Page 1

MN914

1MN914

Instruction Manual For Belt Grinder-Buffer

Model 602E-MT

SAFETY NOTICE

: WARNING statements describe conditions that may lead to personnel injury including

potentially fatal injuries if the machine is not properly used and warnings are not properly

followed.

Caution statements describe conditions that may lead to equipment damage.

WARNING: Do not operate this grinder-buffer until you are sure that you are completely familiar with

the safe operation of the grinder-buffer, all accessories and safety equipment. Improper

use can lead to severe injury. This manual defines proper use of this equipment.

Before using this equipment for any other use, please seek expert advise if you do not

understand any procedure or operation concerning this grinder-buffer or this manual.

WARNING: Prevent electrical shock hazard and accidental machine operation. Always disconnect

grinder-buffer from the power source before servicing, changing accessories (such as

belt, wire wheel, tool rest, spark arrestor, etc.) or before performing maintenance.

WARNING: Avoid accidental starting. Make sure switch is in “OFF” position before connecting to

power source.

WARNING: Be sure the system is properly grounded before applying power. Do not apply power

before you ensure that grounds are connected. Electrical shock can cause serious or fatal

injury. Follow the National Electrical Code (NEC) and local codes for the safe installation

of this equipment.

WARNING: Always use safety glasses with side shields (or full face shield) when operating grinder.

Do not use ordinary eyeglasses. Also use face or dust mask if cutting operation is dusty.

WARNING: Unsuitable accessories or attachments added to this machine can create hazards. Baldor

accessories are specifically designed to be used with this grinder-buffer. Use

accessories or attachments only in the proper intended manner. Accessories or

attachments obtained from another source may cause hazards. Consult the manufacturer

before use.

WARNING: To prevent injury, avoid contact with the wire wheel or belt or disc. The abrasive belt when

running is an aggressive cutting tool. Extra care should be exercised when using coarse grit

belts because of their rapid cutting action. Severe burns or cuts may result from contact.

WARNING: Keep guards in place and in working order. Guards are design to prevent injury. Never

operate this equipment if a guard is damaged, missing or improperly installed.

WARNING: Remove adjusting keys and wrenches from this product after use. Check to see that keys

and adjusting wrenches are removed from grinder-buffer before turning it on. Projectiles

can cause severe injury to yourself or others.

WARNING: Keep work area clean and well lighted. Clutter and poor lighting invites accidents.

WARNING: Don't use in dangerous environment. Don't use grinder-buffers in damp or wet locations,

or expose them to rain. Electrical shock can cause serious or fatal injury. Follow the

National Electrical Code (NEC) and local codes for the safe installation of this equipment.

WARNING: Do not wear loose clothing, neckties, rings, bracelets, or other jewelry to get caught in

moving parts. Nonslip footwear is recommended. Wear protective hair covering to contain

long hair.

WARNING: Secure work. Use clamps to secure the work piece when practical. It's safer than using

your hand and it keeps hands away from wheel or belt.

WARNING: Check for damaged parts. Before further use, a guard or other part that is damaged should

be carefully checked to assure that it will operate properly and perform its intended

function. Check for alignment of moving parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that may affect its operation. A guard or other part

that is damaged should be properly repaired or replaced.

Page 2

2 MN914

SAFETY NOTICE

Continued

WARNING: When starting a grinder for the first time, or after installing a replacement belt or wire

wheel, it is most important that the operator stand aside for at least one minute of rotation

at full speed. This is the correct practice since a wire wheel can disintegrate if it received

damage during shipping or handling.

WARNING: Use proper grounded extension cord. Make sure your extension cord is in good condition.

When using an extension cord, be sure it is rated for the voltage and current rating of your

product. An undersized cord will cause a drop in line voltage resulting in loss of power and

overheating. Use the correct wire size depending on cord length and nameplate ampere

rating. If in doubt, use the next heavier gauge. The smaller the AWG gauge number, the heavier

the cord.

WARNING: Always wear a dust mask to prevent dust inhalation when adequate ventilation or extraction

is not available.

WARNING: Dust created during grinding, buffing, sawing, power sanding, drilling, and other activities

may contain chemicals known to the State of California to cause cancer, birth defects or

other reproductive harm.

WARNING: Keep children and visitors away. Remove starter keys turn off master switches. Padlock

equipment or work area when not in use.

