Page 1

Installation Instructions

Micro Jet Replacement Nozzle

Tools required:

Medium sized flathead screwdriverUÊ

Medium sized needle nose pliersUÊ

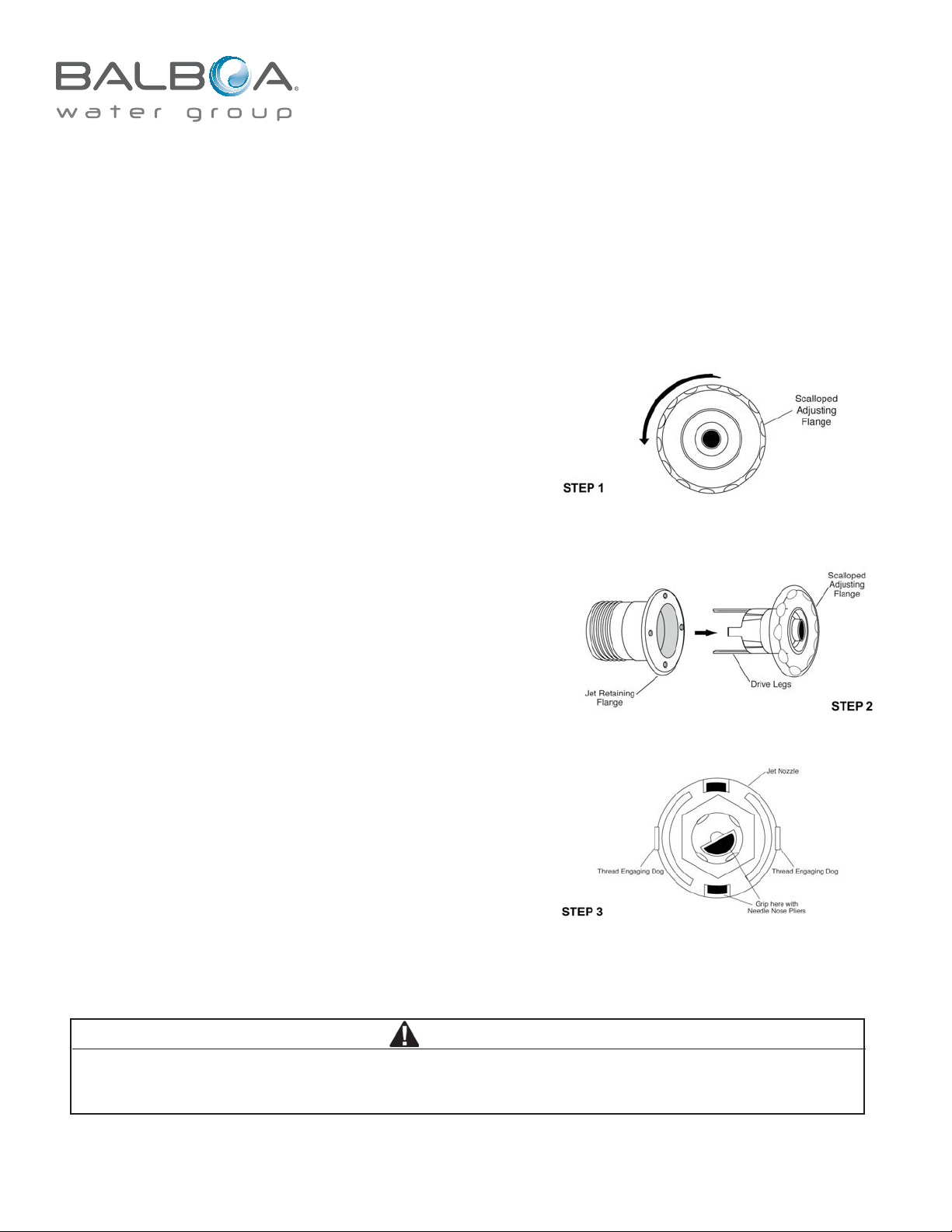

STEP 1 – Adjusting Scalloped Flange

Rotate scalloped adjusting flange counterclockwise (looking

into jet) until it stops.

IMPORTANT SAFETY INSTRUCTIONS

READ & FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

STEP 2 – Removing Scalloped Flange

Remove scalloped adjusting flange from jet retaining

flange by pulling straight out of jet. If it does not easily

release from its snapped-in position, place the flathead

of a screwdriver between the jet flange and the scalloped

adjusting flange and carefully pry it loose.

STEP 3 – Breaking and Removing Old Jet Nozzle

The old jet nozzle will be broken into pieces when

removing. To do this, grip old jet nozzle tightly with needle

nose pliers at points shown, and firmly pull nozzle toward

you. This nozzle will most likely come out in pieces so be

sure to remove all pieces from jet body. Also, be careful not

to damage threads of jet body.

CAUTION

Threads can be damaged when removing old nozzle. If threads are damaged you may not be able to install

the new nozzle and the entire jet may have to be replaced. To avoid this hazard, follow nozzle removal

instructions closely and be sure all broken nozzle pieces are removed from the jet.

