Baja Pulsar200 Owner's manual

Pulsar 200

Users Guide

Stern Technologies, Inc.

Raleigh, NC

Phone: (919) 832-8441

Fax: (919) 832-8441 ext 15

Email: info@sterntech.com

Page 1 of 53

Pulsar Users manual.doc

Table of Contents

Description of the Pulsar 200...................................................................................... 4

Glossary...................................................................................................................... 5

Use of the Guide ......................................................................................................... 7

Pulsar Field Updates ................................................................................................... 7

Section I - Checking Out the Pulsar.................................................................................... 8

Unpacking................................................................................................................... 8

Inspection.................................................................................................................... 8

Care and Handling ...................................................................................................... 8

Guaranty...................................................................................................................... 8

Do Not Open the Pulsar Enclosure!............................................................................ 9

Powering on the Pulsar for the First Time .................................................................. 9

Pulsar Power-on Self Tests (POST)........................................................................ 9

Pulsar 200 Generic Display..................................................................................... 9

Checking the Brightness Control ............................................................................ 9

Section II – Operation of the Pulsar 200........................................................................... 10

Design Goals......................................................................................................... 10

Display Screen.......................................................................................................... 10

Gauge Formats .......................................................................................................... 10

Alarms....................................................................................................................... 12

Status Bar .................................................................................................................. 12

Pilot Controls ............................................................................................................ 12

Inputs......................................................................................................................... 13

Data Logging............................................................................................................. 15

Section III – Installation.................................................................................................... 17

IMPORTANT NOTICE............................................................................................ 17

Installation Planning ................................................................................................. 17

Tools and Materials Required................................................................................... 17

Pulsar 200 Panel Mounting....................................................................................... 17

Installing the Exhaust Gas Temperature (EGT) Probes............................................ 19

Installing the Cylinder Head Temperature (CHT) Probes ........................................ 19

Probe Characteristics................................................................................................. 20

Thermocouple Wiring Harness ................................................................................. 20

Installing Sensors ...................................................................................................... 20

Power and Ground Wiring........................................................................................ 20

Routing the Wiring Harness ...................................................................................... 21

Checking the Installation.......................................................................................... 21

Power on Menu......................................................................................................... 21

Diagnostic Screens and Menus ................................................................................. 22

Section IV - Description................................................................................................... 24

Overview................................................................................................................... 24

Description of Pulsar 200...................................................................................... 24

Inputs..................................................................................................................... 25

Operation Mode ........................................................................................................ 27

Display Pages........................................................................................................ 27

Page 2 of 53

Pulsar Users manual.doc

Specifications............................................................................................................ 28

General Specifications .......................................................................................... 28

Technical Specifications ....................................................................................... 29

Section IV – Configuring the Pulsar 200.......................................................................... 31

Configuration Overview ................................................................................................... 31

Methods of Pulsar Configuration.............................................................................. 31

Sensor Overview............................................................................................................... 31

What is a Sensor?.......................................................................................................... 31

What type of Sensors Can the Pulsar Use?................................................................... 32

Configuration Editor......................................................................................................... 33

Pulsar Connection Utility.................................................................................................. 50

Page 3 of 53

Pulsar Users manual.doc

Description of the Pulsar 200

The Pulsar is an electronic data collection and display device designed specifically for

use in experimental aircraft. The Pulsar 200 has a number of inputs specifically

configured for tachometer and thermocouple inputs. The Pulsar 200 also provides 15

configurable general-purpose inputs suitable for monitoring a wide variety of engine

related sensors. The general-purpose Pulsar inputs can also be used to monitoring nonengine related parameters.

The Pulsar is housed in a single module measuring 6.25 ” W x 4.0” H x 3.0” D. The color

liquid crystal display (LCD) measures 4.0” W x 3.0” H and 5.0” diagonally. The Pulsar

will fit into a standard radio stack. The Pulsar faceplate bezel mounts through the front of

the panel.

