®

High Profile

Unit Cooler

PRODUCT DATA &

INSTALLATION

Bulletin B30-BHPA-PDI-50

1081587-50-1

High & Medium

Temperature

Air Defrost

Electrical Power:

200-220/3/50, 380-400/3/50

CONTENTS

Page

Nomenclature........................................................................................................................ 2

Features & Options..............................................................................................................2

Capacity Data...................................................................................................................... 3

Electrical Data...................................................................................................................... 3

Wiring Diagram................................................................................................................... 4

Dimensional Data................................................................................................................ 5, 6

Specifications................................................................................................................. ...... 6

Installation Instructions......................................................................................................... 7, 8

Service Parts List................................................................................................................. 9

Warranty................................................................................................................................ 11

Project Information................................................................................................................ 11

“As Built” Service Parts List................................................................................................ BACK

NOMENCLATURE

B HP 216 L E - T5 A - S B

B = Bally

High Profile Unit Cooler

Nominal Capacity x 1000

(standard motor/fan blade) @ 10°F TD

Application Range

H = Hi / Medium Temp 7 FPI (0°F to 35°F Evap Temp)

M = Medium Temp 6 FPI (0°F to 35°F Evap Temp)

P = Medium Temp 4 FPI (0°F to 35°F Evap Temp)

L = Low Temp 6 FPI (-5°F to -40°F Evap Temp)

V = Low Temp 4 FPI (-5°F to -40°F Evap Temp)

Defrost

A = Air

E = Electric

T = 3 Pipe Hot Gas w/ Heater

G = Reverse Cycle Hot Gas w/ Heater

H = 3 Pipe Hot gas w/ Loop

R = Reverse Cycle Hot Gas w/ Loop

STANDARD FEATURES

Throw Boosters:

N = None

B = Booster

Motor Option:

S = Standard

T = TEFC

V = High Velocity

† Not available on above

+15°F Evap. Temp. models

Generation

st

A = 1

Voltage:

T3 = 208-230/3/60

T4 = 460/3/60

T5 = 575/3/60

T7 = 200-220/3/50

T9 = 380-400/3/50

†

• Heavy gauge textured aluminum cabinet

with galvanized steel hangers, support channels

and end plates

• Hinged access panels with removable hinge

pins and captive fasteners.

• Hinged drain pan with removable hinge pins

• Rugged heavy-gauge galvanized steel rail

motor mount / support.

OPTIONAL FEATURES

• Factory mounted TX valve, solenoid valve

and thermostat

• Throw boosters

• Insulated drain pan

• St ackable design

• Schrader fitting and external equalizer line.

• Factory installed solenoid valve wire harness

• Unit shipped upright for convenient handling

and quick installation.