WARNING: Don't over reach. Keep proper footing and balance at all times. A rotating wheel can catch

an article of clothing and cause personnel injury.

WARNING: Never leave grinder-buffer running unattended. Always turn power off after use.

Caution: Don't force grinder-buffer. It will do the job better and safer at the feed rate for which it

was designed.

Caution: Use right tool. Don't force tool or attachment to do a job for which it was not designed.

Caution: Maintain grinder-buffer with care. Keep grinder-buffer clean for best and safest

performance.

Table 1 Wire Wheel Selection

Wheel Size

No Load RPM

(on Nameplate)

“D” Diameter

(inches)

“W” Width

(inches)

“H” Arbor Diameter

(inches)

6″

5

/8″

1

/2″ 1800

6″

5

/8″

1

/2″ 3600

Use wire wheels that are rated to meet or exceed RPM shown in Table 1.

Wire Wheel

D

W

H

Page 3

3MN914

Overview

Belt grinding or finishing has many advantages over the use of conventional grinding wheels.

It is possible to remove material up to 5 times faster than the equivalent grade of grinding

wheel with far less heat. The electrostatic process used in the manufacture of an abrasive

belt ensures that the sharp side of each piece of grit is facing outwards on the belt thus giving

cleaner, smoother and faster cutting. The flexing of the belt has a self cleaning action and

also it does not overheat, making it more suitable to any application where heat could

damage the work, for example, grinding leather, plastics, tool sharpening etc.

Select the correct belt for the application, see Table 2.

Disc grinding is a very useful and versatile part of the attachment. It is very useful for dressing

small castings and components, patterns, models, etc., often eliminating costly machining.

