Page 1

Badger M-Series

Model M-2000 Amplifi er

Mag Meter

GENERAL

The innovative design of the Badger® M-Series® mag meter

model M-2000 amplifi er represents the next generation

of electromagnetic (mag) fl ow meter signal processing.

Incorporating the latest developments in microprocessor

signal conditioning, the advanced design of the M-2000

meter allows for an accuracy of ±0.25 percent with a flow

range of 300:1. The M-2000 amplifier can be integrally

mounted to the detector or can be mounted remotely, if

necessary. Housed in a NEMA 4X (IP66) enclosure, the

amplifier targets a variety of applications and is well suited

for the diverse water and wastewater treatment industry.

OPERATION

The M-2000 amplifi er receives the detector's analog signal,

amplifi es that signal and converts it into digital information.

At the processor level, the signal is analyzed through a

series of sophisticated software algorithms. After separating

the signal from electrical noise, it is converted into both

analog and digital signals that are used to display rate of

fl ow and totalization. In addition, the processor controls

zero-fl ow stability, analog and frequency outputs, serial

communications and a variety of other parameters. The large

four-line, 20-character LCD display indicates rate of fl ow,

forward and reverse totalizers and diagnostic messages. The

display also serves to guide the user in simple terms through

the user-friendly programmable routines.

Programmable parameters of the amplifi er include, but

are not limited to: calibration factors, totalizer resets,

unit of measure, analog and pulse output scaling, fl ow-

alarm functions, language selection, low-fl ow cutoff, noise

dampening factor and excitation frequency selection.

APPLICATION

The M-2000 amplifi er's main function is to detect and

condition fl ow information from the electromagnetic detector.

The unit is ideally suited for measuring dynamic, noncontinuous fl ow. In applications where a minimum and/

or max imum fl ow rate must be tracked and monitored, the

unit provides pulse signals that can be fed to dedicated

batch controllers, PLCs and other more specialized

instrumentation.

Technical

Brief

M-2000 Amplifi er

FEATURES

• Digital signal processor (32 bit)

• Large, four-line by 20 character LCD display with

backlight

• User-friendly programming procedure

• Digital and analog outputs

• NEMA 4X (IP66) enclosure

• Meter mount or remote wall mount

• Bidirectional fl ow sensing/totalization

• Better than ±0.1% repeatability

• Measures fl uids with as low as 5.0 micromhos/cm

conductivity

• Empty pipe detection

• Power loss totalization

• Modbus RTU via RS232

• Non-volatile programming memory

BadgerMeter, Inc.

• Exterior buttons for easy menu navigation

• Rotating cover

• Enhanced security options

ITB-185-01

6-10

Page 2

SPECIFICATIONS

Power Supply: AC, 85-265 VAC (45-65 Hz)

Power Consumption: 15 Watts

Accuracy: ± 0.25 percent of rate for velocities greater than

1.64 ft/s (0.50 m/s)

± 0.004 ft/s (± 0.001 m/s) for velocities less than

1.64 ft/s (0.50 m/s)

Repeatability: ± 0.1 percent

Flow Range:

Fluid Conductivity: Minimum 5.0 micromhos/cm

Flow Direction: Unidirectional or bidirectional two separate

totalizers (programmable)

Totalization: Programmable/resettable

Unidirectional: T1, T2

Bidirectional: T+ (Fwd), T- (Rev), Tn (Net)

Minimum Fluid Conductivity: 5.0 micromhos/cm

Processing: 32-bit DSP

Analog Output: 4-20 mA, 0-20 mA, 0-10 mA, 2-10 mA

(programmable and scalable)

Voltage sourced 24 VDC – isolated

Maximum loop resistance < 800 ohms

Digital Outputs: Four total, confi gurable

24VDC sourcing active output (up to two),100 mA total,

50 mA each; sinking open collector output (up to four),

30 VDC Max, 100 mA each; AC solid-state relay

(up to two), 48 VAC, 500 mA max.

Pulse Outputs: Scalable up to 10 kHz, passive open

collector up to 10 kHz, active switched 24 VDC. Up

to two outputs (forward and reverse). Pulse width

programmable from 1-1,000 ms or 50 percent duty cycle.

Frequency Output: Scalable up to 10 kHz, open collector.

up to 1 kHz, solid-state relay.

0.10 to 39.4 ft/s (0.03 to 12 m/s)

Misc Outputs: High/low fl ow alarm (0-100 percent of fl ow),

error alarm, empty pipe alarm, fl ow direction, preset

batch alarm, 24 VDC supply.

Noise Dampening: Programmable 0-30 seconds

Empty Pipe Detection: Field tunable for optimum

performance based on specifi c application

Excitation Frequency: 1 Hz, 3.75 Hz, 7.5 Hz or 15 Hz

(factory optimized to pipe diameter).

