Page 1

INSTALLATION AND OPERATING INSTRUCTIONS

COUNTERTOP MODEL

ELECTRIC PIZZA OVEN

Model: EP-2-2828

For Your Safety:

!

!

Initial heating of this oven may generate smoke or fumes and must be done in a well ventilated area.

Overexposuretosmokeor fumes may cause nauseaor dizziness.

This equipment has been engineered to provide you with year round dependable service when used

accordingto the instructionsin this manual andstandard commercialkitchen practices.

+1(914)576-0200 Phone (800)431-2745 US & Canada

+1(914)576-0605 Fax www.bakerspride.com WebAddress

or anyotherappliance.

Warning:

cause property damage, injury or death. Read the Installation, Operating and

Maintenanceinstructions thoroughlybefore installing or servicing this equipment.

Improper installation, adjustment, alteration, service or maintenance can

Do not store or use flammable liquids or vapors in the vicinity of this

ANSI/NSF4

Form #U4186A 5/05

BAKERS PRIDE OVEN CO., INC

30 Pine Street

New Rochelle, NY 10801

1

.

info@bakerspride.com e-mail

!

!

Page 2

TABLE OF CONTENTS

SECTION ITEM PAGE

1 Dimensions & Specifications 3

2 Installation 4

Counter-Top Installation 4

Floor Installation 4

Optional Open Base Feature 5

Double Stacked Ovens 6

3 Electrical Connections 6

4 Explanation Of Controls 7

5 Usage Recommendations 8

6 Troubleshooting 8

7 Cleaning 9

Exterior Cleaning 9

Interior Cleaning 9

8 Maintenance 9

Replacement Parts 9

Wiring Diagrams 9

9 Parts Lists & Exploded Views 10

10 Wiring Diagrams 13

11 Warranty 16

Periodic inspections by your dealer or a qualified service agent is recommended. When corresponding

with the factory or your service agent regarding service problems or replacement parts, be sure to refer to

the oven by the correct model number (including the prefix and suffix letters and numbers and the warranty

serialnumber. The ratingplate affixedto the oven containsthis information.

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual for the life of the equipment. For

WarrantyServiceand/or Parts, thisinformation is required.

ModelNumber SerialNumber DatePurchased

2

Page 3

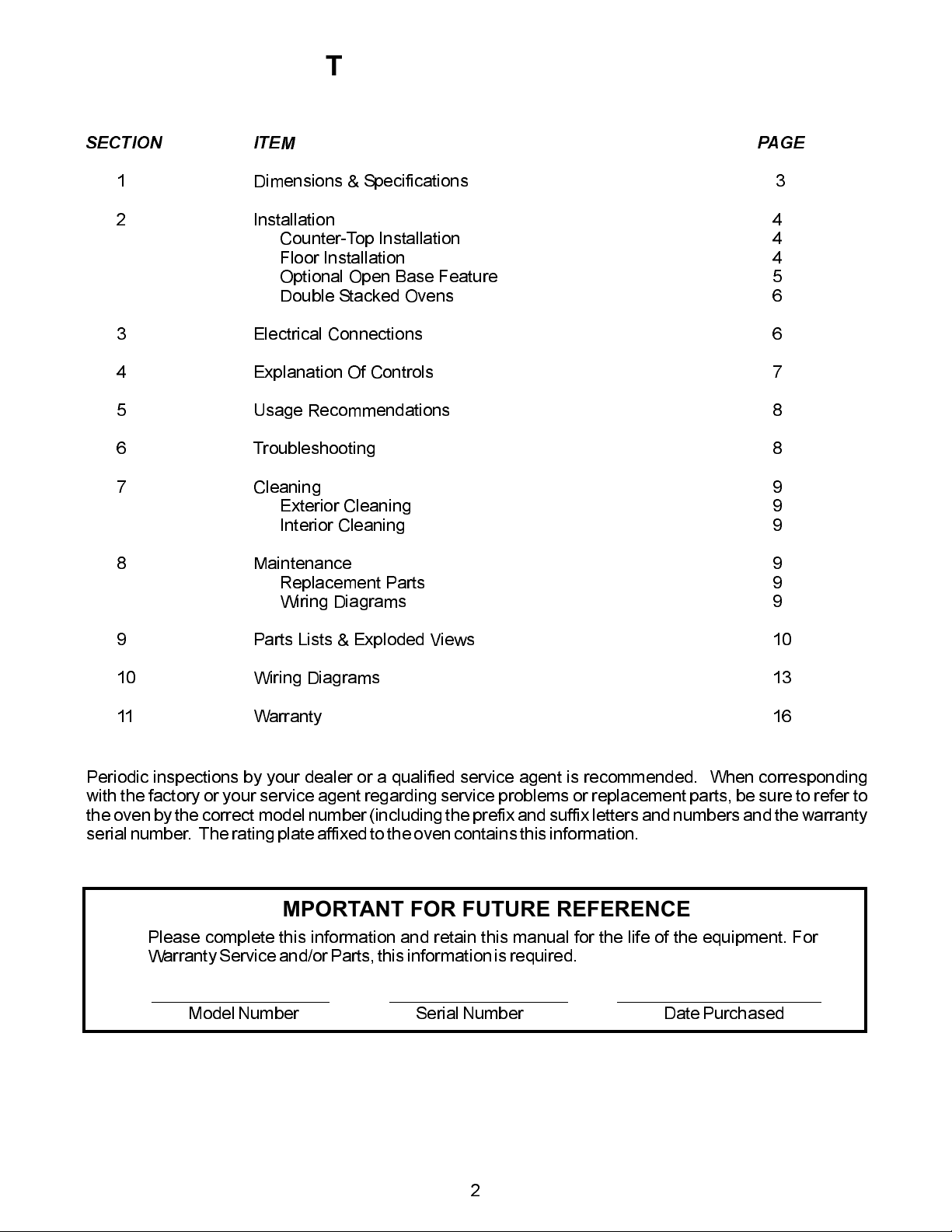

1. DIMENSIONS & SPECIFICATIONS

28

(711mm)

(1067mm)

28

(711mm)

42”

33.25”

(845mm)

2.5” (64mm)

28”

(711mm)

5.25” (133mm)

29”

(737mm)

Volts Amperes kW Nominal Amperes

208-1 44 9.5 44

208-3 25 9.5 30/31/32

230-1 39 9.5 39

240-1 38 9.5 38

240-3 22 9.5 22/23/23

400-3 13 9.5 13/12/13

Interior Dimensions Exterior Dimensions Weight Size

Single 28 5.25 28 42 29 33 458 23.26

Double 42 58 33 916 46.50

NOTE:

!

