Page 1

Installation & Operation Manual

BAKERS PRIDE

®

E300 SPEED OVEN

Page 2

INSTALLATION AND OPERATING INSTRUCTIONS

Bakers Pride® E300 Speed Oven

INTENDED FOR OTHER THAN HOUSEHOLD USE RETAIN

THIS MANUAL FOR FUTURE REFERENCE OVEN MUST BE

KEPT CLEAR OF COMBUSTIBLES AT ALL TIMES

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury or death. Read the installation, operating and maintenance instructions

thoroughly before installing or servicing this equipment.

Cooking Solutions Group

This equipment has been engineered to provide you with year round dependable service when

used according to the instructions in this manual and standard commercial kitchen practices.

Bakers Pride Oven Company, LLC is a wholly owned subsidiary of Standex International Corporation.

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual for the life of the equipment.

For Warranty Service and/or Parts, this information is required.

Model Number Serial Number Date Purchased

1307 N. Watters Road

Suite 180, Allen, TX 75013

9/18

www.bpspeedoven.com

www.bakerspride.com

western@standexcsg.com

central@standexcsg.com

eastern@standexcsg.com

800.527.2100

972.908.6100

Cooking Solutions Group

Page 3

Table of Contents

Safety Information

Microwave Exposure Precautions 4

General Safety Information 5

General Safety Information - French 6

Installation Information

Receiving 7

Set Up 7

Minimum Clearances 8

Electrical Connections 8

Cleaning And Maintenance

Catalytic Converter 9

Cook Rack And Jetplates 9

Oven Cavity 10

Oven Maintenance Guidelines 10

Oven Programming

Home Screen - Cook Screen 11

Cook Screen - Resume Screen 11

Menu Set Up Screen - Group Edit Screen 13

Item Edit Screen 14

System Set Up - Manager Settings Screen 15

Oven Statistics - Controller Settings - Menu File Screens 16

Wiring Diagrams

E300 17

Exploded Views 18

Service Parts

Part Numbers 20

Limited Warranty Information 21

Page 4

Safety Information

FOR YOUR SAFETY: Not For Built-In Installation. For Use Only In Professionally Staffed Commercial

Kitchens. Not For Use In Areas Accessible To The General Public.

FOR YOUR SAFETY: Do not store or use gasoline or other flammable vapors or liquids in the vicinity of

this or any other appliance.

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause property

damage, injury or death. Read the Installation, Operating and Maintenance Instructions thoroughly

before installing or servicing this equipment.

WARNING: Initial heating of oven may generate smoke or fumes and must be done in a well-ventilated

area. Overexposure to smoke or fumes may cause nausea or dizziness.

WARNING: To provide continued protection against electric shock, connect to properly grounded outlets

only.

CAUTION: This Device is to be Serviced Only by Properly Qualified Service Personnel. Consult the

Service Manual for Proper Service Procedures to Assure Continued Compliance With the Federal

Performance Standard for Microwave Ovens and for Precautions to be Taken to Avoid Possible Exposure

to Excessive Microwave Energy.

WARNING: Risk of electric shock. Non-removable fasteners are provided because of internal high

voltages. Do not remove fasteners.

California Residents Only. This product can expose you to chemicals including chromium which is

known to the State of California to cause cancer and birth defects or other reproductive harm. For more

information go to www.P65Warnings.ca.gov.

PRECAUTIONS TO AVOID POSSIBLE EXPOSURE

TO EXCESSIVE MICROWAVE ENERGY

(a) Do not attempt to operate this oven with the door open since open-door operation can

result in harmful exposure to microwave energy. It is important not to defeat or tamper

with the safety interlock switches.

(b) Do not place any object between the oven front face and the door or allow soil or

cleaner residue to accumulate on sealing surfaces.

(c) Do not operate the oven if it is damaged. It is particularly important that the oven door

close properly and that there is no damage to the: (1) Door (bent), (2) hinges and

latches (broken or loosened), (3) door seals and sealing surfaces.

(d) The oven should not be adjusted or repaired by anyone except properly qualified

service personnel.

4

Page 5

Safety Information

• Read all instructions before using the appliance

• Read and follow the specific PRECAUTIONS TO AVOID POSSIBLE EXPOSURE TO EXCESSIVE MICROWAVE

ENERGY located on page 4 of this manual.

• This appliance must be grounded. Connect only to a properly grounded outlet. See GROUNDING INSTRUCTIONS

located on page 8 of this manual.

• Install or locate this appliance only in accordance with the provided installation instructions.

• Some products like whole eggs and sealed containers - for example, closed glass jars - are able to explode and

should not be heated in this oven.

• Use this appliance only for its intended use as described in the manual. Do not use corrosive chemicals or vapors

in this appliance. This type of oven is specifically designed to heat, cook, or dry food. It is no designed for industrial

or laboratory use.

• As with any appliance, close supervision is necessary when used with children.

• Do not operate this appliance if it has a damaged cord or plug, if it is not working properly, or if its been damaged

or dropped.

• This appliance should be serviced only by qualified service personnel. Contact the nearest authorized service

facility for examination, repair, or adjustment.

• Do not cover or block any openings on the appliance.

• Do not store this appliance outdoors. Do not use this product near water - for example, near a kitchen sink, in a

wet basement, near a swimming pool, or similar location.

• Do not immerse cord or plug in water.

• Keep cord away from heated surfaces.

• Do not allow cord to hang over edge of table or counter.

• When cleaning surfaces of door and oven that meet when the door closes, use only mild, nonabrasive soaps, or

detergents applied with a sponge or soft cloth.

• To reduce the risk of fire in the oven cavity:

i) Do not over cook food. Carefully attend appliance when paper, plastic, or other combustible materials are

placed inside the oven to facilitate cooking.

ii) Remove wire twist-ties from paper or plastic bags before placing bag in oven.

iii) If materials inside the oven ignite, keep the oven door closed, turn the oven off, and disconnect the

power cord, or shut the power off at the circuit breaker panel.

iv) Do not use the cavity for storage purposes. Do not leave paper products, cooking utensils, or food in the

cavity when not in use.

• Liquids, such as water, coffee, or tea are able to be overheated beyond the boiling point without appearing to be

boiling.

• Visible bubbling or boiling is not always present when the container is removed from the microwave oven. THIS

COULD RESULT IN VERY HOT LIQUIDS SUDDENLY BOILING OVER WHEN THE CONTAINER IS DISTURBED

OR A UTENSIL IS INSERTED INTO THE LIQUID.

5

Page 6

Consignes De Sécurité Importantes

Lors de l'utilisation d'appareils électriques précautions de sécurité de base doivent être respectées, y compris ce qui suit:

AVERTISSEMENT - Pour réduire les risques de brûlure, électrocution, d'incendie, de blessure ou d'exposition à l'énergie micro-ondes

excessive:

• Lisez toutes les instructions avant d'utiliser l'appareil.

