Balboa Water Group Aqua-Fan User Manual

Aqua-Fan

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

Introduction: As a result of years of research and fine engineering, BWG introduces the Aqua-Fan Jet, an exciting new

sensation, into the hydro massage market. The patented jet derives its unique hydrotherapeutic massaging

action through the use of an oscillating wedge which converts the incoming stream of air/water mixture

into soothing, wave-like, pressure pulsations.

Plumbing: Water Line: 1.0” Pipe Glueable PVC

Air Line: 1.0” Pipe Glueable PVC

The Aqua-Fan Jet is to be located horizontally or vertically 4-18 inches below the water level on a flat wall

10” x 3”. In relation to other standard jets, the Aqua-Fan Jet shall be installed in a dead head plumbing

system with optional grouped or separate air/water combination.

Pump Selection

and Sizing: For optimum jet performance, the system pump shall be selected as shown on Table 1.

No. of Aqua-Fans 3/4 HP 1.0 HP 1 1/2 HP 3/4 HP 1.0 HP 1 1/2 HP 2.0 HP 3.0 HP

One Aqua-Fan

Two Aqua-Fans

Three Aqua-Fans

How To Read Table:

Select pump to be used. 1.

Select number of Aqua-Fan Jets to be installed. 2.

Find number of standard jets to be installed at the intersection between the pump line (vertical) and the number of 3.

Aqua-Fan Jets line (horizontal).

Notes:

Operating data for optimum results are: 9.0 PSI at 22 GPM. 1.

The above combination is based upon BWG’s laboratory test results and computerized spa systems simulation. 2.

Table 1

Number of Standard Jets vs. Number of Aqua-Fan Jets

Number of Standard BWG Jets

Maxim Pumps Ultra-Flow Pumps

2 3 5 4 6 7 8 9

0 0 2 1 2 4 4 5

N/A N/A N/A N/A N/A 1 1 2

98704500 Rev. D October 15, 2009

Installation:

a. After locating a suitable flat area on the spa wall, use the provided template to drill 10 holes using a 1/4” size drill, then cut

a rectangular hole (6 1/2” x 1 7/8”).

b: Apply silicone to seal between the jet body (Item No .2) and the spa wall.

NOTE:

Silicone sealant may not be required if gasket (Item No.10) is used. Install gasket to seal between the jet body and the spa wall.

c. Insert the jet body through the rectangular cut, then secure in place by the 10 supplied nuts, using a 3/8” wrench. Torque nut

to 30 in. lb. maximum. Nuts shall be installed in the direction as shown on the exploded view.

CAUTION

Improperly secured lock nuts can result in leaks in the spa wall which could result in property damage.

Torque all lock nuts to the proper specifications called out in these instructions.

Do not substitute alternate lock nuts or mounting hardware.

d. Orient the tee (Item No.1) to the suitable plumbing direction, then attach to jet body using plastic pipe cement Weld-On

No. 793 (ABS to PVC) or equivalent.

CAUTION

This is an ABS to PVC connection. Improper gluing or improper cement usage can cause leaks at the glued

connection which can result in property damage.

e. Using Weld-On No. 710 (PVC), or equivalent, secure the jet air/water inlet ports (as marked) to the spa plumbing system.

CAUTION

This is a PVC to PVC connection. Improper gluing or improper cement selection can cause leaks at glued

connection, which can result in property damage.

