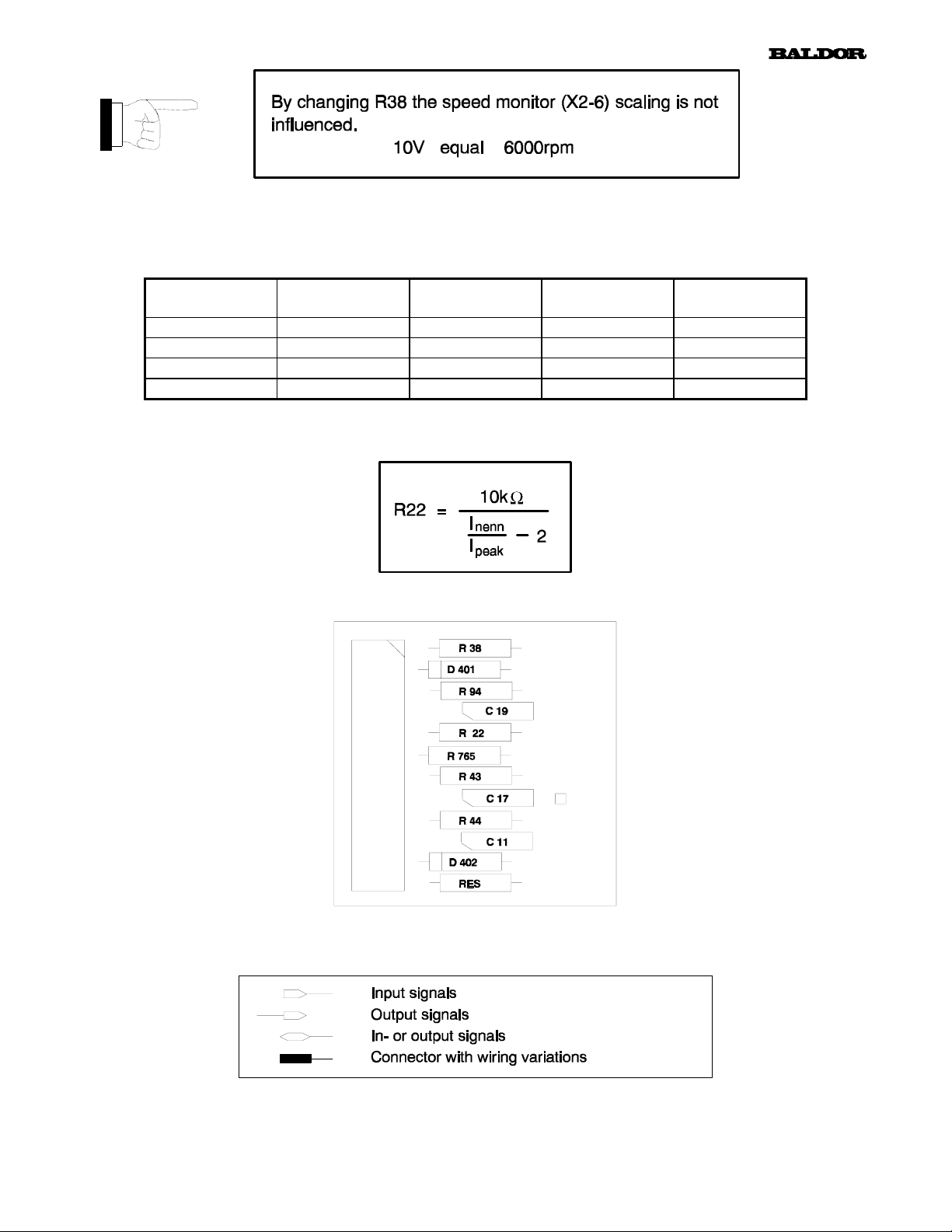

6.3 System Tuning

The BSC amplifier consists of two control loops; current- and velocity loop. The control loops can be optimized by changing

the variable components. The variable components are located on the ID-module (see chapter 9.0).

a) Current Controller

There are two current controllers for motor phase U and V. The current controller setting depends only on

the motor attached. The controllers are adjusted ex factory to the BSM motors. In general there is no need

for optimization.

b) Velocity Controller

The circuit of the velocity controller is shown below. The velocity controller performance depends on the

motor load. Most of all applications do not need an additional optimization.

