Page 1

6/15 Installation & Operating Manual MN703

BC140 / BC140-FBR DC CONTROL

Page 2

Any trademarks used in this manual are the property of their respective owners.

Important:

Be sure to check www.baldor.com to download the latest version of this manual in Adobe

Acrobat PDF format.

Page 3

i

MN703

Chapter 1

Introduction

Introduction ................................................................ 1-1

Safety Notice ............................................................... 1-1

Receiving ................................................................. 1-2

Chapter 2

Installation

Introduction ................................................................ 2-1

Mounting .................................................................. 2-1

Electrical Connections ........................................................ 2-2

AC Power .................................................................. 2-2

Ground Connection .......................................................... 2-2

Permanent Magnet (PM) Motor Armature Connection ................................. 2-2

Motor Field Connection (Shunt Wound Motors Only) .................................. 2-2

Full Voltage Field .......................................................... 2-2

Half Voltage Field ......................................................... 2-3

Plug-In Horsepower Resistor® ................................................. 2-3

Important Considerations ...................................................... 2-4

Startup & Adjustments ........................................................ 2-5

Trimpot Adjustments ......................................................... 2-5

Operation .................................................................. 2-7

Troubleshooting ............................................................. 2-7

Appendix A

Options

Optional auxiliary heat sink (catalog no. BC143) ..................................... A-1

Optional forward -brake-reverse switch (catalog no. BC144)* .......................... A-1

Table of Contents

Page 4

ii

MN703

Page 5

1-1

MN703

Chapter 1

Introduction

Introduction

Thank you for purchasing the BC140™ / BC140-FBR, full-wave variable speed DC motor controls.

Baldor is committed to providing total customer satisfaction by producing quality products that are

easy to install and operate. The BC140 and BC140-FBR offer the user the ultimate in reliability and

performance at an affordable price.

The BC140 and BC140-FBR are able to handle both 115 and 208/230 Volt AC line inputs. In addition,

one model can be used on a wide range of motors by selecting and inserting the appropriate Plug-in

Horsepower Resistor®.

The standard model, BC140, controls all motors through 3/4 HP at 115 Volt AC line input and 1-1/2 HP

at 230 Volt AC line input. By installing the Auxiliary Heat Sink (see Table 1-2), the horsepower range

is increased to 1 HP at 115 Volt AC line input and 2 HP at 230 Volt AC line input. The versatility of the

control is enhanced with the optional Forward-Brake-Reverse Switch Kit (Catalog No. BC144)*.

*Note: Forward-Brake-Reverse Switch Kit, BC144, is factory installed on the BC140-FBR model.

The electronics for the BC140 and BC140-FBR consist of a patented speed control module. Its field-

proven reliability is confirmed by over 100,000 controls presently in operation. The module is housed

in a rugged metal enclosure not plastic. Keyhole slots facilitate mounting and an easily accessible

terminal block simplifies connections.

SAFETY NOTICE

A Warning statement indicates a potentially hazardous situation which, if not avoided, could result in

injury or death.

A Caution statement indicates a potentially hazardous situation which, if not avoided, could result in

damage to property.

A Note indicates additional information that is not critical to the installation or operation.

WARNING: This equipment may contain voltages as high as 1000 volts! Electrical shock can cause serious or fatal

injury. Only qualified personnel should attempt the start-up procedure or troubleshoot this equipment.

WARNING: Be sure the system is properly grounded before applying power. Do not apply AC power before you ensure

that all grounding instructions have been followed. Electrical shock can cause serious or fatal injury.

WARNING: Electrical shock can cause serious or fatal injury. Be sure that all power is disconnected and there is

no voltage present from this equipment or equipment to which it is or will be connected. Electrical

shock can cause serious or fatal injury. Only qualified personnel should attempt the installation and

start-up procedures.

WARNING: Electrical shock can cause serious or fatal injury. Verify there is no voltage phase-to-phase or phase-

to-neutral at the motor leads before connecting motor to this control. Motor may have high voltage

present even when disconnected from this control.

WARNING: Do not use motor overload relays with an automatic reset feature. These are dangerous since the

process may injure someone if a sudden or unexpected automatic restart occurs. If manual reset

relays are not available, disable the automatic restart feature using external control wiring.

WARNING: This unit has an automatic restart feature that will start the motor whenever input power is applied

and a RUN (FWD or REV) command is issued. If an automatic restart of the motor could cause injury to

personnel, the automatic restart feature should be disabled.

WARNING: Using a jumper to eliminate the start/stop function will cause the motor to run at the Main Speed

Potentiometer setting when the AC line is applied.

WARNING: If possible, do not adjust trim pots with the main power applied. Electrical shock can cause serious or

fatal injury. If adjustments are made with the main power applied, an insulated adjustment tool must

be used to prevent shock hazard and safety glasses must be worn.

WARNING: Do not use this drive in an explosive environment. An explosion can cause serious or fatal injury.

This drive is not explosion proof.

WARNING: When the Enable jumper is installed, the drive and motor will start and run when AC power is applied,

when power is restored after a momentary power loss, or after an overload or TCL fault is reset. The

user must ensure that automatic start up of the driven equipment will not cause injury to operating

personnel or damage to the driven equipment. The user is responsible for providing suitable audible or

visual alarms or other devices to indicate that the drive may start at any moment. Failure to observe

this warning could result in severe bodily injury or loss of life.

Page 6

1-2

MN703

SAFETY NOTICE Continued

WARNING: Do not use start/stop, inhibit or enable functions as a safety disconnect. Use only an AC line disconnect

for that purpose. Failure to observe this warning could result in severe bodily injury or loss of life.