Each oven requires its own supply connection to mains.

Ovens are shipped individually.

3

!

Page 4

2. INSTALLATION

It is the responsibility of the purchaser to insure the oven is properly installed in a manner that meets all

applicable codes. In the absence of local codes refer to applicable national codes. In the case of any

discrepancy between this document and any local codes it is recommended you consult your local

inspector.

Users are cautioned that maintenance and repairs shall be performed by authorized service agents or

licensed professionals. Bakers Pride will have no obligation with respect to products that are not properly

installed,adjusted, operatedor maintained.

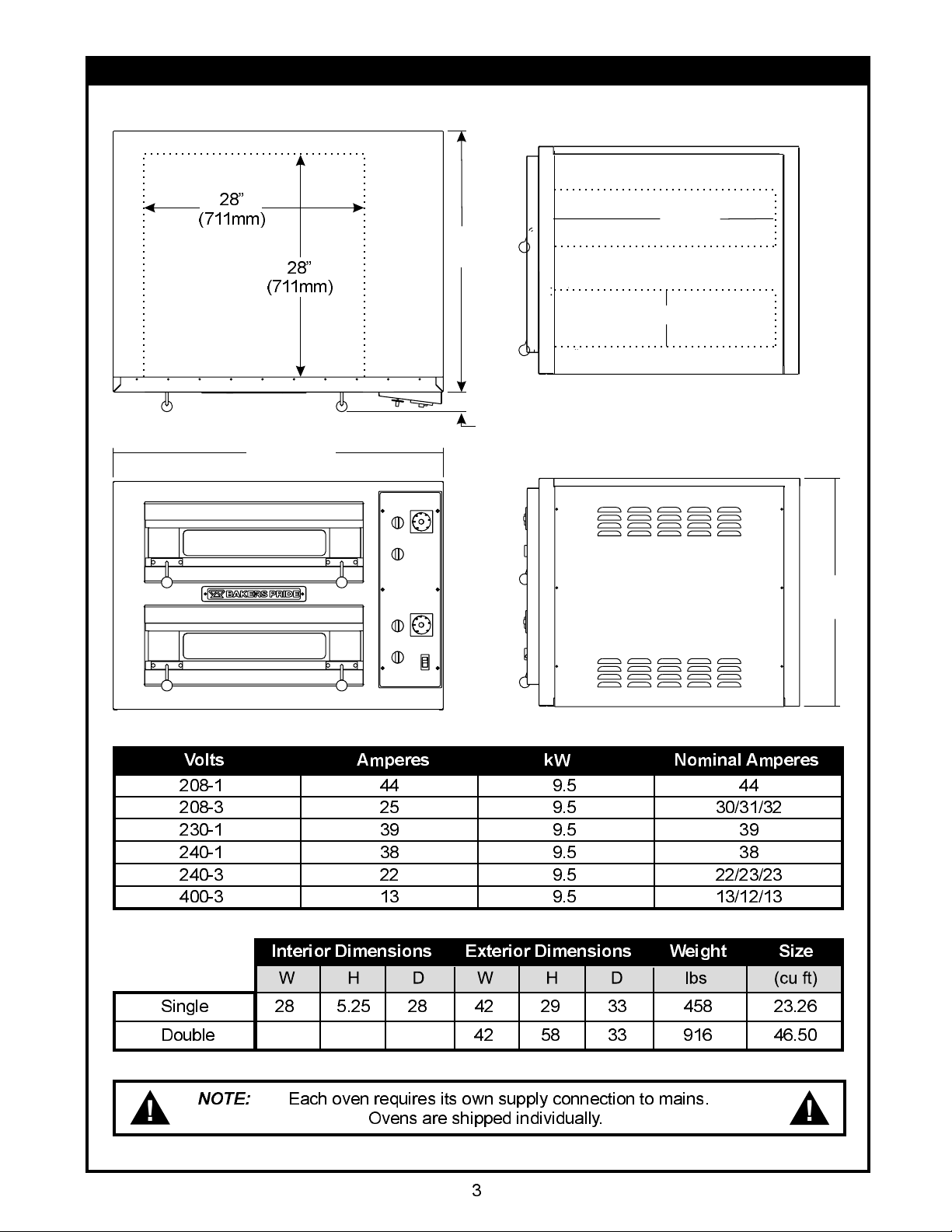

Counter-top Installation

The oven may be installed

4 inch COUNTER TOP LEG (4)

LEG WITH CASTER PLATE (4)

directly on a counter or stand

manufactured of non-

flammable materials. The

oven must be installed on a

surface that is at least as

large as the outer

dimensions of the oven. The

oven must be installed with

CASTER WITHOUT LOCK (2)

MOUNT IN REAR

FLAT WASHER (16)

LOCK WASHER (16)

BOLT (16)

adequate clearance to

combustible and non-

combustible walls. If legs are

not used the oven must be

LEG WITH FOOT INSERT (4)

sealed to the countertop with

anNSF approved sealant.

Minimum operating

clearances to combustible

surfaces is 1 inch [25 mm]. It

is recommendedthe oven be

at least 1 inch from any

CASTER WITH LOCK (2)

MOUNT IN FRONT

FLAT WASHER (12)

BOLT (12)

BULLET FOOT INSERT (4)

adjacent cooking appliance.

Each oven shall be installed with respect to building construction and other equipment to permit access to

theoven. Such clearance may be necessary for servicing and cleaning.

