Page 1

SERIES 5 MICRO INVERTER

NEMA-1 / IP-40

Installation and Operation Manual

For Catalog Number - ID5601- EO

MN785

ADJUSTABLE SPEED DRIV

E

Page 2

2

TABLE OF CONTENTS

Section Page

1 Introduction ......................................................................................................................3

Safety Notice ..................................................................................................................8

2 Quick-Start Instructions....................................................................................................11

3 Mounting Instructions.......................................................................................................15

4 Electrical Connections .............................................................. ......................................15

5 Important Application Information ....................................................................................17

6 Setting Selectable Jumpers .............................................................................................19

7 Trimpot Adjustments ........................................................................................................21

8 Drive Operation................................................................................................................24

9 Pilot Light and Diagnostic LED’s......................................................................................25

10 Troubleshooting ...............................................................................................................26

Baldor District Offices ......................................................................................................31

Limited Warranty..................................................................................................Back Cover

Tables Page

1 Standard Features ...........................................................................................................4

2 Performance Features .....................................................................................................4

3 Protection Features..........................................................................................................5

4 Selectable Jumpers .........................................................................................................5

5 Trimpot Adjustments ........................................................................................................5

6 Optional Accessories .......................................................................................................6

7 Electrical Ratings .............................................................................................................6

8 General Performance Specifications ...............................................................................7

9 Terminal Block Wire and Tightening Torque Specifications ............................................15

10 Drive Operating Condition and Run/Fault Relay Contact Status .....................................17

11 Drive Operating Conditions and Status LED Indications .................................................25

12 Troubleshooting Guide.....................................................................................................27

13 Fault Recovery and Setting Drive ....................................................................................28

Figures Page

1 Quick-Start Connection Diagram .....................................................................................11

2 Cover Layout....................................................................................................................12

3 Drive Layout.....................................................................................................................13

4 Mechanical Specifications................................................................................................14

5 AC Line Input, Motor, and Ground Connections ..............................................................16

6 Run/Fault Relay Output Connection ................................................................................16

7 Maximum Allowed Motor Torque vs. Speed ....................................................................18

8 Open Ventilated Motor with External Fan Cooling ...........................................................18

9 AC Line Input Voltage Selection (Jumper J1) ..................................................................19

10 Motor Horsepower Selection (Jumper J2) .......................................................................19

11 Automatic or Manual Start and Reset Selection (Jumper J3) ..........................................20

12 60 Hz or 50 Hz Motor Selection (Jumpers J4 and J5) .....................................................20

13 Available Torque vs. Output Frequency...........................................................................20

14 120 Hz and 100 Hz Drive Output Frequency Selection (Jumpers J4 and J5) .................21

15 “Run” or “Fault” Output Relay Operation Selection (Jumper J6)......................................21

16 Minimum Speed Trimpot (MIN) Range ............................................................................21

17 Maximum Speed Trimpot (MAX) Range ..........................................................................22

18 Acceleration Trimpot (ACCEL) Range .............................................................................22

19 Deceleration Trimpot (DECEL) Range.............................................................................22

20 Slip Compensation Trimpot (COMP) Range....................................................................22

21 Current Limit Trimpot (CL) Range....................................................................................23

22 I

2

t Trip Time vs. Motor Current.........................................................................................23

Page 3

3

1 INTRODUCTION

Thank you for purchasing the Adjustable Frequency Drive, ID5601-EO. Baldor, Inc. is committed

to providing total customer satisfaction by producing quality products that are easy to install and

operate. The ID5601-EO is manufactured with surface mount components incorporating

advanced circuitry and technology. The ID5601-EO is an Adjustable Frequency Drive which is

capable of variable speed control. In addition, it is housed in a NEMA-1 / IP-40 enclosure. It is

designed to operate 208 – 230 Volt 50 & 60 Hz 3-phase AC induction motors from 1/8 HP thru 1

HP. The sine wave coded Pulse Width Modulated (PWM) output operates at a carrier frequency

of 16 kHz which provides high motor efficiency and low noise. Adjustable Linear Acceleration

and Deceleration make the drive suitable for soft-start applications. The Motor Horsepower

Selection Jumper allows the drive to be used on a wide range of motor horsepower (1/8, 1/4,

1/2, 3/4, 1 HP) without recalibration or programming.

Its user-friendly design makes the ID5601-EO easy to install and operate. Setting the drive to

specific applications is accomplished with selectable jumpers and trimpots, which eliminates the

computer-like programming required on other drives. However, for most applications no

adjustments are necessary.

Main features include adjustable RMS Current Limit and I2t Motor Overload Protection. 1 In

addition, Adjustable Flux Vector Compensation with Static Auto-Tune and Boost provides high

torque and excellent load regulation over a wide speed range. Power Start™ delivers over 200%

motor torque to ensure startup of high frictional loads. Electronic Inrush Current Limit (EICL™)

eliminates harmful AC line inrush current. A Run/Fault Relay is provided, which can be used to

turn on or off equipment or to signal a warning if the drive is put into the Stop Mode or a fault has

occurred.

Standard front panel features include an On/Off AC Line Switch, a pilot light for power on, and a

Main Speed Potentiometer. Other features include PC board mounted diagnostic LEDs (Power

On (ON), Drive Status (ST) and Overload (OL)), Barrier Terminal Blocks to facilitate wiring (AC

line, motor, ground (earth), and Run/Fault Relay Output Contacts), adjustable trimpots (MIN,

MAX, ACCEL, DECEL, COMP, CL), customer selectable jumpers (AC Line Input Voltage

Selection, Motor Horsepower, Automatic or Manual Start and Reset

2

, Motor Frequency,

Frequency Multiplier, and a Run/Fault Output Relay). Refer to Tables 1 – 8, on pages 4, 5, and

6.

Optional accessories include: Forward-Stop-Reverse Switch.

Notes: 1. UL approved as an electronic overload protector for motors. 2. The optional ForwardStop-Reverse Switch is required for Manual Start

.

This product complies with all CE directives pertinent at the time of manufacture.

Contact your local Baldor District Office for Declaration of Conformity. Installation of a CE

approved RFI filter is required. Additional shielded cable and/or AC line cables may be

required along with a signal isolator.

