Page 1

Owner’s Manual & Safety Instructions

Save This Manual Keep this manual for the safety warnings and precautions, assembly,

operating, inspection, maintenance and cleaning procedures. Write the product’s serial number in the

back of the manual near the assembly diagram (or month and year of purchase if product has no number).

Keep this manual and the receipt in a safe and dry place for future reference. 19e

!"#"$%&'(%)*+#"$*%,$-%.$$/-00)))1.,(+&(2(*"3.$14&5

65,"7%&'(%$*4.8"4,7%#'//&($%,$-%/(&9'4$#'//&($:.,(+&(2(*"3.$14&5

When unpacking, make sure that the product is intact

and undamaged. If any parts are missing or broken,

please call 1-888-866-5797 as soon as possible.

Copyright© 2019 by Harbor Freight Tools®. All rights reserved.

No portion of this manual or any artwork contained herein may be reproduced in

any shape or form without the express written consent of Harbor Freight Tools.

Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein.

Too l s r e q ui r e d f o r a s s em b l y a n d s e rv i c e m a y n o t b e i n c lu d e d.

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Page 2

E,+7*%&2%F&8$*8$#

Specifications ............................................................2

Safety ........................................................................3

Setup .........................................................................6

Operation ..................................................................13

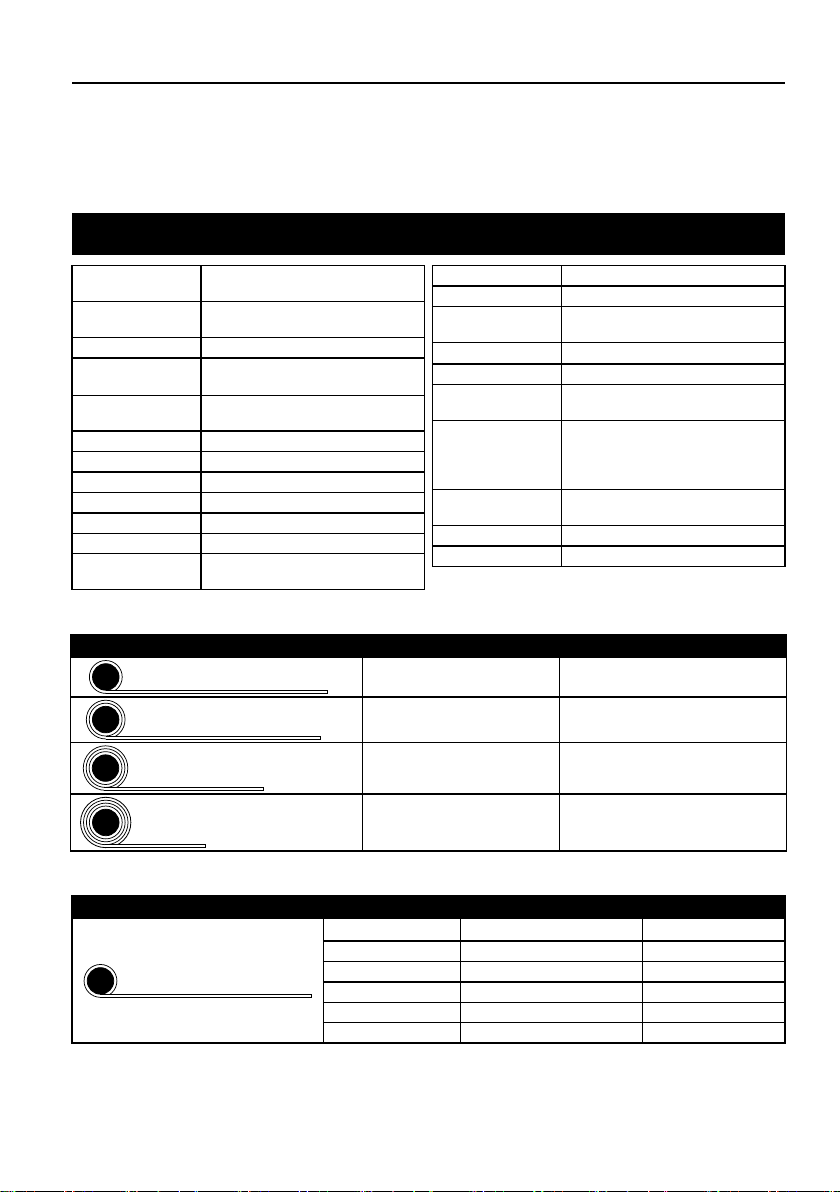

G/*4"2"4,$"&8#

Rated Single

Line Pull

Application

Motor 12 VDC Series Wound

Power IN &

Power OUT

Duty Cycle Rating

Remote Control Wireless / Wired, 12 ft (3.7 m) long

Gear Train 3-Stage Planetary

Gear Ratio 210:1

Freespool Rotating Ring Gear

Brake Automatic Load Holding

Drum (Dia. X L) 2.5" x 8.8" (64 mm x 224 mm)

Clevis Hook

12,000 lb (5443 kg)

Vehicle Recovery /

For Trucks and SUV’s

Yes

5% (45 sec at Max Rated Load;

14 min, 15 sec Rest)

3/8", Replaceable with

Spring-loaded Safety Latch

I,J*( K,$*9%I"8*%L'77 GJ8$.*$"4%K&/*%F,/,4"$J

>

12000 lb (5443 kg) 16.3' (5 m)

Maintenance .............................................................14

Parts List and Diagram .............................................18

Warranty ...................................................................20

Fairlead Aluminum Fairlead

Sound Rating 85 dB

Synthetic Rope

Size / Type

Battery 12 VDC Minimum 650 CCA

Battery Cables Minimum 2 AWG x 6'

Mounting Bolt

Pattern

Mounting

Hardware

Overall Dimensions

(L x D x H)

Shipping Weight 80 lb (36.2 kg)

IP Rating IP68 / IP69K

Ø0.375" x 80' (Ø 9.5 mm x 24.4 m)

10" x 4.5" (254 mm x 114.3 mm)

H"84.-

8 x Gr8.8, M10 x 30 mm

;,"(7*,9-%

2 x Gr8.8, M12 x 40 mm

23.2" x 6.67" x 9.96"

(590 mm x 169.5 mm x 253 mm)

M

N

O

9517 lb (4317 kg) 37' (11 m)

7885 lb (3577 kg) 60' (18.3 m)

6732 lb (3053 kg) 80' (24.4 m)

;"(#$%I,J*(%&2%GJ8$.*$"4%K&/*%L*(2&(5,84*

I"8*%L'77%lb (kg) I"8*%G/**9%fpm (mpm) P5/%Q(,)%(@ 12V)

0 (0) 31.5 (9.6) 60

>

Page 2 ;&(%$*4.8"4,7%<'*#$"&8#=%/7*,#*%4,77%>?@@@?@AA?BCDC1 Item 56385

3000 (1361) 12.1 (3.7) 166

6000 (2722) 8.9 (2.7) 259

9000 (4082) 6.7 (2.0) 349

12000 (5443) 4.7 (1.43) 448

Page 3

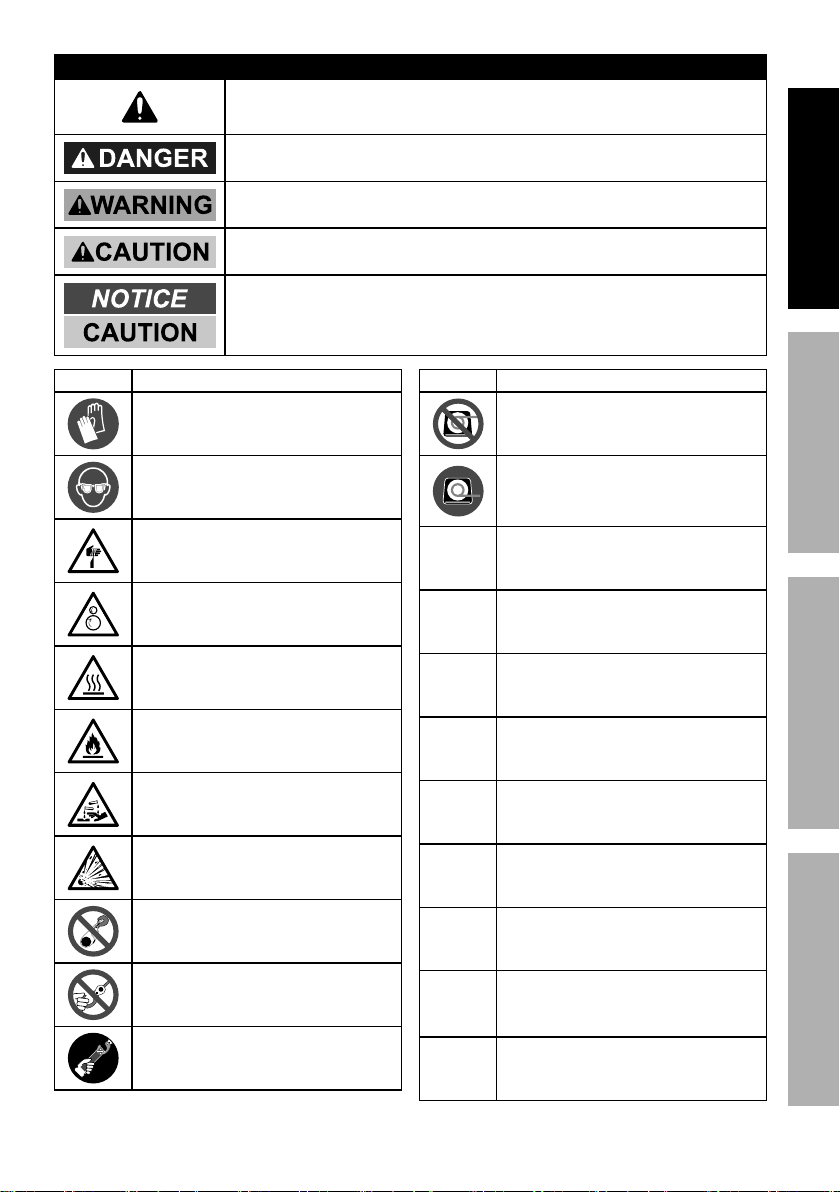

HPKUTUX%GRVYSIG%PUQ%Q6;TUTETSUG

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that

follow this symbol to avoid possible injury or death.

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Addresses practices not related to personal injury.

GP;6ERSL6KPETSUVPTUE6UPUF6 G6EWL

GJ5+&7 L(&/*($J%&(%G$,$*5*8$

H*,(%.*,ZJ?9'$J=%4'$?%,89%

,+(,#"&8-(*#"#$,8$%7*,$.*(%37&Z*#1

H*,(%PUGT?,//(&Z*9%#,2*$J%37,##*#1

F'$%&(%#*Z*(%.,[,(91

K&77*(%*8$,837*5*8$%.,[,(91

\&$%#'(2,4*%+'(8%.,[,(91

;"(*%.,[,(91

F,'#$"4%4.*5"4,7%],4"9^%.,[,(91

6_/7&#"&8%.,[,(91

Q&%8&$%7&&/%$.*%#J8$.*$"4%(&/*%

,(&'89%&+`*4$%,89%.&&a%&8$&%"$#*721

Q&%8&$%/7,4*%2"83*(]#^%$.(&'3.%.&&a1%%

;"83*(#%5,J%+*%4,'3.$%,89%3*$%

/'77*9%"8$&%2,"(7*,9%&(%9('51

L'77%.&&a%'#"83%#$(,/%&87J1

GJ5+&7 L(&/*($J%&(%G$,$*5*8$

Q&%8&$%'#*%)"84.%"8%&Z*()"89%

&("*8$,$"&81%]GJ8$.*$"4%(&/*%

*8$*(#0*_"$#%,$%$.*%$&/1^

W#*%)"84.%&87J%"8%

'89*()"89%&("*8$,$"&81%%

]GJ8$.*$"4%(&/*%*8$*(#0

*_"$#%,$%$.*%+&$$&51^

!QF

FFP

\L

2/5

5/5

KLV

X@

Volts Direct Current

Amperes

P

Cold Cranking Amperes

Horsepower

Feet Per Minute

Meters Per Minute

Revolutions Per Minute

International Protection rating

Classifies the degrees of protection provided

TL

against the intrusion of solid objects,

dust, accidental contact, and water.

Grade 8

A fastener strength rating.

