Bakon Jelly Satellite T Installation Manual

USERS MANUAL

JELLY SATELLITE TWIN

2 September 2005

Serial number:

When ordering or placing queries please

specify this serial number.

Bakon BV food equipment

Stanleyweg 1

4462 GN GOES

Nederland

Tel. : +31 (0)113-244330

Tel.(service): +31 (0)113-244331

Fax. : +31 (0)113-244356

E-mail :service@bakon.nl

Manual Jelly Satellite Twin

VOORWOORD

This manual has been produced to facilitate safe use and maintenance of the Jelly Satellite

Twin. The manual is designed for users of the Jelly Satellite Twin.

The manual is divided into chapters, augmented by appendixes.

Foreword

Contains information on how to use this manual.

Table of contents

Contains a numbered list of all sections in this manual.

Chapter 1 Introduction

Provides general information on the Jelly Satellite Twin, its operation and the requirements

facing its conditions of application and operator.

Chapter 2 Safety

Describes the main safety risks, the safety features employed, the safety regulations that need

to be observed and the meaning of any symbols used on the machine.

Chapter 3 Transport and storage

Specifies how the Jelly Satellite Twin should be transported and stored.

Chapter 4 Installation and commissioning

Describes the basic procedures for putting the machine into use.

Chapter 5 Operation

Describes the operation of the machine and how to correct disturbances.

Chapter 6 Inspection and maintenance

Describes the control and maintenance of the Jelly Satellite Twin.

Chapter 7 Disposal

Describes how the machine should be disposed of in an environmentally correct fashion at the

end of its useful life.

Appendixes

Specifications

List of parts

Electrical diagram

Flow diagram

Certificate of conformity

Manual Jelly Satellite Twin

TABLE OF CONTENTS

1. INTRODUCTION .............................................................................................................................................. 1

1.1. SUPPLIER ................................................................................................................................................. 1

1.2. PRODUCT DESCRIPTION ...................................................................................................................... 1

1.3. APPLICATION ......................................................................................................................................... 1

1.4. CONDITIONS OF APPLICATION .......................................................................................................... 1

1.5. OPERATOR REQUIREMENTS ............................................................................................................... 2

1.6. OPERATING CONTROLS ....................................................................................................................... 2

2. SAFETY .............................................................................................................................................................. 4

2.1. INTRODUCTION ..................................................................................................................................... 4

2.2. SAFETY AND HEALTH RISKS .............................................................................................................. 4

2.3. SAFETY PROVISIONS ............................................................................................................................ 4

2.4. SAFETY MEASURES TO BE OBSERVED ............................................................................................ 4

2.5. MEANING OF SAFETY SYMBOLS USED ............................................................................................ 5

3. TRANSPORT AND STORAGE ....................................................................................................................... 6

3.1. TRANSPORT ............................................................................................................................................ 6

3.2. STORAGE ................................................................................................................................................. 6

4. INSTALLATION AND COMMISSIONING .................................................................................................. 7

4.1. INTRODUCTION ..................................................................................................................................... 7

4.2. UNPACKING ............................................................................................................................................ 7

4.3. INSTALLATION....................................................................................................................................... 7

5. OPERATION ...................................................................................................................................................... 9

5.1 THE USE OF THE JELLY SATELLITE TWIN ....................................................................................... 9

5.2. THE APPLICATION OF THE JELLY SATELLITE TWIN .................................................................. 17

5.3. SHUTTING DOWN ................................................................................................................................ 17

5.4. DISTURBANCES ................................................................................................................................... 18

6. INSPECTION AND MAINTENANCE .......................................................................................................... 20

6.1. INSPECTION .......................................................................................................................................... 20

6.2. MAINTENANCE .................................................................................................................................... 20

7. DISPOSAL ........................................................................................................................................................ 21

APPENDIX A. SPECIFICATIONS .................................................................................................................... 22

APPENDIX B. PARTS ........................................................................................................................................ 23

APPENDIX C. ELECTRICAL DIAGRAM ...................................................................................................... 24

APPENDIX D. FLOW DIAGRAM .................................................................................................................... 25

APPENDIX E. CERTIFICATE OF CONFORMITY....................................................................................... 26

EU-CERTIFICATE OF CONFORMITY .......................................................................................................... 26

NOTES .................................................................................................................................................................. 27

© Bakon BV food equipment

Nothing from this publication may be duplicated and/or published in the form of print, photocopy, microfilm or in any other

way whatsoever, without the prior written consent of Bakon bv food equipment.

Manual Jelly Satellite Twin

1. INTRODUCTION

1.1. SUPPLIER

Bakon bv food equipment

Stanleyweg 1

4462 GN Goes

The Netherlands

Tel: +31 (0)113-244330

Tel (service): +31 (0)113-244331

Fax (service): +31 (0)113-244356

E-mail (service):service@bakon .nl

1.2. PRODUCT DESCRIPTION

The Jelly Satellite Twin has been designed for applying jelly glazing to products.

The machine has a digital display and has digital temperature setting. The hose temperature

can also be set digitally.