Bakers Pride recommends the mounting surface for a single oven be approximately 26 inches [660 mm]

fromthe floor so the oven decks are at a convenient working height.

NOTE:

Referto illustration for allthree leg configurations.

A. CounterTop- Short Legs - 4

B. FloorModel - 30

C. Floor/Double Stack- 16

CounterTopLegs

1. Turnthe oven over onto its left side so youcan easily reach thebolt mounting locationsin the base.

2. Using the four corner most holes in the bottom of the oven insert and tighten the four counter top

legs.

3. Carefully turn the oven upright. Insure the two legs that touch the floor first when you raise the oven

areblocked so they donot slip away.

FloorInstallation

1. At the floor end of each leg install the bullet foot insert or caster as required.

4

Page 5

The fit of the insert to the leg is intended to be snug, you should expect to tap them lightly in place

with a mallet or rubber hammer. Using your fingers screw the ends of the bullet feet into the leg

clockwiseuntil they are at their shortest length.

OR

Casters mount to the bottom of the caster plate with four each: 3/8-16 bolts inserted into a split ring

lockwasher and flat washer.

2. Turnthe ovenover onto itsleft side so you can easily reach the bolt mounting locationsin the base.

3. Thethree holes in thetop of each leg will match the bolt locations at each cornerof the oven base.

4. You will need three 3/8-16 hex head bolts and three 3/8 flat washers to mount each leg. Align the

leg to one of the matching bolt holes on the base and insert a bolt and washer. Install the other bolts

andfinger tighten into place before using a wrenchto fully tighten them all.

5. Be sure to tighten all bolts for each leg. When installing casters, make sure the two casters with

brakesare installed at the front of theoven.

6. Carefully stand up the oven. Insurethe two legs/casters that touch the floor first when you raise the

ovenare blocked and chockedso they do not slip away.

Optional Open Base Feature:

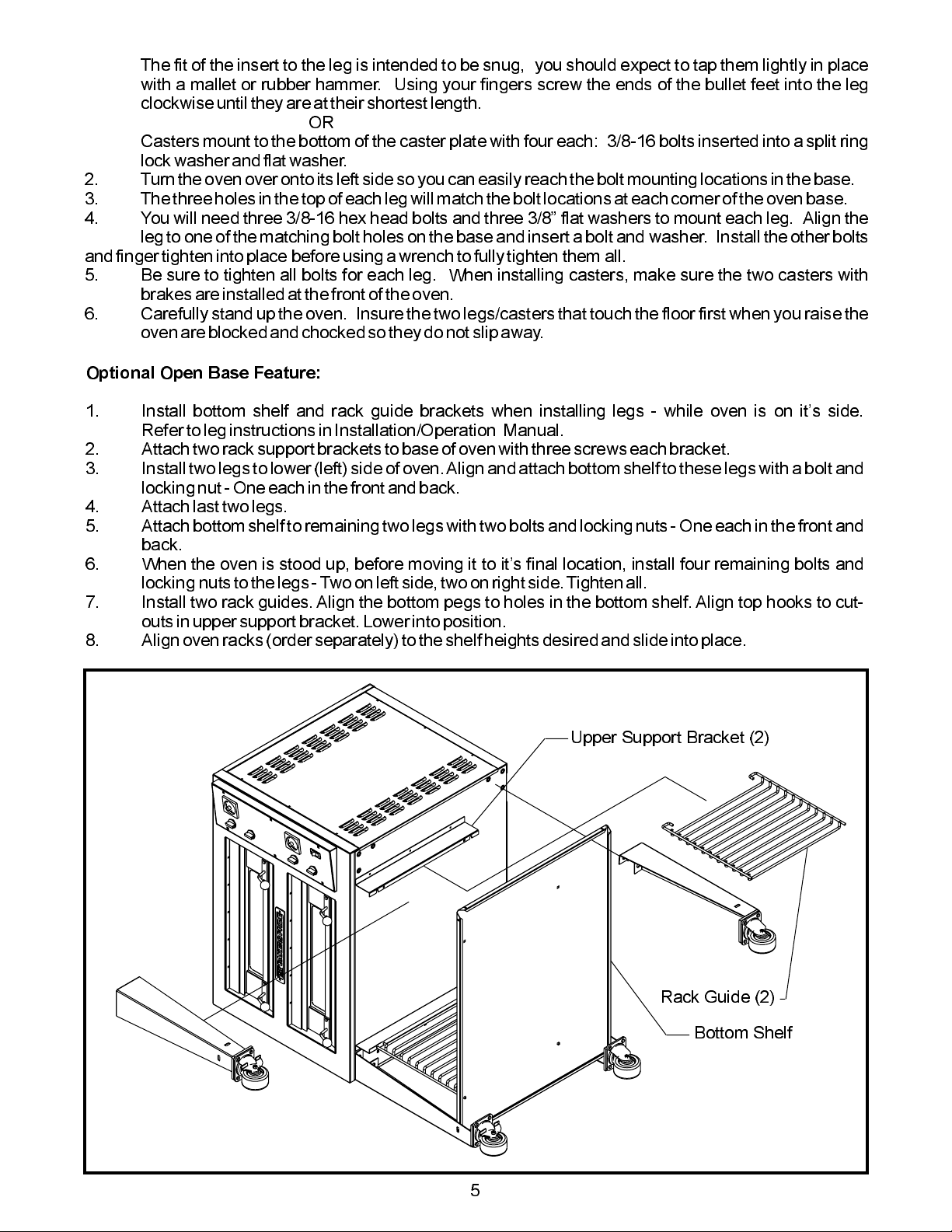

1. Install bottom shelf and rack guide brackets when installing legs - while oven is on its side.

Referto leg instructions in Installation/ Manual.

Operation

2. Attachtwo rack supportbrackets to base of oven with threescrews each bracket.

3. Installtwo legs to lower (left)side of oven.Align and attachbottom shelf to these legs with a bolt and

lockingnut - One eachin the front and back.