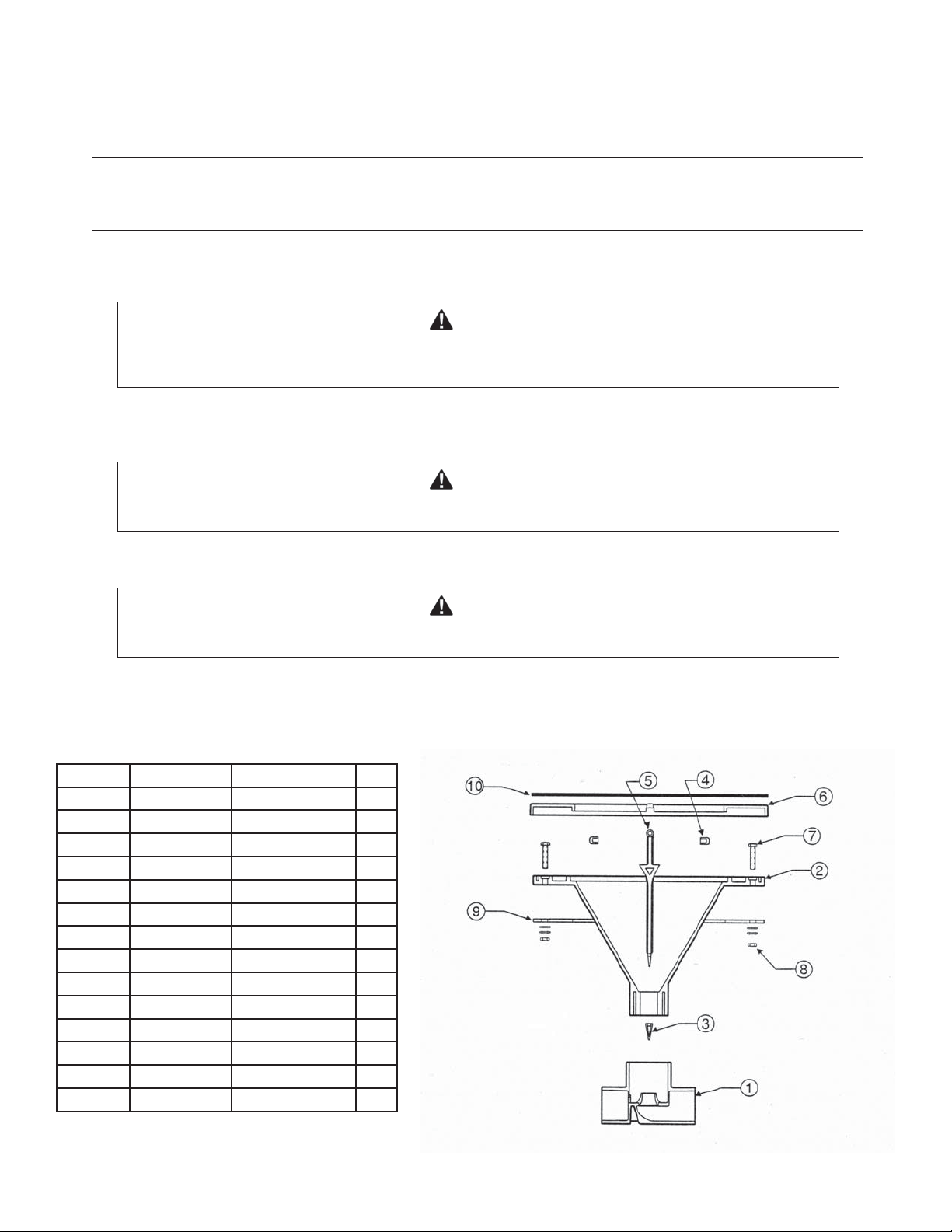

Parts List (See Figure No. 1)

Item No. Part Number Description Qty.

1

2

3

4

5

6

7

8

9

10

46033900 Tee 1

980100 Body 1

46033000 Boot 1

46032000 Hinge 2

46031000 Flapper 1

980200 Cover 1

98211900 Screw 10-24 10

41475000 Nut 10-24 10

46035700 Gasket (opt.) 1

Deco Ring (opt.) 1

46912500 Polished SS

46912600 Polished Brass

46912700 Antique Brass

98719600 Template 1

Figure 1

SAVE THESE INSTRUCTIONS

98704500 Rev. D October 15, 2009

Loading...

Loading...