Caution: Disconnect motor leads (A1 and A2) from control before you perform a Dielectric Withstand test on the motor.

Failure to disconnect motor from the control will result in extensive damage to the control. The control is tested

at the factory for high voltage / leakage resistance as part of Underwriter Laboratory requirements.

Caution: Do not connect AC power to the Motor terminals A1 and A2. Connecting AC power to these terminals

may damage the control.

Caution: Baldor recommends not to use Grounded Leg Delta transformer power leads that may create ground

loops. Instead, we recommend using a four wire Wye.

Caution: Suitable for use on a circuit capable of delivering not more than 5,000 RMS symmetrical short circuit

amperes listed here at rated voltage.

Caution: Adjusting the current limit above 150% of the motor nameplate rating can cause overheating and

demagnetization of the PM motor.

Caution: Do not leave the motor in a locked rotor condition for more than a few seconds since motor damage may occur.

Caution: Shunt wound motors may be damaged if field windings remain energized for an extended period of

time without armature rotation.

Receiving

Each control is thoroughly tested at the factory and carefully packaged for shipment.

When you receive your control, there are several things you should do immediately.

1. Observe the condition of the shipping container and report any damage immediately to the

commercial carrier that delivered your control.

2. Verify that the part number you received is the same as the part number listed on your purchase order.

3. Do not unpack until ready for use.

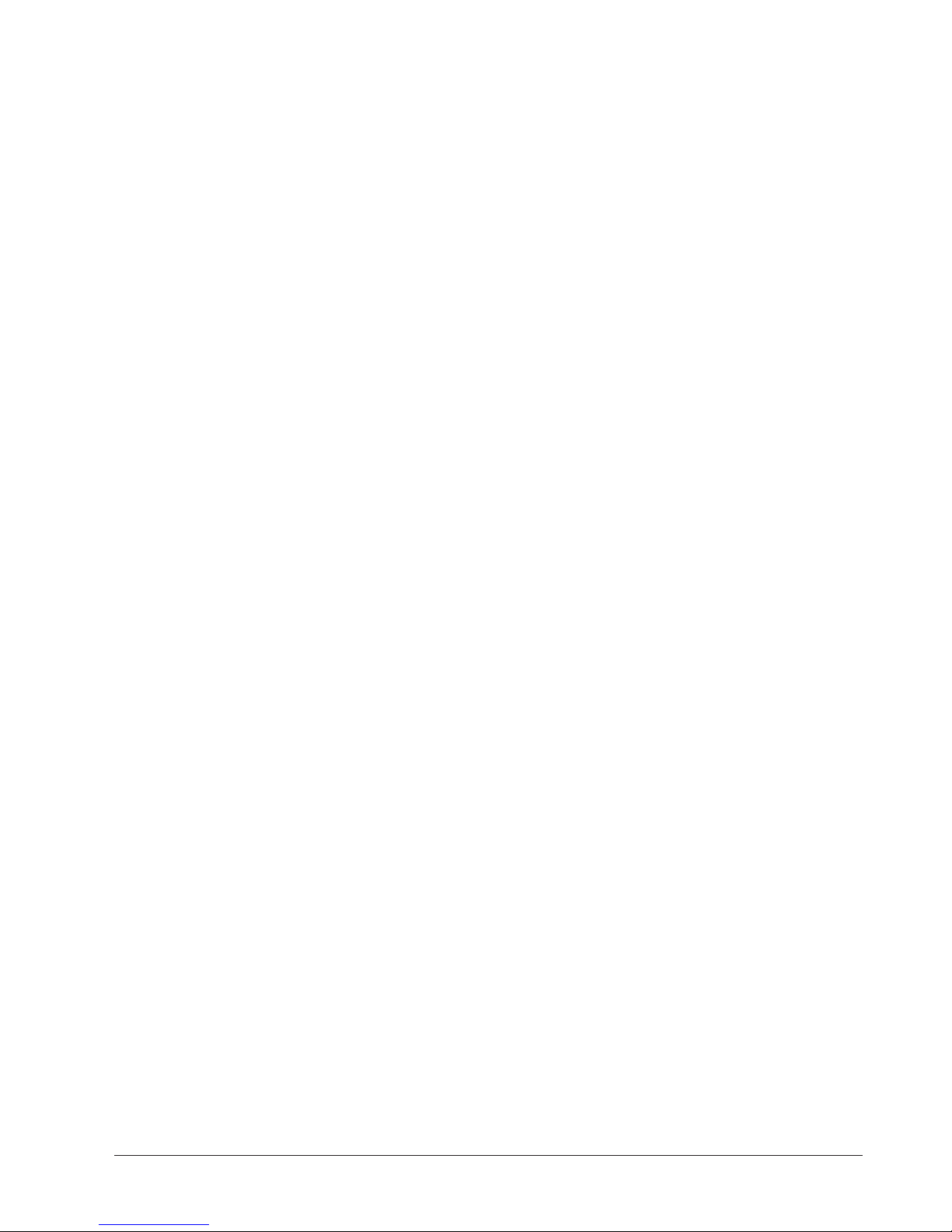

Table Electrical Ratings

AC Voltage

(± 15%, 50/60 Hz)

(VAC)

Motor

Voltage

(VDC)

Maximum Rating without Auxiliary Heat Sink Maximum Rating with Auxiliary Heat Sink

AC Current

(RMS Amps)

DC Load Current

(Avg. Amps)

Power

(HP, (kW))

AC Current

(RMS Amps)

DC Load

Current (Avg.