The Pulsar will work with power inputs ranging from 8 VDC to 28 VDC. Its current draw

is about one amp at 12 VDC with the display at maximum intensity. The Pulsar provides

an input for backup power system. It will detect a failure of the primary power input and

automatically switch to the backup power. The backup power source is external to the

Pulsar.

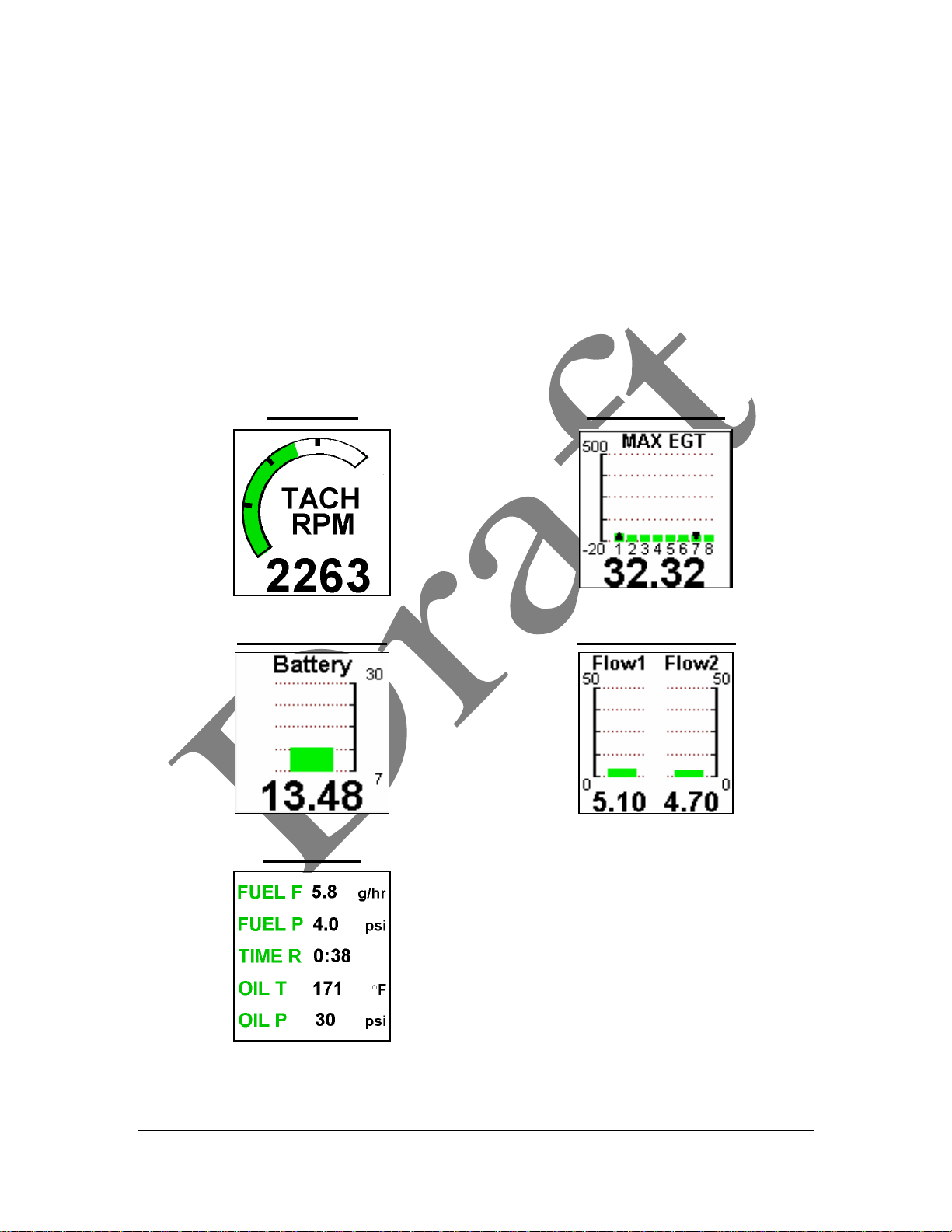

The user interfaces consists of the 5” diagonal LCD and a single control knob. As show

below in figure 1-1, large digital readouts and color-coded gauges make the Pulsar

display easy to read and comprehend. Control knob is the only input required during

normal operation. This pilot-friendly design allows scanning of monitored parameters

with minimal pilot distraction.