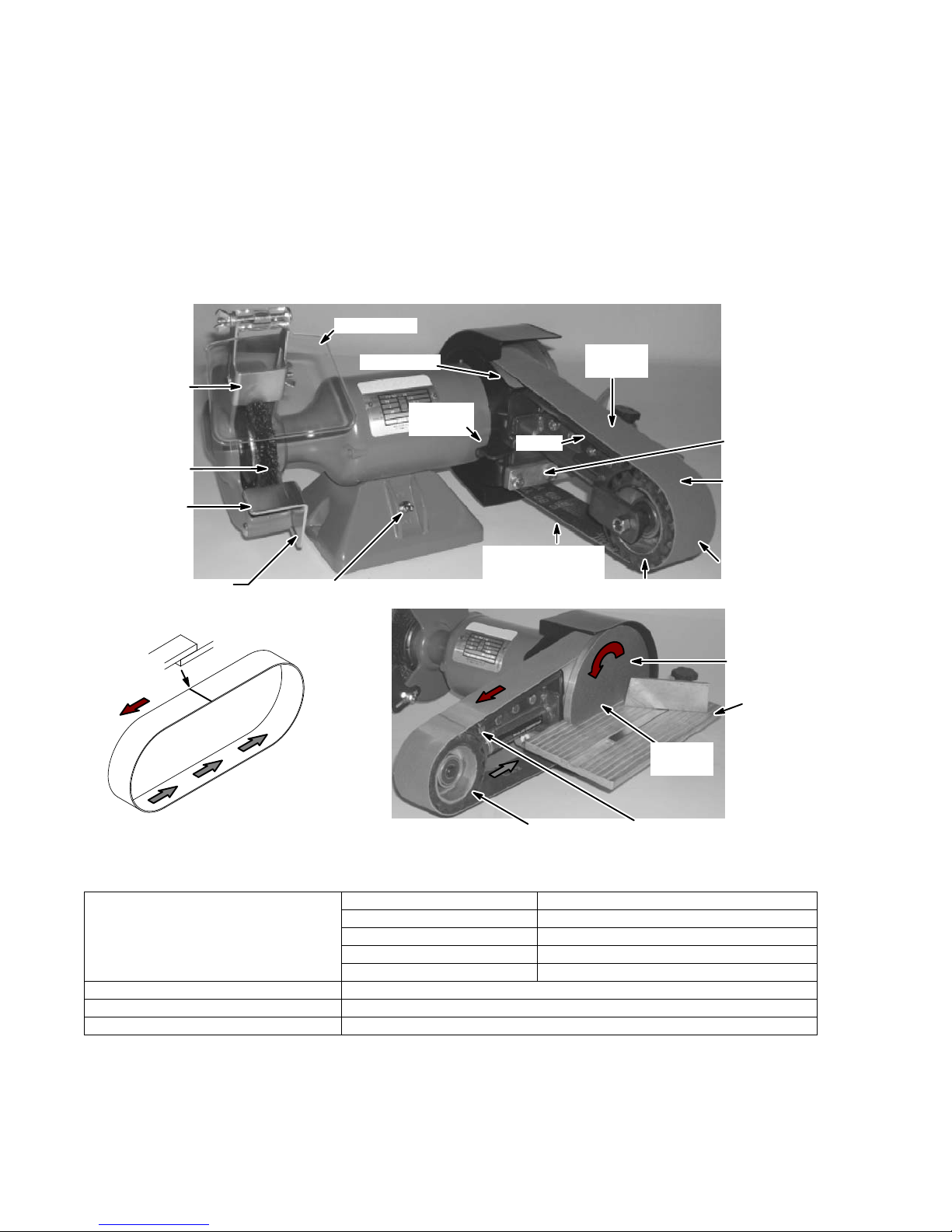

Figure 1

On-Of f Switch

Wire Brush

Tool Rest Support

Eyeshield

Catch

Tool Rest

Optional

Table

Abrasive Disc

Front of Grinder

Rotation

Direction

Belt

Lap

Spark Arrestor

Platen

Abrasive

Belt

Idler Pulley

Tracking

Lever

Contact Wheel

Grinding

Platen

Grinding

Free Strapping

Grinding

Disc

Grinding

Drive Pulley

Idler Pulley

Shown with optional

table installed.

Table Support

Bracket

Belt/Disc Specifications Belt size 36” x 2” (915 x 50); Disc size 7” (178).

Table 2 Belt Applications

All Metals

Coarse Finish Use 40 to 80 Grit Aluminum Oxide Belts.

Medium To Fine Use 100 to 180 Grit

Very Fine Use 240 to 400 Grit

Microfinishing Use 3M Trizact 600 to 2000 Grit

Heavy Grinding Or Thin Sections Use Zirconia Belts 40,60,80 Grits

Aluminum Always use belt grease to prevent clogging

Wood Use Aluminum Oxide Resin Bond open or Close Cote 40,60,80,100,120 Grits

Plastics, Glass Ceramic, General Lapidary Use Silicon Carbide Resin Bond Close Cote 40 to 600 Grit

Page 4

4 MN914

WARNING: When starting a grinder for the first time, or after installing a replacement wire wheel, it is

most important that the operator stand aside for at least one minute of rotation at full

speed. This is the correct practice since a wire wheel can disintegrate if it received

damage during shipping or handling.

Installation

When you receive your unit, there are several things you should do immediately.

1. Observe the condition of the shipping container and report any damage immediately to

the commercial carrier that delivered the product.

2. Verify that the part number you received is the same as the part number listed on your

purchase order.

3. Mount grinder-buffer on solid bench. The grinder-buffer must be securely bolted to a

rigid mounting surface. If a pedestal is used, first bolt pedestal securely to floor and then

bolt grinder-buffer to pedestal.

4. Check grinder-buffer nameplate to make certain the rating is correct for the power

source, voltage and frequency.

Wire Wheel Adjustments (see Figure 1)

1. Disconnect AC Power Cord from 115VAC receptacle.

2. Adjust spark arrestor for approximately

1

/16″ clearance between it and the wheel.

Maintain

1

/8″ or less clearance between spark arrestor and the wheel as wheel wears.

3. Adjust angle of tool rest on support to desired position and tighten nut securely. Adjust

tool rest support on guard to attain approximately

1

/16″ clearance between tool rest and

grinding wheel (or wire brush) and tighten nut securely.

Maintain

1

/8″ or less clearance between tool rest and wheel (or brush) as wheel wears.

4. Adjust eyeshield to position aligning center of eyeshield in line of sight to tool rest.

Belt Grinder Adjustments (see Figure 1)

If the correct belt is not installed on the belt grinder, perform the following:

1. Disconnect AC Power Cord from 115VAC receptacle.

2. Remove the belt. To remove belt simply push down on underside of belt to compress

belt tensioning spring. Catch automatically holds slide in retracted position.

Remove the belt from idler pulley and drive pulley.