The machine has an adjustable pressure setting.

The machine directly removes jelly from a pack, a jerry can, or container by suction, after

which the jelly is sprayed with the spraying gun.

The machine has to be connected to an external pressure facility.

The machine is equipped with 2 separated systems that can be adjusted completely

independent of each other.

Cold jelly is placed in the machine and only that part of the jelly that is to be used will be

placed in the heated system of the machine. The jelly is heated and maintained at the required

temperature using the au-bain-marie principal and electrically heated gun hoses.

The machine provides digital error messages and instructions to further assist the operator if

required.

1.3. APPLICATION

The Jelly Satellite Twin is intended solely for the spraying of fluid jelly.

1.4. CONDITIONS OF APPLICATION

The Mini Jelly may be used solely under the conditions of application stipulated hereunder

- Place the Jelly Satellite Twin on a hard, flat base.

- Set up the Jelly Satellite Twin as accessibly as possible.

1

Manual Jelly Satellite Twin

1.5. OPERATOR REQUIREMENTS

Only persons who have received instruction in and are familiar with its operation may operate

the Jelly Satellite Twin.

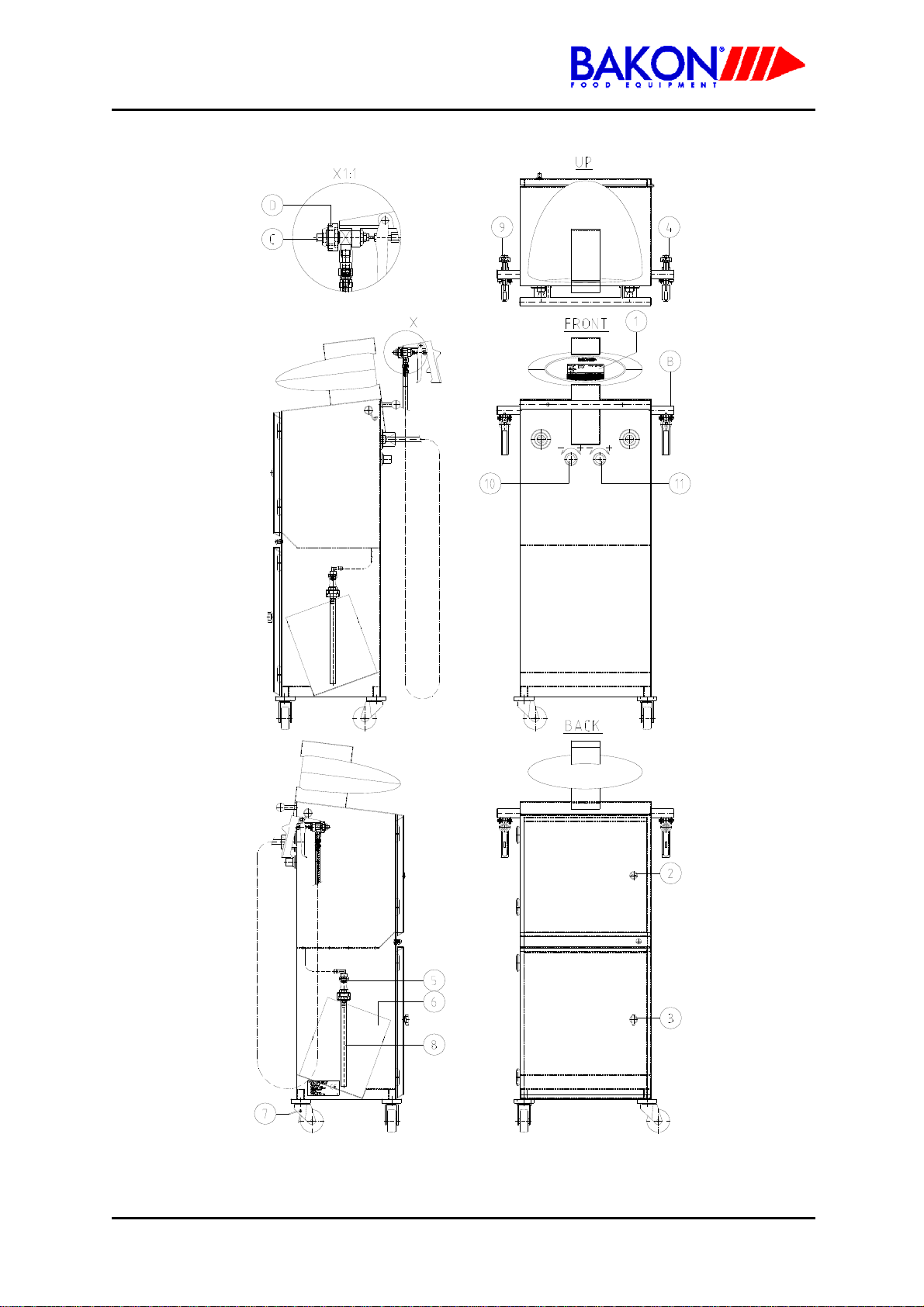

1.6. OPERATING CONTROLS

see figure 1.1.

