Baldor 36M905X262G2 Product Information Sheet

Product Information Packet

36M905X262G2

7HP,1700RPM,1PH,60HZ,184T,3634LC,ODTF,F1

Copyright © All product information within this document is subject to ABB Motors and Mechanical Inc. copyright © protection, unless otherwise noted.

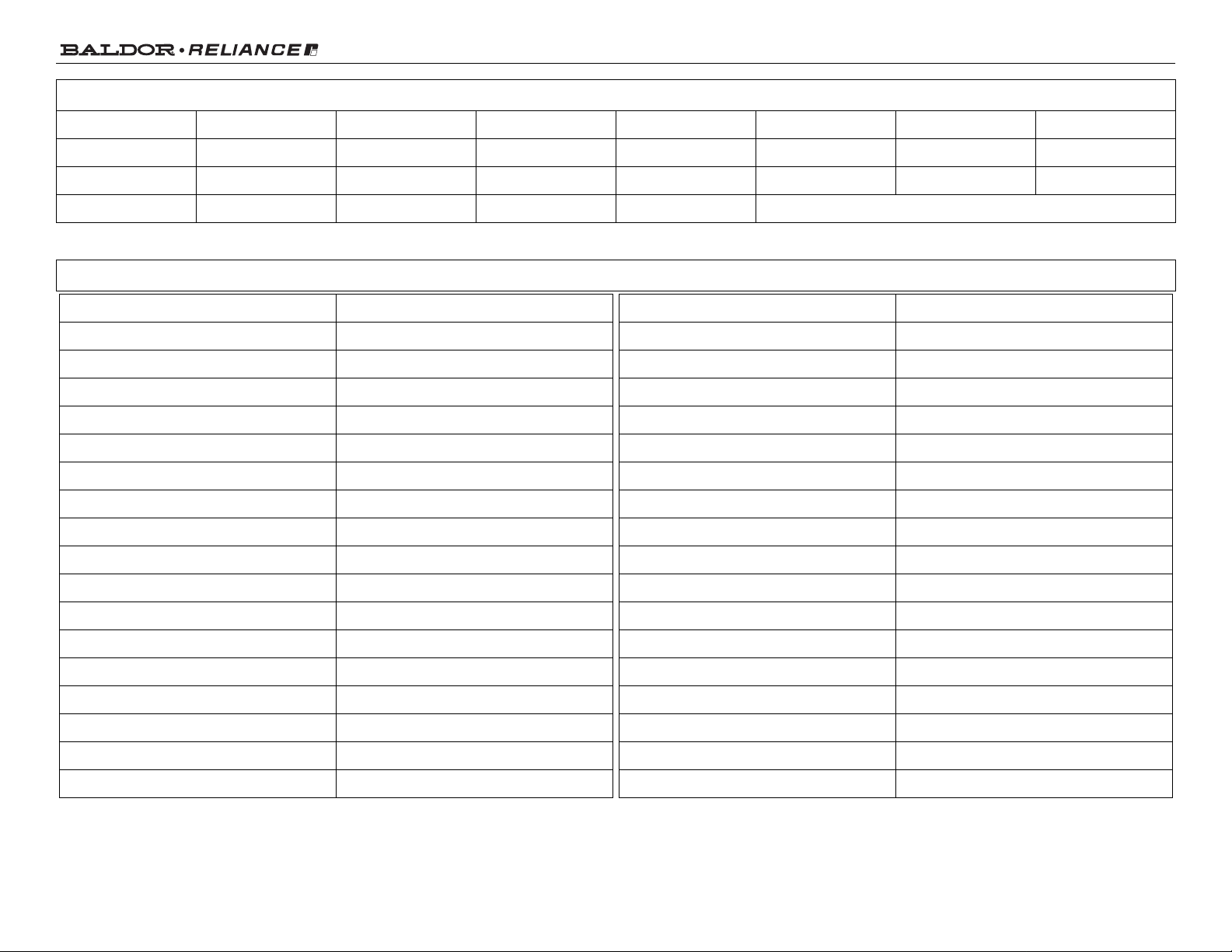

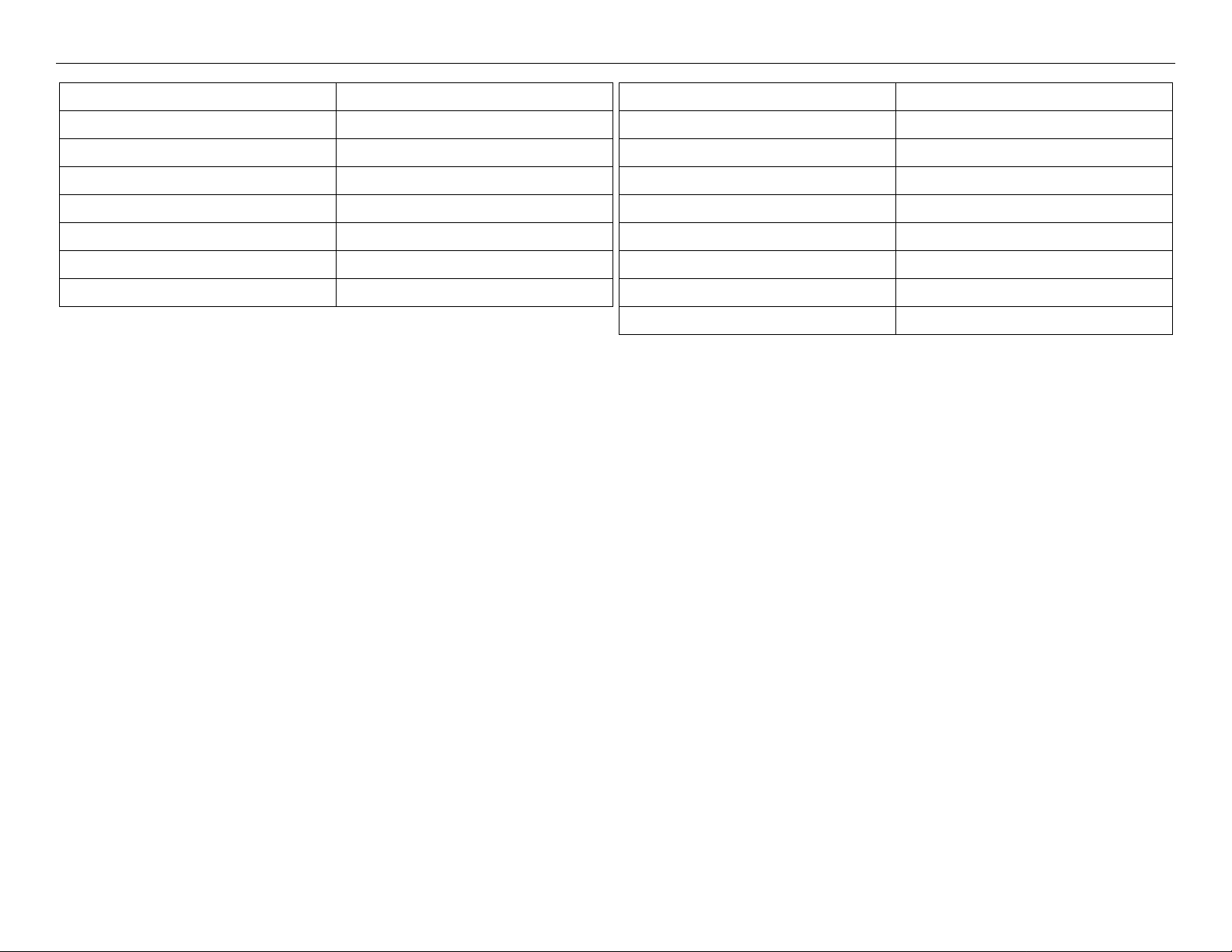

Product Information Packet: 36M905X262G2 - 7HP,1700RPM,1PH,60HZ,184T,3634LC,ODTF,F1

Part Detail

Revision: K Status: PRD/A Change #: Proprietary: No

Type: AC Elec. Spec: 36WGX262 CD Diagram: CD0059A02 Mfg Plant:

Mech. Spec: 36M905 Layout: 36LYM905 Poles: 04 Created Date: 11-16-2010

Base: RG Eff. Date: 04-08-2019 Leads: 2#10 A PH

Specs

Enclosure: ODTF

Frame: 184T

Frame Material: Steel

Output @ Frequency: 7.000 HP @ 60 HZ

Synchronous Speed @ Frequency: 1800 RPM @ 60 HZ

Voltage @ Frequency: 230.0 V @ 60 HZ

XP Class and Group: None

XP Division: Not Applicable

Agency Approvals: CSA

UR

Auxillary Box: No Auxillary Box

Auxillary Box Lead Termination: None

Base Indicator: Rigid

Bearing Grease Type: Polyrex EM (-20F +300F)

Blower: None

Current @ Voltage: 35.900 A @ 208.0 V

33.800 A @ 230.0 V

Inverter Code: Not Inverter

KVA Code: E