Amps)

Power

HP (kW)

115 90 – 130 12.0 6.0 0.75, (0.6) 16.0 12.0 1 (.75)

230 180 12.0 6.0 1.5, (1.1) 16.0 12.0 2 (1.5)

Table 1-2 General Performance Specifications

1

Description Specification Factory Setting

Speed Range (Ratio) 50:1 —

Armature Feedback Load Regulation (0 - Full Load, 50:1 Speed Range)

(% Base Speed)

1

2

—

Line Voltage Regulation (at Full Load, ± 10% Line Variation) (% Base Speed) 0.5

2

—

Control Linearity (% Speed vs. Dial Rotation) 2 —

Acceleration (ACCEL) Trimpot Range (Seconds) 0.2 - 10 2

Deceleration (DECEL) Trimpot Range (Seconds) 0.2 - 10 2

Maximum Speed (MAX) Trimpot Range (% Base Speed) 50 - 110

2

100

Minimum Speed (MIN) Trimpot Range (% Base Speed) 0 - 30

2

0

CL/Torque Range (% Full Load) 0 - 200 150

IR Compensation (IR) Trimpot Range (at Specified Full Load at 90/180 Volts

Output) (Volts DC)

0 - 24 / 0 - 48 3 / 6

Operating Temperature Range without Optional Auxiliary Heat Sink

(Catalog

No. BC143) (°C / °F)

0 - 40 / 32 - 104 —

Operating Temperature Range with Optional Auxiliary Heat Sink

(Catalog No. BC143) (°C / °F)

0 - 50 / 32 - 122 —

1. CE Compliance requires BC24-LF RFI Filter. (See Optional Accessories, Table 1-2).

2. Performance is for 90 Volt PM motors with 115 VAC line input and 180 Volt DC PM motors with 230 VAC line input.

Page 7

2-1

MN703

Chapter 2

Installation

WARNING: Do not use this drive in an explosive environment. An explosion can cause serious or fatal injury.

This drive is not explosion proof.

Introduction

The control is designed with a NEMA-1 / IP-40 enclosure for indoor use. It is recommended that the

control be mounted vertically on a flat surface with adequate ventilation. Leave enough room below

the control to allow for AC line and motor connections and any other connections that are required.

A mounting template is included to facilitate mounting of the control.

Control installation must ensure unrestricted air flow through the heatsink cooling fins.

Note: If drive is mounted in other than a vertical position, decrease maximum allowable ambient

temperature by 10°C.

Front Cover - The control is designed with a removable cover. To remove the cover, the two screws

must be removed.

After mounting the control and all connections are completed, install the cover and secure it with the

two screws. Tighten the screws to 5 lbs-in (6 kg-cm). Do not overtighten.

Figure 2-1 Mounting Hole Locations

Mounting

The control is designed with a NEMA-1 / IP-40 enclosure for indoor use. It is recommended that the

control be mounted vertically on a flat surface with adequate ventilation. Leave enough room below

the control to allow for AC line and motor connections and any other connections that are required.

A mounting template is included to facilitate mounting of the control. See Figure 2-1.

Care should be taken to avoid extreme hazardous locations where physical damage can occur.

The control should be located in an area where it will not be exposed to contaminants such as water,

metal chips, solvents or excessive vibration.

Without the Auxiliary Heat Sink, the temperature around the control must not exceed 50°C (122°F).

With the Auxiliary Heat Sink, the temperature around the control must not exceed 40°C (104 °F).

The control is designed with a removable cover. To remove the cover, the two screws must be

removed.

After mounting the control and all connections are completed, install the cover and secure it with the

two screws. Tighten the screws to 5 lbs-in (6 kg-cm). Do not overtighten.

[178]

7.00

0.2

[5.08]

0.35

9.0

4X Ø

0.39

[9.91]

4X Ø

5.63

[143]

5.00

[105]

[127]

4.125

4.00

[102]

Back View is Shown Dimensioned

without Cover Installed

Side View is Shown Dimensioned with

Cover Installed and Optional

Forward-Brake-Reverse Switch

Two (2) Knockouts

for Standard

3/4” Fittings

Page 8

2-2

MN703

Electrical Connections

Connection terminals are shown in Figure 2-2.

Figure 2-2 AC Line, Armature, Field*, and Ground Connections

A- A+ F- F+ L1 L2 GND

Barrier

Terminal Block

DC Motor

Ground (Earth)

Ground (Earth)

Armature

Field

115 or 208/230 Volts

AC Line Input

AC Power

Verify AC Line voltage matches to control voltage rating, (115/208/230VAC - 50/60 Hz. 1phase).

Connect AC Line to L1 and L2 terminals and tighten to correct torque (Table 2-1). The installer should

provide fuse protection for each ungrounded supply conductor. See Table 2-2.

The AC Line fuse is factory installed. The Armature fuse (supplied separately) must be installed in the

armature fuse holder, as shown in Figure 2-3.

Fuses are available from your distributor. All fuses should be normal blow ceramic 3AG, MDA, or

equivalent. On domestic 230 Volt AC lines, separate branch circuit protection for each line must be

used.