• Lire et suivre les précautions spécifiques “POUR ÉVITER UNE EXPOSITION EXCESSIVE AUX MICRO-ONDES” (Situé ci-dessous et

page suivante).

• Cet appareil doit être mis à la terre. Connectez seulement à une prise de terre. Voir “INSTRUCTIONS DE MISE” trouvés sur la page

8.

• Installer ou placer l'appareil conformément aux instructions d'installation fournies.

• Certains produits comme les œufs entiers et des contenants scellés - par exemple, bocaux en verre fermés - peuvent exploser et ne

devraient pas être chauffés dans ce four.

• Utilisez cet appareil uniquement pour son usage prévu comme décrit dans le manuel. Ne pas utiliser de produits chimiques corrosifs

dans cet appareil. Ce type de four a été spécialement conçu pour chauffer, cuire ou sécher des aliments. Il n’est pas conçu pour un

usage industriel ou de laboratoire.

• Comme pour tout appareil, une surveillance étroite est nécessaire quand il est utilisé par les enfants.

• Ne pas utiliser cet appareil si le cordon ou la fiche est endommagé, s'il ne fonctionne pas correctement, ou si elle a été endommagée

ou supprimée.

• Cet appareil ne doit être effectué que par du personnel qualifié. Contactez le centre de service agréé le plus proche pour examen,

réparation ou réglage.

• Ne pas couvrir ou bloquer les ouvertures de l’appareil.

• Ne pas stocker cet appareil à l'extérieur. Ne pas utiliser ce produit près de l'eau - par exemple près d' un évier de cuisine , dans un

sous-sol humide , près d’une piscine , ou des endroits similaires .

• Ne pas immerger le cordon ou la fiche dans l’eau.

• Garder le cordon loin des surfaces chauffées.

• Ne laissez pas le cordon pendre de la table ou du comptoir.

• Lors du nettoyage de surfaces de la porte et du four qui se réunit à la fermeture de la porte , utilisez uniquement douces , savons

non abrasifs ou de détergents appliqués avec une éponge ou un linge doux

• Afin de réduire le risque d'incendie dans la cavité du four :

a. Ne pas trop cuire les aliments. Surveillez attentivement votre four lorsque du papier , du plastique ou d’autres matériaux

combustibles sont placés à l’intérieur du four pour faciliter la cuisson .

b. Retirer les attaches de sacs en papier ou en plastique avant de les placer dans le four.

c. Si les matériaux à l'intérieur du four prennent feu, garder la porte du four fermée , éteindre le four et débranchez le

cordon d’ alimentation ou coupez le courant au fusible ou panneau de disjoncteurs .

d. Ne pas utiliser la cavité à des fins de stockage. Ne laissez pas de produits en papier, ustensiles de cuisine, ou de la

nourriture dans la cavité lorsqu’il n’est pas utilisé.

• Les liquides tels que l’eau, le café ou le thé peuvent être surchauffés au-delà du point d'ébullition sans sembler bouillir. Bullage ou

ébullition visible lorsque le récipient est retiré du four à micro-ondes ne sont pas toujours présents. CELA POURRAIT PROVOQUER

DES LIQUIDES TRÈS CHAUDS SOUDAIN bouillante sur lorsque le récipient est perturbé ou un ustensile est inséré dans le LIQUIDE

Avertissement: Pour assurer une protection continue contre les chocs électriques, se connecter à des

prises correctement mise à la terre

ATTENTION: Cet appareil doit être réparé que par du personnel qualifié de service. Consultez le manuel

d’entretien pour les procédures de service appropriées pour assurer la conformité continue avec

la norme fédérale performance pour Micro-ondes et pour les précautions à prendre pour éviter une

éventuelle exposition excessive à micro-ondes de l’énergie

AVERTISSEMENT: Risque de choc électrique. La non-fixation amovibles sont prévus en raison de fortes

6

tensions internes. Ne pas retirer les attaches.

Page 7

Installation Information

Receiving

Read the notice on the outside carton regarding damage in transit. Damage discovered after opening the carton is

“CONCEALED DAMAGE.” Carrier must be notified immediately to send an inspector and to furnish forms for claims

against the carrier.

When the oven arrives, it should consist of:

• One Peel

• One PTFE Solid Basket

• One PTFE Perforated Mesh Basket

• 2 oz Cleaner

• 2 oz Shield

• Installation & Operation Manual

• A crate or carton containing your new oven.

When unpacking the oven:

• Remove all packing material from unit

• Never lift the oven with only one person

• Retain instruction manual for future reference

• Never lift oven by the handle

Set Up/Mounting

Your oven will be packed sitting on its bottom. The skid may be left under the oven for convenience in further

handling. Unpack carefully, avoiding damage to the Stainless Steel front and/or trim. If concealed damage is found,

follow the instructions detailed in the Receiving section above.

• Keep the area around the ovens free and clear of combustible materials.

• Do not store any materials on top of or under any oven.

• Do not position the unit so that hot air is drawn in from fryers, grill, griddles or other appliances.

• A heat barrier the height of the oven will be required if installed by a burner, fryer, or excessive heat source.

• Adequate air supply to the oven for ventilation is essential. As a minimum, observe the clearances detailed on page

8 (Minimum Clearances and Approved Locations). Provide adequate ventilation and make up air in accordance

with local codes.

• The intake air is located on the left and right sides at the front of the oven. To prevent deteriorating the life and

performance of the oven the intake air should be as cool as possible and not preheated by other appliances.

• Allow sufficient clearance in front of the unit for the door to open completely.

NOTICE: Local codes regarding installation vary greatly from one area to another. The National Fire

Protection Association, Inc., states in its NFPA 96 latest edition that local codes are the “authority

having jurisdiction” when it comes to requirements for installation of equipment. Therefore, installations

should comply with all local codes.

This unit is supplied with a closed cell pad that will seal the unit to the counter top. When using the closed cell foam

pads for final installation, the edges of the pad must be sealed with an FDA/NSF approved silicone sealant after the

unit is placed into position. This unit can also be used with optional 4” legs to by-pass FDA/NSF requirements.

The ovens are designed to be stackable at a maximum height of two units. To stack two units, use the foam pad

provided. Remove the center section of the pad before placing on the bottom oven to allow a more stable installation.

Proper lifting methods must be used for safety. Each oven must have a dedicated power supply. (If the leg option

is used for a stackable installation, only the bottom oven receives the legs, the foam pad must be used between

ovens).

7

Page 8

Installation Information

NOTICE: Local codes regarding installation vary greatly from one area to another. The National Fire

Protection Association, Inc., states in its NFPA 96 latest edition that local codes are the “authority

having jurisdiction” when it comes to requirements for installation of equipment. Therefore, installations

should comply with all local codes.