3. Install the correct belt. Be sure belt lap faces in correct direction and the arrows on the

back side of belt face the correct direction of rotation. See Figure 1.

4. Apply tension to belt. When belt is installed, release catch by lifting it.

5. Check Belt Tracking. Manually rotate the belt while watching the belt movement.

Manually rotate the belt. Belt should track centered on the drive and idler pulleys.

To adjust belt left, move tracking lever down. To adjust right, move lever up.

If tracking lever is set in full Up or full Down position, refer maintenance section.

Optional Table Installation

1. Disconnect AC Power Cord from 115VAC receptacle.

2. Assemble Table hardware as shown in Figure 2 and mount Table Support Bracket in the

location identified in Figure 1.

Figure 2

Table Support Bracket

See Figure 1

Table Adjust

Carriage Bolt

Page 5

5MN914

Operation

WARNING: Do not operate this grinder-buffer until you are sure that you are completely familiar with

the safe operation of the grinder-buffer, all accessories and safety equipment. Improper

use can lead to severe injury. This manual defines proper use of this equipment. Before

using this equipment for any other use, please seek expert advise if you do not

understand any procedure or operation concerning this grinder-buffer or this manual.

WARNING: Always use safety glasses with side shields (or full face shield) when operating grinder.

Do not use ordinary eyeglasses. Also use face or dust mask if cutting operation is dusty.

WARNING: When starting a grinder for the first time, or after installing a replacement wheel or belt, it

is most important that the operator stand aside for at least one minute of rotation at full

speed. This is the correct practice since belts and wire wheels can disintegrate if they

have received damage during shipping or handling.

WARNING: Be sure the system is properly grounded before applying power. Do not apply power

before you ensure that grounds are connected. Electrical shock can cause serious or fatal

injury. Follow the National Electrical Code (NEC) and local codes for the safe installation

of this equipment.

Power On Procedure

1. Be sure the On-Off switch is in the Off position, and the wire wheel and belt grinder

move freely.

2. Connect the AC power cord to a properly grounded 115VAC receptacle.

3. Put on full face shield.

4. Stand to either side of the grinder-buffer and place the On-Off switch in the On position.

Wait at least one full minute of grinder rotation to verify that no pieces of the wire wheel

or belt are being thrown from the grinder. A damaged wheel or belt can disintegrate and

must be replaced.

5. Place the On-Off switch in the Off position to stop grinder-buffer operation.

Wire Wheel Operation

Always use guard and eyeshield. Operating the grinder-buffer without the guard and

eyeshield or with damaged guard and eyeshield must not be attempted because of the

hazard this introduces.

Maintain

1

/8 or less clearance between tool rest and wheel. This clearance is necessary

in preventing the work piece from becoming wedged between the wheel and tool rest and

restricting nip areas in the machine.

Buff on face of brush only.

1. Put on full face shield.

2. Place the On-Off switch in the On position. Grinder-buffer should come up to speed

smoothly and without vibration. If grinder-buffer does not, turn off grinder-buffer

immediately and determine reason.

3. Place work piece on tool rest and buff the work piece on the wire brush face only.

4. Place the On-Off switch in the Off position to stop grinder-buffer operation.

Belt Grinder Operation

Always use guard and eyeshield. Operating the grinder-buffer without the guard and

eyeshield or with damaged guard and eyeshield must not be attempted because of the

hazard this introduces.

Ensure the correct belt is installed so the Belt Lap faces the correct direction, see Figure 1.

1. Put on full face shield.

2. Place the On-Off switch in the On position. Grinder-buffer should come up to speed

smoothly and without vibration. If grinder-buffer does not, turn off grinder-buffer

immediately and determine reason.

3. Belt grind the work piece using one of the methods described.

4. Place the On-Off switch in the Off position when done.

Page 6

6 MN914

Several methods for belt grinding can be used:

see Figure 1.

1. Platen Grinding (Horizontal or Vertical)

a. Be sure the platen is properly adjusted, see Maintenance section of this manual.

b. Work of any length can be surfaced using the platen. For example the sawn edges

of wood from short pieces up to lengths of several meters.

2. Disc Grinding When possible, remove belt (to reduce wear) when disc grinding.

Use only grinding area indicated in Figure 3.

a. Tool and cutter sharpening is a simple task and there is less chance of burning the

work edges. When using the optional table, lengths and angles are easy to adjust.

