Bakers Pride GP-51 Installation Manual

BAKERSBAKERS

D

E

S

I

G

N

C

E

R

T

I

F

I

E

D

PRIDEPRIDE

1

P

G -5

GP-61

INSTALLATION AND OPERATING INSTRUCTIONS

COUNTER TOP GAS DECK OVENS

MODELS: GP-51 and GP-61

INTENDED FOR OTHER THAN HOUSEHOLD USE

RETAIN THIS MANUAL FOR FUTURE REFERENCE

OVEN MUST BE KEPT CLEAR OF COMBUSTIBLES AT ALL TIMES

IMPORTANT INSTRUCTIONS

After the gas supply has been connected to your unit, it is extremely important to check piping for possible

leaks. To do this, use soap and water solution or solutions which are expressly made for this purpose.

DO NOT USE matches, candles, flames, or other sources of ignition since these methods are extremely

dangerous. Post in a prominent location instructions to be followed in the event you smell gas. Obtain these

instructions from your local gas supplier.

For Your Safety: Do not store or use flammable liquids or vapors in the vicinity of this

!

or any other appliance.

Warning: Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the Installation, Operating and

Maintenance instructions thoroughly before installing or servicing this equipment.

Initial heating of oven may generate smoke or fumes and must be done in a wellventilated area. Overexposure to smoke or fumes may cause nausea or dizziness.

Note: Only Pizza or Bread can have direct contact with ceramic decks. All other food products must be

placed in a pan or container to avoid direct contact with ceramic decks.

This equipment has been engineered to provide you with year round dependable service when used

according to the instructions in this manual and standard commercial kitchen practices.

P/N U4128A 1/08

BAKERS PRIDE OVEN CO., INC.

30 Pine Street

(914) 576-0200 Phone (800) 431-2745 US & Canada

(914) 576-0605 Fax www.bakerspride.com Web Address

New Rochelle, NY 10801

!

!!

1

CONTENTS

I. INSTALLATION INSTRUCTIONS

SECTION ITEM PAGE

1. Receiving 2

2. Clearances 3

3. Set-up 3

(a) Counter Top Installation 3

(b) Installation with Casters 3

4. Deck Assembly 4

(a) Pizza Deck 4

(b) Steel Deck 4

5. Gas and Electric Connections 4

6. Flue connection-Ventilation 5

(a) Under Ventilation Hood 5

(b) Direct Venting 5

7. Main Burner Safety Pilot Operation 5

(a) Pilot Burner Lighting Procedure 5

(b) Pilot Burner Flame Adjustments 5

8. Burner Operation 6

(a) Main Burner 6

(b) Aeration & By-Pass Flame Adjustment 6

9. Thermostat Calibration 6

10. Heat Baffle Assembly 6

II. OPERATING INSTRUCTIONS

1. Lighting Procedure 7

2. Breaking In 7

3. Baking 7

4. Recommended Operating Procedure 7

5. Helpful Hints 7

III. CLEANING AND MAINTENANCE

1. (a) Oven Exterior 8

(b) Painted Surfaces 8

2. Control Panel 8

3. Flue Vent 8

4. Oven Interior 8

(a) Baking Chamber 8

(b) Baking Decks 8

(c) Burner Compartment 8

5. Troubleshooting Chart 9

PARTS LISTS & WARRANTY

GP-51 Parts List w/Exploded Views 10

GP-61 Parts List w/Exploded Views 13

Warranty 16

For European Community Countries:

EN 437

Gas

Cat.

I2H

I2L

I2E

I

Model BTU/hr kw

GP-51 40,000 11.71

GP-52 Consists of two GP-51 Ovens

GP-54 32,000 9.37

GP-55 Consists of two GP-54 Ovens

GP-61 45,000 13.18

GP-62 Consists of two GP-61 Ovens

GP-61-H 60,000 17.57

GP-62-H Consists of two GP-61-H Ovens

GP-64 42,000 12.30

GP-65 Consists of two GP-64 Ovens

These model numbers may be followed by a suffix (-1), indicating

units with one door on the Baking Chamber.