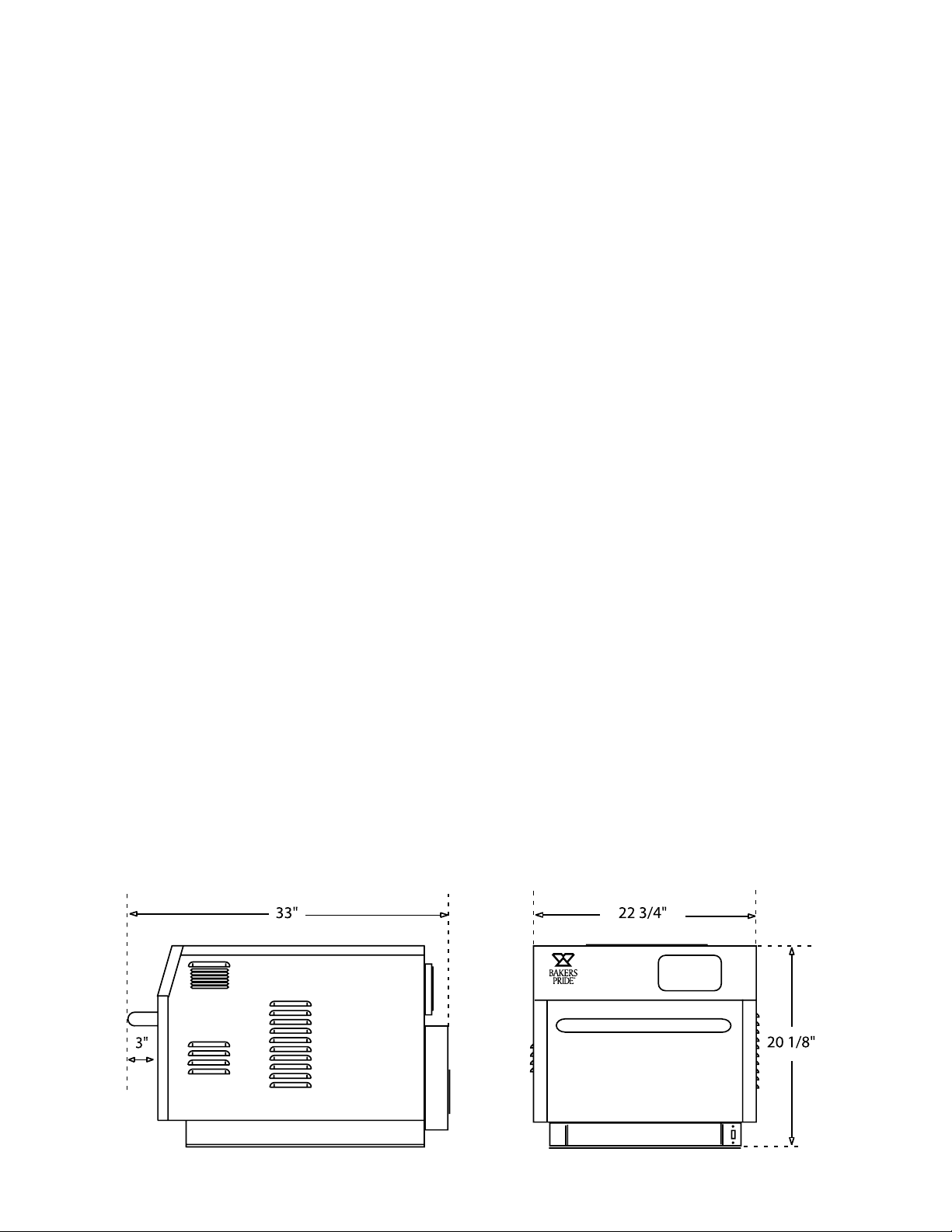

Minimum Clearances and Approved Locations

Move the oven to its final location keeping the minimum clearance from the back of the oven to the wall. This

clearance is necessary for safe operation and to provide proper air flow.

The oven is designed for countertop installation and is not recommended for built-in installation. The oven requires

adequate air to cool the electronic controls. Operating the oven at elevated temperatures may reduce reliability and

overall performance of the oven.

If the oven is to be installed close to a major heat source including char grills, griddles and fryers, minimum

clearances must be observed and a radiant/thermal heat barrier installed between the heat source and the oven.

Adequate access to electrical connections, and side panels must be provided for any future service. The operator

may be responsible for any additional labor fees if required.