With variable components R94 and C19 the velocity controller can be optimized. For this purpose a small

command step (2VDC) should be applied to the command signal input. The step response can be observed

with an oscilloscope on testpoint I

the picture in the middle. R94 and C19 are shown in normalized manner.

For an optimization in more detail, refer to the bode-diagram for velocity controller. It shows all variable

components of the velocity controller and how they act.

(X2.8). Below are shown different step responses. The optimum is

CMD

Page 23

Velocity Controller Circuit:

21

Velocity Controller Response:

Page 24

Velocity Controller Bode-Diagram

22

7.0 Status Monitor

For convience of monitoring the performance, the BSCprovides a status monitor. The indicated signs, as well as the LED

Ready have the following meaning:

LED

Ready

Green OFF Amplifier disabled no fault

Green . (DP) Amplifier enabled no fault

Red 1 Overvoltage

Red 2 Undervoltage

Red 3 Overcurrent

Red 4 Over- or Undervoltage;

Red 5 Resolver fault Parting of the cable or resolver leads short

Red 6 Electronic Fusing (see Fault 7 also) Amplifier or motor active current overload.

Yellow 7 I²t-Limit

Furthermore special display indications for operating modes are available. For detailed informations of these operating mode

indications refer to operating manual.

Monitor Status Cause

Missing, damaged or wrong designed

amplifier DC bus voltage

2x Peak Current Crest Value

Internal 15V supply

If I²t-limit is reached, amplifier will reduce

output current to it´s nominal value. After

1.5s ±0.5s BSC switches off (amplifier

disable) with fault indication "6; electronic

fusing"

regeneration resistor.

Missing wiring of X10 or problems with

BPS2000/3000; see also chapter 4.2.1

Power stage fault or motor leads short

circiut

Internal control voltage fault

circuit or missing plug-in connection

Fault detection via software.

Cycle time between motor acceleration and

deceleration is too short.

Page 25

23

8.0 Testsignals

To allow you an effective set-up of the amplifier and its control loops (PI-controller) three testsignals are acces-sible. These

testsignals allow you an optimal adjustment of the load versus the motor. Also you can monitor these signals during

operations.

Testpoint Function and Scaling

X2 - 6 Speed - Actual velocity of the motor

± 10V equal ± 6000rpm

X2 - 7 DCurrent Actual output current

0..+10V; 10V equal peak current

X2 - 8 Icmd Output of the velocity controller

± 10V equal peak current

9.0 Identity Modul (ID)

9.1 Component Functions

Components Function Value *)

R38 Scaling of Tacho (4000rpm) 4.99kΩ

D401 Plug-in protection -

R94 P-gain for velocity loop 100kΩ

C19 I-gain for velocity loop 47nF

R22 It-switching threshold (nom.current) -

R765 Special function 26.7kΩ

R43 P-gain for current loop phase U 150kΩ

C17 I-gain for current loop phase U 4.7nF

R44 P-gain for current loop phase V 150kΩ

C11 I-gain for current loop phase V 4.7nF

D402 Plug-in protection -

RES Reserved for special applications -

*) Standard values

-Scaling of tacho (R38):

0Ω for 6000rpm

4.99kΩ for 4000rpm

10.0kΩ for 3000rpm

20.0kΩ for 2000rpm

Applications over 6000rpm on request ex factory Munich.