Page 4

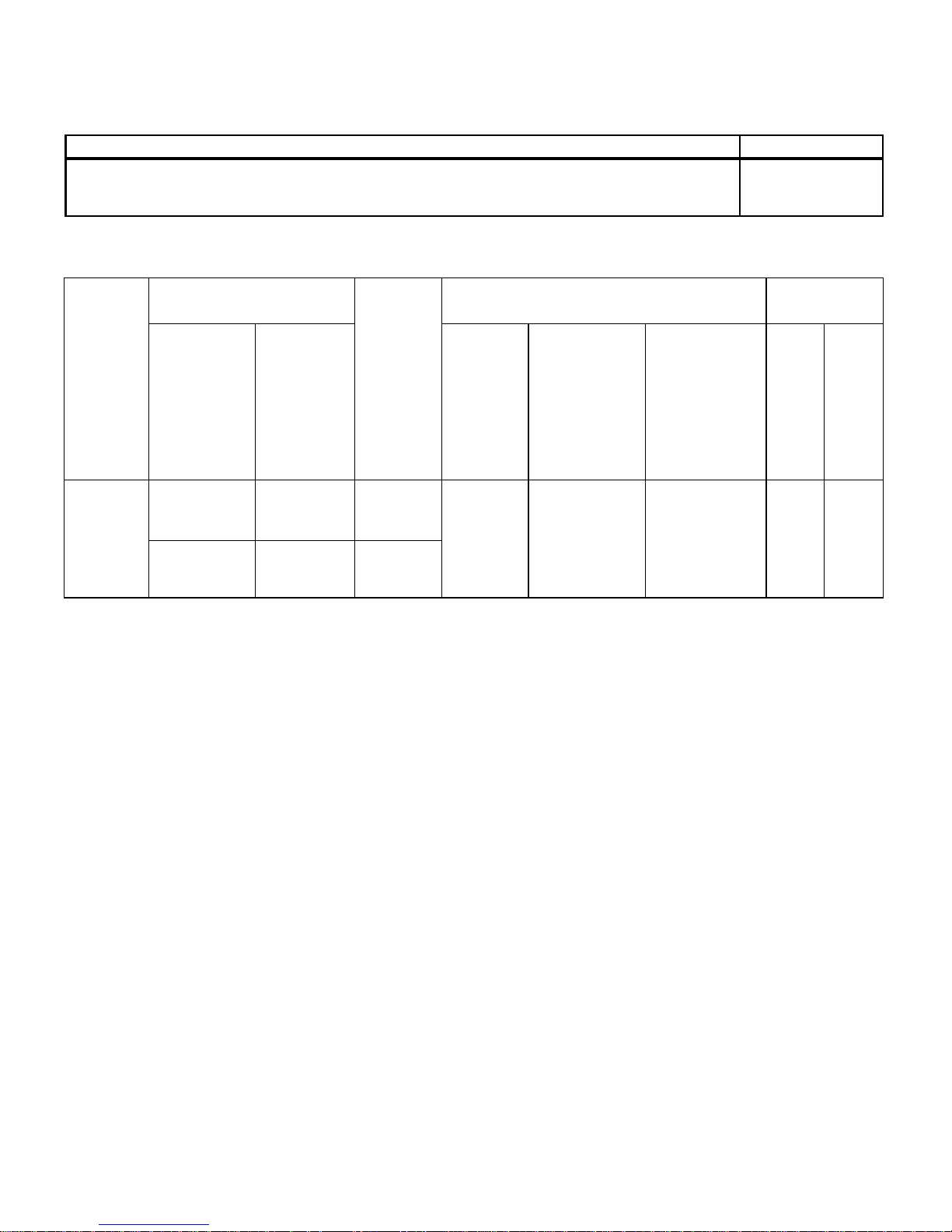

4

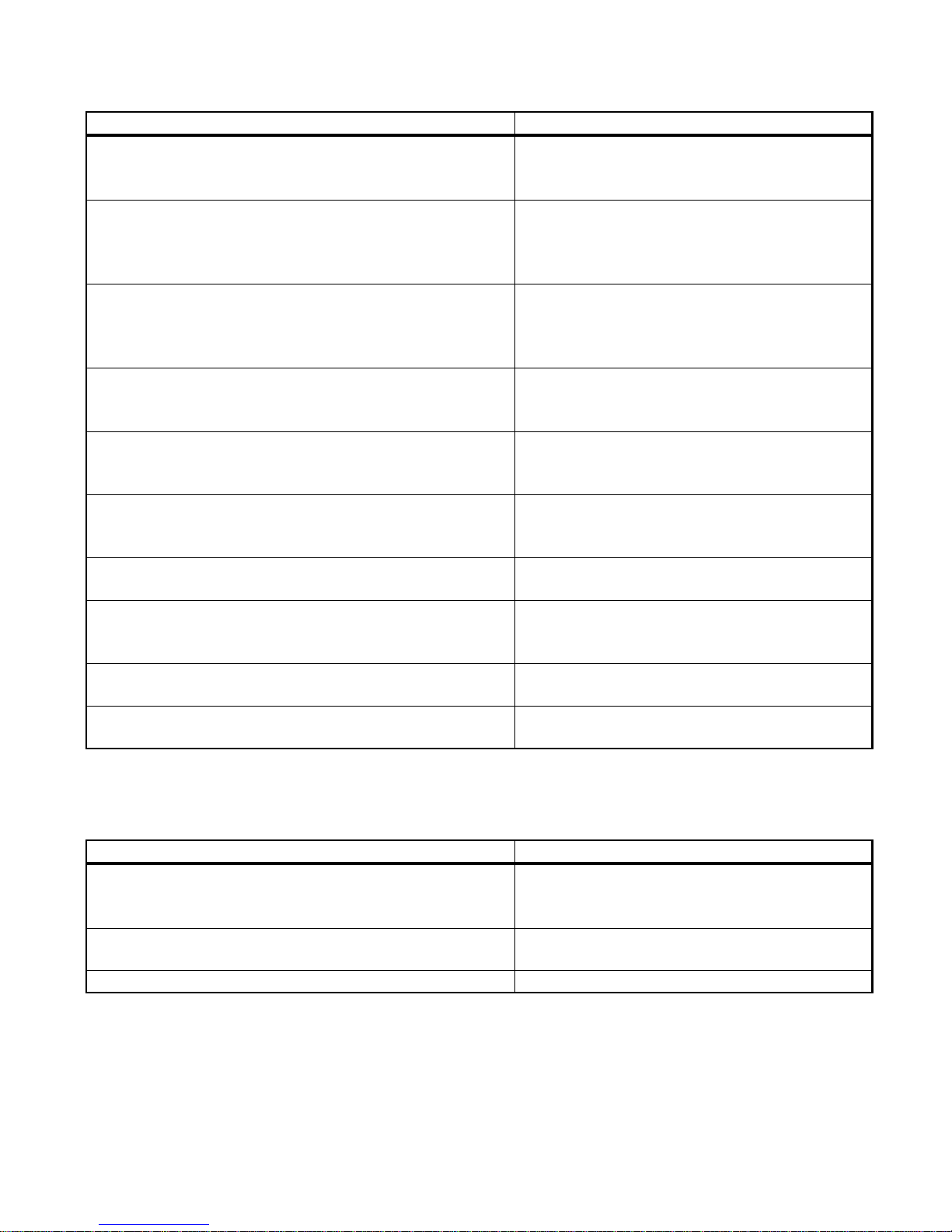

TABLE 1 - STANDARD FEATURES

Feature Description

Simple to Operate

Does not require programming. Uses

trimpots and jumpers which are factory set

for most applications.

Dual AC Line Voltage (115 or 208/230 Volt AC

Operation)

Controls 208 – 230 Volt AC, 50 & 60 Hz,

3-phase motors from 115 or 208/230 Volt

AC line. (Jumper J1 must be installed for

115 Volt AC line operation.)

Motor Horsepower Selection Jumper

Allows the drive to be used on a wide

range of motor horsepower (1/8, 1/4, 1/2,

3/4, 1 HP) without recalibration or

programming.

Diagnostic LED’s

PC board mounted LEDs for Power on

(ON), Drive Status (ST), and Overload

(OL).

Run/Fault Relay Output Contacts

Can be used to turn on and off equipment

or to signal a warning if the drive is put

into a Stop Mode or a fault has occurred.

Barrier Terminal Blocks

Facilitate wiring of AC line, motor, ground

(earth) and Run/Fault Relay Output

Contacts.

On/Off AC Line Switch

Panel mounted. Used to turn on or off

power to the drive.

Pilot Light

Panel mounted. Indicates that power is

applied to the drive and the On/Off AC

Line Switch is set to the “ON” position.

Main Speed Potentiometer

Panel mounted. Provides adjustment of

motor speed.

Jumper Selections of Drive Output Frequency

Increases the motors speed up to two

times the rated RPM.

TABLE 2 - PERFORMANCE FEATURES

Feature Description

Power Start™

Provides more than 200% starting torque

which ensures startup of high frictional

loads.

Flux Vector Compensation with Static Auto-Tune

and Boost

Provides excellent load regulation over a

wide speed range.

Speed Range 60:1

Page 5

5

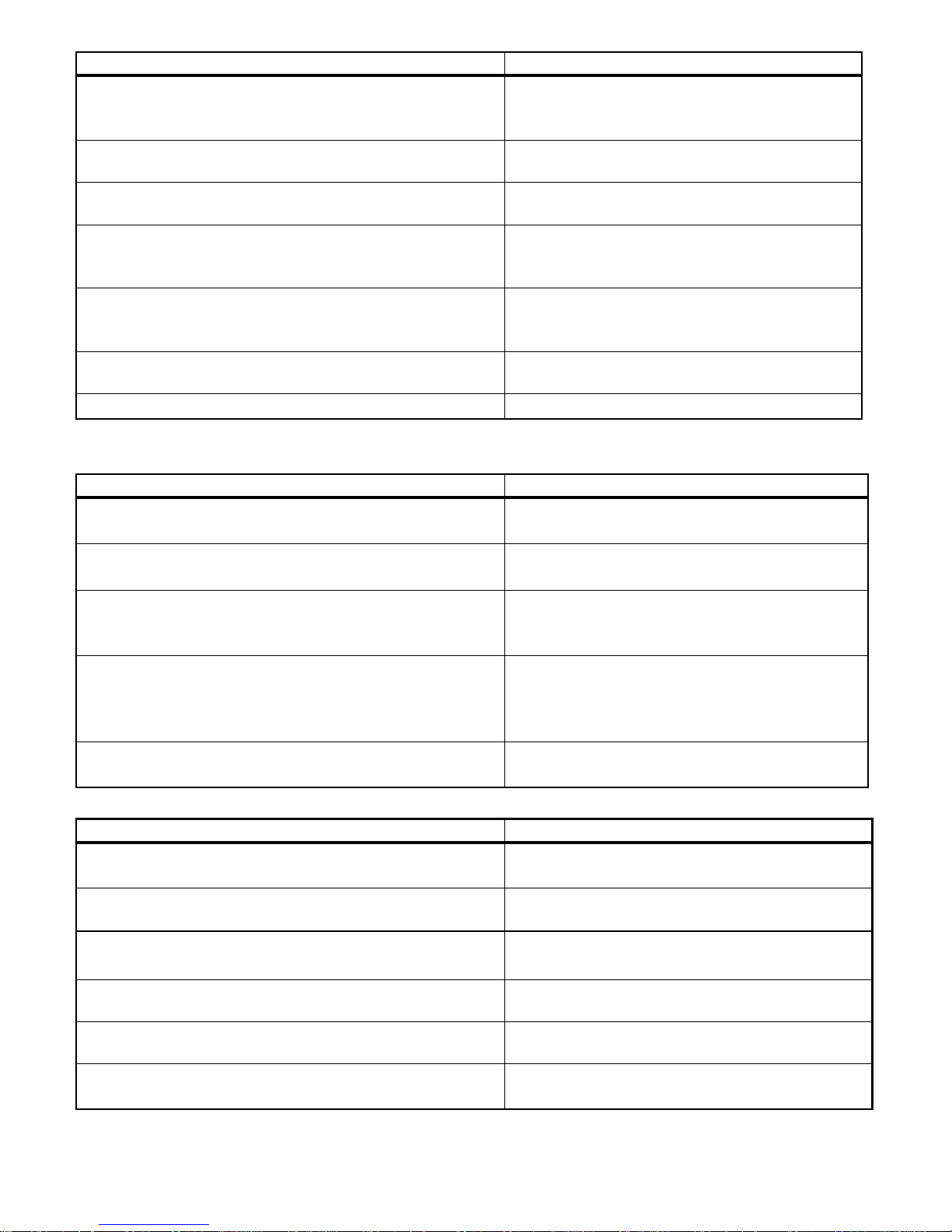

TABLE 3 - PROTECTION FEATURES

Feature Description

Motor Overload (I2t) with RMS Current Limit

Provides motor overload protection which

prevents motor burnout and eliminates

nuisance trips*.

Electronic Inrush Current Limit (EICL™)

Eliminates harmful inrush AC line current

during startup.

Short Circuit

Shuts down the drive if a short circuit

occurs at the motor (phase-to-phase).

Regeneration

Eliminates tripping due to bus overvoltage

caused by rapid deceleration of high

internal loads.

Undervoltage and Overvoltage

Shuts down the drive if the AC line input

voltage goes above or below the

operating range.

MOV input transient suppression.

Prevents failure of power devices caused

by voltage spikes in the AC line.

Microcontroller Feature Self monitoring and auto-reboot.

* UL approved as an overload protector for motors.

TABLE 4 – SELECTABLE JUMPERS (See Section 6, on page 19)

Feature Description

AC Line Input Voltage Selection (115/230 Volts AC)

J1. Refer to Section 6.1, page 19.

Factory set for 208/230 VAC (Install

Jumper for 115 VAC Operation).

Motor Horsepower (1/8, 1/4, 1/2, 3/4, 1 HP) J2.

Refer to Section 6.2, page 19.

Selectable for the motor use.

Automatic or Manual Start and Reset. J3.

Refer to Section 6.3, page 19.

Factory set for Auto. Can be set for

Automatic start or Manual start (Optional

FSR Switch required).

Motor Frequency (50/60 Hz) J5.

Frequency Multiplier (1X, 2X) J4.

Refer to Sections 6.4.1 and 6.4.2, on page 20.

Factory set for 60 Hz. Must be set for the

motor being used. In addition, the drive

may be set for up to 2X the motors rated

RPM.

“Run” or “Fault” Output Relay Operation. J6, Refer

to Section 6.5, page 20.

Factory set to RUN position. Set to either

Run or Fault for intended application.

TABLE 5 - TRIMPOT ADJUSTMENTS (See Section 7, on pages 21 – 24)

Trimpot Description

Minimum Speed (MIN), Refer to Section 7.1, page

21.

Sets the minimum speed of the motor.

Maximum Speed (MAX), Refer to Section 7.2, page

22.

Sets the maximum speed of the motor.

Acceleration (ACCEL), Refer to Section 7.3, page

22.

Sets the amount of time for the motor to

accelerate from zero speed to full speed.