99510500 B January 20, 2010Page 1 of 2

Page 2

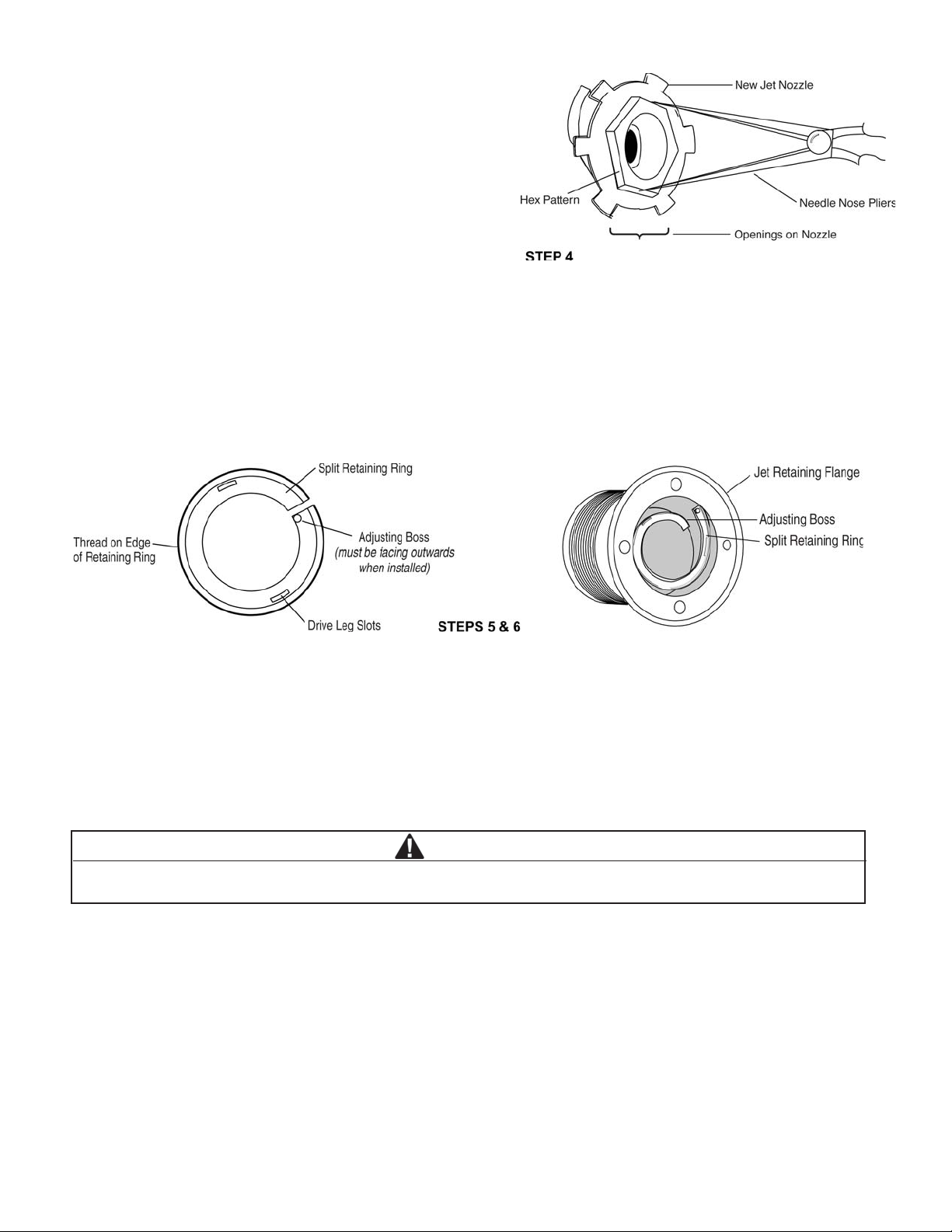

STEP 4 – Installing New Nozzle

Hold new nozzle with needle nose pliers by gripping

nozzle on hex pattern (not on orifice) and insert into jet

body. After nozzle is inserted, be sure nozzle is seated

properly and is rotated clockwise (looking into jet) until

it stops. You may need to push nozzle into final position

with your finger. This will help you to “feel” the seated

position of the nozzle.

STEP 5 – Installing Split Retaining Ring

Insert split retaining ring with adjusting boss facing outward by pushing first one end into jet body and then the

other. Be sure retaining ring has snapped into jet body behind jet retaining flange and is laying flat around hex of

nozzle. Thread on retaining ring must engage internal threads of jet body without crossthreading and turn freely.

STEP 6 – Adjusting the Split Retaining Ring

Rotate the split retaining ring in threads of jet body with tip of screwdriver until it touches the nozzle.

Additionally, turn the ring until drive leg slots in the ring expose the next set of openings on nozzle.

This is the proper adjustment for the retaining ring. Do not over tighten as this may cause damage to the jet or

cause the jet to not operate properly.

CAUTION

Do not over tighten split retaining ring. Over tightening the split retaining ring can cause damage to the jet, or cause

the jet to not operate properly. Tighten until alignment is reached and no further.

STEP 7 – Re-installing Scalloped Adjusting Flange

Re-install scalloped adjusting flange. Be sure that the retaining ring is adjusting as described in Step 6 so that

drive legs of adjusting flange will pass through slots in retaining ring.

SAVE THESE INSTRUCTIONS

Page 2 of 2

Loading...

Loading...