Page 3;&(%$*4.8"4,7%<'*#$"&8#=%/7*,#*%4,77%>?@@@?@AA?BCDC1Item 56385

Page 4

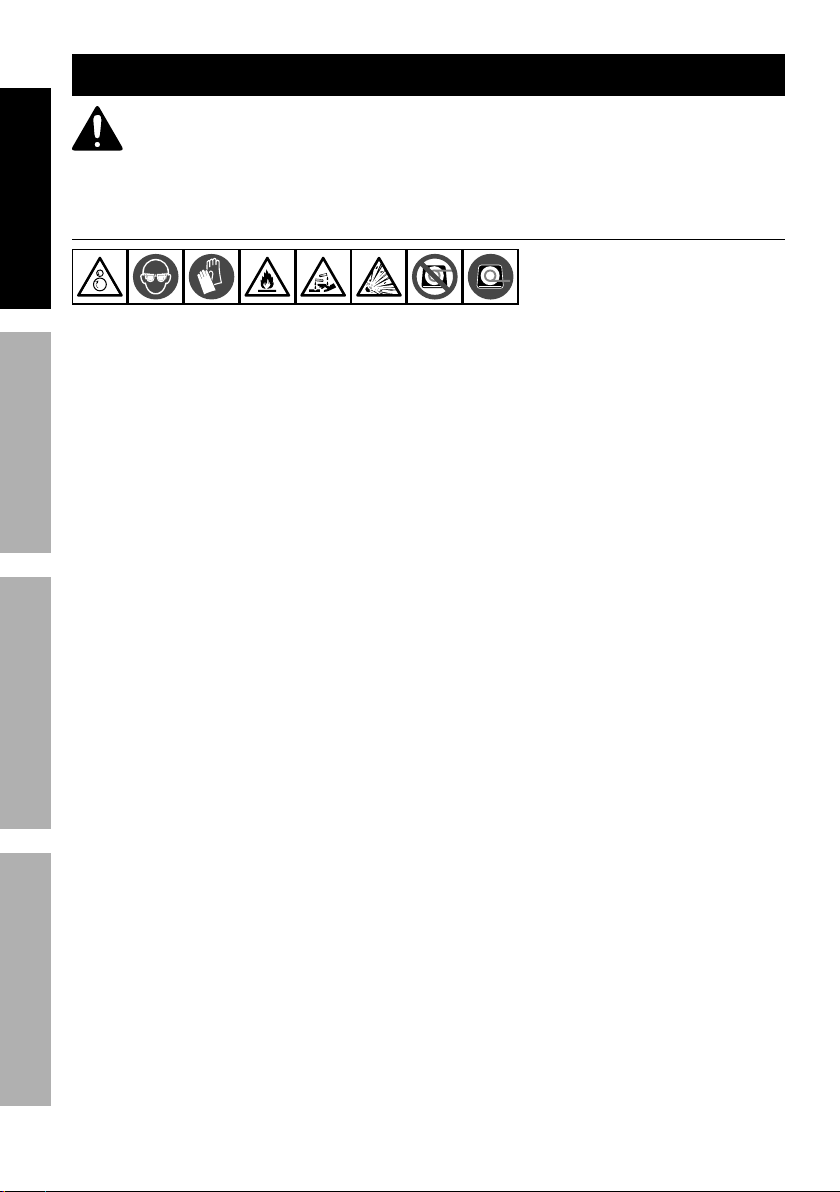

TVLSKEPUE%GP;6ER%TU;SKVPETSU

% HPKUTUXb%K*,9%,77%"8#$('4$"&8#1 ;,"7'(*%$&%2&77&)%,77%"8#$('4$"&8#%7"#$*9%&8%/,3*%O%%5,J%(*#'7$%

"8%2"(*=%#*("&'#%"8`'(J%,890&(%Q6PE\1%

GP;6ER SL6KPETSU VPTUE6UPUF6G6EWL

The warnings and precautions discussed in this manual cannot cover all possible conditions and

situations that may occur. It must be understood by the operator that common sense and caution

are factors which cannot be built into this product, but must be supplied by the operator.

T8#$,77,$"&8%L(*4,'$"&8#

1. Do not wear loose clothing or jewelry,

as they can be caught in moving parts.

Non-skid footwear is recommended.

Wear restrictive hair covering to contain long hair.

2. Wear ANSI-approved safety goggles and

heavy-duty leather work gloves during installation.

3. Before installation confirm that area is clear

of fuel lines, brake lines, electrical wires,

gas tanks or any other component which

could be damaged during drilling.

4. Mounting location and hardware

must support Winch and load.

5. Use supplied power cords and synthetic rope

listed in manual only. Do not use thinner/

longer cables or link multiple cables together.

6. Do not route electrical cables near sharp edges

or parts that will move or become hot.

7. Ventilate area well before and while working

on battery. Explosive invisible hydrogen gas

can accumulate and then explode when ignited

by a spark from the battery connection.

8. Only connect to a clean, corrosion free battery.

9. Do not lean over or come in contact with

battery while making connections.

10. Remove all metal jewelry before

working near battery.

11. Connect the red cable to the Disconnect Switch,

then connect the 12" 2AWG cable to the Disconnect

Switch and the positive battery terminal. Connect

the black cable to the negative battery terminal.

12. Insulate all exposed wiring and

terminals after installation.

13. Install Winch and Fairlead in underwind

orientation, so that the Synthetic Rope enters

and exits the Winch at the bottom of the drum.

Page 4 ;&(%$*4.8"4,7%<'*#$"&8#=%/7*,#*%4,77%>?@@@?@AA?BCDC1 Item 56385

Page 5

G*(Z"4*%L(*4,'$"&8#

1. Wear ANSI-approved safety goggles and

heavy-duty leather work gloves during service.

2. Disconnect power to Winch and allow it

to cool completely before service.

3. Use supplied power cords, synthetic rope or

cables listed in manual only. Do not use thinner/

longer cables or link multiple cables together.

%GP!6%E\6G6%TUGEKWFETSUG1

4. Have the Winch serviced by a qualified

repair person using only identical

replacement parts. This will ensure that

the safety of the Winch is maintained.

5. Maintain labels and nameplates on the Winch.

These carry important safety information.

If unreadable or missing, contact

Harbor Freight Tools for a replacement.

GP;6ERSL6KPETSUVPTUE6UPUF6 G6EWL

Page 5;&(%$*4.8"4,7%<'*#$"&8#=%/7*,#*%4,77%>?@@@?@AA?BCDC1Item 56385

Page 6

T8#$,77,$"&8%,89%G*$'/

% K*,9%$.*%6UETK6%TVLSKEPUE%GP;6ER%TU;SKVPETSU%#*4$"&8%,$%$.*%+*3"88"83%&2%$."#%

5,8',7%"847'9"83%,77%$*_$%'89*(%#'+.*,9"83#%$.*(*"8%+*2&(*%#*$%'/%&(%'#*%&2%$."#%/(&9'4$1