4. Attachlast two legs.

5. Attachbottom shelf to remaining two legs with two bolts and locking nuts - One each in the front and

back.

6. When the oven is stood up, before moving it to its final location, install four remaining bolts and

locking nuts to the legs- Twoon leftside, two onright side. Tightenall.

7. Install two rack guides. Align the bottom pegs to holes in the bottom shelf. Align top hooks to cut-

outsin upper supportbracket. Lower into position.

8. Alignoven racks (order separately) to the shelf heights desiredand slide into place.

Upper Support Bracket (2)

Rack Guide (2)

Bottom Shelf

5

Page 6

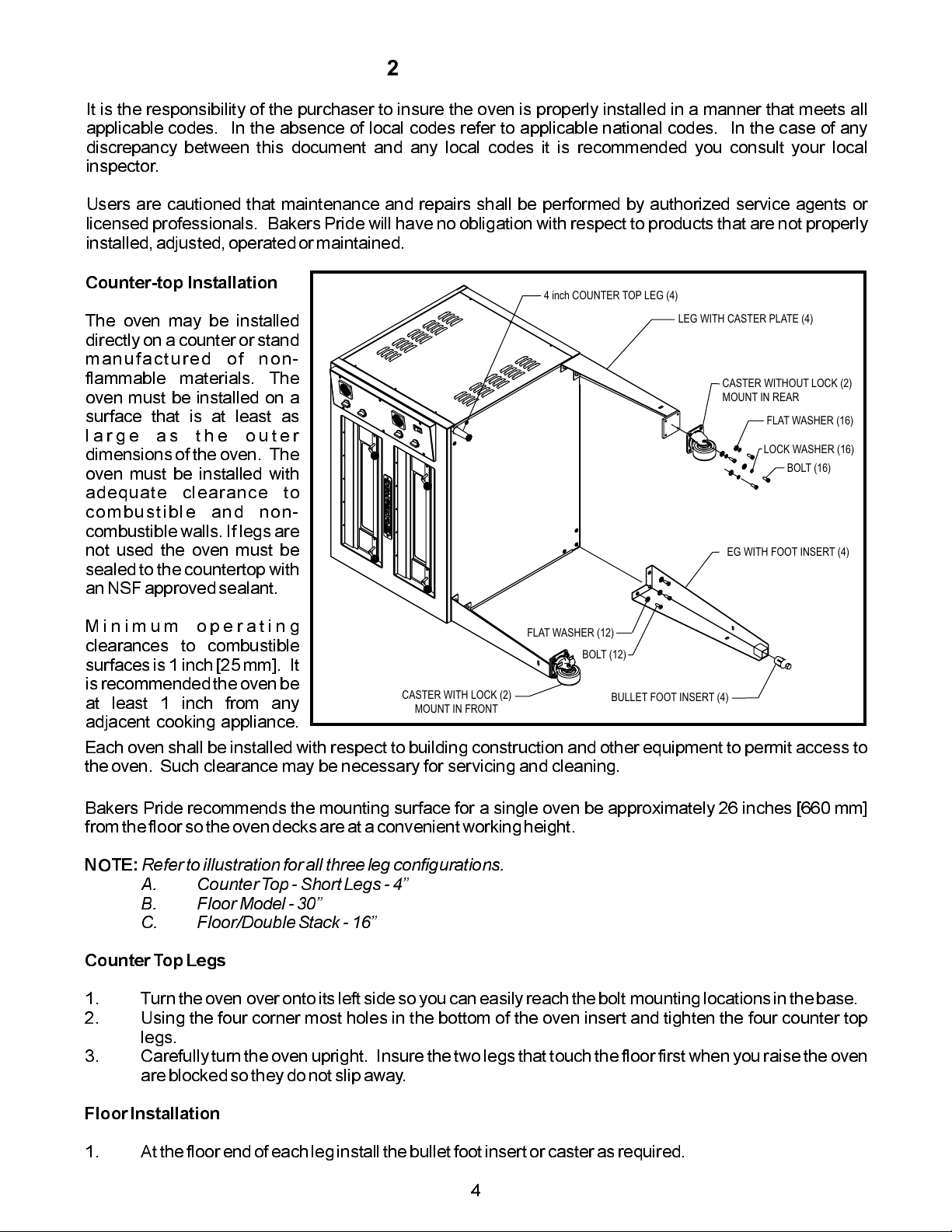

Double Stacked

Ovens

Your EP-2-2828 may be

stacked two ovens on top of

one another. In order to

insure the ovens to not slide

or separate, there is a

stacking bracket kit required

for installation at the rear of

the ovens. Two brackets

are installed, one at each

end of the oven securing the

upper oven to the bottom

oven. Refer to the adjacent

illustration.

3. ELECTRICAL CONNECTIONS

STACKING

C5057X BRACKET (2)

#10 SHEET METAL

SCREW (8)

WARNING:

!

1 Installation must be performed by a licensed electrician.

2 Aseparate electrical connection to the mains must be provided for each oven.

3 An all pole disconnect must be provided by the installer.

4 Connection to the electrical service must be grounded in accordance with local codes. In the

absence of local codes refer to the National Electric Code, ANSI/NFPA 70 or the Canadian Electric

Code,CSAC22.2 as applicable.

5 Only bare copper conductors with a minimum insulation temperature rating of 90ºC to be used.

6 Theinstaller must supply a properly sized strain relief bushing for the mains connection that meets

all codes.

7 Theovenshall be installedusing flexible conduit.

8 Therestraint cord must be securely attached to the rear of the oven and to the building structure to

preventtransmitting unnecessarystress to the flexibleconduit.

Caution:

!

A wiring diagram is affixed to the inner side cover of the oven and included in the rear of this booklet.

The input connection is accessed be removing the right side cover. Field connections are located at the

lowerrear corner of thecontrol compartment.

Risk of electrical shock. Appliance must be secured to building structure.

Disconnect all ovens from electrical supply before servicing.

!

!