Dressing end grain flat and square has always been a difficult task but now it is a

simple and quick operation, making perfect joints possible. A rubber cleaning stick

should be used regularly to prevent built up of wood resin.

b. Three options are available in abrasive discs. 1. Self-Adhesive. 2. Fur backed -

which must be used with an optional hook and loop backing pad. 3. Plain paper or

cloth backed disc which must be attached with a contact adhesive. When changing

a disc pad, remove all remaining adhesive from the disc with solvent (acetone or

lacquer thinner). Do not use household cleaners.

Figure 3 Disc Grinding

Disc Grinding Area

Use only the surface indicated so grinding is in the

downward direction and the force against the work

piece is downward against the table.

3. Contact Wheel Grinding Polishing and Sanding

a. Using the front contact wheel avails the user of material removal many times faster

than a conventional grinding wheel. The unique smooth cutting action is cooler,

faster and safer than conventional grinding methods. A good example of one of the

many uses is the smoothing of welds and casting blemishes prior to plating.

b. Using the extremely fast and easy belt change it is possible to go from a rough weld

finish to a flat, smooth polish suitable to chrome plate in only two belt changes, e.g.

Remove rough weld with 40; 60 or 80 grit belt.

Remove grinding marks with 240 grit belt.

Change ground finish to smooth, brushed finish for plating - Scotch brite super fine.

c. Wood shaping and finishing can be done in a similar manner but belts should

always be kept exclusively for wood especially in the finer grades.

A rubber belt cleaning stick helps prevent clogging on wood use.

4. Free Strapping

a. Free strapping is a method of belt grinding, sanding or polishing where no backing

is used behind the belt. It is especially suitable for round and contoured work and

some sharpening operations. It is done on the underneath side of the belt opposite

the platen.

b. It is ideally suited to narrow belt widths as small as

1

/2″ (13mm).

Belt grades of 180 to 400 are recommended because of the rapid cutting action of

narrow belts.

Page 7

7MN914

Maintenance

WARNING: Prevent electrical shock hazard and accidental machine operation. Always disconnect

grinder-buffer from the power source before servicing, changing accessories (such as

wheels, tool rest, spark arrestor, etc.) or before performing maintenance.

Replace worn wire brush wheel as necessary. The wheel should be replaced after the

diameter is reduced by 1 or 2 inches from original size. When replacing a worn wheel,

remove all dust and other materials from wheel guard.

Motor and pulley bearings are lubricated for life and do not require additional lubrication.

Replacement wheels may be purchased directly from your local industrial supply dealers,

abrasive dealers, tool dealers, etc.

Remove grinding dust from exhaust ports to prevent accumulation.

Replace damaged parts immediately to maintain safety of machine.

Figure 4 Belt Adjustments

Tracking

Lever

1/4” (6mm)

Top Bolt

Top Plate

Tracking Lever

Top Bolt

Top Plate

Catch

Idler

Platen

Idler Pulley

Drive Pulley

Abrasive Disc

Tracking Adjustment see Figure 4

Always ensure belt entirely covers rubber Drive Pulley. Adjustment is made when running or

when belt rotated by hand. To adjust left, move tracking lever down. To adjust right, move

lever up. If tracking lever is set fully in up or down position, coarse tracking adjustment must

be made.

Coarse Tracking

1. Set Tracking Lever in the mid position so it is horizontal.

2. If belt was changed, release the catch so spring loaded idler pulley is in full contact with

belt. Manually rotate belt a few times and observe the position of the belt.

3. If belt wanders toward the disc, loosen Top Bolt slightly and tap Top Plate a small

amount toward the grinder. If belt wanders toward the grinder, loosen Top Bolt slightly

and tap Top Plate a small amount toward the disc.

4. When belt runs evenly on drive pulley and idler pulley, tighten the Top Bolt.

5. Put on full face shield.

6. Place the On-Off switch in the On position. Grinder-buffer should come up to speed

smoothly and without vibration. If grinder-buffer does not, shut grinder-buffer off

immediately and determine reason.

7. Verify the belt runs evenly on drive pulley and idler pulley.

8. Place the On-Off switch in the Off position when done.

Fine Tracking The Tracking Lever is used for the final fine adjustment.

1. Move Tracking Lever slightly Down to move belt left on the platen or Up to move belt

right on the platen.