Deceleration (DECEL), Refer to Section 7.4, page

22.

Sets the amount of time for the motor to

decelerate from full speed to zero speed.

Slip Compensation (COMP) Refer to Section 7.5,

page 22.

Sets the amount of Volts/Hz to maintain set

motor speed under varying loads.

Current Limit (CL), Refer to Section 7.6, page 23.

Sets the current limit and limits the

maximum current (torque) to the motor.

Page 6

6

TABLE 6 - OPTIONAL ACCESSORY

Description Catalog No.

Forward-Stop-Reverse Switch: Provides motor reversing, stop, and manual

start functions.

ID5FRS-2

TABLE 7 - ELECTRICAL RATINGS

AC Line Input Output Net Weight

Catalog

No.

Volts AC

50/60 HZ,

(Phase Φ)

Maximum

Current-

(Amps

AC)

Fuse or

Circuit

Breaker

Rating

(Amps)

Voltage

Range

(Volts

AC)

(Phase

Φ)

Maximum

Continuous

Load

Current

(RMS

Amps/

Phase)

Maximum

Horsepower

(HP(kW))

lbs. kg

115,

1 Φ

16.0 20

ID5601

- EO

208/2301,

1 Φ

10.0

15

0 – 230

3 Φ

3.6 1 (.75) 2.42 1.09

Note : 1. The drive is factory set for 208/230 Volt AC line input (J1 not installed). For 115 volt AC line

input, install Jumper J1 (supplied). See Section 6.1, on page 19.

Page 7

7

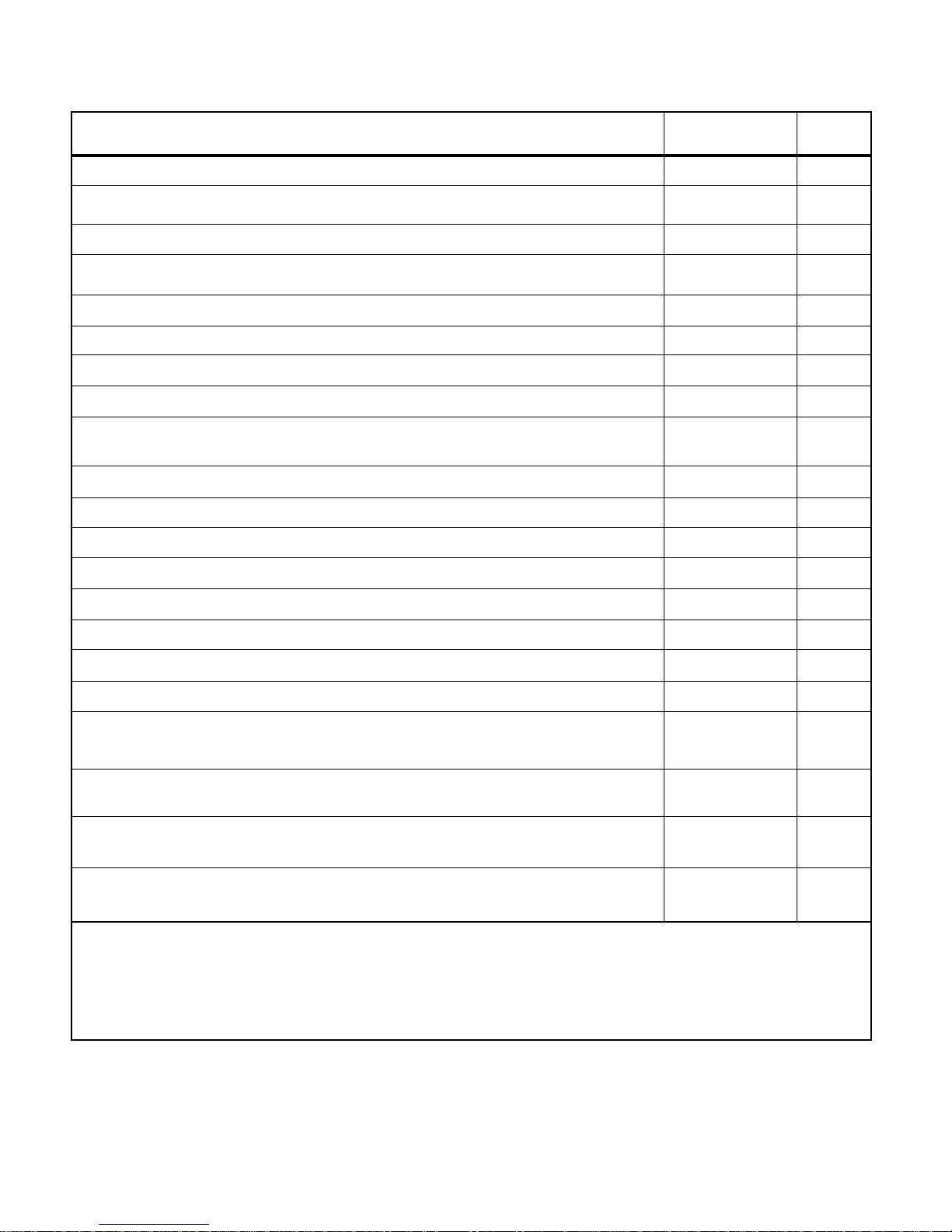

TABLE 8- GENERAL PERFORMANCE SPECIFICATIONS

Description Specification

Factory

Settin

g

115 Volt AC Line Input Voltage Operating Range (Volts AC)1

115 (±15%) ──

208/230 Volt AC Line Input Voltage Operating Range (Volts AC)1

208 (-15%) /

2

30 (+15%)

2

──

Maximum Load (% Current Overload for 1 Minute) 150 ──

Horsepower Selection (HP) (Jumper J2)

1/8, 1/4, 1/2,

1

Carrier Frequency (kHz) 16 ──

Output Frequency Resolution (Bits) 10 ──

Minimum Speed Trimpot (MIN) Range (% Frequency Setting) 0 – 40 0

Maximum Speed Trimpot (MAX) Range (% Frequency Setting) 70 – 110 100

Acceleration Trimpot (ACCEL) and Deceleration Trimpot (DECEL)

Range (Seconds)

.3 – 20 1.5

Slip Compensation Trimpot (COMP) Range at Drive Rating (Volts/Hz) 0 – 3 1.5

Current Limit Trimpot (CL) Range (% Full Load) 0 – 200 160

Motor Frequency Setting (Hz) (Jumper J5) 50, 60 60

Output Frequency Multiplier (1X, 2X) (Jumper J4)3 1, 2 1

Minimum Operating Frequency at Motor (Hz) 0.3 ──

Speed Range (Ratio) 60:1 ──

Speed Regulation (30:1 Speed Range, 0 – Full Load) (% Base Speed)4 2.5 ──

Overload Protector Trip Time for Stalled Motor (Seconds) 6 ──

Undervoltage/Overvoltage Trip Points for 115 Volt AC Line Input (±5%)

(Volts AC)

1

76 / 141 ──

Undervoltage/Overvoltage Trip Points for 208/230 Volt AC Line Input

(±5%)

151 / 282 ──

Run/Fault Relay Output Contact Rating

(Amps at 30 Volts DC, 125 Volts AC, 230 Volts AC)

1, 0.5, 0.25 ──

Operating Temperature Range (°C / °F)

0 – 40 /

32 – 104

──

Notes: 1. Do not operate the drive outside the spec ified AC line input voltage operat ing range. 2.

The drive is factory set for 208/230 Volt AC line input (Jumper J1 not installed). For 115 Volt AC

line input, install Jumper J1 (supplied). See Figure 3, on page 12. 3. Allows the motor to operate

up to two times the rated RPM. Constant motor horsepower will result when operating the drive

in the “2X” mode above the motor rated frequency. 4. Dependant on motor performance.

Page 8

8

SAFETY NOTICE

WARNING - STATEMENT INDICATES A POTENTIALLY HAZARDOUS SITUATION WHICH, IF

NOT AVOIDED, COULD RESULT IN INJURY OR DEATH.

CAUTION - Statement indicates a potentially hazardous situation which, If not avoided, could

result in damage to property.

Note - Additional information that is not critical to the installation or operation.

WARNING! READ ALL SAFETY WARNINGS, ON PAGE 8, BEFORE USING THE

DRIVE. DISCONNECT MAIN POWER BEFORE MAKING CONNECTIONS TO THE DRIVE. TO

AVOID ELECTRIC SHOCK, BE SURE TO PROPERLY GROUND THE DRIVE.

WARNING! THIS EQUIPMENT MAY CONTAIN VOLTAGES AS HIGH AS 1000

VOLTS! ELECTRICAL SHOCK CAN CAUSE SERIOUS OR FATAL INJURY. ONLY QUALIFIED

PERSONNEL SHOULD ATTEMPT THE START-UP PROCEDURE OR TROUBLESHOOT THIS

EQUIPMENT.

WARNING! ELECTRICAL SHOCK CAN CAUSE SERIOUS OR FATAL INJURY. BE

SURE THAT ALL POWER IS DISCONNECTED FROM DRIVE BEFORE THE COVER IS

OPENED. OPENING OF THE COVER IS REQUIRED TO MAKE INSTALLATION

CONNECTIONS. ELECTRICAL SHOCK CAN CAUSE SERIOUS OR FATAL INJURY IF THE

COVER IS REMOVED AND POWER IS STILL APPLIED.

WARNING! ELECTRICAL SHOCK CAN CAUSE SERIOUS OR FATAL INJURY.

VERIFY THERE IS NO VOLTAGE PHASE-TO-PHASE OR PHASE-TO-NEUTRAL AT THE AC

LINE CONDUCTORS BEFORE TOUCHING THE AC INPUT WIRES. DO NOT TOUCH LIVE

WIRES. ALL POWER MUST BE DISCONNECTED BEFORE PROCEEDING.

WARNING! IT IS THE RESPONSIBILITY OF THE EQUIPMENT MANUFACTURER

AND INDIVIDUAL INSTALLER TO SUPPLY THIS SAFETY WARNING TO THE ULTIMATE END

USER OF THIS PRODUCT. (SW/FSC 5/2005) BE SURE TO FOLLOW ALL INSTRUCTIONS

CAREFULLY. FIRE AND/OR ELECTROCUTION CAN RESULT DUE TO IMPROPER USE OF

THIS PRODUCT.

WARNING! DO NOT USE THIS DRIVE IN AN EXPLOSIVE ENVIRONMENT. AN

EXPLOSION CAN CAUSE SERIOUS OR FATAL INJURY. THIS DRIVE IS NOT EXPLOSION

PROOF.