6

Page 7

HOOK UP

L1

L2

L3

CONTROL PANEL

4. EXPLAINATION OF CONTROLS

The oven has a main power switch at the bottom

portion of the control panel. This switch must be

on for the oven to operate. When switched to the

ONposition the lampsin each cavity light.

Each cavity has separate temperature controls.

The thermostat dial may be adjusted from 200°F

100ºC) to 700°F (370ºC).

(

Each cavity has top and bottom infinite control

switches. Turning the dial of the infinite control to

0 will turn off the heat for that portion of the oven

cavity. The proportion of heat decreases as the

dial is adjusted from a maximum of 10 to a

minimumof 1.

By changing the adjustment of the infinite control

switches an operator can vary the heat in the

cavity for more or less top heat, more or less

bottomheat or equal heattop and bottom.

7

Page 8

Each cavity has a timer that may be used when cooking product. The timer DOES NOT control the oven.

To set a cook time turn the dial clock wise to the desired setting. The timer will count down until the time

expires. A buzzer will sound continuously until the dial is turned to the OFF position slightly to the left of

0.

5. USAGE RECOMMENDATIONS

1. Pre-heatthe oven thoroughlybefore use. Allow onehour and fifteenminutes for pre-heat.

2. Pre-heatovens @ 75°F (24°C) desiredcook/bake temperature.

3. Donot move baking locationin the middle of a bake, but spinningis okay.

4. Keepdecks clean of flour, cheese,etc using a deck/scraperbrush.

5. Duringidle periods, reduceheat by 75°F (24°C).

6. Minimizewater content of products for fastercook/bake times.

7. Forlarger & thick products,reduce temperature& increase bake/cook time.

8. Cooking times and temperatures will vary depending upon such factors as size of the load,

temperature, mixture of products (particularlymoisture) and densityof products.

9. Keep a record of the times, temperature and load sizes you establish for various products.

Once you have determined these, they will be similar for succeeding loads.

10. When practical, start cooking the lowest temperature product first and gradually work up to the

highertemperatures.

11. When loadingthe oven, work as quickly as possibleto prevent loss ofheat.

12. Oven will continue to heat even though the timer goes off. Product should be removed from the

ovenas soon as possibleto avoid overcooking.

13. Whenbaking, weigh or measure the product ineach pan to assure even cooking.

14. Onlybread and pizza maybe placed directly on a stone baking hearth.

BELOW

6. Trouble Shooting

There are no user serviceable components under the covers. Contact your service agent.

PROBLEM CAUSE TO INVESTIGATE

No power on - lights do not

come on, oven does not heat-up

No cavity heat - oven lights

come on, elements do not heat up

Uneven heat

Oven won't reach temperature

No power to oven - check supply voltage

Circuit breaker tripped - reset and check oven for fault condition

High temperature thermostat tripped - reset and check oven for

fault condition

Circuit breaker tripped - reset and check oven for fault condition

Thermostat faulty - replace

Contactor faulty - replace

Bad element - replace

Infinite control thermostat faulty - replace

Bad element - replace

Thermostat faulty - replace

8

Page 9

7. CLEANING

!

When the oven is new, operate it for at least one hour at a setting of at least 500°F (250ºC). Due to normal

manufacturing processes, a small amount of steam and/or smoke will exit the oven from moisture and oils

on the oven components. Shut off andallow the oven to cool.

After cooling wipe down the interior of the oven with a clean damp cloth. Brushing of the baking hearth is

recommended.

ExteriorCleaning

It is recommendedthat a regular cleaning schedule be maintained to keep your oven operating and looking

itsbest. Spillsshould becleaned immediately.

The oven should always be allowed to cool sufficiently before cleaning. Exterior surfaces should be wiped

with a soft cloth and mild detergent. Stubborn stains may be cleaned with a light weight, non-metallic

cleaningpad. Apply onlylight pressure and rub in the direction of the surface grain.

The control panel surface is easily cleaned with a soft cloth and mild detergent. Do not use abrasives,

solvent cleaners or metallic scouring pads on the control panel. They may scratch or damage the label

surface.

Never spray steam or water directly onto or into the oven. This could adversely affect the ceramic

cookinghearth and/or electricalcomponents.

Caution:

Disconnect all ovens from electrical supply before servicing.

!

InteriorCleaning

Internal metallic surfaces should be allowed to cool before cleaning. Wipe interior surfaces with a wet cloth

or light weight scouring pad.

Food particles or spills that accumulate on the baking hearth may be brushed off with a normal oven brush.

Stubbornspills should be heated to a maximum temperature for approximately one hour to burn the spill so

it will crumble and easilybrush out afterwards.

Do not use oven cleaners, caustic solutions or mechanical means that may damage the interior of your

oven.

8. MAINTENANCE

Users are cautioned that maintenance and adjustments should only be performed by authorized service

agentsusing Baker's Pride replacement parts.

Minor periodic maintenanceto your oven should provide many years of useful service to you. Any time the

unit is serviced it is recommended all components be checked and their performance verified. At least

once each year your oven should be inspected by a qualified service provider to insure your oven is

operatingat its peakperformance.

ReplacementParts

Enclosed in this booklet are diagrams of likely replacement parts that may be required for normal

maintenance. Specifications are subject to change without notice. Be sure to verify the current

specificationwith your qualifiedservice provider or Bakers Pride before orderingreplacement parts.

WiringDiagrams

The current wiring diagram at the date of your oven's manufacture was affixed to the unit for reference.

Copies of the proper wiring diagrams effective on the date this booklet is printed are enclosed.

Specificationsare subject to change without notice. If there is any uncertainty or discrepancy between the

wiringdiagram and your oven refer to Bakers Pride Technical Service forclarification.