Gases and Supply

Pressures

G20 @ 20mbar

G25 @ 25mbar

G20 @ 20mbar

G20/25 @ 20/25mbar

2E+

Type of Gas

Natural

LP

For North America:

Models Covered

Designated European Market = ÿ

AT BEDKFI F

R GRDEIE ITLUNL PT ES SE GB

ÿ

ÿ

ÿ

ÿ

Manifold Pressure

3.5” Water Column

10.0” Water Column

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ ÿ ÿ

ÿ

ÿ

I

I. INSTALLATION INSTRUCTIONS

1. RECEIVING:

Read the notice on the outside carton

regarding damage in transit. Damage

discovered after opening the crate(s)

/carton(s) is 'CONCEALED DAMAGE' and

the carrier must be notified immediately to

send an inspector and also to furnish forms

for the consignee's claim.

When the oven arrives, it should consist of:

A carton containing your new oven (Two for

a stacked unit).

Installation must conform with local

codes and/or to the latest edition of the

ANS Z-223.1 National Fuel Gas Code in

USA ( CAN/CGA-B 149.1 or 2 Installation

Code in Canada).

In MASSACHUSETTS: All gas

pro d ucts mu st be install e d by a

“Massachusetts” licensed p l u m b e r or

gas fitter. Ventilation hoods must be

installed in accordance with NFPA-96,

current edition, with interlocks as

described in that standard.

This appliance must be installed

by a competent person in accordance

with the rules in force. In the U.K. Corgi

2

registered installers (including the regions of British Gas) undertake to work to safe and

satisfactory standards. This appliance must be installed in accordance with the current Gas Safety

(Installation and Use) Regulations and the relevant Building Regulations / IEE Regulations.

Detailed recommendations are contained in the British Standard Codes Of Practice BS 6172, BS

5440:Part 2 and BS 6891.

Place the oven and parts as close as possible to the area of final installation before un-crating.

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual for the life of the equipment. For

Warranty, Service and/or Parts, this information is required.

_____________________ ______________________ _____________________

Model Number Serial Number Date Purchased

2. CLEARANCES:

Minimum Clearance from Combustible Construction Non-Combustible Construction

Left Side 2" (51mm) 2” (51mm)

Right Side 1" (25mm) 0

Rear 5" (127mm) 2" (51mm)

3. SET UP: The oven must be installed in a well-ventilated area.

Your oven is packed in a carton and strapped to a skid. Remove the oven and carton from the skid before

unpacking. Unpack carefully to avoid damage to the oven. If concealed damage is found, follow the

instructions detailed in Section 1.

Keep the area around the oven free and clear of combustible materials. Do not store any materials on top of

or under any oven. The provision of an adequate air supply to your oven for ventilation and proper gas

combustion is essential. As a minimum, observe the clearances detailed in Section 2. Provide adequate

ventilation and make up air in accordance with local codes.