Figure 1-1

Page 4 of 53

Pulsar Users manual.doc

Glossary

Alarm Levels: Alarm levels define the point at which a data value is out of limits. When a data

value is out of limits, it will go into an alarm state. The user can define both minimum and

maximum alarm limits for the Pulsar.

Alarm: The audio and/or visual warnings produced by the Pulsar when a data value is outside of its

defined limits.

Block: During normal operation, the Pulsar display is divided into six equal squares – called blocks.

The user can control the type of information shown in each display block.

Cylinder head temperature (CHT): The temperature, measured by thermocouple, at the top of the

engine cylinder.

Data Logging: Users can selected inputs to monitor and store internally. The Pulsar will place

readings from the selected inputs into a section of memory that is saved even through power on-off

cycles. This section of memory can be downloaded from the Pulsar. The downloaded data is used

for historical analysis of operation.

Display: The Pulsar uses a color video monitor for its display. The Pulsar display can show highresolution graphics and text. During normal operation, the Pulsar display is divide d into six equal

blocks.

Download and Downloading: Downloading is the transfer of electronic information from one

computing device to another.

Engine parameter: An engine parameter is any engine data monitored by the Pulsar. A parameter

may be a directly monitored value, such as oil temperature. An engine parameter may also be a

calculated value, such as the EGT span – the difference from the highest to lowest EGT reading.

Exhaust gas temperature (EGT): The temperature, as measure by thermocouple, at the immediate

outlet of each cylinder’s exhaust port.

Fuel totalizer: A summary status of important fuel system information. The fuel totalizer reports on

fuel flow, fuel pressure, fuel used, fuel remaining (volume) and flight time to empty.

Inputs: External electrical signals brought into the Pulsar on its back panel pins. The external

electrical signals are typically from sensors.

Liquid crystal display (LCD) The Pulsar display is a liquid crystal display (LCD). Modern LCD

technology allows the use of displays that are compact, rugged and low power while still producing

high brightness and full color.

Page: The user can control the Pulsar display to show different views of monitored data. The

control knob switches from one view of display data to the next. Each unique screen of the display

with its associated gauges and data represents a Page.

Range: The span from a gauge’s minimum value to its maximum value is its range. A temperature

gauge that displays from 100 to 250 ºF has a range of 150 ºF.

Red line: Indicates the danger zone alarm for a data value.

Sensors: Sensors are devices for converting physical properties (such as pressure, temperature and

flow) into electrical signals. The Pulsar can then read these electrical signals.

Set Up: The initial steps required to prepare the Pulsar for operation. Set up steps may include

setting Pulsar alarm limits or customizing the display.

Page 5 of 53

Pulsar Users manual.doc

Thermistor: A temperature sensor that changes its resistance in response to a change in

temperature. Thermistors are typically used for measuring lower temperatures (up to 200 °F).

Thermocouple: A temperature sensor constructed by welding two wires of different metal alloys

into a junction. A temperature difference between the bi-metallic junction and a remote section of

the wires will produce a very small voltage differential. For different combinations of metals linear

voltage vs. temperature charts can be produced. Thermocouples are used for measuring high

temperatures (up to several thousand degrees Fahrenheit).

Yellow line: Indicates the warning or caution zone alarm for a data value.

Page 6 of 53

Pulsar Users manual.doc

Use of the Guide

The Pulsar Basic User’s Guide is divided into six sections.

Section I – Checking out the Pulsar 200 describes the initial preparation and handling

steps.

Section II – Operation of the Pulsar 200 describes the operation of the unit including

inputs, outputs, the display, pilot controls and data logging.

Section III - Installation covers the mounting of the unit, sensor installation, and wiring

connections.

Section IV – Description shows how to download the Pulsar 200 customization software

from the supplied CD-ROM to your PC.