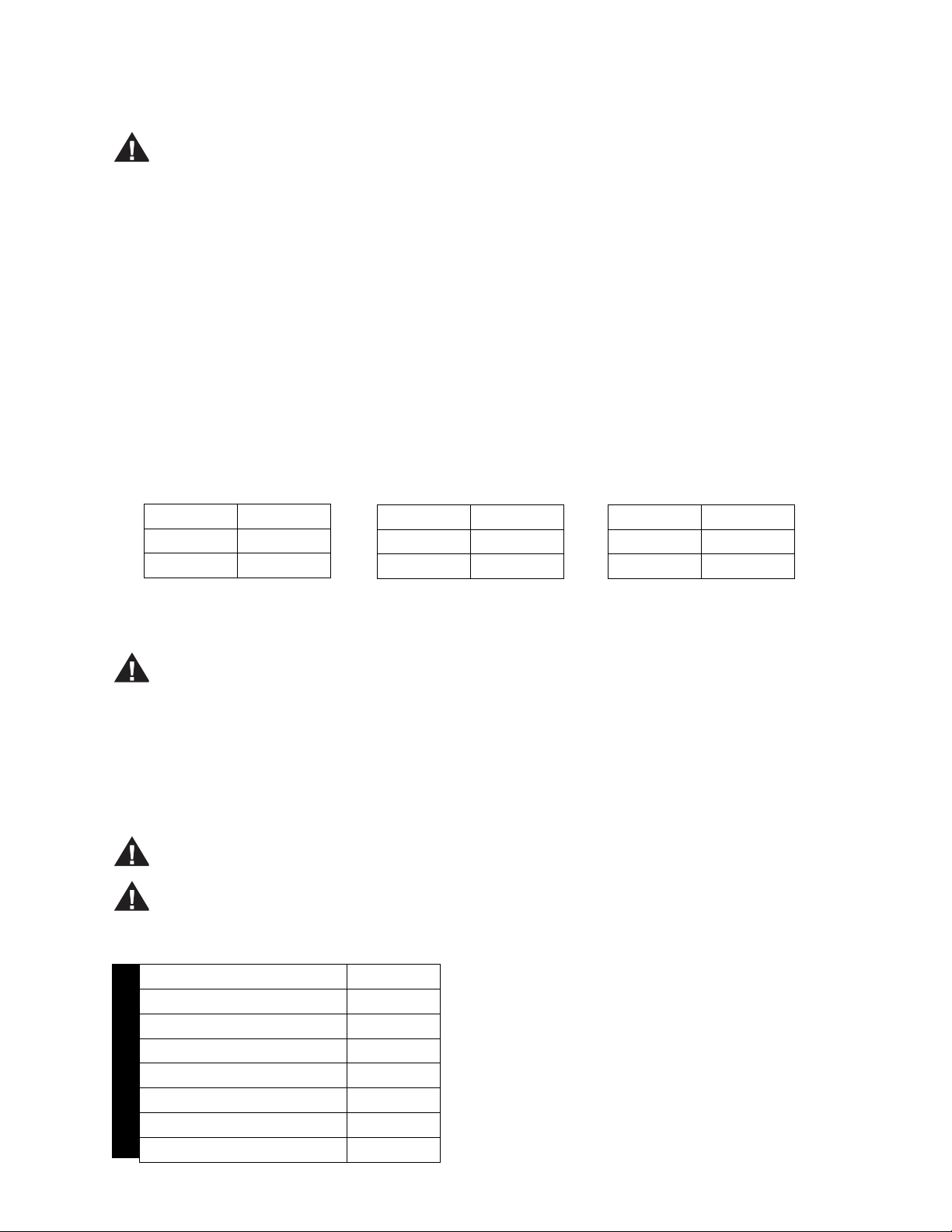

Minimal Clearances from Combustible and Noncombustible Construction

Sides 2 Inches

Rear 2 Inches

Top 2 Inches

No Surrounding Heat Source

CAUTION: Do not set the oven with its back flat against the wall. It will not operate properly unless there

is at least two inches breathing space behind the oven.

Sides 6 Inches

Rear 2 Inches

Top 2 Inches

Minor Surrounding Heat

Source; e.g. Heat Lamps & Warmers

Sides 12 Inches

Rear 2 Inches

Top 2 Inches

Major Surrounding Heat Source;

e.g. Fryers, Grills & Griddles

Electrical Connection

Install according to the spacing requirements listed in the installation section of this manual. We strongly

recommend having a competent professional install this equipment. A licensed electrician should make the

electrical connections and connect power to the unit. Local codes should always be used when connecting these

units to electrical power. In the absence of local codes, use the latest version of the National Electrical Code.

CAUTION: This Appliance Must be Grounded. Failure to do so May Result In Electrical Shock and Death.

CAUTION: The oven, when installed, must be electrically grounded in accordance with local codes and/

or the latest edition of the National Electrical Code ANSI/NFPA No. 70 in the USA (Canadian Electrical

Code CSA Standard C22.1, Part 1 in Canada).

VOLTAGE 208/240

FREQUENCY 60 HZ

SERVICE REQUIRED 30 AMP

PHASE SINGLE

TOTAL WATTAGE 5.4 kW

MAGNETRON WATTS 2.2 kW

MODEL E300

HEATER WATTAGE 3.2 kW

RECEPTACLE REQUIRED NEMA 6-30

8

Page 9

Cleaning and Maintenance

WARNING: Unit is not waterproof. To avoid electrical shock or personal injury, DO NOT submerge in

water. DO NOT operate if it has been submerged in water. DO NOT clean the unit with a water jet. DO NOT

steam clean or use excessive water on the unit.

CAUTION: Use mild detergent or soap solution for best results. Abrasive cleaners could scratch the

finish of your unit, marring its appearance and making it susceptible to dirt accumulation. DO NOT use

abrasive cleaners or a cleaner/sanitizer containing chlorine, iodine, ammonia or bromine chemicals as

these will deteriorate the stainless steel and glass material and shorten the life of the unit. Use nylon

scouring pads. Do not use steel wool.

Catalytic Converter

The oven utilizes a catalytic converter system that filters the cooking cavity air reducing grease and odors from the

room. This catalyst contains a microscopic layer of a specific compound that reduces the ignition temperature of

grease. When the cavity air is moved through the catalyst, the grease laden air is reduced to CO2 and H2O. The

catalyst is maintenance free and will continue to operate without issue through the life of the oven. However, proper

care is required when choosing the chemicals used to clean the cavity in order to ensure longevity.

The catalyst is sensitive to particular compounds found in common degreaser and industrial cleaners. Potassium

salts, phosphates, silicates, and other caustic compounds can cause irreversible damage. This damage can result in

reduced catalyst performance causing grease, smoke and odors to be in the room.

Bakers Pride provides an approved cleaner for purchase and recommends any alternatives be checked to determine

their chemical content so not to cause damage.

The catalyst is located directly behind the back wall and does not need to be removed for cleaning

Cook Rack

Open the door and remove the wire rack. Take rack to the sink and thoroughly clean in warm water with mild

detergent or soap. Use a nylon scouring pad or stiff nylon brush.

Do not use steel wool.

Lower Jetplate

Open the door and remove the wire cooking rack and remove lower jet plate by pushing back and lifting up on

the knob. Take the panel to the sink and thoroughly clean in warm water with mild detergent or soap. Use a nylon

scouring pad or stiff nylon brush.

Do not use steel wool.

Upper Jetplate

The upper jet plate may not need removed for daily cleaning. A simple wipe may be all that is needed based on

usage and product type.

Open the door and remove the upper jet plate by pushing back and pulling down on the knob. Take the panel to the

sink and thoroughly clean in warm water with mild detergent or soap. Use a nylon scouring pad or stiff nylon brush.

Do not use steel wool.

9

Page 10

Cleaning and Maintenance

Oven Cavity

With the door open, the rack and jet plate(s) removed, wipe out inside of the oven with a clean, damp cloth. Use a

nylon scouring pad dampened with approved cleaning chemical or stiff nylon brush to remove any baked on debris.

Use a clean towel dampened with clean water to thoroughly wipe out inside to remove any cleaner residue and food

particles.

Do not use steel wool.

Keep cleaning fluids away from electrical wires, light sockets, switches, and the control panel.

Oven Exterior

To remove common dirt or product residue from stainless steel, use ordinary soap and water (with or without

detergent) applied with a sponge or cloth. Dry thoroughly with a clean cloth. Never use vinegar or corrosive cleaner.

Do not use chlorine based cleaners.

To remove grease and food splatter or condensed vapors that have baked on the equipment, apply cleaners to a

damp cloth or sponge and rub cleanser on the metal in the direction of the polished lines on the metal. Rubbing

cleanser as gently as possible in the direction of the polished lines will not mar the finish of the stainless steel. To

remove discoloration, use a non-abrasive cleaner. NEVER use a wire brush, steel or abrasive scouring pads, scraper,

file or other steel tools. NEVER RUB WITH A CIRCULAR MOTION.

Oven Maintenance

NOTE: This appliance must be serviced by a factory authorized service agent. Unauthorized service or

repairs may void the manufacturers warranty.

• Power supply to the unit must be disconnected before any service is performed.

• Most of the service on this unit can be performed from the top and/or right side.

• It will be necessary to have access to the back of the oven for service needs related to the electric power supply.

However, for proper servicing, access to all sides is recommended.

• A system wiring diagram is provided in the back of this document as well as attached to the inside of the right side

oven panel.