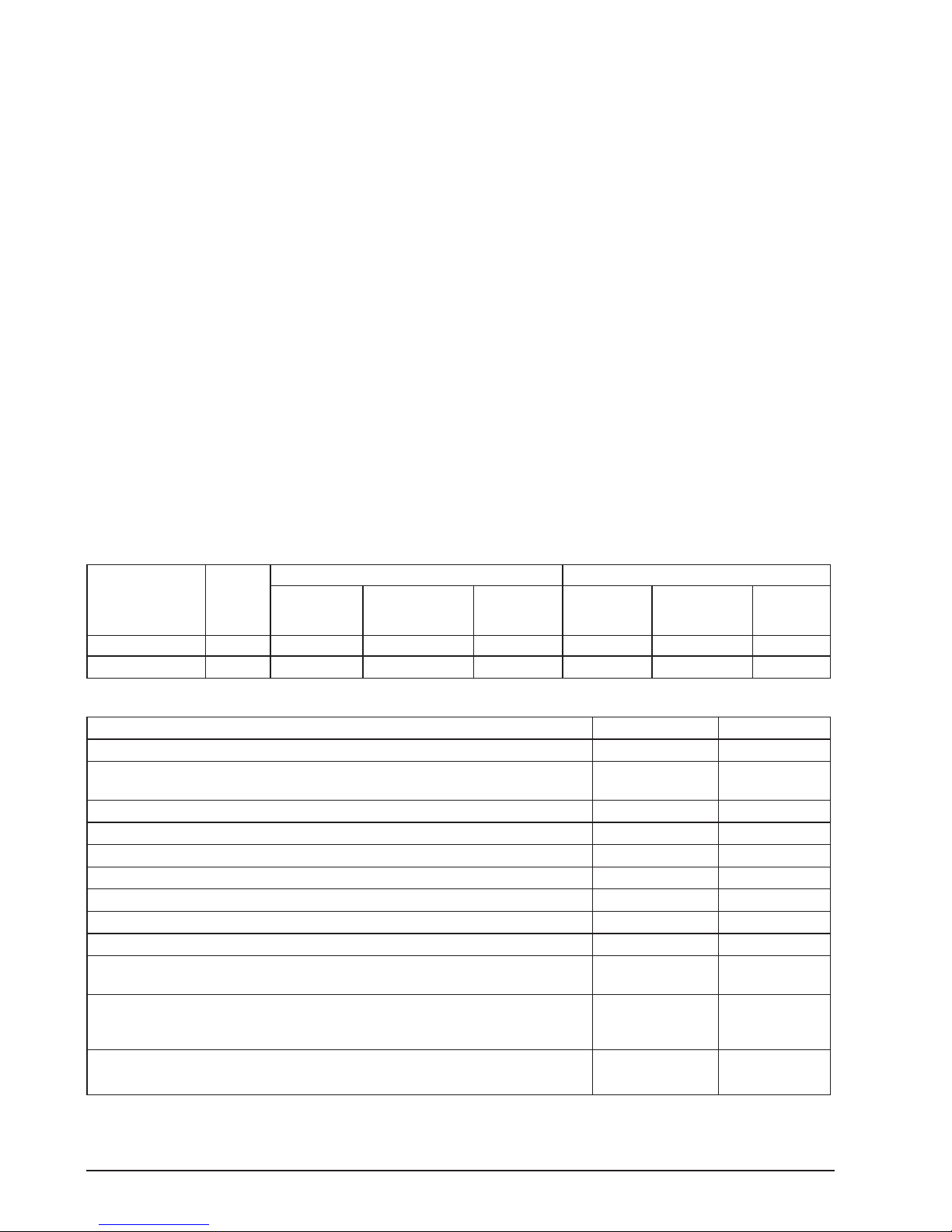

Table 2-1 Terminal Block Wire and Tightening Torque Specifications

Maximum

Motor Current

(ADC)

90 – 130

VDC Motors

(Max HP)

180 VDC

Motors

(Max HP)

Maximum Wire Size (Cu)

Recommended

Tightening Torque

Maximum

50 Ft.

Maximum

100 Ft.

AWG mm

2

AWG mm

2

lb-in kg-cm

6 1/2 1 16 1.3 14 2.1 12 13.8

12 1 2 14 2.1 12 3.3 12 13.8

The AC Line Fuse acts as a disconnect in case of a catastrophic failure. If the AC Line Fuse blows, the

control is miswired, the motor is shorted or grounded, or the control is defective.

Ground Connection

Connect all ground wires (earth), of connections to the control, to the green ground screw on the

chassis, tighten to correct torque (Table 2-2).

Permanent Magnet (PM) Motor Armature Connection

Connect the motor armature positive lead (+) to Terminal A+ and negative lead (-) to Terminal A-, as

shown in Figure 2-1.

Motor Field Connection (Shunt Wound Motors Only)

CAUTION! Do not connect motor armature leads to Terminals F+ and F-. Do not use Terminals F+ and F- for any

purpose other than to power the field of a shunt wound motor. Shunt wound motors may be damaged

if the field remains energized without armature rotation for an extended period of time.

Full Voltage Field

Connect the field positive (+) lead to Terminal F+ and the negative lead (-) to Terminal F-, on the

Barrier Terminal Block (Table2-2).

Half Voltage Field

For 50 Volt DC with 100 Volt rated armature, use Terminal L1 and F+, on the terminal board (Table2-2).

Page 9

2-3

MN703

Table 2-2 Armature and AC Line Fuse Chart

Motor Horsepower Approximate Motor

Current (Amps DC)

Fuse Selection

(AC Amps)

90VDC 180VDC Armature Line

1/100 1/50 0.2 0.5 12

1/50 1/25 0.3 0.5 12

1/30 1/15 0.33 0.5 12

1/20 1/10 0.5 0.75 12

1/15 1/8 0.8 1 12

1/12 1/6 0.85 1.25 12

1/8 1/4 1.3 2 12

1/6 1/3 2 2.5 12

1/4 1/2 2.5 4 12

1/3 3/4 3.3 5 12

1/2 1 5.0 8 12

3/4 1½ 7.5 12 12

1* 2* 10 15 25

*With optional Auxiliary Heat Sink (Catalog No. BC143).