• TEFC motors

• Optional fin spacing

• Optional fin materials

• Optional coil coating

- 2 -

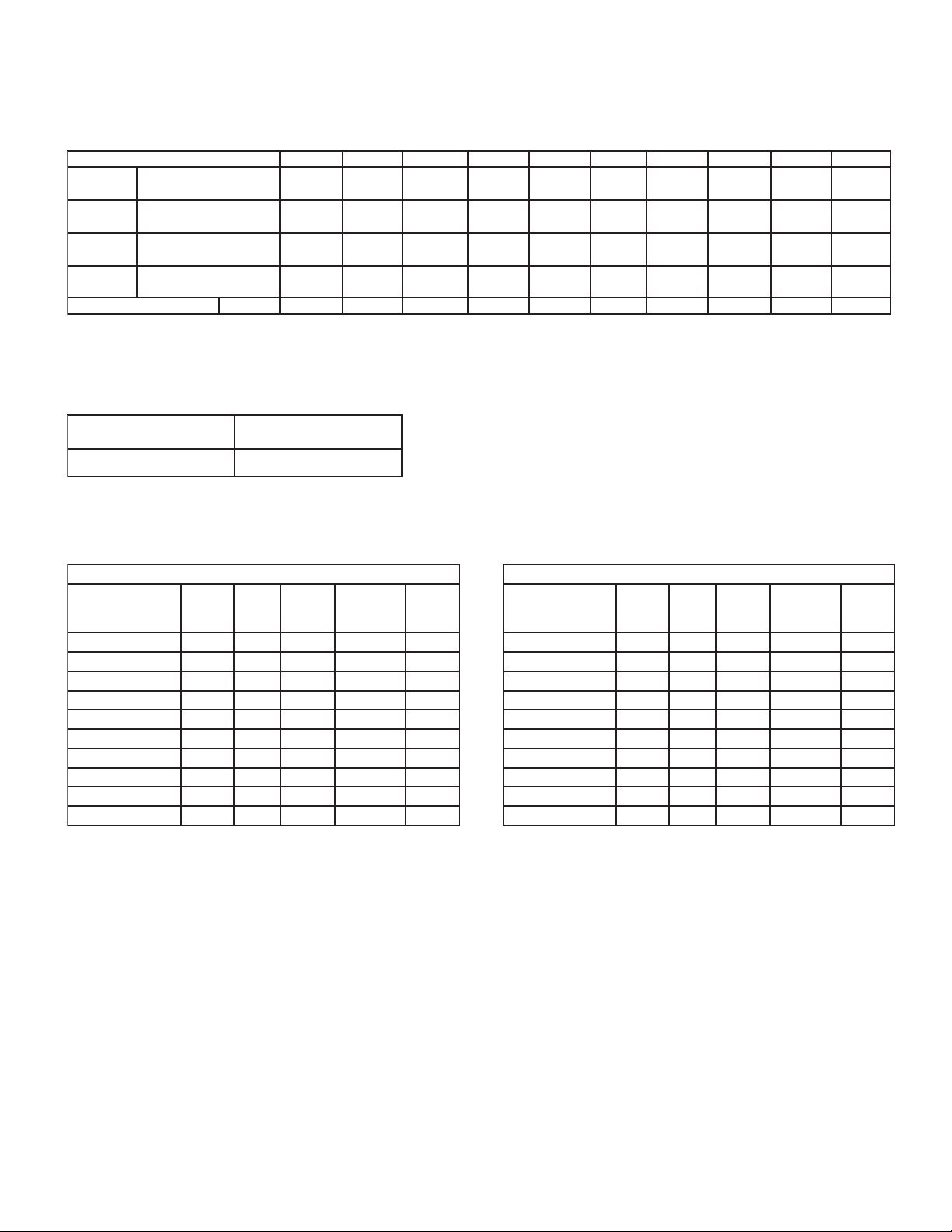

CAPACITY DATA

High and Medium Temperature Models - Capacity @ 7 F.P.I.

sledoM.pmeTmuideM/hgiHAH370AH680AH311AH031AH451AH071AH981AH332AH252AH872

yticapaC

yticapaC

yticapaC

wolFriAMFC ( )S/L

*egrahCtnaregirfeR.BL )GK(

.D.TF°1@HUTB

).D.TC°55.0@STTAW(

.D.TF°01@HUTB

).D.TC°55.5@STTAW(

.D.TF°51@HUTB

3.8@STTAW(

).D.TC°3

* Estimated, based on R404A at +25° S.S.T. with coil 30% full.

Derate capacity by 0.92 and CFM by .85 for Throw Booster Option.

0

276

)8691(

00276

)38691(

008001

)42592(

00631

)8146(

02 )9( 72 )21

0197

)7132(

00197

)86132(

056811

)35743(

00621

)6495(

( 04 )81( 04 )81( 05 )32( 06 )72( 88 )04( 89 )54( 811 )45( 751 )17(

00401

)6403(

000401

)26403(

000651

)29654(

00921

)8806(

06911

)3053(

006911

)13053(

004971

)64525(

00981

)9198(

07141

)0514(

007141

)40514(

055212

)65226(

00

502

)4769(

04651

)1854(

004651

)01854(

006432

)41786(

00591

)2029(

50Hz

09371

)4905(

009371

)53905(

058062

)30467(

00112

)7599(

04412

)0826(

004412

)89726(

006123

)79149(

00592

)12931(

08132

)9876(

008132

)49876(

007743

)148101(

00182

)06231(

08552

)2947(

008552

)42947(

007383

)683211(

00752

)82121(

Average Air Throw - ft (m)

NAFDRADNATS

ROTOMDNA

09 )72( 521 )83(

05/3/022-002

LEDOM

A7T-AH370PHB

A7T-A

H680PHB

A7T-AH311PHB

A7T-AH031PHB

A7T-AH451PHB

A7T-AH071PHB

A

7T-AH981PHB

A7T-AH332PHB

A7T-AH252PHB

A7T-AH872PHB

NAF

ROTOM

YTQ

21 6.98.0151

21 6.98.0151

25.18.113.3151

31 4.416.5102

35.17.712.9152

35.17.712.9152

+35.17.712.9152

45.16.321.5203

45.16.321.5203

45.16.321.5203

PH

ROTOM

ALF

LATOT

†

LANOITPO

RETSOOBWORHT

† Measured in open sp ace. Actual throw may be less in real

applications.