GP;6ER SL6KPETSU VPTUE6UPUF6G6EWL

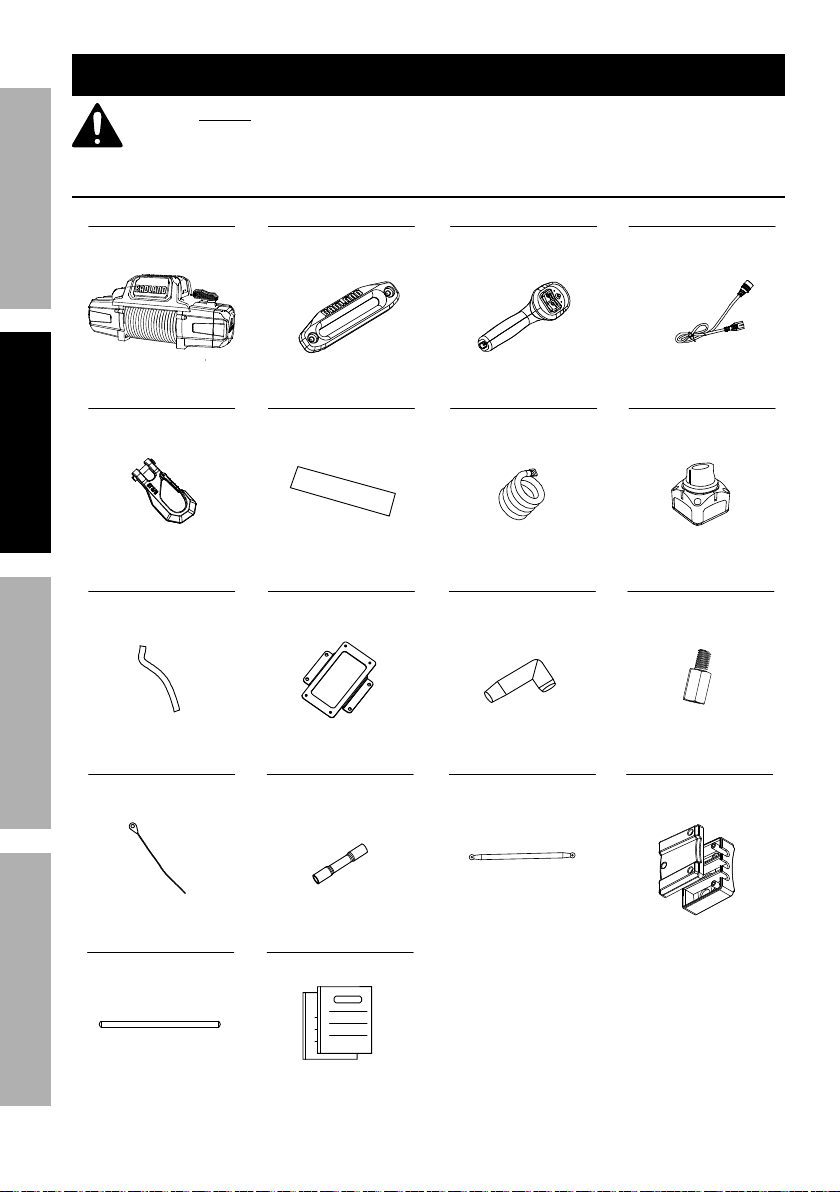

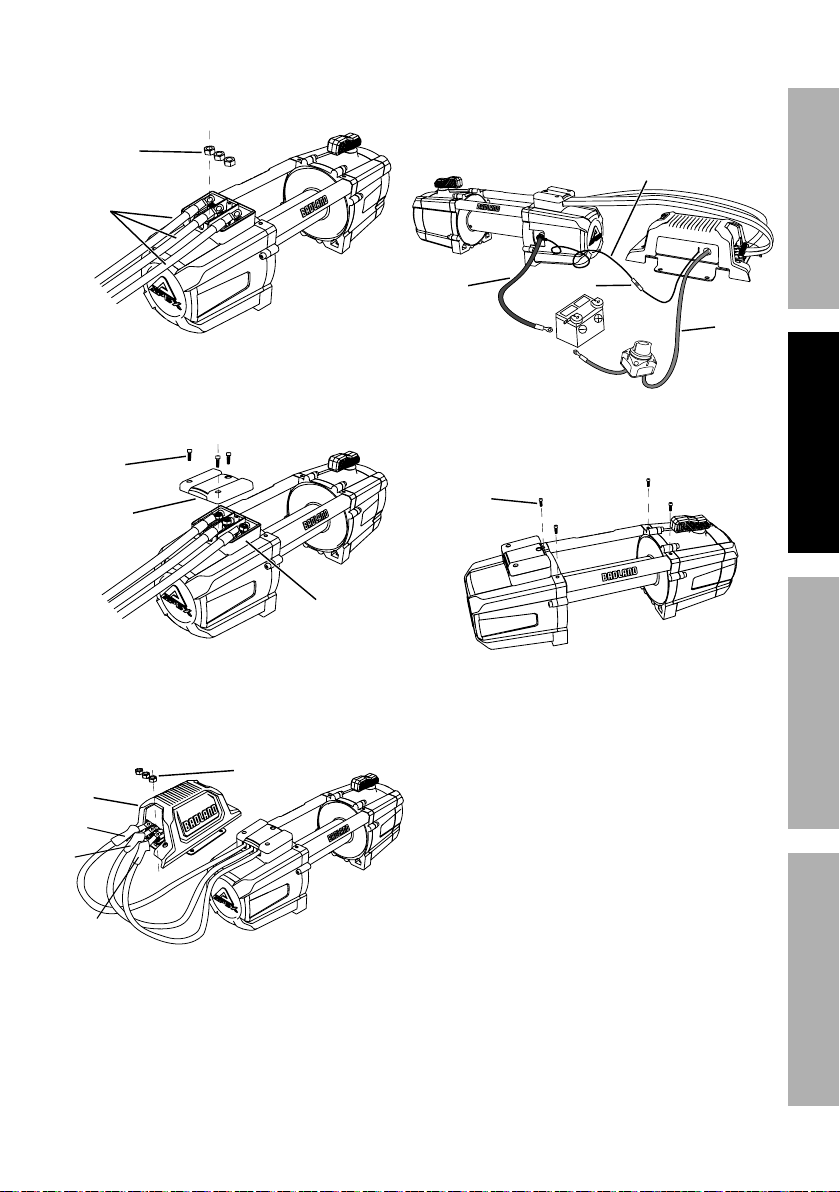

H.,$c#%"8%$.*%Y&_

Winch x 1 Aluminum Fairlead x 1

Hook x 1

Red Hook Strap x 1 Control Box Baseplate x 1 Sheath (red, black, yellow) x 3

Small Black

Wire Extension x 1

Rope Protecting Mat x 2 Ground Cable x 1 Disconnect Switch x 1

Small Black

Wire Connector x 1

Remote Control x 1

Disconnect Switch Cable x 1

Remote Control Cable x 1

Extended Copper Screw x 3

Terminal Box x 1

Terminal Box Cover x 1

Power Cables

(relocation kit) x 3

Instruction Books

• Manual

• Guide to Winching

Page 6 ;&(%$*4.8"4,7%<'*#$"&8#=%/7*,#*%4,77%>?@@@?@AA?BCDC1 Item 56385

Page 7

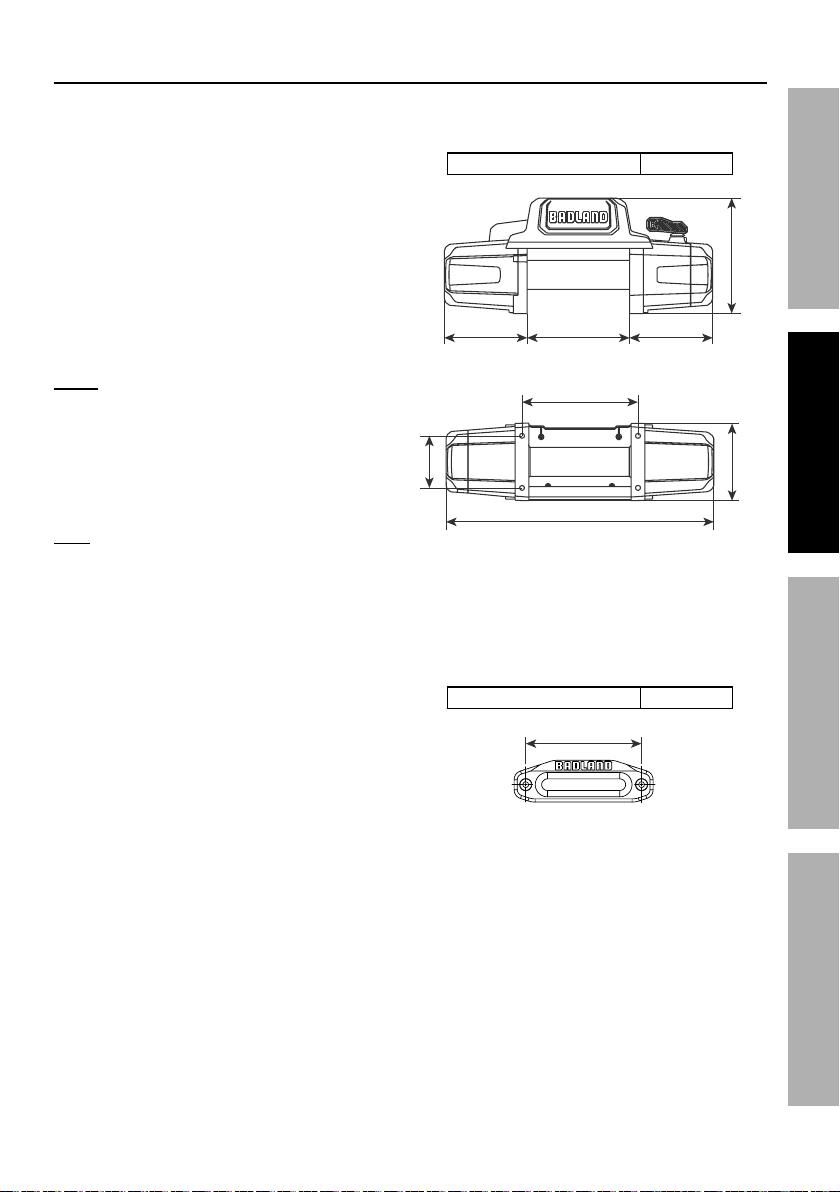

V&'8$"83%$.*%H"84.

1. Make sure the Winch will fit the chosen mounting

area. If relocating the Control Box is necessary

or desired, perform the removal and installation

of cables to the Winch before mounting. Refer

to Relocating the Control Box on page 8.

2. The mounting plate must be rated to

at least the Winch’s capacity.

3. Align the Winch perpendicular to center line of

the vehicle at the desired location, and mark the

locations of the winch base holes. Compare the

dimensions of the marked holes to Figure A.

4. Before drilling, verify that the installation

surface has no hidden components or

structural pieces that will be damaged.

USE6-%%This Winch can generate extreme

forces. Select a location that can withstand the

rated capacity without damage or weakening.

Steel reinforcement plates may be needed or a

certified welder may need to weld on additional

bracing depending on the mounting location.

5. Drill holes appropriate for the hardware

at the marked locations.

U&$*- Depending on the vehicle application, it may

be beneficial to install the wiring before mounting

the Winch. Check all terminal access and plan

wiring routes before mounting the Winch.

6. Install the Winch using hardware specified

on the specification chart. Tighten fasteners

to the following torque values:

Winch mounting fasteners 30 –33 ft-lb

8.82 in. / 224 mm 7.2 in. / 183 mm7.2 in. / 183 mm

10 in. / 254 mm

4.49 in. / 114 mm

23.2 in. / 590 mm

;"3'(*%P-%%H"84.%Q"5*8#"&8#

7. Mount the Fairlead centered on the Winch

to guide the Rope onto the Winch drum.

8. Install the Fairlead using hardware specified

on the specification chart. Tighten fasteners

to the following torque values:

Fairlead mounting fasteners 53 – 57 ft-lb

10 in. / 254 mm

GP;6ERSL6KPETSUVPTUE6UPUF6 G6EWL

9.96 in. / 253 mm

6.67 in. / 169.5 mm

;"3'(*%Y-%%;,"(7*,9%V&'8$"83%Q"5*8#"&8#

Page 7;&(%$*4.8"4,7%<'*#$"&8#=%/7*,#*%4,77%>?@@@?@AA?BCDC1Item 56385

Page 8

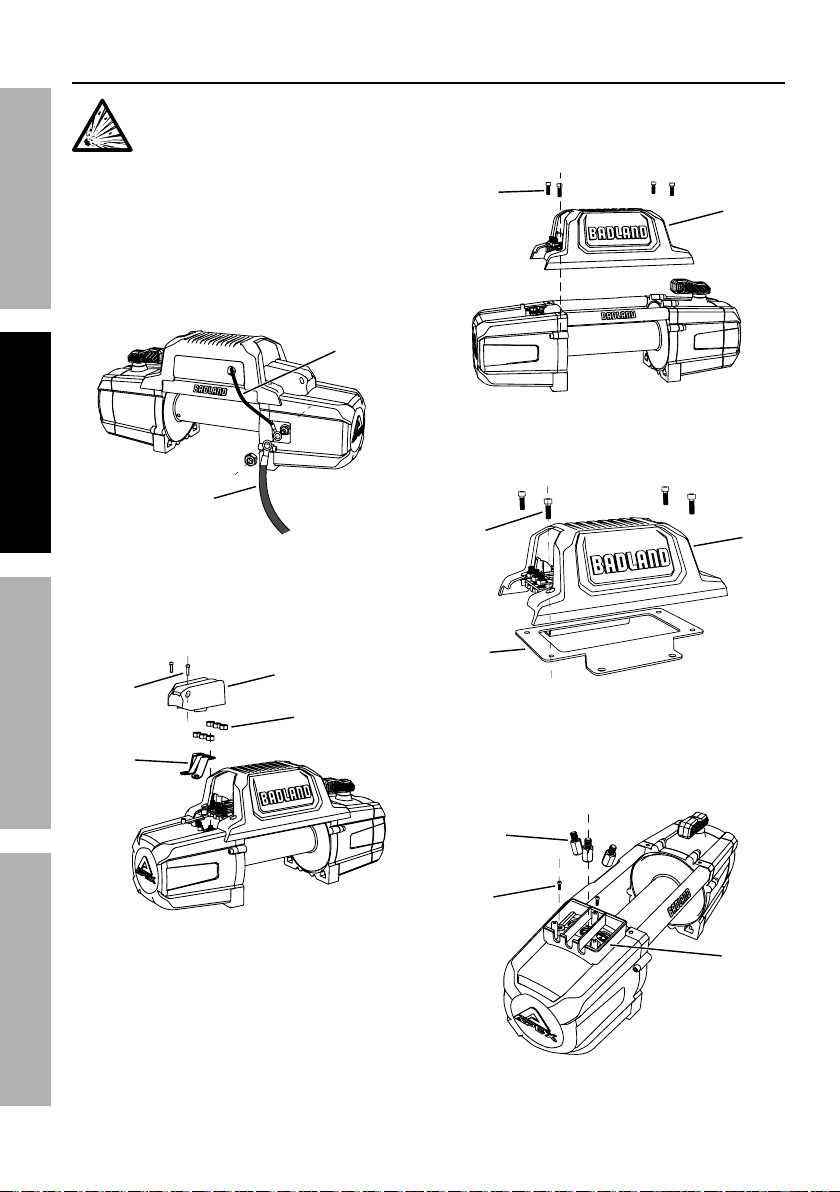

K*7&4,$"83%$.*%F&8$(&7%Y&_%]&/$"&8,7^

ES%LK6!6UE%G6KTSWG%TUdWKR%;KSV%6eLISGTSU%%

QW6%ES%GLPKfTUX%PE%E\6%YPEE6KR%FSUU6FETSU-%

W8/7'3%$.*%K*5&$*%F&8$(&7%F,+7*%,89%9"#4&88*4$%$.*%Y,$$*(J%F,+7*#%%

GP;6ER SL6KPETSU VPTUE6UPUF6G6EWL

1. Engage the clutch on Winch.

2. Disconnect the vehicle battery

3. Disconnect the Ground Cable and Small Black

4. Remove the Terminal Cover by unscrewing two

+*2&(*%5,a"83%&$.*(%)"("83%4&88*4$"&8#1

cables, negative terminal first.

Wire from terminal on rear of Winch. Make

sure the Small Black Wire that connects to the

Control Box is disconnected and hanging freely.

G5,77%

Y7,4a%

H"(*

X(&'89%

F,+7*

M4 x 16 Screws holding it in place. Remove

the six Motor Terminal Nuts and three

Copper Plates. Retain all the hardware.

M4 x 16

G4(*)

F&//*(%

L7,$*#

E*(5"8,7%F&Z*(

V&$&(%

E*(5"8,7%

U'$#

M6 x 25

G4(*)

F&8$(&7%

Y&_

6. Attach the Control Box Baseplate to the Control Box

using the four M6 x 25 Screws removed in step 5.

M6 x 25

G4(*)

F&8$(&7%

Y&_%

Y,#*/7,$*

F&8$(&7%

Y&_

7. Install the three Extended Copper Screws

to the terminal on the motor. Mount the

Terminal Box on the Winch using two M4 x 12

screws. Do not overtighten screws.

6_$*89*9%

F&//*(%

G4(*)

M4 x 12

G4(*)

5. Remove four M6 x 25 Screws holding the Control

Box in place and gently lift it off of the Winch.

E*(5"8,7%

Y&_

Page 8 ;&(%$*4.8"4,7%<'*#$"&8#=%/7*,#*%4,77%>?@@@?@AA?BCDC1 Item 56385

Page 9

8. Connect three Power Cables (Control Box

Relocation Kit) to the Extended Copper

Screws on motor terminal using three of the

Motor Terminal Nuts removed in step 4.