9

Page 10

9. PARTS LISTS & EXPLODED VIEWS EP-2-2828

FIGURE 1 MAIN BODY

9

U1043A

Name Plate

1

Apr 04

FIGURE 2 DOORS

FIGURE 3 CONTROL PANEL

1

2

3

4

5

6

7

8

C5029X

C5058X

U1382X

U1395X

U1383X

M1367X

M1368X

S1306X

M1481X

M1352X

M1382X

M1384X

S1311S

Control Panel w/o Timer

Control Panel w/Timer

Overlay - No Timer

Overlay - 15 Minute Timer

Overlay - 60 Minute Timer

Infinite Switch - 208V

Infinite Switch - 230V & 240V

Knob

Thermostat

Switch

Timer - 60 Minute

Timer - 15 Minute

Knob

1

1

1

1

1

4

4

4

2

1

2

2

2

Apr 04

Sep 04

Apr 04

Sep 04

Sep 04

Sep 04

Apr 04

Apr 04

Apr 04

Apr 04

Sep 04

Sep 04

Sep 04

10

Page 11

DOORS

SEE FIG 2

1

2

FIGURE 1 MAIN BODY

3

9

9

4

5

12

8

8

CONTROL PANEL

SEE FIG 3

DOOR

HARDWARE

SEE FIG 4

7

7

ELECTRICAL

COMPONENTS

SEE FIG 5

5

6

6

FIGURE 2 DOORS

1 2

1

2

FIGURE 3 CONTROL PANEL

5

4

4

3

3

1

2

4

8

6

6

7

5

5

7

8

6

11

Page 12

FIGURE 4 DOOR HARDWARE

FIGURE 5 ELECTRIC COMPONENTS

1

2

3

4

5

6

7

8

9

C5025X

P1003X

P1207X

M1371X

M1372X

M1482X

M1360X

P1018X

P1192X

P1208X

P1201X

Component Bracket

Terminal Block - 3 pos

Din Rail

Contactor - 208V

Contactor - 230V & 240V

Thermostat

Transformer

Snap Bushing

Circuit Breaker-3 P 10A 230/400V

Circuit Breaker-3 P 25A 208/240V

Circuit Breaker-1 P 10A

FIGURE 4 DOOR HARDWARE

8

5

1

1

2

4

4

2

1

1

2

2

1

Apr 04

Apr 04

Apr 04

Sep 04

Apr 04

Apr 04

Apr 04

Apr 04

Apr 04

Sep 04

Apr 04

FIGURE 5 ELECTRIC COMPONENTS

5

7

6

10

8

4

1

9

9

7

1

2

6

3

2

3

3

4

5

6

12

Page 13

10. WIRING DIAGRAMS

WIRING DIAGRAM EP-2-2828 230/400, 50HZWIRING DIAGRAM EP-2-2828 230/400, 50HZ

13

ELEMENT LOAD:

P1 = R6 + R7

P2 = R2 + R3 + R4

P3 = R1 + R5

L1

L2

TERMINATE

WHT & RED

ORG

BLK

S1

TR 1

P1

S1

P2

S2

22

33

14

21

33

19 1517

22

TH 1

4

19

1 5

L1 EL2 L3 N

TB1

UPPER OVEN

87 8881

T3 T4

L3 L4

R 15 750 WATTS

92

R 16 750 WATTS

93

R 17 750 WATTS

94

A2

32

54

56

58

LOWER ELEMENTS

45

H1

S5

L1

31

91

90

89

89 91 92

T3 T4

T2

T1

A1

34

H2

L2

20

A2

K4

34

L3 L4

L2

L1

54 58 1256

COMPONENT LIST

CB1 - CONTROL CIRCUIT BREAKER

CB2 - LOWER OVEN CIRCUIT BREAKER

87

83

82

81

T2

T1

A1

K3

L2

L1

53 57 1055

YEL

BLU

R 1 750 WATTS

68

R 2 500 WATTS

64

R 3 500 WATTS

65

R 4 500 WATTS

66

UPPER ELEMENTS

LOWER OVEN

67 68

T3

L3

T4

L4

72

73

74

A2

28

48

50

52

R 5 750 WATTS

R 6 750 WATTS

R 7 750 WATTS

LOWER ELEMENTS

41

H1

S3

L1

27

16

71

70

69

69 71 72

T1

T2

T3

T4

A1

41

K2

L1

L2

L3

L4

48 52 850

30

H2

L2

18

67

63

62

61

61

T1

T2

A1

39

K1

L1

L2

474551 649

39

28

H1

H2

S2

L1

L2

25

16

14

R 11 750 WATTS

88

R 12 500 WATTS

84

R 13 500 WATTS

85

R 14 500 WATTS

86

UPPER ELEMENTS

A2

30

43

43

32

H1

H2

S4

L1

L2

29

20

18

CB3 - UPPER OVEN CIRCUIT BREAKER

K1 - LOWER OVEN UPPER ELEMENT CONTACTOR

2321

49 51

17

15

CB1

TH 2

47

CB2

25 27

1

2

TH 3

CB3

55 57

53

23 29

2

TH 4

31

1

K2 - LOWER OVEN LOWER ELEMENT CONTACTOR

K3 - UPPER OVEN UPPER ELEMENT CONTACTOR

K4 - UPPER OVEN LOWER ELEMENT CONTACTOR

L1 - UPPER OVEN LAMP

L2 - LOWER OVEN LAMP

R1 THRU R17 - HEATER ELEMENTS

13

5 9

1

13

TB 2

8

23

10

12

6

4

1

7 11

3

S1 - MAIN POWER SWITCH

S2 - LOWER OVEN UPPER ELEMENT SWITCH

S3 - LOWER OVEN LOWER ELEMENT SWITCH

S4 - UPPER OVEN UPPER ELEMENT SWITCH

S5 - UPPER OVEN LOWER ELEMENT SWITCH

TB1 - MAIN POWER TERMINAL BLOCK

TB2 - NUETRAL DISTRIBUTION

2

3

7911

2

TB1

3

7911

1 5

L1 EL2 L3 N

2

TH1 - LOWER OVEN HIGH LIMIT THERMOSTAT

TH2 - UPPER OVEN HIGH LIMIT THERMOSTAT

TH3 - LOWER OVEN THERMOSTAT

TH4 - UPPER OVEN THERMOSTAT

TR1 - STEP DOWN TRANSFORMER

THREE PHASE

OPTIONAL SINGLE PHASE

U4187A

Page 14

WIRING DIAGRAM EP-2-2828 208/240, 60HZ (DOMESTIC)WIRING DIAGRAM EP-2-2828 208/240, 60HZ (DOMESTIC)