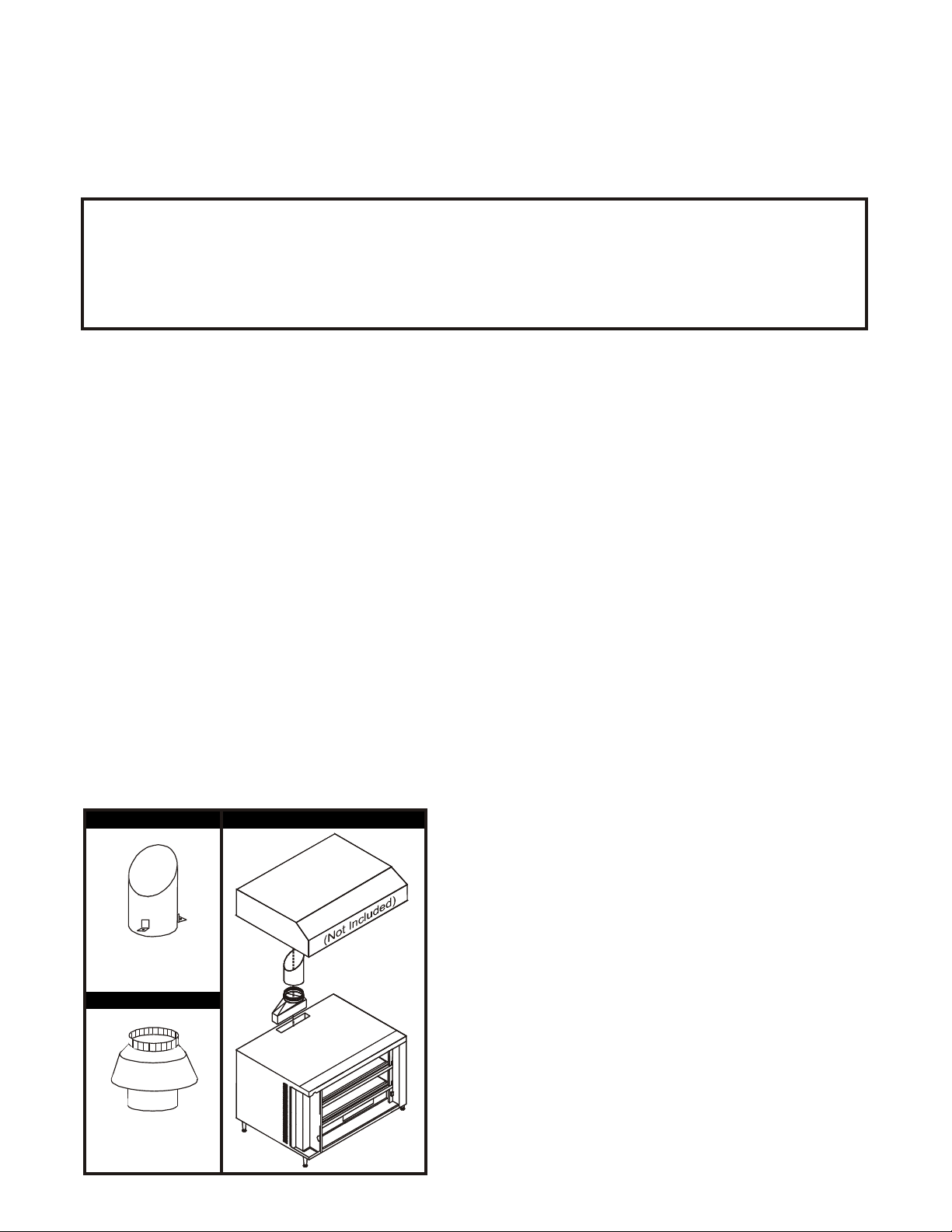

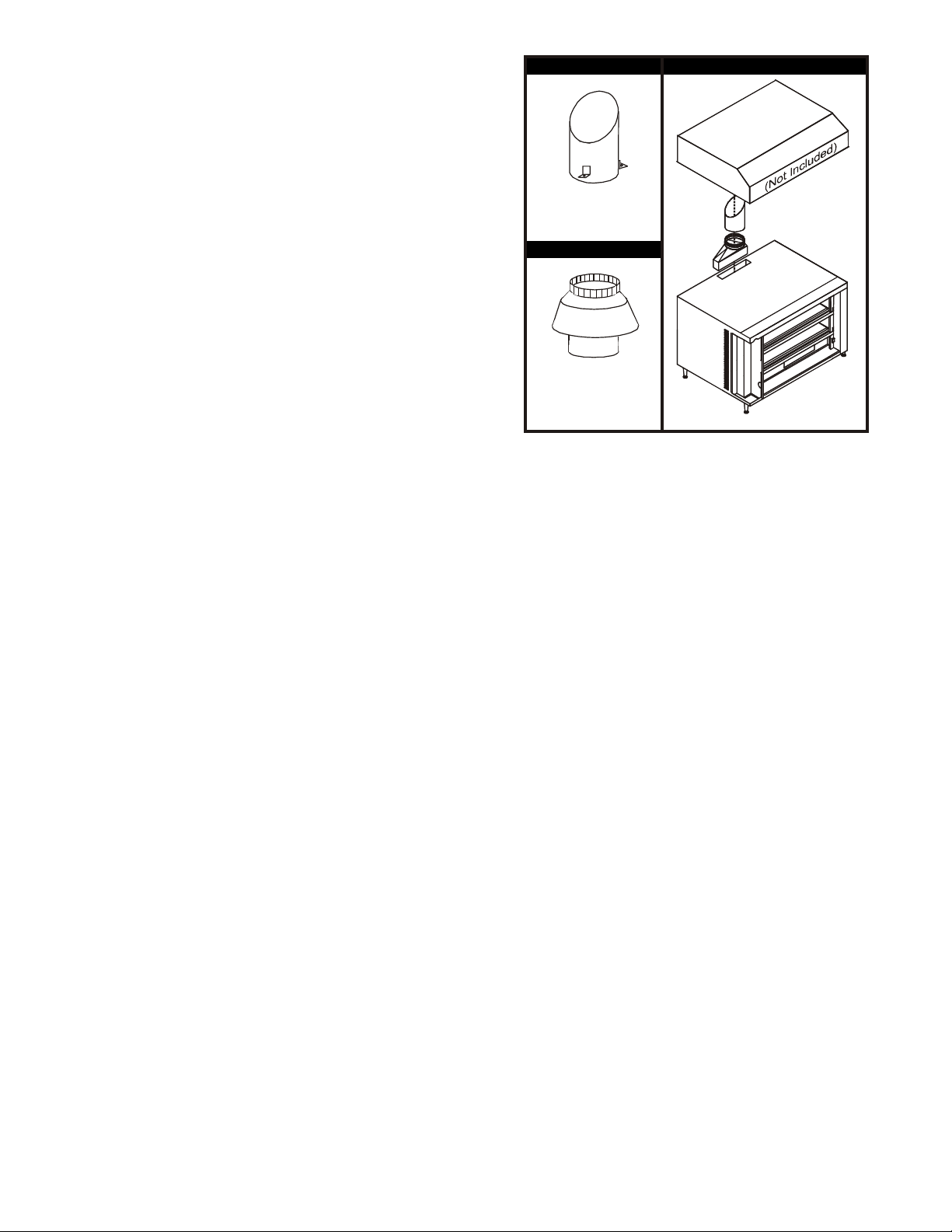

Fit the flue diverter (See fig.1) and the flue transition piece into the rectangular opening located at top near

the middle rear of the oven for installing the oven under a ventilation hood. For Direct Venting, Optional

Draft Hood (Fig. 2) must be used instead of the flue diverter. Direct Venting not available for European

Community Countries. Local inspectors and ventilation specialists should be consulted to make sure that

the installation of the hood conforms to the local codes and requirements (See fig. 3). In UK ventilation

requirements as detailed in BS 5440 should be followed.

Access to the bottom front door and left side control panel

Figure #1

Figure #3

is required for day-to-day operation of the oven and for

servicing. Make sure that these areas are kept

unobstructed for easy access.

d

o

o

H

t

n

e

V

A. COUNTER TOP INSTALLATION:

Oven is shipped with standard 4” legs installed.

(1) Move the oven to its final location keeping the

Flue Diverter

ith(For use w

Collection Hood)

Figure #2

minimum clearance detailed in section 2

above. This clearance is essential to provide

adequate airflow to the burner chamber and for

safe operation of the oven.

(2) Level the oven by making required adjustments

to the legs.

Draft Hood

ith(For use w

Direct Venting)

B. INSTALLATION WITH CASTERS (OPTIONAL):

Four casters (two with wheel brakes) and the mounting

hardware is packed and included in the shipment if

ordered. Install casters with wheel brakes on the

front of the unit.

3

NOTE: Installation should be made with a connector that complies with the latest edition of the

Standard for Connectors for Movable Gas Appliances ANSI Z21.69 in the USA (CAN CGA -6.16 in

Canada) and a quick disconnect device that complies with the latest edition of the Standard for Quick

Disconnect Devices for use with gas fuel ANSI Z21.41 in the USA (CAN CGA1-6.9 in Canada) and

adequate means must be provided to limit the movement of the appliance without depending on the

connector and any quick disconnect device or its associated piping.

The restraint should be attached to the rear legs of the oven on which casters are mounted. If disconnection

of the restraint is necessary to move the oven for servicing needs, the restraint should be reconnected after

the appliance has been returned to its originally installed position.

