Bakers Pride COC-E1 Service Manual

OPERATION MANUAL

CYCLONE SERIES HALF-SIZE ELECTRIC CONVECTION OVENS

SERIES: COC-E

BUILT BY CRAFTSMEN. TESTED BY TIME®.

ELECTRIC CONVECTION OVEN OPERATION MANUAL

ELECTRIC CONVECTION OVENS

Models:

CO11-E and COC-E

Bakers Pride Oven Company, LLC is a wholly owned

subsidiary of Standex International Corporation.

All gas operated Bakers Pride® ovens are intended for

use with the type of gas specified on the rating plate and

for installation will be in accordance with National Fuel

Gas Code ANSI Z223.1 (latest edition).

WARNING

FOR YOUR SAFETY: Do not store or use gasoline

or other flammable vapors or liquids in the vicinity

of this or any other appliance.

WARNING

CAUTION

Improper installation, adjustment, alteration,

service or maintenance can cause property

damage, injury or death. Read the installation,

operating and maintenance instructions

thoroughly before installing or servicing this

equipment.

WARNING

Initial heating of oven may generate smoke or

fumes and must be done in a well-ventilated

area. Overexposure to smoke or fumes may cause

nausea or dizziness.

Please retain this manual for future references.

This equipment is design engineered for commercial

use only.

California Residents Only

WARNING: This product can expose you to

chemicals including chromium which is known to

the State of California to cause cancer and birth

defects or other reproductive harm. For more

information go to www.P65Warnings.ca.gov.

BAKERS PRIDE OVEN COMPANY, LLC.

1307 N. Watters Rd., Suite 180

Allen, TX 75013

Phone: 800.527.2100 | Fax: 914.576.0605 | www.bakerspride.com

P/N 8839140 9/18

TABLE OF CONTENTS

ELECTRIC CONVECTION OVEN OPERATION MANUAL

INSTALLATION INSTRUCTIONS 1

RECEIVING 1

LOCATION & MINIMUM CLEARANCES 1

SET-UP/MOUNTING FOR COC-E1 2

SET-UP/MOUNTING FOR CO11-E 2

ELECTRICAL CONNECTIONS 3

INITIAL STARTUP 4

SYSTEM CHECK – ROTARY CONTROLS 4

STEAM INJECTION (OPTIONAL) 5

OPERATING INSTRUCTIONS 5

GENERAL INSTRUCTIONS 5

SYSTEM OPERATION SEQUENCE 5

COOK ONLY (ROTARY CONTROL) 5

TIMED COOKING (ROTARY CONTROL) 6

COOK & HOLD (ROTARY CONTROL) 6

STEAM INJECTION (ROTARY CONTROL) 6

OVEN COOL DOWN (ROTARY CONTROL) 6

C&H-3 PLUS CONTROLLER INSTRUCTION 7

OPERATING INSTRUCTIONS 9

OPTIONAL STEAM INJECTION 9

OVEN COOL DOWN 9

OPERATING NOTES 9

STARTING A COOK CYCLE 9

HOLDING TIMERS 9

DISPLAY DESCRIPTIONS 9

CONTROLLER FEATURES 10

FAHRENHEIT OR CELSIUS TEMPERATURE DISPLAY 10

PROGRAMMABLE TIMES 10

PROGRAMMABLE TEMPERATURES 10

PROGRAMMABLE HOLD 10

PROGRAMMABLE FAN 10

FLASHING DISPLAY 10

PROGRAMMING THE OVEN CONTROLLER 10

CLEANING 12

SERVICING 13

HELPFUL HINTS 14

TROUBLESHOOTING CHART 14

WIRING DIAGRAMS 15

CO11-E COC-E 208/220/240V 3PH 15

CO11-E COC-E 208/220/240V 1PH 16

CO11-E COC-E 230/400V 3PH 17

CO11-E COC-E 2230/400V 1PH 18

STEAM INJECTION WIRING DIAGRAM 220/240V 19

PARTS LIST & EXPLODED VIEW, CO11-E 20

PARTS LIST & EXPLODED VIEW, COC-E 23

WARRANTY 27

INSTALLATION INSTRUCTIONS

Receiving

Read the notice on the outside carton regarding damage

in transit. “CONCEALED DAMAGE,” damage discovered

after opening the crate(s) must be reported immediately

to the carrier. The carrier will perform an inspection of

the damage and furnish forms for the consignee’s claim

against the carrier. Retain all packing material - including

the outer carton until the inspection has been completed.