ELECTRICAL DATA

.CRIC.NIM

YTICAPMA

)A(

.XAM

ESUF

)SPMA(

680PHB

05/3/004-083

LEDOM

A9T-AH370PHB

A9T-AH

A9T-AH311PHB

A9T-AH031PHB

A9T-AH451PHB

A9T-AH071PHB

A9T-AH981PHB

A9T-AH332PHB

A9T-AH252PHB

A9T-AH872PHB

NAF

ROTOM

YTQ

21 2.47.451

21 2.47.451

25.15 6.551

31 3.68.651

35.15.71.851

35.15.71.851

+

35.15.71.851

45.1016.0151

45.1016.0151

45.1016.0151

PH

ROTOM

ALF

LATOT

.CRIC.NIM

YTICAPMA

)A(

.XAM

ESUF

)SPMA(

NOTE: 3+ indicates 3-fan “long” configuration (see dimensional data for details)

- 3 -

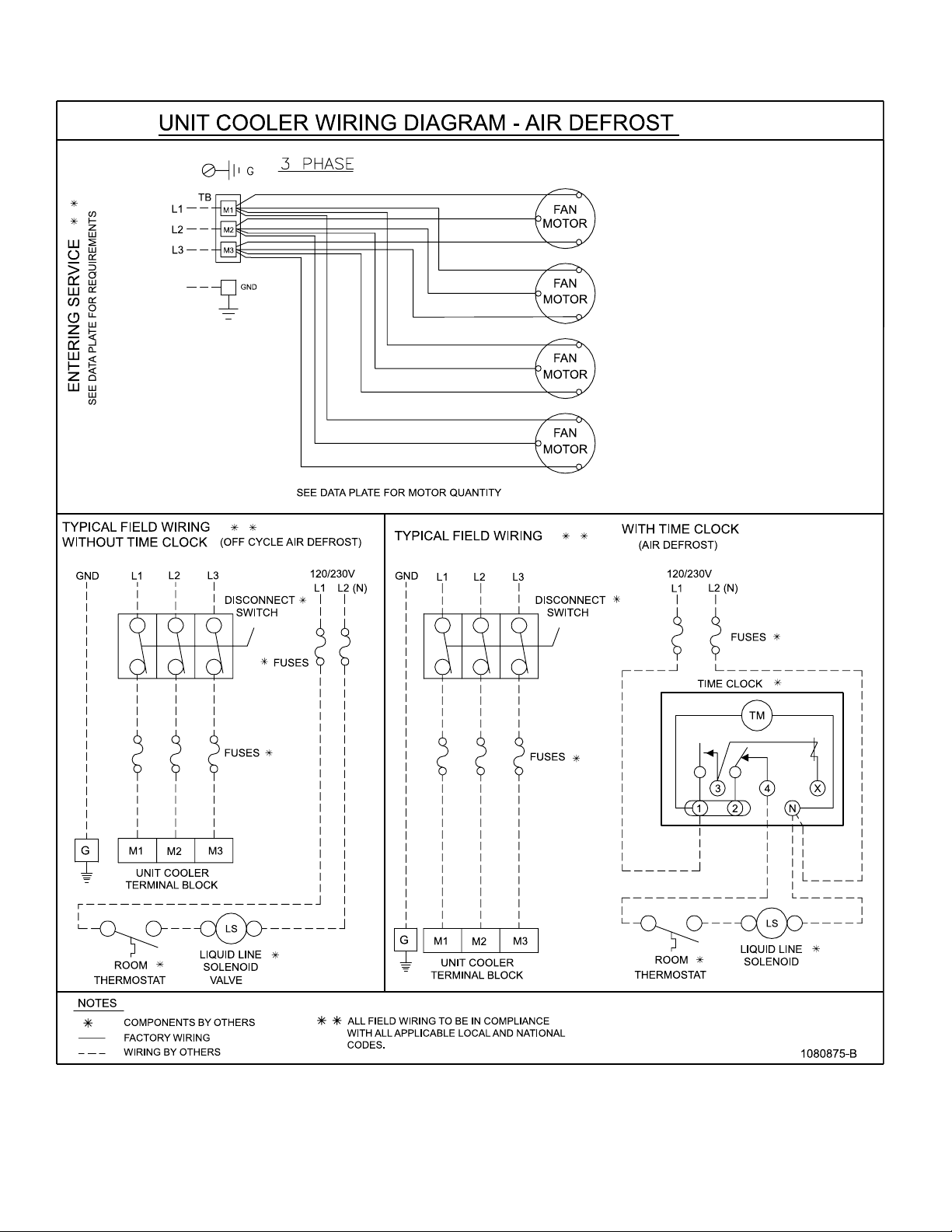

WIRING DIAGRAM

- 4 -

DIMENSIONAL DATA

2 Fan Models

Drain connections 1-1/4” FPT .