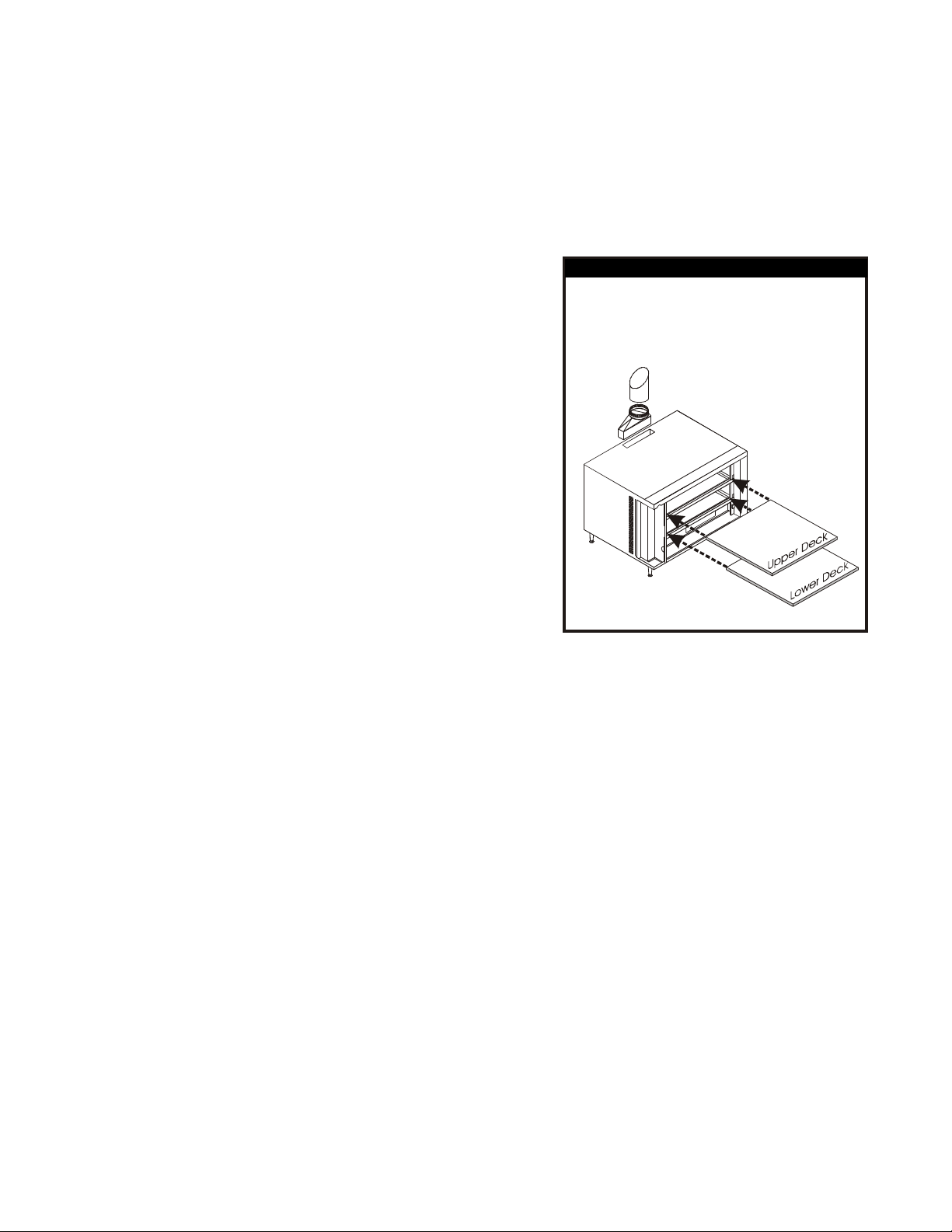

4. DECK ASSEMBLY:

A. PIZZA DECK:

(a) Remove all packing material, samples, shims, etc.

from the baking chamber.

(b) Two slabs of the Pizza Deck are provided with the

oven. Each deck is wrapped separately. Remove

the wrapping and handle the decks carefully. The

material is heavy and fragile.

Slab Installation (Fig. 4):

(a) Slide one deck into the oven over the bottom hearth

pan.*

(b) Slide the second deck onto the support angles on the

sides and back.*

B. STEEL DECK INSTALLATION:

Steel decks come installed in the oven from the factory and

no assembly is required. Before use, remove all packing

material and samples etc. from the baking chamber.

5. GAS AND ELECTRIC CONNECTIONS:

Propane gas units are not available in the European Community Countries.

NOTE: Use your hand to support the

deck from below, until deck is fully

installed in it’s final position.

Figure #4

DO NOT LET

DECKS DROP

INTO POSITION.

(a) The appliance when installed, must be electrically grounded in accordance with local codes and/or

the latest edition of the National Electric Code ANSI/NFPA 70 in USA (Canadian Electric Code CSA

C22.2 in Canada).