When the oven arrives, it should consist of: a crate or

carton containing your new oven, and a carton containing

four 3-” legs with mounting hardware (for CO11-E only).

A set of four 6” legs (for CO11-E2 stacked installations)

and legs for COC-E are packed inside oven.

Location & Minimum Clearances

a. Provision of adequate air supply to the oven for

ventilation is essential.

b. The oven should be located no closer than 1”

(COC-E) / 2” (CO11-E) on the left side, 1” on the

right side and 1” on the rear from any combustible

or non-combustible construction.

c. Keep the area around your oven free and clear of

combustible materials.

d. Provision of adequate air supply to the oven for

ventilation is essential. Minimum clearances must

be maintained at all times.

Minimum Clearances

COC-E1 CO11-E1

Inches mm Inches MM

RIGHT 1 25 1 25

LEFT 1 25 2 50

REAR 1 25 1 25

Suitable for installation on combustible floors when

installed on factory supplied legs or casters.

1

ELECTRIC CONVECTION OVEN OPERATION MANUAL

INSTALLATION INSTRUCTIONS

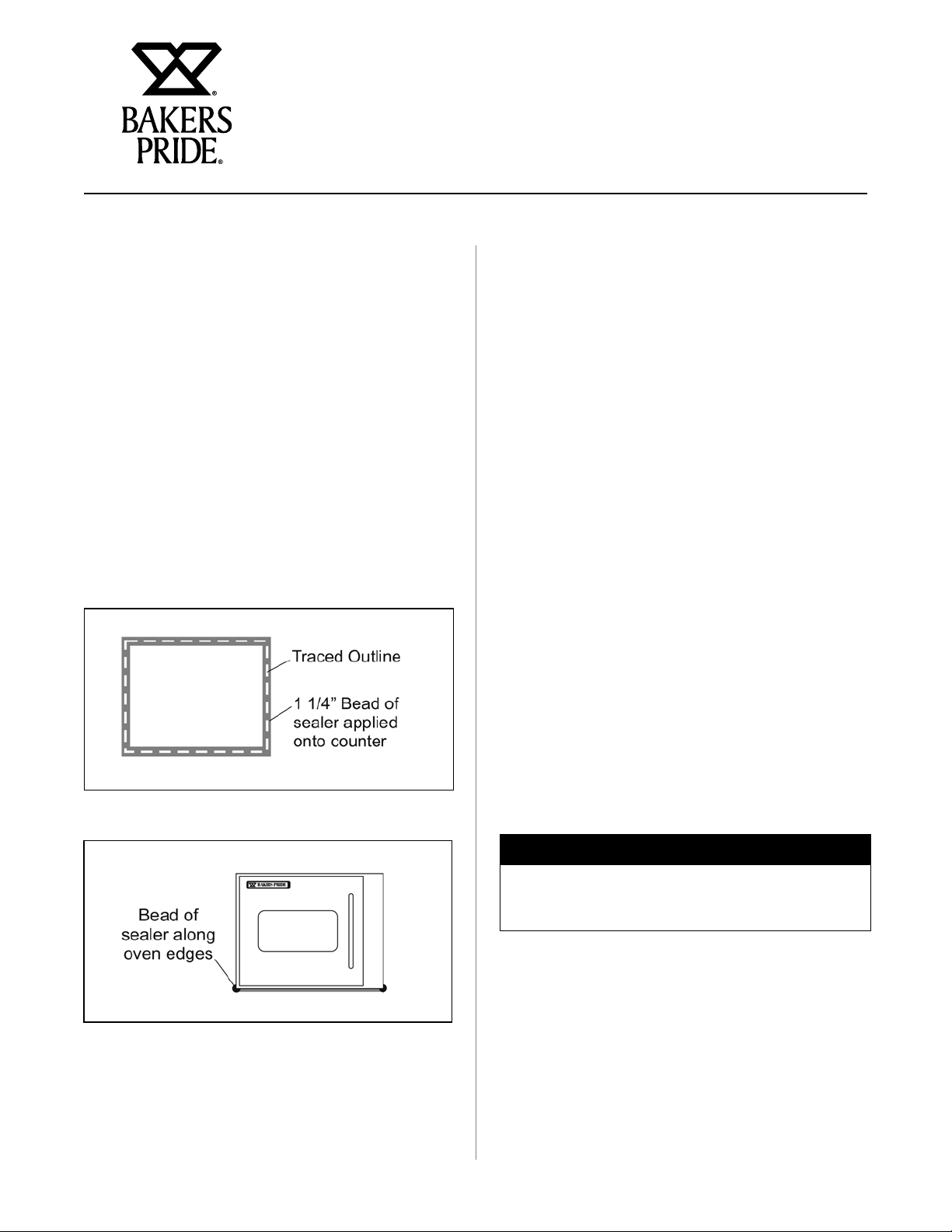

Set Up / Mounting for COC-E1

1. COC-E1 Direct Placement on Counter

a. Make sure the counter is level.

b. Clean area where unit is to be installed.

c. Place the unit in position on the counter and

mark the outline of the unit.

d. Remove the unit and apply 1-1/4” bead of

sealer (Dow Corning RTV 72 Multipurpose

sealant or equivalent).

e. Place the unit in position over the sealant on

the counter.

f. With the unit in place, apply an additional heavy

bead of sealer along all edges (see Sketch B).

g. Wipe clean any excess sealer.

2. COC-E1: Installation / Mounting 6” Legs (optional)

a. The adjustable legs are not shipped mounted

to unit. The legs are packed inside the unit with

the wire shelves.

b. After unpacking the unit, remove legs and any

other material from inside the oven.

c. Place the unit on a counter or other flat, stable

surface.

d. With sufficient help, tilt the unit back far

enough to mount the two front legs.

e. Tighten the upper part of the leg with an

adjustable wrench.

f. After installing the front legs, lift the rear of the

unit more than 6” off the surface and block

in position using wood or some other solid

material.

g. Mount the two rear legs and tighten them in the

same fashion.

h. Using proper equipment, move the unit to its