3 Fan Models

- 5 -

DIMENSIONAL DATA

3 Fan (Long) Models

Drain connections 1-1/4” FPT .

snaFfOrebmuN

.nnoCrotubirtsiD

)taewSDO(

noCnoitcuS

.n

)taewSDO(

teN.xorppA

thgieW

.BL )GK(

4 Fan Models

SPECIFICATIONS

sledoM.pmeTmuideM/hgiHAH370AH680AH311AH031AH451AH071AH981AH332AH252AH872

222 3333 4 4 4

sehcnI

)mm(

sehcnI

)mm(

8/1-1

)92(

8/5-1

)14(

076

)813(

8/3-1

)53(

8/5-1

)14(

247

)733(

8/3-1

)53(

8/1-2

)45(

738

)973(

8/3-1

)53(

8/1-2

)45(

1701

)584(

8/3-1

)53(

8/1-2

)45(

5411

)915(

8/5-1

)14(

8/1-2

)45(

8021

)845(

8/3-1

)53(

8/5-2

)76(

3921

)685(

8/3-1

)53(

8/5-2

)76(

0951

)127(

8/3-1

)53(

8/5-2

)76(

6961

)077(

8/5-1

)14(

8/5-2

)76(

9191

)078(

- 6 -

INSTALLATION INSTRUCTIONS

The installation and start-up of Unit Coolers should only

be performed by qualified refrigeration mechanics.

This equipment should be installed in accordance with

all applicable codes, ordinances and local by-laws

INSPECTION

Inspect all equipment before unpacking for visible signs of

damage or loss. Check shipping list against material

received to ensure shipment is complete.

IMPORTANT: Remember , you, the consignee, must make

any claim necessary against the transportation company .

Shipping damage or missing parts, when discovered at

the outset, will prevent later unnecessary and costly

delays.

If damage or loss during transport is evident, make

claim to carrier, as this will be their responsibility,

not the manufacturer’s.

Should carton be damaged, but damage to equipment is

not obvious, a claim should be filed for “concealed damage” with the carrier.

IMPORTANT: The electrical characteristics of the unit

should be checked at this time to make sure they correspond to those ordered and to electrical power available at

the job site.

Save all shipping papers, tags and instruction sheets for

reference by installer and owner .

LOCATION

The unit location in the room should be selected to ensure

uniform air distribution throughout the entire space to be

refrigerated. Be sure that the unit does not draw air in, or

blow directly out, through an opened door and that the

product does not obstruct the free circulation of air.

Consideration should be given to the coil location in order

to minimize the piping run length to the condensing unit

and floor drain

CLEARANCES

This evaporator draws air through the coil and discharges

air from the fan side, and thus adequate clearance should

be made on the entering face of the coil to ensure even

unrestricted air flow through the coil. This distance should

be equal to the height of the coil or more.

Ensure enough room is left at the ends of the coil for

servicing.

MOUNTING

This evaporator is supplied with shipping legs to allow

units to be shipped in an upright position. Units can be

lifted into place with shipping skid attached to mounting

legs.

Hanger brackets take up to 5/8” (15.9 mm) hanger rods.

After the evaporator is hung in place, remove the bolts

attaching the skid to the legs.

DRAIN LINE

If the evaporator is mounted flush to ceiling, the staggered hanger will provide a positive pitch for drainage.

If units are suspended below the ceiling, the installer

must provide adequate pitch to the unit by adjusting the

location of the hanger rod nuts.

Note: Check for adequate drainage by pouring water into

the drain pan.

Ensure that the drain pan has sufficient slope for

proper drainage (prevention of ice build up /

blockage in pan).

Insulated copper tube should be run from the drain

connection, sloping at least 4” (102mm) per foot. A trap

located outside of the room should be provided to

prevent warm air entering through the tubing. Connection

should be made to proper drainage facilities that comply

with local regulations.