Lifting Lugs: No Lifting Lugs

Locked Bearing Indicator: No Locked Bearing

Motor Lead Quantity/Wire Size: 2 @ 10 AWG, A PH

Motor Lead Exit: Pipe Or Pipe Adaptor

Motor Lead Termination: Cord

Motor Type: 3634LC

Mounting Arrangement: F1

Product Family: General Purpose

Pulley End Bearing Type: Sealed Bearing

Pulley Face Code: Standard

Pulley Shaft Indicator: Standard

Rodent Screen: None

Shaft Extension Location: Pulley End

Shaft Ground Indicator: No Shaft Grounding

Shaft Rotation: Fixed Opposite Standard

Design Code: -

Shaft Slinger Indicator: No Slinger

Page 2 of 10

Product Information Packet: 36M905X262G2 - 7HP,1700RPM,1PH,60HZ,184T,3634LC,ODTF,F1

Drip Cover: Drip Cover

Duty Rating: S3 50%

Electrically Isolated Bearing: Not Electrically Isolated

Feedback Device: NO FEEDBACK

Front Face Code: Standard

Front Shaft Indicator: None

Heater Indicator: No Heater

Insulation Class: F

Speed Code: Single Speed

Motor Standards: NEMA

Starting Method: Direct on line

Thermal Device - Bearing: None

Thermal Device - Winding: Do Not Use

Vibration Sensor Indicator: No Vibration Sensor

Winding Thermal 1: Manual Thermal Overload

Winding Thermal 1 Location: KO

Winding Thermal 2: None

Page 3 of 10

Loading...

Loading...