final location.

Sketch A: Top View

Sketch B: Front View

i. To ensure proper operation, the unit must be

level. Each leg can be adjusted separately to

achieve proper leveling.

j. Install the shelf supports and the wire shelves.

Set-Up / Mounting For CO11-E

NOTICE

Units must be leveled after leg installation. Each leg

is individually adjustable.

1. CO11-E1: Installation / Mounting 30” Legs

a. After unpacking the unit, remove legs and any

other material from inside the oven.

b. Tilt the oven onto its left side and attach the two

right legs using three 1/2” bolts and washers

for each leg. Tighten firmly.

c. Use proper lifting equipment to raise the unit,

and while suspended attach the two left legs in

the same manner.

2

ELECTRIC CONVECTION OVEN OPERATION MANUAL

INSTALLATION INSTRUCTIONS

2. CO11-2E: Installation / Mounting 6” Legs

a. After unpacking the unit, remove legs and any

other material from inside the oven.

b. Tilt the bottom oven onto its left side and attach

the two mounting plates to the right underside

using 1/2” bolts and washers and tighten firmly.

Screw the 6” legs into the center holes.

c. Use proper lifting equipment to raise the

unit, and while suspended attach the two left

mounting plates and legs in the same manner.

d. Use the lifting equipment to raise the top oven

to the proper height, and slide it on top of the

bottom oven. Line up the sides and front and

use the supplied stacking brackets, screws

and lock washers to fasten the two ovens in the

back.

3. CO11-E1: Assembly of an Open Rack Stand (see

Sketch “D”)

a. Slightly loosen the (12) 30” leg bolts.

b. Remove (4) inner bolts, (1) from each of the

four legs, place the top right angle underneath

as shown, and tighten these (4) bolts.

c. Insert Open Rack Shelf and tighten into place

with (8) 3/8”-16 screws, washers and nuts.

d. Position Rack Supports and tighten in place

using (4) 5/16”-18 hex nuts and flat washers.

4. COC-E / CO11-E1: Installation Of Casters (Optional)

a. (4) Casters (2) with wheel brakes and the

mounting hardware is packed and included in

the shipment if ordered.

b. Install casters with wheel brakes on the front of

the unit. Note: See sketch D.

c. Install rear legs with casters on the back of

the unit with the restraining plate affixed firmly

between the right rear leg & the bottom of the

appliance as shown on Sketch D.