If room temperatures are below freezing, it is necessary

to heat the drain line to prevent condensate from

freezing in the drain line. Electric heating cable or

electric tape (by others) is used for this purpose. The

drain line heater should be connected for continuous

operation; it is also recommended that the drain line be

insulated. A heat output of 20 watt s per lineal foot of 1”

(25mm) drain line in a 0°F (-18 °C) room is usually

satisfactory . 1 15 volt cable and tape is available from

your local refrigeration wholesaler. Two 1 15 volt s heaters

(by others) of the same wattage may be wired in series

for use on 230 volt system

- 7 -

INSTALLATION INSTRUCTIONS (cont’d)

PIPING

Refrigerant line sizes are important and may not be the

same size as the coil connections (depends on the

length of run). If in doubt, consult “Recommended

refrigerant line sizes” charts.

WIRING

Wire system in accordance with governing standards

and local codes. Enclosed typical wiring diagrams are

for reference only . Refer to unit data plate for operating

current, minimum ampacity and maximum fuse sizing

for fan motors.

NOTE: Electrical wiring is to be sized in accordance

with minimum ampacity rating.

For ease of identifying the proper wiring terminals, unit

wiring is colour coded and terminal block connections

are identified. When fan delay thermostats (combination fan delay and defrost termination) are installed, on

start-up, the fans do not operate until the coil temperature is reduced to approximately 20 °F (-6.7 °C). It is

normal for the fans to cycle a few times until the room

temperature is brought down. At higher evaporating

temperatures this control is of an adjustable type, and

proper adjustment is required.

The defrost termination control is adjustable and may

be set at a minimum of 40 °F (4.4 °C) (fully CW) to a

maximum of 75 °F (23.8 °C) (fully CCW). Normal setting

is 55 °F (12.8 °C). This can be increased if the defrost

heaters are terminated too soon (frost still left) or if

terminated too long (steaming of coil). Time clock

should be set for a fail-safe termination of approximately

45 minutes.

A hinged end panel provides quick access to the electrical compartment.

SYSTEM CHECK

Before Start-Up:

1. All wiring should be in accordance with local codes.

2. All refrigerant lines should be properly sized.

3. Electric defrost systems should include a liquid line

solenoid valve.

4. Thorough evacuation and dehydration has been

performed.

5. The suction, discharge and receiver service valves

must be open.

6. The system should include a liquid line drier moisture

indicator and suction filter.

7. Pour enough water into the drain pan to allow a good

check on drainage and seal the trap.

After Start-Up:

1. If necessary , temporarily by-pass fan delay control to

run fans until room temp is lowered. (Run jumper wire

from terminal N to F on circuit terminal block).

2. Check the compressor oil level to ensure the correct

oil charge.

3. Be sure that the expansion valve is properly set to

provide the correct amount of superheat (should be

around 70% of operating T .D.)

4. Heavy moisture loads are usually encountered when

starting the system for the first time. If the coil

temperature is below freezing, this will cause a

rapid build-up of frost on the coil. During the initial pull

down, frost build-up should be watched and defrosted

manually as required.

5. Check for proper evaporator fan blade rotation.

MAINTENANCE

1. Periodic checking and cleaning of the coil surface

when necessary should be done, using a whisk or

brush. Drain pans are hinged to provide convenient

access to the inside coil surface (except hot gas loop

pans).

2. Ensure coil and pan does not have any excessive ice

build-up from improper defrost operation. Any build-up

of ice can cause fins and refrigerant tubes to be

crushed. When replacing heater elements, first remove

heater slot covers and heater clips

3. Motors are permanently lubricated type and require

no further lubrication.

- 8 -

SERVICE PARTS LIST

SROTOMSLEDOM#TRAPPDO#TRAPCFET

05/3/022-002MPR058PH1031,680,37073708011470801

05/3/022-002MPR0411PH5.1 872,252,

05/3/004-083MPR058PH1031,680,37073708011470801

05/3/004-083MPR0411PH5.1 872

SEDALBNAFSLEDOM#TRAP

SROTOMPH1ROF031,680,3709470801

SROTOMPH5.1ROF872,25

.CSIMSLEDOM#TRAP

DRAUGNAFLLA4358701

SROTOM-KCOLBLANIMRETLLA7105401

332,981,071,451,31193708013470801

,252,332,981,071,451,31193708013470801

2,332,981,071,451,311 0570801

- 9 -

NOTES

- 10 -

FINISHED GOODS WARRANTY

The terms and conditions as described below in the General Warranty Policy cover all products

manufactured by National Refrigeration.

