Bakbar E85, E85-12 Installation Manual

INSTALLATION / OPERATION

E85 PROVER

MANUAL

F21804-8

MANUFACTURED BY

Moffat Limited

PO Box 10001

Christchurch

New Zealand

Ph: (03) 389 1007

Fax: (03) 389 1276

WORLD-WIDE BRANCHES

UNITED KINGDOM

Blue Seal

Units 6-7, Mount Street Business Park

Mount Street, Nechells

Birmingham B7 5QU

Ph: (121) 327 5575

Fax: (121) 327 9711

UNITED STATES

Moffat Inc

3765 Champion Blvd

Winston-Salem

North Carolina 27115

Ph: (336) 661 0257

Fax: (336) 661 9546

CANADA

Serve Canada

22 Ashwarren Road

Downview

Ontario M3J1Z5

Toll Free:800 263 1455

Ph: (416) 631 0601

Fax: (416) 631 0315

info@servecanada.com

www.servecanada.com

www.moffat.com

NEW ZEALAND

Christchurch

Moffat Limited Moffat Limited

PO Box 10-001 4 Waipuna Road

16 Osborne Street Mt Wellington

Christchurch Auckland

Ph: (03) 389 1007 Ph: (09) 574 3150

Fax: (03) 389 1276 Fax: (09) 574 3159

AUSTRALIA

Victoria

Moffat Pty Limited Moffat Pty Limited

740 Springvale Road 3/142 James Ruse Drive, Rose Hill

Mulgrave, Melbourne PO Box 913, Smithfield

Victoria 3171 Sydney, N.S.W. 2142

Ph: (03) 9518 3888 Ph: (02) 8833 4111

Fax: (03) 9518 3838 Fax: (02) 8833 4133

Western Australia

Moffat Pty Limited Moffat Pty Limited

67 Howe Street 30 Prosperity Place

Osbourne Park Geebung, Brisbane

WA 6017 Queensland 4034

Ph: (08) 9202 6820 Ph: (07) 3630 8600

Fax: (08) 9202 6836 Fax (07) 3630 8623

Auckland

New South Wales

Queensland

The reproduction or copying of any part of this manual by any means whatsoever is strictly forbidden unless authorized previously in

writing by the manufacturer.

In line with policy to continually develop and improve its products, Moffat Ltd. reserves the right to change the specifications and

design without prior notice.

© Copyright Moffat Ltd. November 2006.

Contents

Introduction ........................................................................................................2

Installation..........................................................................................................3

Before Connection

Location

Electrical Connection

Water Connection (Auto Fill Models Only)

Rack Width

Stacking Instructions

Specifications.....................................................................................................5

Operation............................................................................................................9

Description of Controls

Condensation Channel

Operating the Prover

Bake-Off

Problem Solving

Hints

Cleaning and Maintenance.............................................................................. 13

Trouble Shooting .............................................................................................14

Spare Parts.......................................................................................................15

Circuit Schematics...........................................................................................16

E85 Prover (Manual Fill)

E85A Prover (Auto Fill)

Date Purchased................................................................. Serial No ..........................................................

Dealer............................................................................................................................................................

Service Agent ................................................................................................................................................

1

Introduction

We are confident that you will be delighted with your E85 PROVER, and it will become a most valued

appliance in your commercial kitchen.

A new oven can seem very complex and confusing at first glance. To ensure you receive the utmost

benefit from your new Prover, there are two important things you can do.

Firstly

Please read the instruction book carefully and follow the directions given. The time taken will be well

spent.

Secondly

If you are unsure of any aspect of the installation, instructions or performance of your prover, contact your

E85 dealer promptly. In many cases a phone call could answer your question.

2

Installation

Installation Requirements

It is most important that this prover is installed correctly and that operation is correct

before use.

Installation shall comply with local electrical, health and safety requirements.

Before Connection to Power Supply

• Remove all packing.

• Check equipment and parts for damage. Report any damage immediately to the carrier and

distributor.

• Remove protective plastic coating from the side panels.

• Check that the available power supply is correct to that shown on the rating plate located on the

right -hand side panel.

E85 220-240 Volts A.C, 50 Hz, 1P+N+E, 1.65 kW, 7.2A

Location

• To ensure correct ventilation for the motor and controls the following minimum installation

clearances are to be adhered to:

Rear 0mm / 0”

Left-hand side 0mm / 0”

Right-hand side 25mm / 1”

Electrical Connection

• E85 provers are supplied with pre-fitted cords. Ensure unit is fitted with appropriate cord and plug.

• To access the electrical connection terminal block, grounding lug and strain relief, remove the

right hand side panel.