Page 26

24

- It-switching threshold adjust:

With resistor R22 on the ID-card it is possible to adjust the It-switching threshold (It-Limit) from 0% upto 100%. Table

below shows nom. current to peak current by changing R22:

R22 BSC x015

I

= 30A

peak

- I

20kΩ

10kΩ

5kΩ

x: 2 or 3; e.g.: BSCx015 stands for BSC2015 and BSC3015

= 15,0A I

nenn

I

= 12,0A I

nenn

I

= 10,0A I

nenn

I

= 7,5A I

nenn

BSC x025

I

= 50A

peak

= 25,0A I

nenn

= 20,0A I

nenn

= 16,7A I

nenn

= 12,5A I

nenn

BSC x035

I

= 70A

peak

= 35,0A I

nenn

= 28,0A I

nenn

= 23,3A I

nenn

= 17,5A I

nenn

BSC 2045

I

= 90A

peak

= 45,0A

nenn

= 36,0A

nenn

= 30,0A

nenn

= 22,5A

nenn

Equation for R22:

9.2 Component Layout

10.0 I/O Hardware Description

- Legend:

Page 27

10.1 Input Signals

Analog Input Connector X2

Function Signal PIN Hardware

Velocity- or

Current-

Command

CMD+

CMD-

AGND

25

1

2

3

U

cmd

= ±10V

DC

Digital Inputs Connector X2

Function Signal PIN Hardware

Enable

Emergency

Stop

CW-Limit

CCW-Limit

Current

Control

Ground Return

ENABLE

CWLimit

CCWLimit

CurrentC

EMStop

CREF

- Low Active:

9

10

11

- High Active:

12

13

14

min. Input Impedance R

opto coupled; U

max. current at 24V; I = 10mA

= 2.2kΩ;