V&$&(%

E*(5"8,7%

U'$#

L&)*(%

F,+7*#

11. Use the Small Black Wire Connector and

Small Black Wire Extension to lengthen

the Small Black Wire from the Control Box.

Reconnect the Ground Cable and Small Black

Wire to the backside of the Winch motor.

G5,77%Y7,4a%

H"(*%6_$*8#"&8

GP;6ERSL6KPETSUVPTUE6UPUF6 G6EWL

9. Install the Terminal Box Cover on the Terminal

Box using three M4.8 x16 Self-Tapping

Screws. Do not overtighten screws.

M4.8 x 16

G4(*)

E*(5"8,7%

Y&_%F&Z*(

E*(5"8,7%

Y&_

10. Connect three Power Cables (control box

relocation kit) to the Control Box using remaining

three Motor Terminal Nuts removed in step 4.

V&$&(%

E*(5"8,7%

F&8$(&7%

Y&_

black

red

U'$#

Y7,4a%

X(&'89%

F,+7*

F&88*4$&(

12. Install the four decorative M6 x12

Screws onto the Winch.

M6 x 12

G4(*)

13. Place the Control Box on a solid mounting

surface in a suitable place near enough to the

Winch to allow the cables to be routed properly.

14. Verify that the installation surface has no

hidden components or structural pieces

that will be damaged before drilling.

15. Secure the Control Box assembly in place

with Baseplate mounting hardware.

K*9%

Y,$$*(J%

F,+7*

yellow

Page 9;&(%$*4.8"4,7%<'*#$"&8#=%/7*,#*%4,77%>?@@@?@AA?BCDC1Item 56385

Page 10

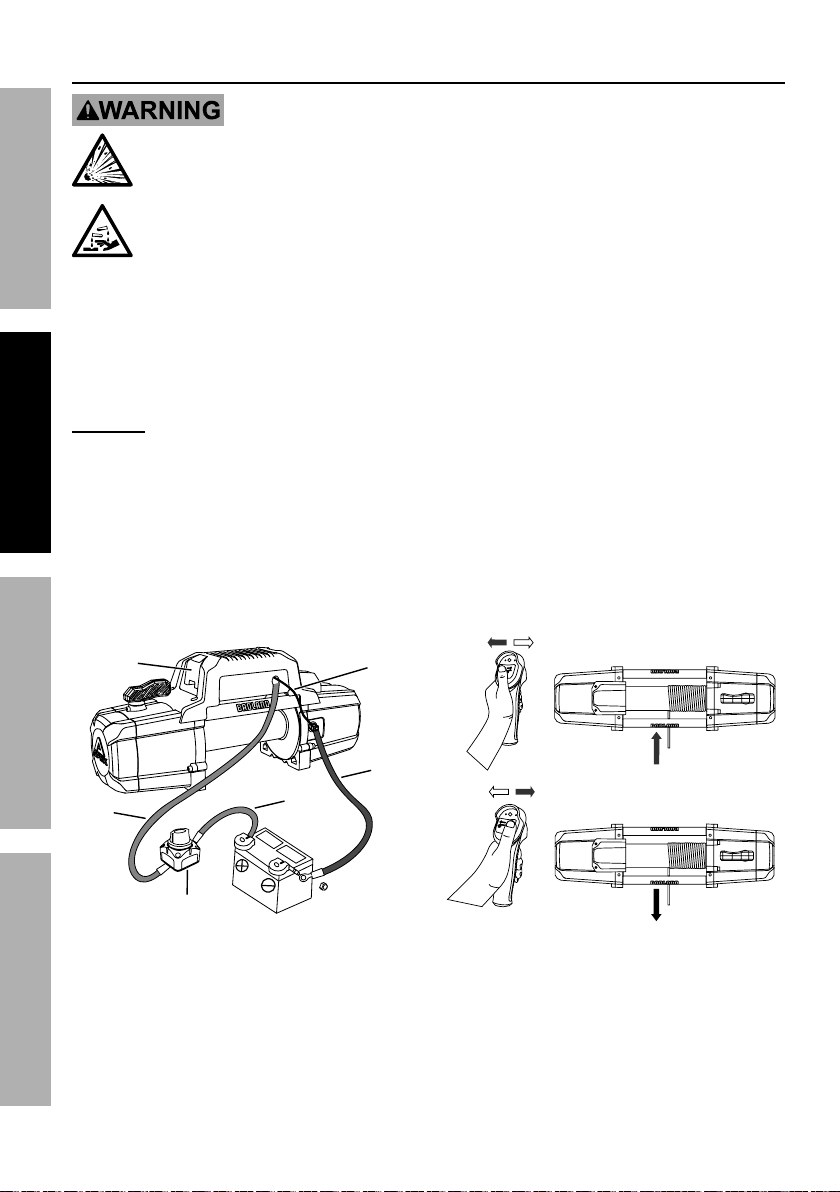

H"("83

ES%LK6!6UE%G6KTSWG%TUdWKR%;KSV%6eLISGTSU%%

GP;6ER SL6KPETSU VPTUE6UPUF6G6EWL

1. Plan a route for the wiring from the point of the

HPKUTUXb Do not attach the wires to the exhaust

system, drive shaft, emergency brake cable, fuel line, or

any other components which may create damage to the

wiring through heat or motion, or create a fire hazard.

2. If you drill through the bumper or any part

3. Route the Cables from the Winch to the battery,

QW6%ES%GLPKfTUX%PE%E\6%YPEE6KR%FSUU6FETSU-%

W8/7'3%$.*%K*5&$*%F&8$(&7%F,+7*%,89%9"#4&88*4$%$.*%Y,$$*(J%F,+7*#%%

+*2&(*%5,a"83%&$.*(%)"("83%4&88*4$"&8#1

ES%LK6!6UE%G6KTSWG%TUdWKR%;KSV%I6PfTUX%YPEE6KR%PFTQ-%

Q&%8&$%'#*%,%9"($J=%4&((&9*9%&(%7*,a"83%+,$$*(J1%%%

Only use a 12 V automotive (or equivalent) battery, in good condition.

vehicle where the Winch will be mounted, or

used, to the battery. This route must be secure,

out of the way of moving parts, road debris, or

any possibility of being damaged by operation or

maintenance of the vehicle. For example, you

may wish to route the wires under the vehicle,

attaching it to the frame using suitable fasteners.

of the body to route the wires, be sure

to install a rubber grommet in the hole to

prevent fraying of the wires at that point.

following the precautions discussed above.

Refer to Figure C.

G&4a*$%

F&Z*(

G5,77%

Y7,4a%

H"(*

6. Attach the red Battery Cable from the Winch to

the remaining terminal on the Disconnect Switch.

7. Attach the black Ground Cable and the Small Black

Wire to the terminal at the rear of the Winch.

8. Attach the black Ground Cable from the Winch

directly to the negative terminal of the battery.

9. Lift the Socket Cover exposing the Remote Control

socket and Wireless Receiver Switch. Connect

the Remote Control Cable to the socket and the

Remote for wired remote control. For wireless

control do not use the Remote Control Cable and

turn on the Wireless Receiver Switch. Refer to

Remote Control Instructions on page 12.

10. Turn on the Disconnect Switch and operate the

remote controls briefly to test Winch function

and drum rotation direction. If operation is

reversed, the Battery Cables may be connected

backwards. Correct any such issue before use.

Y7,4a%

X(&'89%

K*9%

Y,$$*(J%

F,+7*

Q"#4&88*4$%

G)"$4.

;"3'(*%F-%%H"("83%F&88*4$"&8#

4. Attach the 12" 2AWG Disconnect Switch Cable

to the positive terminal on the battery.

5. Attach the 12" 2AWG Cable from the battery

to either terminal on the Disconnect Switch.

>Mg%

F,+7*

F,+7*

;"3'(*%Q-%%K*5&$*%F&8$(&7#

11. Disconnect and turn off the Remote

Control when not in use.

12. Turn off the Disconnect Switch when the

Winch is not in use or when the vehicle

has returned to on-highway operation.

TU

SWE

Page 10 ;&(%$*4.8"4,7%<'*#$"&8#=%/7*,#*%4,77%>?@@@?@AA?BCDC1 Item 56385

Page 11

Q"#4&88*4$%G)"$4.

HPKUTUXb Off-highway driving subjects the vehicle and wiring to much higher vibrations than on-highway driving

which can cause a breakdown of wiring insulation over time. Use the high current Disconnect Switch included

with this Winch to turn OFF the power to the Winch when it is not in use to help reduce the risk of a short circuit.

1. To use the Winch, use the Disconnect Switch

to turn the power to the Winch ON.

2. When the Winch is not in use, turn the

Disconnect Switch OFF to reduce the risk of

a short on the main power to the Winch.

L(*/,("83%$.*%GJ8$.*$"4%K&/*

GP;6ERSL6KPETSUVPTUE6UPUF6 G6EWL

The Synthetic Rope must be properly coiled under

tension to be able to support a load without damage.

1. Find a suitable location where the Rope can be

spooled onto the Winch while anchored to a solid

object. Approximately 70 feet will be required.

Alternately, a snatch block (sold separately) may

be used to reduce the distance to 35 feet.

2. Move the Clutch Handle to the Freespool

position and uncoil the Synthetic Rope until

5 wraps remain on the drum. Move the Clutch

Handle back to the Engaged position.

3. Slowly and carefully move the vehicle in

reverse to remove slack from the line.

4. Place the vehicle in neutral. Spool the Synthetic

Rope back into the Winch while gently applying

the brakes. If the ground is flat, shallow

mud or dirt, the brakes can be fully applied.

Pavement can generate much higher loads,

in which case only light braking is needed.

5. Use a second person to monitor the rope

spooling evenly onto the drum.

6. The last layer of Rope can be

put on without tension.

Page 11;&(%$*4.8"4,7%<'*#$"&8#=%/7*,#*%4,77%>?@@@?@AA?BCDC1Item 56385

Page 12

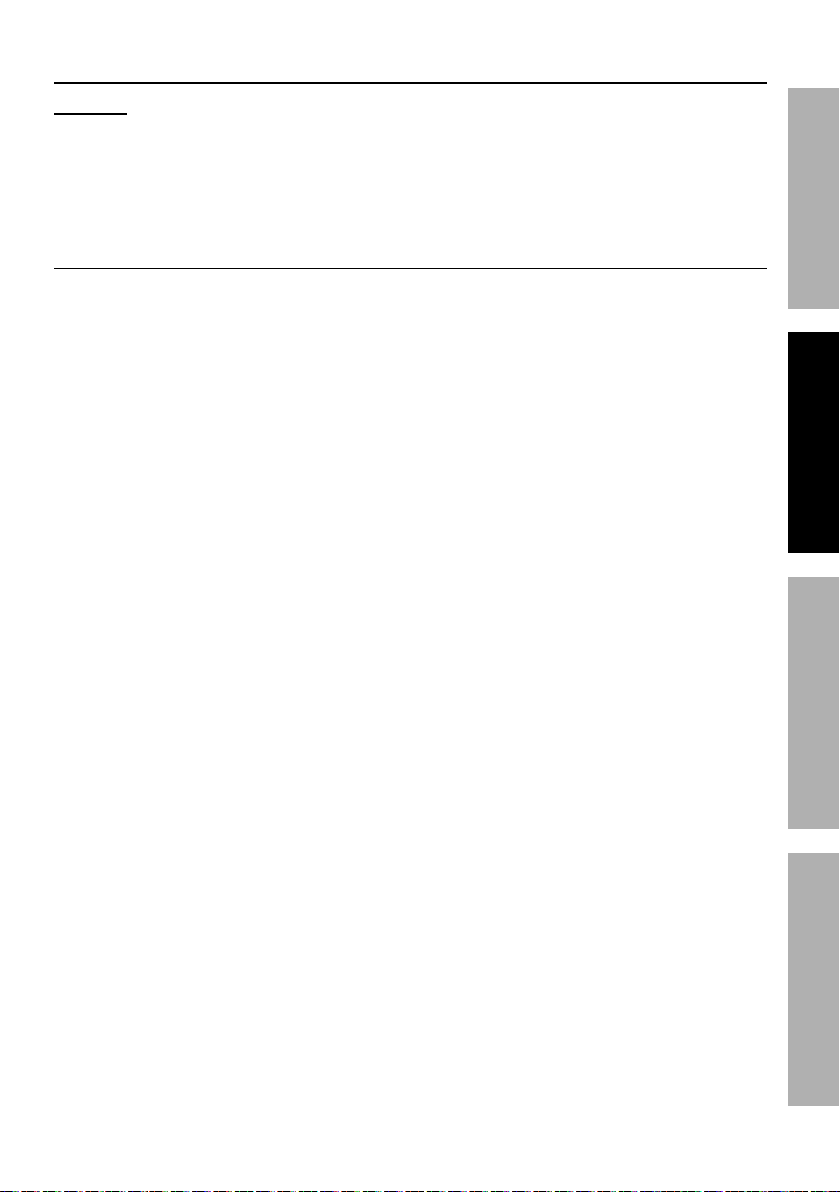

K*5&$*%F&8$(&7%T8#$('4$"&8#

H"(*9%S/*(,$"&8

1. To use the Remote Control in a wired

GP;6ER SL6KPETSU VPTUE6UPUF6G6EWL

configuration, connect the Remote Control Cable

to the bottom of the Remote Control and to the

Remote Control Socket on the Control Box.