Section V – Configuring the Pulsar 200 describes the procedure for basic customization

of the software for your Pulsar 200.

Section VI – Specifications provides detailed electrical and mechanical specifications for

the Pulsar 200 and other useful information.

The basic software configuration has many present selections. For complete

customization of all the configurations of the Pulsar 200 refer to the Pulsar 200 Advanced

User’s Guide.

Pulsar Field Updates

From time to time Stern Technologies will provide updates for the Pulsar. These updates

may add new features or correct reported problems. The field updates will change the

program memory resident on the Pulsar. Field update distribution will be via CD-ROM or

from the Stern Technologies web site.

Field updates must be downloaded to the Pulsar using the front panel serial port and a

PC. Windows application documentation provides detailed instructions for performing

Pulsar field updates.

Page 7 of 53

Pulsar Users manual.doc

SECTION I - CHECKING OUT THE PULSAR

Unpacking

Unpack the Pulsar and verify that you have received the following materials:

? Pulsar 200

? Packing list and/or detail receipt

? Connector/harness kit (contents will vary depending on order - see packing list for

specific items delivered)

? Sensor package (contents will vary depending on order – see packing list for

specific items delivered)

? Pulsar 200 User’s Guide

? AC power adapter

? *Pulsar 200 Configuration CD-ROM

? *Serial data cable (3.5mm audio jack to 9-pin DB)

* - Optional material for PC-based customization of the Pulsar.

Inspection

? Carefully inspect the contents of this package for damage. If damage is found, save all

packaging for carrier insurance claims.

? Inspect the contents of the shipment to ensure receipt of all component parts and

materials.

? Visually inspect all components for proper identification or damage. Report any

discrepancies to Stern Technologies within 15 days.

Care and Handling

The Pulsar can withstand rugged use. However, standard precautions for electronic

equipment are required:

? Do not expose to rain or water

? Handle with care – do not drop

? Be sure that all electrical connections are correct and properly made

? The Pulsar display may be cleaned with a soft cloth and mild non-abrasive

cleaning solution

? If the display cracks, it is possible for the liquid crystal to escape from the panel.

Use soap and immediately wash any contact with the liquid crystal.

Guaranty

Stern Technologies provides a 60-day money back guaranty on all its products. This

provides you with ample time to determine that you are pleased with your purchase. If at

any time during this 60-day period you determine that you would like to return the

product please contact Stern Technologies customer support department for a return

Page 8 of 53

Pulsar Users manual.doc

material authorization (RMA) number. Do not return material to Stern Technologies

without first obtaining an RMA number.

Stern Technologies will not charge a restock fee for equipment returned complete and

undamaged during the initial 60-day evaluation period.

Do Not Open the Pulsar Enclosure!

There are no user serviceable parts or adjustments inside the Pulsar. Opening the Pulsar

enclose will break the internal safety seals and VO ID your warranty and guaranty.

Powering on the Pulsar for the First Time

Connect the supplied AC voltage adapter to the Pulsar rear panel connector J1 (six pin

connector). The connector on the AC voltage adapter is keyed and cannot be inserted

incorrectly. Plug the AC voltage adapter into a convenient AC outlet.

Pulsar Power -on Self Tests (POST)

? When powered on the Pulsar will test its internal memory and processors. A screen

message will briefly display the results of the power-on self-test (POST).

? After a successful completion of the POST the Pulsar will proceed to normal operation

mode.

? If any errors are detected during the POST the Pulsar will attempt to repair the errors

and will inform the user. Note if errors keep reoccurring you should contact Stern

Technologies as soon as possible.

Pulsar 200 Generic Display

? The Pulsar 200 ships with generic software loaded. After a successful power-on, the

first page of the generic display is shown. Rotate the control knob clockwise to

change display pages.

? Rotate the control knob counter-clockwise to return to the first display page. When the

display stops changing, you have scrolled through to the first (turning counterclockwise) or the last (turning clockwise) page in the display.

Checking the Brightness Control

? The control knob on the front panel adjusts display brightness when the knob is

pushed in and turned.

