Page 1

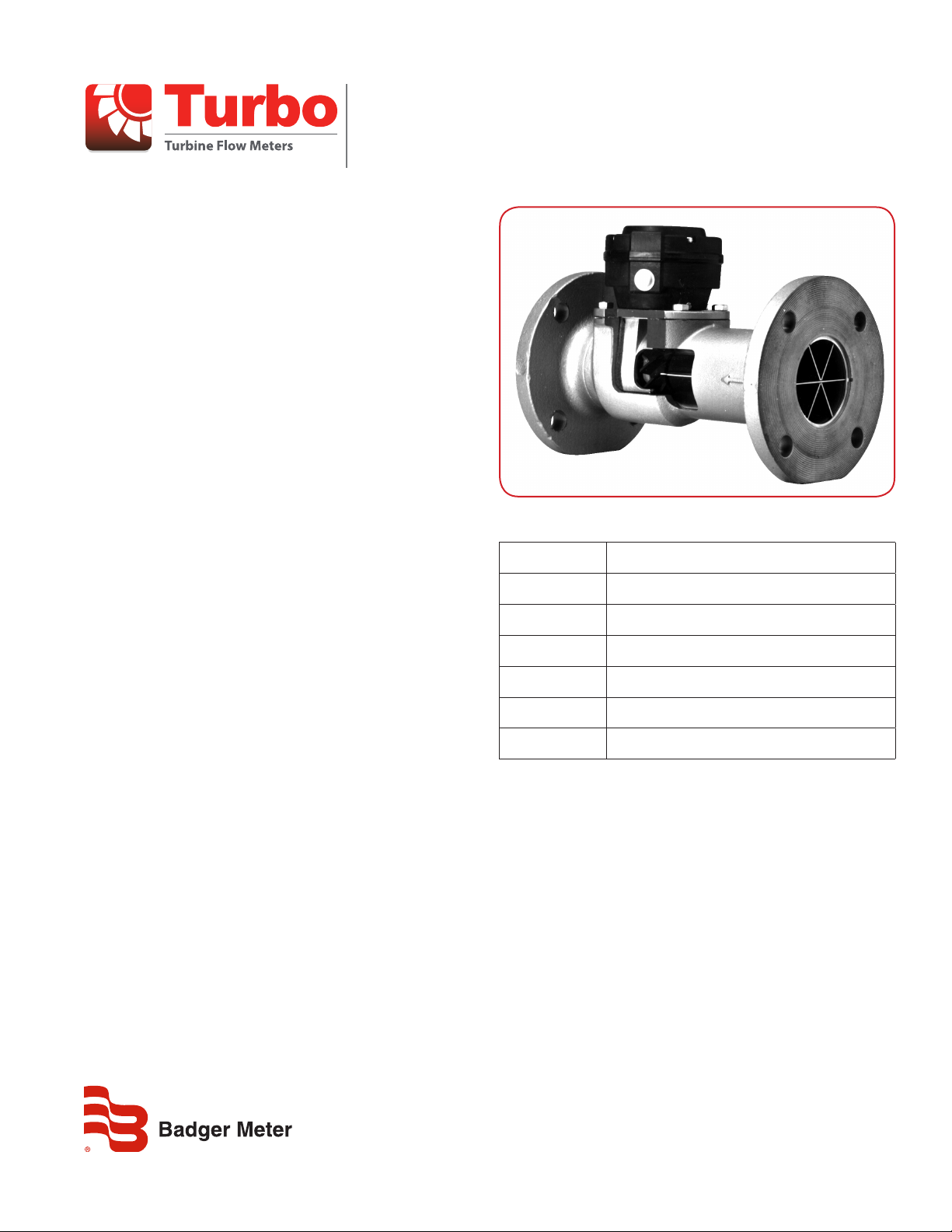

Industrial Turbine Meters

Turbo Model

DESCRIPTION

The Badger Meter® Industrial Turbine is a rugged, reliable meter

ideally suited for industrial fluid applications. Its compact size and

ease of serviceability without removal from the line make this a cost

effective selection. Designed with performance in mind, the meter

provides a high level of accuracy over a wide flow range with a

minimum of pressure loss.

The Turbine meter is available in line sizes of 2 in., 3 in., 4 in. and

6 in.. Its unique straight-through flow profile and ceramic bearing

design optimize performance.

To complement the meter, Badger Meter offers a complete

line of accessories that includes electromechanical and

state-of-the-art electronic transmitters, totalizers, indicators

and process controllers.

OPERATION

The Badger Meter Industrial Turbine is a volumetric liquid flow

meter that works on the time proven principle of a rotor turning at

an angular velocity proportional to the fluid velocity through the

turbine. The meter has straightening vanes and a nose cone in the

inlet side which minimize upstream turbulence and direct the flow

to the rotor effectively. Electronic pickups generate signals from the

rotor magnet. The signals are translated to an open

collector-transistor pulse output. Mechanical pickups and

electromechanical outputs are also available.