Table 2-3 Field Connection (Shunt Wound Motors Only)

AC Input Voltage

(Volts AC)

Voltage Selector

Switch (Position)

Armature Voltage

(Volts DC)

Field Voltage

(Volts DC)

Terminal

Connections

115 115 0 – 90

100 F+, F-

50 F+, L1

208/230 230

0 – 180 200 F+, F-

0 – 90* 100 F+, L1

Plug-In Horsepower Resistor®

A Plug-In Horsepower Resistor® (supplied separately) must be installed to match the control to the

motor so the IR Compensation and Current Limit settings to be correct. Select the proper Plug-In

Horsepower Resistor® according to Table 2-3. Plug-In Horsepower Resistors® are available from

your distributor. Install the Plug-In Horsepower Resistor®, as shown in Figure 2-3.

Note: Be sure the Plug-In Horsepower Resistor® is inserted completely into the mating sockets.

Table 2-4 Plug-In Horsepower Resistor® and Armature Fuse Kit Information

Motor Horsepower

Approximate

Motor Current

(ADC)

Plug-In HP Resistor® and

Armature Fuse Kit

Armature

VDC

90 – 130

Armature

VDC

180

Plug-In HP

Resistor Value

(Ohms)

Armature Fuse Rating

(Amps)

Catalog No.

1/100 1/50 0.2 1.0 0.5 BR1000

1/50 1/25 0.3 0.51 0.5 BR0510

1/30 1/15 0.33 0.35 0.5 BR0350

1/20 1/10 0.5 0.25 0.75 BR0250

1/15 1/8 0.8 0.25 1 BR0251

1/12 1/6 0.85 0.18 1.25 BR0180

1/8 1/4 1.3 0.1 2 BR0100

1/6 1/3 2 0.1 2.5 BR0101

1/4 1/2 2.5 0.05 4 BR0050

1/3 3/4 3.3 0.035 5 BR0035

1/2 1 5 0.025 8 BR0025

3/4 1½ 7.5 0.015 12 BR0015SP

1* 2* 10 0.01 15 BR0010SP

Page 10

2-4

MN703

Figure 2-3 Control Layout and Internal Connection Diagram

A- A+ F- F+ L1 L2 GND

F-

ARMATURE FIELD LINE

Important Considerations

Motor Type

The BC140 / BC140-FBR is designed for permanent magnet (PM) and Shunt Wound DC motors.

Controls operated on 115 Volt AC line input are designed for 90 Volt SCR rated motors. Controls

operated on 230 Volt AC line input are designed for 180 and 90 Volt (step-down) SCR rated motors.

Use of higher voltage motors will result in a reduction of the available maximum speed. Also, if motor

is not an SCR rated type, the actual AC line amperage of the control, at full load, should not exceed the

motor’s DC nameplate rating.

Torque Requirements

The motor selected for the application must be capable of supplying the necessary torque. To ensure

the motor is not overloaded, a DC ammeter should be connected in series with the armature. Be sure

the current under full load does not exceed the motor nameplate rating.

Acceleration Start

The BC140 / BC140-FBR contains an adjustable acceleration start feature which allows the motor to

smoothly accelerate from zero speed to full speed over a time period of 0.2-10 seconds.

The acceleration trimpot (ACCEL) is factory set for 2 seconds.

Limitation In Use

The BC140 / BC140-FBR control is designed for use on machine applications.

Page 11

2-5

MN703

Startup & Adjustments

The Voltage Select Switch is located under the cover and must be set before applying power to the

control. Figure 2-4.

For 208/230 Volt AC Line Input

Set the Voltage Select Switch to the 230 position (factory setting). The switch toggle should be in the

lower position with 230 displayed at the top.

For 115 Volt AC Line Input

Set the Voltage Select Switch to the 115 position. The switch toggle should be in the upper position

with 115 displayed at the bottom.

Figure 2-4 Voltage Select Switch Setting

After the control has been mounted properly and electrical connections have been completed,

1. Verify the speed adjust potentiometer is set fully counterclockwise.

2. Apply AC power.

3. Observe the Power ON LED indicator is illuminated. If not on, refer to troubleshooting.

4. Verify correct direction of motor rotation.

Start the control. The motor shaft should begin to rotate as the potentiometer knob is turned

clockwise, or the analog speed reference signal is increased.

Verify the motor shaft is rotating in the desired ‘forward’ direction.

If the direction of rotation is incorrect, stop the control and disconnect AC power.

Switch the motor lead connections at the A+ and A- terminals.

If a tachometer is connected, the leads may also need to be switched for correct signal polarity.

If the CL LED is on, refer to troubleshooting.

WARNING: If possible, do not adjust trim pots with the main power applied. Electrical shock can cause serious or

fatal injury. If adjustments are made with the main power applied, an insulated adjustment tool must

be used to prevent shock hazard and safety glasses must be worn.

TRIMPOT ADJUSTMENTS

The control contains trimpots which have been factory set for most applications. Some applications

may require readjustment to tailor the control for a specific performance requirement.

Minimum Speed Trimpot (MIN)

The MIN Trimpot sets the minimum speed of the motor when the Main Speed Potentiometer is set

fully counterclockwise. The MIN Trimpot is factory set to 0% of base motor speed. To increase the

minimum speed, rotate the MIN Trimpot clockwise. To decrease the minimum speed, rotate the MIN

Trimpot counterclockwise. The MIN Trimpot range is 0% – 30% of base motor speed.