? Turning counter clockwise dims the display. If the knob continues to be rotated in the

counter-clockwise direction (while being pushed in) the background will change to

black for low light viewing.

Page 9 of 53

Pulsar Users manual.doc

SECTION II – OPERATION OF THE PULSAR 200

Design Goals

The major design goals for the Pulsar 200 are:

? To present many engine parameters in an easy to comprehend format

? To make selections of engine data simple and easy

? To provide the aircraft owner with an extremely flexible customization of all the

Pulsar’s operating characteristics (displays, inputs selections, special functions,

parameter ranges and alarm levels)

Display Screen

? The five-inch diagonal color screen presents sensor data from 36 inputs (such as

cylinder head temperatures) as well as calculated data (such as rate of change of

cylinder head temperature)

? Up to ten different display pages can be assessed during normal operation. Each page

has six individual blocks – two rows of three columns. Each block can be set to

display one or multiple gauge formats.

? The control knob is used to scroll between display pages.

Figure 2-1: Pulsar display screen

Gauge Formats

Each display page block can be set to display one or multiple gauge formats. Five

different types of gauge formats are available: four types of analog gauges and one type

of text gauge. The gauge format selected will depend on the parameter or parameters to

be displayed and the preference of the user. The five gauge formats are shown below:

Some of the gauges include special features. The multi-bar gauge indicates which of the

parameters shown has the highest value (up pointer) and which has the lowest value

(down pointer).

Page 10 of 53

Pulsar Users manual.doc

The user can configure text gauges to display up to five parameters in one block. For

diagnostic purposes, an entire page can be devoted to text gauges. This allows

simultaneous viewing and comparison up to 30 parameters.

The user can also set the range of a gauge. For example, the RPM range might be set

from 0 to 3000 RPM for a Lycoming engine – or it could be set from 0 to 3500 for a

Jabiru engine.

The user sets the alarm limits separately from the gauge displays. Alarms can be set for

minimum and maximum values. Alarm limits can be set to indicate a warning range

(yellow) and a danger range (red).

Figure 2-2: Gauge Formats

Arc gauge Multi-bar gauge

Single bar gauge Double bar gauge

Text gauge

Page 11 of 53

Pulsar Users manual.doc

Alarms

The user can configure different alarm levels on the Pulsar. A warning level alarm

(normally indicated with a yellow color) tells the pilot a parameter is about to enter a

dangerous level. A danger level alarm (normally indicated with a red color) tells the pilot

a parameter has entered the danger zone.

The Pulsar provides both audio and visual indications for alarms. If the audio alarm pins

on the J1 connector are attached to an audio device (such as an intercom), a tone will be

generated when an alarm is active. In addition, the gauge containing the out-of -level

parameter will be display in its alarm color (yellow or red – depending on the alarm

level) and begin to blink.

The pilot can acknowledge this alarm by pushing in the control knob. The audio alarm

and display blinking will stop. The gauge will remain in its alarm color as long as the

value of the parameter stays in the alarm range. An alarm status indicator will also appear

in a status area at the bottom of the display. The alarm status will always be display, even

if the pilot switches pages.

If the parameter remains at the danger alarm level (red), the alarm sequence (audio and

display blinking) will reoccur every 5 minutes to remind the pilot of the alarmed

parameter. The user can modify this interval if desired.

Status Bar

A status bar is placed at the bottom of each page and is the same for all pages. The status

bar includes the date and time and indicates if any parameters are in an alarm condition.

If multiple parameters are in an a larm condition, only one alarm is shown.

The time display is in 24-hour format. The user can set both date and time. The format

for the date and time display is:

MM/DD/YYYY HH/MM/SS

Pilot Controls

A single knob on the front panel provides the pilot with three functions during normal

operation.

1. Page Selection – Turning the control knob scrolls the display pages. Turning the

knob counter clockwise will scroll up toward the first page. Turning the knob

clockwise will scroll down toward the last page. Scrolling will stop when the

reaching the first or last page .