14

ELEMENT LOAD:

Z-X=R6+R7

X-Y=R2+R3+R4

Y-Z = R 1 + R5

RED 208V

ORG 240V

BLK

21

33

S1

19

22

4

L1

L2

P1

P2

TERMINATE

WHITE AND

UNUSED

26

24

24

22

14

TR 1

S1

S2

T2

T1

19 1517

TH 1

1

3

X

TB1

THREE PHASE

37

33

17

35

35

5

9

7

YZ

87

83

82

81

A1

T1

K3

5384558157

UPPER OVEN

88

L4T4L3T3L2T2L1

92

R 16 750 WATTS

93

R 17 750 WATTS

94

A2

32

54

56

58

R 15 750 WATTS

LOWER ELEMENTS

45

H1

S5

L1

31

91

90

89

89

T1

A1

45

34

H2

L2

20

A2

K4

34

L4T4L3T3L2T2L1

5493569258

COMPONENT LIST

CB1 - CONTROL CIRCUIT BREAKER

CB2 - LOWER OVEN CIRCUIT BREAKER

BLU

YEL

R 1 750 WATTS

68

R 2 500 WATTS

64

R 3 500 WATTS

65

R 4 500 WATTS

66

UPPER ELEMENTS

LOWER OVEN

67

63

62

61

R 5 750 WATTS

72

R 6 750 WATTS

73

R 7 750 WATTS

74

LOWER ELEMENTS

71

70

69

R 11 750 WATTS

88

R 12 500 WATTS

84

R 13 500 WATTS

85

R 14 500 WATTS

86

UPPER ELEMENTS

73

68

T1

A1

39

4764496151

39

28

H1

H2

S2

L1

L2

25

16

14

K1

A2

28

L4T4L3T3L2T2L1

48

50

52

41

41

30

H1

H2

S3

L1

L2

27

16

69

T1

A1

18

A2

K2

30

L4T4L3T3L2T2L1

48

507252

43

43

32

H1

H2

S4

L1

L2

29

20

18

CB3 - UPPER OVEN CIRCUIT BREAKER

K1 - LOWER OVEN UPPER ELEMENT CONTACTOR

K2 - LOWER OVEN LOWER ELEMENT CONTACTOR

2321

49 51

15

CB1

TH 2

47

CB2

25 27

1

2

TH 3

CB3

55 57

53

23 29

2

TH 4

31

1

K3 - UPPER OVEN UPPER ELEMENT CONTACTOR

K4 - UPPER OVEN LOWER ELEMENT CONTACTOR

L1 - UPPER OVEN LAMP

L2 - LOWER OVEN LAMP

R1 THRU R17 - HEATER ELEMENTS

S1 - MAIN POWER SWITCH

13

5 9

1

13

4

7 11

3

S2 - LOWER OVEN UPPER ELEMENT SWITCH

S3 - LOWER OVEN LOWER ELEMENT SWITCH

S4 - UPPER OVEN UPPER ELEMENT SWITCH

S5 - UPPER OVEN LOWER ELEMENT SWITCH

T1 - LOWER OVEN TIMER

T2 - UPPER OVEN TIMER

TB1 - MAIN POWER TERMINAL BLOCK

OPTIONAL SINGLE PHASE ELMENT WIRING

67

68

64

9

11

E

1

3

X

11

YZ

E

TB1

61

T1

A1

K1

L4T4L3T3L2T2L1

73

72

69

T1

A1

A2

K2

L4T4L3T3L2T2L1

87

88

84

81

T1

A1

A2

K3

93

92

89

T1

A1

A2

L4T4L3T3L2T2L1

K4

A2

L4T4L3T3L2T2L1

OPTIONAL SINGLE PHASE

TH1 - LOWER OVEN HIGH LIMIT THERMOSTAT

TH2 - UPPER OVEN HIGH LIMIT THERMOSTAT

TH3 - LOWER OVEN THERMOSTAT

TH4 - UPPER OVEN THERMOSTAT

TR1 - STEP DOWN TRANSFORMER

U4188A

Page 15

WIRING DIAGRAM EP-2-2828 480V, 60HZ, 3PHWIRING DIAGRAM EP-2-2828 480V, 60HZ, 3PH

15

ELEMENT LOAD:

Z-X=R6+R7

X-Y=R2+R3+R4

Y-Z=R1+R5

ORG

BLK

21

33

S1

19

CB4

22

4

37

L1

L2

P1

P2

TERMINATE

WHITE AND

RED

26

24

24

22

14

TB1

TR 1

S1

S2

37

T2

33

T1

19 1517

TH 1

1

3

X

THREE PHASE

35

35

17

5

7

YZ

87

83

82

81

A1

T1

K3

5384558157

UPPER OVEN

88

L4T4L3T3L2T2L1

92

93

94

A2

32

54

56

58

R 15 750 WATTS

R 16 750 WATTS

R 17 750 WATTS

LOWER ELEMENTS

45

H1

S5

L1

31

91

90

89

89

T1

A1

45

5493569258

34

H2

L2

20

A2

K4

34

L4T4L3T3L2T2L1

COMPONENT LIST

CB1 - CONTROL CIRCUIT BREAKER

CB2 - LOWER OVEN CIRCUIT BREAKER

BLU

YEL

R 1 750 WATTS

68

R 2 500 WATTS

64

R 3 500 WATTS

65

R 4 500 WATTS

66

UPPER ELEMENTS

LOWER OVEN

67

63

62

61

T1

A1

39

39

H1

S2

L1

25

14

K1

4764496151

28

H2

L2

16

R 5 750 WATTS

72

R 6 750 WATTS

73

R 7 750 WATTS

74

LOWER ELEMENTS

68

A2

28

L4T4L3T3L2T2L1

48

50

52

71

70

69

73

69

T1

A1

41

K2

L4T4L3T3L2T2L1

48

507252

41

30

H1

H2

S3

L1

L2

27

18

16

A2

30

R 11 750 WATTS

88

R 12 500 WATTS

84

R 13 500 WATTS

85

R 14 500 WATTS

86

UPPER ELEMENTS

43

43

32

H1

H2

S4

L1

L2

29

20

18

CB3 - UPPER OVEN CIRCUIT BREAKER

CB4 - CONTROL CIRCUIT BREAKER

K1 - LOWER OVEN UPPER ELEMENT CONTACTOR

2321

27

49 51

15

CB1

TH 2

47

CB2

25

1

2

TH 3

CB3

55 57

53

23 29

2

TH 4

31

1

K2 - LOWER OVEN LOWER ELEMENT CONTACTOR

K3 - UPPER OVEN UPPER ELEMENT CONTACTOR

K4 - UPPER OVEN LOWER ELEMENT CONTACTOR

L1 - UPPER OVEN LAMP

L2 - LOWER OVEN LAMP

R1 THRU R17 - HEATER ELEMENTS

13

5 9

1

35

36

7 11

3

S1 - MAIN POWER SWITCH

S2 - LOWER OVEN UPPER ELEMENT SWITCH

S3 - LOWER OVEN LOWER ELEMENT SWITCH

S4 - UPPER OVEN UPPER ELEMENT SWITCH

S5 - UPPER OVEN LOWER ELEMENT SWITCH

T1 - LOWER OVEN TIMER

T2 - UPPER OVEN TIMER

TR 2

13 35

X1

H1

9

11

E

X2

H2

X3

H3

TB1 - MAIN POWER TERMINAL BLOCK

TH1 - LOWER OVEN HIGH LIMIT THERMOSTAT

TH2 - UPPER OVEN HIGH LIMIT THERMOSTAT

TH3 - LOWER OVEN THERMOSTAT

TH4 - UPPER OVEN THERMOSTAT

TR1 - STEP DOWN TRANSFORMER - LIGHTS

TR2 - STEP DOWN TRANSFORMER - CONTROL

X4

H4

3637

U4189A

Page 16

BAKERS PRIDE LIMITED WARRANTY

914 / 576 - 0200 US & Canada: 1 - 800 - 431 - 2745 fax 914 / 576 - 0605

30 Pine Street New Rochelle, New York 10801

WHATISCOVERED This warranty covers defects in material and workmanship under normal use, and applies only to the original purchaser

WHO IS COVERED This warranty is extended to the original purchaser and applies only to equipment purchased for use in the U.S.A.

COVERAGE PERIOD Cyclone Convection Ovens:

WARRANTY

COVERAGE for all

EXCEPTIONS All removable parts in BAKERS PRIDE Char-broilers, including but not limited to: Burners, Grates, Radiants, Stones and

EXCLUSIONS

Negligence or acts of God,

Thermostat calibrations after (30) days from equipment

installation date,

Air and Gas adjustments,

Light bulbs,

Glass doors and door adjustments,

Fuses,

Char-broiler work decks and cutting boards,

Tightening of conveyor chains,

Adjustments to burner flames and cleaning of pilot burners,

Tightening of screws or fasteners,

providing that:

The equipment has not been accidentally orintentionally damaged, altered or misused;

!

The equipment is properly installed, adjusted, operated and maintained in accordance with National and local

!

codes, and in accordance with the installation instruction provided with the product;

The serial number rating plate affixed to the equipment has not been defaced or removed.

!

GDCO Models: Two(2)Year limited parts and labor; (2) Yearlimiteddoor warranty.

CO11 Models:

All Other Products: One (1) Year limited parts and labor. Warranty period begins the date of dealer invoice to customer or

ninety (90) days after shipment date from BAKERS PRIDE - whichever comes first.

This warranty covers on-site labor, parts and reasonable travel time and travel expenses of the authorized service

representative up to (100) miles, round trip, and (2) hours travel time. The purchaser, however, shall be responsible

expenses related to travel, including time, mileage and shipping expenses on smaller counter models that may be carried into

a Factory Authorized Service Center, including the following models: PX-14, PX-16, P18, P22S, P24S, PD-4, PDC, WS

Series and BK-18.

Valves,arecovered for a period of SIX MONTHS.

All Ceramic Baking Decks are covered for a period of THREE MONTHS. The installation of these replacement decks is the

responsibility of the purchaser.

The extended Cyclone door warranty years 3 through 5 is a parts only warranty and does not include labor,travel, milage or

any other charges.

Two (2) Yearlimitedpartsand labor; (5) Yearlimited door warranty.

BCO Models: One (1) Yearlimitedpartsand labor; (1) Yearlimiteddoor warranty.

Failures caused by erratic voltages or gas supplies,

Unauthorized repair by anyone other than a BAKERS PRIDE

Factory Authorized Service Center,

Damage in shipment,

Alteration, misuse or improper installation,

Thermostats and safety valves with broken capillary tubes,

Accessories spatulas, forks, steak turners, grate lifters,

oven brushes, scrapers, peels, etc.,

Freight other than normal UPS charges,

Ordinary wear and tear.

INSTALLATION Leveling and installation of decks, as well as proper installation and check out of all new equipment per appropriate

REPLACEMENT BAKERS PRIDE genuine Factory OEM parts receive a (90) day materials warranty effective from the date of

PARTS BAKERS PRIDE FactoryAuthorizedService Center.

This Warranty is in lieu of all other warranties, expressed or implied, and all other obligations or liabilities on the manufacturers part. BAKERS PRIDE

shall in no event be liable for any special, indirect or consequential damages, or in any event for damages in excessof the purchase price of the unit. The

repair or replacement of proven defective parts shall constitute a fulfillment of all obligations under the terms of this warranty.

installation and use materials is the responsibility of the dealer or installer,notthemanufacturer.

installation by a

Form #U4177A 3/04

16

Loading...

Loading...