Page 1

M-Series® M3000

Electromagnetic Flow Meter

DESCRIPTION

The innovative design of the Badger Meter M-Series M3000 meter

represents the next generation of electromagnetic flow meter

technology. Incorporating the latest developments in micro

processing signal conditioning the advanced design of the M3000

allows an accuracy of better than ± 0.25% with a flow range of

300:1. Targeted to a variety of industrial and municipal applications,

the M3000 is virtually unaffected by density, temperature, pressure,

and viscosity changes and provides an accurate and reliable

long term metering solution. This meter complies with ANSI/NSF

Standard 61, Annex G.

OPERATION

The operating principle of the electromagnetic flow meter is based

on Faraday’s law of magnetic induction: The voltage induced across

any conductor, as it moves at right angles through a magnetic

field, is proportional to the velocity of that conductor. The voltage

induced within the fluid is measured by two diametrically opposed

internally mounted electrodes. The induced signal voltage is

proportional to the product of the magnetic flux density, the

distance between the electrodes and the average flow velocity of

the fluid.

ELECTRODES

When looking from the end of the meter into the inside bore,

the two measuring electrodes are positioned at three o’clock and

nine o’clock. As a conductive fluid flows through the magnetic

field, a voltage is induced across the electrodes. This voltage

is proportional to the average flow velocity of the fluid and is

measured by the two electrodes. This induced voltage is then

amplified and processed digitally by the converter to produce an

accurate analog or digital signal. The signal can then be used to

indicate flow rate and totalization or to communicate to remote

sensors and controllers.

M3000 meters also have an “empty pipe” detection feature. This

is accomplished with a third electrode positioned in the meter

between twelve o’clock and one o’clock. If this electrode is not

covered by fluid for minimum of five seconds, the meter will display

an “empty pipe” condition. When the electrode again becomes

covered with fluid, the error message will disappear and the meter

will continue measuring.

DETECTOR

The flow meter is a stainless steel tube lined with a non-conductive

material. Outside the tube, two DC powered electromagnetic coils

are positioned opposing each other. Perpendicular to these coils,

two electrodes are inserted into the flow tube. Energized coils

create a magnetic field across the whole diameter of the pipe. With

the no moving parts, open flow tube design there is no pressure

lost and practically no maintenance required.

APPLICATION

The M3000 meter is suited for use in applications where indication

of rate and totalization is required. The ability to display flow

parameters locally at the flow meter, or remotely by mounting the

amplifier up to 100 feet away from the detector, provides a versatile

solution for most industrial and municipal flow applications.

Whether the fluid is water or something highly corrosive, very

viscous, contains a moderate amount of solids, or requires special

handling, the meter is able to accurately measure it. Housed in a

Class 1, Division 2, NEMA 4X/6P (IP66/IP67) enclosure, the M3000

design has been tested and approved by Factory Mutual (FM) in

the United States and the Canadian Standards Association (CSA

international) in Canada.

FEATURES

• Sizes 1/4…24 in. (6…600 mm)

• Accuracy of ± 0.25%

• Better than 0.1% repeatability

• Large 4-line by 16-character, back-lit, LCD display

• Digital Signal Processor (DSP) based

• Bi-directional flow sensing and totalization

• Automatic zero point stability

• Measures fluids with as low as 5.0 micromhos/cm conductivity

• Empty pipe detection

• No pressure loss for low operational costs

• Long life, corrosion-resistant liners

• Precise calibration

• NEMA 4X/6P (IP66/IP67) enclosure

• FM approved for Class I, Div 2 hazardous locations

• CE and FCC compliant

• CSA Certified

MAG-DS-00493-EN-06 (August 2018)

Product Data Sheet

Page 2

M-Series® M3000, Electromagnetic Flow Meter

SPECIFICATIONS

Sizes 1/4…24 in. (6…600 mm)

Flow Range 0.10…39.4 ft/s (0.03…12 m/s)

Accuracy ± 0.25% of rate for velocities greater than 1.64 ft/s (0.50 m/s)

Repeatability 0.1% of rate

Power Supply AC or optional 24V DC

Analog Outputs 0…10 mA, 0…20 mA, 4…20 mA (programmable and scalable)

Digital Outputs (2) Open Collector, (programmable – scaled pulse, flow alarm, status, or frequency output) Max. 24V DC, 0.5 W