Note: Readjusting the MIN Trimpot will affect the maximum speed setting. Therefore, it is necessary

to readjust the MAX Trimpot if readjusting the MIN Trimpot. It may be necessary to repeat these

adjustments until both the minimum and maximum speeds are set to the desired levels.

Maximum Speed Trimpot (MAX)

The MAX Trimpot sets the maximum speed of the motor when the Main Speed Potentiometer is

set fully clockwise. The MAX Trimpot is factory set to 100% of base motor speed. To increase the

maximum speed, rotate the MAX Trimpot clockwise. To decrease the maximum speed, rotate the MAX

Trimpot counterclockwise. The MAX Trimpot range is 50% – 110% of base motor speed.

Note: The MAX trimpot is inoperative in the voltage following mode.

Caution: Do not set the maximum speed above the rated motor RPM since unstable motor operation ay occur.

Note: Do not adjust the maximum speed above the rated motor RPM or unstable operation may occur.

208/230 Volt AC Line Input

(Factory Setting) 115 Volt AC Line Input

Page 12

2-6

MN703

For moderate changes in the maximum speed, there will be a slight effect on the minimum speed

setting when the minimum is set to zero. There may be significant variation in the minimum speed

setting if the minimum speed is at a higher than zero setting.

Acceleration Trimpot (ACCEL)

The ACCEL Trimpot is provided to allow for a smooth start over an adjustable time period each time

the AC power is applied or the Main Speed Potentiometer is adjusted to a higher speed. The ACCEL

Trimpot is factory set to 2 seconds, which is the amount of time it will take for the motor to accelerate

from zero speed to full speed. To increase the acceleration time, rotate the ACCEL Trimpot clockwise.

To decrease the acceleration time, rotate the ACCEL Trimpot counterclockwise. The ACCEL Trimpot

range is 0.2 – 10 seconds.

Deceleration Trimpot (DECEL)

The DECEL Trimpot controls the amount of rampdown time when the Main Speed Potentiometer is

adjusted to a lower speed. The DECEL Trimpot is factory set to 2 seconds, which is the amount of

time it will take for the motor to decelerate from full speed to zero speed. To increase the deceleration

time, rotate the DECEL Trimpot clockwise. To decrease the deceleration time, rotate the DECEL Trimpot

counterclockwise. The DECEL Trimpot range is 0.2 – 10 seconds.

Current Limit Trimpot (CL)

The CL Trimpot is used to limit the maximum current (torque) to the motor. The CL also protects the

control from excessive current during startup. The CL Trimpot is factory set to 150% of the full load

current rating of the motor. To increase the current limit, rotate the CL Trimpot clockwise (do not

exceed 200% of the full load current rating of the motor (maximum clockwise position)). To decrease

the current limit, rotate the CL Trimpot counterclockwise. On cyclical loads, it may be normal for the

CL LED to momentarily flash.

(Visible only if the cover is removed.) The CL Trimpot range is 0% – 200% of the full load current

rating of the motor. Some application may require a lower value so as not to damage process material

or drive train components.

Note: For the Current Limit to operate properly, the correct Plug-In Horsepower Resistor® must be

installed for the particular motor and input voltage being used. Calibration of the CL Trimpot is

normally not required when the proper Plug-In Horsepower Resistor® is installed.

Caution: do not leave motor shaft locked for more than 2 – 3 seconds or motor damage may result.

To Recalibrate the CL Trimpot:

1. Disconnect the AC power and connect a DC ammeter in series with either motor armature lead.

If only an AC ammeter is available, connect it in series with either AC line input lead.

2. Set the Main Speed Potentiometer to approximately 30% – 50% clockwise position.

3. Set the CL Trimpot fully counterclockwise. The CL LED will illuminate red.

4. Load the motor shaft in accordance with application requirements.

Apply power and rotate the CL Trimpot clockwise until the desired current reading is observed on the

DC ammeter. Factory Current Limit setting is 150% of the full load current rating of the motor. If using

an AC ammeter connected in the AC line input, the factory Current Limit setting will read 75% of the

full load current rating of the motor. Do not exceed 200% of the full load current rating of the motor

(maximum clockwise position).

IR Compensation Trimpot (IR)

The IR Trimpot sets the amount of compensating voltage required to keep the motor speed constant

under varying loads. If the load does not vary substantially, the IR Trimpot may be set to a minimum

level (approximately 1/4 of full clockwise rotation). The IR Trimpot is factory set to provide 3 Volts of

compensation for controls with 90 Volt DC output and 6 Volts of compensation for controls with 180

Volt DC Output. To increase the amount of compensating voltage, rotate the IR Trimpot clockwise. To

decrease the amount of compensating voltage, rotate the IR Trimpot counterclockwise.

To Recalibrate the IR Trimpot:

1. Set the IR Trimpot to approximately 25% rotation.

2. Run the motor unloaded at approximately 1/3 speed and record the RPMs.

Page 13

2-7

MN703

3. Run the motor with the maximum load and adjust the IR Trimpot so that the motor speed under

load equals the unloaded speed recorded in step 2.

4. Remove the load and recheck the RPMs.

If the unloaded RPM has changed, repeat steps 2 and 4 for better regulation. The control is now

compensated to provide minimal speed change due to changing loads.

Operation

Set the AC Line Switch to the ON position. Observe that the Pilot Light illuminates. Gradually increase

the Main Speed Potentiometer. The motor should smoothly come up to the desired speed and remain

stable.

Troubleshooting

The BC140 / BC140-FBR has LEDs to display the control’s operational status.