2. Acknowledge – The pilot acknowledges warnings and alarms by pushing in the

control knob.

3. Screen brightness – The pilot can push in and turn the control knob to adjust the

screen brightness. Turning counter clockwise will dim the screen while turning

clockwise will brighten the screen. As the screen dims, the screen contrast will

Page 12 of 53

Pulsar Users manual.doc

change from dark characters on a light background to light characters on a dark

background.

The control knob is a lso used for various selections when the Pulsar is in menu mode.

Inputs

The Pulsar directly monitors 36 inputs. In many applications, not all of the inputs are

used.

Some Pulsar inputs work with specific types of signals such as thermocouple voltages or

the signals from magneto P leads. The configurable inputs can handle signals from a

variety of sender types.

Page 13 of 53

Pulsar Users manual.doc

Table 2-1: Pulsar Inputs

Input Connector Pins Input Type

J2-9 (-), J2-10 (+) thermocouple

J2-11 (-), J2-12 (+) thermocouple

J2-13 (-), J2-14 (+) thermocouple

J2-15 (-), J2-16 (+) thermocouple

J3-9 (-), J3-10 (+) thermocouple

J3-11 (-), J3-12 (+) thermocouple

J3-13 (-), J3- (+) thermocouple

J3-15 (-), J3-8 (+) thermocouple

J2-1 (-), J2-2 (+) thermocouple

J2-3 (-), J2-4 (+) thermocouple

J2-5 (-), J2-6 (+) thermocouple

J2-7 (-), J2-8 (+) thermocouple

J3-1 (-), J3-2 (+) thermocouple

J3-3 (-), J3-4 (+) thermocouple

J3-5 (-), J3-6 (+) thermocouple

J3-7 (-), J3-8 (+) Thermocouple

J4-15 (+), J4-16 (-) Inductive input

J5-1 AC voltage (coil, magne to, alternator)

J4-1 AC voltage (coil, magneto, alternator)

J5-15 Configurable

J4-11 Configurable

J5-13 Configurable

J5-14 Configurable

J5-11 Configurable

J5-12 Configurable

J5-6 Configurable

J4-6 Configurable

J5-3 Configurable

J4-3 Configurable

J5-9 Configurable

J4-9 Configurable

J4-14 Configurable

J4-13 Configurable

J4-12 Configurable

J1-1 (+), J1-2 (-) Voltage

J1-3 (+), J1-4 (-) Voltage

J1-6(+), J1-5(-) Alarm Output

Configurable inputs will accurately measure resistive, voltage or frequency output

senders.

? The input range for resistive senders is from 10 ohms to 12,000 ohms

? The input range for voltage senders is from 0.4V DC to 4.5V DC

? The input range for frequency senders is 5 Hz to 10,000 Hz.

? The input range for coil inputs is 0 Hz to 500 Hz.

Page 14 of 53

Pulsar Users manual.doc

Figure 2-4 shows the rear panel connections for the Pulsar. J1 through J5 are printed

circuit board mounted connectors. Sensor inputs are terminated to cable plugs with a

screw down latch. These connections are gas tight and provide long-term reliability.