WARNING - THIS APPLIANCE MUST BE EARTHED / GROUNDED

Water Connection (Auto Fill Models Only)

• A cold water supply should be fitted to the water inlet (¾” BSP connection) which is located near

the rear of the right hand side of the unit.

• Alternately, a connection elbow and sealing washer is supplied with this unit for direct connection

of a ½” ID hose, and is recommended for easy installation and service.

• Connect water supply - Max inlet pressure 80psi / 550kPa.

• Turn on water supply to check for leaks.

Rack Width

• The E85 prover has been designed to accept either 18” or

16” wide trays.

• The prover comes factory set for 18” trays, to change to 16”

trays:

• Remove the RH side rack (lift and extract).

• Undo the thumb screws (A) holding the RH rack

supports (B) and turn RH rack supports around, then

re-secure with thumbscrew.

3

A

For 18” trays

A

B

B

B

For 16” trays

B

A

A

Installation

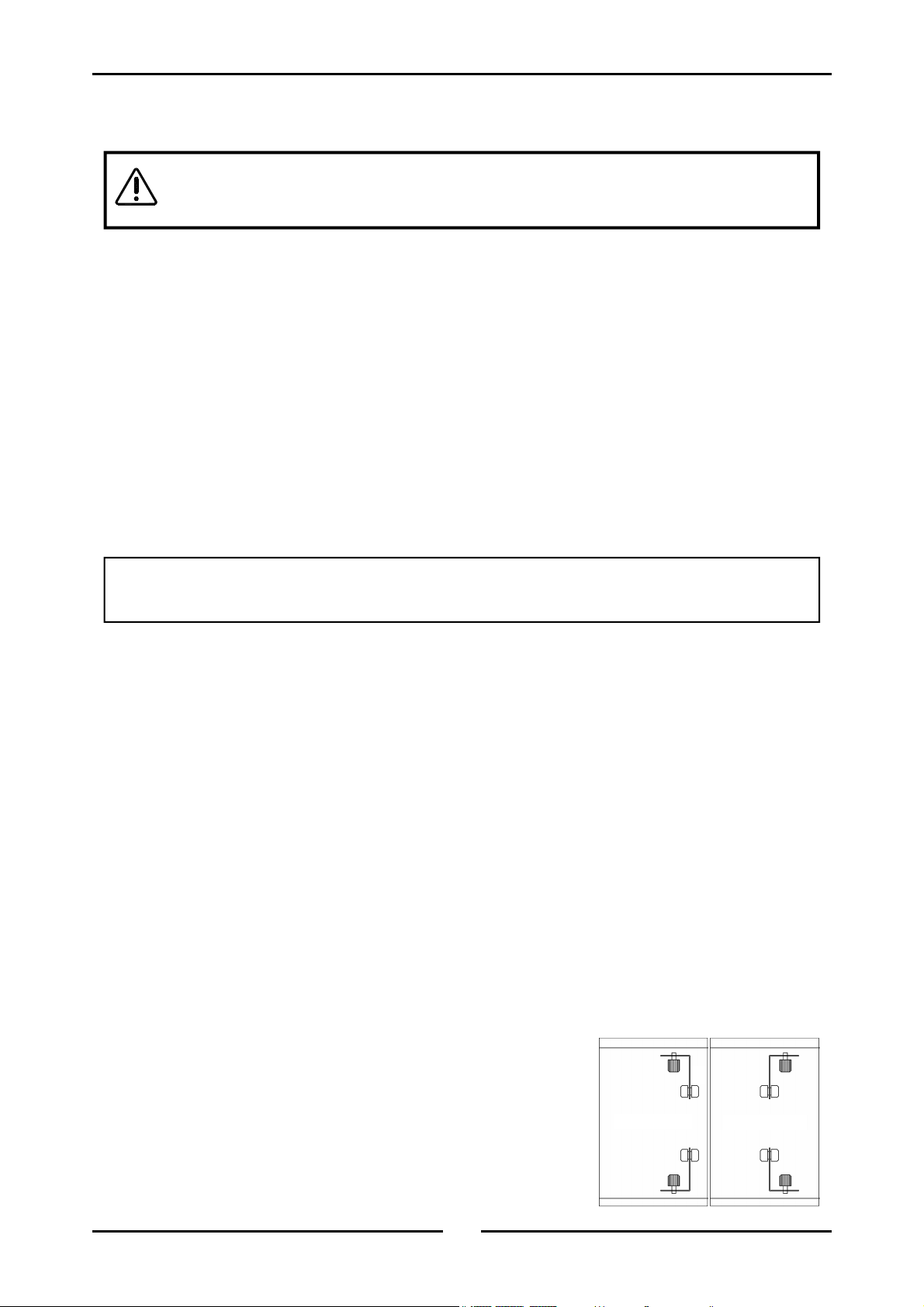

Stacking Instructions

• The E85 prover has been designed to be stacked underneath E35 Turbofan Ovens.