Page 9

9

SAFETY NOTICE(Continued)

WARNING! HIGH VOLTAGE IS PRESENT IN THIS DRIVE. DISCONNECT MAIN

POWER BEFORE MAKING CONNECTIONS TO THE DRIVE. THE COVER MUST BE

PROPERLY INSTALLED AFTER ALL SETUP, CONNECTIONS, AND ADJUSTMENTS ARE

COMPLETE. IT REDUCES ELECTRICAL SHOCK HAZARD. FAILURE TO OBSERVE THIS

WARNING COULD RESULT IN ELECTRICAL SHOCK OR ELECTROCUTION.

WARNING! HIGH VOLTAGE IS PRESENT IN THE DRIVE. DISCONNECT MAIN

POWER BEFORE MAKING CONNECTIONS TO THE DRIVE. DO NOT ADJUST TRIMPOTS

WITH THE MAIN POWER APPLIED. IF ADJUSTMENTS ARE MADE WITH THE MAIN POWER

APPLIED, AN INSULATED ADJUSTMENT TOOL (PROVIDED) MUST BE USED AND SAFETY

GLASSES MUST BE WORN. FIRE AND/OR ELECTROCUTION CAN RESULT IF CAUTION IS

NOT EXERCISED.

WARNING! HIGH VOLTAGE IS PRESENT IN THIS DRIVE. DISCONNECT MAIN

POWER BEFORE MAKING CONNECTIONS TO THE DRIVE. TO PREVENT ACCIDENTAL

CONTACT WITH HIGH VOLTAGE, IT IS REQUIRED THAT THE COVER BE PROPERLY

INSTALLED AFTER ALL SETUP, CONNECTIONS, AND ADJUSTMENTS ARE COMPLETE.

THIS REDUCES ELECTRICAL SHOCK HAZARD. FAILURE TO OBSERVE THIS WARNING

COULD RESULT IN ELECTRICAL SHOCK OR ELECTROCUTION.

WARNING! AUTOMATIC START AND RESET: JUMPER J3 IS FACTORY SET TO

THE “AUTO” POSITION TO AUTOMATICALLY START THE DRIVE WHEN THE POWER IS

APPLIED AND THE ON/OFF AC LINE SWITCH IS SET TO THE “ON” POSITION.

WARNING! THE DRIVE WILL AUTOMATICALLY RESTART AFTER FAULT HAS

CLEARED. IF AN I

2

T OR SHORT CIRCUIT FAULT OCCURS, THE DRIVE MUST BE

RESTARTED BY SETTING THE ON/OFF AC LINE SWITCH TO THE “OFF” POSITION FOR A

MINIMUM OF 5 SECONDS.

WARNING! DO NOT DEPEND ON THE PILOT LIGHT OR THE PC BOARD

MOUNTED LED’s FOR A GUARANTEED POWER OFF INDICATION. BE SURE ALL AC

POWER IS "OFF" BEFORE SERVICING THE DRIVE TO AVOID ELECTRICAL SHOCK

HAZARD.

WARNING! MAKE SURE THAT THE POTENTIOMETER IS SET FULLY

COUNTERCLOCKWISE PRIOR TO APPLYING POWER. IF THIS IS NOT DONE, THE MOTOR

WILL RUN AT THE SPEED SETTING AT POWER UP. THIS MAY CAUSE BODILY INJURY IF

ONE IS IN CLOSE PROXIMITY OF MOVING PARTS.

Page 10

10

SAFETY NOTICE (Continued)

CAUTION!

1. Some motors have low speed characteristics, which cause overheating and

winding failure under light load or no load conditions. If the motor is operated in this

manner for an extended period of time, it is recommended that the unloaded motor current

be checked from 2 - 15 hz (60 - 450 rpm) to ensure motor current does not exceed the

nameplate rating. Do not use motor if the motor current exceeds the nameplate rating. 2. It

Is Recommended that the Drive be used with Inverter Duty or TENV Motors.

CAUTION!

Disconnect motor leads (U, V and W) from control before performing a "Leakage

Resistance" test on the motor. Failure to disconnect motor from the control may result in

extensive damage to the control. The control is tested at the factory for high voltage I

leakage resistance as part of Underwriter Laboratory requirements.

CAUTION!

Suitable for use on a circuit capable of delivering not more than 5,000 RMS

symmetrical short circuit amperes listed here at rated voltage.

CAUTION!

Proper shielding, grounding, and filtering of this product can reduce the

emission of radio frequency interference (RFI) which may adversely affect sensitive

electronic equipment.

CAUTION!

Do not use the "115V" position for 230 Volt AC line input voltage. Damage will

occur to the drive. The 115V position provides 2 times the AC input voltage to the motor.

CAUTION

! GFCI Operation: Do Not Connect This Drive To An AC Power Source Controlled

By A Ground-Fault circuit-Interrupter.

CAUTION!

If the current limit is adjusted above 160% of the motor nameplate rating, this

can cause overheating of the motor.

CAUTION!

Do not leave the motor in a locked rotor condition for more than a few seconds

since damage may occur.

Page 11

11

FIGURE 1 - QUICK-START CONNECTION

DIAGRAM

*For 115 VAC line, install jumper J1 (supplied).

Recommended Tightening Torque

lb-in (7), kg-cm (8)

2 QUICK-START INSTRUCTIONS

Important: You must read these simplified instructions before proceeding. These instructions

are to be used as a reference only and are not intended to replace the details provided herein.

You must read the “ALL” Safety Warnings on, page 8, before proceeding.

Note: This drive contains bus capacitors which must be reconditioned if the drive has been in

storage for over 1 year. To recondition the bus capacitors, apply the AC line, with the main

speed potentiometer set to zero, for a minimum of 30 minutes.

See Figures 1 – 4, on pages 11 - 14. See Section 5 - Important Application Information, on

page 17.

WARNING! HIGH VOLTAGE IS PRESENT IN THIS DRIVE. DISCONNECT MAIN

POWER BEFORE MAKING CONNECTIONS TO THE DRIVE. TO PREVENT ACCIDENTAL

CONTACT WITH HIGH VOLTAGE, IT IS REQUIRED THAT THE COVER BE PROPERLY

INSTALLED AFTER ALL SETUP, CONNECTIONS, AND ADJUSTMENTS ARE COMPLETE.

THIS REDUCES ELECTRICAL SHOCK HAZARD. FAILURE TO OBSERVE THIS WARNING

COULD RESULT IN ELECTRICAL SHOCK OR ELECTROCUTION.

Note: It is recommended that both FeedThrough Bushings (See Figure 4, on page

13) be used to connect the drive. If signal

wiring (for the Run/Fault Relay Output

Contacts or for a remote Main Speed

Potentiometer) is required, it is

recommended that the extra Feed-Through

Bushing (supplied with the drive) be used to

replace the center Hole Plug. Standard 3/4”

fittings (not supplied) can also be used in lieu

of the Feed-Through Bushings.

2.1 MOUNTING INSTRUCTIONS: See

Section 3, on page 15.

WARNING! DO NOT USE THIS

DRIVE IN AN EXPLOSION-PROOF

APPLICATION.

2.2 AC LINE INPUT CONNECTION: Connect the single-phase AC line input to Terminal Block

TB1 (Terminals “L1”, “L2”), as shown in Figure 1. See Section 4.1, on page 15.

Application Note: Do not connect this drive to a GFCI.

Note: The drive is factory set for 208/230 Volt AC line input (Jumper J1 not installed). For 115

Volt AC line input, install Jumper J1 (supplied). See Section 6.1, on page 19.

2.3 AC LINE FUSING: It is recommended that a fuse(s) or circuit breaker be installed in the AC

line. Fuse each conductor that is not at ground potential. For the recommended fuse size,

see Table 7, on page 5. Also see Section 4.1, on page 15.

2.4 GROUND CONNECTION: Connect the ground wire (earth) to Terminal Block TB1

(Terminal “GND”), as shown in Figure 1 and Table 9, on page 15.

Page 12

12

2.5 MOTOR CONNECTION: Connect the motor to Terminal Block TB1 (Terminals “U”, “V”,

“W”), as shown in Figure 1, on page 10. (Load reactors may be required for cable lengths

over 100 ft. (30 m) – contact the local Baldor District Office). See Section 4.3, on page 16.

2.6 JUMPER SETTINGS: All jumpers have been factory set for most applications, as shown in

Figure 3, on page 10. Some applications require setting of the jumpers in order to set the

drive for a specific application. Jumper J2 must be set to match the horsepower of the

motor being used. Refer to Table 4, on page 5 and Section 6, on pages 19 - 21.

2.7 60 Hz and 50 Hz MOTOR OPERATION: The drive is factory set for 60 Hz motor operation

(Jumper J5 set to the “60Hz” position). See Section 6.4, on page 20.

2.8 PILOT LIGHT: After applying power to the drive and setting the On/Off AC Line Switch to

the “ON” position, the panel mounted Pilot Light will illuminate.

2.9 DIAGNOSTIC LEDs: After applying power to the drive and setting the On/Off AC Line

Switch to the “ON” position.

2.10 TRIMPOT SETTINGS: All trimpots have been factory set for most applications, as shown

in

Figure 3, on page 13. Some applications require adjustment of the trimpots in order to

setup the drive for a specific requirement. See Section 7, on page 21.

FIGURE 2 – COVER LAYOUT

■ Front Cover Screws

■ Main Speed

Potentiometer

■ On/Off AC Line

Switch

■ Pilot light

■ Provision for

Optional

Forward-Stop-

Reverse

Switch

■ Hole Plug

Page 13

13

FIGURE 3 – DRIVE LAYOUT

Page 14

14

FIGURE 4 – MECHANICAL SPECIFICATIONS (INCHES/MM)

Side View is shown dimensioned

with the cover installed.

Recommended tightening torque for the

two (2) front cover screws are, 5 inch lbs (6 kg-cm).

Back View is shown dimensioned

without the cover installed.

"Knockouts" for Standard

3

4

inch Fittings.

109

4.30

126

4.95

7.6

0.30

5.08

0.2

0.39

9.91

4X Ø

4X Ø

27.9

1.10

5.10

130

7.00

178

9.0

0.35

3.20

81.3

Feed-Through Bushing

1.75

44.5

0.95

130

5.10

24.1

59.7

2.35

1.45

36.8

25.4

1.00

4.15

105

0.95

24.1

1.10

27.9

Note: All Dimensions are measured in "Inches & mm".

Page 15

15

3 MOUNTING INSTRUCTIONS

The drive is designed with a NEMA-1 / IP-40 enclosure for indoor use. It is recommended that

the drive be mounted vertically on a flat surface with adequate ventilation. Leave enough room

below the drive to allow for AC line, motor connections, and any other wiring that is required.