Electrical Connections

1. General Instructions

a. A licensed electrician must make electrical

connections.

b. When installed, unit must be electrically

grounded in accordance with the local codes

and/or the latest edition of the National

Electrical Code ANSI/NFPA No. 70 in USA or

Canadian Electrical Code, CSA Standard C22.1,

Part 1 in Canada.

c. Make sure electrical supply corresponds with

that specified on the rating plate.

d. For single phase 2-wire or three phase 3-wire

supplies, the controlling branch circuit is designed

to operate at 208-240 volts AC and is pre-wired at

the factory between L1 and L2 of the field wiring

terminal block (in North America).

e. For three phase 4-wire 230/400 Volts AC

50hz supplies, the controlling branch circuit is

designed to operate at 230 volts AC and is prewired at the factory between L2 and N of the

field wiring terminal block.

f. Only use copper conductors rated at 90°C.

g. All pole disconnect must be provided by the

installer.

h. FOR CE UNITS: The appliance must be

connected by an earthing cable to all other

units in the complete installation and thence to

an independent earth connection in compliance

with EN 60335-1 and/or local codes. If flexible

line cordage is used to connect the equipment,

it should be a minimum of H07RN-F type

conforming to EN60335-1, EN60335-2-42 and/

or local codes.

d. Provide a suitable restraining chain or cable to

securely tether the appliance to the building

structure. The restraining chain or cable should

be of such length, that it will stop movement of

the appliance before there is any strain on the

power supply cable.