Frequency Output Open Collector; Max. full scale flow = 10 Khz

Communication RS232C serial, standard ANSI terminal compatible data stream

Pulse Width Open Collector, 5 ms to 1 second (programmable) or automatic 50% duty cycle

Min-Max Flow Alarm Open collector or solid-state relay (programmable, 0 to 100% of flow)

Empty Pipe Detection Field tunable for optimum performance based on specific application

Excitation Frequency Programmable, 3.75 Hz, 7.5 Hz or 15 Hz

Auxiliary Input Max. 24V DC (programmable – positive zero return, external totalizer reset or preset batch start)

Noise Dampening 1 to 30 seconds (programmable)

Low Flow Cutoff 0…100% of full scale (programmable)

Zero-Point Stability Automatic correction

Galvanic Separation 500V

Fluid Conductivity Min. 5.0 micromhos/cm

Fluid Temperature With Meter-Mounted Amplifier:

Ambient Temperature – 4…122° F (–20…50° C)

Relative Humidity Up to 90% non-condensing

Altitude Maximum 6500 ft (2000 m)

Flow Direction Uni-directional or bi-directional

Totalization 3 separate displayable totalizers; 10 digits (programmable – forward, reverse and net)

Units of Measure U.S. gallons, imperial gallons, million gallons per day, cubic feet, cubic meters, liters, oil barrels, pounds, ounces, acre feet

LC Display 4-line by 16-character, alphanumeric, back light

Programming Internal 3-button or external magnetic wand

Field Wiring Entry Ports (3) 1/2" NPT, internal thread

Amplifier Housing Amplifier enclosure and remote junction enclosure: cast aluminum (powder coated paint)

Amplifier Housing

Rating

Detector Pipe Spool

Material

Detector Spool Housing

Material

Electrode Materials Alloy C, 316 stainless steel (standard), gold/platinum plated, tantalum, platinum/rhodium

Liner Material PFA from 1/4…3/8 in. (6…10 mm), PTFE from 1/2…24 in. (15…600 mm), hard rubber from 1…24 in. (25…600 mm),

Flanges Carbon steel or 316 stainless steel (ANSI B16.5 Class 150 RF)

Coil Power Pulsed DC

Pressure Limits Max. 150 psi (10 bar)

Mounting Direct detector mount or remote wall mount, bracket included. For remote mount, max. cable distance = 100 ft (30 m)

Junction Enclosure

Material

Optional Stainless Steel

Grounding Rings

Optional Grounding

Electrodes

Electrical Classification FM approved for Class I, Div 2, Groups A-D; Class II, Div 2, Groups F and G, – CSA Certified

± 0.004 ft/s (± 0.001 m/s) for velocities less than 1.64 ft/s (0.50 m/s)

AC Power Supply: 85…265V AC, 45…65 Hz

Voltage Fluctuation = ± 10% of nominal

Over Voltage = Catagory II

Power Consumption = 20 W

DC Power Supply (optional): 24V DC ± 10% 8 W

Voltage sourced (18V DC) isolated

Max. loop resistance = 750 Ω

(2) AC solid-state relay (programmable – flow alarm or status) Max. 24V D C @ 0.5 A

PFA, PTFE & Halar®: -4…212° F (-20…100° C) @ max. ambient

temperature of 122° F (50° C).

Hard rubber: 32…178° F (0…81° C) @ max. ambient

temperature of 122° F (50° C).

(programmable).

Displays: 3 totalizer values, flow rate, alarm status, output status, error/diagnostic messages

Amplifier enclosure and remote junction enclosure: NEMA 4X/6P (IP66/IP67)

316 stainless steel

Carbon steel, welded, NEMA 4X/6P (IP66/IP67)

Halar from 12…24 in. (300…600 mm)

For remote mounted amplifier option: Cast aluminum, powder-coated paint, NEMA 4X/6P (IP66/IP67)

Meter Size Thickness (of 1 ring)

1/4…10 in. (6…250 mm) 0.135 in. (3.43 mm)

10…24 in. (250…600 mm) 0.187 in. (4.75 mm)

Alloy C, 316 stainless steel, gold/platinum plated, tantalum, or platinum/rhodium

With Remote Amplifier:

PFA, PTFE & Halar: -4…248° F (-20…120° C) @ max. ambient

temperature of 122° F (50° C).