• All servicing should be performed by a factory-authorized technician only.

• For proper maintenance and repairs, call the factory toll free (800.431.2745) for an authorized service agency in

your area.

CAUTION: This product, when stacked, has more than one power-supply connection point. Disconnect all

power supplies before servicing.

10

Page 11

Oven Programming

Home Screen

Open Door to Speed Cooling/Oven Temp = 187F

SERIAL NUMBER:

MANUFACTURED DATE:

SOFTWARE VERSION:

Oven is Cooling Down

Press Power Button to Turn On

Home Off Screen

• This screen will turn the oven power ON. Turning the

oven power OFF from subsequent screens will return

to this screen.

• This screen displays the manufactured date, serial

number of the unit and the current software versions

installed.

Cook Menu Setup System Setup Help

Bakers Pride SPEED COOKING

562071502001

02/15/15

GEMINI_DC_00.98

GEMINI_IO_00.05

11:20:45 AM

Friday, February 27

Cook Screen

Cook Menu Setup System Setup Help

Select Group

Vegetables

Hot Dog Pizza Wings

Back

Breakfast Dinner

Page 1 of 2

Cook Group Screen

• Pressing the COOK tab will show all the groups.

• Groups are menu categories that have sub categories

called items. Groups can be programed with

independent set cook temperatures.

• The program supports 16 groups with each group

having 24 items for a total of 384 possible recipes

stored in memory.

• Press the arrow buttons to move between pages.

• Press the BACK button to return to the Home ON

screen.

• Press the power icon to return to the Home OFF

screen.

French Fries

Quesadilla

Oven Warming Select Operation

Home On Screen

• After pressing the ON icon from the previous screen,

the oven will warm and display this screen.

• This Home ON screen displays the current time

and date and the message “Oven Warming Select

Operation”.

• This message will remain displayed until a function

tab is pressed.

• The oven will warm to the lowest group set point

temperature.

• Pressing the green OFF icon in the bottom right will

return to the Home OFF screen.

• Pressing the BACK key in any mode will eventually

return to this Home ON screen.

Set Point 500 F

Dinner

12%

80 F

Preheating Oven. Please wait...

Cancel

Pre Heat Screen

• After choosing a group, the oven must be at the set

temperature before the item screen is displayed.

• The screen displays the group name, set point and

actual cavity temperatures with a bar graph showing

progress.

• A pre heated oven will not display this screen.

11

Page 12

Oven Programming

Cook Screen

Selected Group: Dinner Selected Group: Dinner

Select Item

Add New

Potato

Back

Lasagna

Mac &

Cheese

Page 1 of 3

Fish Sticks Hamburger

Shrimp

Egg Roll

Cook Item Screen

• After choosing the group, the items are displayed.

• Press the arrow buttons if more than 8 items are

programmed in that particular group.

• Place the product in the oven and select the

corresponding icon to start a cook cycle.

• Press Back to return to the Group screen.

Selected Group: Dinner

Cook

More

Brown

More

Cook &

Brown

Time Remaining 00:42

Hamburger

Cooking...

66%

Cook

More

Brown

More

Cook &

Brown

Cancel

Time Remaining 00:00

Hamburger

Cooking Complete

100%

Cook Complete Screen

• At the completion of the cook cycle, the three “More”

buttons become active to add to the cook cycle if

desired.

• Cook More is microwave only, Brown More is

impingement air only, and Cook & Brown is both.

• Each press of the button adds 20% of the total cook

time of the last cycle, but not less than 15 seconds or

more than one minute.

• Additional time can be added by pressing the same

“More” button. Each press of the button will add

another 15 seconds to the time remaining to a

maximum of 5 minutes.

Alert!

Alert!

-- Door Closed --

12

Cancel

Cook Screen

• The cook screen displays the group name at the top

and the item name below.

• A countdown timer with a status bar showing

percentage of progress.

• Three buttons for adding more time to the cook are

shown on the left. These remain inactive until the end

of the programmed cook cycle.

• Pressing the cancel button or opening the door stops

the cook cycle

• An option to resume the cook cycle is displayed after

the door has been re-closed.

Press Screen to Resume Cooking or

Press Cancel to End the Cook Cycle

Cancel

Alert!

Alert!

Resume Screen

• The resume screen is displayed after a completed

cook cycle and after the door is closed.

• Pressing cancel will return to the item screen.

• Pressing any other part of the screen will return to

the “More” screen to add additional time to the cook

cycle.

Page 13

Oven Programming

Menu Set Up

Cook Menu Setup System Setup Help

11:20:45 AM

Friday, February 27

Bakers Pride SPEED COOKING

Oven Warming Select Operation

Home ON Screen (menu setup)

• Selecting the Menu Setup tab allows the operator

access to group and Item menu editing.

• In this example, the operator is selecting the tab from

the Home Screen, but it can be selected from any

screen that presents the operator with tabs.

Cook Menu Setup System Setup Help

Select Group

Add New

Vegetables

Back

Hot Dog Pizza Wings

Breakfast Dinner French Fries

Page 1 of 2

Menu Setup Group Screen

• Selecting Menu Setup will display the temperature

groups that have been programmed into the oven

along with the “Add New” group.

• If no groups have been programmed in the oven, the

“Add New” icon will be the only icon displayed.

• Selecting an existing group or Add New will advance to

the Group Edit Screen.

• The oven has the ability to store 16 groups with

24 items embedded in each group. The maximum

number of stored recipes is 384.

Group Edit / Create

Group Name:

Group Temperature:

PIZZA

500 F

Group Image:

Back

Save Delete Edit Item

Menu Setup Group Edit Screen

• Selecting the Group Name field brings up an alpha

numeric keyboard. A maximum of 24 characters can

be entered for the description.

• Selecting the Group Temperature field brings up a

numeric keypad. The temperature range is 150F 525F in 5 degree increments. 500F is recommended

for most speed oven recipes. Every item within

this particular group will cook at the this selected

temperature.

• Selecting the Group Image field brings up a collection

of pre-programmed images. Press the desired image

to select.

• Selecting Back will cancel the editing, discard any

changes, and return to the Group Programming

screen.

• Selecting Save will display a dialog box asking for

confirmation, selecting OK will save all changes.

• Selecting Delete after a previously save group will

bring up a dialog box asking for the manager PIN

before deleting the entire group.

• Selecting Item Edit will change the display to the

Item Edit screen. If changes were made to the Group

Edit screen prior to pressing Item Edit, press Save to

ensure any changes will be stored in memory before

moving forward.

• Selecting the green power icon in the lower right

corner of any screen will place the oven in the Off

mode. If the oven cavity temperature is above 150F,

the oven will enter a Cool Down Mode. The oven will

run the cooling fans and the blower motor until the

cavity temperature drops below 150F. The fans will

automatically shut off and the display will return to the

Home Off Screen.