Figure 2-4: Pulsar Rear Panel Connections

Data Logging

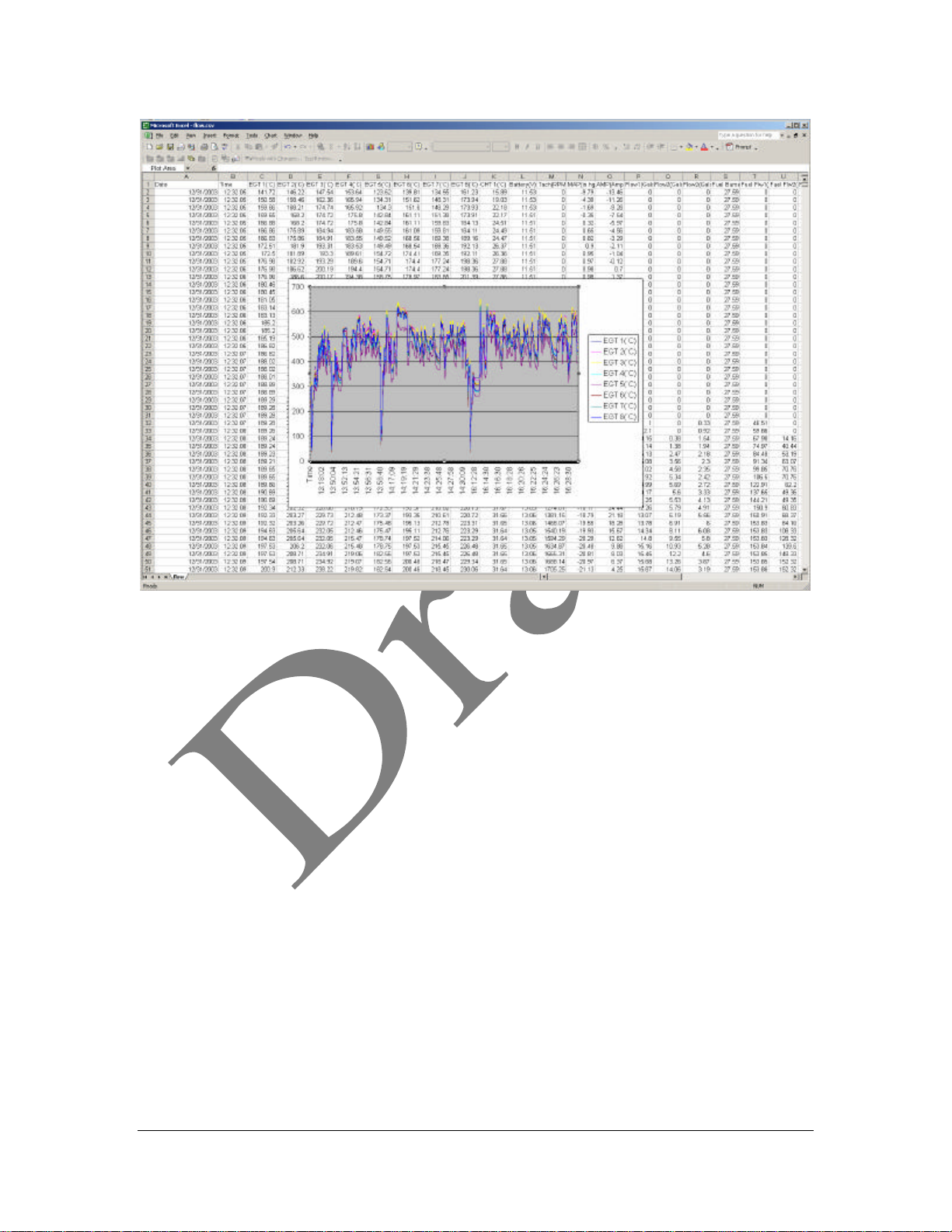

The Pulsar 200 provides a data logging capability. The user determines the parameters to

log and the rate of data logging ( the maximum data logging rate is 10 samples per

second). The depth of data logging (number of hours that can be record) is determined

by:

1. the number of parameters logged, and

2. the frequency of data logging

Logging twelve parameters (for example: 4 EGT’s, 4 CHT’s, tachometer, oil pressure, oil

temperature and fuel flow) at a sample rate of once per second (all parameters record

each second) will provide approximately 100 hours of data recording time. Each sample

includes a time and date stamp.

Users retrieve logged data from the Pulsar front panel serial port. A PC is required to

download data from the Pulsar. Downloaded data can be directly imported into a number

of computer programs for analysis or graphing. Figure 2-5 shows data logged by the

Pulsar and graphed in a Microsoft Excel spreadsheet. Chapter xx provides details on data

logging, downloading and analysis.

Page 15 of 53

Pulsar Users manual.doc

Figure 2-5: Logged Pulsar data graphed in an Excel spreadsheet

Page 16 of 53

Pulsar Users manual.doc

Loading...

Loading...