• The prover comes with the stacking assembly ready to place an E35 on top, unless specified at

time of order to be fitted with a top panel for stand alone use.

When stacking on an E85 prover, the legs on an E35 Turbofan oven should not be fitted.

Note:

1) For 26” oven only, Remove rear spacer panel (A) from stacking kit by removing four screws

(B). (Retain screws - discard panel)

2) Position oven onto prover (on stacking kit) with front and sides flush with prover.

3) Remove side panels from oven (each side panel is held on by four screws).

4) 26” Oven - Remove rear RH side corner panel (power and water entry points), secured with

three screws at front edge of panel (D).

5) Remove the two front bottom side panel support

brackets (E), two screws (F) each.

6) Secure oven to prover using two screws (B / C) in

each corner of the unit (down from the sides).

Note:

corners only.

7) Replace side panel support brackets (E) at

bottom front of oven, using original screws (F).

8) Replace rear RH panel (D) on oven using

original screws (26” oven only).

9) Replace side panels, using original screws.

26” oven in all corners, 30” oven front

E

F

C

4

A

B

D

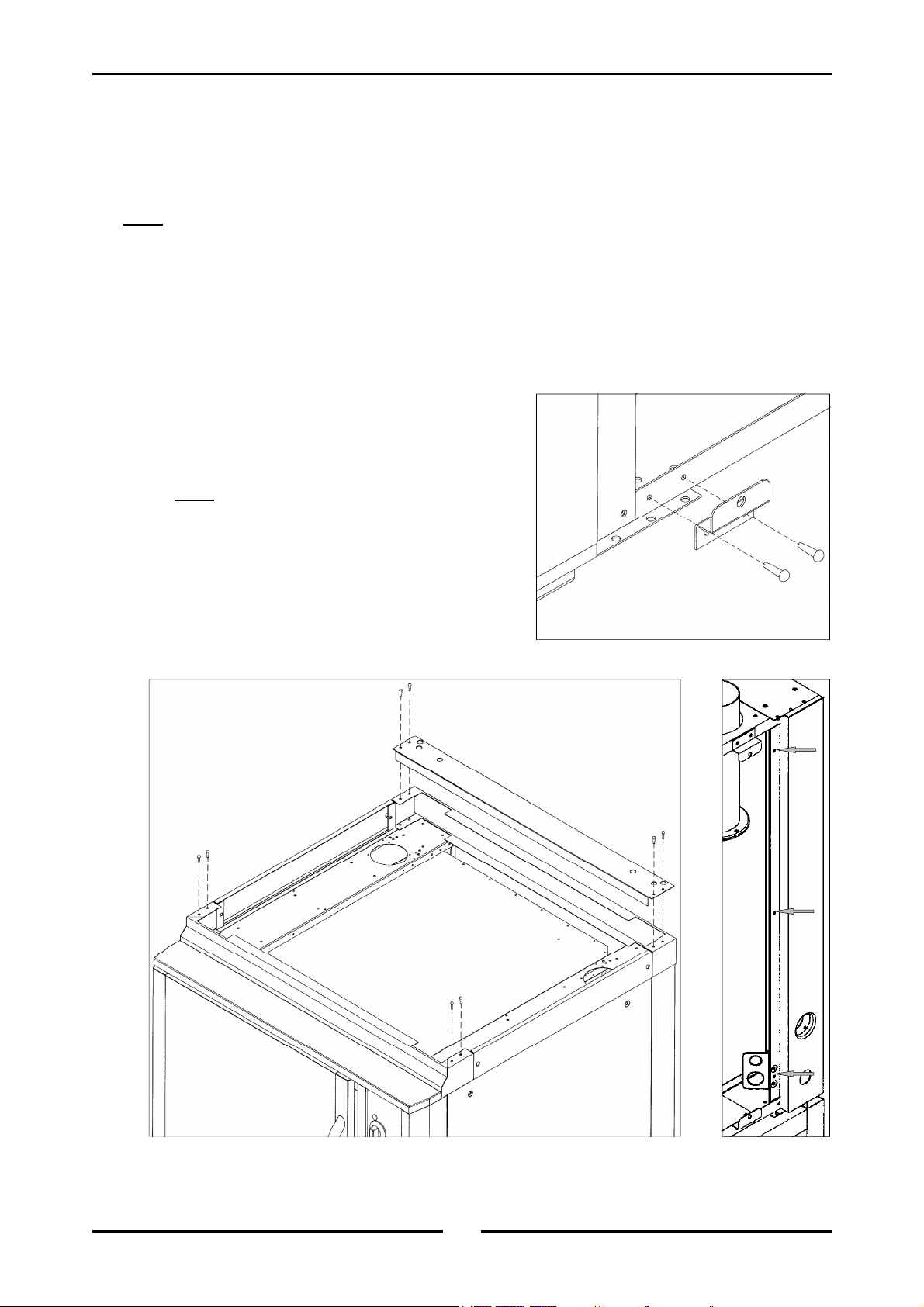

Specifications

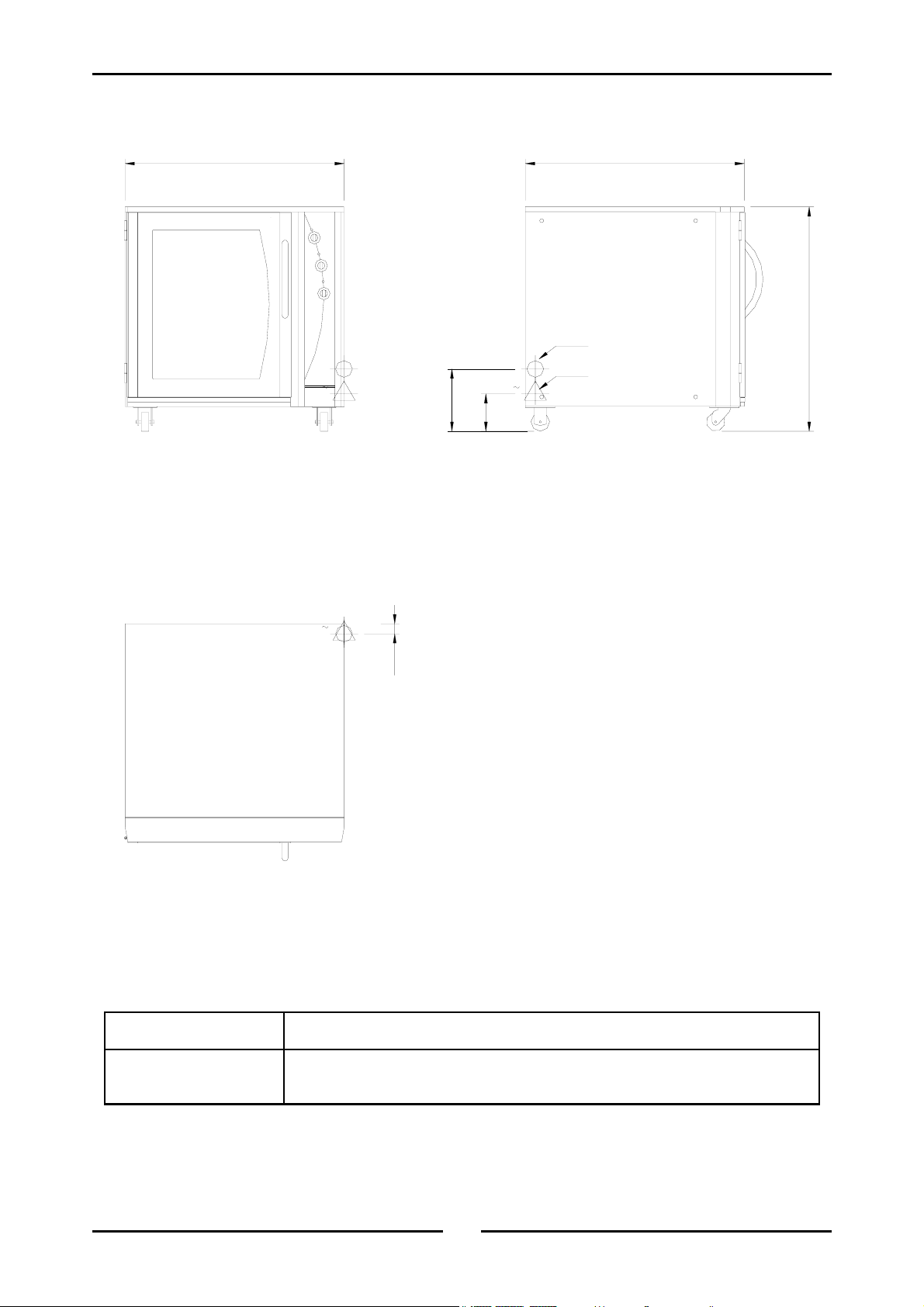

E85-8 Prover

880

Front

880

902

WATER ENTRY

MWS

E

1

MWS

E

1

ELECTRICAL ENTRY

250

150

Side

E

1

MWS

40

Plan

Electrical Connection 220-240 Volts A.C, 50 Hz, 1P+N+E, 1.65 kW, 7.2 A

Cold Water Connection

(Auto Fill Models Only)

¾” B.S.P. or 1/2 ID hose (550kPa / 80psi maximum pressure)

5

Loading...

Loading...