K*9%T89"4,$&(%I"3.$

SWE

K&4a*(%

G)"$4.

Y7'*%T89"4,$&(%I"3.$

K*5&$*%

F&8$(&7%G&4a*$

TU

2. The blue indicator light will come on indicating

the Remote Control is ready for use.

H"(*7*##%S/*(,$"&8

1. For wireless Remote Control operation, turn on

the Wireless Receiver Switch on the Control Box.

H"(*7*##%K*4*"Z*(%

G)"$4.

F&8$(&7%

Y&_

K*5&$*%

F&8$(&7%F,+7*

3. With the Clutch Handle in the Engaged

position, press IN on the Rocker Switch

to retract the Synthetic Rope — the red

indicator light will flash during winding.

TU

SWE

4. Press OUT on the Rocker Switch to

extend the Synthetic Rope out.

3. With the Clutch Handle in the Engaged

position, press IN on the Rocker Switch

to retract the Synthetic Rope — the red

indicator light will flash during winding.

4. Press OUT on the Rocker Switch to

extend the Synthetic Rope out.

2. Press and hold the ON/OFF Switch on the

Remote for approximately 2 seconds until

the red indicator light comes on, indicating

the Remote Control is ready for use.

K*9%T89"4,$&(%I"3.$

SU0S;;%

TU

SWE

G)"$4.

K&4a*(%

G)"$4.

TU

5. To turn off the Remote Control, press and

hold the ON/OFF Switch until the red indicator

light goes out, approximately 2 seconds.

Turn off the Wireless Receiver Switch.

U&$*- The Remote Control will automatically shut itself

off after 2 minutes of inactivity to save the battery.

SWE

Page 12 ;&(%$*4.8"4,7%<'*#$"&8#=%/7*,#*%4,77%>?@@@?@AA?BCDC1 Item 56385

Page 13

S/*(,$"&8

Before operating this Winch, refer to the Harbor Freight Tools publication Guide to Winching included with the

Winch for important operational safety information, winch basics, winching tips, and general winch operating

procedures. If this guide is unreadable or missing, contact Harbor Freight Tools for a replacement.

% K*,9%$.*%6UETK6%TVLSKEPUE%GP;6ER%TU;SKVPETSU%#*4$"&8%,$%$.*%+*3"88"83%&2%$.*%

Guide to Winching%"847'9"83%,77%$*_$%'89*(%#'+.*,9"83#%$.*(*"8%+*2&(*%'#*%&2%$."#%/(&9'4$1%

E.*%"8#$('4$"&8#%"847'9*9%"8%$.*%Guide to Winching%,(*%+,#"4%3'"9*7"8*#%&87J%,89%4,88&$%

4&Z*(%,77%#"$',$"&8#%*84&'8$*(*9%9'("83%'#*1%%E.*%&/*(,$&(%,89%,##"#$,8$#%5'#$%4,(*2'77J%

/7,8%'#,3*%$&%/(*Z*8$%,44"9*8$#1

GP;6ERSL6KPETSUVPTUE6UPUF6 G6EWL

Page 13;&(%$*4.8"4,7%<'*#$"&8#=%/7*,#*%4,77%>?@@@?@AA?BCDC1Item 56385

Page 14

V,"8$*8,84*%,89%G*(Z"4"83

% L(&4*9'(*#%8&$%#/*4"2"4,77J%*_/7,"8*9%"8%$."#%5,8',7%5'#$%

+*%/*(2&(5*9%&87J%+J%,%<',7"2"*9%$*4.8"4",81

GP;6ER SL6KPETSU VPTUE6UPUF6G6EWL

ES%LK6!6UE%G6KTSWG%TUdWKR%;KSV%PFFTQ6UEPI%SL6KPETSU-%

W8/7'3%$.*%K*5&$*%F&8$(&7%F,+7*%,89%9"#4&88*4$%$.*%Y,$$*(J%F,+7*#%+*2&(*%/*(2&(5"83%,8J%

"8#/*4$"&8=%5,"8$*8,84*=%&(%47*,8"83%/(&4*9'(*#1

ES%LK6!6UE%G6KTSWG%TUdWKR%;KSV%HTUF\%;PTIWK6-%

Q&%8&$%'#*%9,5,3*9%*<'"/5*8$1%%T2%,+8&(5,7%8&"#*%&(%Z"+(,$"&8%

&44'(#=%.,Z*%$.*%/(&+7*5%4&((*4$*9%+*2&(*%2'($.*(%'#*1

F7*,8"83=%V,"8$*8,84*=%,89%I'+("4,$"&8

1. Y6;SK6%6PF\%WG6= inspect the general

condition of the Winch. Check for:

• loose hardware

• misalignment or binding of moving parts

• cracked or broken parts

• damaged electrical wiring

• corroded or loose terminals

• any other condition that may

affect its safe operation.

Examine the Synthetic Rope. Do not use the

Winch if the Rope is frayed or has cut strands.

GJ8$.*$"4%K&/*%K*/7,4*5*8$

1. Move Clutch Handle to the Freespool position.

2. Extend the Synthetic Rope to its full

length, noting how the existing Rope is

connected to the inside of the drum.

3. Remove old Synthetic Rope and

attach new assembly.

FPWETSUb Do not replace with inferior synthetic rope.

Only use a synthetic rope rated to the same

rating cited on the specification chart or better.

2. P;E6K%WG6= wipe external surfaces of

the Winch with clean cloth. If the Winch

is submerged during use, rinse thoroughly

with fresh, clean water when finished.

3. The Winch’s internal mechanism is permanently

lubricated. Do not open the housing.

4. Retract Synthetic Rope onto Rope

drum. Refer to instructions for tensioning

the Synthetic Rope under Preparing

the Synthetic Rope on page 11.

5. Test Winch for proper operation.

Page 14 ;&(%$*4.8"4,7%<'*#$"&8#=%/7*,#*%4,77%>?@@@?@AA?BCDC1 Item 56385

Page 15

E(&'+7*#.&&$"83

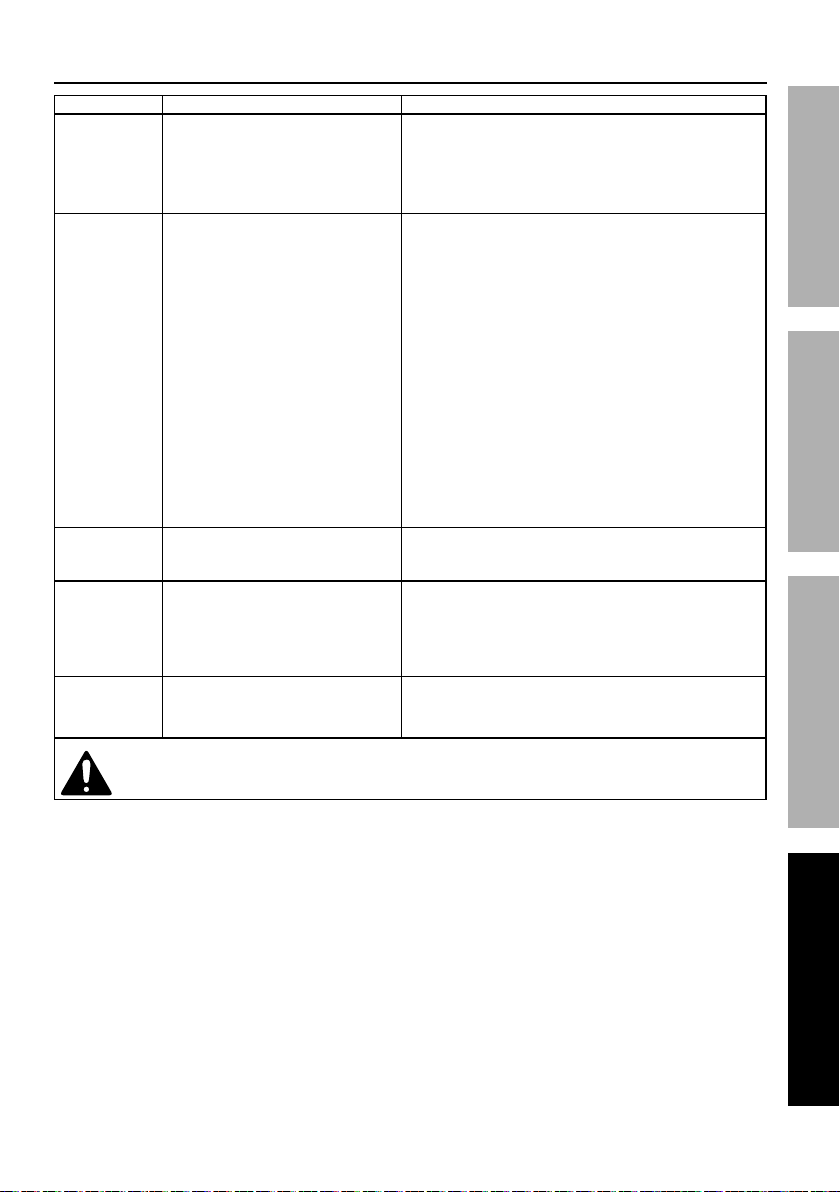

L(&+7*5 L&##"+7*%F,'#*# I"a*7J%G&7'$"&8#

Motor

overheats.

Motor does

not turn on.

Motor runs

but drum does

not turn.

Motor runs

slowly or

without normal

power.

Motor runs in

one direction

only.

1. Incorrect power cords.

2. Winch running time too long.

3. Insufficient current or voltage.

4. Loose motor connections.

1. Remote Socket not

connected properly.

2. Loose battery cable connections.

3. Insufficient current or voltage.

4. Defective contactor.

5. Wireless Receiver

Switch turned OFF.

6. Wireless Remote turned OFF.

7. Winch Disconnect

Switch turned OFF.

8. Low batteries in Wireless Remote.

9. Defective motor.

10. Loose Control Box ground cable.

11. Internal wear or damage.

Clutch not engaged. Move the Clutch Handle to the Engaged position.

1. Insufficient current or voltage.

2. Loose or corroded battery

cable connections.

3. Incorrect power cords.

1. Defective contactor.

2. Defective Wireless Remote.

3. Loose motor connections.

1. Use only supplied power cords.

2. Allow Winch to cool down periodically.

3. Fully charge battery. Run Winch

with vehicle motor running.

4. Check and tighten motor connections to Control Box.

1. Insert Remote Socket all the way into connector.

2. Tighten nuts on all cable connections.

3. Fully charge battery. Run Winch

with vehicle motor running.

4. Replace Control Box.

5. Turn ON Wireless Receiver Switch.

6. Turn ON Wireless Remote.

7. Turn ON Winch Disconnect Switch.

8. Replace Remote batteries — CR2032, quantity two.

9. Check for voltage at armature port with Switch

pressed. If voltage is present, replace motor.

10. Check and tighten ground cable to Control Box.

11. Replace motor.

If problem persists, a qualified technician

needs to check and repair.

1. Battery weak, recharge.

Run Winch with vehicle motor running.

2. Clean, tighten, or replace.

3. Use only supplied power cords.

1. Replace Control Box.

2. Replace Wireless Remote.

3. Check and tighten motor connections to Control Box.

GP;6ERSL6KPETSUVPTUE6UPUF6 G6EWL

% ;&77&)%,77%#,2*$J%/(*4,'$"&8#%).*8*Z*(%9",38&#"83%&(%#*(Z"4"83%

$.*%$&&71%%Q"#4&88*4$%/&)*(%#'//7J%+*2&(*%#*(Z"4*1

Page 15;&(%$*4.8"4,7%<'*#$"&8#=%/7*,#*%4,77%>?@@@?@AA?BCDC1Item 56385

Page 16

LI6PG6%K6PQ%E\6%;SIISHTUX%FPK6;WIIR

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY DIAGRAM

IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR DISTRIBUTOR

MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS

QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED TO REPLACE

GP;6ER SL6KPETSU VPTUE6UPUF6G6EWL

ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY

STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND

LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY

ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS

THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

Page 16 ;&(%$*4.8"4,7%<'*#$"&8#=%/7*,#*%4,77%>?@@@?@AA?BCDC1 Item 56385

Page 17

K*4&(9%L(&9'4$c#%G*(",7%U'5+*(%\*(*-%

U&$*- If product has no serial number, record month and year of purchase instead.