3

ELECTRIC CONVECTION OVEN OPERATION MANUAL

INSTALLATION INSTRUCTIONS

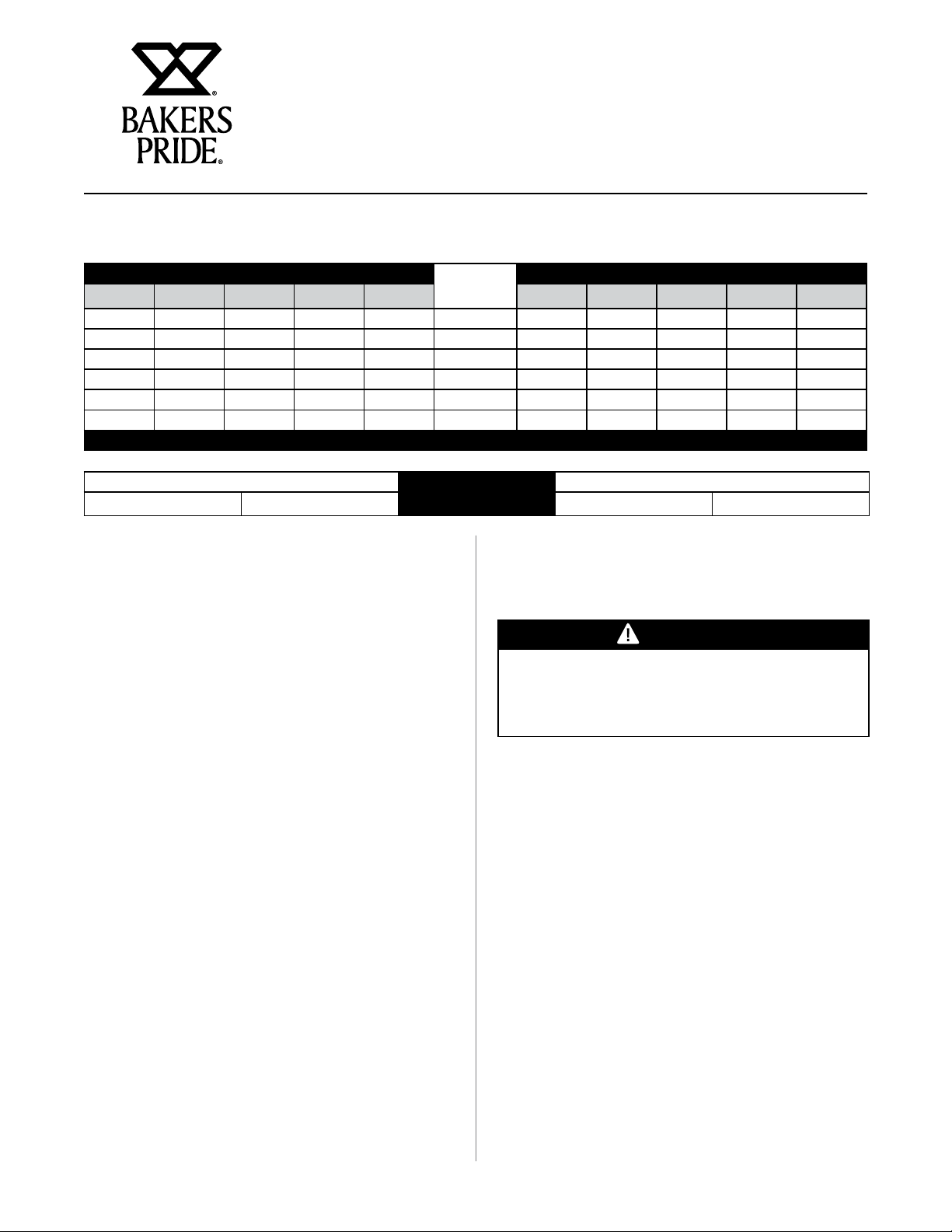

COC-E Power and Current per Deck Power Supply

KW L1 (amp) L3 (amp) L2 (amp) N (amp) KW L1 (amp) L3 (amp) L2 (amp) N (amp)

9.5 45.7 45.7 208 (1) 10.5 50.5 50.5

9.5 27.0 25.0 27.0 208 (3) 10.5 30.0 27.8 30.0

8.7 - 10.3 39.5 - 43.0 39.5 - 43.0 220-240 (1) 9.6 - 11.4 43.7 - 47.6 43.7 - 47.6

8.7 - 10.3 23.4 - 25.5 21.6 - 23.6 23.4 - 25.5 220-240 (3) 9.6 - 11.4 25.8 - 28.2 24.0 - 26.2 25.8 - 28.2

9.5 41.3 41.3 400-Y (1) 10.5 45.7 45.7

9.5 13.0 15.2 13.0 2.2 400-Y (3) 10.5 14.5 16.7 14.5 2.2

NOTE: EACH OVEN REQUIRES A SEPARATE CONNECTION !

Volts (Phase)

CO11-E Power and Current per Deck

208V and 220-240V (60hz) Motor / Blower

High = 1725 RPM Low = 1140 RPM High = 1425 RPM Low = 950 RPM

2. Field Connections

a. Remove access panel from the right side of the

oven.

Speeds

d. After 1/2 hour, increase the temperature to 500°F

(260°C) for at least 1/2 hour more. This procedure

will dry out the insulation and will help to insure

best baking results.

400-Y (50hz)

b. Feed power cable (supplied by the customer)

through the access hole in the rear of

CAUTION

the oven and pull the cable to the front of the

oven under the access panel where it may be

attached to the cable support bracket.

c. Following the appropriate wiring diagram

Overexposure to smoke or fumes may cause

nausea and dizziness. Be sure the oven is placed

in a well ventilated area.

conforming to the rating plate, connect the

power supply leads to the field wiring terminal

block. The ground wire should be connected

to the grounding lug attached to the cable

support bracket.

d. Make sure all connections are tight, and

replace the access cover.

System Check: Rotary Control

a. Open the oven door(s).

b. Turn selector switch to high. The green indicator

light near the selector switch and oven light(s) will

illuminate.

Initial Start-Up

After installation, your oven will need approximately 1

hour to burn off. The following steps must be completed

before your new oven is ready for use:

c. Close the door(s). Oven light(s) will go off and fan

will run. Make sure fan is rotating clockwise looking

from front.

d. Press oven light switch. Oven light(s) will go on and

a. Place the oven in a well ventilated area as the

following procedure may produce smoke and

fumes.

b. Open the door(s) and remove any instructions or

samples shipped with the unit. Make sure the oven

cavity is empty and the wire shelves are properly

installed.

go off as the switch is released.

e. Turn the thermostat knob. The amber indicator light

near the thermostat will illuminate and the elements

will come on.

f. Turn the timer knob and set a time of 2 minutes. At

the end of 2 minutes, you will hear the buzzer. Turn

the timer knob to “0”.

c. Close the oven door(s) and set the temperature

knob to 300°F (150°C) for 1/2 hour.

