Page 1

Recordall® Disc Meter

Cold Water Top Load Bronze, Size 1-1/2" (40 mm)

NSF/ANSI Standard 61 Certied, Annex G

DESCRIPTION

Badger Meter Meter offers the Recordall Disc meter in Cast Bronze

and a Lead-Free Alloy. The Lead-Free Alloy (Trade designation:

M120-LL) version has been certified to comply with NSF/ANSI

Standard 61, Annex G and carries the NSF-61 Mark on the housing.

All components of the Lead-Free Alloy meter, i.e., disc, chamber,

housing, seals, etc. comprise the certified system.

Applications

For use in measurement of potable cold water in residential,

commercial and industrial services where flow is in one direction

only.

Operation

Water flows through the meter's strainer and into the measuring

chamber where it causes the disc to nutate. The disc, which moves

freely, nutates on its own ball, guided by a thrust roller. A drive

magnet transmits the motion of the disc to a follower magnet

located within the permanently sealed register. The follower magnet

is connected to the register gear train. The gear train reduces the

disc nutations into volume totalization units displayed on the

register dial face.

Operating Performance

The Badger Meter Recordall Disc meters meet or exceed registration

accuracy for the low flow rates (95%), normal operating flow rates

(100 ± 1.5%), and maximum continuous operation flow rates as

specifically stated by AWWA Standard C700.

Construction

Badger Meter Recordall Disc meter construction, which complies

with ANSI/AWWA standard C700, consists of three basic

components: bronze meter housing, measuring chamber, and

permanently sealed register. A corrosion-resistant lead-free material

is used for the measuring chamber.

To simplify maintenance, the register, measuring chamber, and

strainer can be replaced without removing the meter housing

from the installation. No change gears are required for accuracy

calibration. Interchangeability of parts among like-sized meters also

minimizes spare parts inventory investment.

Magnetic Drive

Direct magnetic drive, through the use of high-strength magnets,

provides positive, reliable and dependable register coupling for

straight-reading or automatic meter reading options.

Sealed Register

The standard register consists of a straight-reading odometer-type

totalization display, 360° test circle with center sweep hand and flow

finder to detect leaks. Register gearing consists of self-lubricating

engineered polymer gears to minimize friction and provides

long life. Permanently sealed; dirt, moisture, tampering and lens

fogging problems are eliminated. Multi-position register simplifies

meter installation and reading. Automatic meter reading systems

are available for all Recordall Disc meters. All reading options are

removable from the meter without disrupting water service.

Tamper-Proof Features

Customer removal of the register to obtain free water can be

prevented when the optional tamper detection seal wire screw or

TORX® tamper resistant seal screw is added to the meter. Both can

be installed at the meter site or at the factory.

Model 120 shown with optional 1" Test Plug

Maintenance

Badger Meter Recordall Disc meters are designed and manufactured

to provide long-term service with minimal maintenance. When

maintenance is required, it can be performed easily either at

the meter installation or at any other convenient location. As an

alternative to repair by the utility, Badger Meter offers various

maintenance and meter component exchange programs to fit the

needs of the utility.

Connections

Tailpieces/Flanges for installations of meters on various pipe types

and sizes, including misaligned pipes, are available as an option.

SPECIFICATIONS

Typical Operating Range

(100% ± 1.5%)

Low Flow (Min. 95%) 1.25 gpm (0.28 m3/hr)

Max. Continuous Operation 80 gpm (18 m3/hr)

Pressure Loss at Max. 4.8 psi at 80 gpm (0.33 bar at 18 m3/hr)

Max. Operating Temperature 80° F (26° C)

Max. Operating Pressure 150 psi (10 bar)

Measuring Element Nutating disc, positive displacement

Register Type Straight reading, permanently-sealed

Registration 100 gallons, 10 cubic feet, 1 m3, 0.1 m

Register Capacity 100,000,000 gallons

Meter Connections 1-1/2" AWWA two bolt elliptical

Test Plugs 1" NPT test plug (TP) available on elliptical

2.5…120 gpm (0.57…27 m3/hr)

magnetic drive standard. AMR/AMI units

optional.

10,000,000 cubic feet, 1,000,000 m

100,000 m

6 odometer wheels

flange, drilled or 1-1/2…11-1/2 NPT

internal pipe threads.

long and short versions.

3

3

3

MATERIALS

Meter Housing Cast Bronze, Lead-Free Alloy

Housing Top Plates Bronze, Lead-Free Alloy

Measuring Chamber Engineered Polymer

Disc Engineered Polymer

Trim Stainless Steel, Bronze

Strainer Engineered Polymer

Disc Spindle Stainless Steel

Magnet Ceramic

Magnet Spindle Stainless Steel

Register Lid and Shroud Engineered Polymer, Bronze

Generator Housing Engineered Polymer

RD-T-1-1/2-EN (July 2012)