IN

= 12 .. 29VDC; Delay time Td = 60μs

IN

Page 28

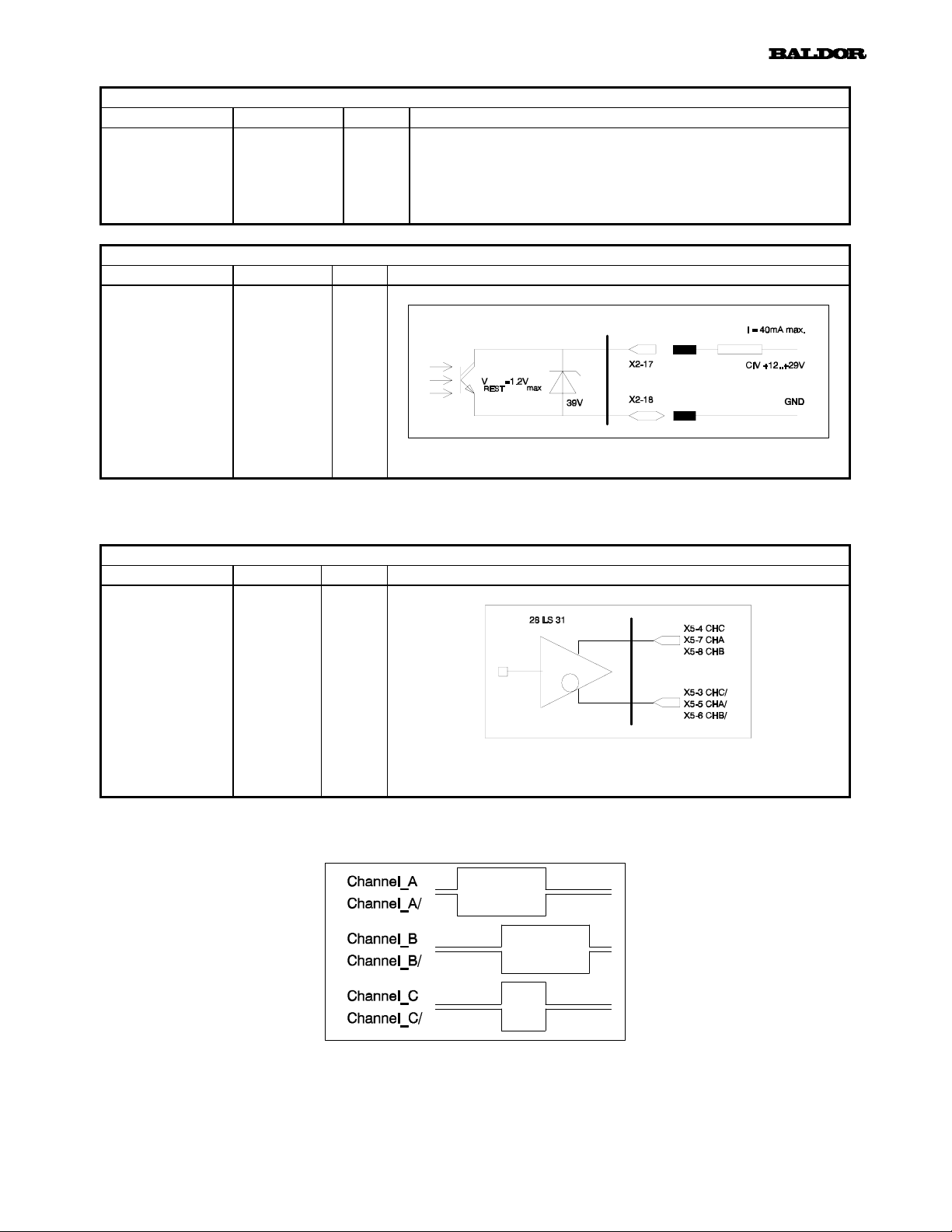

RESET - Input Connector X2

Function Signal PIN Hardware

RESET-

Input

Reset

DGND

19

20

26

10.2. Output signals

±15V - Output Connector X2

Function Signal PIN Hardware

±15VDC

Outputs

+15VDC

AGND

-15VDC

Pull-up to +5V; not opto coupled

Connect RESET to DGND, this resets the following faults:

- Overvoltage

- Undervoltage

- Resolver fault

- Electronic fusing

4

3

5

Digital Outputs Connector X2

Function Signal PIN Hardware

Fault

Relay

Fault+

Fault-

CAUTION: A short circuit will generate a "RESET"

Short circuit proof; I

15

16

contact is closed, if system works correct

U

U

AC

DC

= 110V I

= 24V I

max

max

= 0.3A

= 0.8A

= 100mA

max

Page 29

Analog Outputs Connector X2

Function Signal PIN Hardware

Testsignals

see

chapter 8

Digital Outputs Connector X2

Function Signal PIN Hardware

It - Warning

Speed-

DCurrent

Icmd

Warn_C

Warn_E

27

17

18

6

All testsignals are terminated with a resistor R = 4.7kΩ

7

and scaled to 10V

8

Load resistor R ≥ 100kΩ

10.3 Encoder Output

Encoder Signals Connector X5

Function Signal PIN Hardware

Encoder

Channel_C

Encoder

Channel_A

Encoder

Channel_B

CHC/

CHC

CHA/

CHA

CHB/

CHB

10.3.1 Encoder Signals

It-Limit and overtemperature warning

3

4

5

7

6

8

I/O-standard RS422

TTL-Signal; (f < 275kHz)

This drawing shows the encoder signals if the motor shaft rotates clock wise (view at the motor shaft).