U&$*- Some parts are listed and shown for illustration purposes only,

and are not available individually as replacement parts.

GP;6ERSL6KPETSUVPTUE6UPUF6 G6EWL

Page 17;&(%$*4.8"4,7%<'*#$"&8#=%/7*,#*%4,77%>?@@@?@AA?BCDC1Item 56385

Page 18

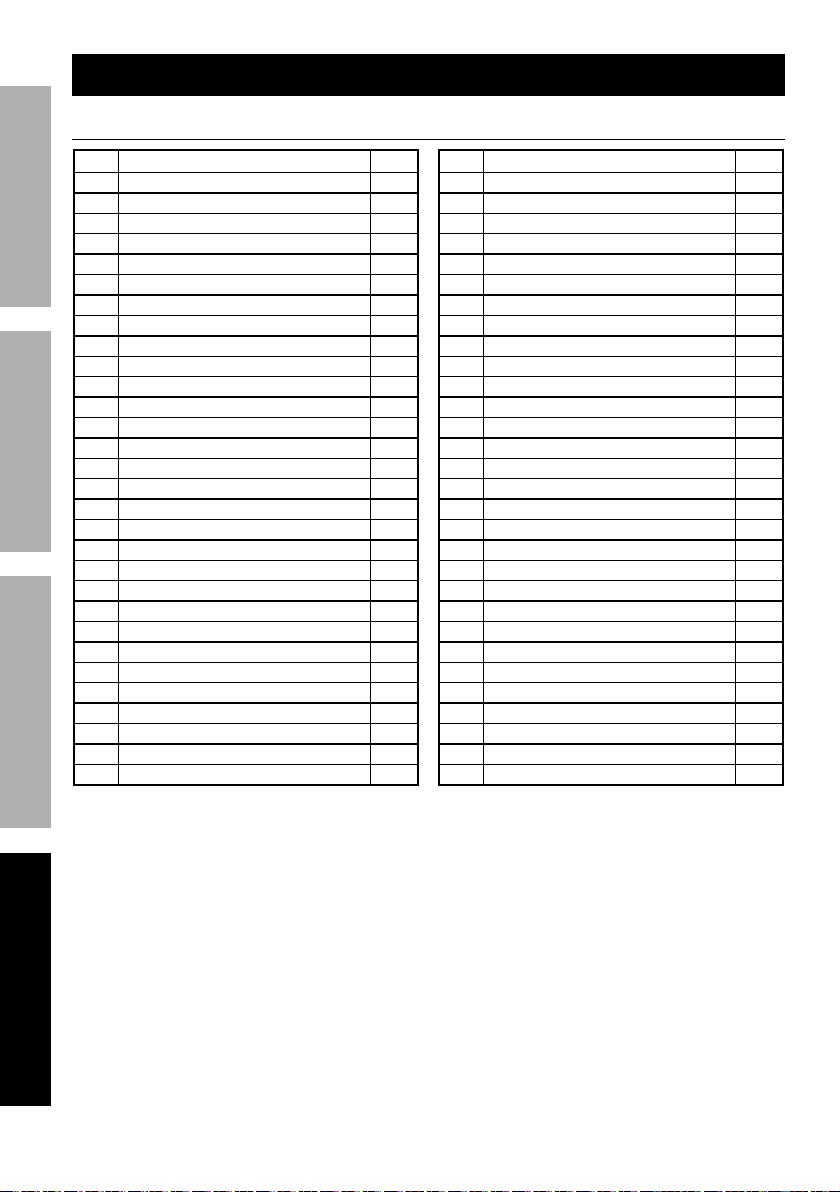

L,($#%I"#$%,89%Q",3(,5

L,($#%I"#$

GP;6ER SL6KPETSU VPTUE6UPUF6G6EWL

L,($ Q*#4("/$"&8 h$J

1 Gearbox End Cover 1

2 Washer 1

3 Star Screw M6 x 20 10

4 Gear Box Z69 1

5 Clutch Retaining Bolt 1

6 Clutch Handle 1

7 Clutch Handle Washer 1

8 Hex Socket Screw M5 x 20 4

9 Bearing 1

10 Hex Sun Gear 1

11 Planetary Gear Assembly 1 1

12 Planetary Gear Assembly 2 1

13 Washer 1

14 Ring Gear Z66 1

15 Circlip Washer Ø125 1

16 Planetary Gear Assembly 3 1

17 Ring Gear Z57 1

18 O-Ring Ø126 x 2 1

19 Star Screw M8 x 25 4

20 Gearbox Base 1

21 Pin 2

22 Drum Assembly 1

23 Tie Bar 2

24 Star Screw M6 x 25 4

25 Control Box Assembly 1

26 Transmission Shaft S8 x 289 1

27 Brake Assembly 1

28 Spline Drive Sleeve 1

29 Ta b 2

30 Waterproof Sealing Ring 2

L,($ Q*#4("/$"&8 h$J

31 Radial Ring 2

32 Iron Bushing 2

33 Motor Assembly 1

34 Terminal Cover 1

35 Star Screw M4 x 16 2

36 Motor Cover 1

37 Winch Mounting Hardware 4 sets

38 Synthetic Rope 1

39 Fairlead 1

40 Fairlead Mounting Hardware 2

41 Hook 1

42 Remote Control Cable 1

43 Wireless / Wired Remote Control 1

44 Rope Protecting Mat 2

45 Ground Cable 1

46 Disconnect Switch 1

47 Red Hook Strap 1

48 Power Cables (relocation kit) 3

49 Terminal Box 1

50 Screw M4 x 12 2

51 Terminal Box Cover 1

52 Self-Tapping Screw M4.8 x 16 3

53 Control Box Baseplate 1

54 Baseplate Mounting Hardware 4 sets

55 Extended Copper Screw 3

56 Sheath 3

57 Small Black Wire Extension 1

58 Small Black Wire Connector 1

59 Screw M6 x 12 4

60 Disconnect Switch Cable 1

Page 18 ;&(%$*4.8"4,7%<'*#$"&8#=%/7*,#*%4,77%>?@@@?@AA?BCDC1 Item 56385

Page 19

P##*5+7J%Q",3(,5

25

26

27

28

29

30

31

32

19

34

35

36

3

38

37

33

40

39

42

55

54

53

59

41

43

56

58

57

60

14

15

16

24

23

9

10

11

12

13

44

50

49

48

20

21

22

6

7

8

45

51

17

18

19

GP;6ERSL6KPETSUVPTUE6UPUF6 G6EWL

1

2

3

4

5

47

52

46

Page 19;&(%$*4.8"4,7%<'*#$"&8#=%/7*,#*%4,77%>?@@@?@AA?BCDC1Item 56385

Page 20

I"5"$*9%Dj%Q,J%H,((,8$J

Harbor Freight Tools Co. makes every effort to assure that its products meet high quality and durability

standards, and warrants to the original purchaser that this product is free from defects in materials

and workmanship for the period of 90 days from the date of purchase. This warranty does not apply to

damage due directly or indirectly, to misuse, abuse, negligence or accidents, repairs or alterations outside

our facilities, criminal activity, improper installation, normal wear and tear, or to lack of maintenance.

We shall in no event be liable for death, injuries to persons or property, or for incidental, contingent,

special or consequential damages arising from the use of our product. Some states do not allow the

exclusion or limitation of incidental or consequential damages, so the above limitation of exclusion

may not apply to you. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us with transportation charges

prepaid. Proof of purchase date and an explanation of the complaint must accompany the merchandise.

If our inspection verifies the defect, we will either repair or replace the product at our election or we may

elect to refund the purchase price if we cannot readily and quickly provide you with a replacement. We will

return repaired products at our expense, but if we determine there is no defect, or that the defect resulted

from causes not within the scope of our warranty, then you must bear the cost of returning the product.

This warranty gives you specific legal rights and you may also have other rights which vary from state to state.

MABO>%P3&'(,%K&,9%%i%%F,7,+,#,#=%FP%D>NjM%%i%%>?@@@?@AA?BCDC

Page 21

GUIDE TO WINCHING

WWW.HARBORFREIGHT.COM

Copyright© 2019 by Harbor Freight Tools®. All rights reserved. No portion of this guide or any artwork contained herein may be reproduced in

any shape or form without the express written consent of Harbor Freight Tools. Diagrams within this guide may not be drawn proportionally.

19e

Page 22

Table of Contents

Warning Symbols .......................................... 3

Important Safety Information ......................... 4

Basic Winching Tips ...................................... 7

Before You Go ............................................... 7

Estimating Load ............................................. 8

Read the ENTIRE IMPORTANT SAFETY INFORMATION section beginning

on page 4 of this guide including all text under subheadings therein before

use of this product. The instructions that follow are basic guidelines

only and cannot cover all situations encountered during use. The

operator and assistants must carefully plan usage to prevent accidents.

Winch Basics ................................................ 10

Single Line Winching – Straight Pull .............. 14

Single Line Winching – Snatch Block ............ 16

Double Line Winching................................... 18

Page 2 For technical questions, please call 1-888-866-5797. Winching

Guide

Page 23

WARNING SYMBOLS AND DEFINITIONS

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow

this symbol to avoid possible injury or death.

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Addresses practices not related to personal injury.

Symbol Property or Statement

Wear heavy-duty, cut- and

abrasion-resistant leather gloves.

Wear ANSI-approved safety glasses.

Cut or sever hazard.

Roller entanglement hazard.

Hot surface burn hazard.

Fire hazard.

Caustic chemical (acid) hazard.

Explosion hazard.

Do not loop the wire or synthetic rope

around object and hook onto itself.

Do not place finger(s) through hook.

Fingers may be caught and get

pulled into fairlead or drum.

Pull hook using strap only.

Symbol Property or Statement

Do not use winch in overwind

orientation. (Rope enters/

exits at the top.)

Use winch only in

underwind orientation.

(Rope enters/exits at the bottom.)

VDC

CCA

HP

fpm

mpm

RPM

G8

Volts Direct Current

Amperes

A

Cold Cranking Amperes

Horsepower

Feet Per Minute

Meters Per Minute

Revolutions Per Minute

International Protection rating

Classifies the degrees of protection provided

IP

against the intrusion of solid objects,

dust, accidental contact, and water.

Grade 8

A fastener strength rating.

Guide

Page 3For technical questions, please call 1-888-866-5797.Winching

Page 24

IMPORTANT SAFETY INFORMATION

WARNING! Read all instructions. Failure to follow all instructions listed on

pages 4 to 6 may result in fire, serious injury and/or DEATH.

The warnings and precautions discussed in this manual cannot cover all

possible conditions and situations that may occur. It must be understood

by the operator that common sense and caution are factors which cannot

be built into this product, but must be supplied by the operator.

Operation Precautions

1. Do not exceed load capacity. Be

aware of dynamic loading! Sudden

load movement may briefly create

excess load causing product failure.

2. Do not maintain power to the Winch

if the motor stalls. Verify load is within

rated capacity for the wire or synthetic

rope layer. Make sure the battery is

fully charged. Use double line rigging

whenever possible. Refer to Double

Line Winching on page 18.

3. Wear ANSI-approved safety

goggles and heavy-duty leather

work gloves during operation.

4. Do not disengage clutch under load.

Engage clutch before starting.

5. Keep clear of fairlead when operating.

Do not try to guide rope.

6. Do not place finger(s) through hook.

Fingers may be caught and get pulled

into fairlead or drum. Use included

strap to hold hook instead.

7. Stay out of the direct line that the rope

is pulling. In case it slips or breaks,

it will “whiplash” along this line.

8. Do not use for lifting or moving people.

9. Use a spotter to assist you in assuring

that it is safe to operate the Winch.

Make sure the spotter is out of the

way of the vehicle and the rope

before activating the Winch.

10. Do not use vehicle to pull on the

rope and “assist” the Winch.