Care should be taken to avoid extreme hazardous locations where physical damage can occur.

When mounting the drive in an enclosure, the enclosure should be large enough to allow for

proper heat dissipation so that the ambient temperature does not exceed 45°C (113 °F) at full

rating. A mounting template is included to facilitate mounting of the drive. See Figure 4, on page

14.

The drive is designed with a removable cover. To open the cover, the two front cover screws

must be removed. After mounting and connections, install and tighten the two front cover

screws to 5 lbs-in (6 kg-cm). Do not overtighten.

4 ELECTRICAL CONNECTIONS

See Table 9, on page 14 for terminal block wire and tightening torque specifications.

WARNING! READ ALL SAFETY WARNINGS, ON PAGE 8, BEFORE USING THE

DRIVE. DISCONNECT MAIN POWER BEFORE MAKING CONNECTIONS TO THE DRIVE.

TO AVOID ELECTRIC SHOCK, BE SURE TO PROPERLY GROUND THE DRIVE.

Application Note: To insure proper operation, position and separate the AC line and motor

connections, signal connections, signal following circuitry, or start/stop contacts. Also, do not

combine (or in close proximity) motor wires from multiple drives in the same conduit. Use

shielded cables on all signal wiring over 12" (30 cm). The shield should be earth grounded on

the drive side only. Connect the drive in accordance with the National Electrical Code

requirements and other local codes that may apply.

Be sure to properly fuse each AC line conductor that is not at ground potential. Do not fuse

neutral or grounded conductors. A separate AC line switch or contactor must be connected as

a disconnect, so that each ungrounded conductor is opened. For fuse or circuit breaker rating,

see Table 7, on page 6. Also see Section 4.1.

TABLE 9 - TERMINAL BLOCK WIRE AND TIGHTENING TORQUE SPECIFICATIONS

Maximum Wire Size

(Copper)

Insulation (75°C)

Recommended

Tightening Torque

Terminal Block Description

AWG mm

2

lb-in kg-cm

TB1

AC Line Input and Motor

Wiring

12 3.3 7 8

TB2

Run/Fault Relay Output

Contacts

16 1.3 3.5 3

4.1 AC LINE INPUT CONNECTION: Connect the single-phase AC line input to Terminal Block

TB1 (Terminals “L1”, “L2”). See Figure 5, on page 16.

Page 16

16

FIGURE 6 - RUN/FAULT RELAY OUTPUT

CONNECTIONS

Relay Common

Normally Closed

Normally Open

TB2

Recommended Tightening Torque

lb-in (3.5), kg-cm (3)

FIGURE 5 – AC LINE INPUT, MOTOR

AND CONNECTIONS

*For 115 VAC line, install jumper J1 (supplied).

Recommended Tightening Torque

lb-in (7), kg-cm (8)

The rated AC line voltage of the drive must

match the actual AC line input voltage

setting of Jumper J1. The drive is factory

set for 208/230 Volt AC line input (Jumper

J1 not installed). For 115 Volt AC line input,

install Jumper J1 (supplied). See Section

6.1, on page 17.

CAUTION

! GFCI Operation: Do Not

connect this drive to an AC power

source controlled by a Ground-Fault

Circuit-Interrupter.

4.1.1 AC Line Fusing: The drive does not

contain line fuses. Most electrical

codes require that each ungrounded

conductor contain circuit protection.

Do not fuse neutral or ground

connections. It is recommended to

install a fuse (Littelfuse 326, Buss ABC, or equivalent) or a circuit breaker in series

with each ungrounded conductor. Connect the drive in accordance with the National

Electrical Code requirements and other local codes that may apply to the application.

Do not fuse motor leads. For the recommended fuse size, see Table 7, on page 6.

4.2 GROUND CONNECTION: Connect the ground (earth) wires from the AC line and motor to

Terminal Block TB1 (Terminal “GND”). See Figure 5.

4.3 MOTOR CONNECTION: Connect the motor to Terminal Block TB1 Terminals "U", "V", and

“W". See Figure 6. Motor cable length should not exceed 100 ft (30 m) – special reactors

may be required – consult our Sales Department. Be sure Jumper J2 is set to the

corresponding motor horsepower rating, as described in Section 7.2, on page 22.

Note: If the motor rotates in the incorrect direction, it will be necessary to disconnect the AC

line and change the position of the jumper on CON2 from “F” to “R” or reverse any

two motor leads.

4.4 RUN/FAULT RELAY CONNECTION:

The Run/Fault Relay Output Contacts

are located at TB2 and can be used to

turn on or off equipment or to signal a

warning if a fault has occurred or the

drive is put into the Stop Mode*. See

Figure 6. The Run/Fault Relay Contact

status for various drive operating

conditions is shown in Table 10. Also

see Section 6.5, on page 19.

Relay Contacts Ratings: 1 Amp at 30

Volts DC, 0.5 Amps at 125 Volts AC,

and 0.25 Amps at 250 Volts AC.

*In order for the Run/Fault Relay to give “Stop Mode” indication, the optional Forwa rd-StopReverse Switch (Catalog No.ID5FRS-2) must be installed.

Page 17

17

TABLE 10 - DRIVE OPERATING CONDITION AND RUN/FAULT RELAY CONTACT STATUS

Run Relay Operation

(J5 Installed in “RUN” Position)

(Factory Setting)

Fault Relay Operation

(J5 Installed in “FLT”

Position)

Drive

Operating

Condition

Description

Normally Open

Contact

Normally Closed

Contact

Normally

Open Contact

Normally

Closed

Contact

Power Off

Main Power

Disconnected

Open Closed Open Closed

Run Mode1

Normal Drive

Operation

Closed Open Closed Open

Stop Mode2

Selected by

Operator

Open Closed Closed Open

Fault3 Drive Tripped Open Closed Open Closed

Notes: 1. Run Mode is selected with the optional Forward-Stop-Reverse Switch or with the

j

umper installed in CON2 (jumper installed in the “F-S” position for forward direction (factory

setting) or jumper installed in the “R-S” position for reverse direction). 2. Stop Mode is selected

using the optional Forward-Stop-Reverse Switch.3. I

2

t, Short Circuit, Undervoltage, Overvoltage.

5 IMPORTANT APPLICATION INFORMATION

WARNING! Do not use this drive in an explosion-proof application.

5.1 MOTOR WITH EXTERNAL FAN COOLING: Most totally enclosed fan-cooled (TEFC) and

open ventilated 3-phase AC induction motors will overheat if used beyond a limited speed

range at full torque. Therefore, it is necessary to reduce motor load as speed is decreased.

CAUTION!

1. Some motors have low speed characteristics, which cause overheating and

winding failure under light load or no load conditions. If the motor is operated in this

manner for an extended period of time, it is recommended that the unloaded motor

current be checked from 2 - 15 hz (60 - 450 rpm) to ensure motor current does not exceed

the nameplate rating. Do not use motor if the motor current exceeds the nameplate rating.

2. It Is Recommended that the Drive be used with Inverter Duty or TENV Motors.

Note: Some fan-cooled motors can be used over a wider speed range. Consult your Baldor

District Office for details.

Inverter duty and most totally enclosed non-ventilated (TENV) motors can provide full rated

torque over an extended speed range without overheating. See Figure 7 on page 18.

Page 18

18

FIGURE 7 – MAXIMUM ALLOWED MOTOR TORQUE

VS.

SPEED

MOTOR SPEED (%)

INVERTER DUTY

AND TENV MOTORS

0 10 20 30 40 50 60 70 80 90 100

MAXIMUM

ALLOWED

MOTOR

TORQUE %

100

80

60

40

20

0

FAN COOLED TEFC AND

OPEN VENTILATED MOTORS

FIGURE 8 - OPEN VENTILATED MOTOR

WITH EXTERNAL FAN COOLING

If external fan cooling is

provided, open ventilated

motors can also achieve an

extended speed range at full

rated torque. A box fan or

blower with a minimum of 100

CFM per HP is recommended.

Mount the fan or blower so the

motor is surrounded by the

airflow. See Figure 8.

5.2 ELECTRONIC MOTOR

OVERLOAD PROTECTION:

The drive contains Modified I

2

t

Overload Protection.* Part of

this function consists of a

Current Limit (CL) circuit, which limits the drive current to a factory preset level of 160% of

the rated drive current. The CL Trimpot is used to recalibrate the drive current from 60%

thru 200%. The Power Start™ circuit provides an overshoot function that allows most

motors to develop more than 200% of starting torque.

Standard I

2

t is undesirable because it causes nuisance tripping. It allows a very high

motor current to develop and will turn the drive off after a short period of time. The RMS

Current Limit Circuit avoids this nuisance tripping while providing maximum motor

protection.

If the motor is overloaded to 120% of full load (75% of the CL setting), the I

2

t Timer starts.

If the motor continues to be overloaded at the 120% level, the timer will shut down the

drive after 30 minutes. If the motor is overloaded to 160% of full load, the drive will trip in

6 seconds. See Section 7.6, on page 23.

*UL approved as an overload protector for motors.

Page 19

19

FIGURE 10 - MOTOR

HORSEPOWER SELECTION

6 SETTING SELECTABLE JUMPERS

WARNING! ELECTRICAL SHOCK CAN CAUSE SERIOUS OR FATAL

INJURY. BE SURE THAT ALL POWER IS DISCONNECTED FROM DRIVE BEFORE THE

COVER IS OPENED. OPENING OF THE COVER IS REQUIRED TO MAKE

INSTALLATION CONNECTIONS. ELECTRICAL SHOCK CAN CAUSE SERIOUS OR

FATAL INJURY IF THE COVER IS REMOVED AND POWER IS STILL APPLIED.

The drive has customer selectable jumpers which must be set before the drive can be used.

For an overview, see Table 4, on page 5. For location of jumpers, see Figure 3, on page 12.

6.1 AC LINE INPUT VOLTAGE (J1): The drive is factory set for 208/230 Volt AC line input

(Jumper J1 not installed). For 115 Volt AC line input, install Jumper J1. See Figure 9.

FIGURE 9 – AC LINE INPUT VOLTAGE SELECTION¹

208/230 Volt AC Line Input

(J1 not Installed (Factory Setting)) 115 Volt AC Line Input (J1 Installed)

2

115VAC

J1

A B

J1-A

J

1

-

B

115VAC

J1-A

A B

J

1

-

B

J1

Notes: 1. The drive is factory set for 208/230 Volt AC line input (Jumper J1 not installed). For

115 Volt AC line input, install Jumper J1 (supplied). 2. Jumper J1 is supplied in the hardware

bag.

6.2 MOTOR HORSEPOWER (J2): Set Jumper J2 to

the corresponding position for the motor being

used. See Figure 10.