Power On (PWR ON) LED and Pilot Light

When the AC power is applied to the control and the On/Off AC Line Switch is set ON, the PWR ON

LED, on the PC board, will illuminate green and the Pilot Light, on the front cover, will illuminate

orange.

Current Limit (CL) LED

The CL LED will illuminate red when the motor is overloaded, indicating that the current limit set point

has been reached (set by the CL Trimpot).

Table 2-4 provides information on symptoms, possible causes, and the suggested corrective action for

controls without optional forward-brake-reverse switch installed.

Table 2-4 Troubleshooting Guide (without Optional Forward-Brake-Reverse Switch)

Symptom Possible Cause Suggested Corrective Action

Motor is not running and

Pilot Light not illuminated.

On/Off AC Line Switch in Off

Position.

Set On/Off Switch to On Position.

Blown Line fuse. Replace Line Fuse.

Defective On/Off AC Line Switch, Replace On/Off AC Line Switch.

Motor does not run and

Pilot Light is illuminated.

Main Speed Potentiometer set fully

counterclockwise.

Rotate Main Speed potentiometer clockwise.

Defective motor. Check for defective motor, worn brushes, etc.

Replace motor, if necessary.

Plug-In Horsepower Resistor® not

installed.

Install the correct Plug-In Horsepower

Resistor®.

Blown Armature Fuse. Replace Armature Fuse.

CL Trimpot set fully

counterclockwise.

Set CL Trimpot

Motor hums, runs at very

low speed, or slows down

substantially when loaded.

Low AC line input voltage. Check AC line input voltage.

Motor continues to run with

Main Speed Potentiometer

set fully counterclockwise.

MIN speed trimpot set higher than

0% of base speed.

Readjust the MIN Trimpot.

IR Comp trimpot set too high. Readjust the IR Trimpot.

Motor runs in wrong

direction.

Motor armature leads are reversed. Reconnect motor armature leads.

Motor will not run in Forward

or Reverse direction.

Faulty wiring or loose connections

to the reversing switch.

Check and correct connections.

Forward-Brake-Reverse Switch is

defective.

Replace Forward-Brake-Reverse Switch

assembly.

Page 14

2-8

MN703

Table 2-4 Troubleshooting Guide (without Optional Forward-Brake-Reverse Switch)

Symptom Possible Cause Suggested Corrective Action

No braking action in brake

mode.

Faulty connections or loose

connections.

Check and correct connections.

Defective Brake Resistor. Replace Forward-Brake-Reverse Switch

assembly.

Erratic motor performance.

Overload condition. Remove overload.

Incorrect Plug-In Horsepower

Resistor®.

Install the correct Plug-In Horsepower

Resistor®.

CL and/or IR Trimpots may be set

incorrectly.

Readjust the CL and/or IR Trimpots

Defective speed control module. Replace speed control.

Voltage Select Switch set to wrong

position.

Recheck line voltage and the correct setting of

the Voltage Select Switch.

Defective motor, worn brushes, etc. Repair or replace motor.

Table 2-5 Electrical Ratings

Line Voltage

(± 15%,

50/60 Hz)

(VAC)

Motor

Voltage

(VDC)

"Maximum Rating without Auxiliary

Heat Sink"

Maximum Rating with Auxiliary Heat Sink

Line Current

(RMS Amps)

Load Current

(ADC)

Power

HP (kW)

Line Current

(RMS Amps)

Load Current

(ADC)

Power

HP (kW)

115 90 – 130 12.0 6.0 0.75, (0.6) 16.0 12.0 1, (.75)

230 180 12.0 6.0 1.5, (1.1) 16.0 12.0 2, (1.5)

Page 15

A-1

MN703

Appendix A

OPTIONAL AUXILIARY HEAT SINK (CATALOG NO. BC143)

The optional Auxiliary Heat Sink (Catalog No. BC143) is used to increase the rating of the control.

The control is mounted on the four (4) holes with four (4) mounting screws (supplied), Figure A-1.

Figure A-1 Optional Auxiliary Heat Si nk Mechanical Specifications

[34.9]

1.375

6.29

[160]

7.00

[178]

[142]

5.61

[143]

5.63

OPTIONAL Forward -brake-reverse switch (CATALOG NO. BC144)*

The optional Forward-Brake-Reverse Switch (Catalog No. BC144)* is used to dynamically brake

the motor and reverse motor direction. The switch assembly is to be installed in the mounting hole

provided on the control.

See the installation instructions MN1372, provided with the Forward-Brake-Reverse Switch kit for

detailed information on mounting and connections.

Figure A-2 shows the connections of the Forward-Brake-Reverse Switch to the speed control and the

Barrier Terminal Block. * BC144 is factory installed on BC140-FBR model.

Figure A-2 Optional Forward-Brake- Reverse Switch Connections

Page 16

A-2

MN703

Optional RFI Filter (BC24-LF)

Panel mount. Rated 24 Amps at 115 and 208/230 Volts AC, single phase. Complies with CE Directive

89/336/EEC (EN55022 and/or EN55011) relating to the EMC Class A Industrial Standard.