Hard rubber: 32…178° F (0…81° C) @ max. ambient

temperature of 122° F (50° C).

Page 2 August 2018MAG-DS-00493-EN-06

Page 3

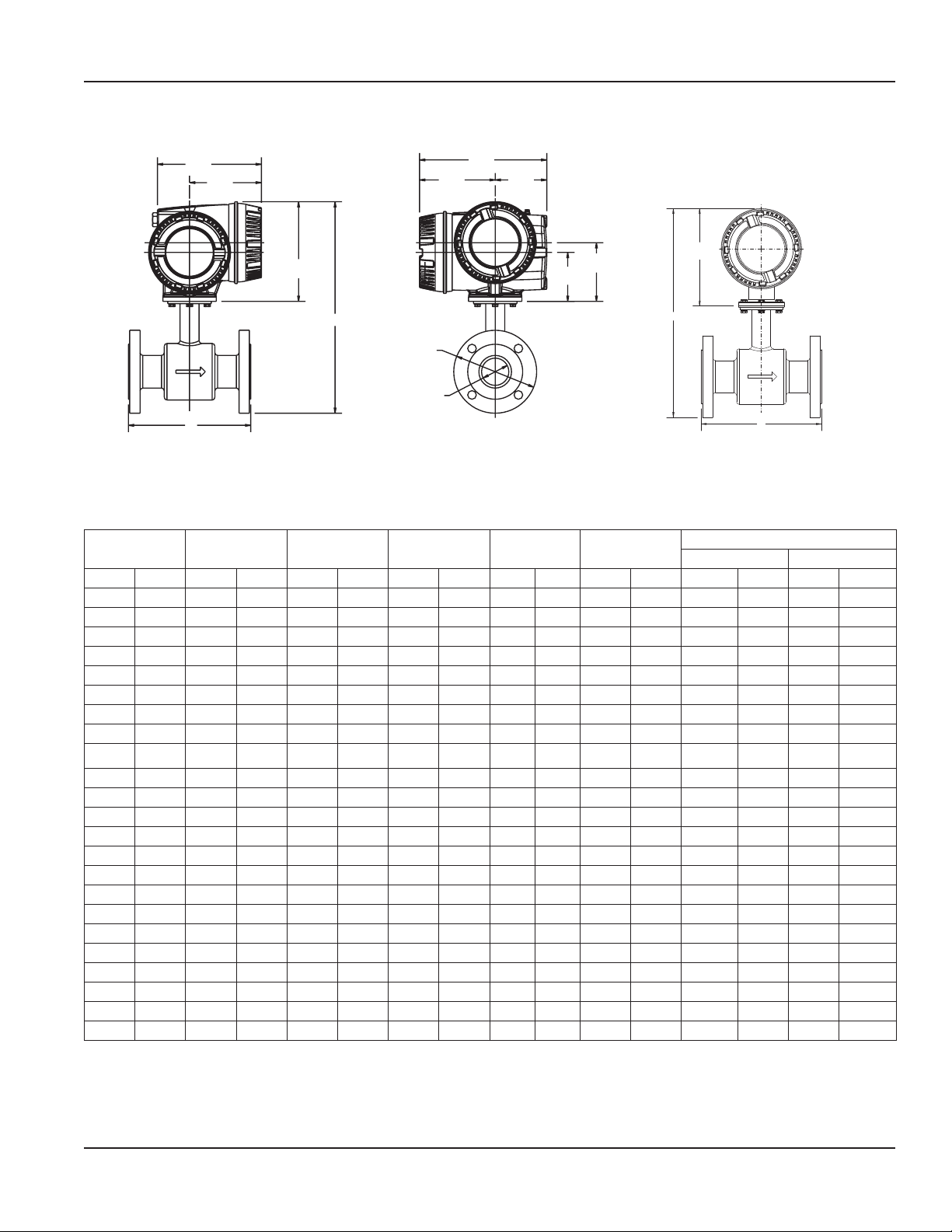

DIMENSIONS

m

Product Data Sheet

5.47"

139mm

9.20"

234mm

3.73"

95mm

3.54"

90mm

4.25"

108m

7.42"

188 mm

B

A

7.52"

191mm

A

5.20"

132mm

7.22"