11. Place a heavy blanket or winch damper

over the rope span 6 feet from hook

to help absorb the force released if

the rope breaks. Refer to Figure A.

Figure A: Whiplash Dampening

Blanket or Winch Damper

12. Use as intended only. Do not lift items

vertically or use for aircraft purposes.

13. Prevent entanglement. Do not wear

loose clothing or jewelry, as they can be

caught in moving parts. Non-skid footwear

is recommended. Wear restrictive hair

covering to contain long hair.

14. Disconnect remote control and turn

off wireless function before working

near the rope, drum, fairlead or load,

to prevent accidental starting.

15. Inspect before every use; do not use

if damaged or parts loose. Examine

the Winch for structural cracks, bends,

damage, frayed or kinked wire rope,

frayed or cut synthetic rope, and any

other conditions that may affect the safe

operation of the Winch. Do not use the

Winch even if minor damage appears.

Page 4 For technical questions, please call 1-888-866-5797. Winching

Guide

Page 25

16. A kink permanently weakens a wire rope,

even after it is straightened out; kinked

wire rope can fail suddenly and must

not be used. Keep wire rope straight

to avoid kinking the wire rope. The

illustrations below show how a kink forms:

a. This illustration shows a kink

about to form. At this point

the winch should be

stopped and the wire rope

should be straightened out

to prevent kinking.

b. This wire

rope is kinked.

It is too late to

reverse the

damage at this

point, the wire rope must be discarded.

It is permanently damaged and must not

be used.

c. This is a kinked wire rope that has

been straightened out. Even though it

has been pulled straight, some wires

in the wire rope are stretched, and

others are severely bent, if not broken.

The unstretched wires will take more

load and can fail suddenly before the

rope reaches its capacity. This wire rope

must be discarded and not be used.

A kink permanently weakens the wire

rope, even after it is straightened

out; kinked wire rope can fail

suddenly and must not be used.

17. Keep children and bystanders

away while operating. Distractions

can cause you to lose control.

18. Stay alert, watch what you are doing

and use common sense when operating.

Do not use a winch while you are

tired or under the influence of drugs,

alcohol or medication. A moment of

inattention while operating winches

may result in serious personal injury.

19. Do not overreach. Keep proper

footing and balance at all times.

This enables better control of the

Winch in unexpected situations.

20. Hook onto the object using a pulling point,

tow strap or chain. Do not wrap the rope

around the object and hook onto the

rope itself. This can cause damage to the

object being pulled and kink or fray the rope.

21. Do not use a Recovery Strap while

winching. They are designed to stretch

and can suddenly whip back towards the

operator during a winching operation.

22. Do not operate the Winch at extreme

angles. Do not exceed the angles

shown in Figure B for a roller fairlead

and Figure C for a hawse fairlead.

15°

15°

45°

45°

Figure B: Roller Fairlead

Maximum Winching Angles

15°

15°

15°

15°

Figure C: Hawse Fairlead

Maximum Winching Angles

Guide

Page 5For technical questions, please call 1-888-866-5797.Winching

Page 26

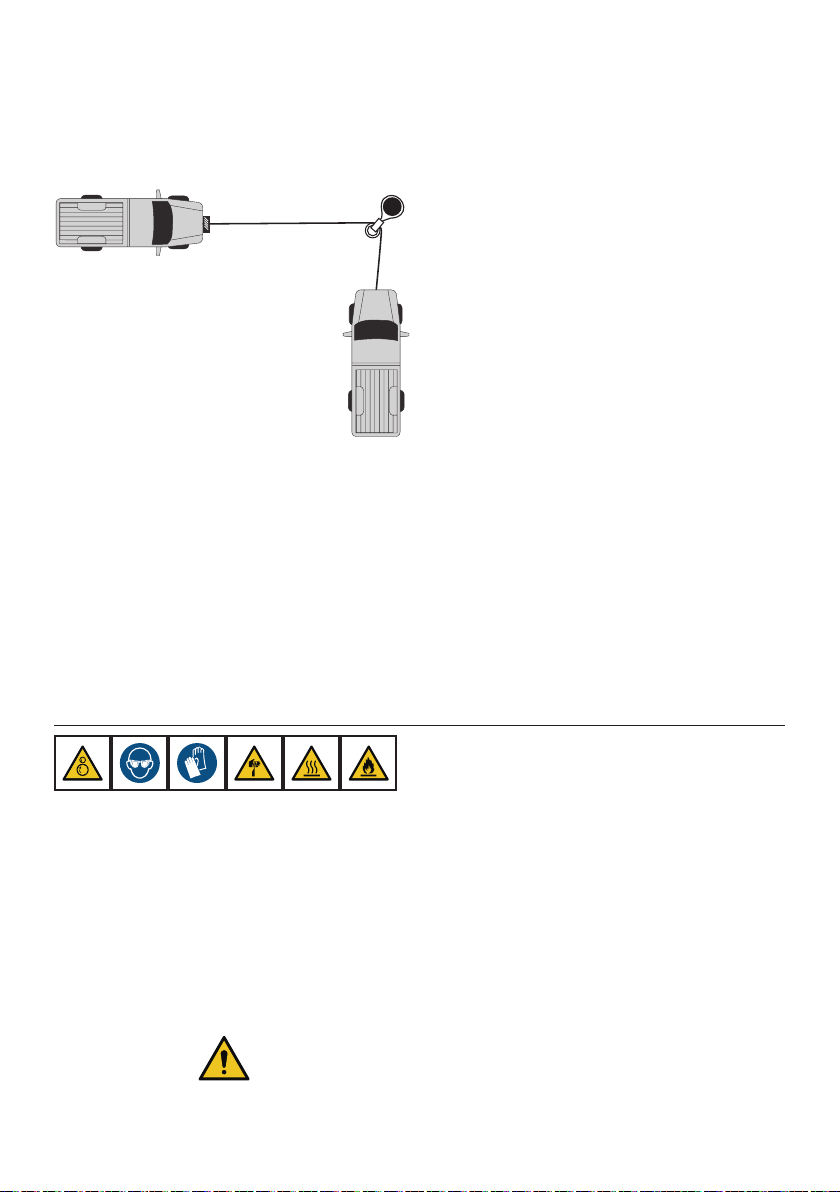

23. If the object to be pulled must be pulled

at an angle in relation to the Winch,

use a snatch block (sold separately)

and an anchor point directly in front

of the Winch, as shown in Figure D,

to keep the rope pull straight.

Figure D: Snatch Block

24. Wrap rope under tension before use.

Otherwise, rope may bind during operation.

25. Keep clear of rope, hook, and load while

winching. Do not step over rope.

Do not push sideways against rope

under tension; rope might break under

this load and recoil back, striking the

person pushing against it or a bystander.

26. If rope begins to get entangled, stop Winch

immediately and release rope using switch.

27. Only winch with the winching vehicle′s

transmission in neutral. Winching with

a vehicle′s transmission in gear or

park may damage the transmission.

A vehicle′s transmission is not designed

to handle that type of load.

28. Broken strands of a wire rope will be

sharp. Wear heavy-duty work gloves

when handling a wire rope. Do not

slide a wire or synthetic rope through

hands, even with gloves on.

29. Winch motor will be hot during

and after use. Keep clear.

30. Do not power the hook all the way

into the fairlead or Winch.

31. To prevent accidental starting, unplug

winch controls and any RF receivers

immediately after extending or retracting.

This is especially important before rigging,

installing, free spooling, or servicing.

32. People with pacemakers should

consult their physician(s) before use.

Electromagnetic fields in close proximity to

heart pacemaker could cause pacemaker

interference or pacemaker failure.

Service Precautions

1. Wear ANSI-approved safety

goggles and heavy-duty leather

work gloves during service.

2. Disconnect power to Winch and allow

it to cool completely before service.

3. Use supplied power cords, rope or

cables listed in manual only. Do

not use thinner/longer cables or

link multiple cables together.

4. Have the Winch serviced by a qualified

repair person using only identical

replacement parts. This will ensure that

the safety of the Winch is maintained.

5. Maintain labels and nameplates

on the Winch. These carry important

safety information. If unreadable

or missing, contact Harbor Freight

Tools for a replacement.

SAVE THESE INSTRUCTIONS.

Page 6 For technical questions, please call 1-888-866-5797. Winching

Guide

Page 27

Page 7For technical questions, please call 1-888-866-5797.Winching

Guide

Basic Winching Tips

• ESTABLISH A DANGER ZONE:

At least 20 ft on each side of the winch line and

beyond the vehicle and anchor point. Make sure

no people enter during the winching operation or

when the line is under tension.

• FIRST LAYER WINCHING:

Winch with the most rope out possible to

utilize the maximum power of the winch and

prevent overloading and overheating.

• WINCH RECOVERIES ARE SLOW:

Take time to properly evaluate

the situation, and take all safety

precautions. The loads that the

winch can generate are extreme.

• USE A SNATCH BLOCK:

When in doubt of the

recovery load or if the two

vehicles are within 20 ft of

each other, use a snatch

block for a double line pull.

• KEEP VEHICLE RUNNING:

The winch will place an enormous amount

of strain on the vehicle electrical system.

Keeping the engine at 2000 RPM can

provide some help from the alternator.

• KEEP THE VEHICLE IN NEUTRAL:

The parking brake is not designed to

hold the loads that the winch can apply.

If recovering another vehicle, keep

foot firmly on brake. For self-recovery,

carefully steer vehicle to avoid obstacles

and spotter and keep foot off brake.

• KEEP THE LINE STRAIGHT:

Winch with the rope as straight as possible to the

winching vehicle. Use a snatch block if needed.

Before You Go

1. Check the power cables from the battery

to the winch for abrasion and heat

damage. Replace if worn or damaged.

2. The winch is an intermittently used

product — over time the grease may settle

in the gear train and make it difficult to

freespool. Before a trip, check the winch

for proper operation in three mode

• Power-IN • Power-OUT • Freespool

2. Inspect the rope for signs of abrasion

damage, knots or kinks, or compression

damage. Replace if damaged. See Rope

Inspection on page 13 for more detail.

3. Ensure you have basic rigging

hardware and safety gear such as:

shackles, winch line damper, tree strap,

safety glasses, and gloves. A snatch

block is highly recommended.

Shackle Damper Tree Strap Safety Gear Snatch Block

Page 28

Estimating Load

The ability to determine the load that the recovery will take is an important skill to

learn. It allows you to properly setup rigging for a successful recovery the first time

and reduces the chance of equipment damage and danger to bystanders.

Resistance Types

• Grade Resistance: The resistance

of pulling a vehicle up a slope.

• Mire Resistance: The resistance

of pulling a vehicle from soft terrain,

such as mud, sand or snow.

Grade Resistance

For recoveries or applications that pull a vehicle up a slope, grade resistance is a factor in the

recovery load. This is because there are many other variables to consider off-road that add

resistance. For example, the ground is not smooth or solid like pavement, the vehicle’s wheels

may not turn smoothly, the vehicle’s steering may be broken, and a host of other factors.

For the majority of off-road recoveries, the grade resistance

can be equal to the gross vehicle weight (GVW).

For smooth ramps used to load a trailer or other

situations that are not as varied, you can use the

following to estimate the recovery load. To

estimate load you will need the gross vehicle

weight (GVW) and the grade of the terrain.

• GVW can be found on the nameplate of

the vehicle, or by a weigh station scale.

• % Grade = Rise / Run

Example: Rise 4 ft / Run 10 ft = 40% Grade

• Tackle Resistance: The added resistance

of snatch blocks during winching.

Grade Angle % of GVW

Reference the chart to find the estimated

recovery load resistance.

Example: GVW of 6000 lb on a 60% grade =

recovery load of 51% of 6000 lb = About 3060 lb

Page 8 For technical questions, please call 1-888-866-5797. Winching

20% 11 20%

40% 22 37%

60% 31 51%

80% 39 62%

100% 45 71%

Guide

Page 29

Mire Resistance

For recoveries in mud, sand, or snow, mire resistance becomes a factor. Mire resistance

is the added resistance that the soft terrain adds as the vehicle is submerged beneath

the ground level. The vehicle’s GVW is used to estimate the recovery load.

• Wheel Depth = 1 x GVW

• Fender Depth = 2 x GVW

• Cab Depth = 3x GVW

Fender Depth Mire

Cab Depth Mire

A snatch block is a great

way to double the pulling

power of your winch.

Tackle Resistance

Each shackle that is used in the recovery rigging adds a small amount of

resistance to the winch. Each snatch block used in the recovery adds about

10% to the recovery load — add this to the recovery load on the winch.