Digital Input: Max. 30 VDC (programmable – positive zero

return, external totalizer reset or preset batch start)

Units of Measure: Ounces, pounds, liters, US gallon,

imperial gallon, barrel, hectoliter, megagallon, cubic

meters, cubic feet, acre feet

Galvanic Separation: 250 volts

Low-fl ow-cutoff: Programmable 0-10 percent of max. fl ow

LCD Display: 4 x 20 character display with backlight

Programming: Three-button, external manual or remotely

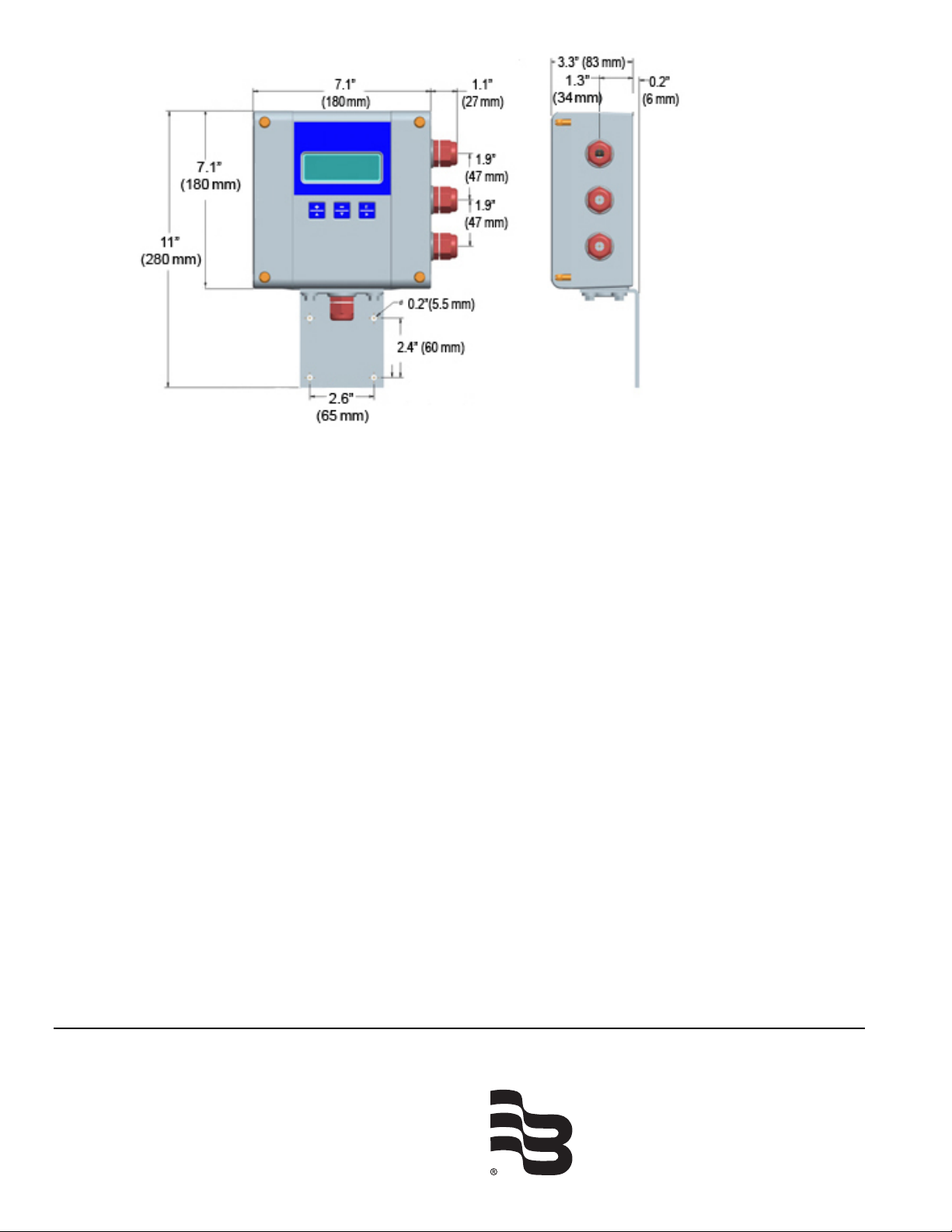

Housing: Cast aluminum, powder-coated paint

Housing Rating: NEMA 4X (IP66)

Mounting: Meter mount or remote wall mount

(bracket supplied)

Cable Connection: 1/2-inch NPT Cord Grip (three)

Ambient Temperature: -4 to 140° F (-20 to 60° C)

Serial Communication: RS232 – Modbus RTU or remote

display

Logging: Power loss totalization

Relative Humidity: Up to 90 percent non-condensing

Locations: Indoor and outdoor

Altitude: Maximum 6,500 feet (2000 m)

Badger and M-Series are registered trademarks of Badger Meter, Inc.

Please see our Web site at

www.badgermeter.com

for specifi c contacts.

© 2010 Badger Meter, Inc. All rights reserved.

Due to continuous research, product improvements and enhancements,

Badger Meter reserves the right to change product or system

specifi cations without notice, except to the extent an outstanding bid

obligation exists.

BadgerMeter, Inc.

P.O. Box 245036

Milwaukee, WI 53224-9536

800-876-3837

infocentral@badgermeter.com • www.badgermeter.com

Loading...

Loading...