13

Page 14

Oven Programming

Menu Set Up

Selected Group: Dinner

Select Item

Add New

Potato

Back

• Selecting a group from the Group Edit screen will

display the Item Edit screen shown above.

• The “Add New” button is available in the upper left

corner to create additional recipes.

• A maximum of 24 items in memory are possible for

every group.

• Scroll through the item pages by pressing the

highlighted arrow located at the bottom of the screen.

• The left side arrow advances through the listing and

the right side arrow returns backwards.

Selected Group: Dinner

Item Name: Lasagna

Stage Time %Air %MW Order Image

1 01:00 20 80 10

2 01:00 30 60

3 02:00 50 50

4 00:30 80 50

5

6

Lasagna

Mac &

Cheese

Fish Sticks Hamburger

Shrimp

Page 1 of 3

Menu Setup Item Screen

Egg Roll

Total Time:

04:30

• Selecting either the Time, %Air, or the %MW will bring

up a numeric keyboard.

• The maximum cook time in any event and recipe is 10

minutes. The control will not accept longer times.

• The Total Time field is automatically populated as the

time is entered into the stage(s).

• Airflow in the oven cavity is controlled with the %Air

setting. Adjustments can be made from 0% to 100%

in 10% increments.

• Microwave energy is controlled with the %MW button.

Percentage settings reflect the amount of time the

microwaves are being directed to the product in that

particular cooking stage.

• Selecting Order will bring up a numeric keyboard.

This number dictates the order in which this particular

item appears on the Item Screen. Positioning

frequently cooked items on the first page can increase

productivity.

• Selecting the Image Icon will bring up the list of preprogrammed images. Choose the image and press

Save to continue back to the Item Edit Screen. (See

illustration below).

• Selecting Delete with erase all information regarding

this particular Item. A prompt will appear asking to

confirm before erasing.

• Selecting Save will place all changes into memory. The

Back button will need to be pressed to return to the

Menu Setup Item Screen, and then again to return to

the Menu Setup Group Edit Screen. Then once more

to return to the Menu Setup Screen.

• Select Cook to enter the cooking mode.

Image Select

14

Back

Save Delete

Item Edit Screen

• Selecting the Item Name field brings up a numeric

keyboard. A maximum of 24 characters can be used

for the description.

• Depending on the density and characteristics of the

product, the oven can utilize a maximum of 6 stages

or events during the total cook time.

• The stages are used to allow the food to rest between

microwave events to keep internal temperatures

uniform throughout and without extreme temperatures

during the cooking process.

Back

Page 1 of 2

Image Select Screen

Page 15

Oven Programming

System Set Up

Cook Menu Setup

System Setup Help

Manager Settings

Manager

Settings

System Setup Screen

Service

Settings

• Full access to the System Setup Screen must be done

with the oven in the Off state. With the oven in the On

state, multiple functions are not available. Press the

green icon in the lower right corner return to off.

• If the oven cavity temperature is above 150F, the oven

will enter a cool down mode. This mode will continue

until the oven cavity temperature drops below 150F.

• NOTE: To by-pass the cool down mode, use the

momentary rocker switch located under the right front

panel of the oven to reset the control. This switch

interrupts the power supplied to the controls which

returns the oven to the off state after the rebooting

process.

• The System Setup Screen displays two function

buttons, Manager Settings and Service Settings. Both

require passwords to enter.

• The Cool Down Screen appears if the oven cavity

temperature is above 150F when the oven is turned

off.

Cook Menu Setup

System Setup Help

Enter Manager Pin

1234

1 2 3

4 5 6

7 8 9

Back

Cancel 0 Enter

Manager PIN Screen

• The blower motor speed is 40%.

• The oven ships with the Manager PIN factory set at

1234.

• This PIN can be changed upon entry.

Cook Menu Setup

System Setup Help

Manager Settings

Oven

Statistics

Controller

Settings

Menu

Files

Back

Manager Setting Screen

Open Door to Speed Cooling/Oven Temp = 187F

SERIAL NUMBER:

MANUFACTURED DATE:

SOFTWARE VERSION:

Oven is Cooling Down

Press Power Button to Turn On

562071502001

02/15/15

GEMINI_DC_00.98

GEMINI_IO_00.05

Cool Down Screen

• The cabinet cooling fans, magnetron cooling fan, and

the blower motor operate until the temperature drops

below 150F.

• Press 1-2-3-4-ENTER to access the manager settings

screen.

• The dialog box “Incorrect PIN” will appear if the

incorrect PIN is entered allowing another attempt.

• If the manager has changed the password and is not

available, a master PIN has been developed in order

to gain access.

• NOTE: Contact Bakers Pride service support to unlock

password settings with the master PIN.

• The Manager Settings Screen allows access to Oven

Statistics, Controller Settings, and Menu Files.

15

Page 16

Oven Programming

16

System Setup

Oven Statistics

Door Cycles: XXXXX

Cook Cycles: XXXXX

Oven On Time: XXXXD XXH XXM

Mag 1 On Time: XXXXD XXH XXM

Mag 2 On Time: XXXXD XXH XXM

Heater 1 On Time: XXXXD XXH XXM

Heater 2 On Time: XXXXD XXH XXM

Blower On Time: XXXXD XXH XXM

Back Reset

Oven Statistics Screen

• Operation is logged by days, hours and minutes for

magnetron, heaters, blower and overall on time.

• Door cycles and cook cycles are also counted.

• These numbers can be reset by pressing the reset

button. A prompt will appear asking for confirmation

before resetting.

• Selecting the Date, or Time field brings up a numeric

keypad. The date and time is used in the Oven

Statistics function and in the Home On Screen.

Controller Settings

Date: XXM / XXD / XXXXY

Time: 00H:00M AM

Speaker Volume: 80% + –

Display Brightness: 90% + –

Speaker Volume: F

Enable/Disable Recipe Edit: Enable

Manager PIN Manintenance: 1234

Back Save

Controller Setting Screen

• Selecting Speaker Volume + or - will change the

volume only after saving the settings and leaving the

screen.

• Selecting Display Brightness + or - will change the

intensity of the display.

• Selecting Temperature Scale will toggle between

Celsius and Fahrenheit.

• Selecting Enable/Disable Recipe Edit will toggle

between allowing changes to be made in the Menu

Setup Tab.

• Selecting Manager PIN Maintenance will allow the

manager PIN to be changed to any 4 digit number.

Menu File Management

Back

Load

Menu

Menu File Management Screen

Save

Menu

• Menu files are transported through the use of a USB

storage drive. The USB terminal is located at the

bottom right corner under the front panel.

• Insert the USB storage drive into the oven.

• Select “Load Menu” to import the menu files into the

oven from the USB storage drive.

• Select “Save Menu” to export the menu from the oven

into the USB storage drive.

• NOTE: All files are over written during any transaction.

Multiple files can not be stored in either the oven or in

the same folder directory on the USB storage drive.