4

ELECTRIC CONVECTION OVEN OPERATION MANUAL

INSTALLATION INSTRUCTIONS

g. Open the oven door(s). Oven light(s) will go on, and

elements and fan will go off.

h. With the door(s) open turn the selector switch to

“Cool Down” position. The fan will run to cool down

the oven.

i. Turn selector switch to “0” position.

j. Close the oven door(s).

NOTICE

The oven will begin to heat as soon as the door(s)

is/are closed, if the oven temperature is lower than

the temperature set and the selector switch is in

the “High” or “Low” cook position.

The thermostat indicator light will turn on and stay

on while the oven is heating up, and will turn off

when the set temperature has been reached.

The door(s) interlock switch will deactivate the

motor and heating elements and turn on the light

when the door(s) is/are opened.

Steam Injection Option

The solenoid valve for steam injection is mounted

behind the service panel on the right hand side of the

unit on COC-E and on the back of the unit on CO11-E.

It is pre-wired at the factory. The electronic timer is preset at the factory.

A 1/4” copper tubing with a compression fitting for

water connection is provided on the solenoid valve. Be

sure to check for leaks after installation.

OPERATING INSTRUCTIONS

General Instructions:

a. This equipment has an Electronic Temperature

Control.

b. Due to increased efficiency of this oven, the

temperature of standard recipes may be reduced

50°F (30°C).

c. Always load each shelf evenly. Space pans away

from each other and from sides and back of oven to

allow maximum air flow between them.

d. Large tempered glass window(s) and interior light(s)

allow for a close check of the product making it

unnecessary to open the door(s) too frequently.

e. Products cook faster in a convection oven as

compared to a conventional oven, therefore,

depending upon the product and type of pans

used, time saving may range anywhere from 20%

to 50%.

System Operating Sequence

Cook Only Rotary Control:

a. Close the oven door(s).

b. Turn selector switch to “High” or “Low” position.

The green indicator light near the selector switch

will be illuminated.

c. Turn the thermostat knob to the desired cooking

temperature.

d. Upon reaching the set temperature, the amber

indicator light near the thermostat will turn off.

e. Load the oven with the product to be cooked.

f. Remove the product from the oven when done.

5

ELECTRIC CONVECTION OVEN OPERATION MANUAL

OPERATING INSTRUCTIONS

Timed Cooking Rotary Control:

a. Close the oven door(s).

b. Turn selector switch to “High” or “Low” position.

The green indicator light near the selector switch

will be illuminated.

c. Turn the thermostat knob to the desired cooking

temperature.

d. Upon reaching the set temperature, the amber

indicator light near the thermostat will turn off.

e. Load the oven with the product to be cooked.

f. Turn the timer knob to the desired bake time and

timer will begin counting down.

g. When the timer reaches zero, a buzzer will sound.

h. Turn the timer knob to “0” position.

I. Remove the product from the oven.

NOTICE

The timer does not control the oven. It is only a

reminder that the set time has elapsed.

Optional Steam Injection Rotary control:

a. The solenoid valve for steam injection is mounted

behind the service panel on the right hand side

of the unit on COC-E and on back of the unit on

CO11-E1.

b. The electronic timer is pre-set at the factory.

c. For steam injection, press the steam injection

switch.

NOTICE

Do not use steam injection at temperatures below

275°F (135°C).

Oven Cool Down Rotary Control:

To cool down the oven to a lower desired temperature,

follow the steps detailed below:

a. Open the oven door(s).

b. Turn selector switch to “Oven Cool Down” position.

Fan will now operate and cool down the oven.

Cook and Hold Rotary Control:

a. Close the oven door(s).

b. Turn selector switch to “High” or “Low” position.

The green indicator light near the selector switch

will be illuminated.

c. Turn the thermostat knob to the desired cooking

temperature.

d. Upon reaching the set temperature, the amber

indicator light near the thermostat will turn off.

e. Load the oven with the product to be cooked.

f. Turn the timer knob to the desired bake time and

timer will begin counting down.

g. When the timer reaches zero, a buzzer will sound.

h. Turn the timer knob to “0” position.

i. Turn the thermostat knob to the desired holding

temperature.

j. Remove the product from the oven as desired.

c. When the oven has cooled to the desired

temperature, turn the selector switch to the “0”

position.