Page 30

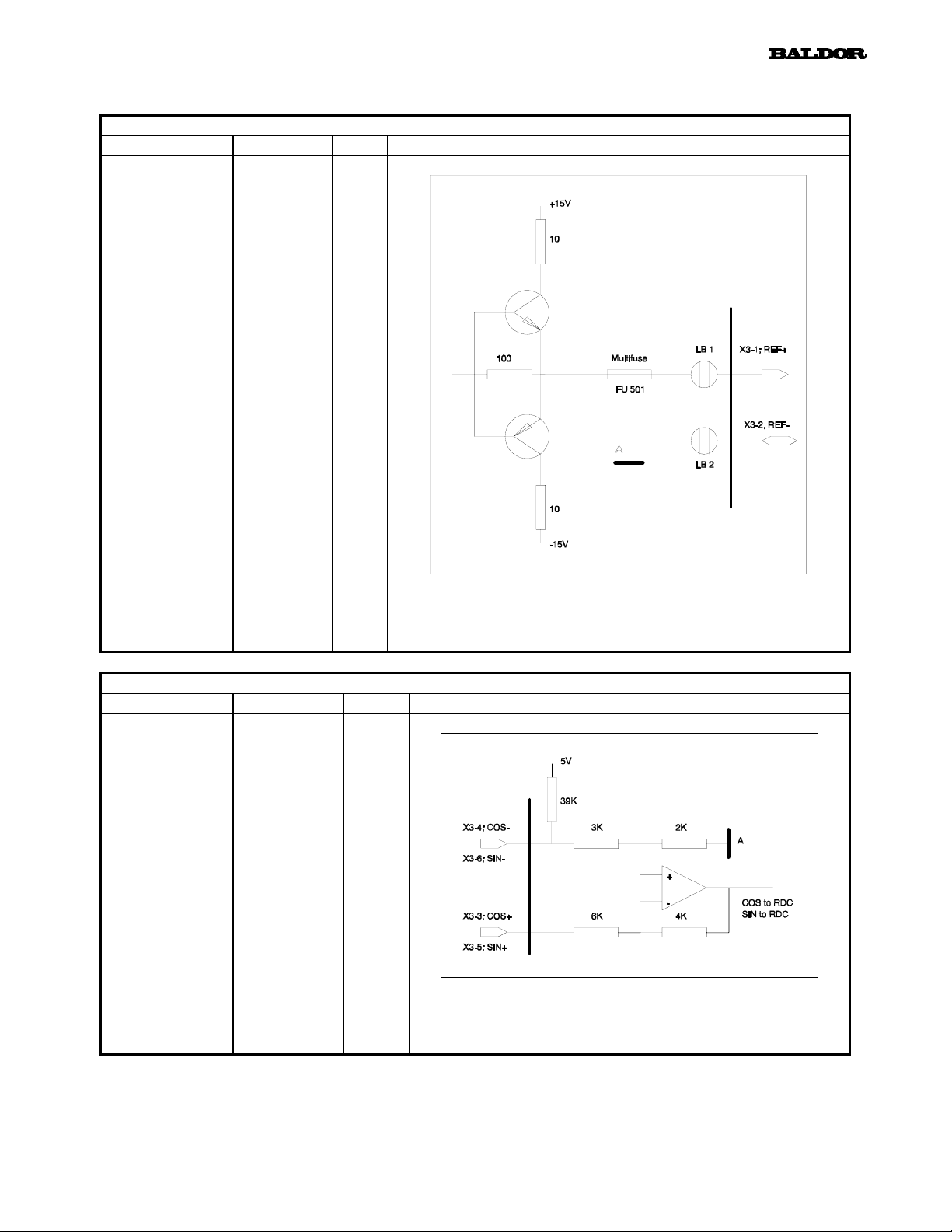

10.4 Resolver

Resolver Signals Connector X3

Function Signal PIN Hardware

Reference

Signal

REF+

REF-

28

1

2

Resolver Signals Connector X3

Function Signal PIN Hardware

COSINE

Input

SINE

Input

Cos+

Cos-

Sin+

Sin-

Signal waveform sinusoidal; f = 7.2 .. 8.0kHz;

17.0V

3

4

5

6

±5% + 0 .. 0.4 VDC; I

pp

Signal waveform sinusoidal;

UIN = 0 .. 10Vpp + 0 .. 0,4VDC; 7.2 .. 8.0kHz

= 0.2A; short circuit proof

peak

Loading...

Loading...