6.3 AUTOMATIC OR MANUAL START AND

RESET SELECTION (J3): See Figure 11, on

page 20.

WARNING! AUTOMATIC START

AND RESET: JUMPER J3 IS FACTORY SET TO THE “AUTO” POSITION TO

AUTOMATICALLY START THE DRIVE WHEN THE POWER IS APPLIED AND THE

ON/OFF AC LINE SWITCH IS SET TO THE “ON” POSITION.

WARNING! THE DRIVE WILL AUTOMATICALLY RESTART AFTER FAULT

HAS CLEARED. IF AN I

2

T OR SHORT CIRCUIT FAULT OCCURS, THE DRIVE MUST

BE RESTARTED BY SETTING THE ON/OFF AC LINE SWITCH TO THE “OFF”

POSITION FOR A MINIMUM OF 5 SECONDS.

Page 20

20

6.3.1 Manual Start and Reset*: In Manual Start Mode, the drive must be manually

restarted, after a fault has cleared, using the optional Forward-Stop-Reverse Switch.

If a Short Circuit or I

2

t Fault occurs, the drive can be restarted by setting either the

On/Off AC Line Switch to the “OFF” position for a minimum of 5 seconds or setting

the Forward-Stop-Reverse Switch to the “STOP” position.

*Note: The optional Forward-Stop-Reverse Switch must be installed in order to use

the drive for Manual Start operation.

FIGURE 11 - AUTOMATIC OR MANUAL START AND RESET SELECTION

Automatic Start and Reset

(Factory Setting)

(J3 Installed in “AUTO” Position)

Manual Start and Reset

(J3 Installed in “MAN” Position)

6.4 60 Hz OR 50 Hz MOTOR OPERATION AND DRIVE OUTPUT FREQUENCY (J4 AND

J5): Both jumpers must be set for the appropriate motor nameplate frequency rating.

6.4.1 Setting the Drive for 60 Hz or 50 Hz Motor Operation: The drive is factory set to

operate 60 Hz motors. Jumper J5 is factory set to the “60Hz” position. For 50 Hz

motors, set Jumper J5 to the “50Hz” position, and be sure Jumper J4 is set to the

“1X” position. See Figure 12.

FIGURE 12 - 60 HZ OR 50 HZ MOTOR SELECTION

60 Hz Motor Operation

(Factory Setting)

(J4 Installed in “1X” Position)

(J5 Installed in “60Hz” Position)

50 Hz Motor Operation

(J4 Installed in “1X” Position)

(J5 Installed in “50Hz” Position)

6.4.2 Setting the Drive for

Two Times the Rated

Motor RPM: The drive

can also be used to

operate the motor up to

two times the rated

RPM. However,

constant horsepower will

result when operating

the drive in the “2X”

mode above the motor

rated frequency. See

Figure 13.

FIGURE 13 – AVAILABLE

TORQUE vs OUTPUT FREQUENCY

% TORQUE

0

50

150

0 2

100 / 12050 / 60

OUTPUT FREQUENCY (HZ)

CONSTANT

HORSEPOWER

Page 21

21

FIGURE 16 - MINIMUM SPEED

TRIMPOT RANGE

(Shown Factory Set to 0%

For 120 Hz output with 60 Hz motor, set Jumper J4 to the “2X” position and

be sure Jumper J5 is set to the “60Hz” position. For 100 Hz output with 50

Hz motor, set Jumper J4 to the “2X” position and set Jumper J5 to the “50Hz”

position. See Figure 14.

FIGURE 14 – 120 Hz AND 100 Hz DRIVE OUTPUT FREQUENCY SELECTION

120 Hz Output with 60 Hz Motor

(J4 Installed in “2X” Position)

(J5 Installed in “60Hz” Position)

100 Hz Output with 50 Hz Motor

(J4 Installed in “2X” Position)

(J5 Installed in “50Hz” Position)

6.5 RUN/FAULT OUTPUT RELAY OPERATION (J6): Jumper J6 is factory set to the “RUN”

position for “Run” operation of the Run/Fault Relay. For “Fault” operation of the Run/Fault

Relay, set Jumper J6 to the “FLT” position. See Figure 15.

FIGURE 15 - “RUN” OR “FAULT” OUTPUT RELAY OPERATION SELECTION

“Run” Output Relay Operation

(Factory Setting)

(J6 Installed in “RUN” Position)

“Fault” Output Relay Operation

(J6 Installed in “FLT” Position)

7 TRIMPOT ADJUSTMENTS

The drive contains trimpots that are factory set for most applications. See Figure 3, on page

12, for the location of the trimpots and their approximate factory calibrated positions. Some

applications may require readjustment of the trimpots in order to set the drive for a specific

requirement. The trimpots may be readjusted as described.

WARNING! IF POSSIBLE, DO NOT ADJUST TRIMPOTS WITH THE MAIN

POWER APPLIED. IF ADJUSTMENTS ARE MADE WITH THE MAIN POWER APPLIED, AN

INSULATED ADJUSTMENT TOOL MUST BE USED AND SAFETY GLASSES MUST BE

WORN. HIGH VOLTAGE EXISTS IN THIS DRIVE. FIRE AND/OR ELECTROCUTION CAN

RESULT IF CAUTION IS NOT EXERCISED. “ALL” SAFETY WARNINGS ON, PAGE 8,

MUST BE READ AND UNDERSTOOD BEFORE

PROCEEDING.

7.1 MINIMUM SPEED (MIN): Sets the minimum

speed of the motor. The MIN Trimpot is factory

set to 0% of frequency setting. For a higher

minimum speed, setting, rotate the MIN Trimpot

clockwise. See Figure 16.

Page 22

22

FIGURE 18 - ACCELERATION

TRIMPOT RANGE

(Shown Factory Set to 1.5 Seconds)

FIGURE 19 - DECELERATION

TRIMPOT RANGE

(Shown Factory Set to 1.5 Seconds)

FIGURE 20 - SLIP

COMPENSATION TRIMPOT

RANGE

(Shown Factory Set to 1.5 Volts/Hz)

FIGURE 17 - MAXIMUM SPEED

TRIMPOT RANGE

(Shown Factory Set to 100% of

Frequency Setting)

7.2 MAXIMUM SPEED (MAX): Sets the maximum

speed of the motor. The MAX Trimpot is factory

set for 100% of frequency setting. For a lower

maximum speed setting, rotate the MAX Trimpot,

counterclockwise. For a higher maximum speed

setting, rotate the MAX Trimpot clockwise. See

Figure 17.

7.3 ACCELERATION (ACCEL): Sets the amount of

time for the motor to accelerate from zero speed

to full speed. The ACCEL Trimpot is factory set to

1.5 seconds. For a longer acceleration time, rotate

the ACCEL Trimpot clockwise. For more rapid

acceleration, rotate the ACCEL Trimpot

counterclockwise. See Figure 18.

Note: Rapid acceleration settings may cause the

current limit circuit to activate, which will extend

the acceleration time.

7.4 DECELERATION (DECEL): Sets the amount of

time for the motor to decelerate from full speed to

zero speed. The DECEL Trimpot is factory set to

1.5 seconds. For longer deceleration time, rotate

the DECEL Trimpot clockwise. For more rapid

deceleration, rotate the DECEL Trimpot

counterclockwise. See Figure 19.

Application Note: On applications with high

inertial loads, the deceleration may automatically

increase in time. This will slow down the rate of

speed of decrease to prevent the bus voltage from

rising to the Overvoltage Trip point. This function

is called Regeneration Protection. It is

recommended that for very high inertial loads that

both the ACCEL and DECEL Trimpots be set to

greater than 10 seconds.

7.5 SLIP COMPENSATION (COMP): Sets the amount

of Volts/Hz to maintain set motor speed under

varying loads. The COMP Trimpot is factory set to

1.5 Volts/Hz, which provides excellent speed

regulation for most motors. To increase the slip

compensation, rotate the COMP Trimpot clockwise.

To decrease the slip compensation, rotate the

COMP Trimpot counterclockwise. See Figure 20.

Page 23

23

FIGURE 21 – CURRENT

LIMIT TRIMPOT RANGE

FIGURE 22 – I

2

T TRIP TIME vs.

MOTOR CURRENT

The slip compensation may be adjusted as follows:

A. Connect an AC RMS ammeter in series with one motor phase.

B. Run the motor and set the unloaded speed to

approximately 50% (900 RPM on 4-pole 1500/1725 RPM motors).

C. Using a tachometer, record the unloaded speed.

D. Increase motor loading until motor current is equal to the nameplate rated current

(AC Amps).

E. Adjust the COMP Trimpot until the loaded RPM is equal to the unloaded RPM.

The motor is now compensated to provide constant speed under varying loads.

7.6 MOTOR OVERLOAD (I

2

t) WITH RMS

CURRENT LIMIT (CL)*: Sets the current limit

(overload), which limits the maximum current to

the motor, preventing motor burnout and

eliminating nuisance trips. The CL Trimpot is

factory set to 160% of the drive rated current. To

increase the current limit, rotate the CL Trimpot

clockwise. To decrease the current limit, rotate

the CL Trimpot counterclockwise. See Figure

21.

Figure 22, shows the I

2

t Trip Time vs. Motor Current. Also see Section 5.2, on page 17.

*UL approved as an electronic overload protector for motors.

CAUTION!

If the current limit is adjusted above 160% of the motor nameplate rating,

this can cause overheating of the motor.

CAUTION!

Do not leave

the motor in a locked

rotor condition for more

than a few seconds since

damage may occur.

Notes: 1. In order to

ensure that the motor is

properly protected with

the I

2

t feature, it is

required that the CL

Trimpot be set for 160%

of the motor nameplate

rated current, as

described above. 2. This

adjustment must be

made within 6 seconds

or the I

2

t Trip will occur.

Page 24

24

The current limit may be adjusted as follows:

A. Connect an AC RMS ammeter in series with one motor phase.

B. Set the CL Trimpot fully counterclockwise.

C. Adjust the speed setting to 30%.

D. Lock the motor shaft and adjust the CL Trimpot to 160% of the motor nameplate

rated current.

8 DRIVE OPERATION

8.1 START-UP PROCEDURE: After the drive has been properly setup (jumpers and

trimpots set to the desired positions) and wiring completed, the start-up procedure can

begin.

WARNING! MAKE SURE THAT THE POTENTIOMETER IS SET FULLY

COUNTERCLOCKWISE PRIOR TO APPLYING POWER. IF THIS IS NOT DONE, THE

MOTOR WILL RUN AT THE SPEED SETTING AT POWER UP. THIS MAY CAUSE BODILY

INJURY IF ONE IS IN CLOSE PROXIMITY OF MOVING PARTS.