2. Move Tracking Lever slightly Up or Down as needed to obtain

1

/4″ (6mm) clearance

between Disc and Top Plate.

Page 8

P.O. Box 2400 Ft. Smith, AR 72901-2400

(479) 646-4711 Fax (479) 648-5792

www.baldor.com

© Baldor Electric Company

Printed in USA

8/08

8 MN914

LIMITED WARRANTY

Unless otherwise provided, Baldor grinders are warranted against defects in Baldor workmanship and

materials for a period of Thirty-Six months. All warranty claims must be submitted to a Baldor repair facility

prior to the expiration of the warranty period. Baldor shall have no responsibility or liability for any defect,

latent or otherwise, discovered after the expiration of the warranty period provided herein. Extended

warranties are available for certain Baldor products. These warranties are described in Baldor's catalog

and other sales literature. Extended warranties are subject to the terms and conditions of this Limited

Warranty as modified by the additional terms of the extended warranty. If a Baldor product is defective due

to Baldor workmanship or materials and the defect occurs during the warranty period, then Baldor will

either repair the product or replace it with a new one, whichever Baldor believes to be appropriate under the

circumstances. Warranty service is available for all Baldor products from Baldor's Customer Service

Department in Fort Smith, Arkansas, and from Baldor repair facilities. A list of Baldor's repair facilities may

be obtained by contacting Baldor at: Baldor Electric Company, 5711 R.S. Boreham, Jr. St., Fort Smith,

Arkansas, 479-646-4711 (phone), 479-648-5792 (fax). All Baldor products requiring warranty service

shall be transported or shipped freight pre-paid, at the risk of the party requiring warranty service, to

Baldor's Customer Service Department in Fort Smith, Arkansas or to a Baldor repair facility. Written

notification of the alleged defect in addition to a description of the manner in which the Baldor grinder is

used, and the name, address and telephone number of the party requiring warranty service must be

included. Baldor is not responsible for removal and shipment of the Baldor product to the service center

nor for the reinstallation of the Baldor product upon its return to the party requiring warranty service.

Customers who are unable to take or ship the Baldor product to a Baldor repair facility, or who desire a

repair to be made by other than a Baldor repair facility, should contact Baldor's Customer Service

Department at 479-646-4711. Repair by anyone other than a Baldor repair facility must be approved in

writing by Baldor in advance of such service. Problems with Baldor products can be due to improper

maintenance, faulty installation, non-Baldor additions or modifications, or other problems not due to

defects in Baldor workmanship or materials. If a Baldor repair facility determines that the problem with a

Baldor product is not due to defects in Baldor workmanship or materials, then the party requiring warranty

service will be responsible for the cost of any necessary repairs. Parties requiring warranty service not

satisfied with a determination that a problem is outside of warranty coverage should contact Baldor's

Customer Service Department at 479-646-4711 for further consideration.

EXCEPT FOR THE EXPRESS WARRANTY SET FORTH ABOVE, BALDOR DISCLAIMS ALL OTHER

EXPRESS AND IMPLIED WARRANTIES INCLUDING THE IMPLIED WARRANTIES OF FITNESS FOR

A PARTICULAR PURPOSE AND MERCHANTABILITY. NO OTHER WARRANTY, EXPRESS OR

IMPLIED, WHETHER OR NOT SIMILAR IN NATURE TO ANY OTHER WARRANTY PROVIDED

HEREIN, SHALL EXIST WITH RESPECT TO THE GOODS SOLD UNDER THE PROVISIONS OF

THESE TERMS AND CONDITIONS. ALL OTHER SUCH WARRANTIES ARE HEREBY EXPRESSLY

WAIVED BY THE BUYER. UNDER NO CIRCUMSTANCES SHALL BALDOR BE LIABLE OR

RESPONSIBLE IN ANY MANNER WHATSOEVER FOR ANY INCIDENTAL, CONSEQUENTIAL OR

PUNITIVE DAMAGES, OR ANTICIPATED PROFITS RESULTING FROM THE DEFECT, REMOVAL

REINSTALLATION, SHIPMENT OR OTHERWISE.

This is the sole warranty of Baldor and no other affirmations or promises made by Baldor shall be deemed

to create an express or implied warranty. Baldor has not authorized anyone to make any representations

or warranties other than the warranty contained herein.

Loading...

Loading...