Example: 4000 lb recovery load +10% = 4400 lb winch load

Wheel Depth Mire

Guide

Page 9For technical questions, please call 1-888-866-5797.Winching

Page 30

Page 10 For technical questions, please call 1-888-866-5797. Winching

Guide

Winch Basics

Rope Layer

Imagine trying to hold a full length shovel horizontal by the

very end of the handle — pretty hard, right?

Now imagine holding a shorter shovel by the end of the handle. Maybe

not easy, but certainly easier than the full length shovel.

This is an example of how the winch must exert torque on the drum for the various

layers of rope on the drum. The outermost layer of rope is represented by the full

length shovel, and the first layer of rope is represented by the short shovel.

The winch and the vehicle electrical system have a limited amount of power

available, so it is important to use the power in the most efficient way possible.

The winch can pull to 100% full rated

load only on the first layer of rope

that touches the drum.

For a constant load, as each layer of

rope winds on, the winch must exert

more torque on the drum, because of

the added leverage of each layer.

WARNING! To prevent serious injury from

sudden detachment of the winch rope leave

at least 5 full wraps of rope on the drum.

Page 31

Rope Angle

Your winch is designed to handle off-angle pulls for brief periods. However, extended pulls

on one side of the drum can cause damage to the winch and rope. Use a snatch block to

change the direction or move the anchor point.

Try to winch with the rope as straight into the winch as possible.

If you do have to winch off-angle, do not exceed the angles shown below.

Spotter must be outside danger zone. Have spotter watch for even winding of rope on

drum. If rope starts winding unevenly on the drum, stop winching and adjust rigging

or vehicle position. Freespool the winch to remove the rope bunching on the drum

flange and evenly spool the rope back on the drum, then continue the recovery.

Or, plan ahead and use a snatch block to ensure that an off-angle pull will be

avoided. Periodically check your fairlead for wear and replace as needed.

15º MAX

15º MAX

Roller Fairlead Maximum Winching Angles

Roller Fairlead

15º MAX

15º MAX

Hawse Fairlead Maximum Winching Angles

45º MAX

45º MAX

15º MAX

15º MAX

Guide

Hawse Fairlead

Page 11For technical questions, please call 1-888-866-5797.Winching

Page 32

Page 12 For technical questions, please call 1-888-866-5797. Winching

Guide

Snatch Blocks

Snatch blocks are the second most important accessory for your winch

(the first being shackles). Being able to change the line direction for

pulls around corners and multiple line pulls makes them extremely

versatile. Let’s understand how they work before we show examples

of vehicle recoveries.

The most basic use of a snatch block is to change the direction

of a rope. In the diagram a 4 ton vehicle is attached to a rope

which passes around a snatch block to a winching vehicle.

Notice that the tension in each of the ropes is

equal to the total load weight, and the snatch block

must carry the combined load of the ropes.

This is a simplified example neglecting the angle of

pull of the ropes. As the angle between the ropes

increases, the load on the snatch block will decrease.

Example 1: Direction Change

In a direction change situation, the objective is

to pull from a direction that has a greater impact

on the stuck vehicle. In this example the weight

is the stuck vehicle and the snatch block is

attached to an anchor point. The snatch block

does not provide any increase to the recovery

force but it does change the direction of the pull.

Example 2: Recovery Force Increase

In a situation where the recovery will take more

force than the winch can provide, a double line

pull should be used. This can help reduce the

load on the winch and decrease the electrical

load on the vehicle.

In this example the weight becomes the

vehicle with the winch, and the snatch block

is again connected to an anchor point. The

usefulness of this rigging is to leverage

the doubled force of the two ropes that the

snatch block carries, allowing the recovery

force to be double that of a single line pull.

Additionally the double line rigging will require

more rope off the drum, allowing the winch to

work on lower layers and provide more available

pull force.

8T

Snatch Block

Winching

Vehicle

Recovery

Vehicle

4T

4T

4T

Load

DANGER ZONE

DANGER ZONE

Page 33

Rope Inspection

The rope on the winch is the highest wear item in the winching system, and the

most dangerous if not inspected regularly. Wire rope and synthetic rope have

different wear and replacement criteria — it is important to highlight both.

Wire Rope –Always Replace

WARNING! To prevent serious Injury from razor sharp broken strands, wear heavyduty work gloves when handling wire rope. Do not run hands along wire rope, even

with gloved hands — some wire strands can be sharp enough to pierce gloves.

• Kinked Strands: Replace

• Separated Strand: Replace

• Broken Strands: Replace

• Twisted Rope: Replace

Synthetic Rope

CAUTION! Wear work gloves to protect from cuts from

debris when working with synthetic rope.

• Abrasion: Severe abrasion must

be replaced; minor abrasion or a

fuzzy look can be monitored.

• Cut Strands: Replace immediately.

• Pulled Strand: Repair — work the

strand carefully back into the rope.

• Compression: Commonly seen on

drums. Repair — flex the rope without

load to remove the compression.

Guide

Page 13For technical questions, please call 1-888-866-5797.Winching

Page 34

Single Line Winching — Straight Pull

Setup

WARNING! To prevent serious injury from electrical fire: check the

electrical cables to your winch for abrasion or heat damage before

use. Replace worn or damaged cables immediately.

1. MAKE A PLAN. Pick a sturdy anchor

such as a large tree, large rock, or other

vehicle that is generally straight on and

that allows for sufficient rope out to

obtain maximum power from the winch.

Rigging

1. Pull the hook out using the strap to the anchor point. Don’t forget any

rigging you will need, such as a tree strap and shackle.

WARNING! To prevent serious injury from sudden detachment of the

winch rope leave at least 5 full wraps of rope on the drum.

2. Secure the winch rope to the anchor point.

Do not wrap the winch rope directly around

a tree or rock. Not only will this damage or

kill the tree, but it will also damage the rope

where the hook attaches back to the rope.

3. If possible, have the latch side of the hook

facing up. This will help force the hook to

the ground if the hook should fail or slip off

the rigging.

2. PUT ON GLOVES. Regardless of

synthetic or wire rope, heavy-duty work

gloves are always a good idea.

3. Place the winch into freespool.

4. Make sure the hook is fully engaged

on the shackle or vehicle anchor point.

THE HOOK LATCH MUST CLOSE.

5. Place a winch damper or other heavy object

on the line, 1/3 of the total distance from the

hook end of the rope.

Use double line rigging whenever practical to prevent

overloading and overheating of the winch.

Page 14 For technical questions, please call 1-888-866-5797. Winching

Guide

Page 35

6. ESTABLISH A DANGER ZONE. At least

20 ft on each side of the winch line and

beyond the vehicle and anchor point. Make

sure no people enter during the winching

operation or when the line is under tension.

WARNING!

Do not allow anyone to stand near

the rope, or inline with the rope behind the

winch or anchor point while it is under power. If the rope should slip or break, it can

suddenly whip back towards the winch or anchor, causing a hazard for anyone in the

area established by the danger zone. Stand well to the side when winching.

Winching

For self recovery:

Place winch vehicle in NEUTRAL • Keep foot OFF brake

For other vehicle recovery:

Place winch vehicle in NEUTRAL • Keep foot ON brake

1. Re-engage the freespool clutch, and plug-

in or connect the remote to the winch.

2. Slowly take up slack in the winch line

to do a final check on the rigging setup.

Designate one person as a spotter to watch

for vehicle hazards and to make sure the

rope is spooling on the drum correctly.

3. Perform the winching operation, with the

vehicle in NEUTRAL or DRIVE. Watch your

spotter, and monitor the battery voltage

while winching. Increase the engine

RPM to raise the battery voltage level.

4. When the vehicle is recovered engage

parking brakes, remove all rigging

and wind the rope fully into the winch

USING THE HOOK STRAP.

5. Unplug or disconnect the remote and

store it in the vehicle for the next use.

NOTICE: Your winch is designed

for INTERMITTENT USE ONLY. If

the motor stalls, STOP OPERATION

and use a snatch block.

Duty Cycle (Duration of Use)

Avoid damage to the Winch by not winching for more than the prescribed

duty cycle time. The Duty Cycle defines the amount of time, within a

15 minute period, during which a Winch can operate at its maximum

capacity without overheating. For example, a Winch with a

5% duty cycle at its maximum load must be allowed to rest

for at least 14 minutes, 15 seconds after every 45 seconds

of continuous operation. Failure to carefully observe duty

cycle limitations can easily over-stress a Winch contributing

to premature Winch failure.

Guide

45 seconds winching

at least

14 minutes,

15 seconds

of rest

Page 15For technical questions, please call 1-888-866-5797.Winching

Page 36

Page 16 For technical questions, please call 1-888-866-5797. Winching

Guide

Single Line Winching — Snatch Block

Overview

Not every recovery can be handled with a straight line pull. Often the most effective recovery

requires an angle that cannot be accomplished from straight on. By using a snatch block on

a single line pull, the pull direction can be changed without moving the winching vehicle.

Around a Corner

When stuck on a hill or tight trail and an anchor point is too close to winch effectively, a

snatch block can be used. Not only does this lower the rope layer so that the winch can

pull harder, it also allows the vehicle to remain connected to the farthest anchor once the

snatch block is removed.

Pay special attention to the danger zone, since it is much larger than a straight line pull.

DANGER ZONE

USE ALL OF THE PRECAUTIONS AND STEPS

FROM SINGLE LINE WINCHING — STRAIGHT PULL

Snatch

Block

Tree Strap

& Shackle

Tree Strap

& Shackle

Rigging Needed:

• 2 x Tree Straps

• 2 x Shackles

• 1 x Snatch Block

Page 37

Page 17For technical questions, please call 1-888-866-5797.Winching

Guide

Vehicle Off Trail

If a vehicle leaves the trail and becomes stuck, often the most effective way to return the

vehicle to the road is using an angled pull since this pulls the vehicle most directly onto the

trail. Find a suitable anchor on the opposite side of the trail to attach a snatch block to, and

perform the recovery.

Pay special attention to the danger zone, since it is much larger than a straight line pull.

DANGER ZONE

USE ALL OF THE PRECAUTIONS AND STEPS

FROM SINGLE LINE WINCHING — STRAIGHT PULL

Snatch

Block

Tree Strap

& Shackle

Rigging Needed:

• 1 x Tree Strap

• 2 x Shackles – Possibly more depending

on tow points of stuck vehicle

• 1 x Snatch Block

For self recovery:

Place winch vehicle in NEUTRAL • Keep foot OFF brake

For other vehicle recovery:

Place winch vehicle in NEUTRAL • Keep foot ON brake

Page 38

Page 18 For technical questions, please call 1-888-866-5797. Winching

Guide

Double Line Winching

Overview

Certain recoveries require more force than a single line pull can provide. In these situations

a double line pull is necessary to develop enough force to recover the vehicle.

Double Line — Self Recovery

For self recovery efforts that require more force than a single line pull can provide, use a

double line rigging back to the winching vehicle. Make sure the rigging at the anchor is

rated to withstand the estimated load to recover the vehicle.

DANGER ZONE

USE ALL OF THE PRECAUTIONS AND STEPS

FROM SINGLE LINE WINCHING — STRAIGHT PULL

Snatch

Block

Tree Strap

& Shackle

Rigging Needed:

• 1 x Tree Strap

• 2 x Shackles – Possibly more depending

on tow points of stuck vehicle

• 1 x Snatch Block

For self recovery:

Place winch vehicle in NEUTRAL • Keep foot OFF brake

Page 39

Page 19For technical questions, please call 1-888-866-5797.Winching

Guide

Double Line — Other Vehicle Recovery

By placing the hook end at a stationary anchor or other vehicle and attaching a snatch

block to the recovery vehicle, the load on the winching vehicle is reduced by 50%.

This can be especially helpful in low traction conditions such as snow or mud.

Pay special attention to the danger zone, since it is much larger than a straight line pull.

DANGER ZONE

USE ALL OF THE PRECAUTIONS AND STEPS

FROM SINGLE LINE WINCHING — STRAIGHT PULL

Snatch

Block

Tree Strap

& Shackle

Rigging Needed:

• 1 x Tree Strap

• 2 x Shackles – Possibly more depending

on tow points of stuck vehicle

• 1 x Snatch Block

For other vehicle recovery:

Place winch vehicle in NEUTRAL • Keep foot ON brake

Page 40

26541 Agoura Road • Calabasas, CA 91302 • 1-888-866-5797

Loading...

Loading...