• A status indicator bar will display the transaction

progress. A dialog box will announce the completion of

the file transfer.

• Press the Back button to return to the Manager

Settings Screen.

Alert!

Alert!

Oven Over Temperature Fault

Please Remove Power and Call

Service Immediately

800-733-2203

Alert!

Fault Screen

Alert!

• The Fault Screen will appear if one of the three

possible fault codes occur.

• Oven Over Temperature, Magnetron Over

Temperature, and Open Thermocouple are the three

faults that will shut down a cook cycle and display the

Fault Screen.

• In the event of a fault screen, cycle power to the unit.

If problem persists, call for service.

Page 17

NOTES:

1. DOOR SWITCH POSITION IS SHOWN WITH THE OVEN DOOR CLOSED

2. WIRES 17, 19, & 45 MUST PASS THRU CURRENT TRANSFORMER COIL T2

3. WIRES 15 & 16 MUST PASS THRU CURRENT TRANSFORMER COIL T1

1

I/O BOARD DETAIL

SECONDARY C SWITCH

OVERTEMP

HIGH LIMIT

MONITOR

MON & PRI

PRIMARY

PRIMARY DOOR SWITCH

(RH SIDE - NO PADDLE)

MONITOR DOOR SWITCH

(RH SIDE - WITH PADDLE)

SECONDARY DOOR SWITCH

(LEFT SIDE)

SAFETY INTERLOCKS DETAIL

MAG OVER TEMP

SWITCH LEFT

MAGNETRON THERMOSTAT DETAIL

EMI CHANGES, GENERAL UPDATES

B

OF

SHEET

NONE

58

54

VOLTAGE

DATE

DRAWN

2

PART NAME REV.

E300 FIELD SERVICE

WIRE DIAGRAM

05/18/16

DATE

GREG HAUN

APRVD.

uF

0.85

44

RELAY

PART NUMBER

Cooking Solutions Group

1

1

21926999

FINISH

SPEC.

TYPE

E300 Speed Oven Wiring Diagram

17

L2

G

L1

G

L1

SURGE PROTECTOR

EMI FILTER

COOLING FANS

LOWER REAR

95

96

UPPER REAR

56

31

RIGHT SIDE

29

30

LEFT SIDE

32

33

L1

62

MOLEX

2

1

36

2

1

28

MOLEX

BROWN

65

ORANGE

24 VAC

1.25 AMP

YELLOW

34

SPEAKER

DISPLAY &

GUI BOARD

22

35

25

23

34

66

65

MOMENTARY

RESET SWITCH

P22

USB

43

27

43

27

1

STIRRERS

24 VAC IN

1

2

55

55

P8

P7

41

41

1

COOLING

1

46

25

26

25

26

2

FANS

VOLTAGE

49

P16

P13

1

24

24

1

2

MAGNETRON

FAN

I/O

CONTROL

RELAY

50

1

1

89

37

38

NO

51

17

51

CT COIL

SEE NOTE 2

2

1

HEATER 1

BOARD

P6

1

P10

2

1

90

MAG

22

46

62

36

28

66

21

19

CT COIL

SEE NOTE 2

1

HEATER 2

P11

1

39

40

C

NO

MX1

MX1

MX1

MX1

MX1

MX1

MX1

MX1

MX1

MX1

MX1

21

2

42

NO

MX2

MOLEX

74

MX2

MOLEX

73

MX2

MOLEX

72

MX2

MOLEX

71

MX2

MOLEX

70

MX2

MOLEX

MX2

MOLEX

63

MX2

MOLEX

67

MX2

MOLEX

68

MX2

MOLEX

69

MX2

MOLEX

I/O BOARD

P10 1 & 2

HTR 1

THERMOCOUPLE

SEE NOTE 1

CT COIL

13

90

89

HTR 2

1600W

CT COIL

P8 P7

SEE NOTE 2

52

45

52

21

1112

223132

1600W

HEATER and FAN

WIRES 17, 19, & 45

T2

J3

RED -

YELLOW +

P11-3

42

C

NO

12

12

20

P16

P13

NC

87

MX3

CT COIL

MAGNETRON

T1

CANBUS to

BLOWER

64

MX4

MOLEX

HI-LIMIT THERMOSTAT

18

WIRES 15 & 16

P6

P10

P4

MOTOR

P11-1

39

M

MAGNETRON COOLING

FAN

2

1

M

RIGHT STIRRER

MOTOR

2

M

1

LEFT STIRRER

MOTOR

BLOWER

BLUE

GRAY

BLOWER MOTOR

POWER SUPPLY

66

BLACK

BLUE

CONTROL TRANSFORMER

35

P3

I/O CONTROL

BOARD

MOTOR

BLACK

P4

I/O CONTROL

BOARD

ECR

DATE

051816

060117

BY

GH

GH

DESCRIPTION

RELEASE

A

B

REV

LINE

208/240 VOLTS

60 HZ 30 AMPS

NEMA-6-30P

L2

LINELOAD

L2

86

76

9

9

LEFT

MAG

P11

P11-2

40

C

NC

NO

8

M2

44

44

15

221

POWER &

COMM to

47

57

MX3

MX3

57

SEE NOTE 3

MONITOR

INTERLOCK

GUI

86

87

MX4

MOLEX

MX4

MOLEX

CT COIL

16

1

CIRCUIT

P11 & P13

P3

P13-4

37

38

C

NO

RIGHT

P13-3

76

75 77

L2

INPUT

L1

84

83

82

81

MX4

MX3

MOLEX

88

MX4

MX3

MOLEX

85

MX4

MX3

MOLEX

MX3

MOLEX

MX4

MX3

MOLEX

MX3

MOLEX

MX4

MX3

MOLEX

51

MX3

MOLEX

75

1010

MX4

MX3

MOLEX

LEFT

MAG

61

RED

RED

3

11

I/O BOARD

P16

CT COIL

SEE NOTE 3

M1

MAG

INTERLOCK CURCUIT

LED STATUS

INDICATORS

PRIMARY

SECONDARY

MONITOR

NC

FUSE BLOCK

L2

F1 FUSE

30 AMP

FUSED

OUTPUT

L1

F2 FUSE

12 AMP

MX4

MX4

MX4

uF

0.85

60

1

2

57

14

2

50

49

4

15

8

P30

P15

47

P10-4

7

2

P10-3

6

1

2

1

2

1

5

1

2

1

2

4

3

79

78

80

RIGHT

3

MOLEX

MOLEX

MAG

RED

6

8

84

83

82

81

76

7577

3

53

16

MAG OVER TEMP

SWITCH RIGHT

SCALE

80

79

78

59

RED

7

Page 18

34

5

33

32

6

31

29

28

30

26

27

7

11

24

25

22

23

4

21

20

19

14

13

12

15

10

17

9

18

18

16

10

13

12

2

1

8

3

Page 19

36

37

38

39

40

52

49

51

48

50

47

46

45

53

54

43

44

42

41

35

19

Page 20

20

Item E300 Part Number Description

1 21926252 Top Cover

2 21926254 Left Side Panel

3 21926109 Display Panel

4 21926253 Right Side Panel

5 21926251 Back Panel

6 3100733 Finger Guard

7 98325020 Cordset, Molded,10-3, NEMA 6-30P

8 1400044 Display Cover

9 21926920 Door Assembly

10 8606900 Hinge Assembly

11 8979200 Strain Relief

12 21926479 Actuator Block

13 103610 Door Switch (Primary or Secondary)