Technical Brief

Page 2

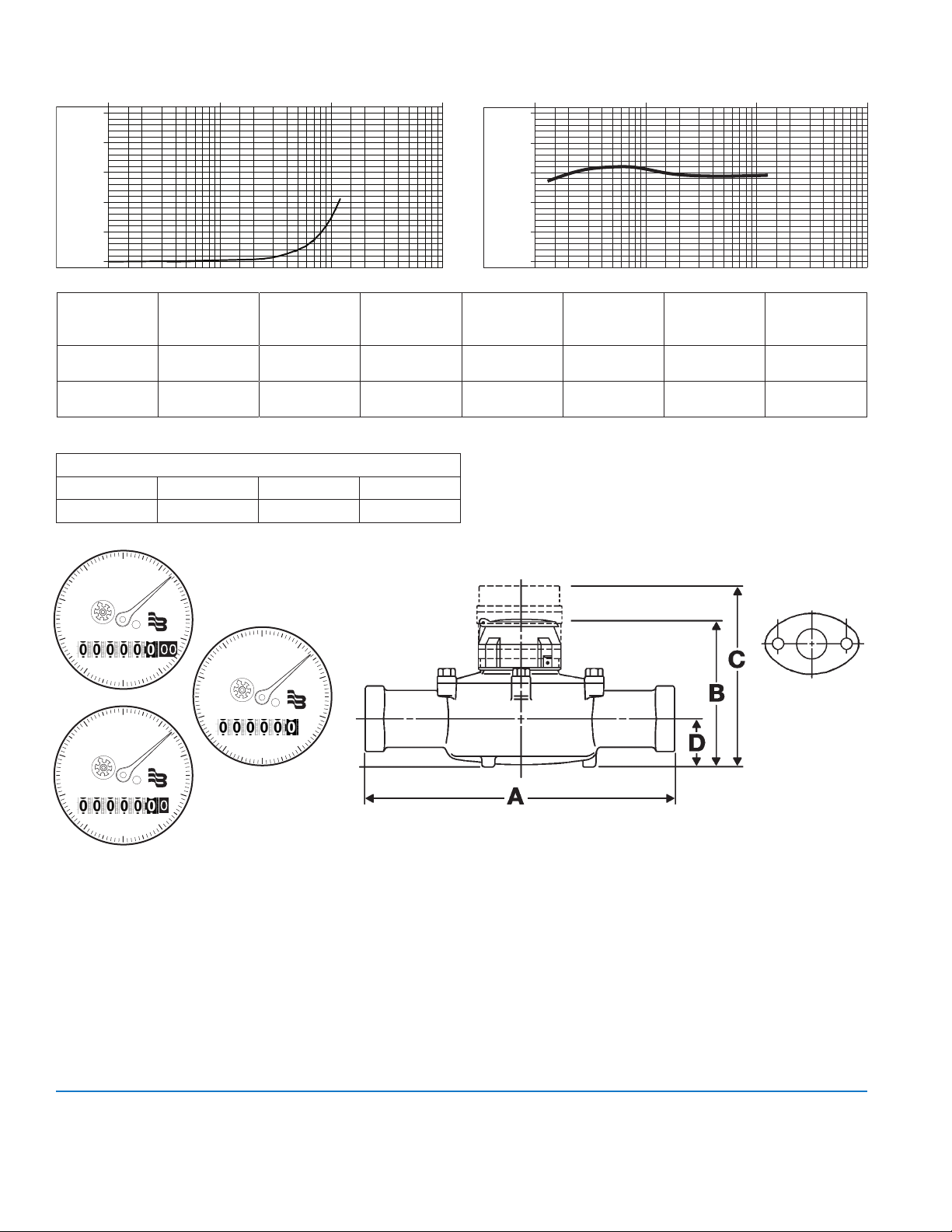

PRESSURE LOSS CHART ACCURACY CHART

0

0,1

0,4

0,5

0,6

0,7

0,8

0,9

0,2

0,3

Badger Meter

®

m

Model

120

Recordall

®

3

63961-014

1 1/2"

30 m

3

0

1

4

5

6

7

8

9

2

3

Badger Meter

®

Cubic Feet

Model

120

Recordall

®

63961-012

1 1/2"

0

Badger Meter

®

Model

120

Recordall

®

0

10

40

50

60

70

80

90

20

30

Gallons

63961-011

1 1/2"

Over

Register

Under

Register

Accuracy Percent

15

10

5

0

5

10

-

+

1.0 10 100 1000

2468 20 40 60 80 200 400 600

RATE OF FLOW IN GALLONS PER MINUTE

BADGER METER

PRESSURE LOSS CHART

Pressure Loss

P.S.I.

110 100 1000

0

5

10

15

20

25

46820406080 200 400 600 8002

MODEL 120 RECORDALL T.L. 1-1/2

Rate of Flow, in Gallons per Minute Rate of Flow, in Gallons per Minute

Meter Size Meter ModelA Laying Length

1-1/2" (40 mm) 120 EL, Hex

120 EL, TP

1-1/2" (40 mm) 120 ELL

120 ELL, TP

12-5/8"

(321 mm)

13"

(330 mm)

B

Height Reg./

RTR

7"

(178 mm)

7"

(178 mm)

C

Height Gen.

8-3/8"

(213 mm)

8-3/8"

(213 mm)

D

Centerline to

Base

2-3/8"

(60 mm)

2-3/8"

(60 mm)

Approx.

8-3/4"

(222 mm)

8-3/4"

(222 mm)

Shipping

19 lb

(8.6 kg)

19 lb

(8.6 kg)

EL = Elliptical ELL = Elliptical Long Hex = Hexagon, 1-1/2" - 11-1/2 NPT Thread TP=Test Plug 1"

Sweep Hand Registration

Model Gallon Cubic Feet Cubic Meter

M120 100 10 1/.1

RTR and Recordall are registered trademarks of Badger Meter Inc. Other trademarks appearing in this document are the property of their respective entities.

Due to continuous research, product improvements and enhancements, Badger Meter reserves the right to change product or system specications without notice, except to the extent an outstanding

contractual obligation exists. © 2012 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuffen | Germany | +49-7025-9208-0

Czech Republic | Badger Meter Czech Republic s.r.o. | Maříkova 2082/26 | 621 00 Brno, Czech Republic | +420-5-41420411

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacific | Badger Meter | 80 Marine Parade Rd | 21-04 Parkway Parade | Singapore 449269 | +65-63464836

China | Badger Meter | Rm 501, N° 11 Longyue Apartment | N° 180 Longjin Rd, Jiuting Songjiang District | Shanghai, China | 201615 | +86-21-5763 5412

Loading...

Loading...