(b) In Europe, appliance must be connected by an earthing cable to all other units in the complete

installation and thence to an independent earth connection in compliance with EN 60335-1 and/or

local codes

(c) The ovens should not be installed on the same line with space heaters, boilers or other gas

equipment with high intermittent demand.

(d) Use a pipe joint compound that is resistant to the action of liquefied petroleum gases when

making gas connections.

(e) For Propane gas, use at least 1/2" (13 mm) pipe or tubing with a 5/8" (16 mm) inside diameter. For

Natural gas, use 3/4" (19 mm) pipe.

(f) The appliance must be isolated from the gas supply piping system by closing its manual

shut-off valve during any pressure testing of the gas supply piping system at test pressures

equal to or less than 1/2" psig (3.45kpa).

(g) The appliance and its shut-off valve must be disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in excess of 1/2" psig (3.45kpa).

(h) The gas pressure regulator is part of the combination valve and is adjusted to yield a pressure of

3.5" water column (9mbar) for Natural Gas. If the oven is ordered for use on Propane Gas, the

pressure regulator in the combination valve is preset at the factory to yield a pressure of 10" water

column (25 mbar). Units for use on Propane Gas are not available for European Community

Countries.

(i) A separate shut-off valve for each oven must be provided. It should be as close as possible

to the place where the gas supply line goes into the oven. It must be located such that it is

4

easily accessible.

Figure #1

Figure #3

(j) When stacking with another oven, two shut-off

valves, one for each of the two ovens, must be

provided.

H

t

n

After the Gas Supply has been connected, it is

e

V

extremely important to check all the piping for leaks.

Use a soap and water solution or a product expressly

made for this purpose. Do not use Matches, Candles

or a flame etc to check leaks since these methods are

extremely dangerous.

Flue Diverter

ith(For use w

Collection Hood)

Figure #2

6. FLUE CONNECTION - VENTILATION:

(a) INSTALLATION UNDER VENTILATION HOOD

(STANDARD):

If the oven is not vented directly and is installed

under a collection hood, use the flue diverter

(fig.1) supplied. Local inspectors and ventilation

Draft Hood

ith(For use w

Direct Venting)

and environmental specialists should be

consulted so that the design and the installation of the hood conforms to the local / municipal codes

(see fig.3).

(b) DIRECT VENTING (Optional) NOT AVAILABLE FOR EUROPEAN COMMUNITY COUNTRIES:

If direct venting, it is necessary to install a draft hood (fig.2). The flue pipe from the draft hood must

not run downwards at any point from the oven to the final outlet. It should always slant slightly

upwards. For best results it should rise straight up.

d

o

o

NOTE: Do not put a damper in the flue and do not connect a blower directly to the flue. If the flue

runs directly to the free air outside the building, use a wind deflector or a UL listed vent cap at the end of the

flue pipe. Termination of the vent must be at least 2 feet above the highest part of the roof within 10 feet (Ref:

American Gas Association Catalog No. Xh0474)

7. MAIN BURNER SAFETY PILOT OPERATION:

The purpose of the safety pilot system is to lock the gas supply to the main burner at the combination

valve, if for any reason the pilot burner is not lit. Oven should be relighted by following the steps

given below. However, in normal service, the pilot flame stays lit indefinitely, day and night or

weekends. This prolongs the life of the safety valve.

The safety pilot valve is in effect a two-stage control. After initial lighting, the pilot burner stays on without

the gas cock dial being held pressed in. After 1-2 minutes, the valve opens fully to let the gas

flow past the safety pilot valve into the burner system.

A. PILOT BURNER LIGHTING PROCEDURE:

(a) Partially depress and turn the gas cock dial to 'OFF'() position.

(b) Wait for five minutes to allow gas, which may have accumulated in the burner compartment, to

escape.

.

(c) Turn gas cock dial to 'PILOT'( ) position.

(d) Depress gas cock dial and light Pilot Burner. Hold in pressed position for about ½ minute (30

Seconds), and release the gas cock dial. The Pilot Burner should now remain lit.

If Pilot Burner fails to ignite or does not remain lit, repeat the steps (a) through (d).

B. PILOT BURNER FLAME ADJUSTMENT:

It is important to have the correct Pilot Burner Flame size as shown in Fig.5. If necessary, adjust the

Pilot Burner Flame by turning Pilot Adjust Screw (See fig. 6) clockwise to reduce or counter-clockwise

to increase.

5

Loading...

Loading...