14 103600 Door Switch (Monitor w/Paddle)

15 21926082 Door Switch Mounting Plate, Right Side

16 21926080 Door Switch Mounting Plate, Left Side

17 1531810 USB Cable

18 1400055 Display/Control Board (GUI)

19 1202400 Stirrer Motor

20 8400490 Stirrer Motor Drive Belt

21 8400480 Stirrer Motor Drive Wheels

22 21926930 Stirrer Shaft Assembly

23 21926099 Stirrer Blade

24 21926465 Waveguide

25 21926940 Catalyst Assembly

26 21926125 Heater Element Assembly

27 1200800 Blower Motor Assembly

28 3110019 Fuse, 600V, 12 Amp, Class CC

29 3110018 Fuse, 600V, 20 Amp, Class CC

29 3110017 Fuse, 600V, 30 Amp, Class CC

30 1380300 High Temperature Limit Switch

31 1504810 Fuse Block

32 1215400 Rear Cooling Fan

33 1400189 Surge Protector

34 1400188 EMI Filter

35 784682 Side Cooling Fan

36 1202300 Magnetron Cooling Fan

37 1200840 Blower Motor Power Supply

38 1400045 I/O Control Board

39 1400250 Thermocouple

40 1200830 CAT 3 Communication Cable (Motor to I/O)

Page 21

Item E300 Part Number Description

41 51201400 High Voltage Transformer

42 1215000 Magnetron

43 1379000 Magnetron Over Temperature Thermostat

44 54001600 Diode

45 53310700 Capacitor 0.85 microfarad

46 1451700 Control Transformer 24VAC

47 1303300 Voltage Relay

48 1037000 Waveguide Cover

49 21926532 Waveguide Cover Mounting Clip

50 21926183 Cooking Rack

51 21926015 Upper Jetplate

52 21926013 Bottom Jetplate

53 3110139 Fuse, 20 Amp, 250V, 125 VDC

54 1303400 Switch, On-Off, Momentary

Bakers Pride Limited Warranty

What is Covered?

This warranty covers defects in material and workmanship under normal use, and applies only to the original

purchaser providing that:

The equipment has not been accidentally or intentionally damaged, altered or misused.

The equipment is properly installed, adjusted, operated and maintained in accordance with National and local codes

and in accordance with the installation instruction provided with the product.

The serial number rating plate affixed to the equipment has not been defaced or removed.

Who is Covered?

This warranty is extended to the original purchaser and applies only to equipment purchased for use in the U.S.A.

Coverage Period

Full size gas and electric deck ovens: Two (2) year limited parts and labor: Cyclone Convection Ovens: BCO Models:

One (1) year limited parts and labor; GDCO Models: Two (2) year limited parts and labor; (5) year limited door

warranty. HD Series Models; BPHHP/BPHHPS/BPHMG/BPHTG/BPHCB/BPHRB: Two (2) year parts and labor. All

other products: One (1) year limited parts and labor. Warranty period begins the date of dealer invoice to customer or

ninety (90) days after shipment date from Bakers Pride - whichever comes first.

Warranty Coverage

This warranty covers on site labor, parts and reasonable travel time and travel expenses of the authorized service

representative up to (100) miles, round trip, and (2) hours travel time. The purchaser, however shall be responsible

for all expenses related to travel, including time, mileage and shipping expenses on smaller counter models that may

be carried into a Factory Authorized Service Center, including the following models: PX-13, PX-16, P18, and BK-18.

21

Page 22

Exceptions

All removable parts in Bakers Pride® cooking equipment, including but not limited to: Burners, Grates, Radiants,

Stones and Valves are covered for a period of SIX MONTHS.

All Ceramic Baking Decks are covered for a period of THREE MONTHS. The installation of these replacement decks

is the responsibility of the purchaser.

The extended cyclone door warranty years 3 through 5 is a parts only warranty and does not include labor, travel,

mileage or any other charges.

Exclusions

• Negligence or acts of God

• Thermostat calibrations after (30) days from equipment installation date.

• Air and Gas adjustments.

• Light bulbs

• Glass doors and door adjustments

• Fuses

• Char broiler work decks and cutting boards.

• Tightening of conveyor chains.

• Adjustments to burner flames and cleaning of pilot burners.

• Tightening of screws or fasteners.

• Failures caused by erratic voltages or gas supplies.

• Unauthorized repair by anyone other than a Bakers Pride Factory Authorized Service Center.

• Damage in shipment.

• Alteration, misuse or improper installation.

• Thermostats and safety valves with broken capillary tubes.

• Accessories - spatulas, forks, steak turners, grate lifters, oven brushes, scrappers, peels, etc.

• Freight = other than normal UPS charges.

• Ordinary wear and tear.

22

Installation

Leveling and installation of decks, as well as proper installation and check out of all new equipment - per appropriate

installation and use of materials - is the responsibility of the dealer or installer, not the manufacturer.

Replacement Parts

Bakers Pride genuine Factory OEM parts receive a (90) day materials warranty effective from the date of installation

by a Bakers Pride Factory Authorized Service Center.

This warranty is in lieu of all other warranties, expressed or implied, and all other obligations or liabilities on the

manufacturers part. Bakers Pride shall in no event be liable for any special, indirect or consequential damages, or

in any event for damages in excess of the purchase price of the unit. The repair or replacement of proven defective

part shall constitute a fulfillment of all obligations under the terms of this warranty.

How to Arrange for Service

All warranty service should be coordinated through the Technical Service Department at Bakers Pride. You can

reach us, toll free, at 1-800-431-2745. All warranty service calls will be immediately dispatched by Bakers Pride

to the local Factory Authorized Service Center in your area. When requesting service or parts identification, always

specify:

• Model Number • Phase or Wattage

• Serial Number • Date Code

• Type of Gas or Voltage

Page 23

Notes

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

23

Page 24

Food Service Equipment Group

The Standex Food Service Equipment Group (FSEG) is a manufacturer of innovative commercial food

service equipment offering a wealth of refrigeration and cooking expertise. Products include walk-in

coolers and freezers; hot and cold display cabinets, cases, and storage systems; commercial ovens,

rotisseries, and cooking equipment; and rotary vane pumps.

Ask your sales representative about how the power of all Standex brands can work for you.

www.standex.com/segments/food-service

Be sure to keep up with new product announcements

and events on social media!

Loading...

Loading...