To start the drive, set the On/Off AC Line Switch to the “ON” position. If the AC power

has been properly brought to the drive, the Pilot Light will illuminate. If the optional

Forward-Stop-Reverse Switch has been installed, set it to the “FWD” or “REV” position.

The motor will begin to accelerate to the set speed. The PC board mounted “ST” and

“OL” LED’s will indicate the drive status, as described in Section 9.3 and 9.4 on page 25.

8.2 RESTARTING THE DRIVE AFTER A FAULT HAS BEEN CLEARED: The drive

monitors four faults (Undervoltage, Overvoltage, Short Circuit (at the motor (phase-tophase)), and Overload). The PC board mounted “ST” and “OL” LED’s will indicate the

drive status, as described in Section 9.3 and Section 9.4, on page 25. Also see Section

6.3, on page 19, for Automatic or Manual Start and Reset selection with Jumper J3. In

addition, Section 10.2 on page 26.

WARNING! THE DRIVE WILL AUTOMATICALLY RESTART AFTER FAULT

HAS CLEARED. IF AN I

2

T OR SHORT CIRCUIT FAULT OCCURS, THE DRIVE MUST BE

RESTARTED BY SETTING THE ON/OFF AC LINE SWITCH TO THE “OFF” POSITION

FOR A MINIMUM OF 5 SECONDS.

8.2.1 Drive Set for Automatic Start and Reset (Factory Setting): The drive will

automatically restart after an Undervoltage or Overvoltage Fault has cleared. For

an I

2

t Fault, be sure the fault has been cleared before restarting the drive. Check

the motor current with an AC RMS responding ammeter. Also, the CL setting

may be set too low. See Section 7.6, on page 23. For an I

2

t or Short Circuit

Fault, the drive must be restarted by setting the On/Off AC Line Switch to the

“OFF” position for a minimum of 5 seconds.

Page 25

25

8.2.2 Drive Set for Manual Start and Reset *:. In Manual Start Mode, the drive must

be manually restarted after a fault has cleared, using the optional Forward-StopReverse Switch. If a Short Circuit or I

2

t Fault occurs, the drive must be restarted

by setting either the On/Off AC Line Switch to the “OFF” position for a minimum of

5 seconds or setting the Forward-Stop-Reverse Switch to the “STOP” position.

* Note: The optional Forward-Stop-Reverse Switch must be installed in order to

use the drive for Manual Start operation.

9 PILOT LIGHT AND DIAGNOSTIC LED’s

WARNING! DO NOT DEPEND ON THE PILOT LIGHT OR THE PC BOARD

MOUNTED LED’s FOR A GUARANTEED POWER OFF INDICATION. BE SURE ALL AC

POWER IS "OFF" BEFORE SERVICING THE DRIVE TO AVOID ELECTRICAL SHOCK

HAZARD.

9.1 PILOT LIGHT: The Pilot Light will illuminate orange when the AC line is applied to the

drive and the On/Off AC Line Switch is set to the “ON” position.

9.2 POWER ON LED (ON): Located on the PC board, the “ON” LED will illuminate green

when the AC line is applied to the drive and the On/Off AC Line Switch is set to the “ON”

position.

9.3 STATUS LED (ST): Located on the PC board, the “ST” LED is a green LED, which

provides indication of a fault or abnormal condition. The information provided can be

used to diagnose an installation problem such as incorrect input voltage and drive output

miswiring. It also provides a signal, which informs the user that all drive and

microcontroller operating parameters are normal. Table 11, summarizes the “ST” LED

functions.

9.4 OVERLOAD LED (OL): The “OL” LED is a red LED, which provides indication of an

overload condition. Table 11, summarizes the “OL” LED functions.

TABLE 11 - DRIVE OPERATING CONDITIONS AND LED INDICATIONS

LED and Flash Rate

1

Information

Drive Operating Condition

ST (Green) OL (Red)

Normal operation Slow Flash Off

Overload

(

120% - 160% Full Load)

Off On

2

I2t (Drive Timed Out) Off Quick Flash

Short Circuit Off Slow Flash

Undervoltage Quick Flash3 On

Overvoltage Slow Flash3 On

Stop On On

Notes: 1. Slow Flash = 1 second on and 1 second off. Quick Flash = 0.25 second on and 0.25

second off. 2. When the Overload is removed, before the I2t times out and trips the drive, the “ST”

LED will flash green and the “OL” LED will turn off. 3. In Manual Restart Mode, when the

Undervoltage or Overvoltage condition is cleared, the “ST” and “OL” LED’s will flash red / (red and

green) / green.

Page 26

26

10 TROUBLESHOOTING

WARNING! HIGH VOLTAGE IS PRESENT IN THIS DRIVE. DISCONNECT MAIN

POWER BEFORE MAKING CONNECTIONS TO THE DRIVE. THE COVER MUST BE

PROPERLY INSTALLED AFTER ALL SETUP, CONNECTIONS, AND ADJUSTMENTS ARE

COMPLETE. IT REDUCES ELECTRICAL SHOCK HAZARD. FAILURE TO OBSERVE

THIS WARNING COULD RESULT IN ELECTRICAL SHOCK OR ELECTROCUTION.

WARNING! HIGH VOLTAGE IS PRESENT IN THE DRIVE. DISCONNECT MAIN

POWER BEFORE MAKING CONNECTIONS TO THE DRIVE. DO NOT ADJUST TRIMPOTS

WITH THE MAIN POWER APPLIED. IF ADJUSTMENTS ARE MADE WITH THE MAIN

POWER APPLIED, AN INSULATED ADJUSTMENT TOOL (PROVIDED) MUST BE USED

AND SAFETY GLASSES MUST BE WORN. FIRE AND/OR ELECTROCUTION CAN

RESULT IF CAUTION IS NOT EXERCISED.

10.1 TROUBLESHOOTING GUIDE: Table 12, on page 25 provides information on

symptoms, possible causes, and the suggested troubleshooting solutions for the drive.

See Section 9, on page 24, for detailed information on LED status indicators.

10.2 FAULT RECOVERY: The drive monitors four faults (Undervoltage, Overvoltage, Short

Circuit at the motor (phase-to-phase), and Overload). Section 8, on page 24, describes

how the drive will automatically start (factory setting) after the fault has cleared.

Application Note: In Manual Start Mode, the drive must be manually reset for any fault.

Use the Forward-Stop-Reverse Switch, as described in Section 8.2.2, on page 24. Also

see Section 6.3, on page 19.

Page 27

27

TABLE 12 - TROUBLESHOOTING GUIDE

Symptom Possible Cause Suggested Solution

The line fuse or circuit breaker

installed is the incorrect rating.

See Table 7, on page 6, for the

correct line fuse or circuit

breaker rating.

Line fuse blows or

circuit breaker trips.

Drive or Motor Failure.

Check and replace defective

part.

On/Off AC Line Switch is in the

OFF position.

Set the On/Off AC Line Switch

to the ON position.

The Main Speed Potentiometer

is set to zero speed.

Set the Main Speed

Potentiometer for the desired

speed.

The Main Speed Potentiometer,

signal input, or motor connection

are open.

Verify Main Speed

Potentiometer, signal input, or

motor connections.

Motor does not run.

The Forward-Stop-Reverse

Switch (when installed) is set to

the “STOP” position.

Set the Forward-Stop-Reverse

Switch to the “FORWARD” or

“REVERSE” position.

The motor may be overloaded.

Check the motor current with an

AC RMS responding ammeter.

Reduce load.

The CL setting may need to be

increased. See Section 7.6, on

page 23.

Verify Motor Horsepower

Jumper, J2 is set correctly. See

Section 6.2, on page 19.

The Drive Trips due to overload

(I

2

t Fault).

The drive must be manually

restarted by either of the

following methods: 1.

Disconnect and reconnect the

AC power (the "ST" LED must

change from quick flashing red

to flashing red/yellow). 2. Set

the Main Speed Potentiometer

to zero (fully counterclockwise).

3. Open and close the ForwardStop-Reverse Switch (or

contact) or Run Switch (or

contact). See Section 6.3, on

page 19. Reduce load.

The Acceleration setting may

be too fast.

Reduce the ACCEL Trimpot

setting, as described in Section

7.3, on page 22.

Overvoltage Fault

Rapid Deceleration change.

Verify drive setting. See Section

7.4, on page 22.

Motor runs then stops after

a short time.

Short circuit Fault. Verify motor condition.

Page 28

28

TABLE 13 - FAULT RECOVERY AND RESETTING THE DRIVE*

Fault Automatic Start Mode (Factory Setting)

Undervoltage

Drive will automatically start after the bus voltage returns

to the operational level or when the drive is first turned on

(power up).

Overvoltage

Drive will automatically start after the bus voltage returns

to the operational level.

Short Circuit

Drive will automatically start after the short circuit is

removed.

I

2

t Drive must be manually restarted.

*The fault must be cleared before the drive can be reset.

10.3 STARTING THE DRIVE AFTER AN I

2

t FAULT HAS BEEN CLEARED: The drive can

be restarted after an I

2

t Fault has cleared by any of the following methods.

Note: If an I

2

t Fault occurs, the motor may be overloaded. Check the motor current with

an AC RMS responding ammeter. Also, the CL setting may be set too low. See

Section 7.6, on page 23.

10.3.1 Disconnect the AC power. Wait 15 seconds. Reconnect the AC power. The

"ST" LED will change. Refer to Table 11, on page 25 for correct indication.

10.3.2 Set the Main Speed Potentiometer to zero (fully counterclockwise).

10.3.3 Open and close either the Forward-Stop-Reverse Switch (or contact) or Run

Switch (or contact). See Sections 6.3.1, on page 20.