NOTICE

Programming Menus: MiniChef or FAST Option

See Set-Up & Operation Booklet for Programmable

Oven Control with Bakers Pride Software for

Cyclone Series Convection Ovens supplied with this

option.

6

ELECTRIC CONVECTION OVEN OPERATION MANUAL

OPERATING INSTRUCTIONS

Operating/Programming Instructions -

TM

Cook & Hold-3 Plus

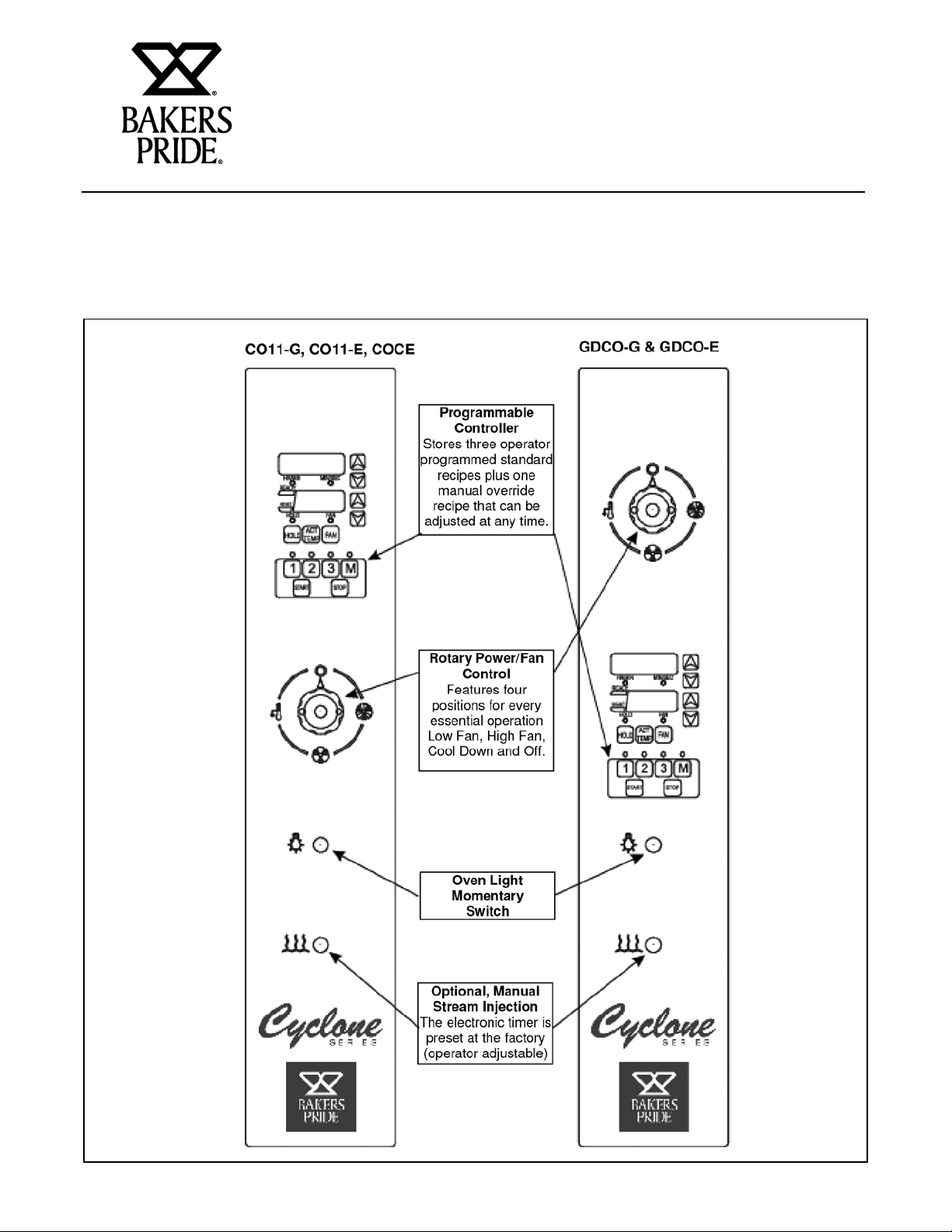

Controller (For Convection

Ovens: CO11-G, CO11-E, COC-E, GDCO-G & GDCO-E)

7

Loading...

Loading...