GENERAL WARRANTY POLICY

Subject to the terms and conditions hereof, the Company warrants all Products, including Service

Parts, manufactured by the Company to be free of defects in material or workmanship, under normal

use and application for a period of one (1) year from the original date of installation, or eighteen (18)

months from the date of shipment from the Company, whichever occurs first. Any replacement

part(s) so supplied will be warranted for the balance of the product’s original warranty. The part(s) to

be replaced must be made available in exchange for the replacement part(s) and reasonable proof of

the original installation date of the product must be presented in order to establish the effective date

of the warranty , failing which, the ef fective date will be based upon the date of manufacture plus thirty

(30) days. Any labour, material, refrigerant, transportation, freight or other charges incurred in connection with the performance of this warranty will be the responsibility of the owner at the current

rates and prices then in effect. This warranty may be transferred to a subsequent owner of the

product.

THIS WARRANTY DOES NOT COVER

(a) Damages caused by accident, abuse, negligence, misuse, riot, fire, flood, or Acts of God (b) damages

caused by operating the product in a corrosive atmosphere (c) damages caused by any unauthorized

alteration or repair of the system affecting the product’s reliability or performance (d) damages caused

by improper matching or application of the product or the product’s components (e) damages caused

by failing to provide routine and proper maintenance or service to the product (f) expenses incurred for

the erecting, disconnecting, or dismantling the product (g) parts used in connection with normal

maintenance, such as filters or belts (h) products no longer at the site of the original installation (i)

products installed or operated other than in accordance with the printed instructions, with the local

installation or building codes and with good trade practices (j) products lost or stolen.

No one is authorized to change this WARRANTY or to create for or on behalf of the Company any

other obligation or liability in connection with the Product(s). There is no other representation, warranty

or condition in any respect, expressed or implied, made by or binding upon the Company other than the

above or as provided by provincial or state law and which cannot be limited or excluded by such law , nor

will we be liable in any way for incidental, consequential, or special damages however caused.

The provisions of this additional written warranty are in addition to and not a modification of or subtraction

from the statutory warranties and other rights and remedies provided by Federal, Provincial or State

laws.

PROJECT INFORMATION

metsyS

rebmuNledoM pU-tratSfoetaD

rebmuNlaireS rotcartnoCecivreS

tnaregirfeRenohP

ylppuSlacirtcelExaF

- 11 -

“AS BUILT” SERVICE PARTS LIST

04/14/2008

Service Parts ListService Parts List

Service Parts List

Service Parts ListService Parts List

LL

abelabel

L

abel

LL

abelabel

TT

o Be Ao Be A

T

o Be A

TT

o Be Ao Be A

HEREHERE

HERE

HEREHERE

ttachedttached

ttached

ttachedttached

®

General Sales, PGeneral Sales, P

General Sales, P

General Sales, PGeneral Sales, P

135 Little Nine Drive, Morehead City135 Little Nine Drive, Morehead City

135 Little Nine Drive, Morehead City

135 Little Nine Drive, Morehead City135 Little Nine Drive, Morehead City

252-240-2829 • 1-800-24-BALL252-240-2829 • 1-800-24-BALL

252-240-2829 • 1-800-24-BALL

252-240-2829 • 1-800-24-BALL252-240-2829 • 1-800-24-BALL

e-mail: ballysales@ballyrefboe-mail: ballysales@ballyrefbo

e-mail: ballysales@ballyrefbo

e-mail: ballysales@ballyrefboe-mail: ballysales@ballyrefbo

Due to Manufacturer’s policy of continuous product improvement,

the Manufacturer reserves the right to make changes without notice.

arar

ts & Serts & Ser

ar

ts & Ser

arar

ts & Serts & Ser

vice Manufacturing & Engineeringvice Manufacturing & Engineering

vice Manufacturing & Engineering

vice Manufacturing & Engineeringvice Manufacturing & Engineering

xx

x

xx

, NC 28557, NC 28557

, NC 28557

, NC 28557, NC 28557

Y • FY • F

AX: 252-240-0384AX: 252-240-0384

Y • F

AX: 252-240-0384

Y • FY • F

es.com • wwwes.com • www

es.com • www

es.com • wwwes.com • www

AX: 252-240-0384AX: 252-240-0384

.ballyrefbo.ballyrefbo

.ballyrefbo

.ballyrefbo.ballyrefbo

xx

es.comes.com

x

es.com

xx

es.comes.com

DISTRIBUTED BY:

Loading...

Loading...