Page 17

Page 18

Page 19

Baldor District Offices

NEW YORK

AUBURN

ONE ELLIS DRIVE

AUBURN, NY 13021

PHONE: 315-255-3403

FA X: 315-253 -992 3

NORTH CAROLINA

GREENSBORO

1220 ROTHERWOOD ROAD

GREENSBORO, NC 27406

PHONE: 336-272-6104

FAX: 336-273-6628

OHIO

CINCINNATI

2929 CRESCENTVILLE ROAD

WEST CHESTER, OH 45069

PHONE: 513-771-2600

FAX: 513-772-2219

OHIO (Continued)

CLEVELAND

8929 FREEWAY DRIVE

MACEDONIA, OH 44056

PHONE: 330-468-4777

FAX: 330-468-4778

OKLAHOMA

TULSA

5555 E. 71ST ST., SUITE 9100

TULSA, OK 74136

PHONE: 918-366-9320

FAX: 918-366-9338

OREGON

PORTLAND

16201 SE 98TH AVENUE

CLACK AMAS, OR 97015

PHONE: 503-691-9010

FA X : 50 3-691- 9 012

PENNSYLVANIA

PHILADELPHIA

103 CENTRAL AVENUE

SUITE 400B

MOUNT LAUREL, NJ 08054

PHONE: 856-840-8011

FAX: 856-840-0811

PITTSBURGH

159 PROMINENCE DRIVE

NEW KENSINGTON, PA 15068

PHONE: 724-889-0092

FAX: 724-889-0094

ILLINOIS

CHICAGO

340 REMINGTON BLVD.

BOLINGBROOK, IL 60440

PHONE: 630-296-1400

FAX: 630-226-9420

INDIANA

INDIANAPOLIS

5525 W. MINNESOTA STREET

INDIANAPOLIS, IN 46241

PHONE: 317-246-5100

FAX: 317-246-5110

IOWA

DES MOINES

1943 HULL AVENUE

DES MOINES, IA 50313

PHONE: 515-263-6929

FA X: 515-263 -6515

MARYLAND

BALTIMORE

7071A DORSEY RUN RD

ELKRIDGE, MD 21075

PHONE: 410-579-2135

FAX: 410-579-2677

MASSACHUSETTS

BOSTON

6 PULLMAN STREET

WORCESTER, MA 01606

PHONE: 508-854-0708

FAX: 508-854-0291

MICHIGAN

DETROIT

5993 PROGRESS DRIVE

STERLING HEIGHTS, MI 48312

PHONE: 586-978-9800

FAX: 586-978-9969

MINNESOTA

MINNEAPOLIS

13098 GEORGE WEBER DR,

SUITE 400

ROGERS, MN 55374

PHONE: 763-428-3633

FAX: 763-428-4551

MISSOURI

ST LOUIS

13678 LAKEFRONT DRIVE

EARTH CITY, MO 63045

PHONE: 314-373-3032

FAX: 314-373-3038

KANSAS CITY

9810 INDUSTRIAL BLVD.

LENEX A, KS 66215

PHONE: 816-587-0272

FAX: 816-587-3735

TENNESSEE

MEMPHIS

4000 WINCHESTER ROAD

MEMPHIS, TN 38118

PHONE: 901-365-2020

FAX: 901-365-3914

TEXAS

DALLAS

2920 114TH STREET SUITE 100

GRAND PRAIRIE, TX 75050

PHONE: 214-63 4-7271

FAX: 214-634-8874

HOUSTON

10355 W. LITTLE YORK ROAD

SUITE 300

HOUSTON, TX 77041

PHONE: 281-977-6500

FAX: 281-977-6510

UTAH

SALT LAKE CITY

2230 SOUTH MAIN STREET

SALT LAK E CITY, UT 84115

PHONE: 801-832-0127

FAX: 801-832-8911

WISCONSIN

MILWAUKEE

1960 SOUTH CALHOUN ROAD

NEW BERLIN, WI 53151

PHONE: 262-784-5940

FA X: 262 -7 8 4 -12 15

INTERNATIONAL SALES

FORT SMITH, AR

P.O. BOX 2400

FORT SMITH, AR 72902

PHONE: 479-646-4711

FAX: 479-648-5895

UNITED STATES

ARIZONA

PHOENIX

4211 S 43RD PLACE

PHOENIX, AZ 85040

PHONE: 602-470-0407

FAX: 602-470-0464

ARKANSAS

CLARKSVILLE

706 WEST MAIN STREET

CLARKSVILLE, AR 72830

PHONE: 479-754-9108

FAX: 479-754-9205

CALIFORNIA

LOS ANGELES

6480 FLOTILLA STREET

COMMERCE, CA 90040

PHONE: 323-724-6771

FAX: 323-721-5859

HAYWARD

21056 FORBES STREET

HAYWARD, CA 94545

PHONE: 510-785-9900

FAX: 510-78 5-9 910

COLORADO

DENVER

3855 FOREST STREET

DENVER, CO 80207

PHONE: 303-623-0127

FAX: 303-595-3772

CONNECTICUT

WALLINGFORD

65 SOUTH TURNPIKE ROAD

WALLINGFORD, CT 06492

PHONE: 203-269-1354

FAX: 203-269-5485

FLORIDA

TAMPA/PUERTO RICO/

VIRGIN ISLANDS

3906 E AST 11TH AVENUE

TAMPA, FL 33605

PHONE: 813-248-5078

FAX: 813-241-9514

GEORGIA

ATL ANTA

62 TECHNOLOGY DRIVE

ALPHARETTA, GA 30005

PHONE: 7 70-772-7 000

FAX: 770-772-7200

Page 20

Baldor Electric Company

P.O. Box 2400, Fort Smith, AR 72902-2400 U.S.A., Ph: (1) 479.646.4711, Fax (1) 479.648.5792, International Fax (1) 479.648.5895

www.baldor.com

© Baldor Electric Company

MN703

All Rights Reserved. Printed in USA.

(A40244B) - Rev E 6/15

MN703-0615

Loading...

Loading...