APPLICATIONS

The Turbo model is used in a wide range of fluid applications

covering from water to oils and solvents to acids. The meter is used

in water treatment systems, loading and unloading of tankers or

rail cars, batching systems, or simply inventory control of a process

fluid. Anywhere high volume and/or high flow rates are at least

sometimes required in the application, the Turbo meter is likely the

right choice.

MATERIALS

Housing Cast iron, bronze or 316 stainless steel

Head Bronze or stainless steel

Rotor &

Nose Cone

Bearings Ceramic

Straightening

Vanes

O-Ring and

Tetraseal

Head Gasket

Nitrile Binder (used with Buna N seals) or

Chloroprene Binder (used with EPR and Viton seals)

Ryton

316 Stainless Steel

Buna N, EPR or Viton

FEATURES

• Long lasting ceramic bearings

• Simple inline serviceability

• Accuracy of ± 0.5% to ± 1.5%

• Repeatability of 0.25%

• Low pressure loss

• Three housing materials available

TRB-DS-01191-EN-05 (April 2017)

Product Data Sheet

Page 2

Industrial Turbine Meters, Turbo Model

Pressure Loss (PSI)

Pressure Loss (Bar)

SPECIFICATIONS

System Size 2 in. 3 in. 4 in. 6 in.

Accuracy ±0.5% @ indicated Flow Range

Accuracy ±1.5% @ indicated Flow Range

20…160 gpm

(76…606 lpm)

8…200 gpm

(30…757 lpm)

60…350 gpm

(227…1325 lpm)

10…450 gpm

(38…1703 lpm)

Repeatability* 0.25%

Temperature Range 32…250° F (0…121° C)

Minimum Operating Pressure 7 psi (0.5 bar)

Maximum Operating Pressure

Standard: 125/150 psi (9/10 bar)

Optional: 250/300 psi (17/21 bar)

* Reading over full range tested with potable water at 60° F (16° C).

Flange Face Configurations: (ANSI Standards)

Flat Faced Flanges: 125 lb (57 kg) cast Iron, 150 lb (68 kg) and 300 lb (136 kg) bronze housings

Raised Face Flanges: 250 lb (113 kg) cast iron, 150 lb (68 kg) stainless steel housings

DIMENSIONS

A

B

C

D

E

Est. Wt.

100…1000 gpm

(378…3785 lpm)

25…1250 gpm

(95…4732 lpm)

250…2000 gpm

(946…7570 lpm)

40…2500 gpm

(151…9464 lpm)

2 in. 3 in. 4 in. 6 in.

10.00 in.

(254 mm)

13.67 in.

(347 mm)

6.00 in.

(152 mm)

2.75 in.

(70 mm)

6.86 in.

(174 mm)

30…40 lb

(14…18 kg)

12.00 in.

(305 mm)

13.67 in.

(347 mm)

7.50 in.

(191 mm)

3.50 in.

(89 mm)

6.86 in.

(174 mm)

40…50 lb

18…23 kg)

14.00 in.

(356 mm)

15.34 in.

(390 mm)

9.00 in.

(229 mm)

4.25 in.

(108 mm)

8.53 in.

(217 mm)

60…75 lb

(27…34 kg)

18.00 in.

(457 mm)

16.34 in

(415 mm)

11.00 in.

(279 mm)

5.25 in.

(133 mm)

10.03 in

(255 mm)

100…125 lb

(45…57 kg)

PRESSURE LOSS CHART

Flow Rate in US GPM (LPM)

10

(38)

20

(76)

40

(151)60(227)80(303)

100

(378)

200

(757)

400

(1514)

600

(2271)

800

(3028)

1000

(3785)

2000

(7571)

10

3” 4”

5

2”

6”

0

Control. Manage. Optimize.

Trademarks appearing in this document are the property of their respective entities. Due to continuous research, product improvements and enhancements, Badger Meter reserves

the right to change product or system specications without notice, except to the extent an outstanding contractual obligation exists. © 2017 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Eastern Europe Branch Oce (for Poland, Latvia, Lithuania, Estonia, Ukraine, Belarus) | Badger Meter Europe | ul. Korfantego 6 | 44-193 Knurów | Poland | +48-32-236-8787

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Europe, Middle East Branch Oce | Badger Meter Europe | PO Box 341442 | Dubai Silicon Oasis, Head Quarter Building, Wing C, Oce #C209 | Dubai / UAE | +971-4-371 2503

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 21-06 Parkway Parade | Singapore 449269 | +65-63464836

China | Badger Meter | 7-1202 | 99 Hangzhong Road | Minhang District | Shanghai | China 201101 | +86-21-5763 5412

Switzerland | Badger Meter Swiss AG | Mittelholzerstrasse 8 | 3006 Bern | Switzerland | +41-31-932 01 11 Legacy Document Number: CTB-054 and ITB-0517

3000

(11356)

0.7

0.3

0

Loading...

Loading...