The Jelly Satellite Twin is operated by operating controls on the control panel and with the

spray gun. The packaging with jelly should be placed in the cabinet.

Control instrument Function

1 Display and function keys To set and take readings from the machine.

2 Door with lock (key) To access the machine components.

3 Door with rotary lock To access the jelly compartment

4 Spraying gun For spraying jelly. (right)

5 Coupling Uncoupling the suction lance

6 Protective cabinet Pack containing jelly. (bag in box)

7 Handle For locking the front wheels (brake)

8 Suction lance (in the cabinet) Removing jelly from the pack by suction.

9 Spraying gun For spraying jelly. (left)

10

Reducing valve Regulates the pressure of the liquid (left)

11

Reducing valve Regulates the pressure of the liquid (right)

2

Manual Jelly Satellite Twin

Fig. 1.1: Operating controls

3

Manual Jelly Satellite Twin

2. SAFETY

2.1. INTRODUCTION

This chapter will address all the safety aspects of the Jelly Satellite Twin. It is therefore of

great importance that everyone who works with the Jelly Satellite Twin is familiar with the

contents of this chapter. Local safety regulations are also important in this connection.

Besides the details in this chapter the regulations of competent (government) authorities must

be observed.

This manual must be present at all times at the location of the machine or installation.

2.2. SAFETY AND HEALTH RISKS

Using the machine can present a hazard when:

- personnel who are not trained in its operation use the machine.

- the machine is used for purposes for which it is not intended.

- the machine is operated improperly.

Remark:

All the safety features incorporated by the manufacturer in the machine and the instructions

given in the manual are prerequisite to safe operation of the machine. The owner together

with the personnel involved is responsible for safe working with the machine.

The owner must ensure that:

- the appropriate members of staff are trained for their responsibilities.

- the safety regulations are observed.

2.3. SAFETY PROVISIONS

In order to render operation of the Jelly Satellite Twin as safe as possible, the following

safety provision has been introduced:

- Safety valve on the heat exchanger. (1.2 bar)

- All electrical components in the machine have their own fuse.

2.4. SAFETY MEASURES TO BE OBSERVED

Safe use of the Jelly Satellite Twin requires that a number of safety measures be adopted;

these are summarised by category hereunder.

Preparation for safe operation

- Ensure that activities involved in operation, maintenance and positioning, setting up and

relocating the Jelly Satellite Twin are carried out only by qualified personnel, that is

appropriately trained personnel who are familiar with the contents of this manual.

- Ensure that the Jelly Satellite Twin is placed on a secure and stable base.

- Connect the Jelly Satellite Twin to a 230 VAC, 50 Hz.

4

Manual Jelly Satellite Twin

- Ensure that all the shields are in place.

Safety measures during operation

- Safe operation of the machine supplied can be assured only if it is used as intended and

specified. This machine has been designed on the basis of the operating conditions

specified. The specifications stipulated should be regarded as limit values and may

never be exceeded.

- Never work with the Jelly Satellite Twin when the shields are missing.

- Never point the guns at people.

- Keep the surroundings of the Jelly Satellite Twin free of materials and other obstacles.

- Never pull the hoses or the cable in order to move the machine.

Safety measures during inspection, cleaning and maintenance

- The management must ensure that all inspection, cleaning and maintenance procedures

are carried out by competent and qualified personnel, who after reading the users

manual is properly informed about the machine/installation.

- Work may be carried out on the machine with the power switched off. The procedure

for switching the machine off is described in this users manual and must be observed at

all times.

- Should adjustments be made to a machine in operation, qualified personnel, who are

fully aware of all potential hazards, must make them.

- All safety facilities and shields must be replaced and ready for use as soon as the work

has been completed.

- Before restoring operation the points stipulated in this manual must be observed.

Measures for maintaining the Jelly Satellite Twin in good condition

- Ensure that the Jelly Satellite Twin is always in good condition. Use for repairs only

sound materials and operational procedures appropriate to the application.

- Modifications and alterations to the machine may be made only with the manufacturer’s

approval. Original spare parts and accessories approved by the manufacturer contribute

to safety. When alternative parts are used this shall relieve the manufacturer/supplier

from every form of liability for the consequences thereof.

2.5. MEANING OF SAFETY SYMBOLS USED

figure 2.1: Hazardous electrical voltage

5

Manual Jelly Satellite Twin

3.1. TRANSPORT

Transport by public highway

The Jelly Satellite Twin is packaged in a crate at the factory and can then be moved by

forklift.

The packaging is suitable for re-use.

Transport in the bakery

The Jelly Satellite Twin is constructed with four swivel castors making it easy to move.

- Disconnect the electrical power cable before moving the machine.

- Place the guns in their holders.

Caution: Never pull the hoses or the cable in order to move the machine.

3.2. STORAGE

Carry out the following procedures before placing the Jelly Satellite Twin in storage:

- Disconnect the Jelly Satellite Twin from the electricity supply.

- Clean the Jelly Satellite Twin (refer also to chapter 6).

3. TRANSPORT AND STORAGE

6

Loading...

Loading...