Page 29

29

- Notes -

Page 30

30

- Notes -

Page 31

31

BALDOR DISTRICT OFFICES

UNITED STATES

ARIZONA

PHOENIX

4211 S 43RD PLACE

PHOENIX, AZ 85040

PHONE: 602-470-0407

FAX: 602-470-0464

ARKAN SAS

CLARKSVILLE

1001 COLLEGE AVE.

CLARKSVILLE, AR 72830

PHONE: 479-754-9108

FAX: 479-754-9205

CALIFORNIA

LOS ANGELES

6480 FLOTILLA

COMMERCE, CA 90040

PHONE: 323-724-6771

FAX: 323-721-5859

HAYWARD

21056 FORBES STREET

HAYWARD, CA 94545

PHONE: 510-785-9900

FAX: 510-785-9910

COLORADO

DENVER

2520 W BARBERRY PLACE

DENVER, CO 80204

PHONE: 303-623-0127

FAX: 303-595-3772

CONNECTICUT

WALLINGFORD

65 SOUTH TURNPIKE ROAD

WALLINGFORD, CT 06492

PHONE: 203-269-1354

FAX: 203-269-5485

FLORIDA

TAMPA/PUERTO RICO/VIRGIN ISLANDS

3906 EAST 11TH AVENUE

TAMPA, FL 33605

PHONE: 813-248-5078

FAX: 813-247-2984

GEORGIA

ATLANTA

62 TECHNOLOGY DR.

ALPHARETTA, GA 30005

PHONE: 770-772-7000

FAX: 770-772-7200

ILLINOIS

CHICAGO

1601 FRONTENAC ROAD

NAPERVILLE, IL 60563

PHONE: 630-848-5100

FAX: 630-848-5110

INDI ANA

INDIANAPOLIS

5525 W. MINNESOTA STREET

INDIANAPOLIS, IN 46241

PHONE: 317-246-5100

FAX: 317-246-5110

IOWA

DES MOINES

1800 DIXON STREET, SUITE C

DES MOINES, IA 50316

PHONE: 515-263-6929

FAX: 515-263-6515

MARYLAND

BALTIMORE

6660 SANTA BARBARA RD.

SUITE 22-24

ELKRIDGE, MD 21075

PHONE: 410-579-2135

FAX: 410-579-2677

MASSACHUSETTS

BOSTON

6 PULLMAN STREET

WORCESTER, MA 01606

PHONE: 508-854-0708

FAX: 508-854-0291

MICHIGAN

DETROIT

33782 STERLING PONDS BLVD.

STERLING HEIGHTS, MI 48312

PHONE: 586-978-9800

FAX: 586-978-9969

GRAND RAPIDS

668 3 MILE ROAD NW

GRAND RAPIDS, MI 49504

PHONE: 616-785-1784

FAX: 616-785-1788

MINNESOTA

MINNEAPOLIS

21080 134TH AVE. NORTH

ROGERS, MN 55374

PHONE: 763-428-3633

FAX: 763-428-4551

MISSOURI

ST LOUIS

422 INDUSTRIAL DRIVE

MARYLAND HEIGHTS, MO 63043

PHONE: 314-298-1800

FAX: 314-298-7660

KANSAS CITY

1501 BEDFORD AVENUE

NORTH KANSAS CITY, MO 64116

PHONE: 816-587-0272

FAX: 816-587-3735

NEW YORK

AUBURN

ONE ELLIS DRIVE

AUBURN, NY 13021

PHONE: 315-255-3403

FAX: 315-253-9923

NORTH CAROLINA

GREENSBORO

1220 ROTHERWOOD ROAD

GREENSBORO, NC 27406

P. O. BOX 16500

GREENSBORO, NC 27416

PHONE: 336-272-6104

FAX: 336-273-6628

OHIO

CINCINNATI

2929 CRESCENTVILLE ROAD

WEST CHESTER, OH 45069

PHONE: 513-771-2600

FAX: 513-772-2219

CLEVELAND

8929 FREEWAY DRIVE

MACEDONIA, OH 44056

PHONE: 330-468-4777

FAX: 330-468-4778

OKLAHOMA

TULSA

2 EAST DAWES

BIXBY, OK 74008

PHONE: 918-366-9320

FAX: 918-366-9338

OREGON

PORTLAND

20393 SW AVERY COURT

TUALATIN, OR 97062

PHONE: 503-691-9010

FAX: 503-691-9012

PENNSYLVANIA

PHILADELPHIA

1035 THOMAS BUSCH

MEMORIAL HIGHWAY

PENNSAUKEN, NJ 08110

PHONE: 856-661-1442

FAX: 856-663-6363

PITTSBURGH

616H BEATTY ROAD

MONROEVILLE, PA 15146

PHONE: 412-380-7244

FAX: 412-380-7250

TENNESSEE

MEMPHIS

4000 WINCHESTER ROAD

MEMPHIS, TN 38118

PHONE: 901-365-2020

-

-

TEXAS

HOUSTON

4647 PINE TIMBERS

SUITE # 135

HOUSTON, TX 77041

PHONE: 713-895-7062

FAX: 713-690-4540

DALLAS

3040 QUEBEC

DALLAS, TX 75247

PHONE: 214-634-7271

FAX: 214-634-8874

UTAH

SALT LAKE CITY

2230 SOUTH MAIN STREET

SALT LAKE CITY, UT 84115

PHONE: 801-832-0127

FAX: 801-832-8911

WISCONSIN

MILWAUKEE

2725 SOUTH 163RD STREET

NEW BERLIN, WI 53151

PHONE: 262-784-5940

FAX: 262-784-1215

INTERNATIONAL SALES

FORT SMITH, AR

P. O. BOX 2400

FORT SMITH, AR 72902

PHONE: 479-646-4711

FAX: 479-648-5895

CANADA

EDMONTON, ALBERTA

4053-92 STREET

EDMONTON, ALBERTA T6E 6R8

PHONE: 780-434-4900

FAX: 780-438-2600

OAKVILLE, ONTARIO

2750 COVENTRY ROAD

OAKVILLE, ONTARIO L6H 6R1

PHONE: 905-829-3301

FAX: 905-829-3302

MONTREAL, QUEBEC

1844 WILLIAM STREET

MONTREAL, QUEBEC H3J 1R5

PHONE: 514-933-2711

FAX: 514-933-8639

VANCOUVER, BRITISH COLUMBIA

1538 KEBET WAY

PORT COQUITLAM, BC V3C 5M5

PHONE 604-421-2822

FAX: 604-421-3113

WINNIPEG, MANITOBA

54 PRINCESS STREET

WINNIPEG, MANITOBA R3B 1K2

PHONE: 204-942-5205

FAX: 204-956-4251

AUSTRALIA

UNIT 3, 6 STANTON ROAD

SEVEN HILLS, NSW 2147,

AUSTRALIA

PHONE: (61) (2) 9674 5455

FAX: (61) (2) 9674 2495

UNIT 8, 5 KELLETTS ROAD

ROWVILLE, VICTORIA, 3178

AUSTRALIA

PHONE: (61) (3) 9753 4355

FAX: (61) (3) 9753 4366

AMÉRICA DEL S UR

APTDO. 9109 0818 ZONA 6

BETHANIA,

CIUDAD DE PANAMÁ, PANAMÁ

PHONE: +507 261-5347

FAX: +507 261-5355

CENTRO AMÉRICA Y CARIBE

RESIDENCIAL PINARES DE SUIZA

POL. 15 #44,

NVA. SAN SALVADOR, EL SALVADOR

PHONE: +503 2288-1519

FAX: +503 2288-1518

CHIN

A

SHANGHAI JIAHUA BUSINES S CENTER

ROOM NO. A-8421

808 HONG QIAO ROAD

SHANGHAI 200030

PHONE: 86-21-64473060

FAX: 86-21-64078620

GERMANY

DIESELSTRASSE 22

D-85551 KIRCHHEIM

MUNICH, GERMANY

PHONE: +49 89 90 5080

FAX: +49 89 90 8492

INDIA

14, COMMERCE AVENUE

MAHAGANESH COLONY

PAUD ROAD

PUNE - 411 038

MAHARASHTRA, INDIA

PHONE: 91 20 25 45 95 31

FAX: 91 20 25 45 95 30

ITALY

BALDOR ASR AG

SUCCURSALE DI MENDRISIO

VIA BORROMINI, 20A

CH-6850 MENDRISIO

SWITZERLAND

PHONE: 0041 91 640 99 50

FAX: 0041 91 630 26 23

JAPAN

DIA BLDG 802,

2-21-1 TSURUYA-CHO,

KANAGAWA-KU

YOKOHAMA, 221-0835, JAPAN

PHONE: 81-45-412-4506

FAX: 81-45-412-4507

KOREA

ROOM 208-37

INCHEON INDUSTRIAL GOODS

CIRCULATING CENTER

SONGHYEON 3-DONG, DONG-GU

INCHEON. KOREA, 401-705

PHONE: 82 32 588 3253

FAX: 82 32 588 3254

MÉXICO

KM. 2.0 BLVD. AL AEROPUERTO

LEÓN 37545, GUANAJUATO,

MÉXICO

PHONE: 52 477 761 2030

FAX: 52 477 761 2010

MIDDLE EAST & NORTH AFRICA

VSE INTERNATIONAL CORP.

3233 NORTH ARLINGTON HEIGHTS

SUITE 100W

ARLINGTON HEIGHTS, IL 60004

PHONE: 847-590-5547

SINGAPORE

51 KAKI BUKIT ROAD 2

KB WAREHOUSE COMPLEX

SINGAPORE 417863

PHONE: (65) 6 744 2572

FAX: (65) 6 747 1708

SWITZERLAND

POSTFACH 73

SCHUTZENSTRASSE 59

CH-8245 FEUERTHALEN

SWITZERLAND

PHONE: +41 52 647 4700

FAX: +41 52 659 2394

TAIWAN

4F, NO. 25, SEC. 1,

TUNHUA S ROAD,

TAIPEI 10557, TAIWAN, R.O.C.

PHONE: (886-2) 2577-4352

FAX: (886-2) 2577-4157

UNITED KINGDOM

6 BRISTOL DISTRIBUTION PARK

HAWKLEY DRIVE

BRISTOL BS32 0BF U.K.

PHONE: +44 1454 85 9000

FAX: +44 1454 85 9001

Page 32

32

LIMITED WARRANTY

For a period of 2 years from the date of original purchase, Baldor will repair or

replace without charge, controls which our examination proves to be defective in

material or workmanship. This warranty is valid if the unit has not been tampered

with by unauthorized persons, misused, abused, or improperly installed and has

been used in accordance with the instructions and/or ratings supplied. The

warranty is in lieu of any other warranty or guarantee, expressed or implied. Baldor

shall not be held responsible for any expense, including installation and removal,

inconvenience, or consequential damage, including injury to any person, caused

by items of our manufacture or sale. (Some states do not allow the exclusion or

limitation of incidental or consequential damages, so the above exclusion may not

apply.) In any event, Baldor’s total liability, under all circumstances, shall not

exceed the full purchase price of the control. Claims for purchase price refunds,

repairs, or replacements must be referred to Baldor with all pertinent data as to the

defect, the date purchased, the task performed by the control, and the problem

encountered. No liability is assumed for expendable items, such as fuses.

Goods may be returned only with written notification including a Baldor Return

Authorization Number and any return shipments must be prepaid.

Baldor Electric Company

P. O. Box 2400

Ft. Smith, AR 72902-2400

(479) 646-4711

Fax (479) 648-5792

(

A40158

)

–

Rev. A - 2/2008

Loading...

Loading...