183mm

B

0 C

SIZE

M3000 Meter Mount M3000 Remote Mount Junction Box on Detector

Size A B C D

Est. Weight

with Amplifier

Flow Range

GPM LPM

inch mm inch mm inch mm inch mm inch mm lb kg min max min max

1/4 6 6.7 170 13.4 342 3.5 89 13.9 351 17 7.7 0.01 5 0.05 20

5/16 8 6.7 170 13.4 342 3.5 89 13.9 351 17 7.7 0.02 10 0.09 36

3/8 10 6.7 170 13.4 342 3.5 89 13.9 351 17 7.7 0.04 15 0.14 57

1/2 15 6.7 170 13.4 342 3.5 89 13.9 351 17 7.7 0.08 34 0.32 127

3/4 20 6.7 170 13.6 347 3.9 99 14 356 17 7.7 0.12 48 0.46 183

1 25 8.9 225 13.8 352 4.3 108 14.2 361 18 8.8 0.21 84 0.79 318

1-1/4 32 8.9 225 14.6 372 4.6 117 15 381 20.3 9.2 0.39 157 1.5 594

1-1/2 40 8.9 225 14.8 376 5.0 127 15.2 386 22 10 0.55 220 2.1 834

2 50 8.9 225 15.3 389 6.0 152 15.7 398 26 11.7 0.94 378 3.6 1431

2-1/2 65 11.0 280 16.5 420 7.0 178 16.9 429 35 15.7 1.63 653 6.2 2471

3 80 11.0 280 16.7 426 7.5 191 17.2 435 38 17.1 2.21 883 8.4 3344

4 100 11.0 280 17.8 452 9.0 229 18.2 461 49 22.1 3.30 1320 12 4997

5 125 15.8 400 19 484 10.0 264 19.4 493 60 27.1 5.29 2115 20 8008

6 150 15.8 400 20 510 11.0 279 20.4 519 71 32.1 7.85 3141 30 11890

8 200 15.8 400 21.9 558 13.5 343 22.9 583 96 43.1 15.69 6278 59 23765

10 250 19.7 500 26.2 677 16.0 406 26.6 676 130 59.1 25.05 10021 95 37934

12 300 19.7 500 28.3 720 19.0 483 28.7 729 219 99.3 33.61 13445 127 50894

14 350 19.7 500 30.2 768 21.0 533 30.7 779 287 130.2 45.75 18300 173 69272

16 400 23.6 590 33.1 842 23.5 597 33.5 851 354 160.9 59.75 23902 226 90477

18 450 23.6 590 34.4 876 25.0 635 34.9 885 409 185.3 75.63 30250 286 114511

20 500 23.6 590 337.6 955 27.5 699 38 964 502 228.3 93.37 37346 353 141371

22 550 23.6 590 39 991 29.5 749 39.4 1000 532 241.3 112.97 45189 428 171059

24 600 23.6 590 41.6 1057 32.0 813 42 1066 561 255.3 134.45 53779 509 203574

Page 3 August 2018 MAG-DS-00493-EN-06

Page 4

M-Series® M3000, Electromagnetic Flow Meter

Control. Manage. Optimize.

M-SERIES is a registered trademark of Badger Meter, Inc. Other trademarks appearing in this document are the property of their respective entities. Due to continuous research,

product improvements and enhancements, Badger Meter reserves the right to change product or system specications without notice, except to the extent an outstanding

contractual obligation exists. © 2018 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Eastern Europe Branch Office (for Poland, Latvia, Lithuania, Estonia, Ukraine, Belarus) | Badger Meter Europe | ul. Korfantego 6 | 44-193 Knurów | Poland | +48-32-236-8787

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuffen | Germany | +49-7025-9208-0

Europe, Middle East Branch Office | Badger Meter Europe | PO Box 341442 | Dubai Silicon Oasis, Head Quarter Building, Wing C, Office #C209 | Dubai / UAE | +971-4-371 2503

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacific | Badger Meter | 80 Marine Parade Rd | 21-06 Parkway Parade | Singapore 449269 | +65-63464836

China | Badger Meter | 7-1202 | 99 Hangzhong Road | Minhang District | Shanghai | China 201101 | +86-21-5763 5412

Switzerland | Badger Meter Swiss AG | Mittelholzerstrasse 8 | 3006 Bern | Switzerland | +41-31-932 01 11 Legacy Document Numbers: ITB-139, ITB-141, ITB-165, ITB-166

Loading...

Loading...